Patents

Literature

50results about How to "Solve easy aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-compressive-deformation and high-conductivity rubber composite material and preparation method thereof

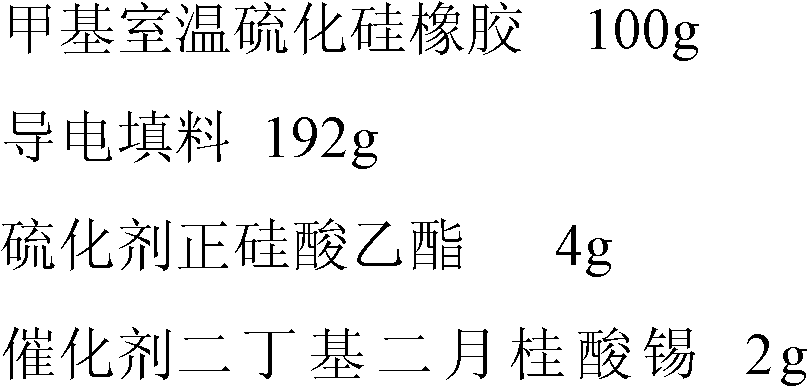

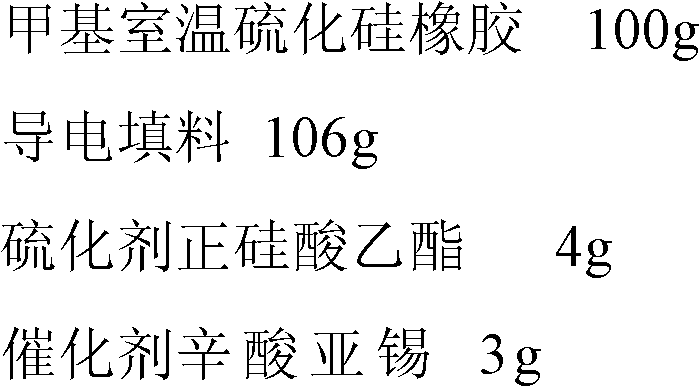

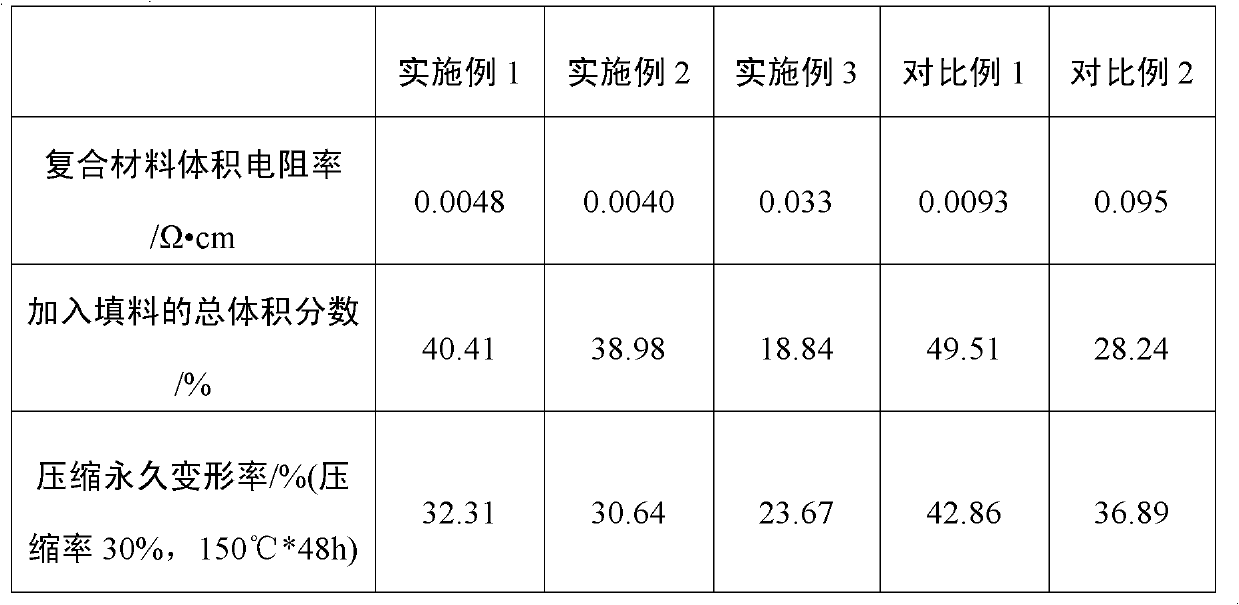

The invention relates to a low-compressive-deformation and high-conductivity rubber composite material and a preparation method thereof. The low-compressive-deformation and high-conductivity rubber composite material is prepared by the following steps of: taking silicon rubber as a base body and utilizing modified grain-shaped and fiber-shaped metal-plating conductive fillers containing a reactive double-bond silane coupling agent under a CO2 supercritical state to prepare low-compressive-deformation and high-conductivity rubber composite material. Under the condition of guaranteeing the high conductivity, the use amount of the conductive fillers is reduced and the composite material has low compressive deformation and high conductive property.

