Patents

Literature

60results about How to "Improve refinement efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

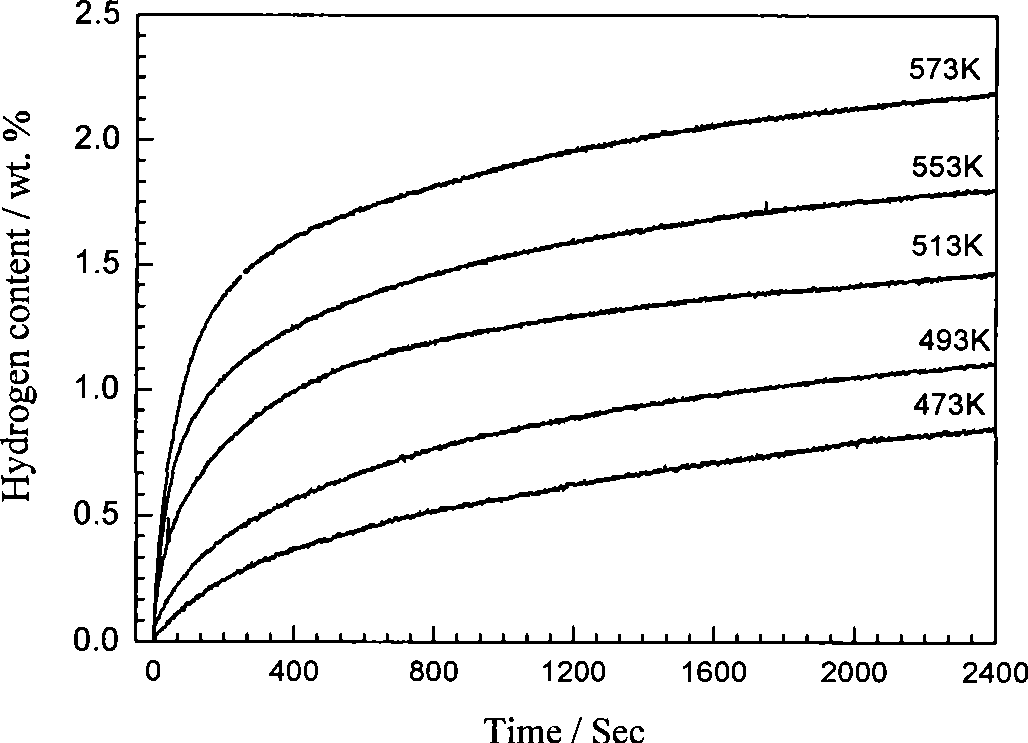

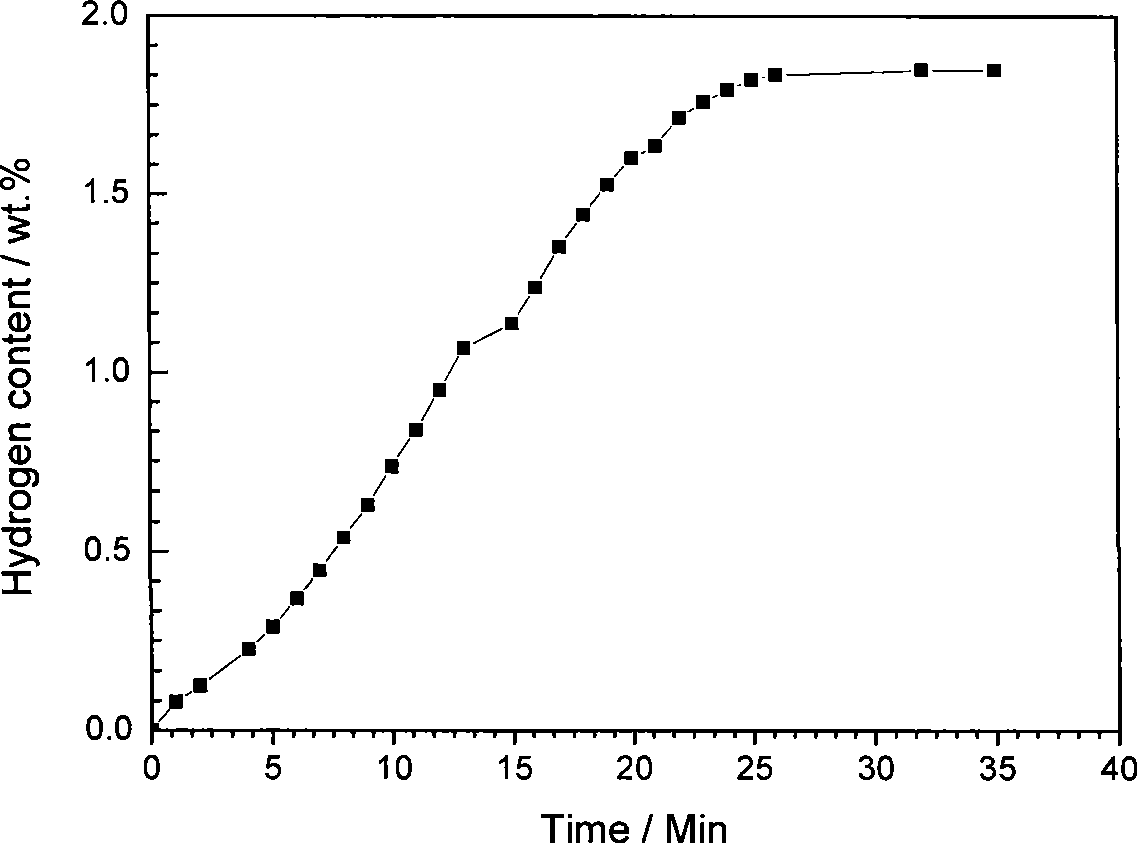

Magnesium base composite hydrogen storage material and preparation method

The invention discloses a magnesium-based composite hydrogen storage material comprising the following compositions by weight percent: 1.0-10.0% of Al, 1.0-5.0% of Ni, and the balance of Mg. A preparation method thereof comprising the following steps: at first, smelting block-shaped metal Mg and Al by a medium frequency induction to prepare Mg17Al12 alloy which is crushed to 300 meshes; hydrogenising Mg powder at 340 DEG C under a hydrogen atmosphere of 4.0MPa to prepare MgH2; then blending Mg17Al12, MgH2, Ni powder in accordance with contents by weight percent for ball-grinding for 60 to 100 hours under an atmosphere of argon. The magnesium-based composite hydrogen storage material can reversely absorb and release hydrogen at low temperature, and has high hydrogen storage capacity, excellent activation performance and superior hydrogen absorbing and releasing kinetics property. The magnesium-based composite hydrogen storage material can be used for manufacturing hydrogen source to facilitate purification and storage and transportation of hydrogen, and can also used for hydrogen storage material for fuel cells.

Owner:ZHEJIANG UNIV

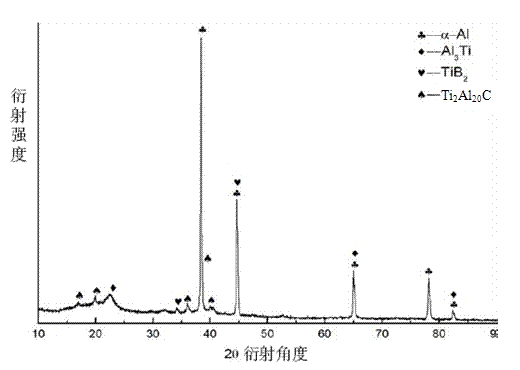

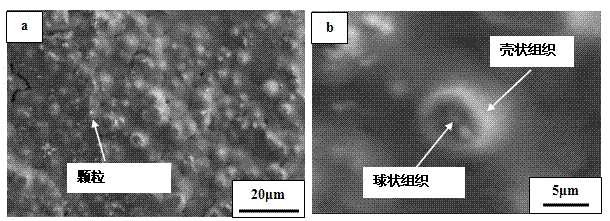

Preparation method of superfine crystal inoculating agent for aluminum alloy grain refinement

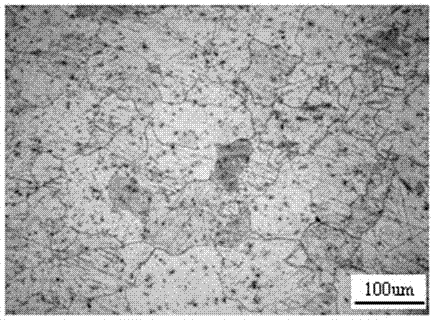

The invention provides a preparation method of a superfine crystal inoculating agent for aluminum alloy grain refinement and relates to aluminum-based alloy and is a method for preparing nano-crystalline Al-Ti-B-Re thin-strip intermediate alloy by a rapid solidification technology of metal, wherein the method comprises steps as follows: proportioning 5-5.4% of Ti, 1-1.04% of B, 1-1.2% of Ce, 0.05-0.2% of La and the balance of Al according to determined ingredients; weighing raw materials Al-5Ti-1B intermediate alloy and lanthanum cerium alloy to proportion the materials; melting in vacuum to obtain blocky Al-5Ti-1B-1Re intermediate alloy; carrying out rapid solidification to obtain the superfine crystal inoculating agent for the aluminum alloy grain refinement, wherein the superfine crystal inoculating agent is the nano-crystalline Al-5Ti-1B-1Re intermediate alloy. With the adoption of the method provided by the invention, adverse impact of needlelike TiAl3 on the matrix structure is eliminated, nucleating particles TiAl3 with thinner size and more dispersed distribution are obtained, and superfine nucleating particles are realized.

Owner:HEBEI UNIV OF TECH

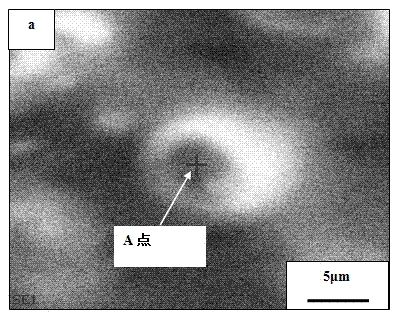

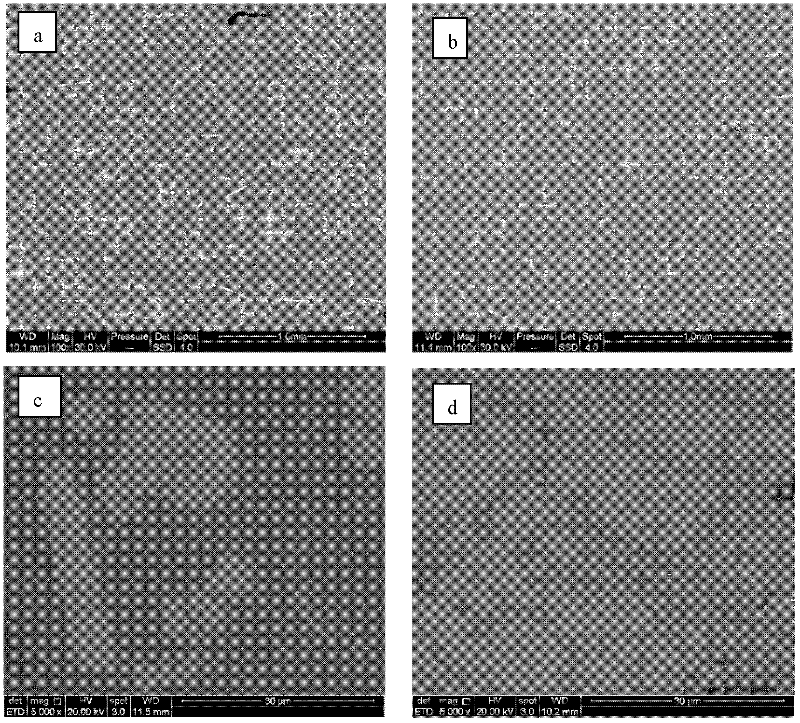

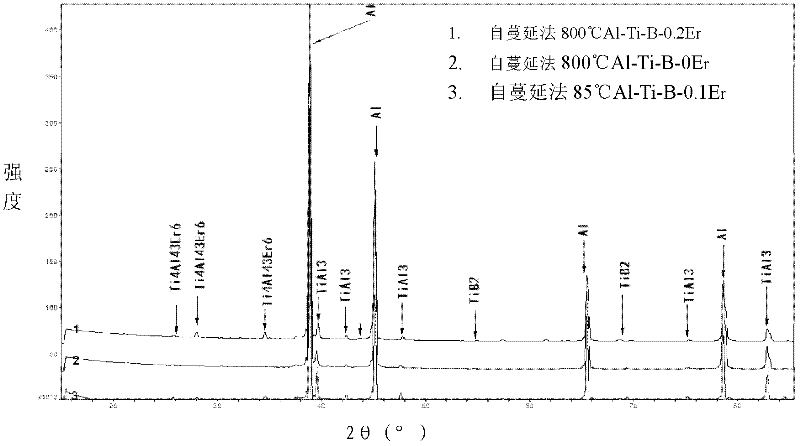

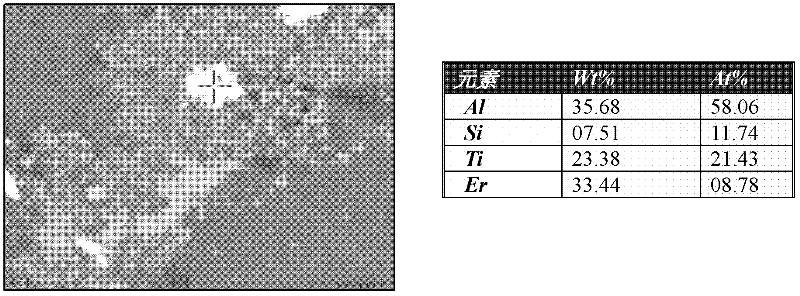

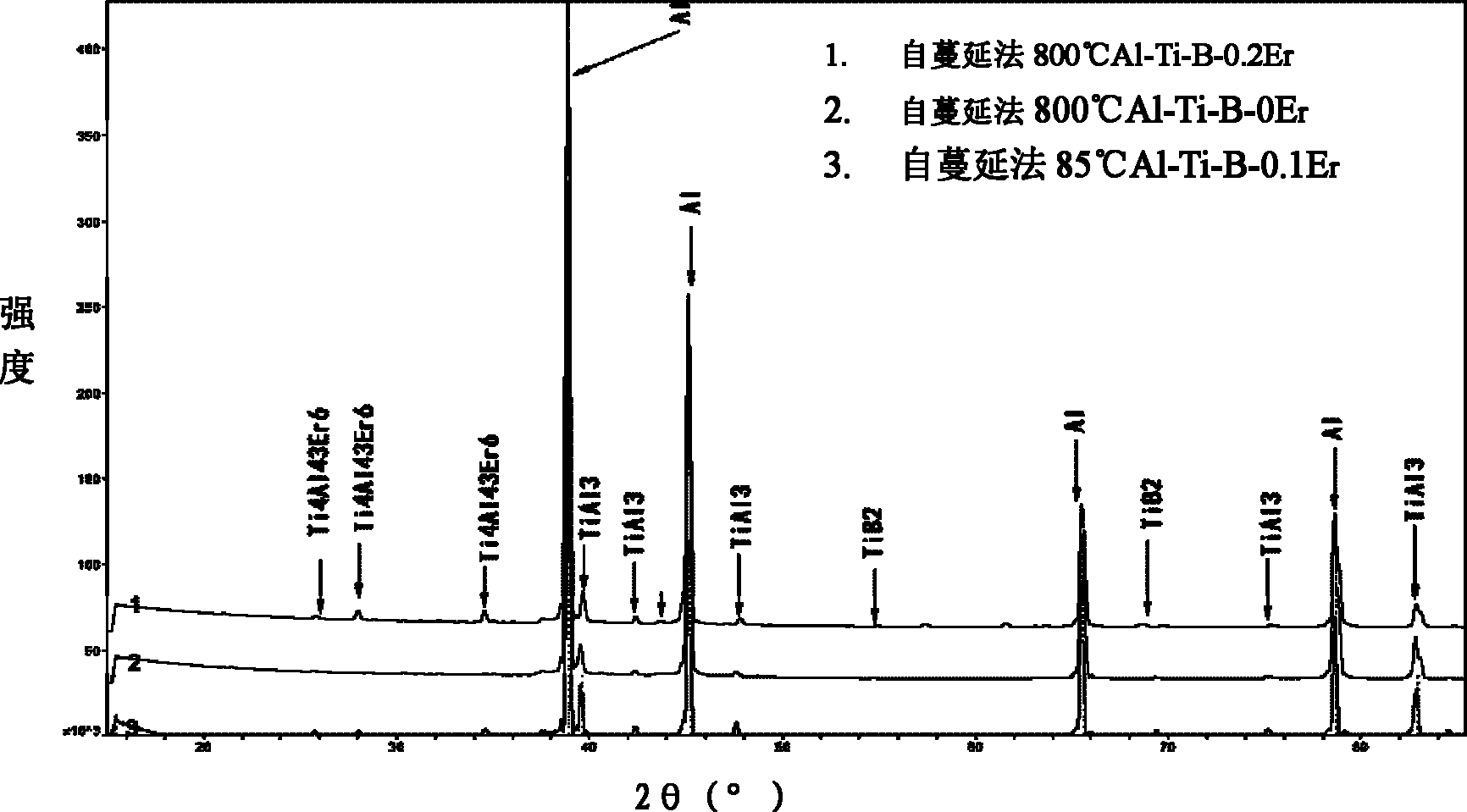

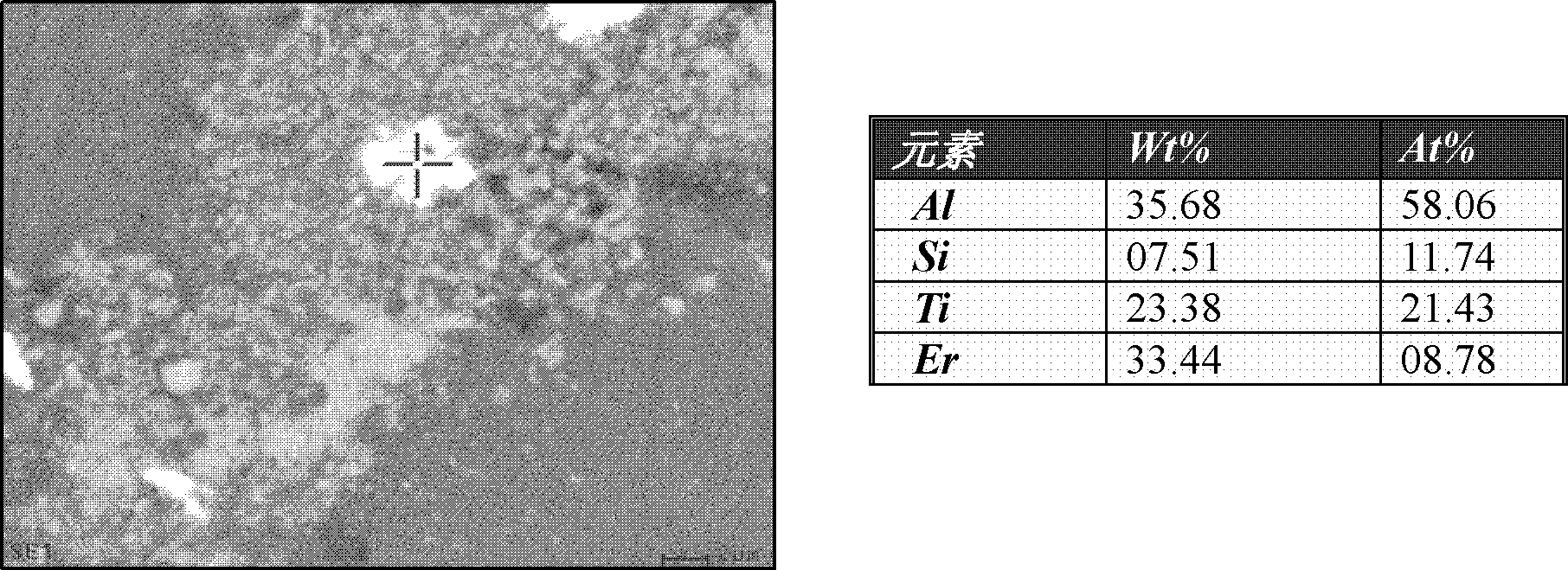

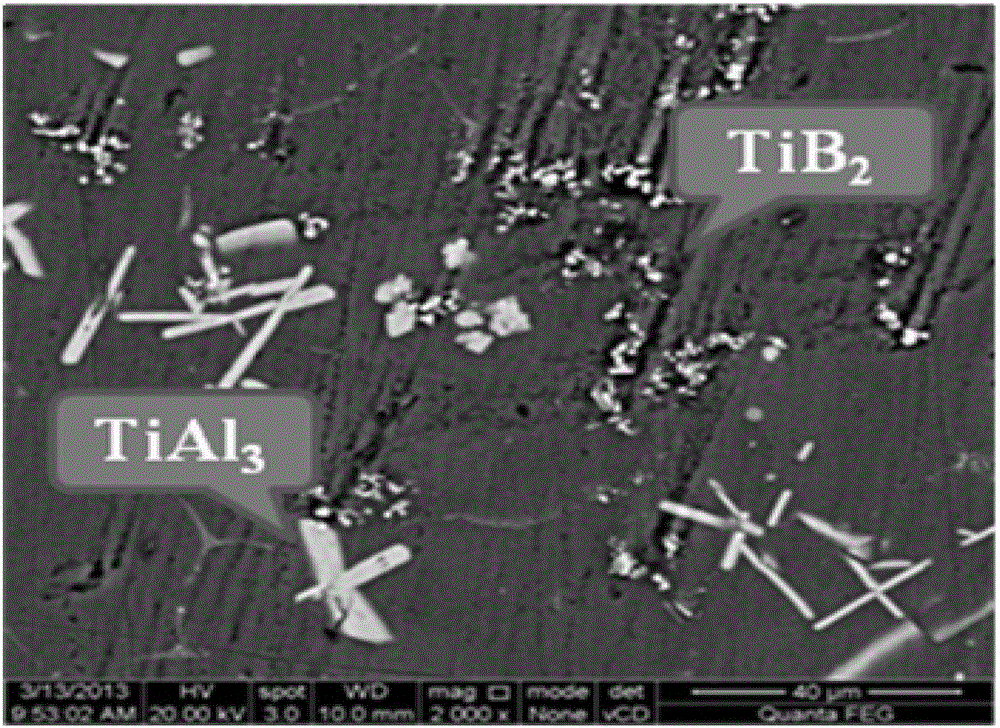

Al-Ti-B-Er refiner and preparation method thereof

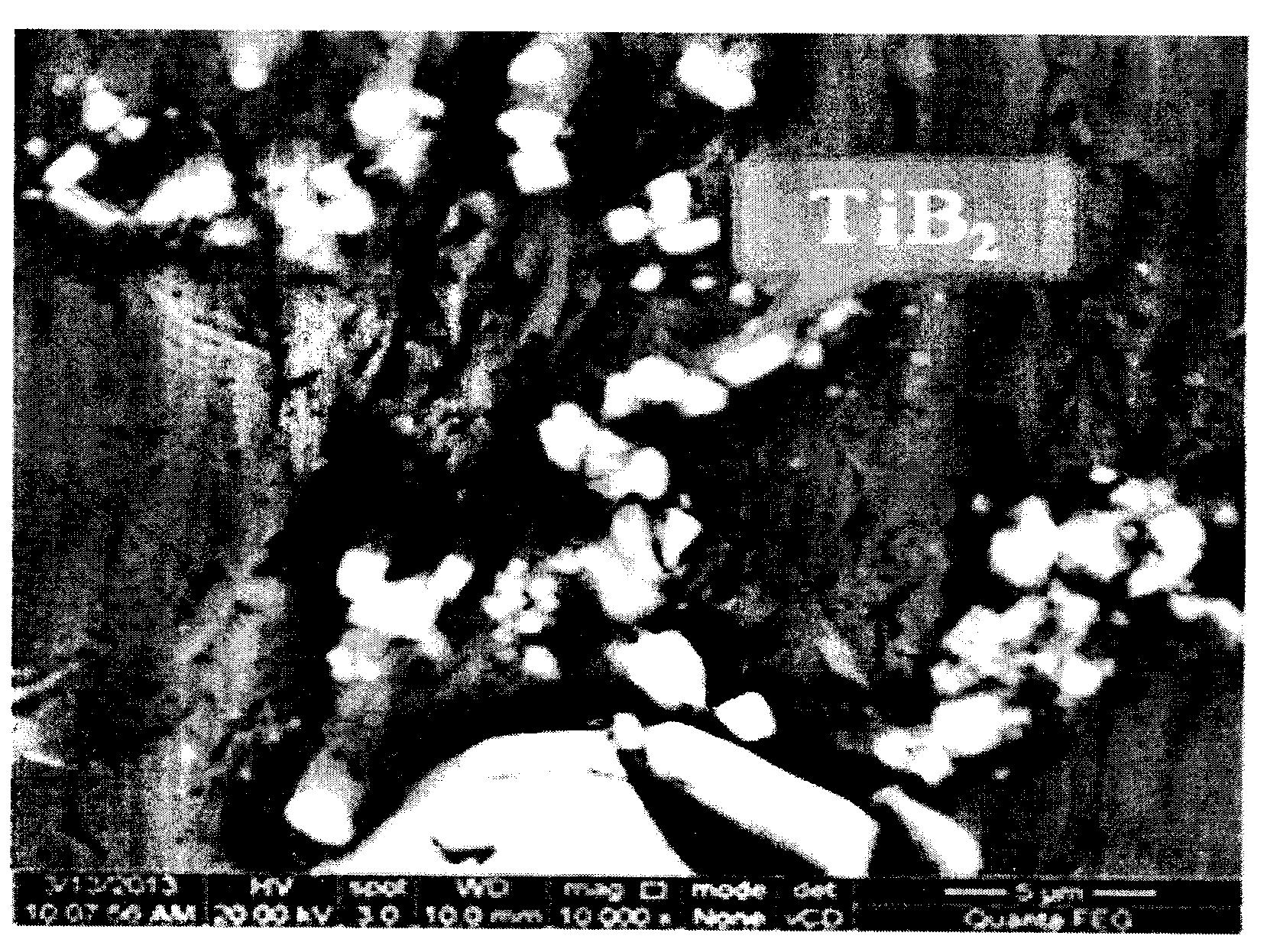

The invention discloses an Al-Ti-B-Er refiner and a preparation method thereof and belongs to the technical field of refiners. The Al-Ti-B-Er refiner comprises the following components in weight percentage: 3.0-10.0 percent of Ti, 0.6-2 percent of B, 0.1-0.3 percent of Er and the balance of Al, wherein the weight ratio of the Ti to the B is 5 / 1. The phase composition comprises alpha-Al, TiAl3, TiB2, Al3Er and AlErTi. The preparation method comprises the following steps of: weighing boron (B) powder, titanium (Ti) powder, aluminum (Al) powder, an Al-Er intermediate alloy and an aluminum ingot as required, wherein the weight ratio of the titanium (Ti) powder to the boron (B) powder is 5, the molar ratio of the aluminum (Al) powder to the titanium (Ti) powder is 2.5-3.0, and the purity of the aluminum ingot is 99.9 percent; evenly mixing the Ti, the Al with the B; putting in a mould; pressing into a block; heating to melt the aluminum ingot; covering by kryocide; pressing in the Al-Er intermediate alloy; standing; heating a melt; pressing in the block; performing stirring reaction; pressing in C2Cl6 for refining; drossing and pouring. According to the Al-Ti-B-Er refiner disclosed by the invention, the problem that the TiB2 can be easily gathered is solved, and the refining efficiency is increased.

