Automatic control type grinding integrated device based on shaft side machining

An automatic control and grinding technology, which is applied to grinding drive devices, machine tools suitable for grinding workpiece edges, and grinding workpiece supports. , Improve the effect of grinding strength and functional improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

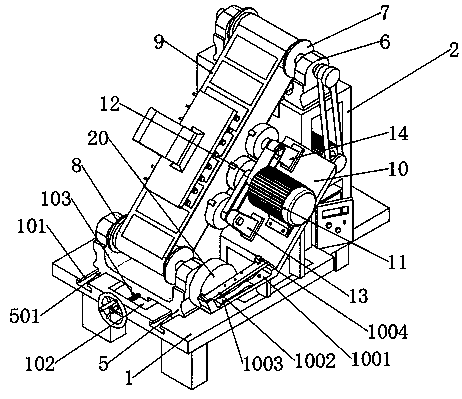

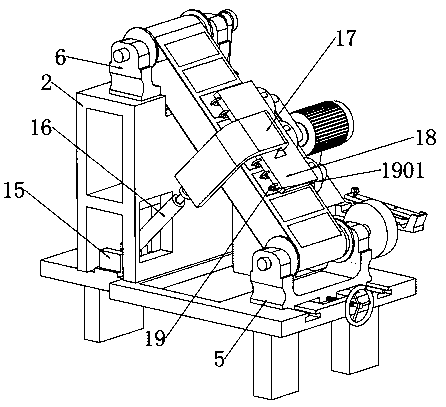

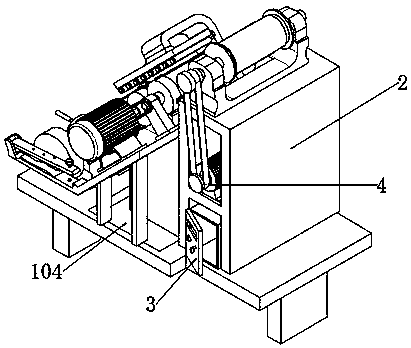

[0027] as attached figure 1 to attach Figure 8 Shown:

[0028] The present invention provides an automatic control grinding integrated device based on axial side processing, which includes a chassis 1, a side guide groove 101, an inner guide groove 102, a screw 103, a right stand 2, an electric control box 3, and a first motor 4. The first swivel seat 5, the guide rail structure 501, the second swivel seat 6, the first connecting wheel 7, the second connecting wheel 8, the polishing belt 9, the tilting frame 10, the extension seat 1001, the pressure seat 1002, and the clip seat 1003 , locking bolt 1004, second motor 11, chuck 12, lower station frame 13, upper station frame 14, fixed seat 15, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com