Owner:BEIJING UNIV OF CHEM TECH +1

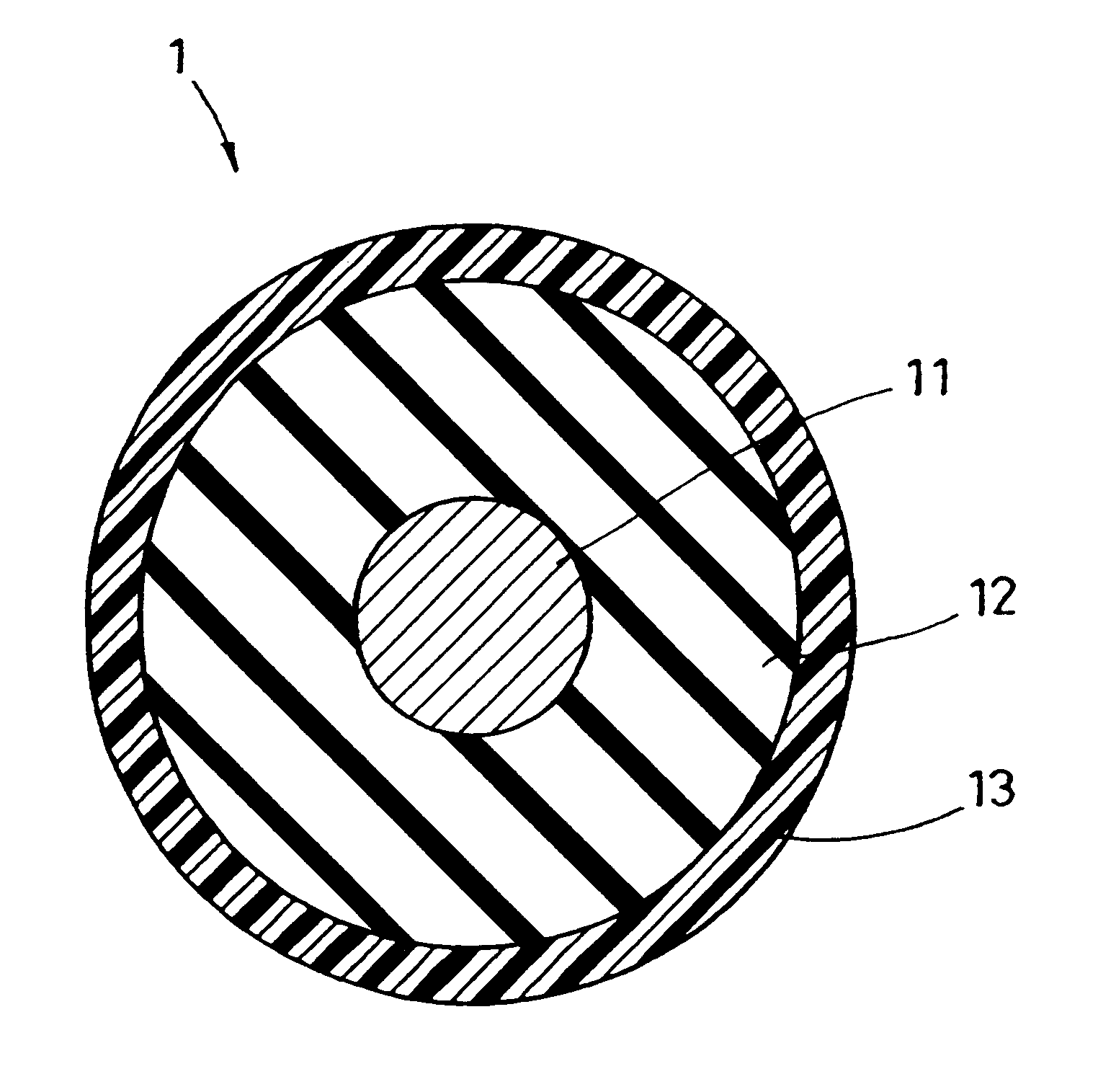

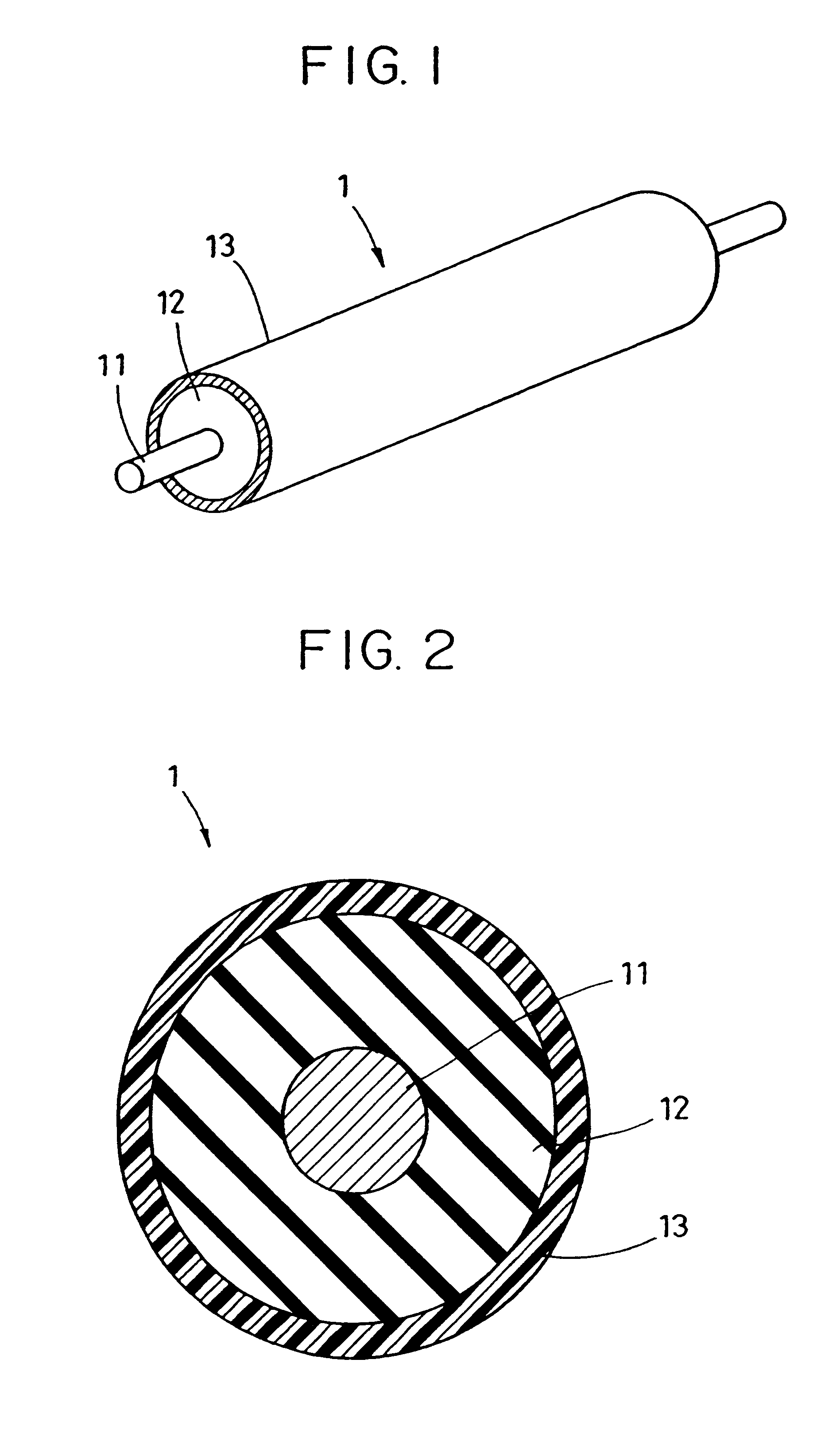

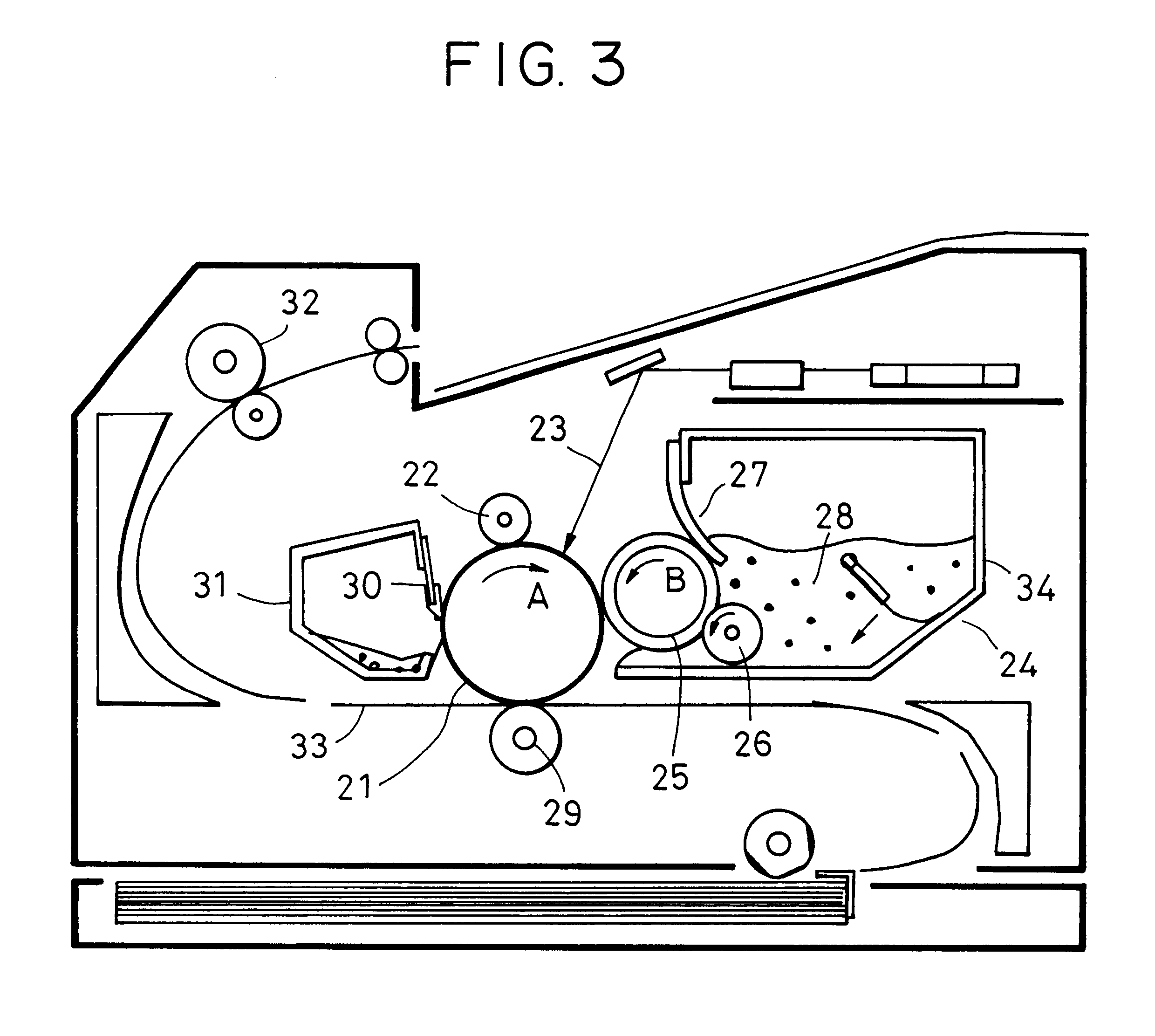

Developing roller and developing device using the same

InactiveUS6393243B1Satisfactory dispersion and stabilityGood dispersionElectrographic process apparatusAdditive ingredientNitrogen

A developing roller having a superior setting ability and having a uniform and high conductivity is provided by improving dispersion and stability of carbon black mixed in a solution of a coating resin, and then forming a resin layer that has a low modulus of elasticity and a high conductivity when coated. The developing roller includes a core shaft, an elastic body layer formed around the core shaft and made of rubber as a main ingredient, and a resin layer coated at least on an outer surface of the elastic body layer. The resin layer contains carbon black having a DBP absorption amount of 80 to 110 ml / 100 g, a ratio of a DBP absorption amount to a nitrogen specific surface area being not more than 0.012 ml / m2, and a ratio of a volatile component to a nitrogen specific surface area being not more than 2.0x10-4 g / m2.