Owner:BEIJING UNIV OF TECH

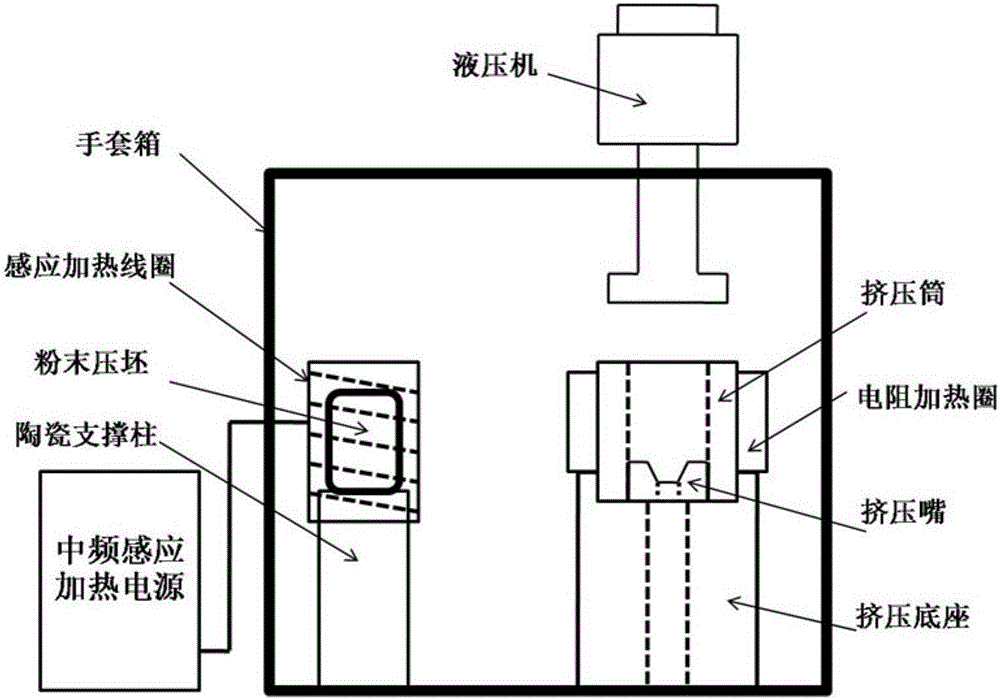

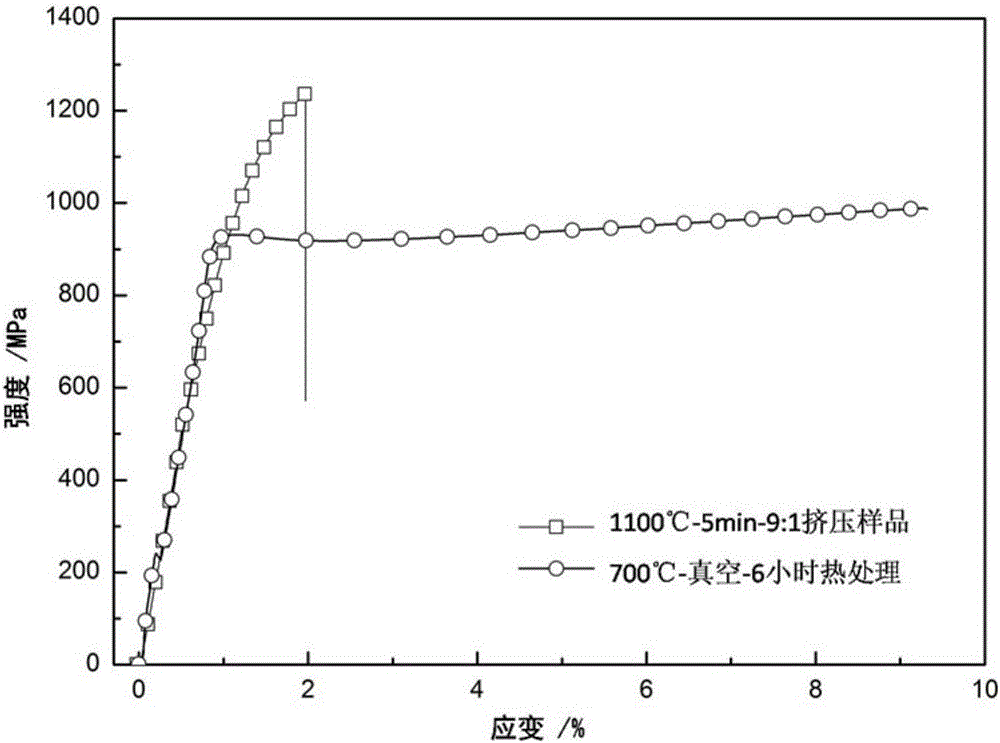

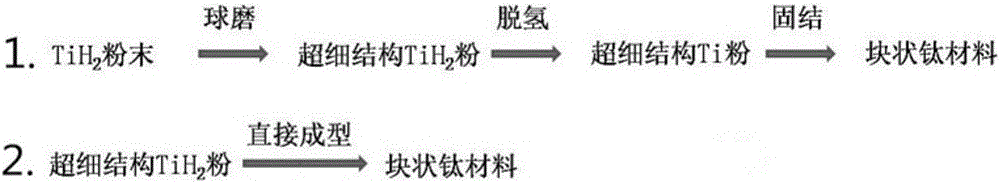

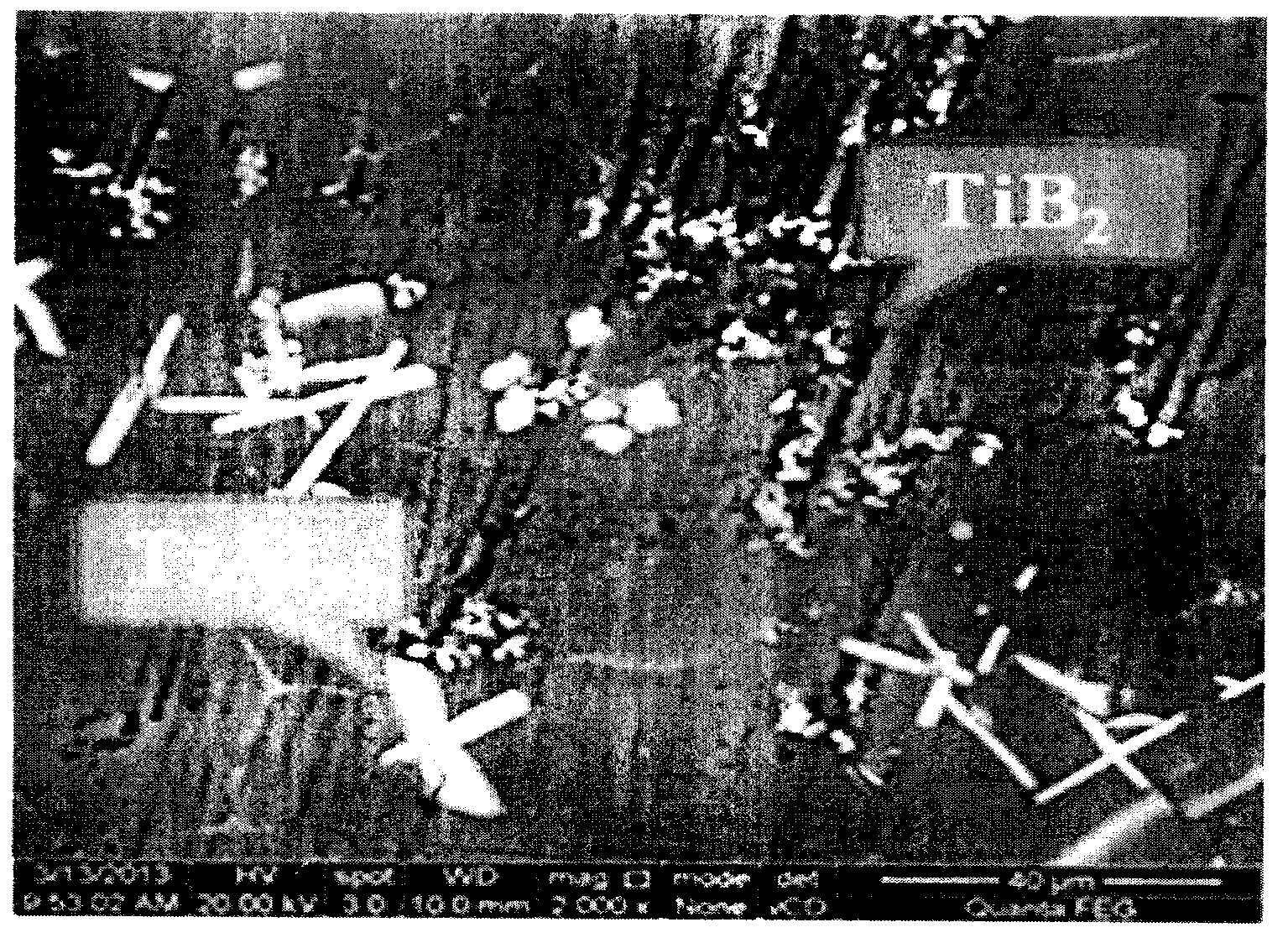

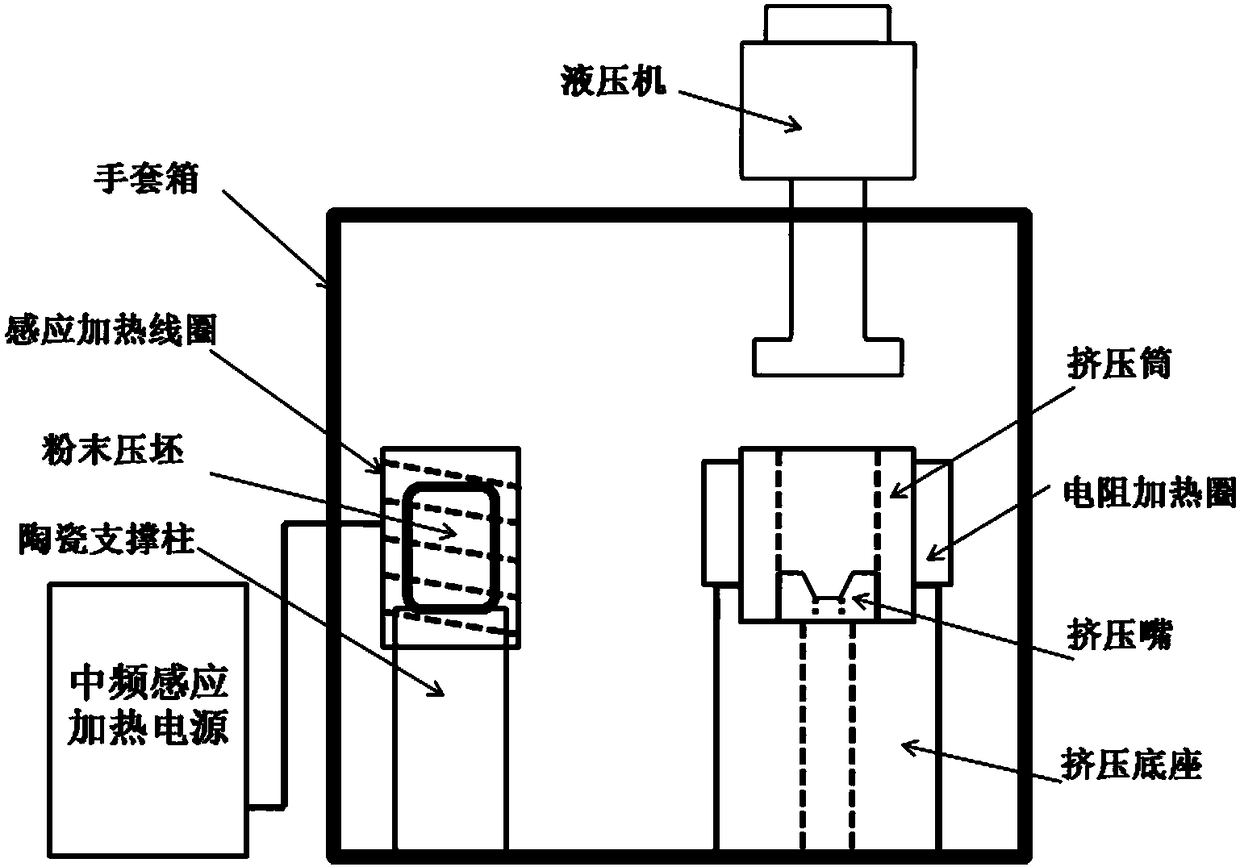

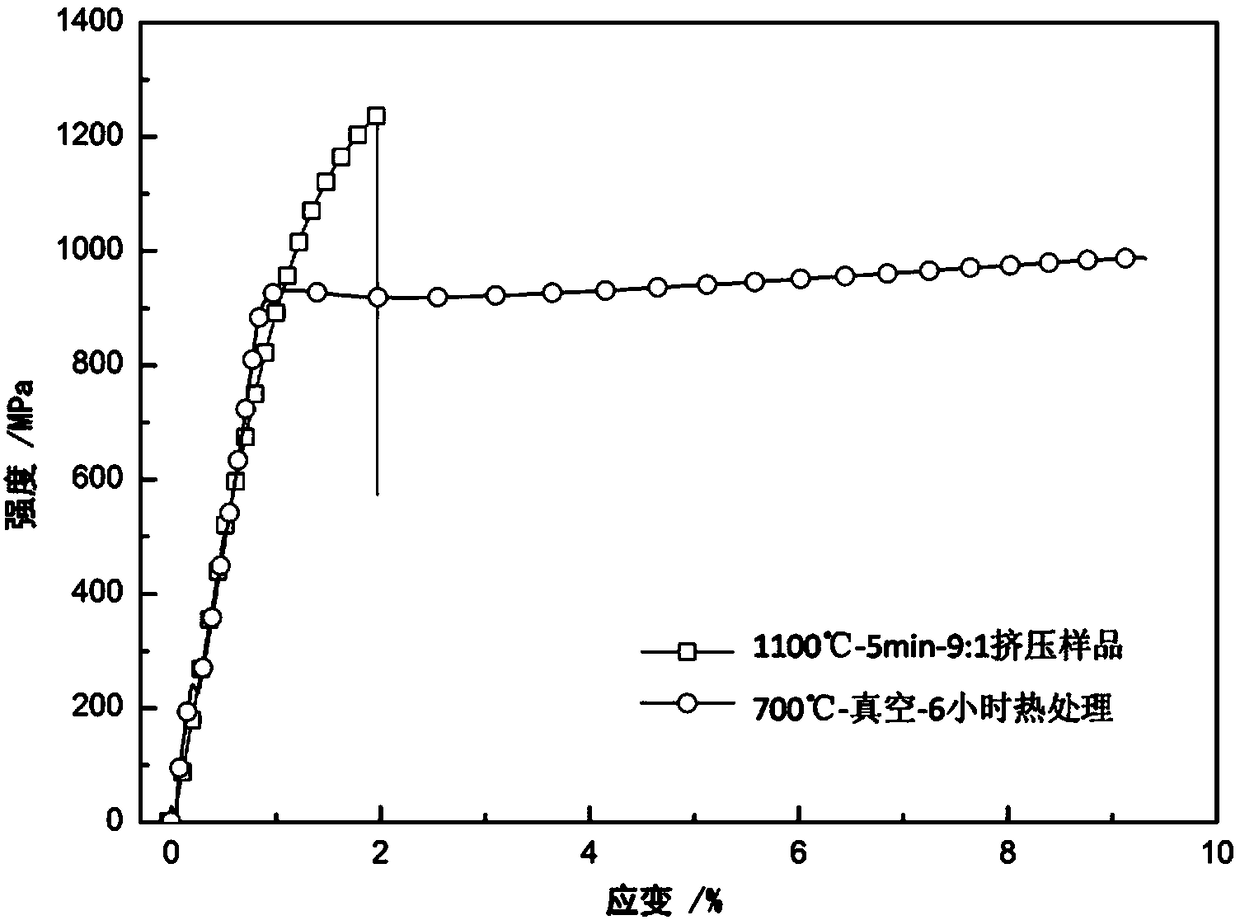

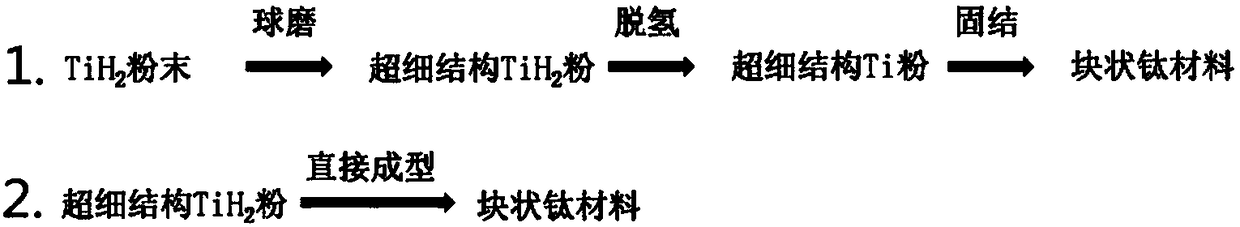

Novel powder metallurgy method for preparing nanometer or ultrafine structured titanium products

InactiveCN106077656AHigh grain refinement efficiencyThe process steps are simpleCrystalliteNanometre

The invention provides a novel powder metallurgy method for preparing nanometer or ultrafine microstructural titanium products. The method includes: step one, reducing grain size of titanium hydride powder to nanocrystalline level; step two, subjecting the titanium hydride powder in the nanocrystalline level to thermal consolidation to form pressed blanks; step three, under inert gas protection, heating the pressed blanks; step four, transferring the heated pressed blanks into an extruding device, and extruding under a certain pressure intensity and extrusion ratio to make the pressed blanks into the nanometer or ultrafine microstructural titanium products through an extruding mould with a certain inner cavity shape; step five, after extrusion is finished, cooling the extruded titanium products to the room temperature, and taking out; step six, heating the titanium products in a vacuum environment. A heating device used at the step three and the extruding device used at the step four are mounted in a same seal system, and insert gas is continuously fed into the seal system in a whole heating and extruding process.

Owner:SHANGHAI JIAO TONG UNIV

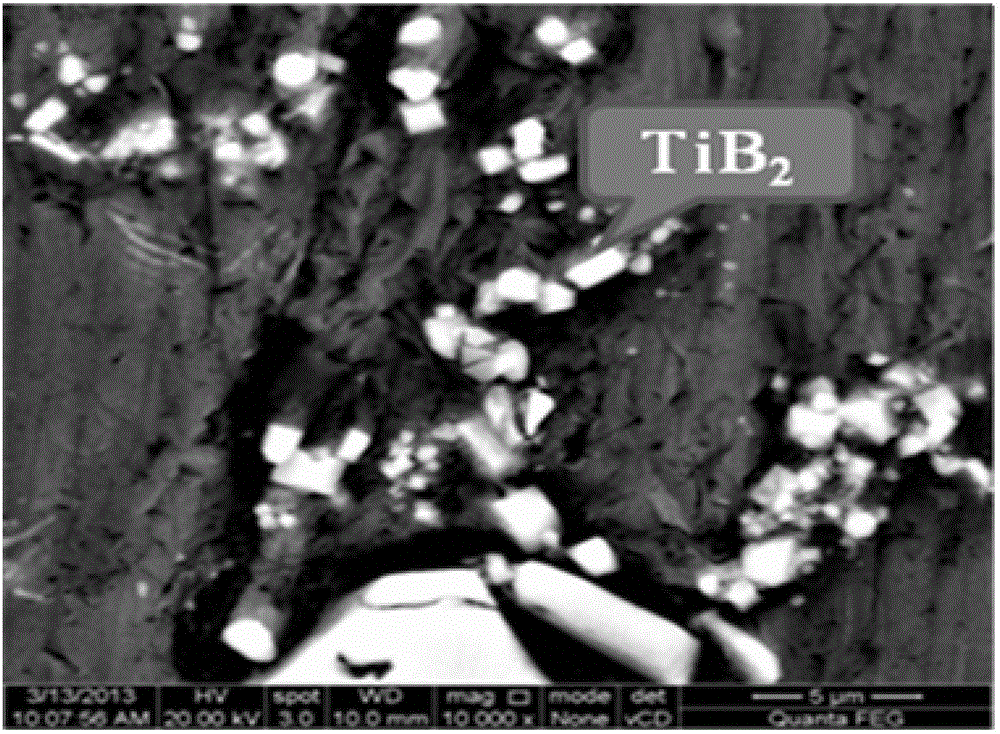

High-efficiency clean Al-Ti-B refiner and preparation method thereof

The invention relates to a high-efficiency clean Al-Ti-B refiner and a preparation method thereof, belonging to the technical field of refiners. The high-efficiency clean Al-Ti-B refiner comprises the following components in percentage by mass: 3.0-6.0% of Ti, 0.6-2% of B and the balance of Al. The phase composition comprises alpha-Al, TiAl3 and TiB2. The preparation method comprises the following steps: weighing B2O3, TiO2, aluminum powder and aluminum ingot according to requirements, wherein the TiO2:B2O3:Al powder ratio is (2.8-3.2):(3.5-4.2):(4.7-5.2)(mol), and the purity of the aluminum ingot is 99.9%; evenly mixing the TiO2 and B2O3, and heating at 300 DEG C for two hours; mixing the heated powder and aluminum powder, putting the mixture in a mold, and pressing into a block; melting the aluminum ingot by heating, and covering cryolite; and heating the melt, pressing into the block, stirring to react, pressing in C2Cl6, refining, removing slag, and casting. The invention utilizes low-cost raw materials; the dimension of the prepared TiB2 is 1 mu m; and the dimension of the TiAl3 is 3-30 mu m, and the TiAl3 is distributed uniformly.

Owner:丹阳百斯特新型合金科技有限公司

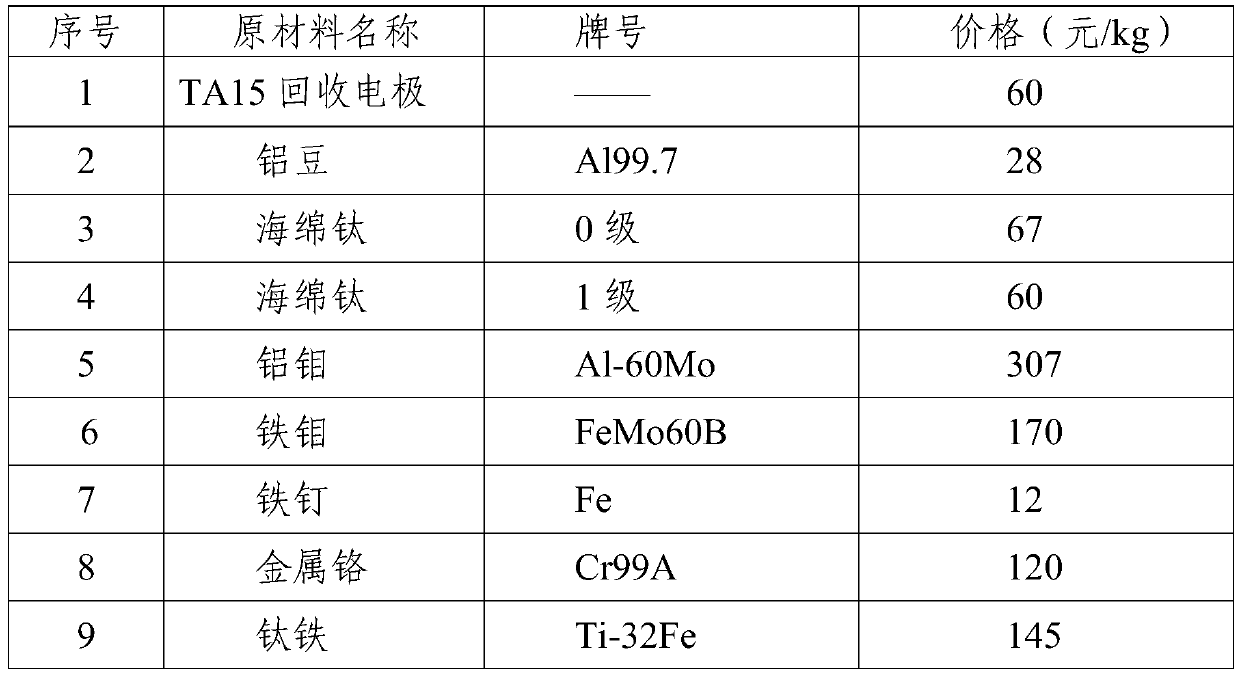

Nearly beta-type high-toughness titanium alloy and preparation method thereof

The invention discloses a nearly beta-type high-toughness titanium alloy. The nearly beta-type high-toughness titanium alloy comprises the following components in percentage by mass: 4.0%-5.5% of Al,0.8%-1.8% of Zr, 3.0%-4.5% of Mo, 1.0%-2.0% of V, 1.5%-2.5% of Fe, 2.5%-3.5% of Cr, no more than 0.12% of B, and the balance Ti and inevitable impurities. The invention also discloses a preparation method of the nearly beta-type high-toughness titanium alloy. According to the preparation method, a large amount of TA15 recycled material is adopted as a raw material; an Al-Zr system is adopted to reinforce an alpha phase in the titanium alloy, and a Mo-V-Cr-Fe system is adopted to reinforce a beta phase in the titanium alloy, so that the coupling reinforcement effect is enhanced; the titanium alloy has good strength and toughness matching; the aluminum equivalent and the molybdenum equivalent of the titanium alloy are controlled, so that the great strength and toughness of the titanium alloyis ensured; and the TA15 titanium alloy recycled material is used as a raw material, so that the preparation cost is greatly reduced.

