A high-efficiency grinding device for tablets used in the preparation of capsule western medicines

A grinding device and western medicine technology, which is applied in the medical field, can solve the problems of tablet powder not being able to meet the requirements, discharge blockage, insufficient grinding force, etc., and achieve the effect of increasing the grinding force, preventing blockage, and sufficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

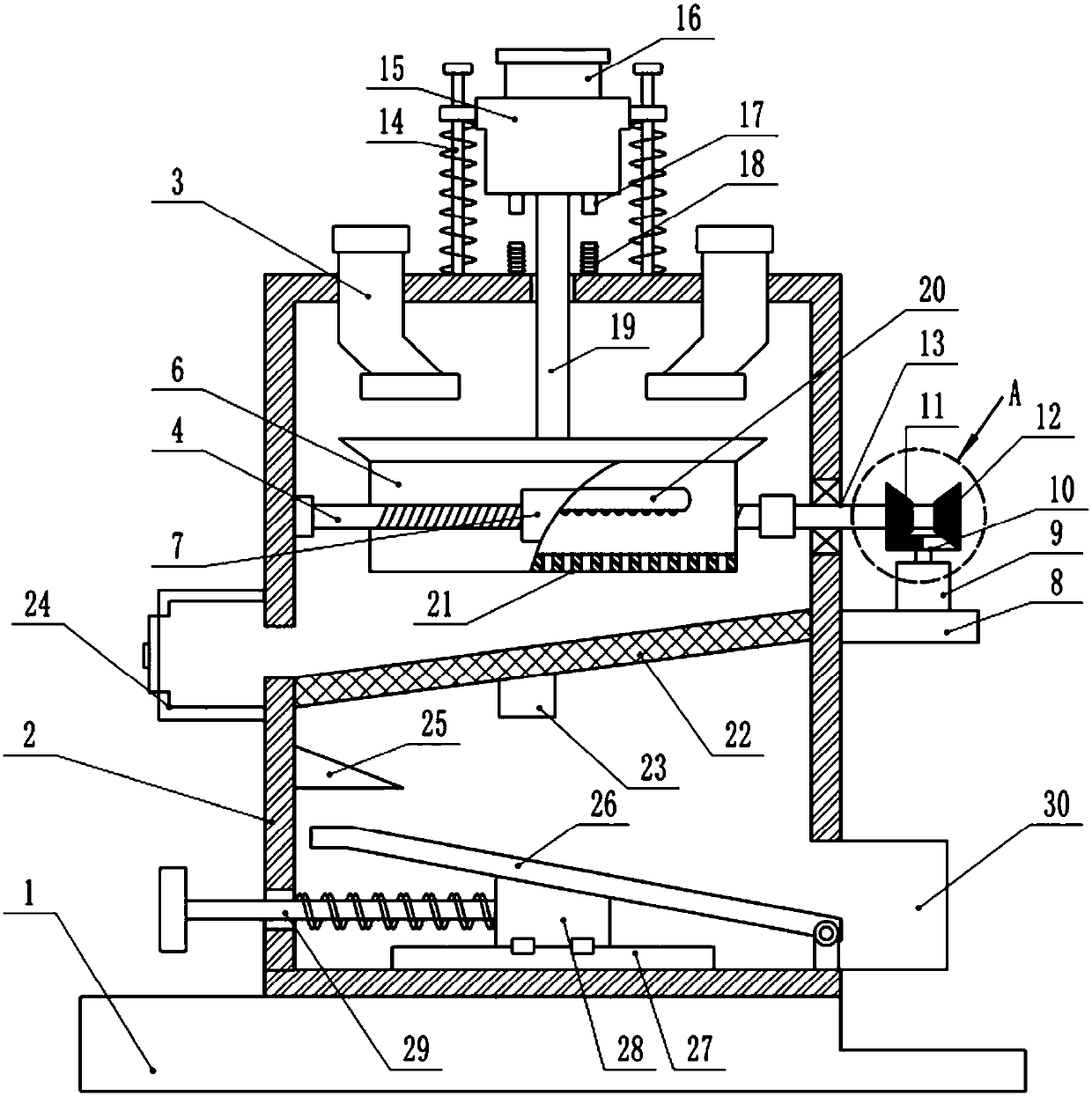