Owner:CANON KK

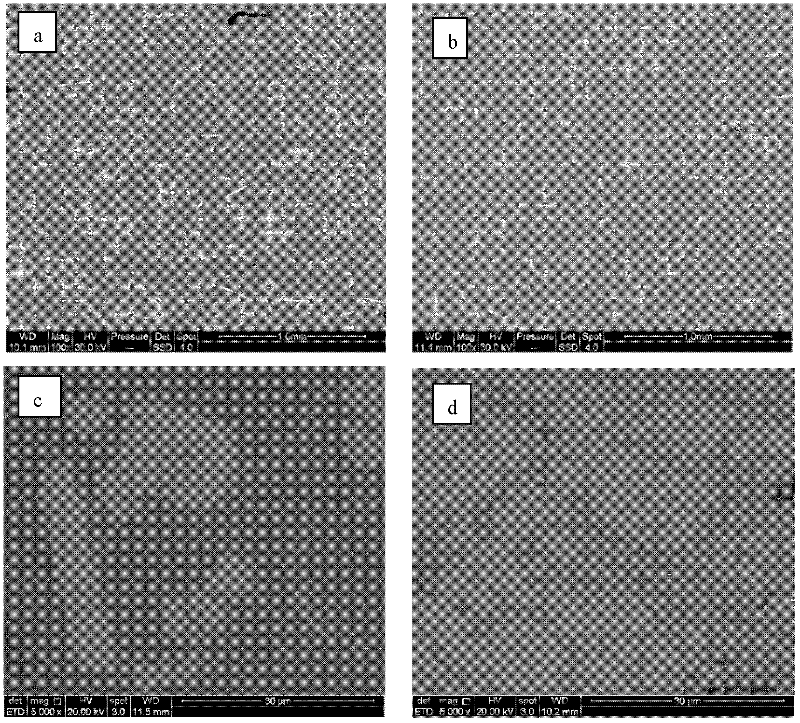

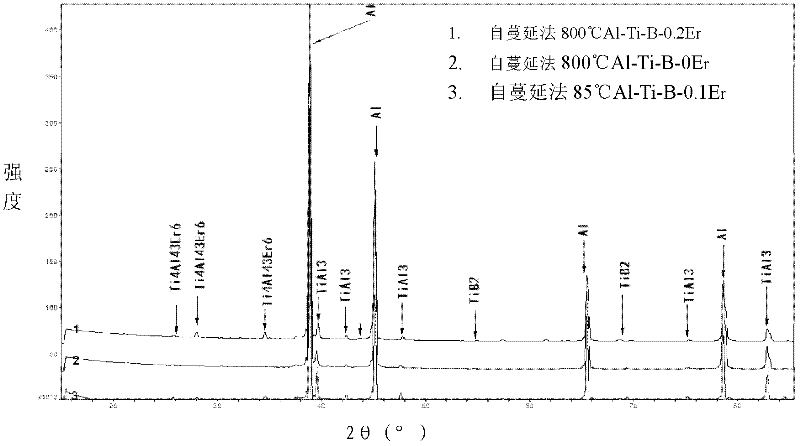

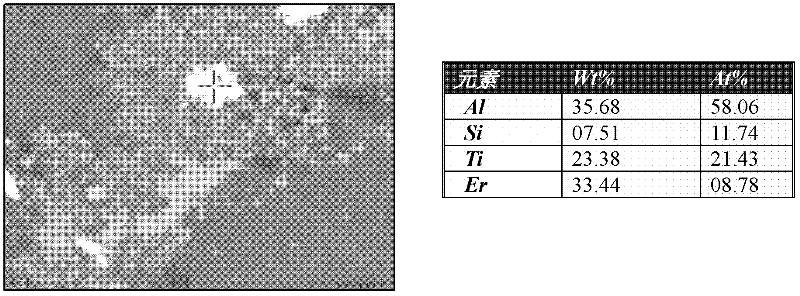

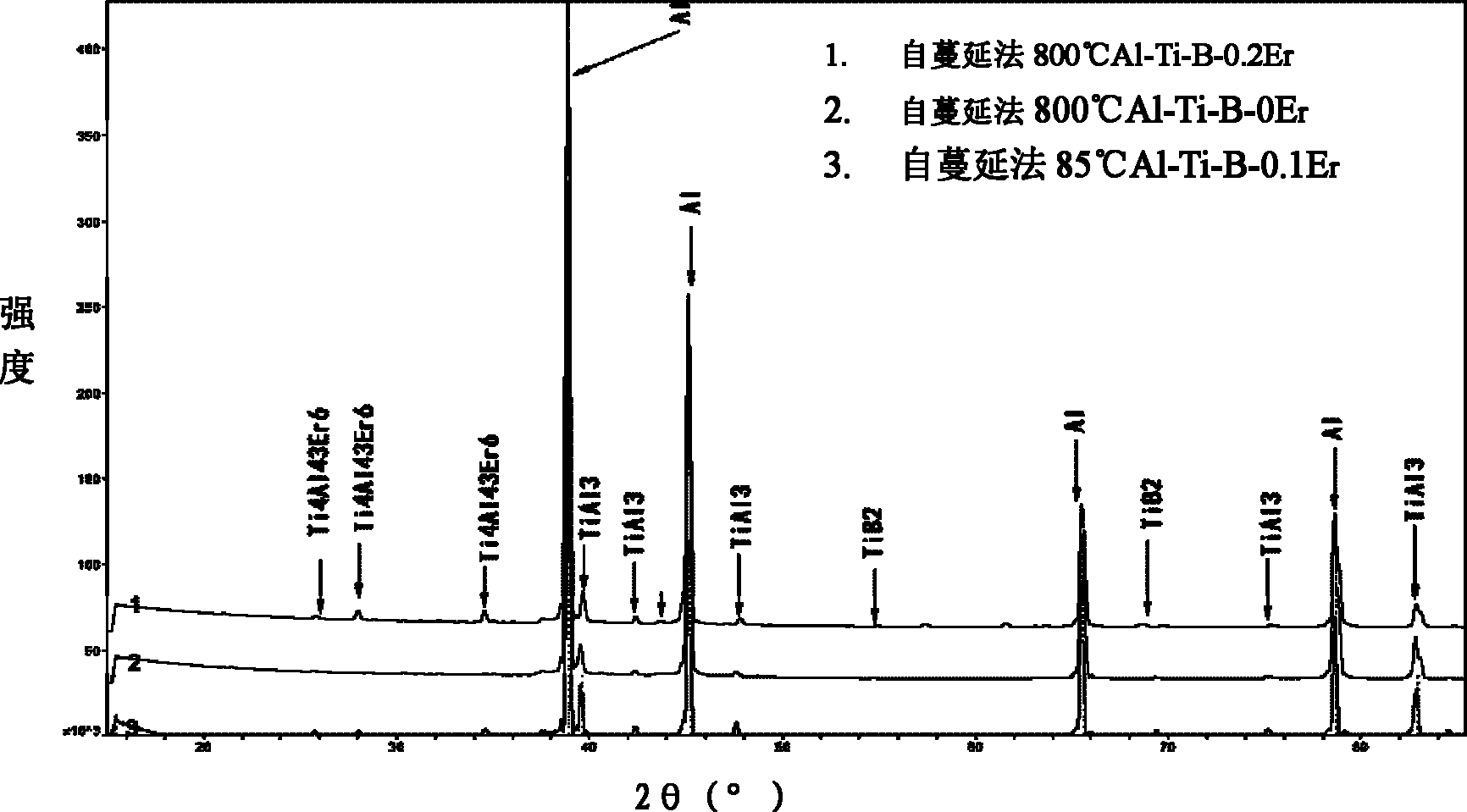

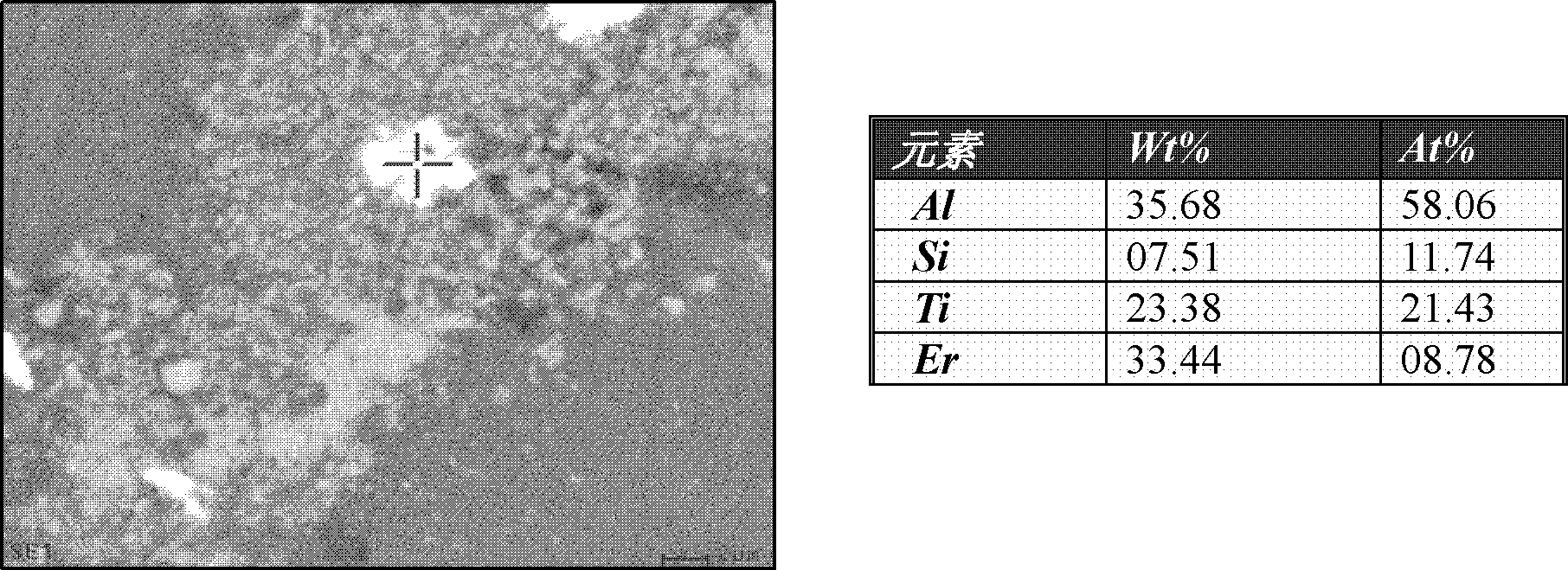

Al-Ti-B-Er refiner and preparation method thereof

The invention discloses an Al-Ti-B-Er refiner and a preparation method thereof and belongs to the technical field of refiners. The Al-Ti-B-Er refiner comprises the following components in weight percentage: 3.0-10.0 percent of Ti, 0.6-2 percent of B, 0.1-0.3 percent of Er and the balance of Al, wherein the weight ratio of the Ti to the B is 5 / 1. The phase composition comprises alpha-Al, TiAl3, TiB2, Al3Er and AlErTi. The preparation method comprises the following steps of: weighing boron (B) powder, titanium (Ti) powder, aluminum (Al) powder, an Al-Er intermediate alloy and an aluminum ingot as required, wherein the weight ratio of the titanium (Ti) powder to the boron (B) powder is 5, the molar ratio of the aluminum (Al) powder to the titanium (Ti) powder is 2.5-3.0, and the purity of the aluminum ingot is 99.9 percent; evenly mixing the Ti, the Al with the B; putting in a mould; pressing into a block; heating to melt the aluminum ingot; covering by kryocide; pressing in the Al-Er intermediate alloy; standing; heating a melt; pressing in the block; performing stirring reaction; pressing in C2Cl6 for refining; drossing and pouring. According to the Al-Ti-B-Er refiner disclosed by the invention, the problem that the TiB2 can be easily gathered is solved, and the refining efficiency is increased.