Owner:WESTERN TITANIUM TECH

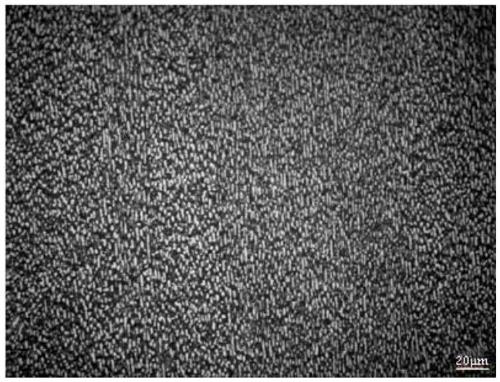

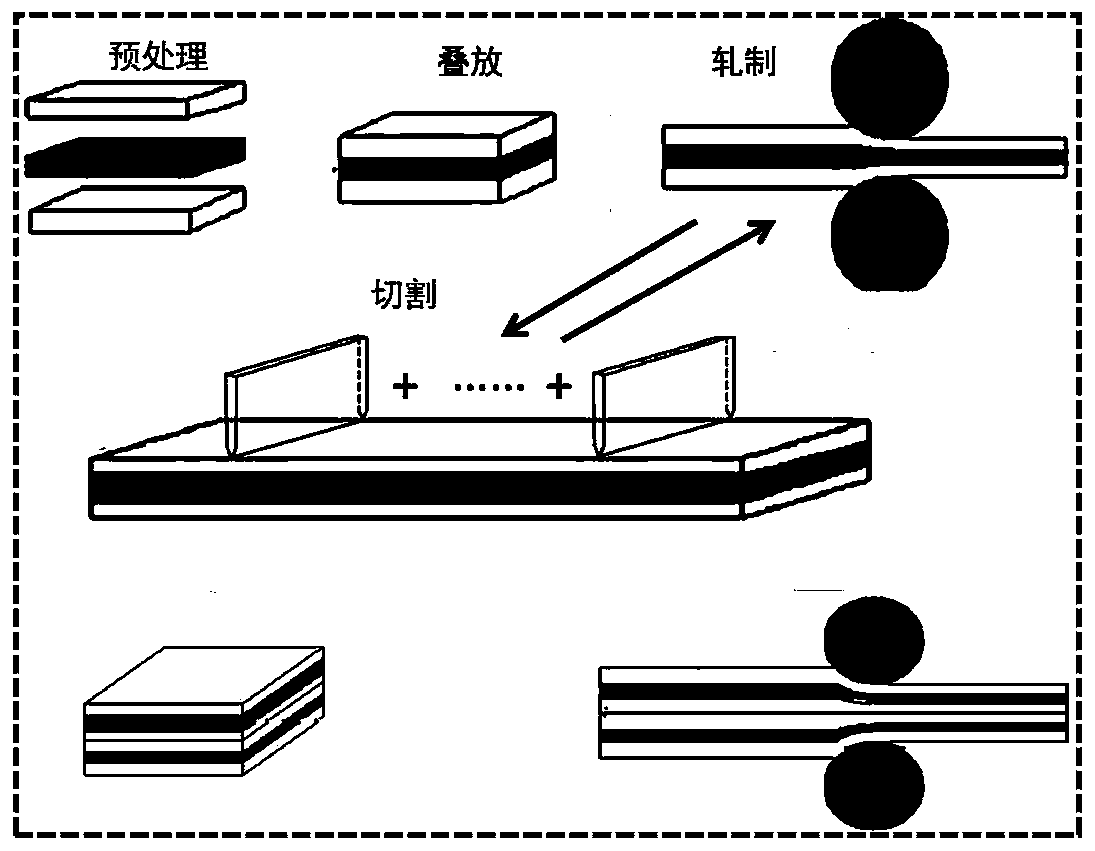

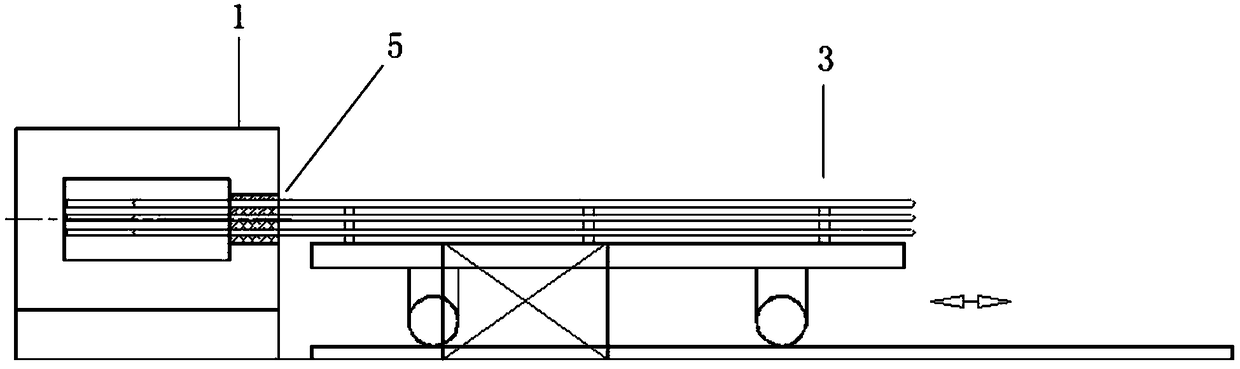

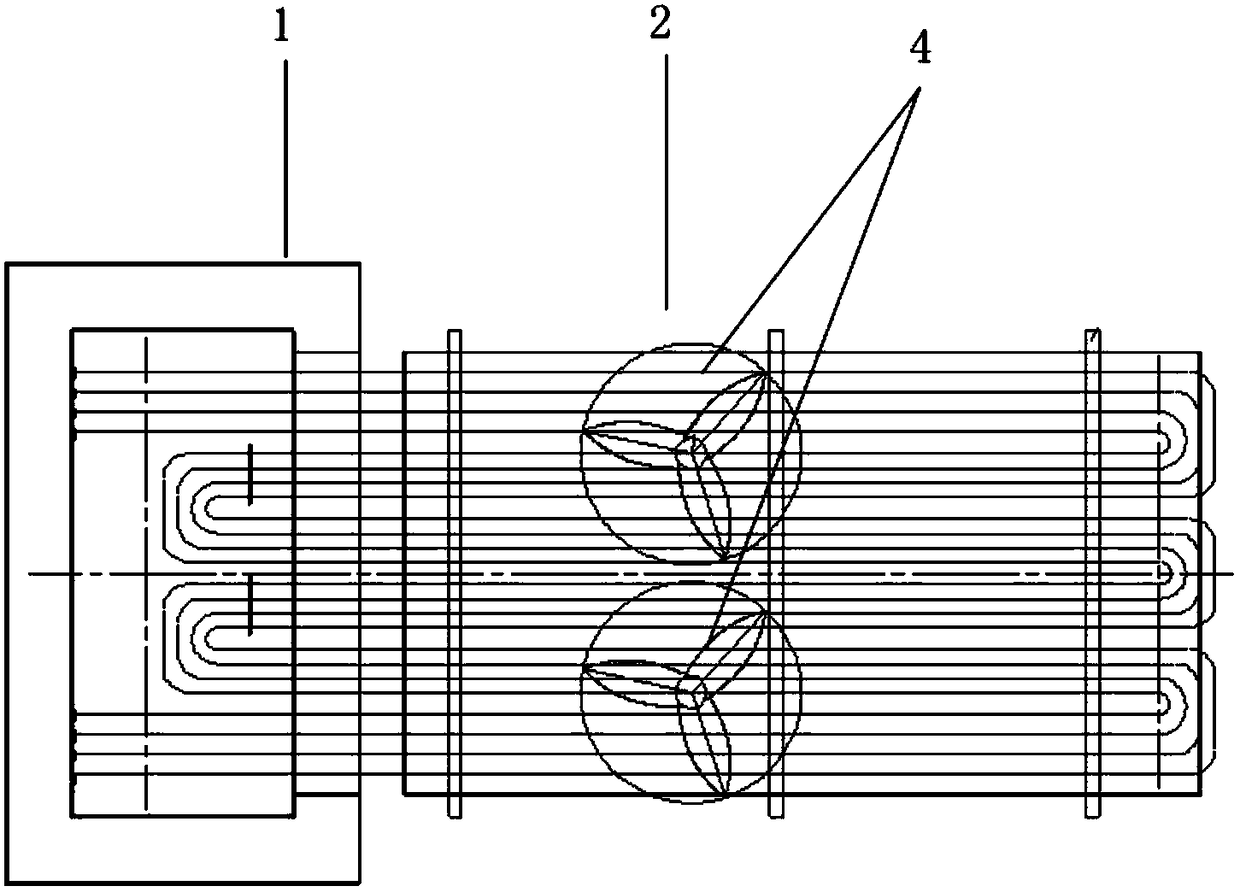

Method for preparing laminated metal composite through multilayer-accumulation ply rolling

ActiveCN111229833AFacilitate success rateImprove refinement efficiencyFurnace typesAuxillary arrangementsTotal thicknessIndustrial engineering

The invention relates to a method for preparing a laminated metal composite through multilayer-accumulation ply rolling. The single-pass rolling reduction in the rolling process and the number of evenly-divided plates obtained after ply rolling are combined, and the total thickness of the ply-rolling plates is controlled on the premise of guaranteeing good binding of material interfaces. By meansof multilayer-accumulation ply rolling, the total thickness of the plates is flexibly controlled by controlling the rolling reduction during rolling and the number of evenly-divided plates obtained after ply rolling. In addition, the lamination refining efficiency is greatly improved, it means that the ply rolling passes needed for obtaining the same lamination thickness are greatly reduced, thenaccumulation of microcracks and other defects in the rolling process is effectively suppressed, and the success rate of ply rolling is further improved. The method for simply and effectively improvingthe typical accumulation ply rolling process, namely, a multilayer-accumulation ply rolling technology, is provided. By means of the method, the situation of lamination instability in the composite ply rolling process can be effectively suppressed, the lamination thickness refining efficiency can be greatly improved, large-size components can be produced, and industrial production can be achievedeasily.

Owner:西北工业大学太仓长三角研究院 +1

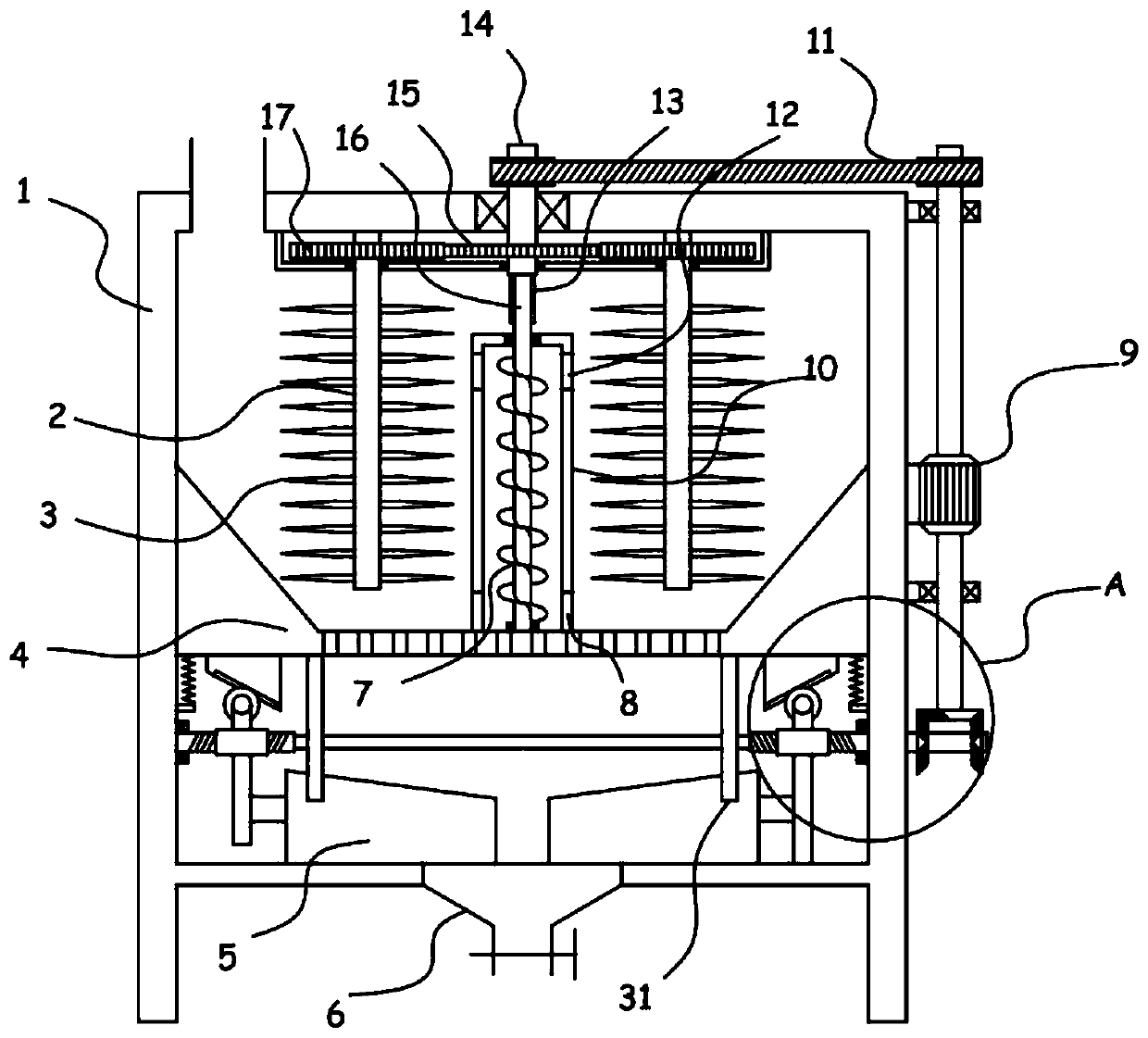

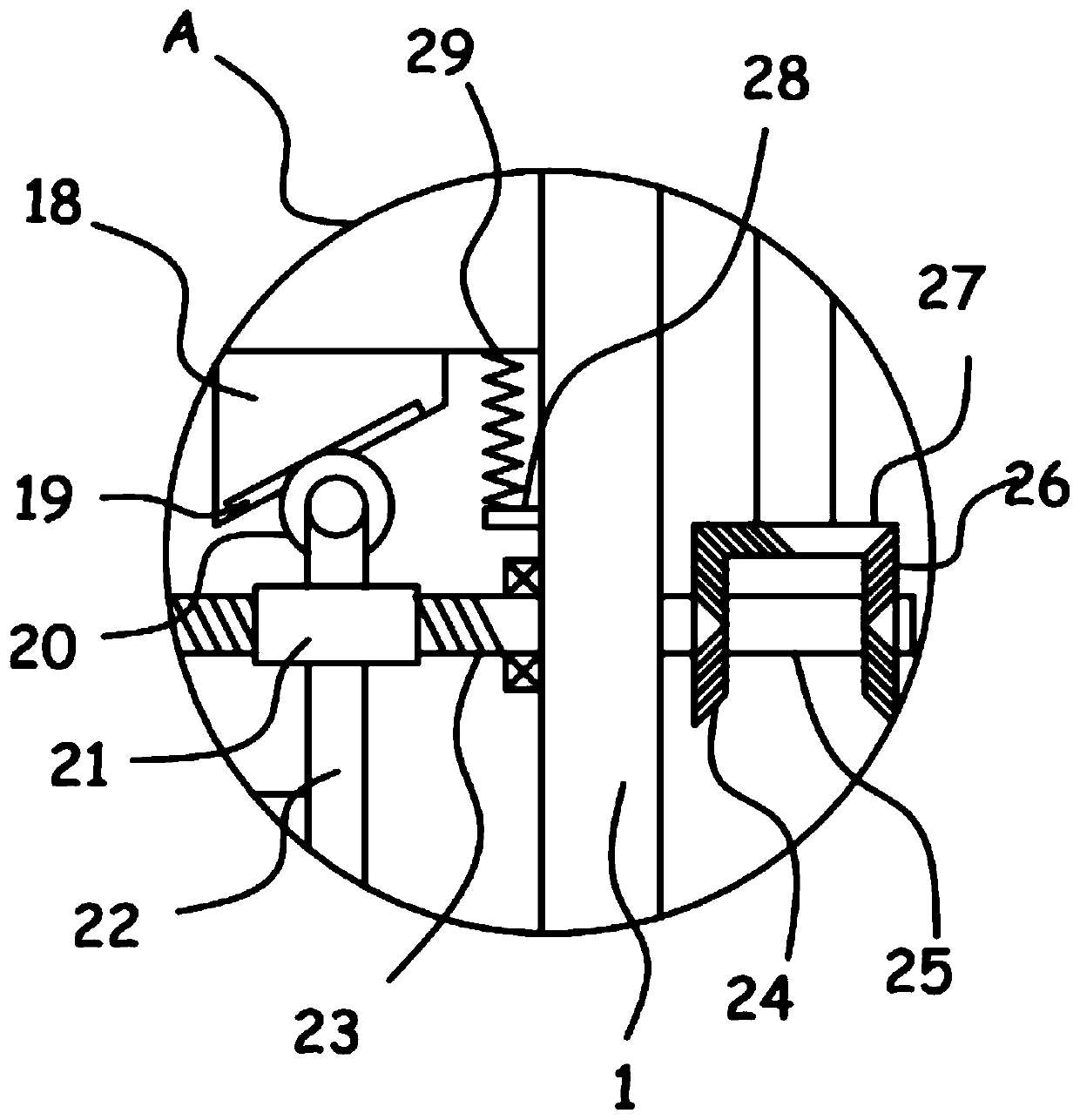

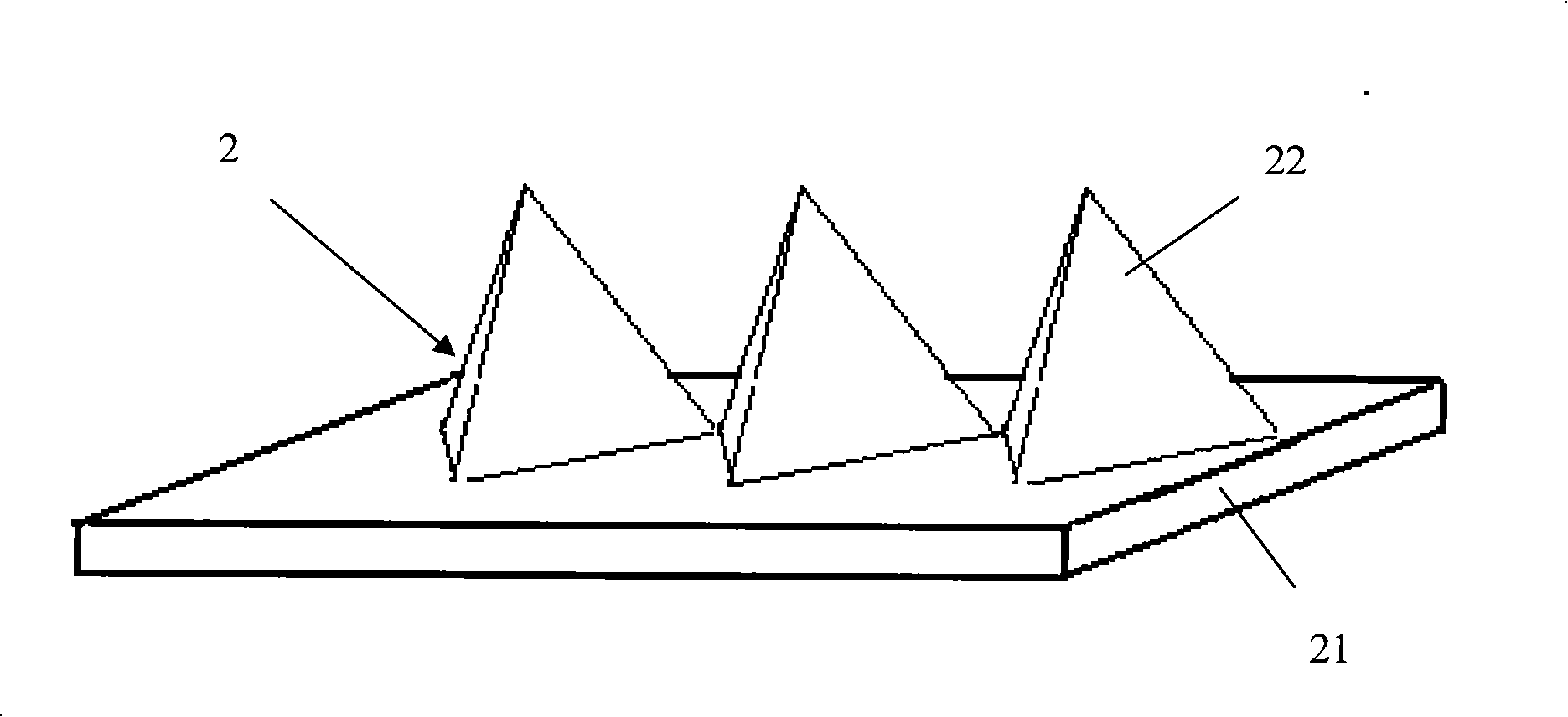

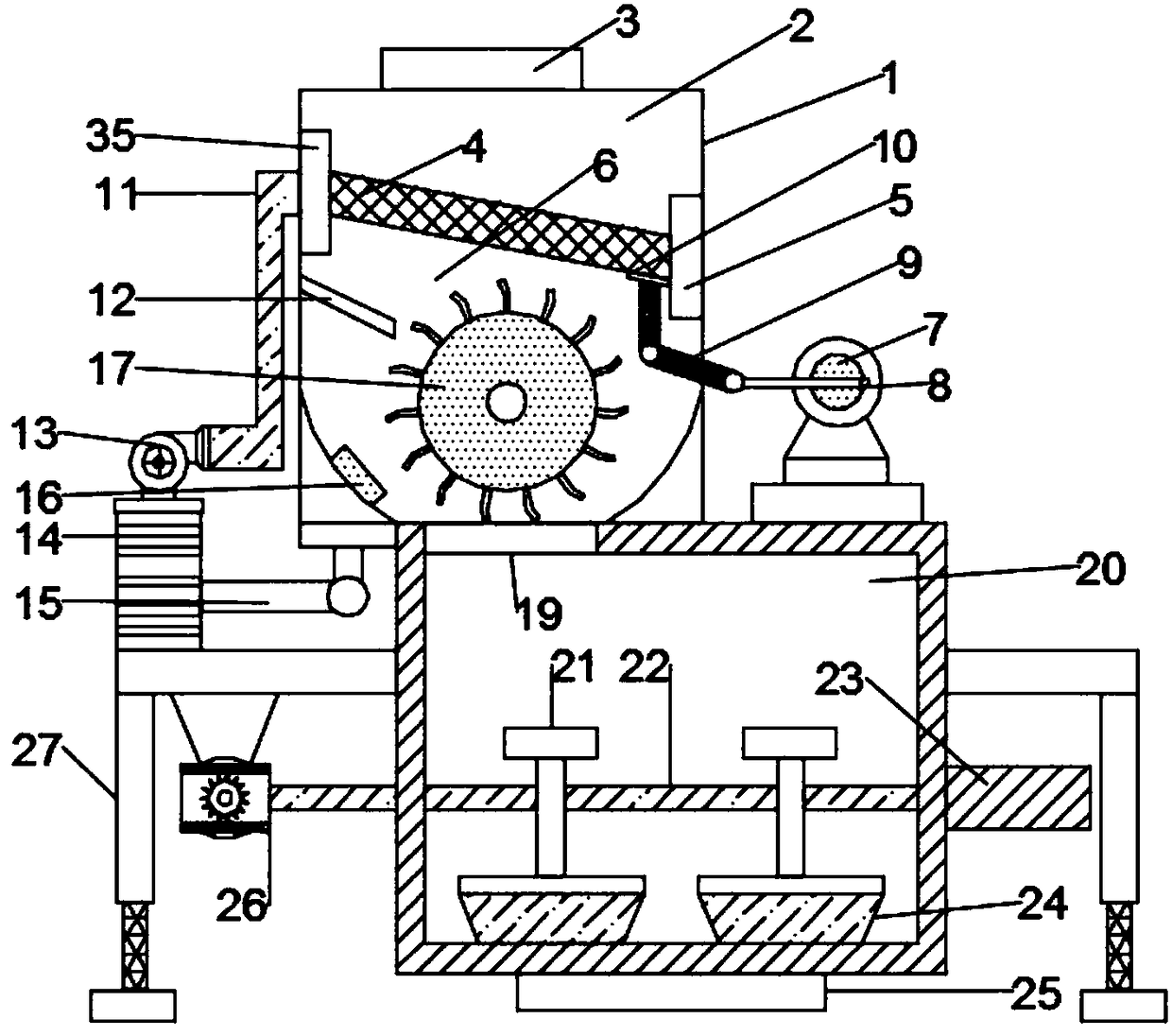

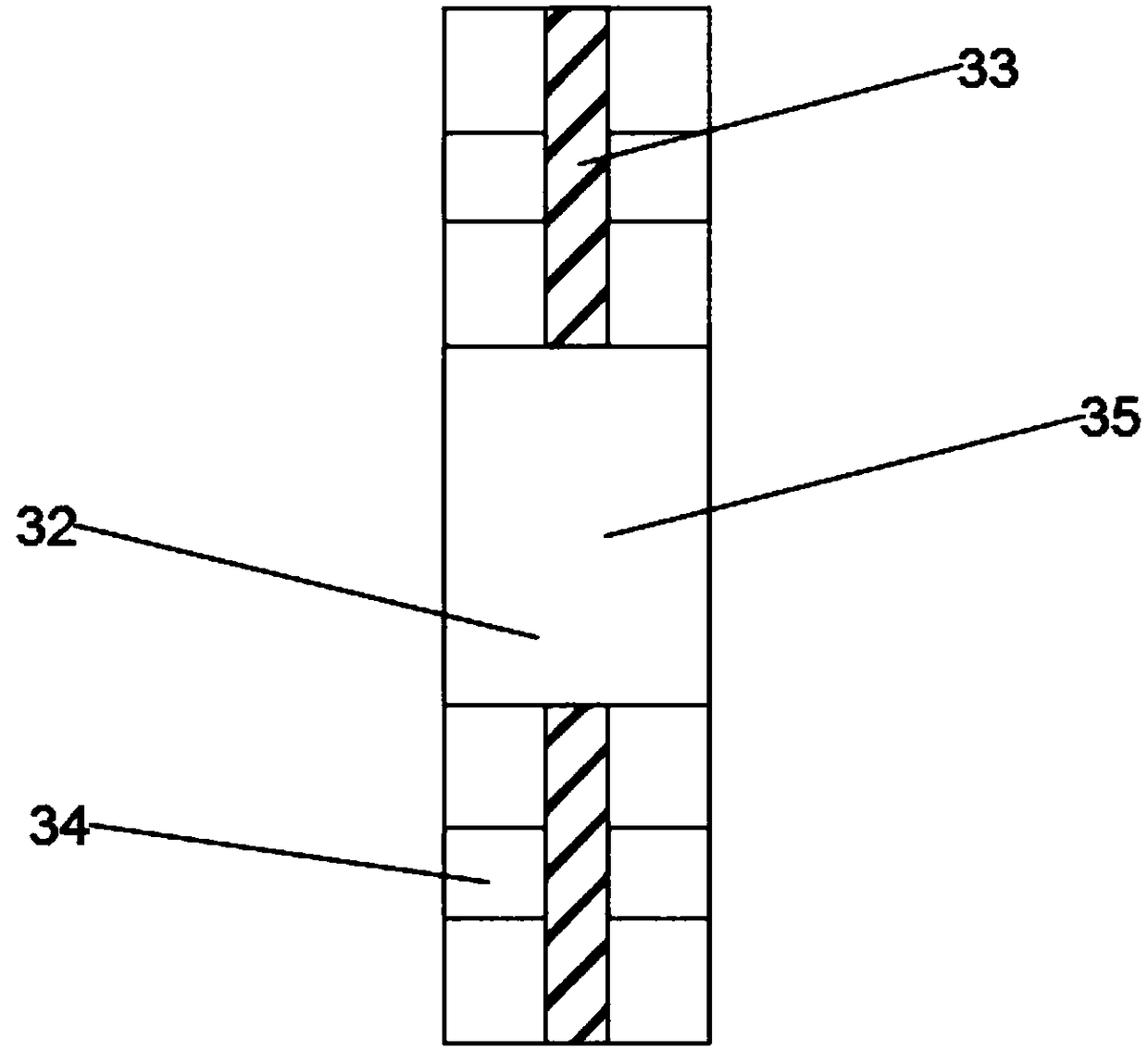

Chemical raw material crushing and refining device

InactiveCN110961208AImprove Flip EffectThe crushing effect is sufficientSievingScreeningDrive shaftCrushing action

The invention discloses a chemical raw material crushing and refining device, and relates to the technical field of chemical engineering. The device comprises a crushing box, a plurality of pairs of crushing blades are fixed to the side wall of a driven shaft at equal intervals, a lifting mechanism used for driving a bearing net plate to vertically ascend and descend is arranged on the crushing box, a crushing mechanism used for impacting and crushing chemical raw materials is arranged on the lifting mechanism, and a discharging hopper is vertically installed at the bottom of the crushing box.Rotation of the driven shaft and a driving shaft is achieved through an arranged transmission mechanism. The driven shaft drives the crushing blades to rotationally crush the chemical raw materials;through the arrangement of the lifting mechanism, materials can be vertically and repeatedly circulated; under the repeated cutting and crushing action of the crushing blades in the circulating process, the arranged lifting mechanism can drive the bearing net plate to vibrate up and down, the turning action of the raw materials is promoted, the raw material crushing effect is more sufficient, arranged extrusion blocks can repeatedly impact and crush the chemical raw materials, and the refining efficiency of the raw materials is greatly improved.

