Stable stainless steel pipe welding device

A stainless steel pipe and welding device technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment and other directions, can solve the problems of affecting the diameter of the welding position of the steel pipe, easily lead to offset, and consume labor, so as to improve the welding effect and accuracy, avoid The effect of fixed welding position and convenient welding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

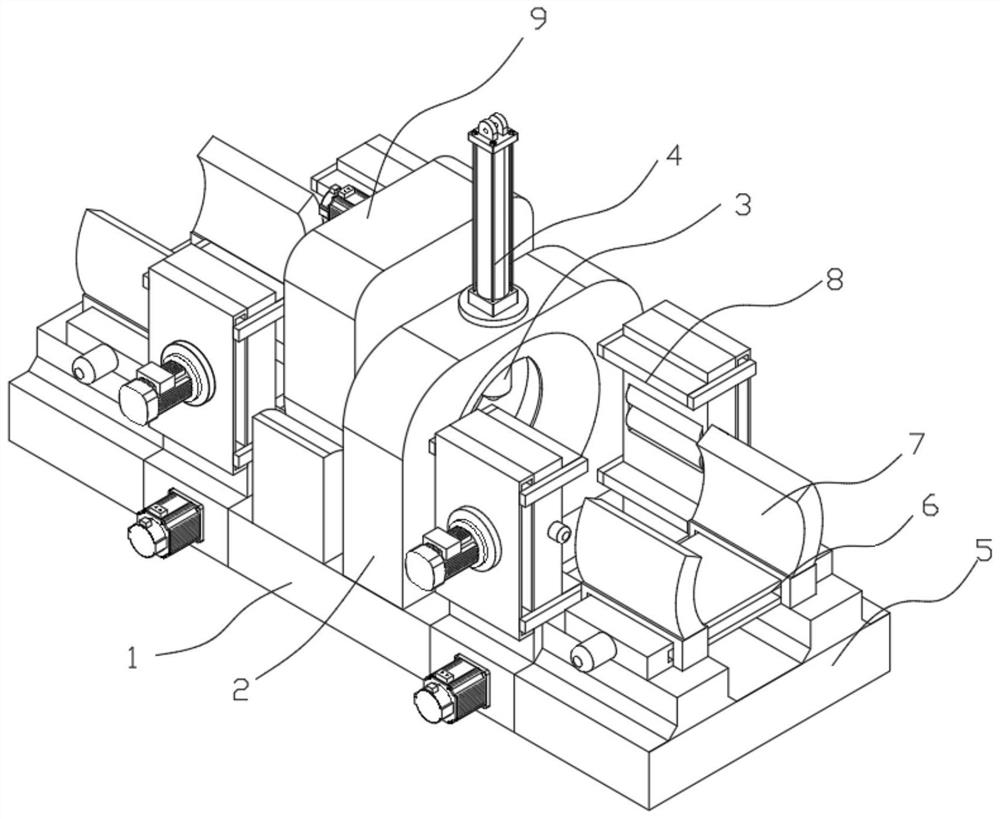

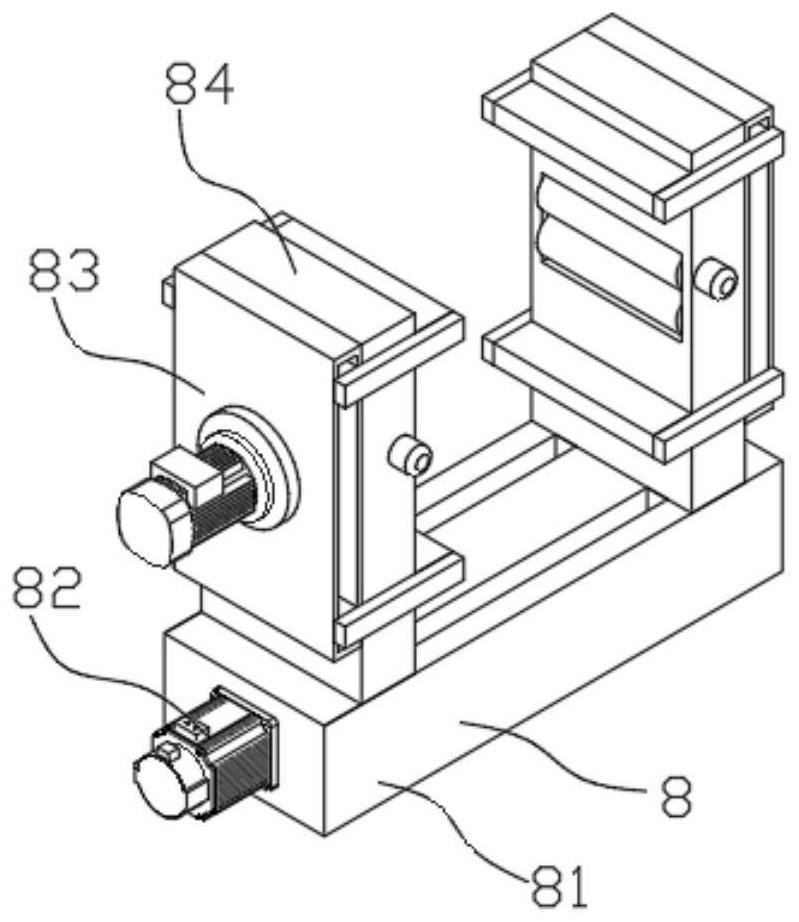

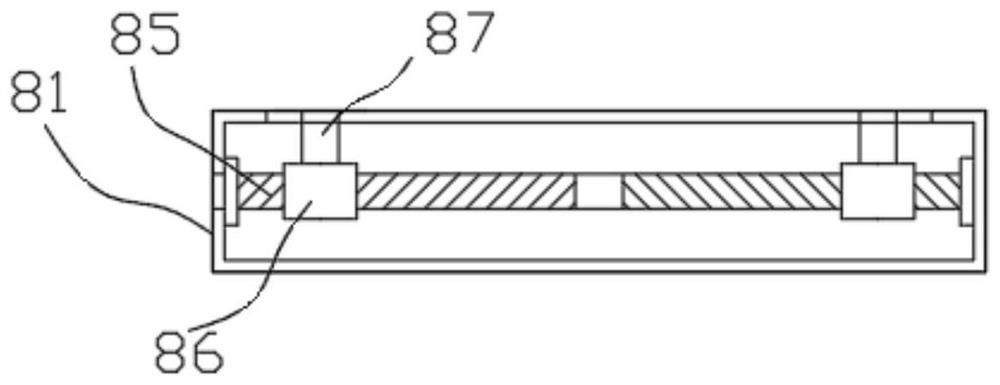

[0042] see figure 1 , the present invention provides a stable stainless steel pipe welding device, comprising a base 1, a welding seat 2 is fixed at the right end of the top of the base 1, a welding head 3 is installed on the upper end of the inner opening of the welding seat 2, and the top of the welding head 3 is connected to the welding seat. 2. Lifting cylinder 4 at the top, the push-out rod at the bottom of lifting cylinder 4 moves up and down with welding head 3, base 1 is provided with base 5 at the left and right relative positions, and a centering slide 6 is installed on the top of base 5, and the top of centering slide 6 is installed Both ends are provided with clamping members 7, and the two sets of clamping members 7 move forward and backward along the centering slide 6, and the center point between the two sets of clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com