Owner:BEIJING UNIV OF TECH

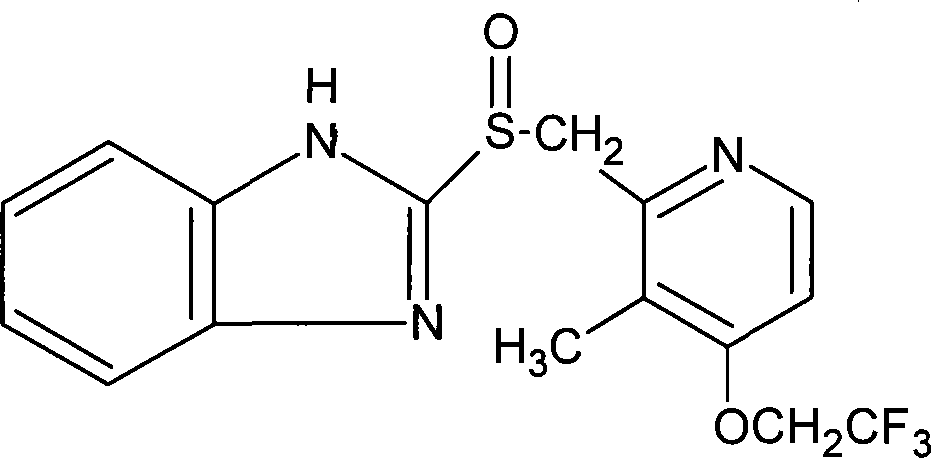

Lansoprazole intestine solution capsule and its preparation method

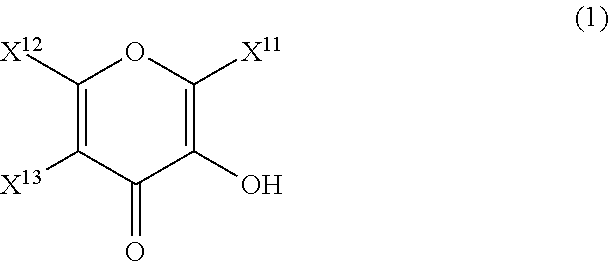

ActiveCN101156852AHigh dissolution rateSolve easy aggregationOrganic active ingredientsDigestive systemIntestinal structureVegetable oil

The invention discloses a lansoprazole enteric liquid capsule which has a simple manufacturing process, avoids water from being led in during the manufacturing process, and has good storage stability and a manufacturing method. The lansoprazole enteric liquid capsule consists of lansoprazole, dispersant, edible vegetable oil, magnesium oxide or magnesium carbonate, an emulsifier, poloxamer, animal and vegetable glue, and sodium citrate. After being mixed uniformly, raw materials enter into a colloid mill, and then the raw materials are infused into a hollow capsule, and polyacrylic resin ethanol solution is used as the sealing material to sleeve and seal the infused capsule. The invention suspends the lansoprazole into hydrophobic excipient oil, forms a protective film around the lansoprazole powder, does not lead in water during the manufacturing process, avoids the degradation of the lansoprazole, does not need to wrap an isolation layer and an enteric coating, and has short production cycle, simple production process, low cost, and good product quality and stability.

Owner:INCREASEPHARM TIANJIN INST CO LTD

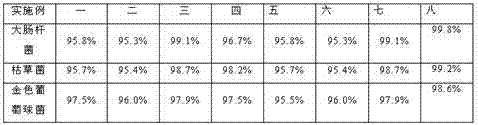

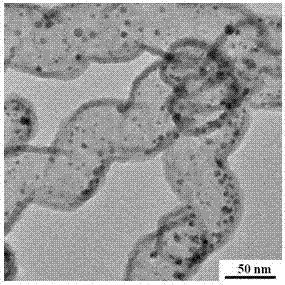

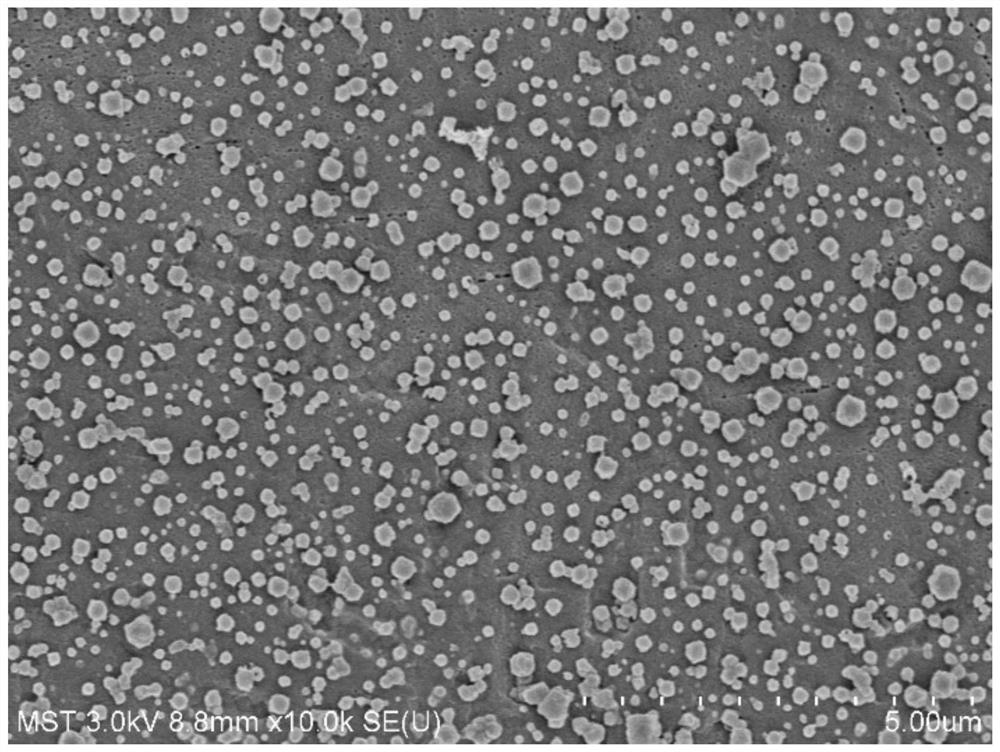

Nano-silver anti-microbial regenerated silk fibroin material and preparation method thereof

ActiveCN106928729AQuick changeLow reduction efficiencyMonocomponent fibroin artificial filamentWet spinning methodsDispersityOrganic solvent