Owner:王淑英

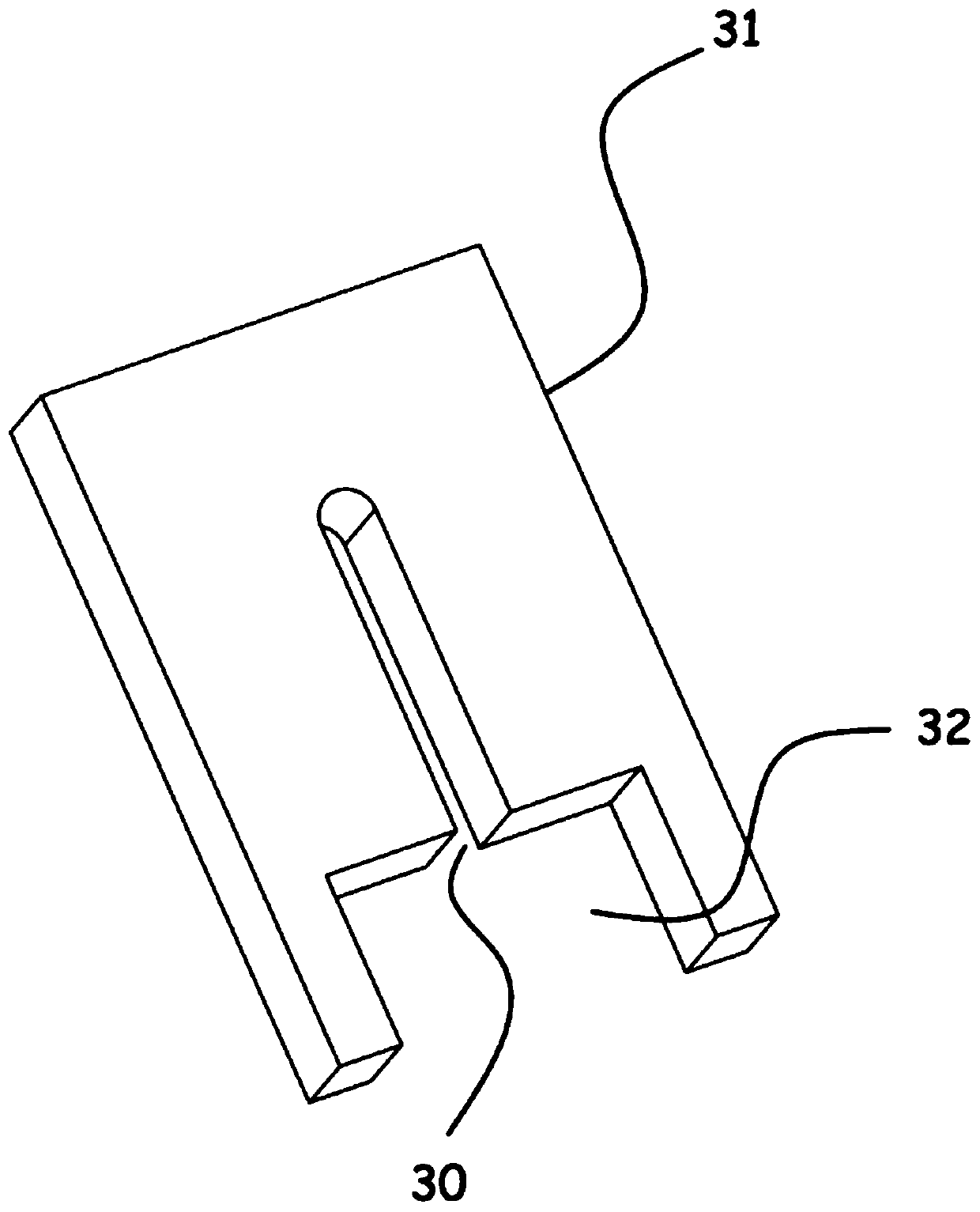

Rope-shaped hemp pulling, cutting and thinning processing equipment with dispersed comb strip

InactiveCN101407952AImprove the efficiency of drawing and cuttingImprove the quality of drawing and cutting refinementDrafting machinesEngineeringRamie

The invention belongs to the textile field, and discloses rope-shaped ramie stripe stretch-breaking refining processing equipment provided with a dispersed hackle, the equipment is newly provided with a dispersed hackle which consists of a hackle bottom plate and pin teeth on the existing rope-shaped ramie stripe stretch-breaking processing equipment. The equipment solves the defects in the existing stretch-breaking refining process that: as rope-shaped ramie stripes after degumming have high strength, a drafting upper leather roller is easy to slip in the drafting process and the rope-shaped ramie stripes are difficult to be treated with complete stretch-breaking and refining, thus not only ensuring the continuous and effective running of the stretch-breaking and refining of the rope-shaped ramie stripes, but also prolonging the abrasion period of the upper leather roller.

Owner:DONGHUA UNIV +1

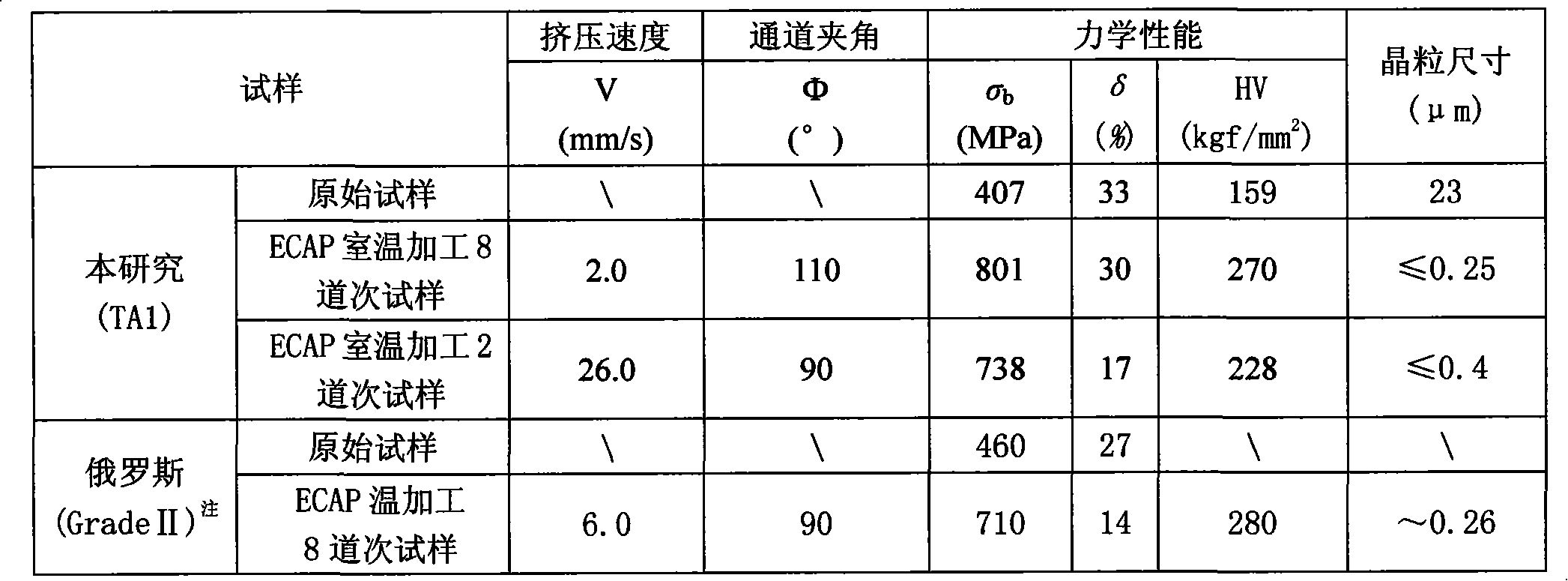

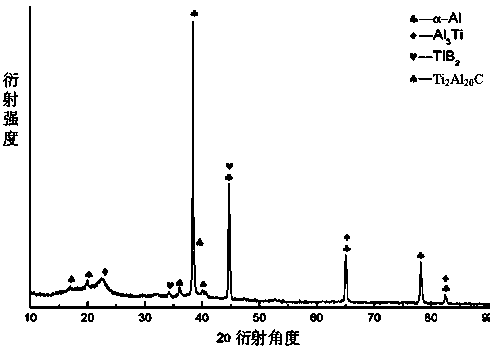

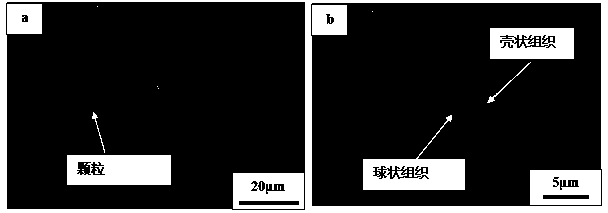

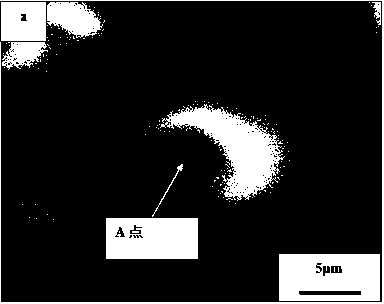

Preparation method for difficult-to-deformation metal block material room temperature equal-diameter bending passage deformation

The invention discloses a preparation method for difficult-to-deformation metal block material room temperature equal-diameter bending passage deformation; the method selects industrially pure titanium hot-rolling sheet material as raw material; after annealing, the industrially pure titanium hot-rolling sheet material is cut into blank; and then surface finish treatment is carried out on the blank, the included angle of the blank is phi=90 degrees to 110 degrees with the passage, and the inner surface of the cavity of a mould, exterior round corner of which is psi=10 degrees to 45 degrees, is coated with compound lubricant comprising molybdenum disulfide and graphite; and finally ECAP deformation is carried out in the room temperature. The invention can increase the room temperature intensity of the pure titanium and the comprehensive mechanical property thereof; in the preparation process, the lesser deformation passage number can be utilized for generating obvious detailing effect, thus obtaining high-strength industrial pure titanium by utilizing lesser passage number, reducing the treatment cost of the pure titanium and increasing rate of finished products.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of superfine crystal inoculating agent for aluminum alloy grain refinement

Owner:HEBEI UNIV OF TECH

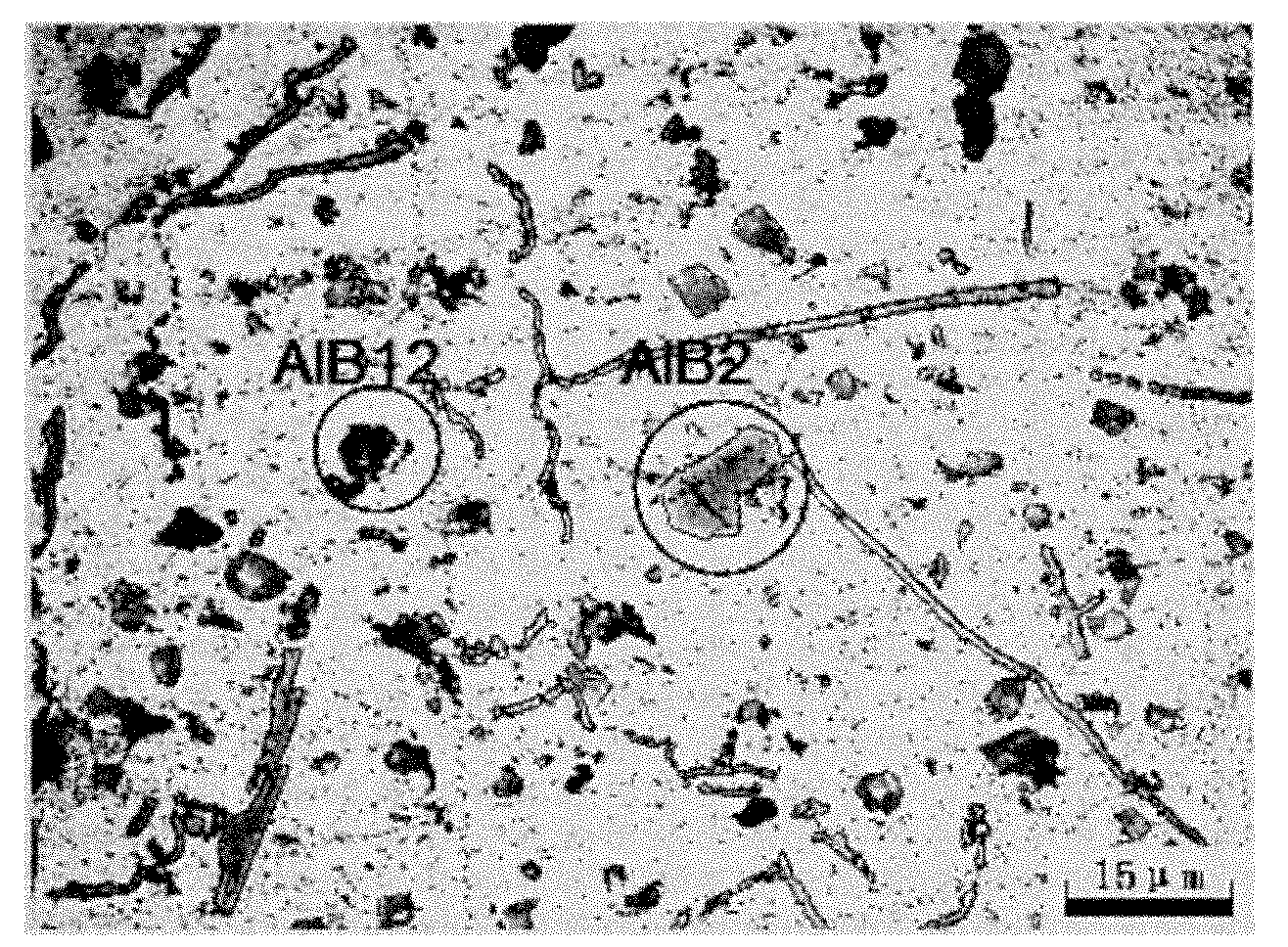

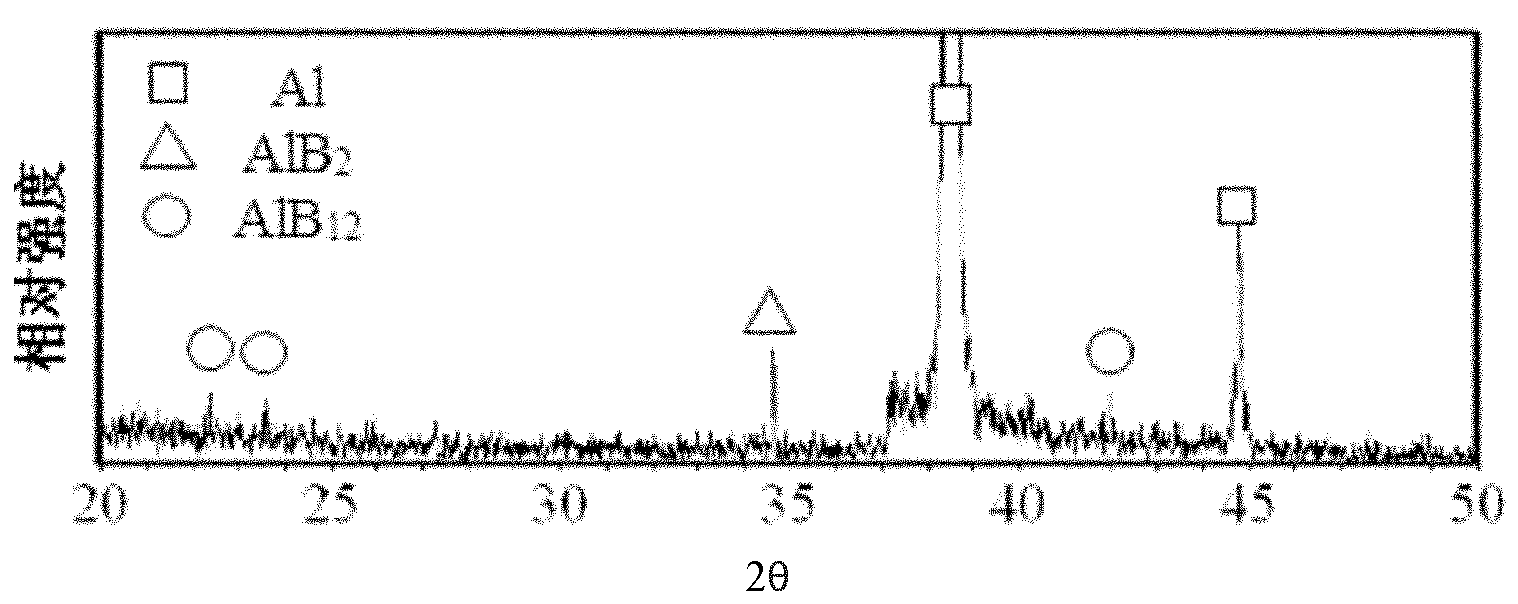

Long-service-life aluminum-silicon alloy grain refiner and preparation method thereof

The invention relates to a long-service-life aluminum-silicon alloy grain refiner and a preparation method thereof. The grain refiner is an Al-B alloy and comprises the following components in percentage by mass: 1.0 to 5.0 percent of boron and the balance of aluminum. The preparation method comprises the following steps of: porphyrizing the boron in the form of KBF4, drying and briquetting; adding into an aluminum melt; and smelting at the temperature of between 900 and 1,200 DEG C to synthesize the Al-B alloy, wherein AlB2 and AlB12 coexist in the Al-B alloy. The refiner prolongs the existing time of nucleation material points in the high-temperature melt, improves the settlement behavior of particles, and has the obvious characteristics of long service life, degradation resistance and high refinement efficiency when used as the grain refiner for casting aluminum-silicon alloys.