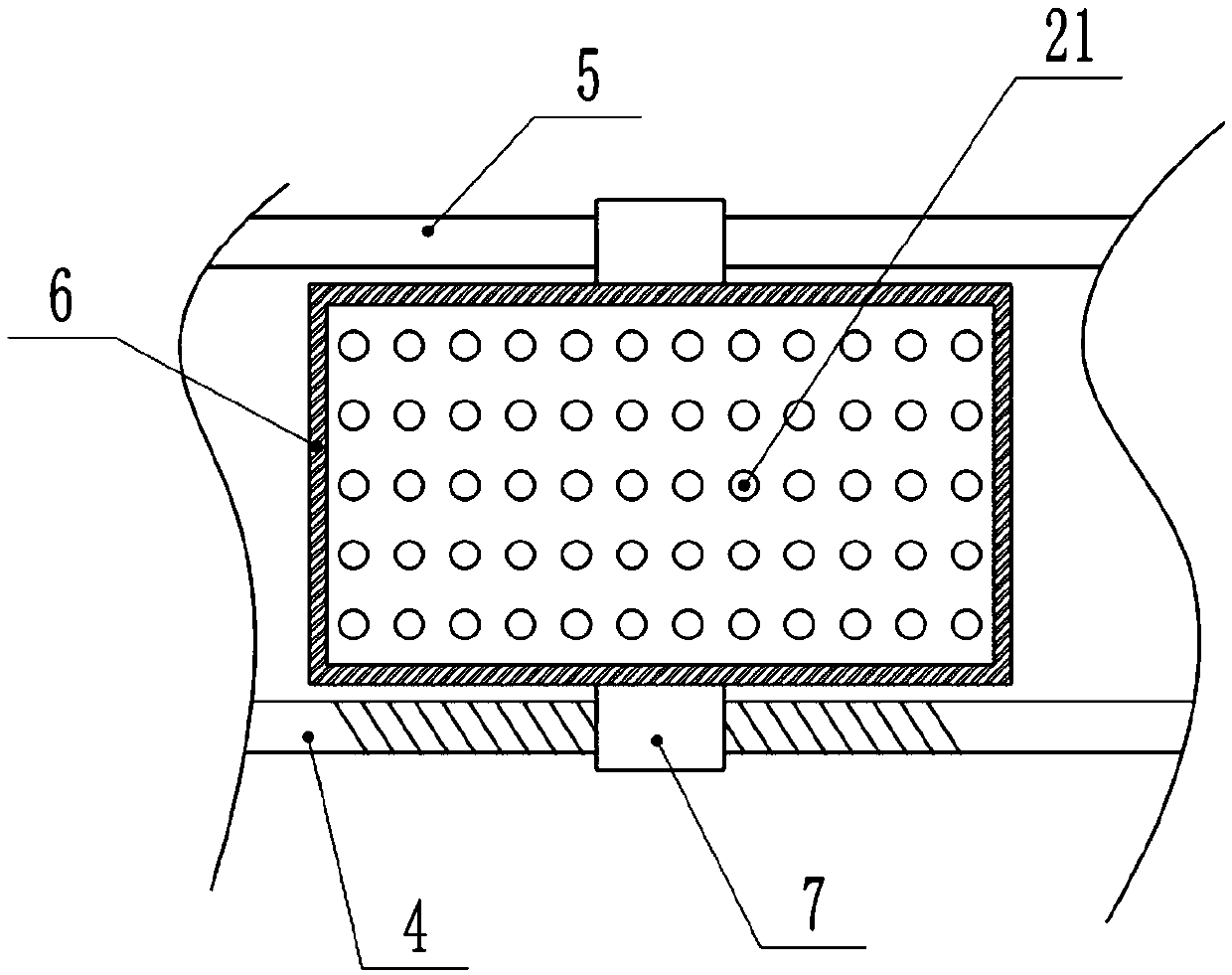

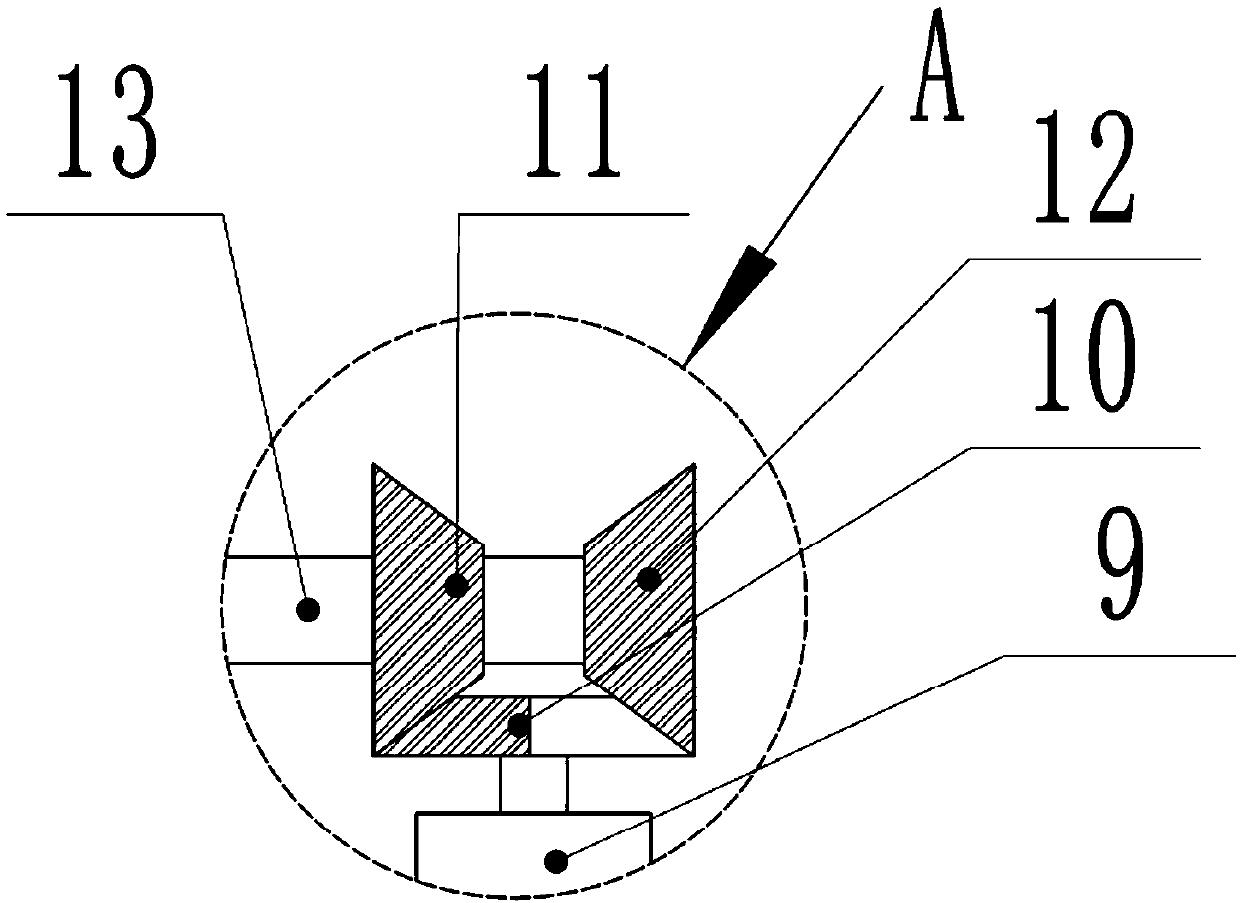

[0021] see Figure 1-3 , a high-efficiency grinding device for tablets used in the preparation of capsule western medicines, comprising a grinding box 2, a grinding tank 6, a drive motor 9, a grinding motor 16, a magnet 17, an electromagnet 18, a grinding turntable 20, a primary sieve plate 21, and a fine screen 22 and the second material guide plate 26, the base 1 is provided with a grinding box 2, the grinding box 2 and the base 1 are fixedly connected by bolts, and the upper side of the grinding box 2 is symmetrically opened with two groups of feeding ports 3, and A feeding pipe is embedded on the feeding port 3, and one end of the feeding pipe extends into the inside of the grinding box 2, and a T-shaped screw rod 4 and a guide rod 5 are installed horizontally inside the grinding box 2, and the T-shaped screw rod 4 is located on the guide rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com