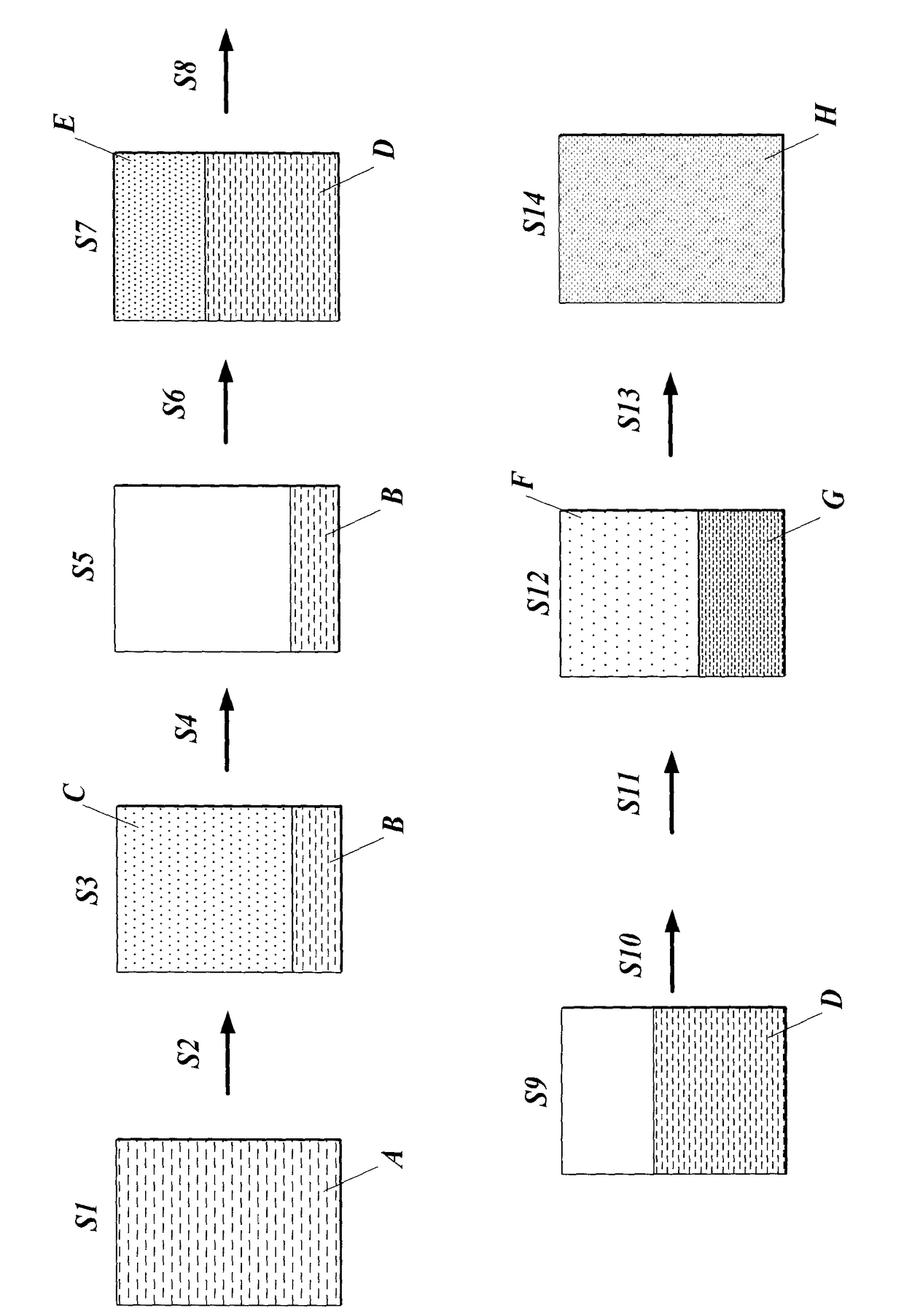

The invention discloses a nano-silver anti-microbial regenerated silk fibroin material and a preparation method thereof. The method comprises the following steps: 1) dissolving degumming silk or regenerated silk fibroin in a solvent taking formic acid as a main component, thereby acquiring a fibroin formic acid solution, and then adding a silver salt, stirring and dissolving; 2) adopting different regenerating technologies for processing the fibroin formic acid solution into the regenerated silk fibroin material in different forms; and 3) performing organic solvent after-treatment on the regenerated silk fibroin material, fully washing with deionized water and drying, thereby acquiring the nano-silver anti-microbial regenerated silk fibroin material. The nanometer silver in the regenerated silk fibroin material provided by the invention has the advantages of small grain size, excellent dispersity, high stability and excellent and long-lasting anti-microbial property. The preparation method is simple, the operation is easy, the cost is low and the material can be easily industrialized.