Owner:DALIAN UNIV OF TECH

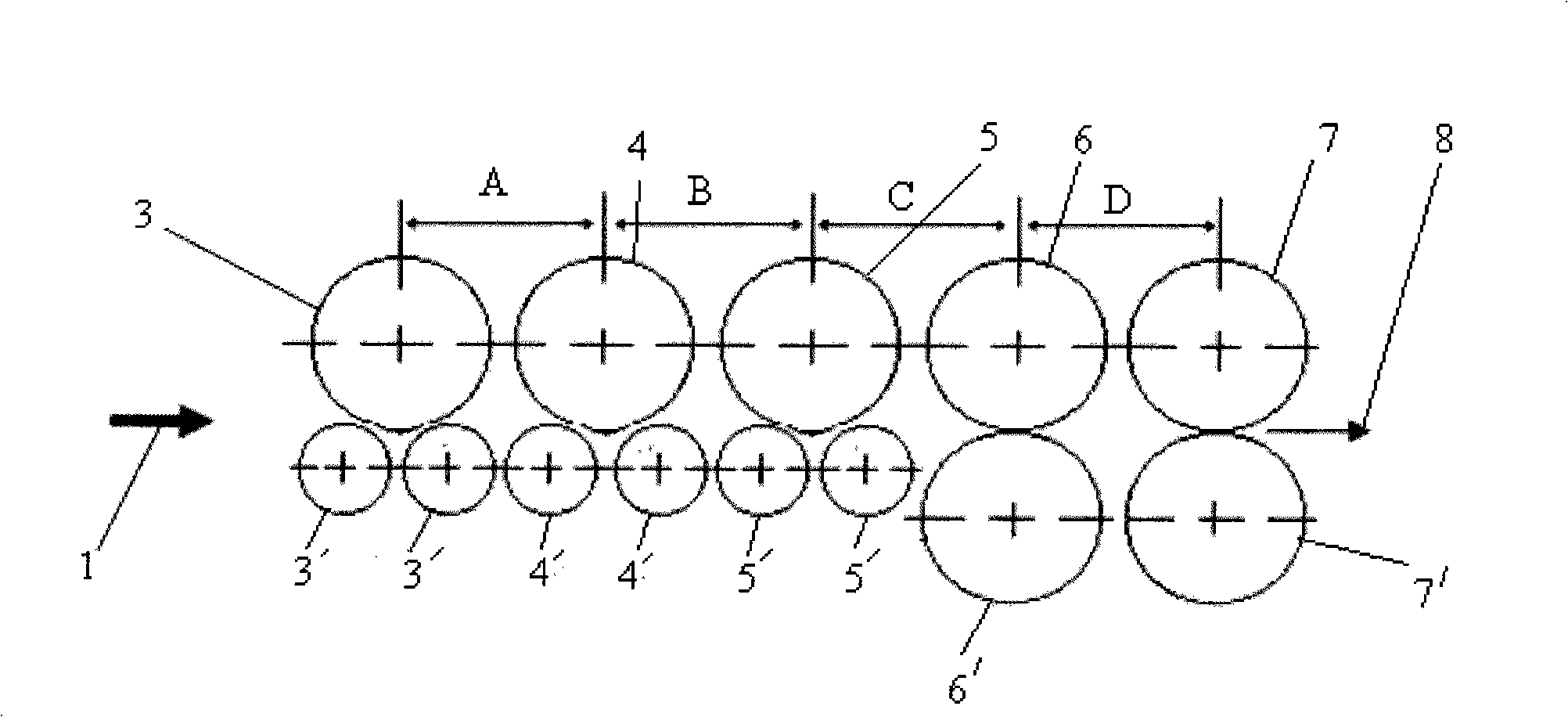

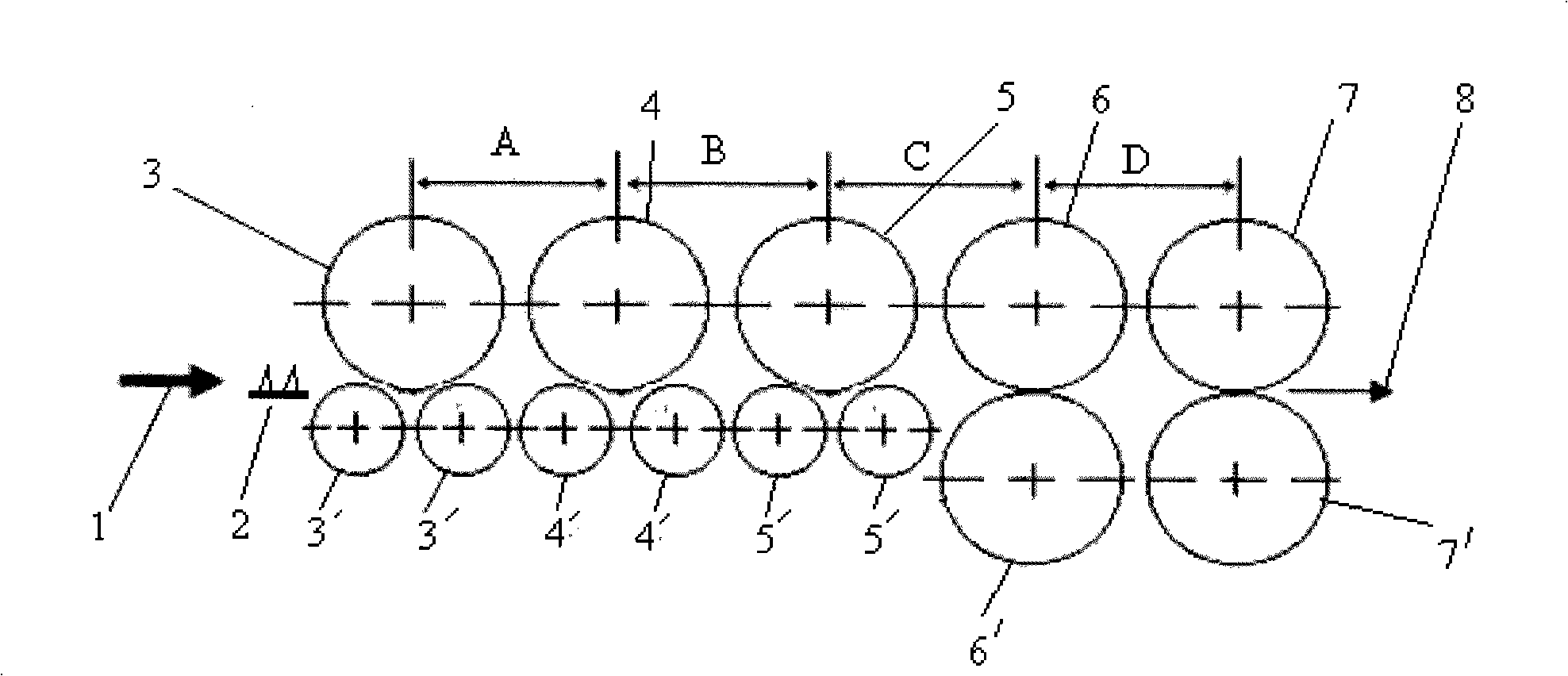

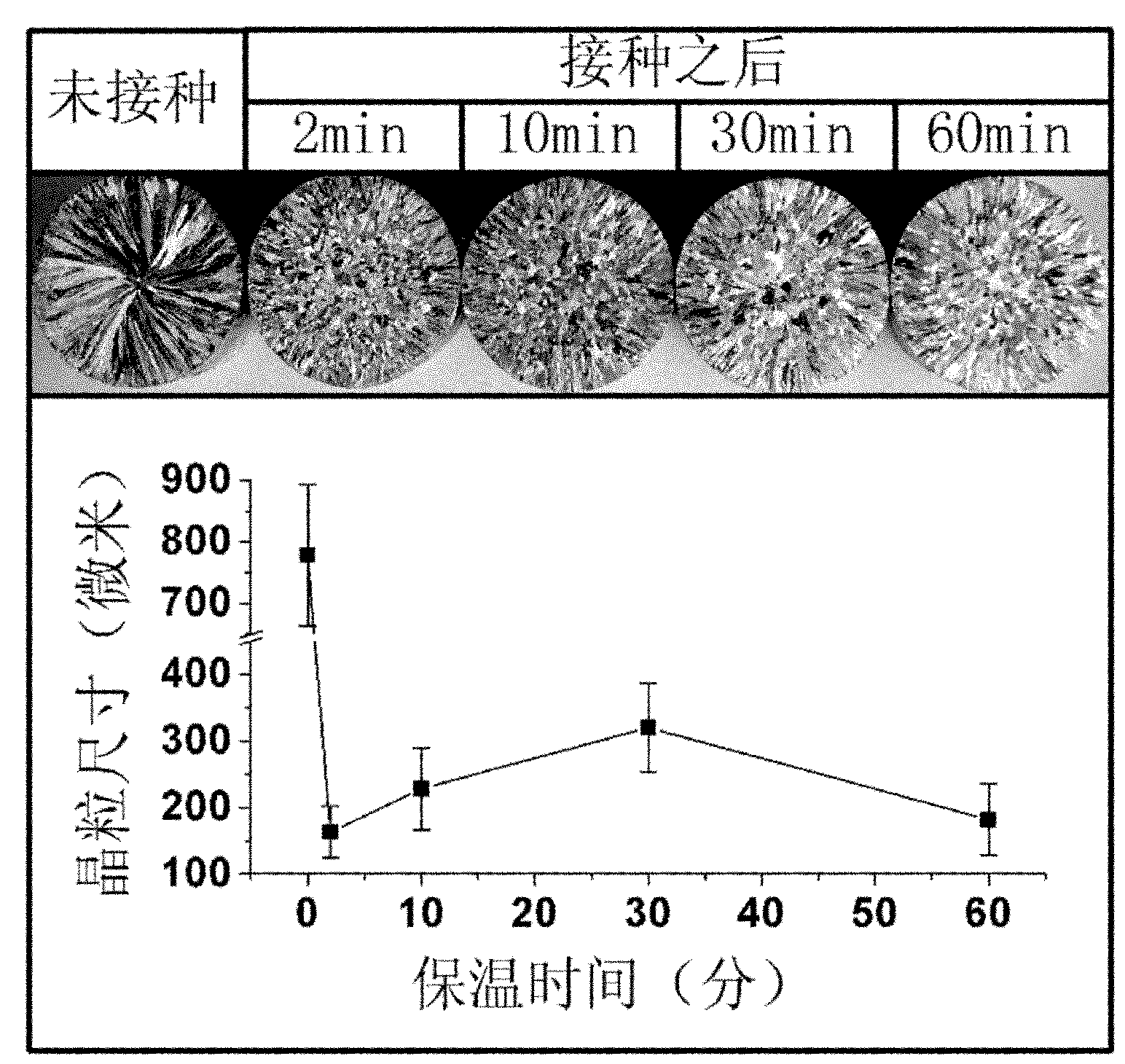

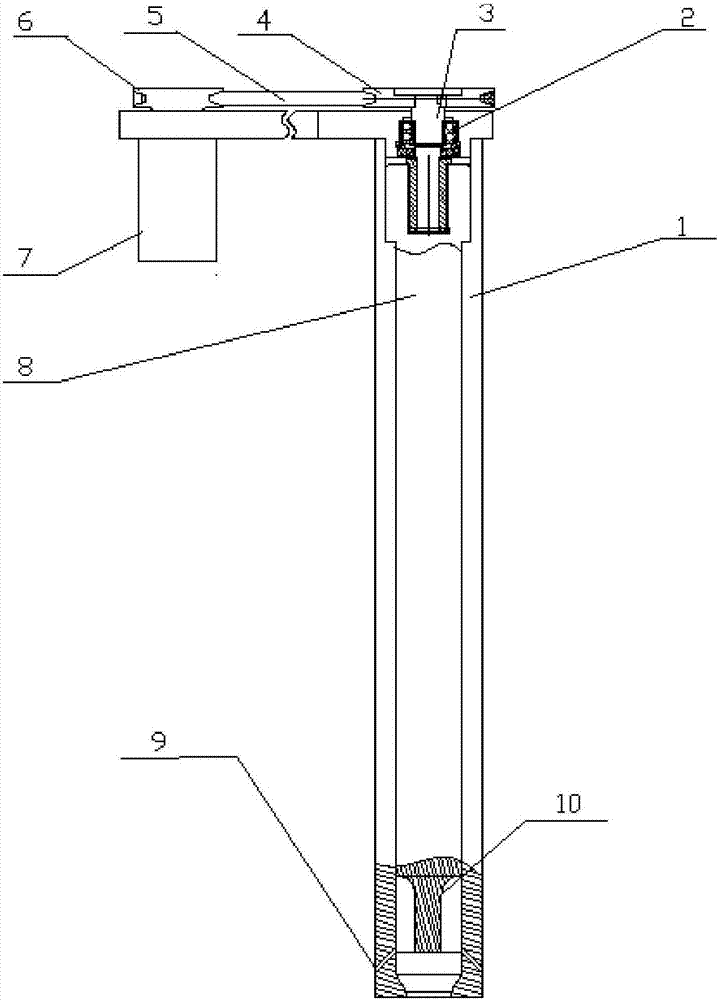

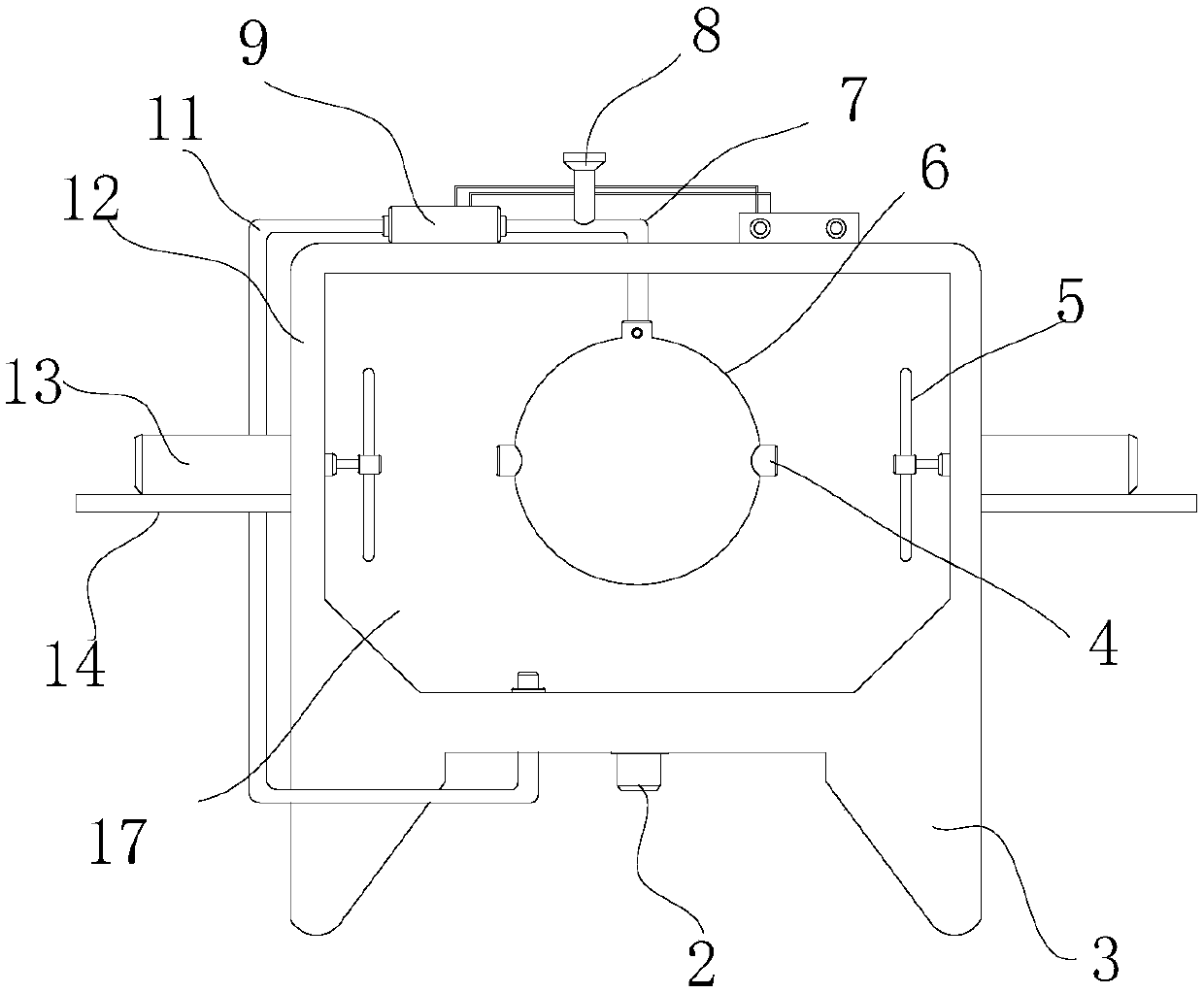

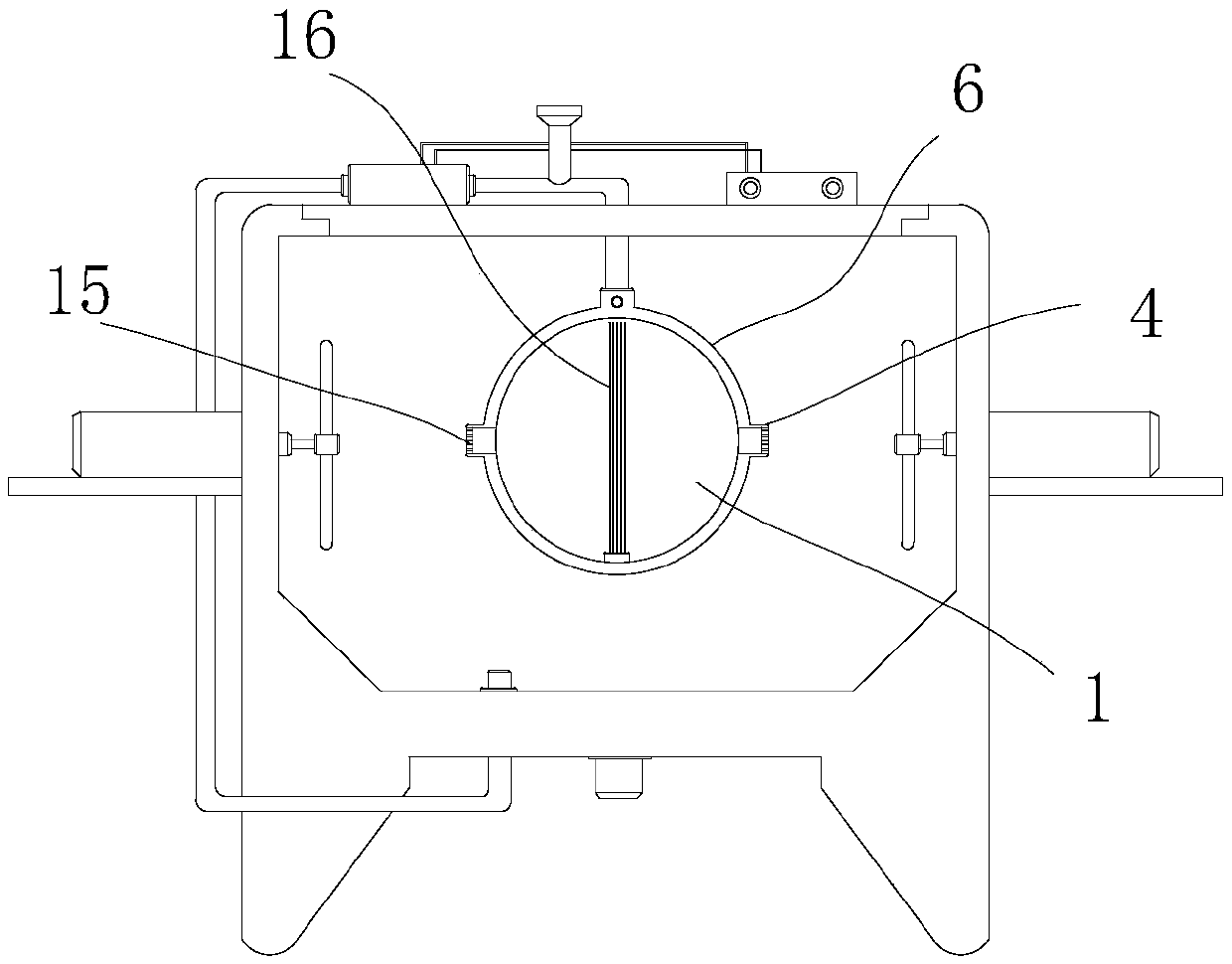

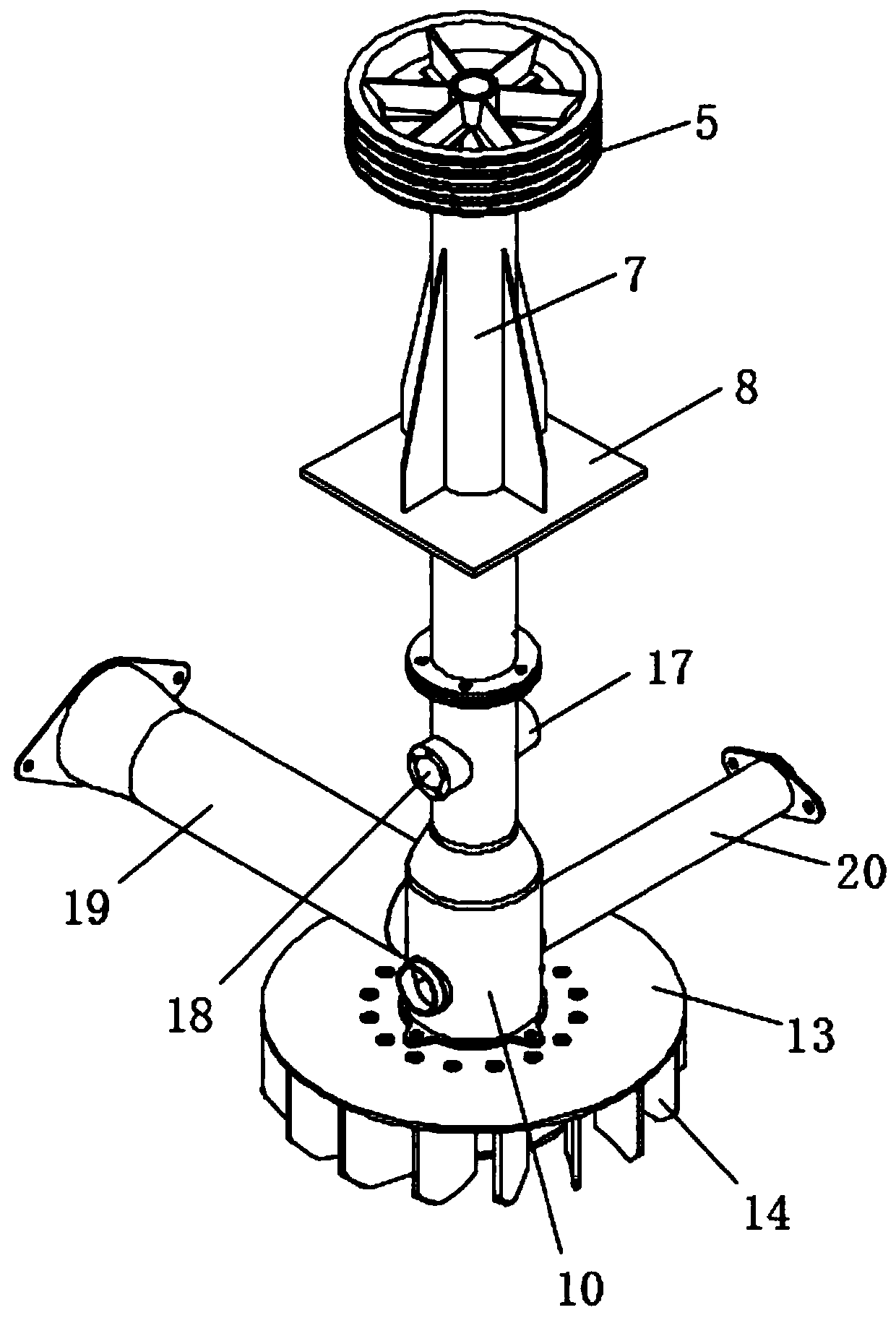

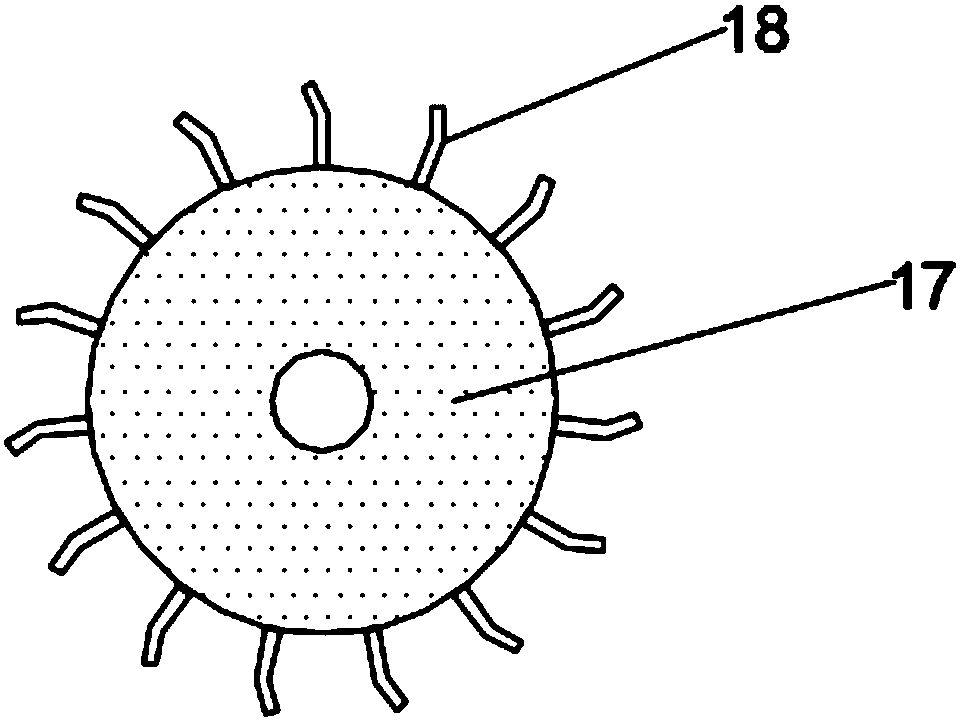

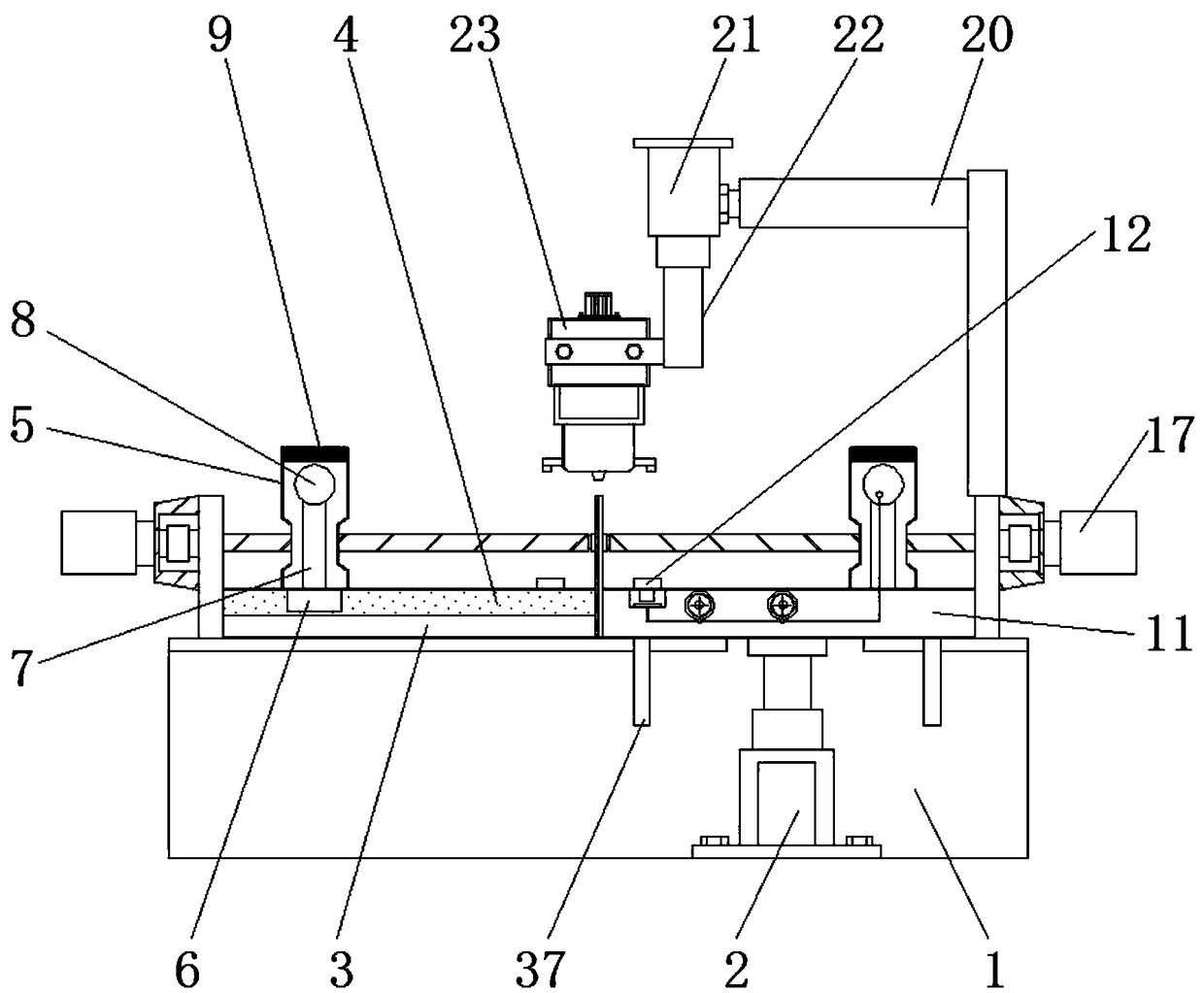

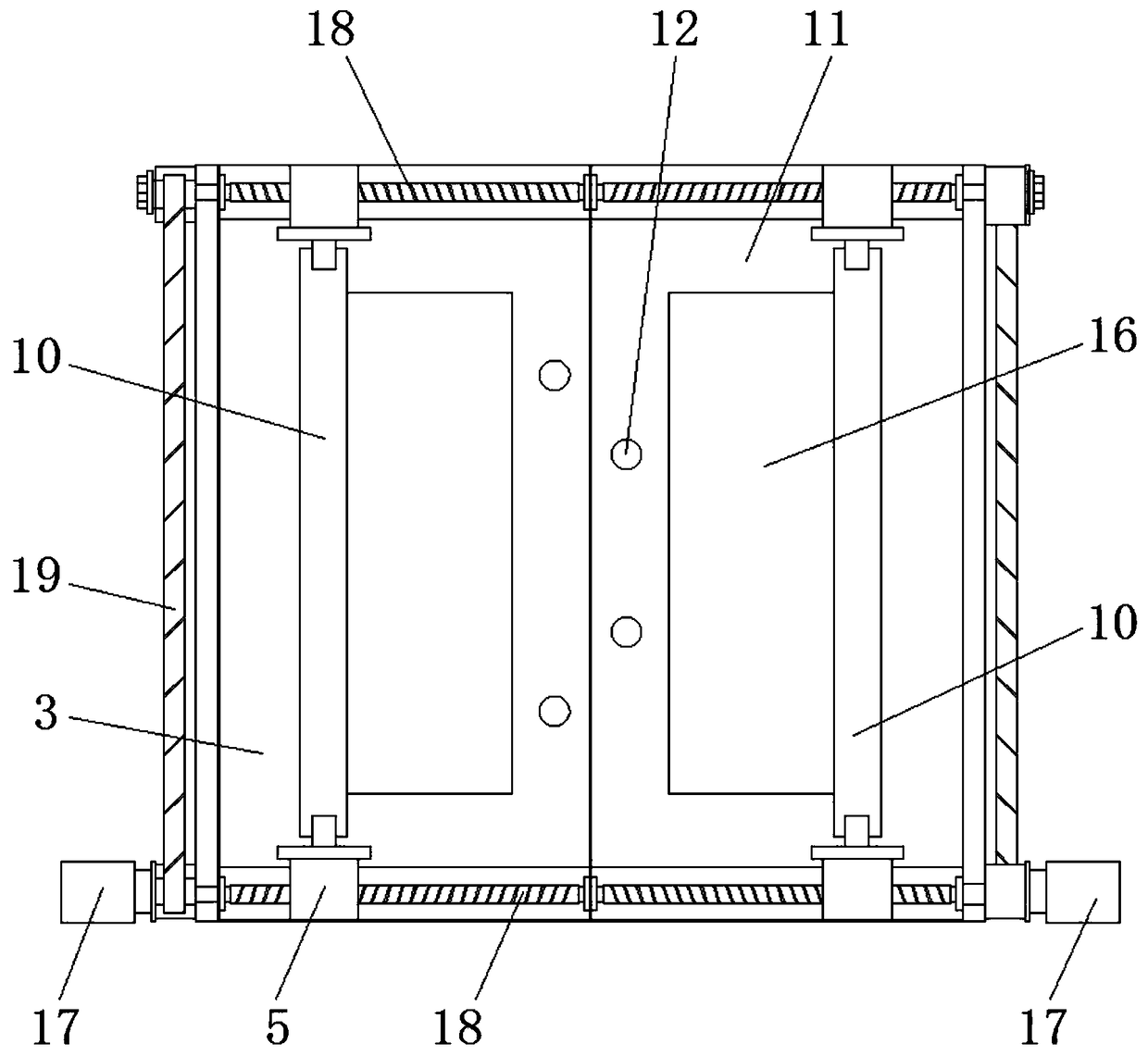

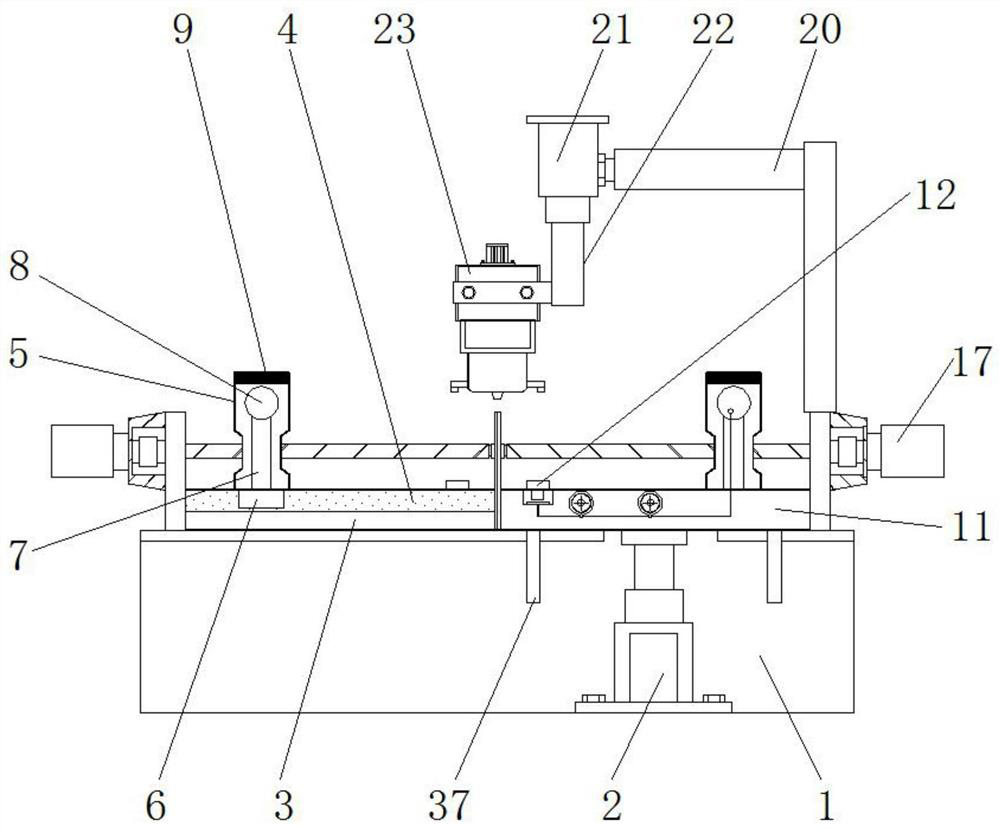

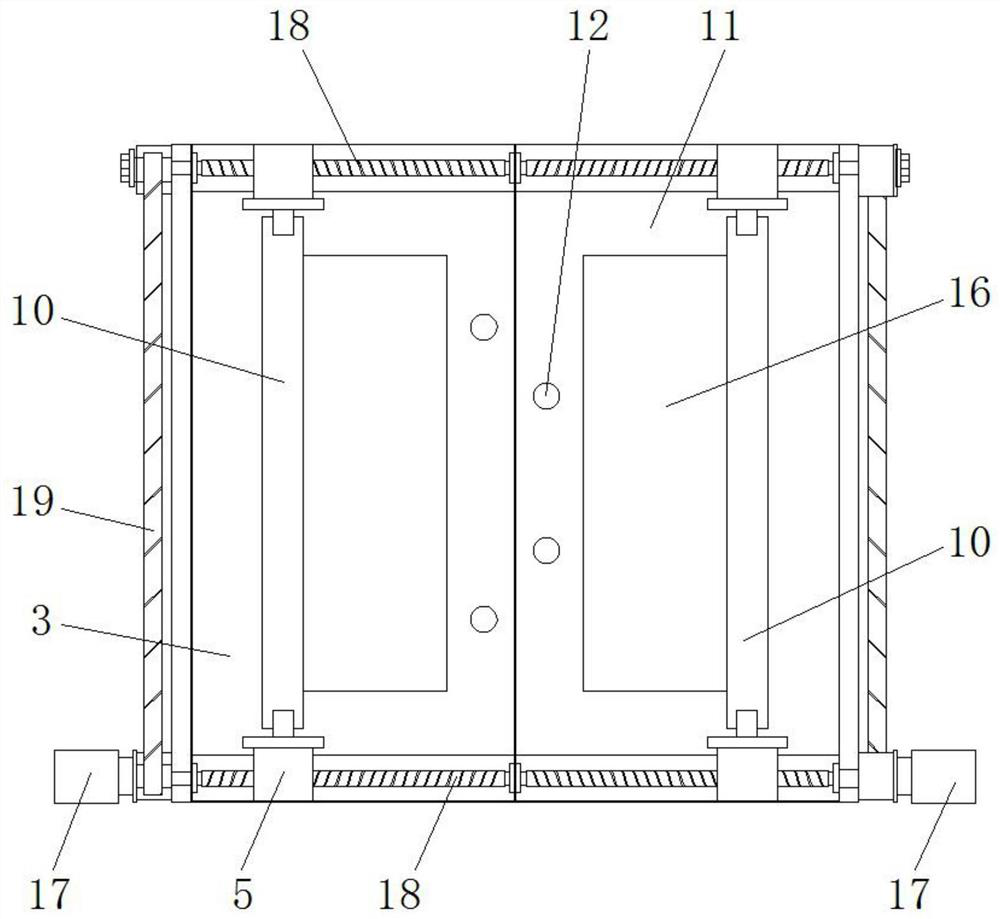

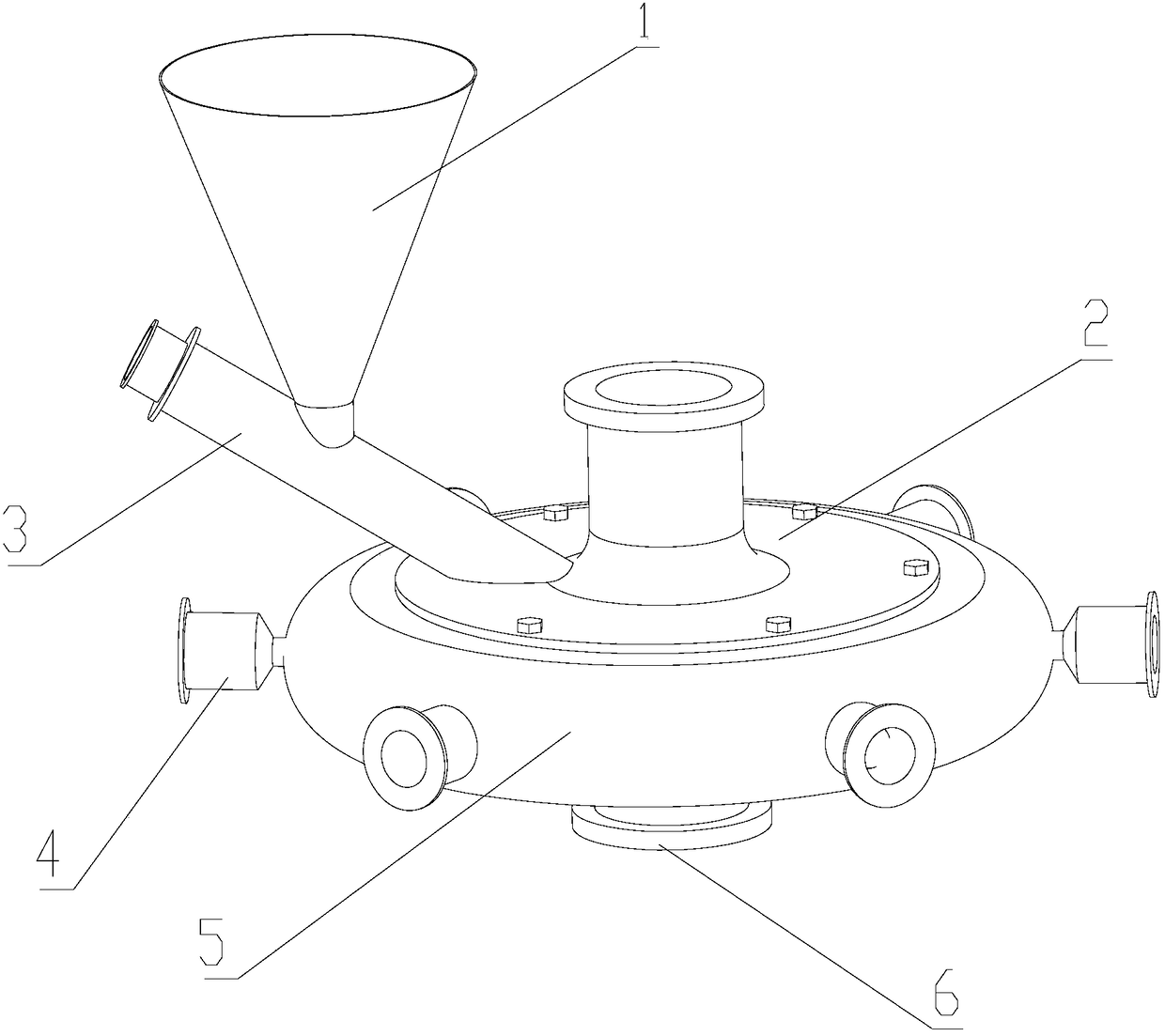

Circulating refining device used for continuously preparing aluminum alloy semisolid slurry

PendingCN107952941AImprove refinement efficiencyConvenient for continuous collection and transportationSpecific gravityCrystallite

The invention discloses a circulating refining device for continuously preparing the aluminum alloy semisolid slurry. The device comprises a driving mechanism and a refining mechanism, wherein the refining mechanism comprises a rotor and a stator, the interior of the stator is hollow, the rotor is arranged inside the stator, and the driving mechanism drives the rotor to rotate inside the stator; arefining part with the stator immersed in the slurry to perform the refining function is provided with a refining cavity, the portion, in the refining cavity, of the rotor is provided with blades, amaterial suction port communicating with the refining cavity is formed in the bottom of the stator, and jet holes are formed in the side wall of the portion, in the refining cavity, of the stator. According to the device, the rotor blades are rotated to form negative pressure, so that the slurry is sucked into the refining cavity with the stator to be refined and then is ejected out from the jet holes to return to a crucible for containing the slurry to be continuously sucked from the material suction port, the steps are repeatedly circulated, and the slurry is continuously refined, so that the refining efficiency for the suspended crystal grains is higher, and due to the specific gravity difference caused by the temperature, the prepared slurry is accumulated on the bottom of the cruciblethen can be conveniently and continuously collected and conveyed.

Owner:FUJIAN RHEOMET LIGHT METAL CO LTD

Cosmetic processing equipment

InactiveCN109092117AImprove work efficiencyImprove refinement efficiencyShaking/oscillating/vibrating mixersRotary stirring mixersBiochemical engineeringCirculating pump

The invention discloses cosmetic processing equipment. The cosmetic processing equipment comprises a casing, wherein supporting legs are arranged at the bottom of the casing, a processing cavity is formed in the casing, a hanging ball is mounted in the processing cavity in a hanging state, a feeding cavity is formed in the middle of the hanging ball, liquid discharging ports are formed in two sides of the feeding cavity, a joint is arranged at the top of the hanging ball, an infusion tube is inserted into the joint, and the top layer of the infusion tube penetrates through the casing and protrudes outside the casing, a circulation pump is connected outside the infusion tube, and a water return pipe is connected at the water return end of the circulation pump. The cosmetic processing equipment disclosed by the invention can utilize the own fluidity of cosmetic liquid to expand and bulge the entire hanging ball, and use the resilience of the hanging ball to extrude internal cosmetic liquid, and then the cosmetic liquid is circularly added, so that the whole process can be in a closed environment, and has less contact with air, thereby being capable of greatly improving the productionquality and the work efficiency of stirring.

Owner:楼阳英

W-shaped bottoming cycle airflow pneumatic flotation machine

The invention discloses a W-shaped bottoming cycle airflow pneumatic flotation machine. The W-shaped bottoming cycle airflow pneumatic flotation machine comprises an ore pulp receiving groove, a stirring mechanism which is located at the upper end of the ore pulp receiving groove and used for stirring ore pulp in the ore pulp receiving groove, and scraper boards which are located at the upper end of the ore pulp receiving groove and used for scraping off mineralized bubbles, by fixedly installing an air inlet pipe at one end of a first installation hole, the air inlet pipe communicates with a second protective shell, moreover, the top end of the air inlet pipe communicates with an air blower, and a circulating air pipe communicates with the second protective shell, so that when air is pressed into the air inlet pipe by the air blower, the air enters the ore pulp receiving groove when under pressure; and when the air and the ore pulp cannot be completely mixed, the air which is pressed in is pressed into the ore pulp receiving groove from the circulating air pipe by the air blower again when under pressure, and thus cycle airflow is generated, so that the defect that when a traditional pneumatic flotation machine presses external air in a single direction, enough air cannot be guaranteed, and full contact among mineral grains and bubbles cannot be guaranteed, so that bubble refining is affected is solved, and the refining efficiency is improved.

Owner:ANHUI ZHONG NENG MACHINERY MFG

Aluminum silicon lanthanum boron quaternary intermediate alloy and preparing method thereof

