Preparation method of superfine crystal inoculating agent for aluminum alloy grain refinement

A technology of grain refinement and ultra-fine grain, applied in the field of aluminum-based alloys, can solve the problems of deterioration of aluminum alloy mechanical properties, easy aggregation and precipitation of particles, and decline of refinement effect, so as to improve the refinement effect, prevent aggregation and precipitation, The effect of increasing the moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step One, Ingredients

[0037] According to the set composition ratio of 5%Ti, 1%B, 1%Ce, 0.05%La and the rest as Al, weigh the required amount of domestic Φ9.5mm rod-shaped Al-5Ti-1B master alloy and the domestic composition is The lanthanum-cerium alloy of 90%Ce and 10%La carries out batching, and above-mentioned percentage is percentage by weight;

[0038] The second step, vacuum smelting to produce bulk Al-5Ti-1B-1Re master alloy

[0039] Put all the ingredients in the first step into the vacuum electric arc furnace, and evacuate to a vacuum degree of 1.26×10 -2 Pa, be heated to the temperature that makes all batching all melt, pour into steel mold after being incubated for 5 minutes, make the Al-5Ti-1B-1Re master alloy of block shape;

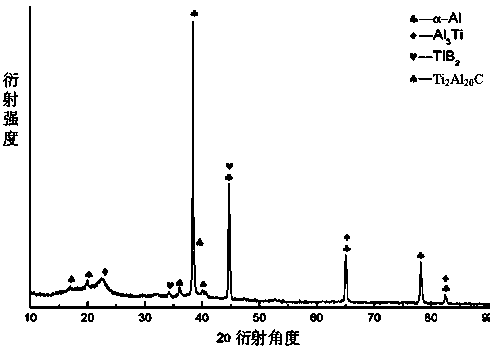

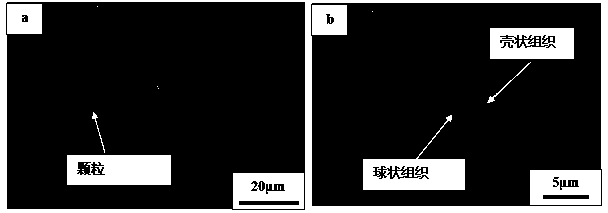

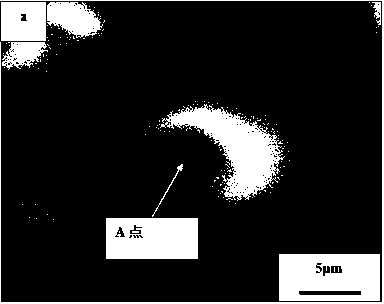

[0040] The third step, rapid solidification treatment to prepare ultra-fine grain inoculants for aluminum alloy grain refinement

[0041] Put the massive Al-5Ti-1B-1Re master alloy obtained in the second step into a vacuum rapid ...

Embodiment 2

[0046] Step One, Ingredients

[0047] According to the set composition ratio of 5.2%Ti, 1.02%B, 1.1%Ce, 0.12%La and the rest as Al, weigh the domestic Φ9.5mm rod-shaped Al-5Ti-1B master alloy and the domestic composition as 90%Ce and The lanthanum-cerium alloy of 10%La carries out batching, and above-mentioned percentage is percentage by weight;

[0048] The second step, vacuum smelting to produce bulk Al-5Ti-1B-1Re master alloy

[0049] Put all the ingredients in the first step into the vacuum electric arc furnace, and evacuate to a vacuum degree of 1.26×10 -2 Pa, be heated to the temperature that makes all batching all melt, be poured into steel mold after the insulation 6 minutes, make the Al-5Ti-1B-1Re master alloy of block shape;

[0050] The third step, rapid solidification treatment to prepare ultra-fine grain inoculants for aluminum alloy grain refinement

[0051] Put the massive Al-5Ti-1B-1Re master alloy obtained in the second step into a vacuum rapid quenching fu...

Embodiment 3

[0053] Step One, Ingredients

[0054] According to the set composition ratio of 5.4%Ti, 1.04%B, 1.2%Ce, 0.2%La and the rest as Al, weigh the domestic Φ9.5mm rod-shaped Al-5Ti-1B master alloy and the domestic composition as 90%Ce and The lanthanum-cerium alloy of 10%La carries out batching, and above-mentioned percentage is percentage by weight;

[0055] The second step, vacuum smelting to produce bulk Al-5Ti-1B-1Re master alloy

[0056] Put all the ingredients in the first step into the vacuum electric arc furnace, and evacuate to a vacuum degree of 1.26×10 -2 Pa, be heated to the temperature that makes all batching all melt, be poured into steel mold after being incubated for 8 minutes, make the Al-5Ti-1B-1Re master alloy of block shape;

[0057] The third step, rapid solidification treatment to prepare ultra-fine grain inoculants for aluminum alloy grain refinement

[0058] Put the massive Al-5Ti-1B-1Re master alloy obtained in the second step into a vacuum rapid quenchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com