Owner:江苏诺阳家居科技有限公司

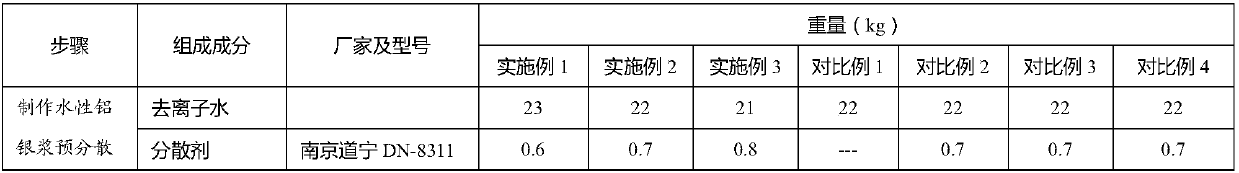

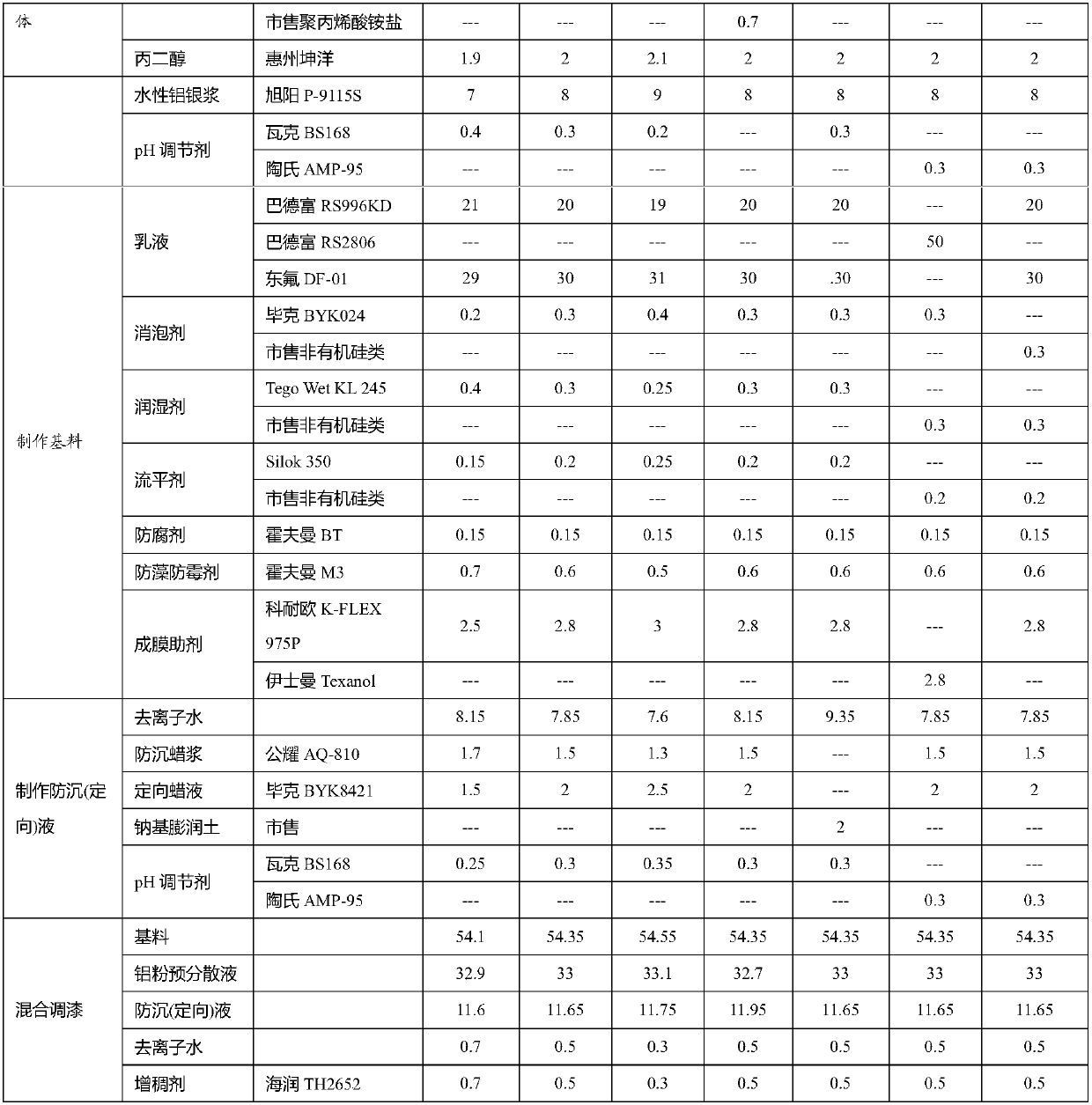

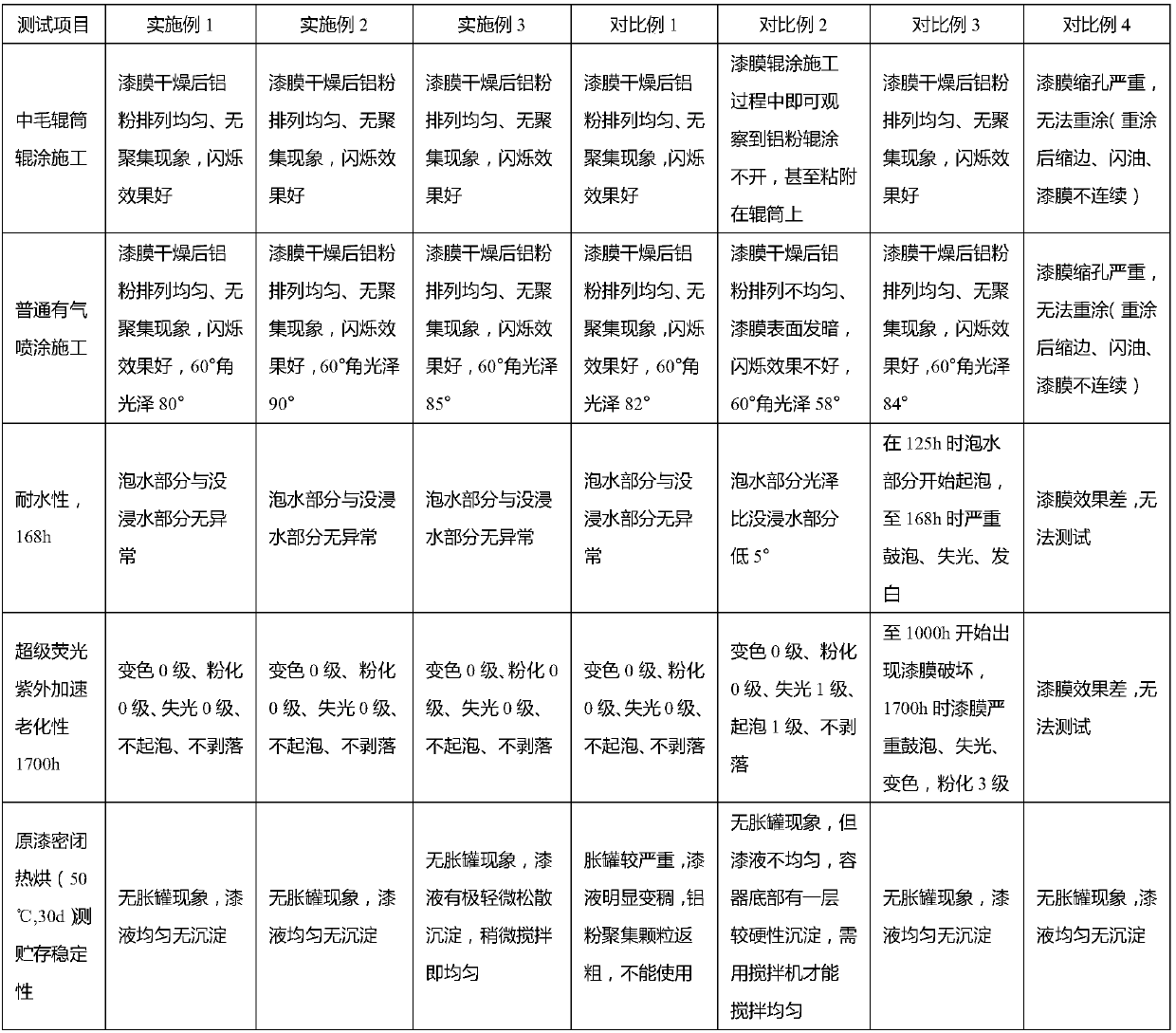

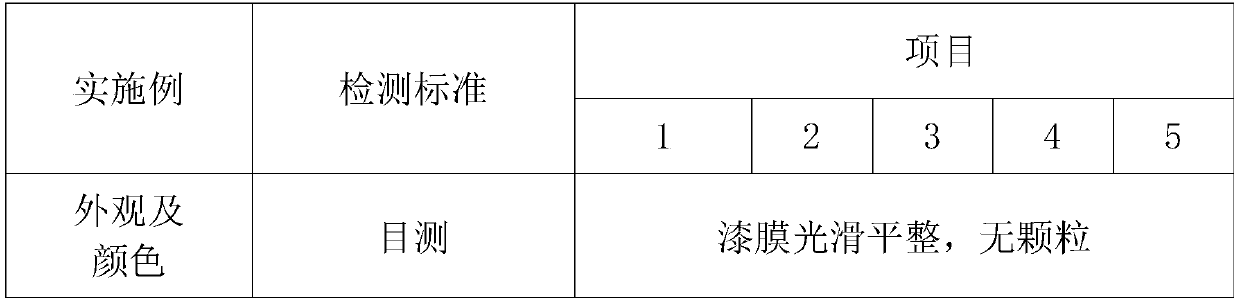

Easily-oriented and high-performance fluorosilicon composite waterborne aluminum powder paint and preparation method thereof

ActiveCN108047834AExcellent fast positioning functionRestricted Brownian motionCoatingsBlock structureDefoaming Agents

The invention discloses easily-oriented and high-performance fluorosilicon composite waterborne aluminum powder paint and a preparation method thereof. The easily-oriented and high-performance fluorosilicon composite waterborne aluminum powder paint is prepared from 54.1 to 54.55 parts of fluorosilicon composite base material, 32.9 to 33.1 parts of waterborne type aluminum paste pre-dispersion solution, 11.6 to 11.75 parts of anti-sinking and fast directional fluid, 0.3 to 0.7 part of deionized water and 0.3 to 0.7 part of thickening agent; the waterborne type aluminum paste pre-dispersion solution is prepared from 21 to 23 parts of the deionized water, 0.6 to 0.8 part of dispersing agent with a linear block structure, 1.9 to 2.1 parts of propylene glycol, 7 to 9 parts of waterborne type aluminum paste and 0.2 to 0.4 part of organosilicon pH modifier; the fluorosilicon composite base material organosilicon is prepared from 19 to 21 parts of organosilicon / acrylic copolymer emulsion, 29to 31 parts of fluorocarbon emulsion, 0.25 to 0.4 part of organosilicon defoaming agent, 0.25 to 0.4 part of organosilicon wetting agent, 0.15 to 0.25 part of organosilicon leveling agent, 0.15 part of preservative, 0.5 to 0.7 part of damp-proof and mildewproof agent and 2.5 to 3 parts of high-efficiency coalescing agent; the anti-sinking and fast directional fluid is prepared from 7.6 to 8.15 parts of the deionized water, 1.3 to 1.7 parts of anti-sediment wax liquor, 1.5 to 2.5 parts of aluminite powder oriented wax liquid and 0.25 to 0.35 part of the organosilicon pH modifier.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Polishing liquid for cmp and polishing method using the same

ActiveUS20120315763A1High polishing rateHigh flatnessOther chemical processesSemiconductor/solid-state device manufacturingNonionic surfactantCerium