The invention discloses an aluminum silicon lanthanum boron quaternary intermediate alloy and a preparing method of the alloy. The aluminum silicon lanthanum boron quaternary intermediate alloy can be used for casting a refined aluminum silicon alloy. Industrial pure aluminum, silicon metal, an Al-10La intermediate alloy and an Al-3B intermediate alloy are taken as a raw material, the mass ratio of the four raw materials is 1:(0.2-0.4):(0.5-0.8):(0.8-1.2), a lanthanum boron compound in the aluminum silicon lanthanum boron quaternary intermediate alloy is evenly divided by eutectic silicon, no obvious agglomeration phenomenon exists, primary aluminum grains in the cast aluminum silicon alloy with the complex component are efficiently refined, particularly, in the high-silicon alloy, the excellent refining effect is obtained, the poisoning effect generated between the high-silicon alloy and metamorphic strontium cannot be generated, and therefore the comprehensive mechanical performance of the cast aluminum alloy is improved, and the casting performance of the aluminum alloy is improved. In addition, a refining agent has hardly any induction period, the refining effect is long in duration time, meanwhile, raw materials are rich, the cost is low, atmosphere protection is not needed, and a preparing device and a preparing technology are simple.

Owner:SOUTHEAST UNIV

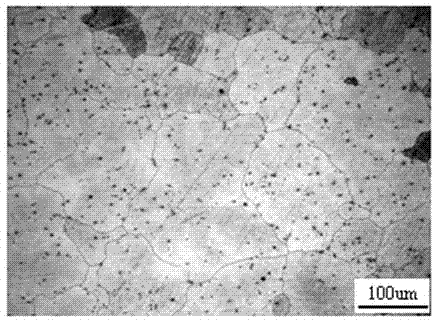

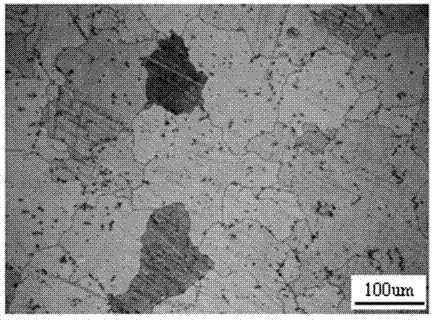

Austenitic stainless steel pipe piece elbow local solid solution treatment method and device

ActiveCN108220572ARelief of residual stressPrevent elbow breakageFurnace typesHeat treatment furnacesAustenitic stainless steelCrystallite

The invention discloses an austenitic stainless steel pipe piece elbow local solid solution treatment method and device. The treatment method is characterized in that a hydraulic manual flatcar is used for feeding a stainless steel pipe piece elbow into an electric heating furnace for heating, homogenizing and heat preservation, the stainless steel pipe piece is quickly far away from the electricheating furnace through the hydraulic manual flatcar after heat preservation, and rapid cooling is achieved through air blowing of a cooling fan. According to the austenitic stainless steel pipe pieceelbow local solid solution treatment method, the deformation temperature and the deformation amount are controlled, so that austenitic stainless steel is uniformly recrystallized, residual stress generated in cold working of a stainless steel pipe is eliminated, and elbow fracture due to stress corrosion and intergranular corrosion is prevented; control is simple, the working procedures are short, and grain refinement efficiency can be greatly improved; and an elbow is continuously bent on one pipe piece, and the elbow on the pip piece is subjected to solid solution treatment at the same time, so that the problems the working amount is large, the flaw detection cost is high and welding deformation is difficult to control due to the fact that the elbow is independently subjected to solid solution and then is welded with the pipe piece are solved.

Owner:HANGZHOU HANGGUO INDUSTRIAL BOILER CO LTD

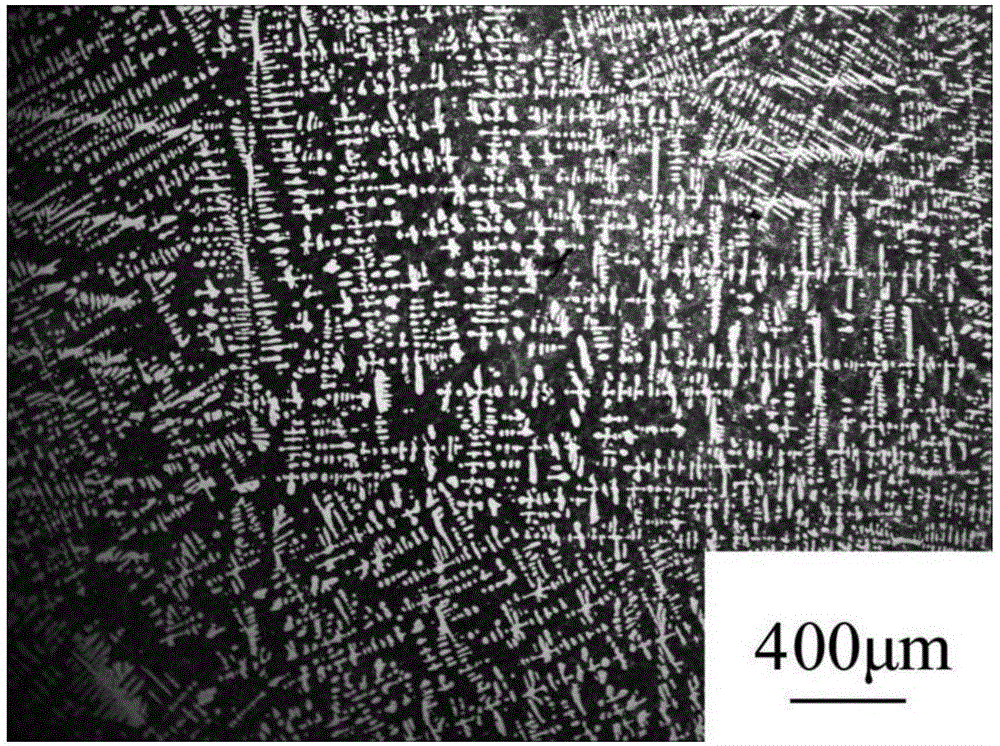

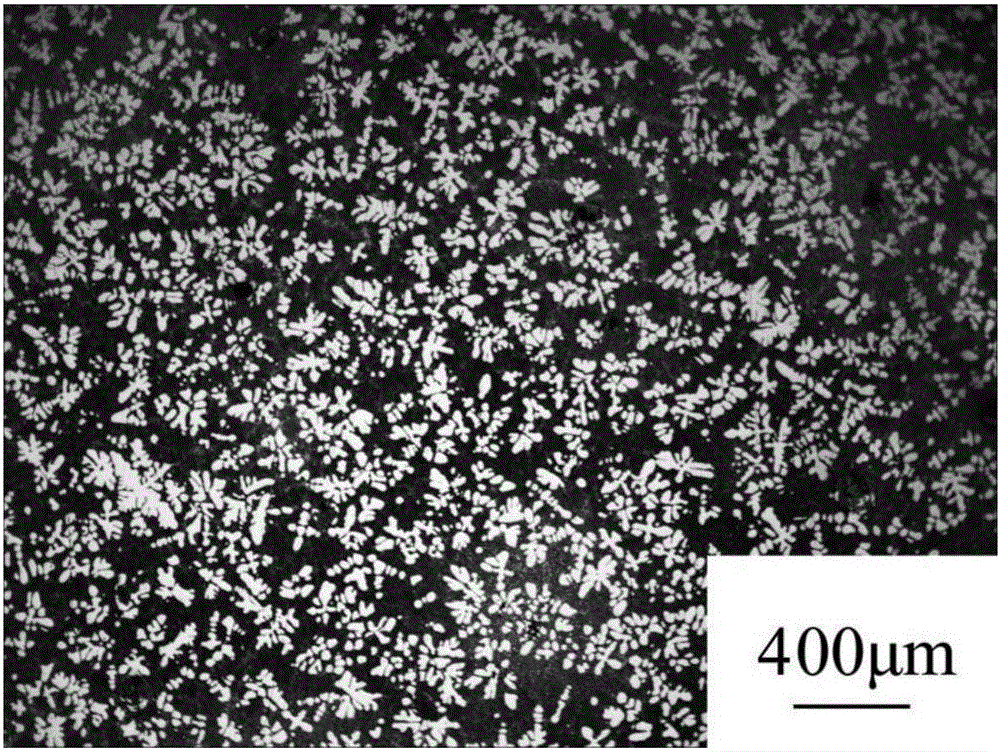

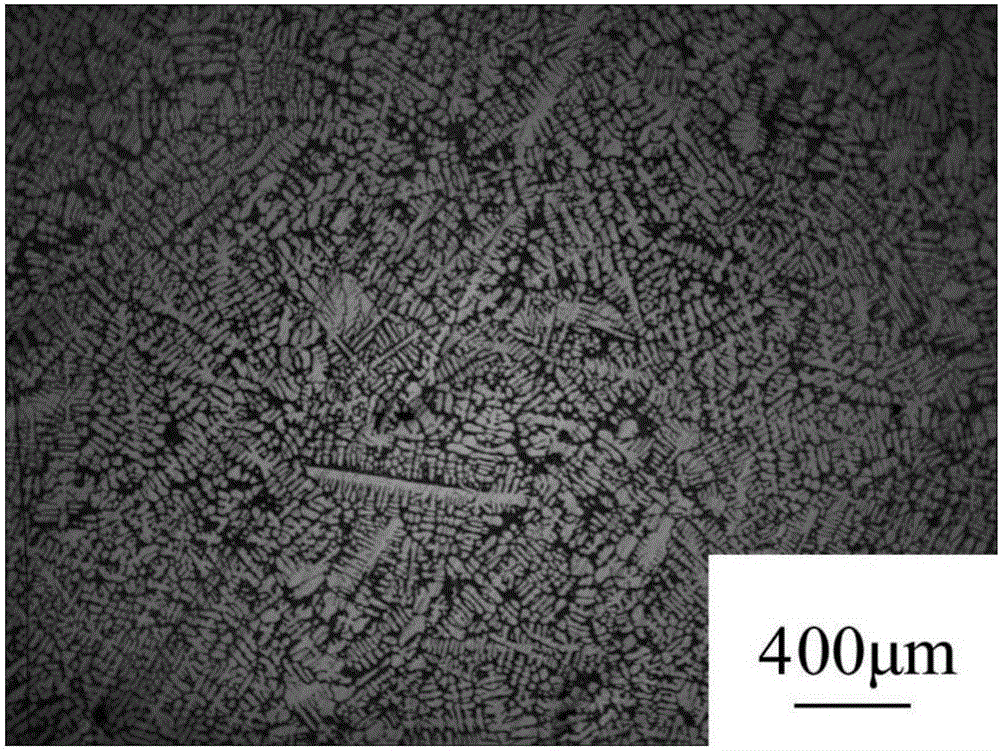

Method for refining magnesium alloy grains by using Zn-Sr intermediate alloy

The invention provides a method for refining magnesium alloy grains by using a Zn-Sr intermediate alloy. The method comprises the following steps of: adding an intermediate alloy containing Zn and 58 to 72 weight percent of Sr into a magnesium alloy, refining the grains of the magnesium alloy, and thus obtaining the grains with the refining efficiency which is higher than that of Al-Sr and Mg-Sr intermediate alloys.

Owner:CHONGQING UNIV OF TECH

Porcelain clay refining equipment for ceramic production

The invention discloses porcelain clay refining equipment for ceramic production. The porcelain clay refining equipment comprises a body, a screening cavity, a screen, a right bearing seat and a primary refining cavity; the screening cavity is formed in the upper part of the body, the screen is obliquely arranged at the inner upper part of the screening cavity, and the two ends of the screen are connected with the two side walls of the screening cavity through the right bearing seat and a left bearing seat correspondingly; a connecting block is arranged inside the left bearing seat, the left end of the screen is fixedly connected with the connecting block, and a vibrating plate is arranged on the right side of the lower surface of the screen; and the primary refining cavity is formed in the lower part of the screening cavity, and a rolling roller is arranged in the center of the interior of the primary refining cavity. According to the equipment, the energy conservation and environmentprotection effects are achieved, dust generated in the refining process of the porcelain clay can be prevented from escaping, wind also can be recycled, the uniformity of the granularity of the porcelain clay is guaranteed, the quality and the appearance of produced ceramics are also guaranteed, moreover, consumption of excessive manpower is avoided, the complete automation of the refining process is realized, and the refining efficiency is improved.