Owner:RESONAC CORP

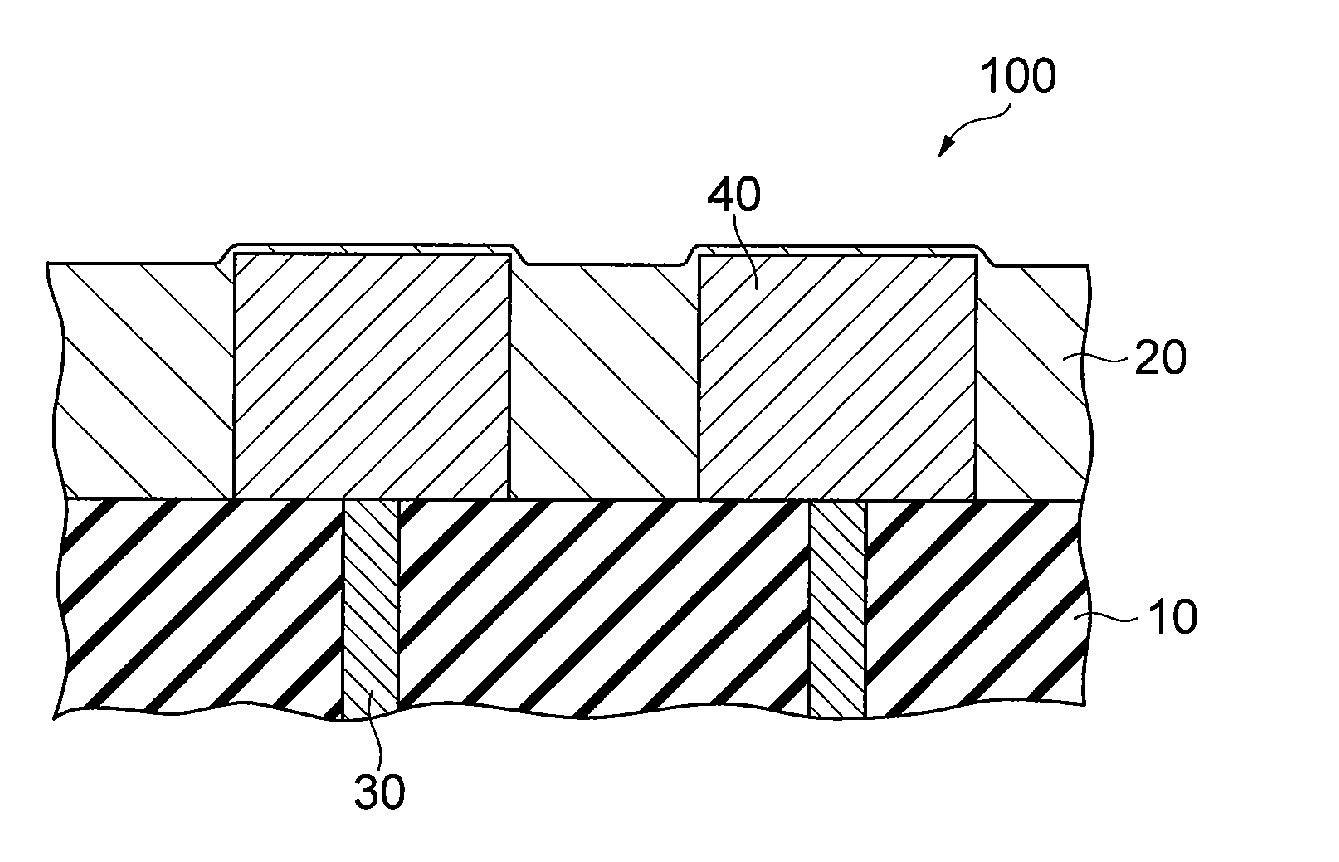

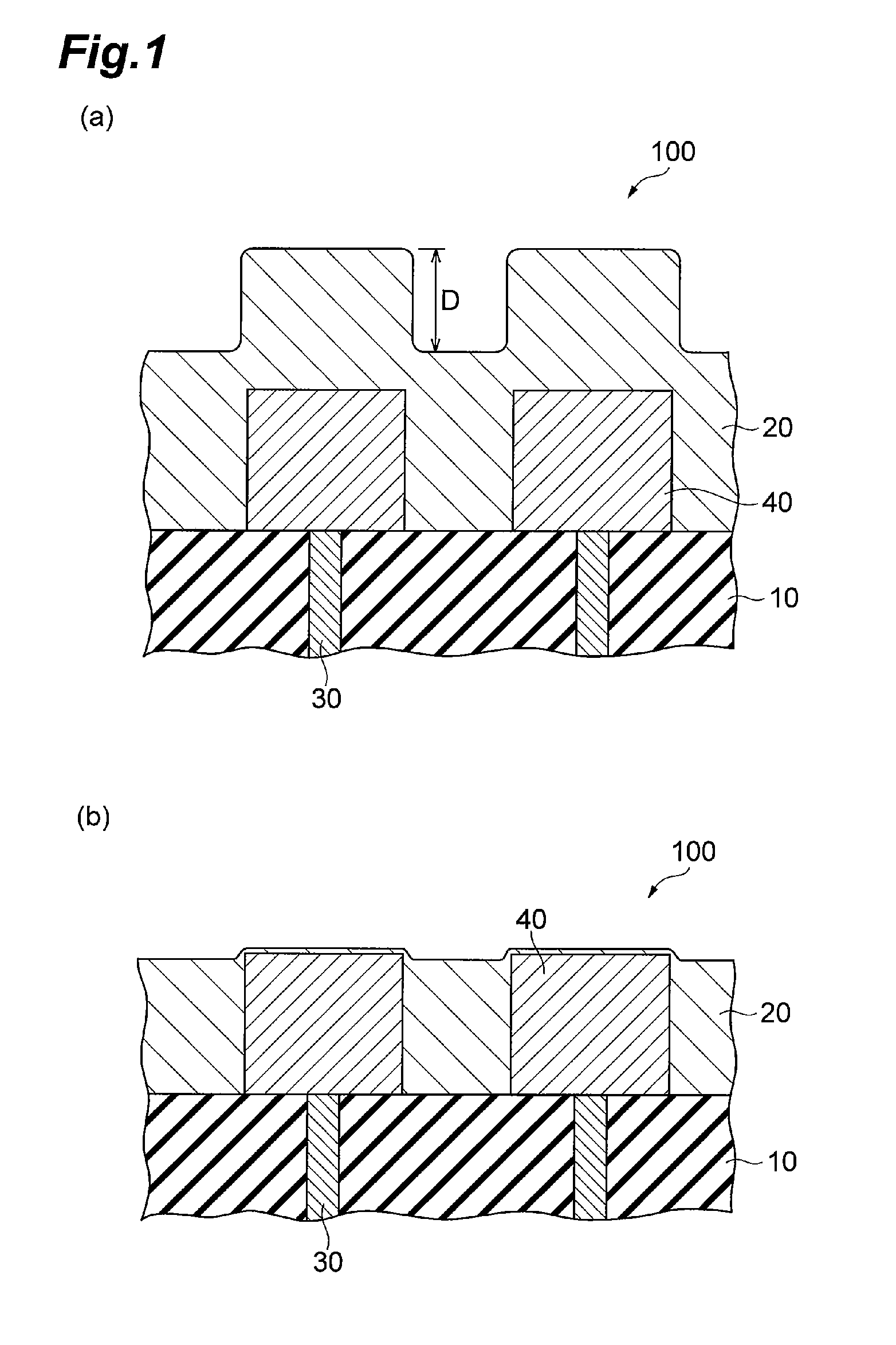

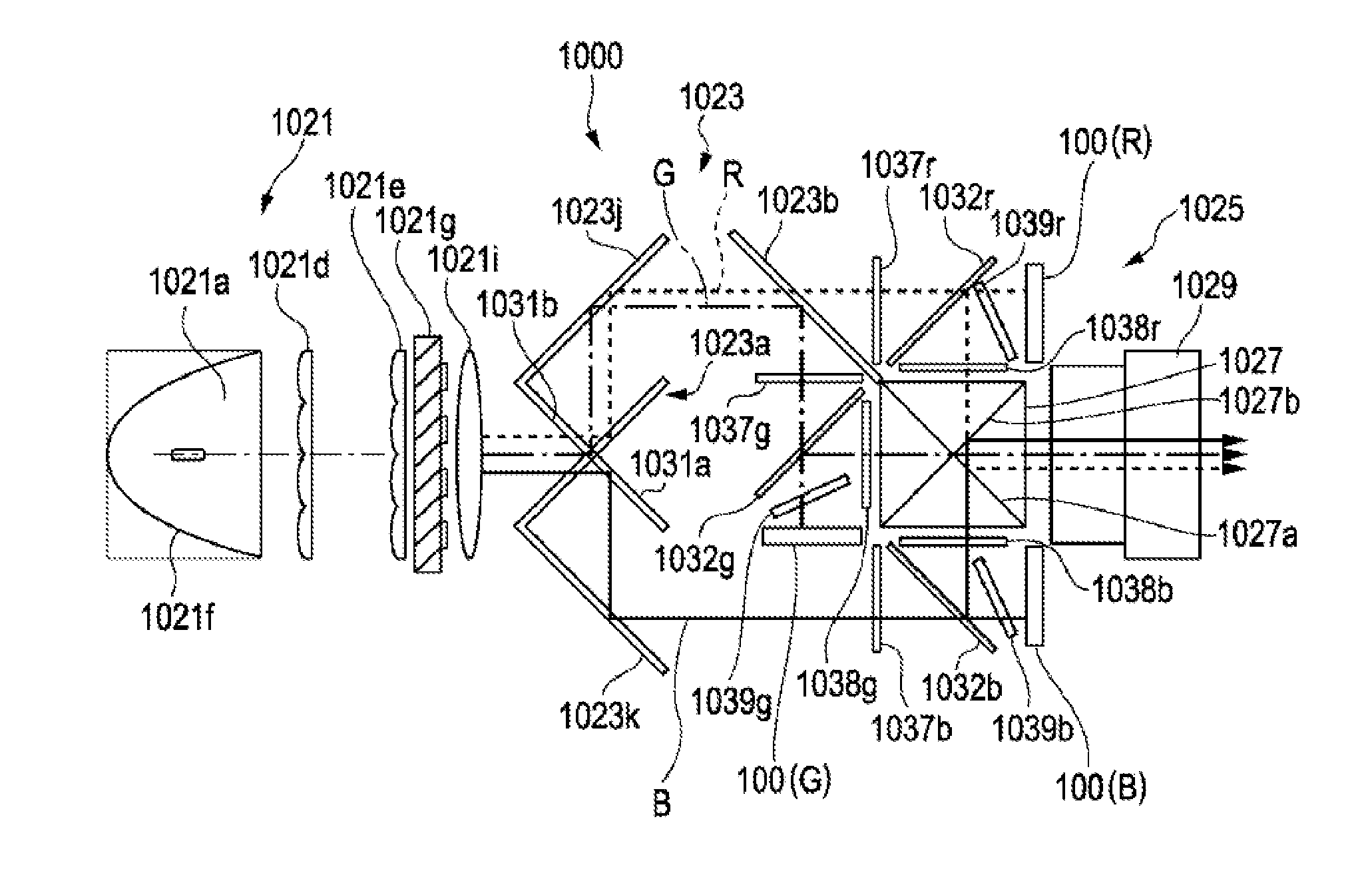