Owner:湖北安广陶瓷有限公司

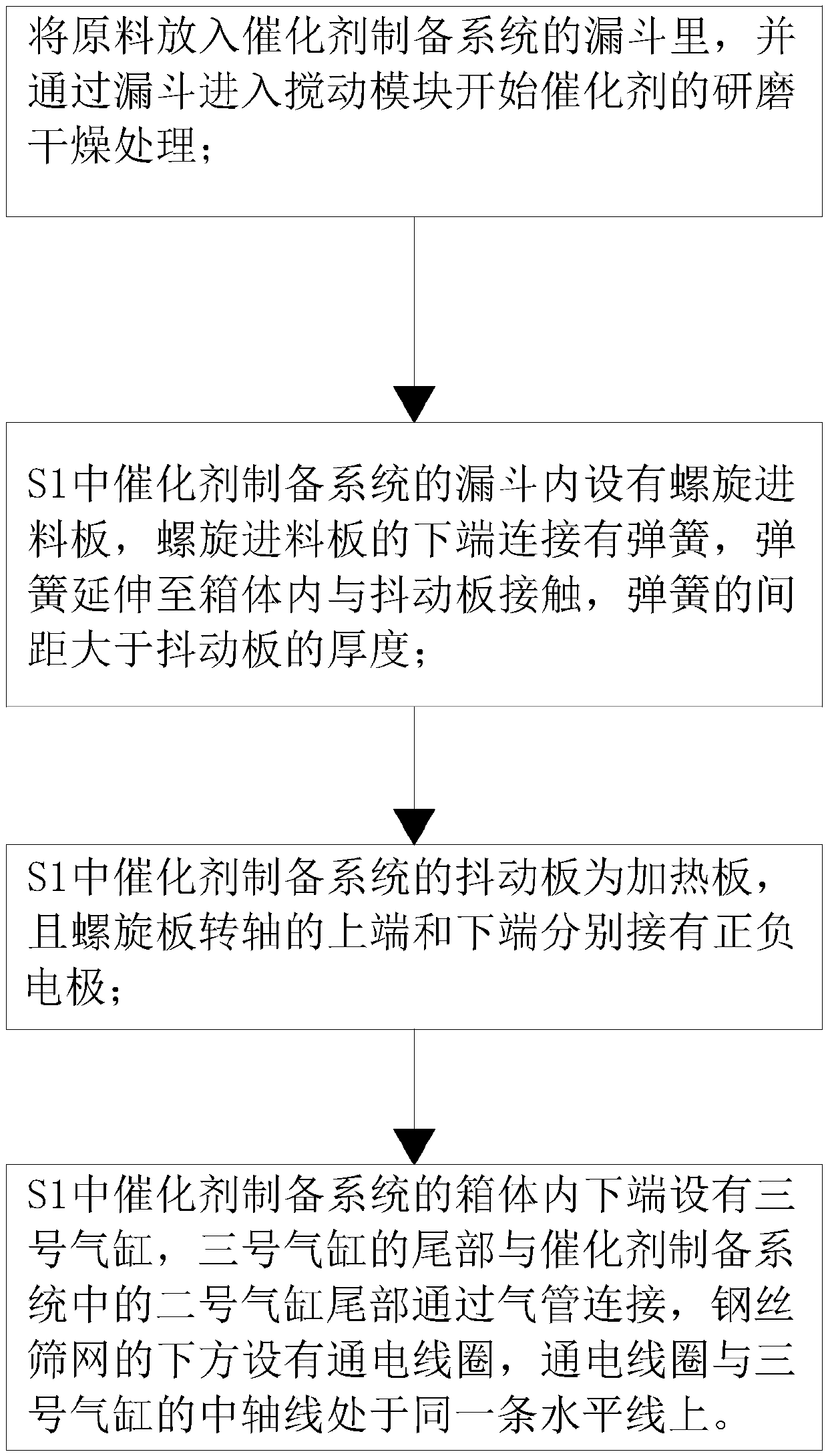

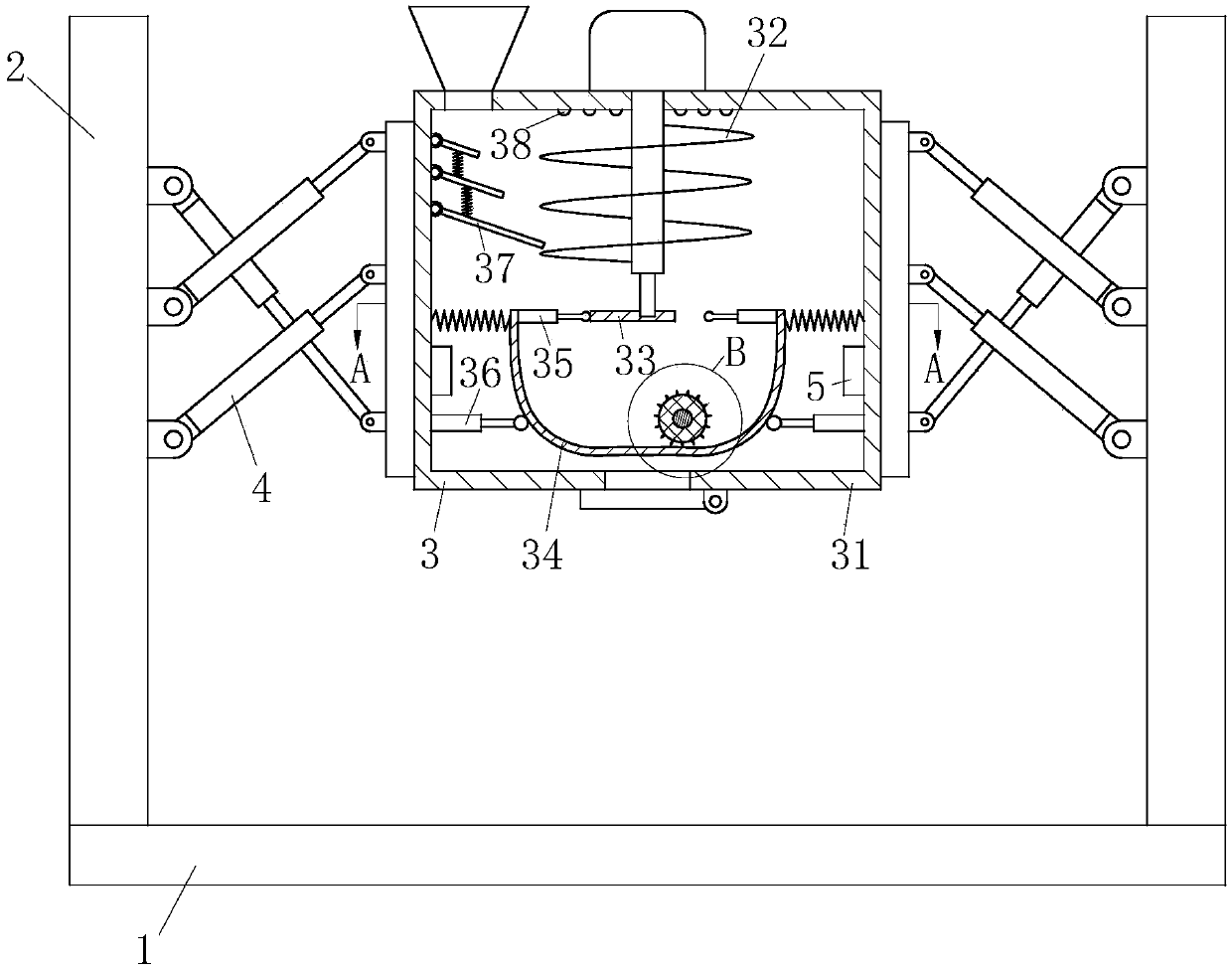

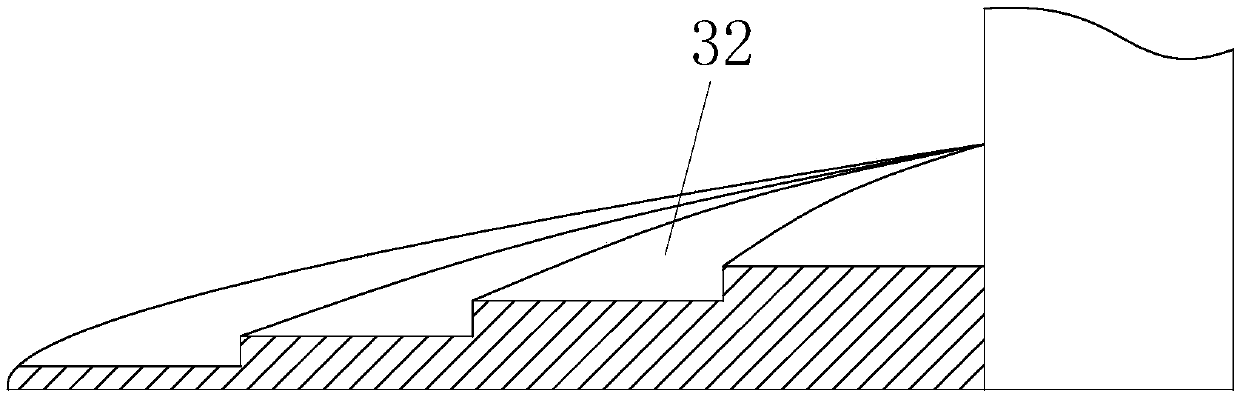

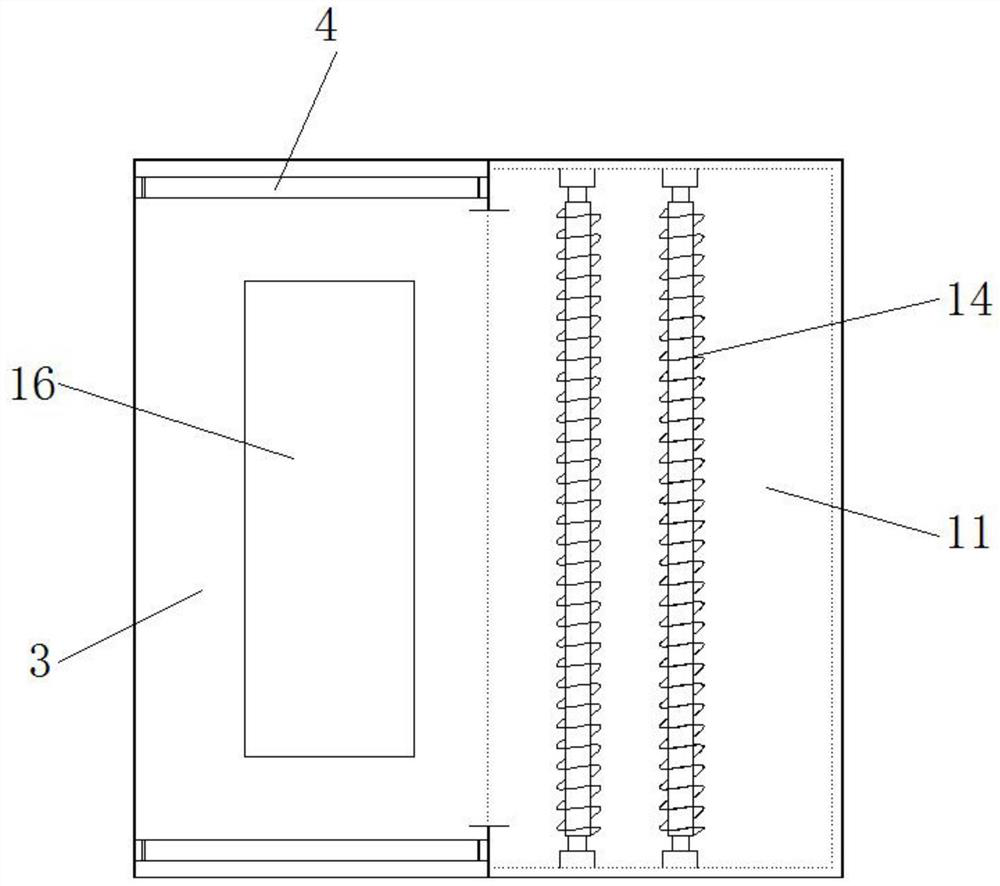

Grinding and drying technology for catalyst

ActiveCN109569829AAvoid damageImprove refinement efficiencySievingGranular material dryingPulp and paper industryRaw material

The invention belongs to the technical field of catalyst preparation, and particularly relates to a grinding and drying technology for a catalyst. The grinding and drying technology for the catalyst comprises the following steps that raw materials are putted into a funnel of a catalyst preparation system and then into a stirring module through the funnel to start the catalyst grinding and drying treatment; a spiral feeding plate is arranged in the funnel, springs are connected to the lower end of the spiral feeding plate, the springs extend into a box body so as to be in contact with shaking plates, and the distance between the springs is larger than the thickness of the shaking plates; the shaking plates are heating plates and the upper end and the lower end of a spiral plate rotary shaftare connected with a positive electrode and a negative electrode respectively; and a third air cylinder is arranged at the lower end of the box body, the tail part of the third air cylinder is connected with the tail parts of second air cylinders in the catalyst preparation system through air pipes, a power-on coil is arranged below a steel wire screen, and the central axis of power-on coil and the central axis of the third air cylinder are located on a same horizontal line. According to the grinding and drying technology for the catalyst, the springs are in contact with the shaking plates, the shaking amplitude and frequency of the shaking plates increase in the rotating process of the springs and the refining efficiency of the raw materials of the catalyst is improved.

Owner:江苏上阳金属新材料有限公司

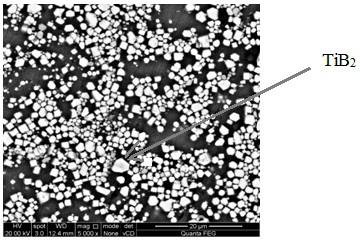

Al-Ti-B refining agent and preparing method thereof

InactiveCN109825736ALow costSolve the problem of preparation difficulty and preparation costIngotPhase composition

The invention discloses an Al-Ti-B refining agent and a preparing method thereof, and belongs to the technical field of refining agents. The Al-Ti-B refining agent comprises components including, by mass percent, 8.0%-12.0% of Ti, 3.0%-5.0% of B and the balance Al. The Ti / B molar ratio is equal to 1 / 2. Phase compositions include alpha-Al and TiB2. According to the requirements, H3BO3, TiO2, aluminum powder and an aluminum ingot are weighed; according to the molar ratio of components of the refining agent, Ti / B=1 / 4, and Ti / TiO2=2 / 3; the purity of the aluminum ingot is 99.9%; TiO2 and H3BO3 areevenly mixed, and heating is conducted at 300 DEG C for 2 h; the heated powder and the heated aluminum powder are mixed to be arranged in a die and are pressed into blocks; the aluminum ingot is heated and melted and is covered with cryolite; and melt is subjected to temperature rise and pressed into the blocks, stirring is conducted for reaction, pressing of C2Cl6 is conducted for refining, and slagging-off and casting are conducted. The size of TiB2 prepared through low-cost raw materials is smaller than 1 micron.

Owner:大连科天新材料有限公司

Large-size AlON transparent ceramic preparation method

The invention discloses a large-size AlON transparent ceramic preparation method, wherein AlON powder is subjected to fine grinding treatment by using a sand mill, such that the characteristics of one time treatment of a large amount of AlON powder, short sanding time, high efficiency and small powder particle size are provided. In addition, the sanded AlON powder has good molding and sintering property, any binders are not required to be added during pressing molding, and the sanded AlON powder added with the sintering aid can be used for preparing the large-size AlON transparent ceramic through the pressure-free sintering. According to the present invention, the method has advantages of high preparation efficiency, simple operation, low cost, and easy industrialization achieving.

Owner:常熟佳合高级陶瓷材料有限公司

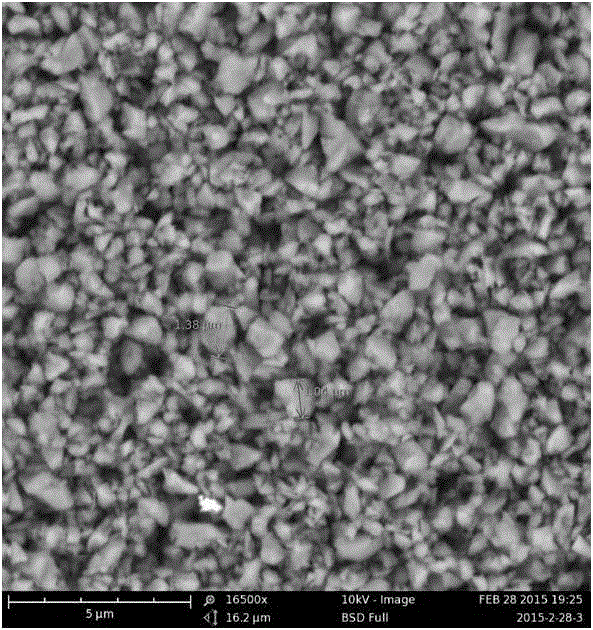

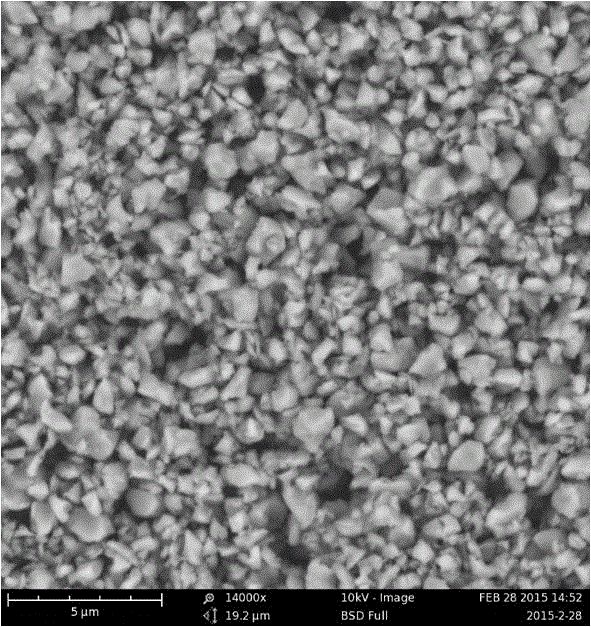

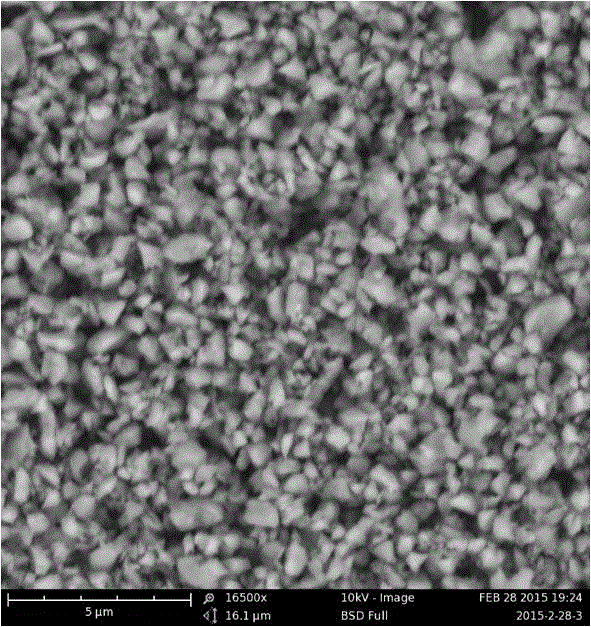

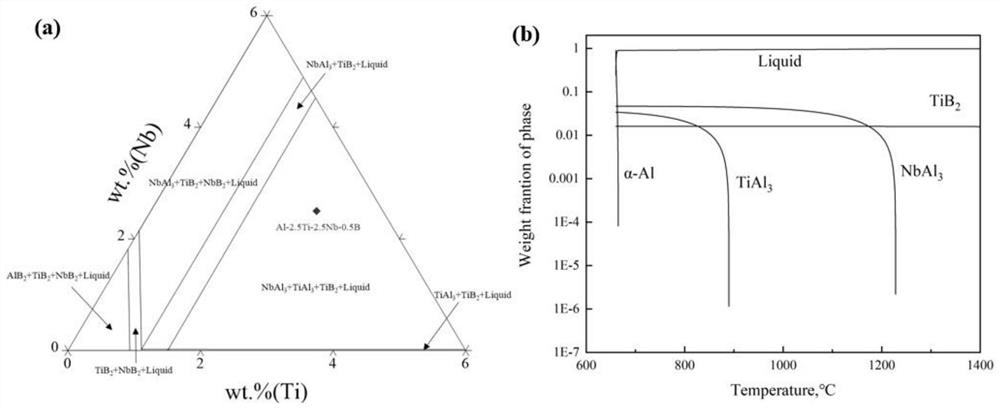

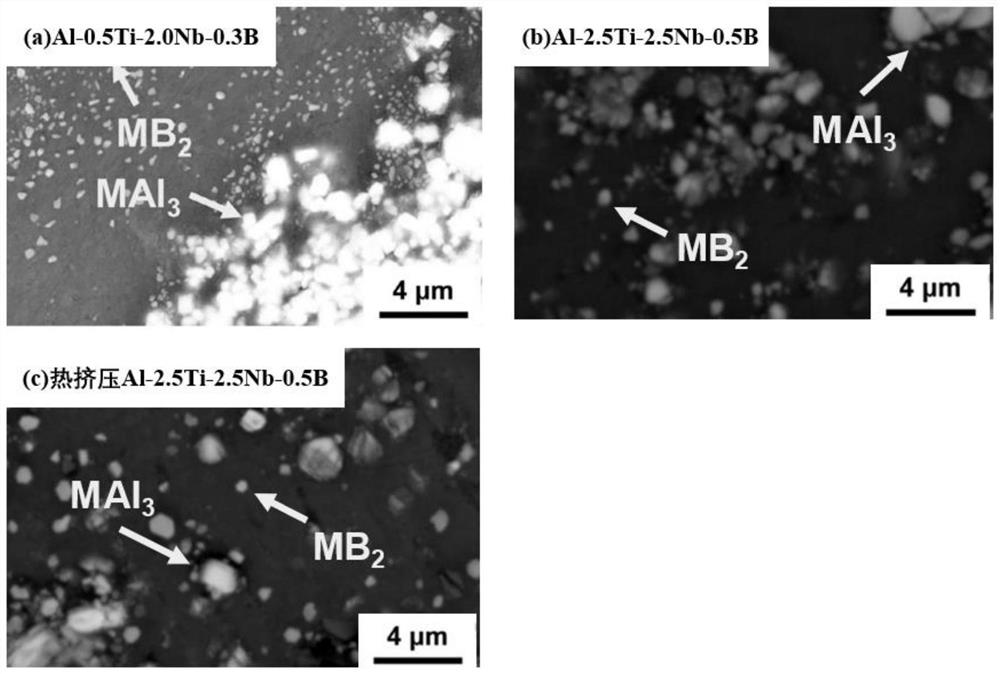

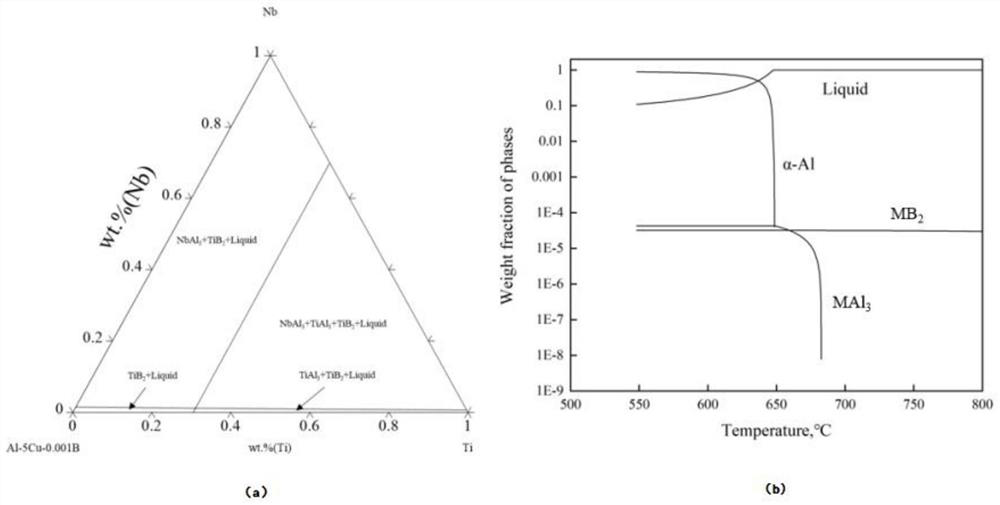

High-strength and high-toughness Al-Cu-(Al-Ti-Nb-B) alloy and preparation method thereof

ActiveCN113943879AHighlight substantiveGood tensile mechanical propertiesAlloyUltimate tensile strength

The invention discloses a high-strength and high-toughness Al-Cu-(Al-Ti-Nb-B) alloy and a preparation method thereof. The ratio of Ti to Nb of an Al-Ti-Nb-B intermediate alloy is determined to be 1: 1 according to thermodynamic calculation, the Al-Ti-Nb-B intermediate alloy is prepared by adopting a villiaumite reaction method, and the Al-Ti-Nb-B intermediate alloy is reprocessed by adopting a hot extrusion method. The Al-Cu-(Al-Ti-Nb-B) alloy disclosed by the invention is prepared from the following components in percentage by mass: 5% of Cu, 0.005-0.0125% of Ti, 0.005-0.0125% of Nb, 0.001-0.0025% of B and the balance of Al; and the phase of the alloy comprises one or more of NbAl3, TiAl3, TiB2 and NbB2 refining and strengthening phases, and the balance of Al2Cu and alpha-Al phase. The preparation method comprises the following steps: preparing an Al-Ti-Nb-B intermediate alloy, and carrying out hot extrusion and reprocessing; carrying out smelting and grain refining process of Al-Cu alloy melt; and preparing an as-cast alloy and carrying out T6 heat treatment. The grain size of the alpha-Al phase of the obtained alloy is smaller than 90 microns; and the maximum room temperature yield strength is 190.4 MPa, the tensile strength reaches 360.0 MPa, and the maximum ductility is 25.2%. The production cost is reduced, and the application range is expanded.

Owner:SHANGHAI UNIV

Ultrasonic-assisted friction stir welding device

ActiveCN109014561AImprove efficiencyImprove softening efficiencyNon-electric welding apparatusUltrasonic generatorMagnet

The invention discloses an ultrasonic-assisted friction stir welding device. The ultrasonic-assisted friction stir welding device comprises a bearing frame, a supporting arm and a limiting strip; a hydraulic cylinder is installed inside the bearing frame; a first board and a second board are installed above the bearing frame from left to right; a fixed magnet is fixed to the upper portion of the side face of the supporting arm; the limiting strip is connected with a sliding groove through connection blocks on the two sides; contact rods are arranged on the upper surface of the first board andthe upper surface of the second board; the first board and the second board are each internally provided with a metal plate and an electromagnetic coil; the lower portions of the metal plates are connected with wires; a fixed head is fixed below a protection cover and connected with a friction plate through a heat conductive plate fixed to the inner surface; and an ultrasonic generator is fixed inside the protection cover. According to the ultrasonic-assisted friction stir welding device, a welding head is in a fixed state when a stirring head rotates, the stirring head transfers heat to the welding head, the stirring head and the welding head perform hot melting on plates at the same time, and the welding efficiency is improved.

Owner:HUNAN UNIV OF ARTS & SCI

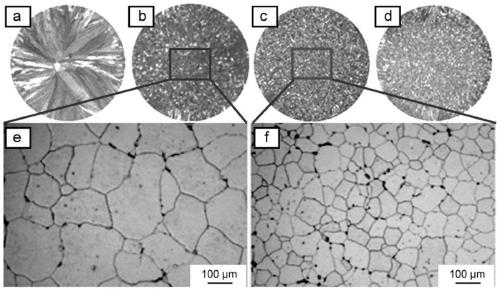

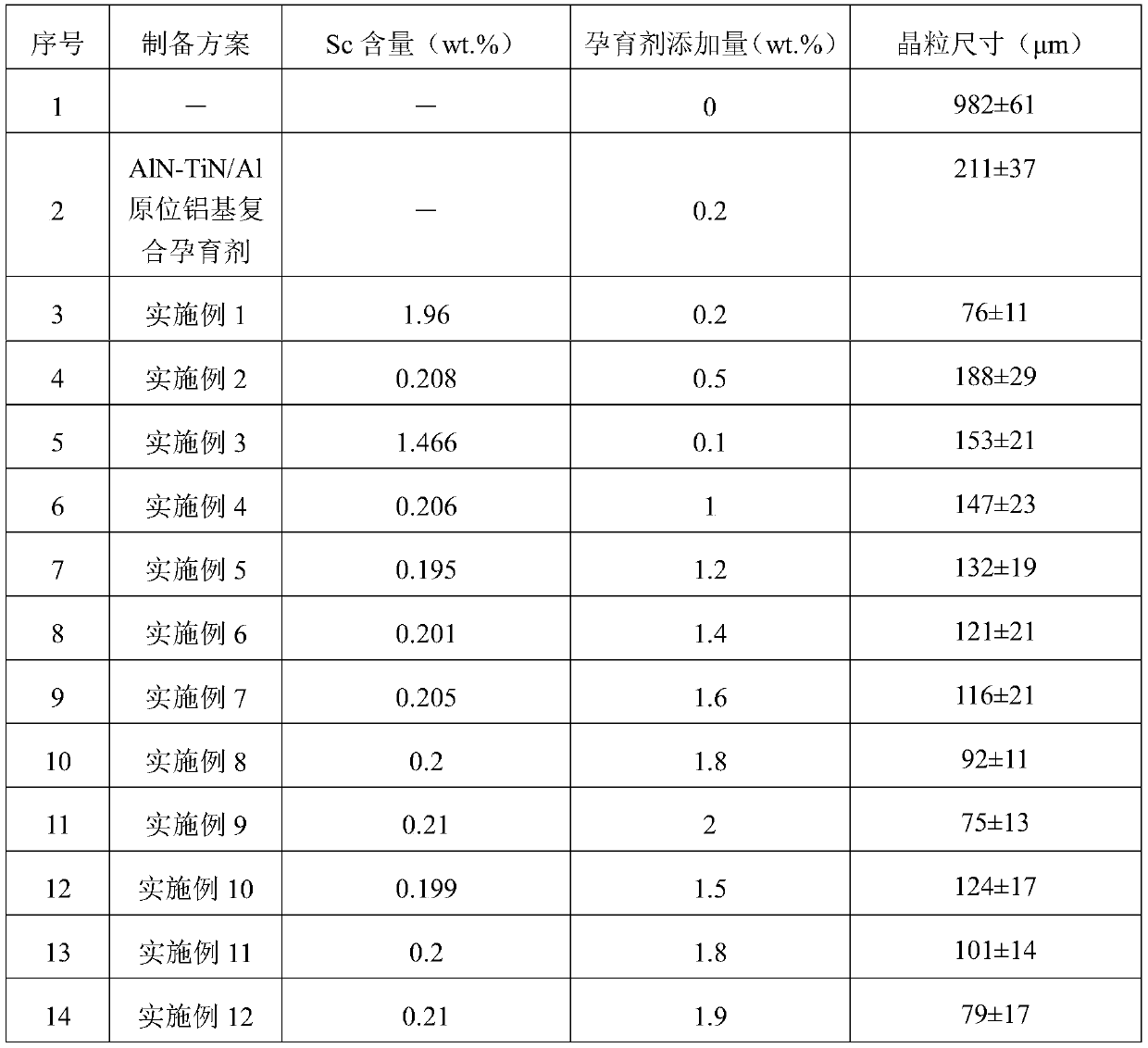

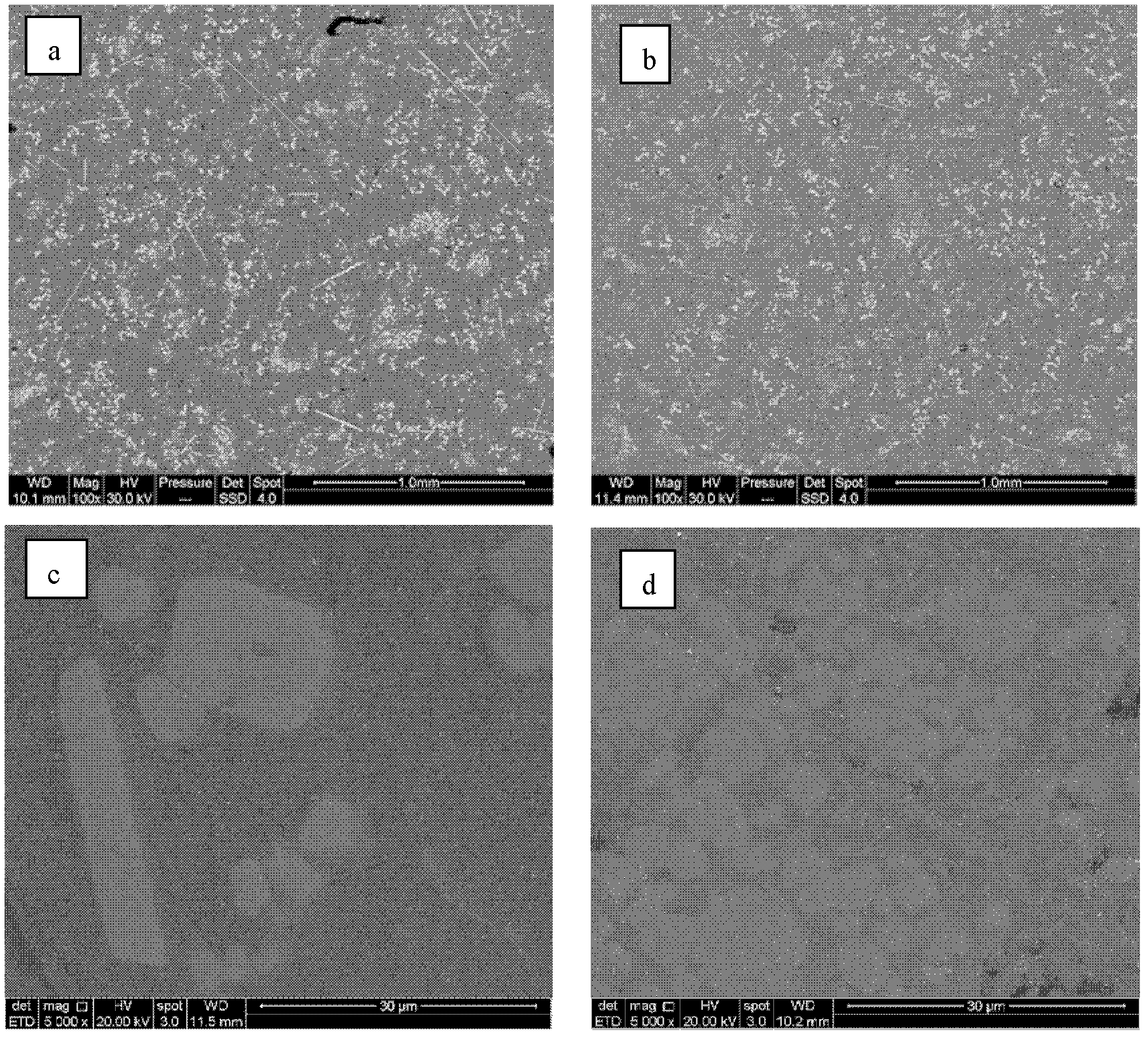

(ScAl3+Al2O3+Sc2O3)/Al-based compound inoculant, preparation method thereof and application

The invention provides a (ScAl3+Al2O3+Sc2O3) / Al-based compound inoculant, a preparation method thereof and application. The preparation method comprises the following steps: (S1) performing ingot making with scandium oxide powder and pure aluminum to obtain an aluminum-scandium-oxygen master alloy ingot; and (S2) performing rapid solidification treatment on the aluminum-scandium-oxygen master alloy ingot to obtain the (ScAl3+Al2O3+Sc2O3) / Al-based compound inoculant. The preparation method can obtain the (ScAl3+Al2O3+Sc2O3) / Al-based compound inoculant by just two steps, and the preparation technique is simple. The ingot making and the rapid solidification treatment are both common techniques in the field of metallurgy, and the production efficiency is high so as to facilitate the industrialapplication. In the obtained (ScAl3+Al2O3+Sc2O3) / Al-based compound inoculant, reinforced phase particles are fine in size and dispersed in distribution so as to overcome the shortcoming that reinforced phase particles in an existing inoculant is coarse in size and prone to segregation.

Owner:CHINA ENFI ENGINEERING CORPORATION

Al-Ti-B-Er refiner and preparation method thereof

The invention discloses an Al-Ti-B-Er refiner and a preparation method thereof and belongs to the technical field of refiners. The Al-Ti-B-Er refiner comprises the following components in weight percentage: 3.0-10.0 percent of Ti, 0.6-2 percent of B, 0.1-0.3 percent of Er and the balance of Al, wherein the weight ratio of the Ti to the B is 5 / 1. The phase composition comprises alpha-Al, TiAl3, TiB2, Al3Er and AlErTi. The preparation method comprises the following steps of: weighing boron (B) powder, titanium (Ti) powder, aluminum (Al) powder, an Al-Er intermediate alloy and an aluminum ingot as required, wherein the weight ratio of the titanium (Ti) powder to the boron (B) powder is 5, the molar ratio of the aluminum (Al) powder to the titanium (Ti) powder is 2.5-3.0, and the purity of the aluminum ingot is 99.9 percent; evenly mixing the Ti, the Al with the B; putting in a mould; pressing into a block; heating to melt the aluminum ingot; covering by kryocide; pressing in the Al-Er intermediate alloy; standing; heating a melt; pressing in the block; performing stirring reaction; pressing in C2Cl6 for refining; drossing and pouring. According to the Al-Ti-B-Er refiner disclosed by the invention, the problem that the TiB2 can be easily gathered is solved, and the refining efficiency is increased.

Owner:BEIJING UNIV OF TECH

A method for preparing titanium products with nanostructure

The invention provides a novel powder metallurgy method for preparing nanometer or ultrafine microstructural titanium products. The method includes: step one, reducing grain size of titanium hydride powder to nanocrystalline level; step two, subjecting the titanium hydride powder in the nanocrystalline level to thermal consolidation to form pressed blanks; step three, under inert gas protection, heating the pressed blanks; step four, transferring the heated pressed blanks into an extruding device, and extruding under a certain pressure intensity and extrusion ratio to make the pressed blanks into the nanometer or ultrafine microstructural titanium products through an extruding mould with a certain inner cavity shape; step five, after extrusion is finished, cooling the extruded titanium products to the room temperature, and taking out; step six, heating the titanium products in a vacuum environment. A heating device used at the step three and the extruding device used at the step four are mounted in a same seal system, and insert gas is continuously fed into the seal system in a whole heating and extruding process.

Owner:SHANGHAI JIAOTONG UNIV

A kind of low-cost al-ti-b refiner and preparation method thereof

The invention relates to a low-cost Al-Ti-B refiner and a preparation method thereof, and belongs to the technical field of the refiner. The refiner comprises, by mass, 3.0-6 .0% of Ti, 0.6-2%of B, and the balance being Al. Phase compositions of the refiner comprise [alpha]-Al, TiAl3 and TiB2. A ratio of TiO2 to H3BO3 to Al powder is (2.8-3.2) : (3.5-4.2) : (4.7-5.2) (mol), and purity of an aluminum ingot is 99.9%. The preparation method comprises the steps of firstly mixing TiO2 and H3BO3 uniformly, heating for two hours at a temperature of 300 DEG C; mixing the heated powder and the Al powder and placing the mixed powder in a mold, pressing the mixed powder into a block; heating the aluminum ingot to melt, covering cryolite, heating the melt, pressing the block into the melt, reacting with stirring, pressing into C2Cl6 for refining, drossing and pouring. The refiner utilizes low cost raw materials; the size of the prepared TiB2 is 1 [mu]m; the size of the prepared TiAl3 is 3-30 [mu]m; and the TiAl3 is distributed uniformly.

Owner:大连科天新材料有限公司

An Ultrasonic Assisted Friction Stir Welding

ActiveCN109014561BImprove welding efficiencyImprove refinement efficiencyNon-electric welding apparatusHydraulic cylinderUltrasonic assisted

The invention discloses an ultrasonic-assisted friction stir welding, which comprises a load-bearing frame, a support arm and a limit bar. A hydraulic cylinder is installed inside the load-bearing frame, and a first plate surface is installed above the load-bearing frame from left to right. and the second board surface, a fixed magnet is fixed above the side of the support arm, the limiting bar is connected to the chute through the connecting blocks on both sides, and the upper surfaces of the first board surface and the second board surface are set There is a contact rod, and a metal sheet and an electromagnetic coil are installed inside the first board surface and the second board surface, a wire is connected under the metal sheet, a fixed head is fixed under the protective cover, and the fixed head passes through the inside The surface-fixed heat conducting sheet and the friction sheet are connected to each other, and an ultrasonic generator is fixed inside the protective cover. In the ultrasonic-assisted friction stir welding, when the stirring head rotates, the welding head is in a fixed state, and the stirring head transfers heat to the welding head, and the stirring head and the welding head heat-melt the plate at the same time, which improves the welding efficiency.

Owner:HUNAN UNIV OF ARTS & SCI

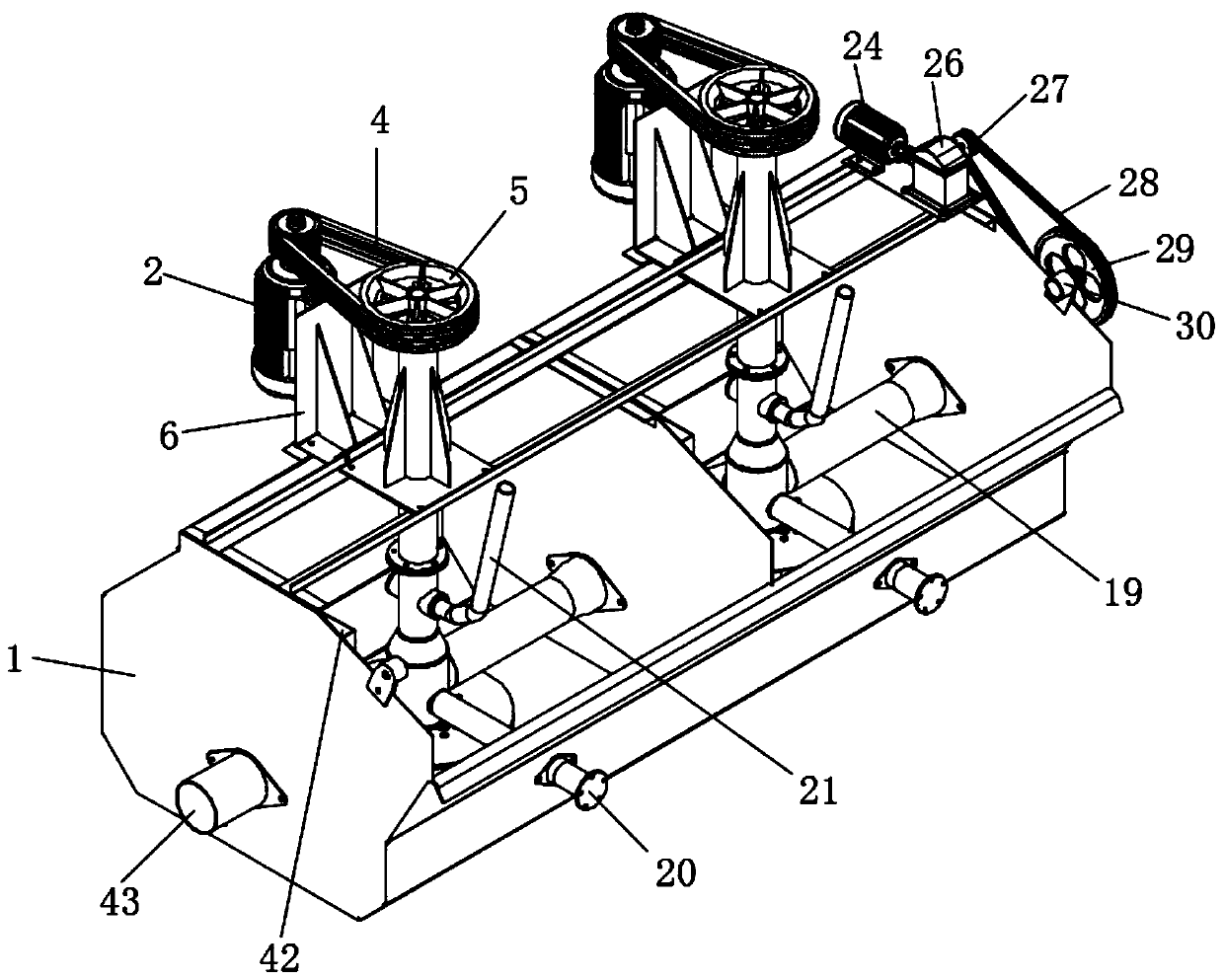

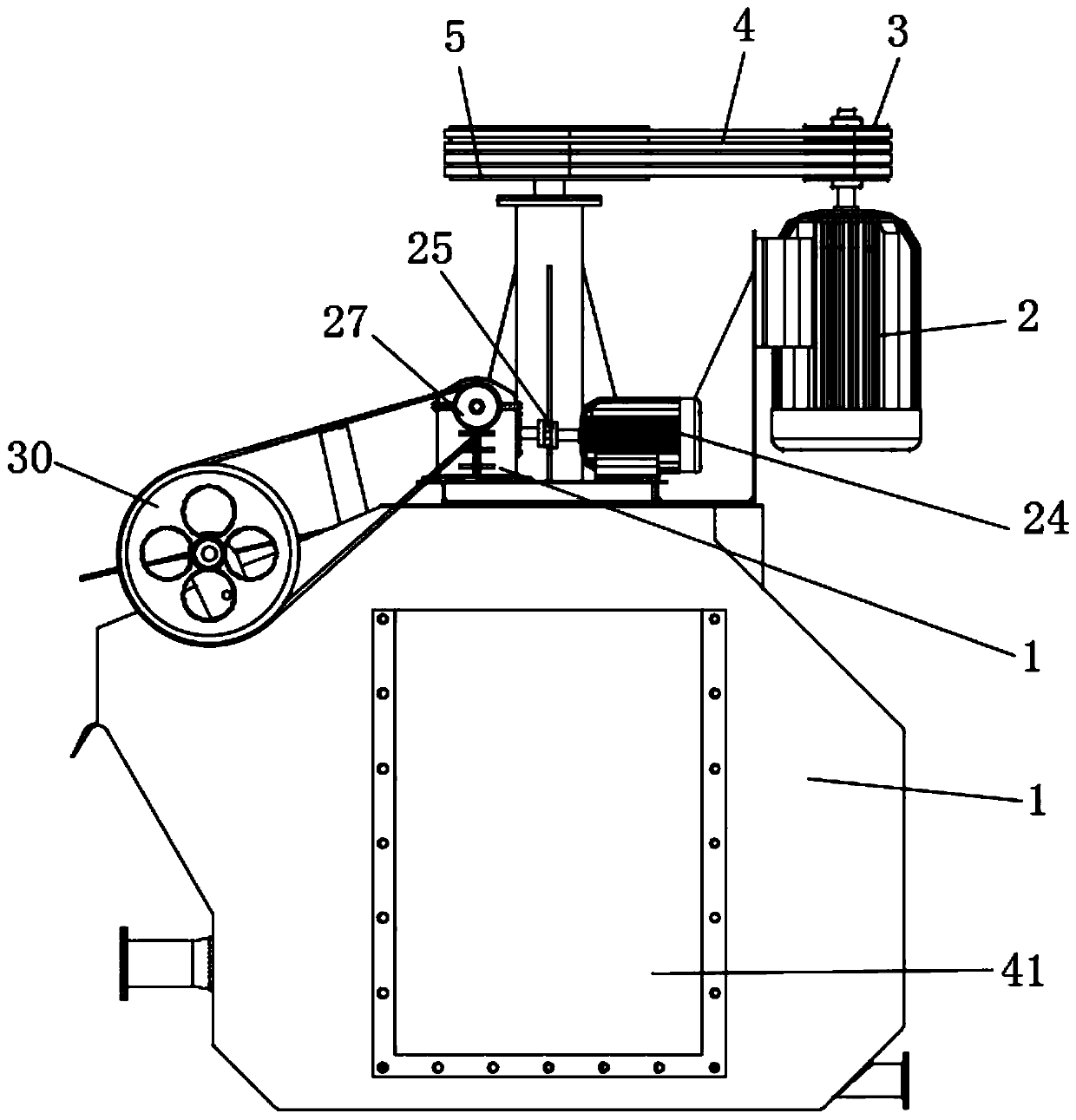

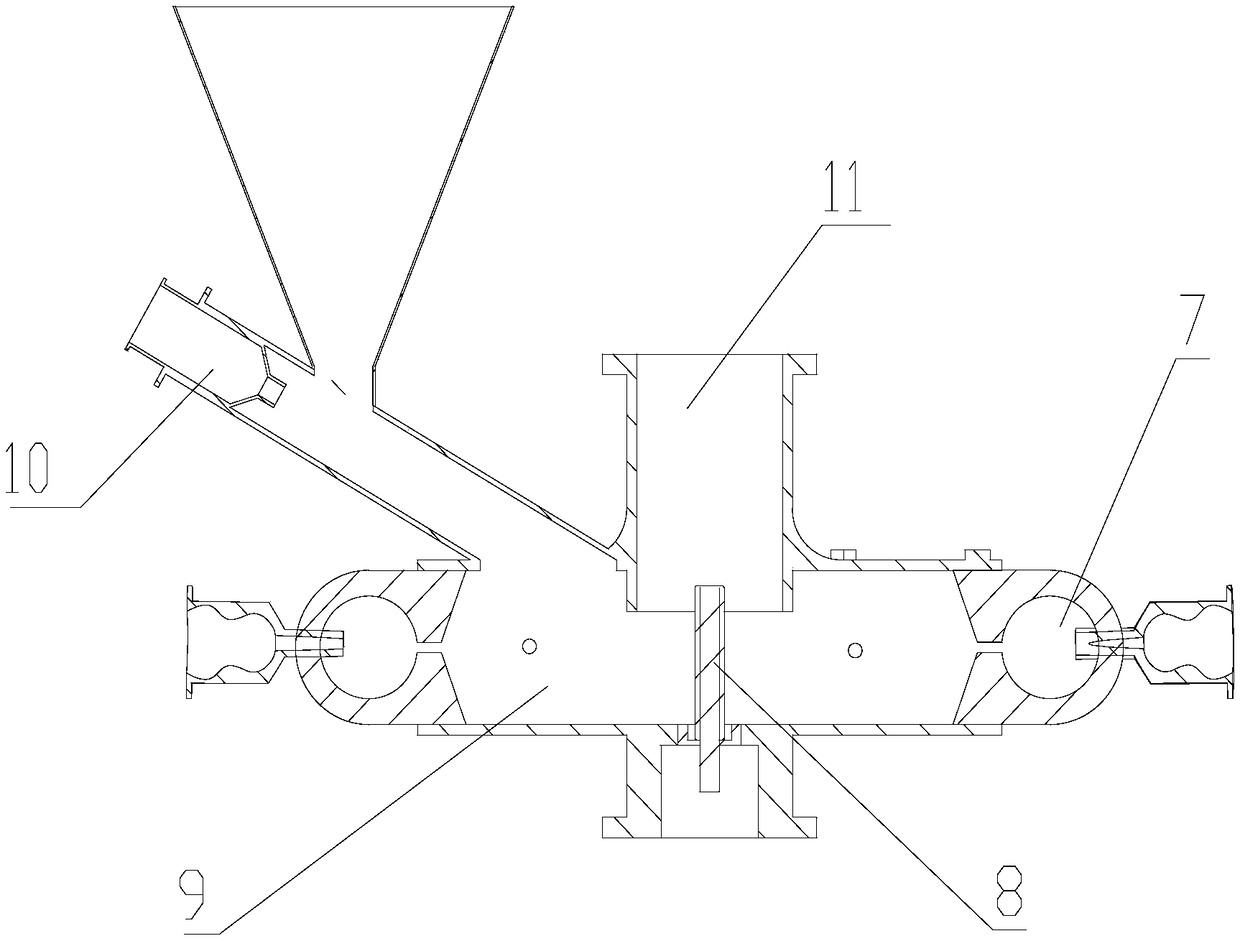

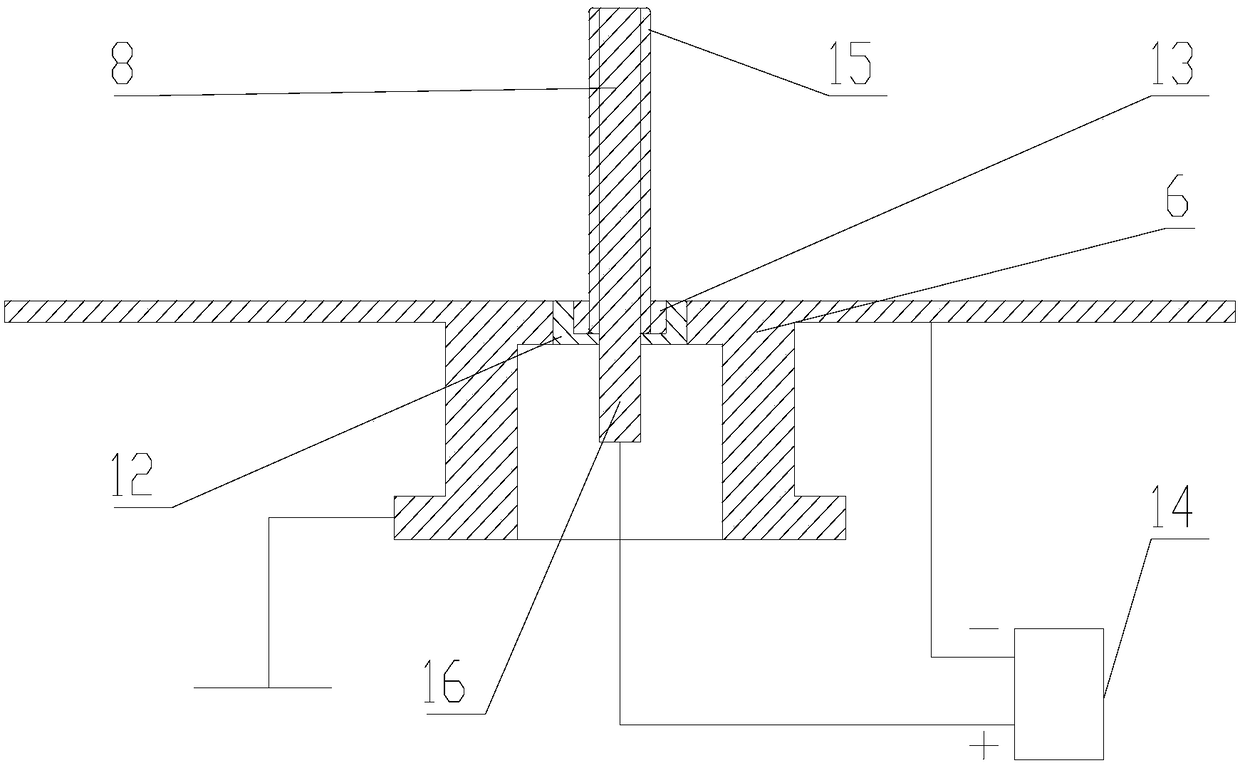

Plasma assisting airflow milling device

ActiveCN108212434ATo achieve an organic combinationImprove refinement efficiencyGrain treatmentsEngineeringAirflow

The invention relates to a plasma assisting airflow milling device which comprises an airflow mill body and an electrode shaft. The airflow mill body is provided with a feeding channel and a grading zone, a smashing chamber is arranged in the airflow mill body, the feeding channel, the grading zone and the smashing chamber are communicated, the airflow mill body is further provided with a high speed gas channel, the high speed gas channel communicates with the smashing chamber, and the electrode shaft is installed at the bottom of the interior of the airflow mill body through a ceramic cap; and the electrode shaft is connected with the positive electrode of a power source, and a shell of the airflow mill body is connected with a negative electrode of the power source and is grounded. The plasma assisting airflow milling device has the beneficial effects that the powder refining efficiency can be improved, the powder activity is strengthened, the follow-up powder synthetic efficiency isimproved. The plasma assisting airflow milling device belongs to the technical field of airflow mills.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com