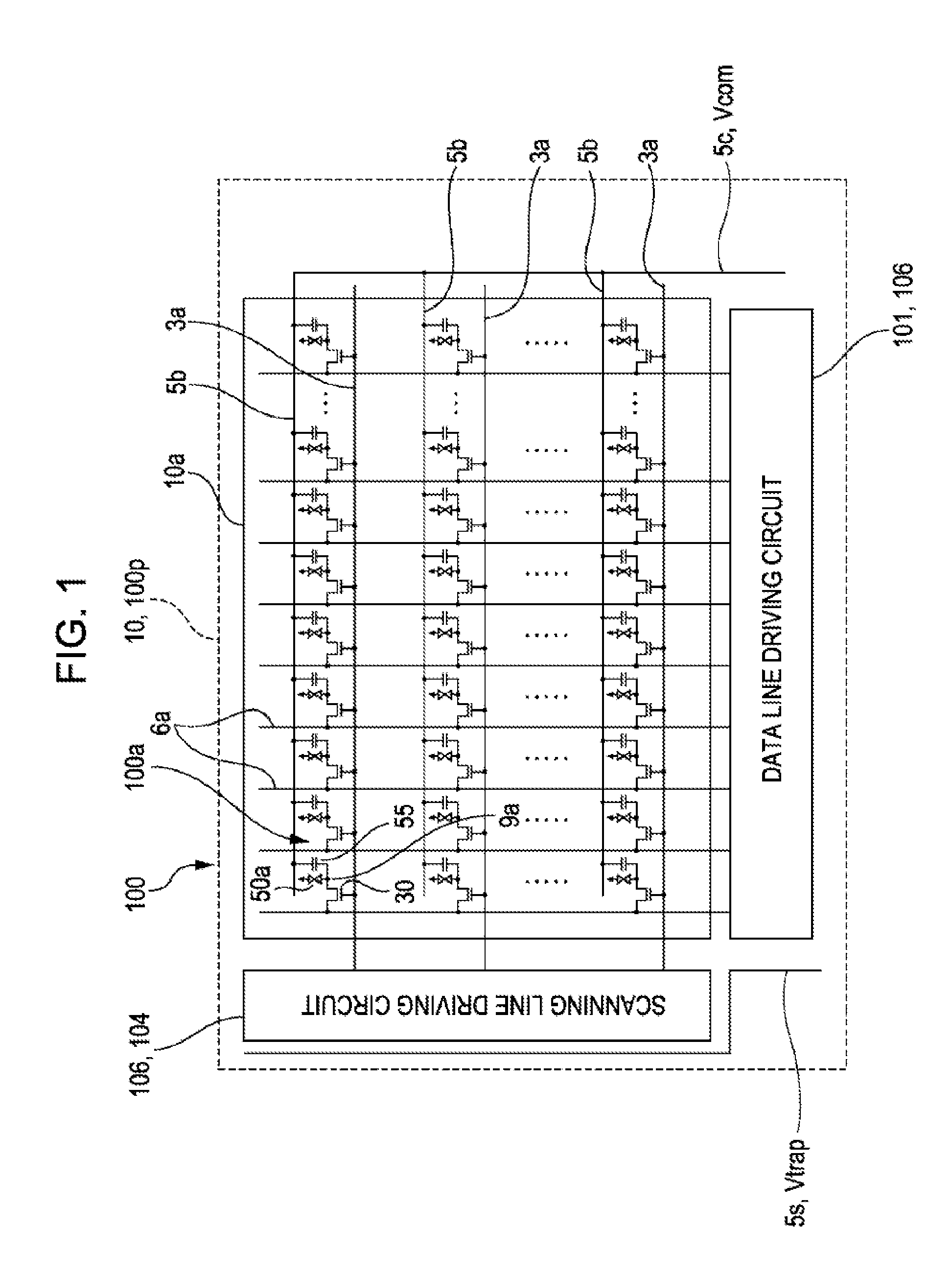

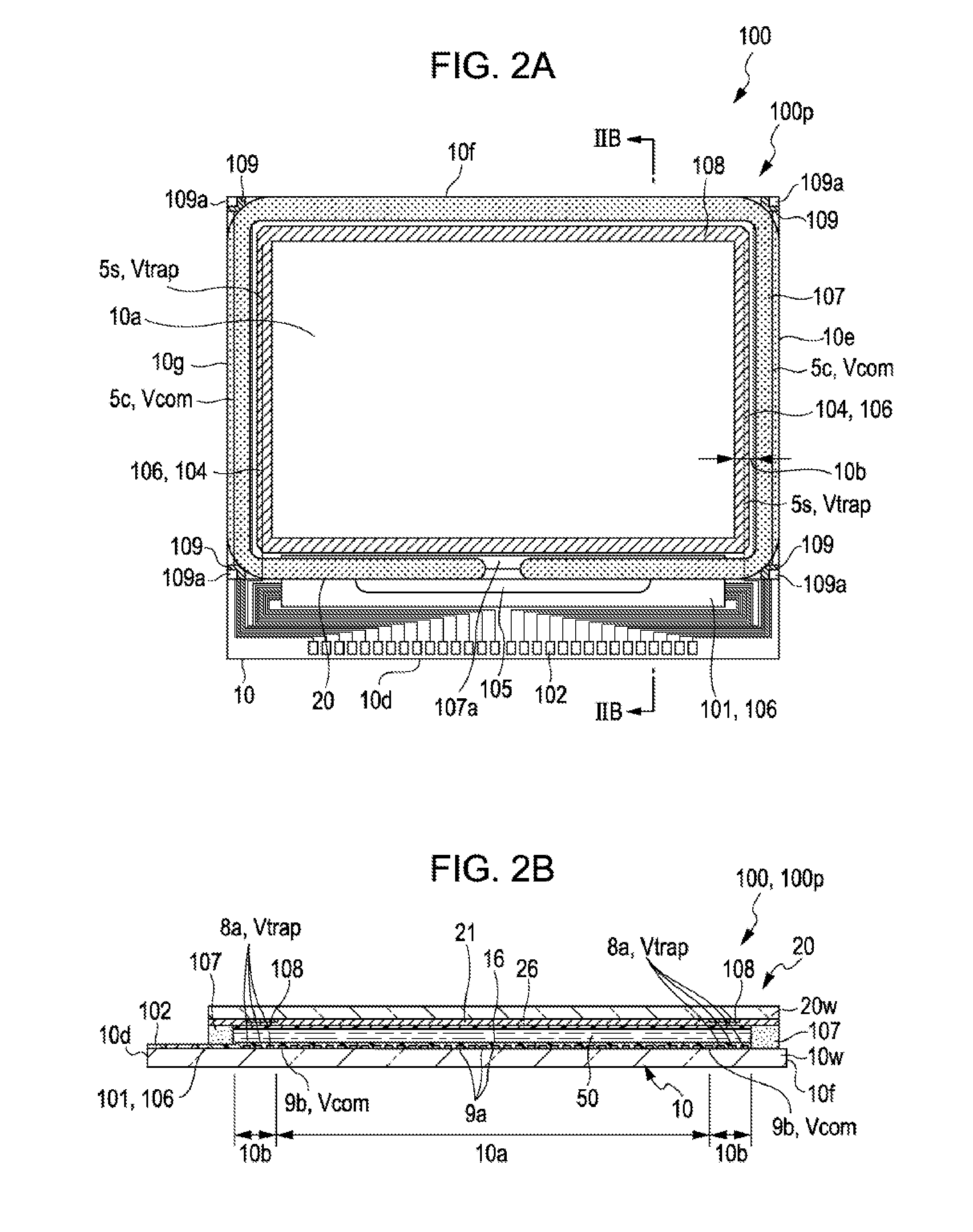

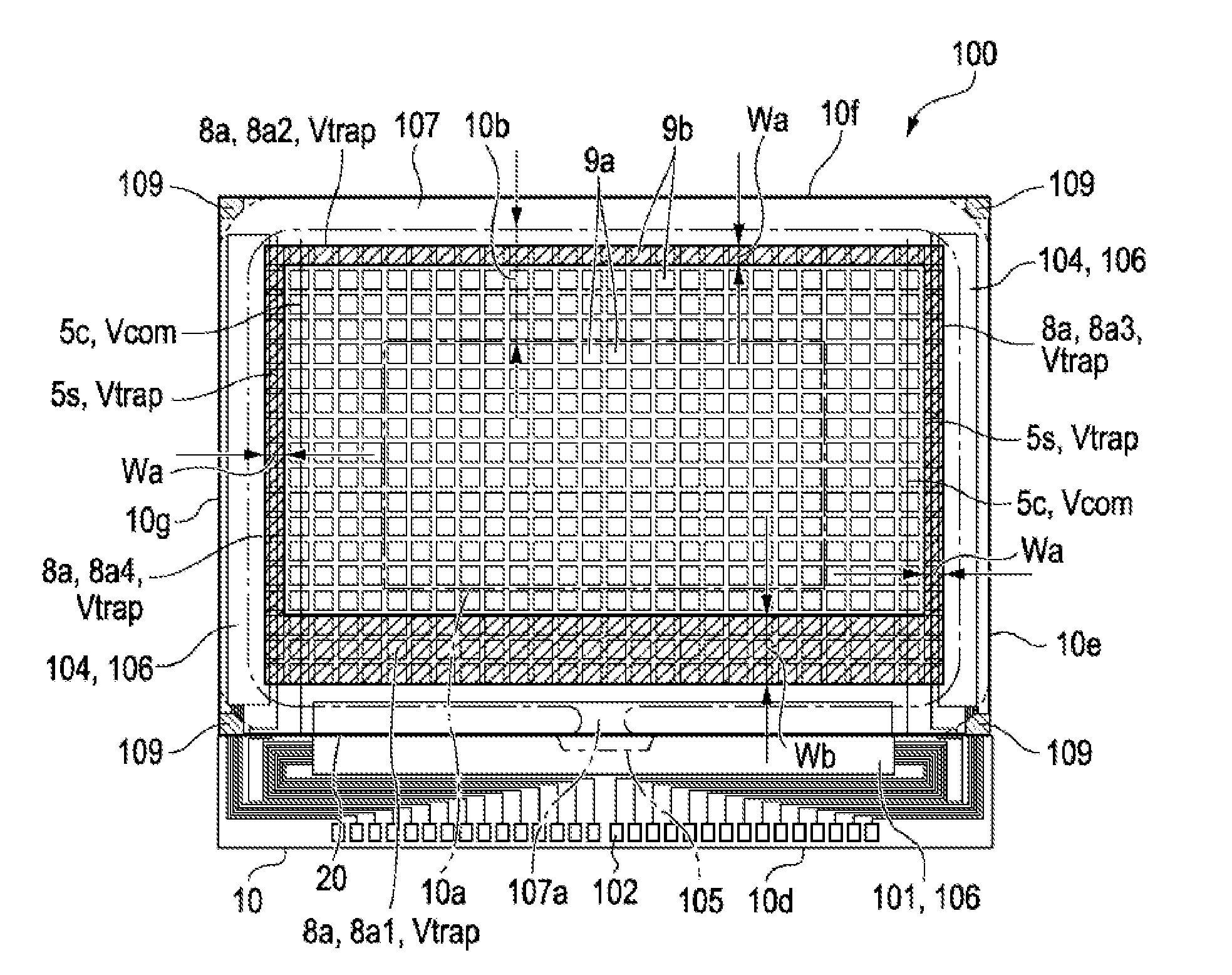

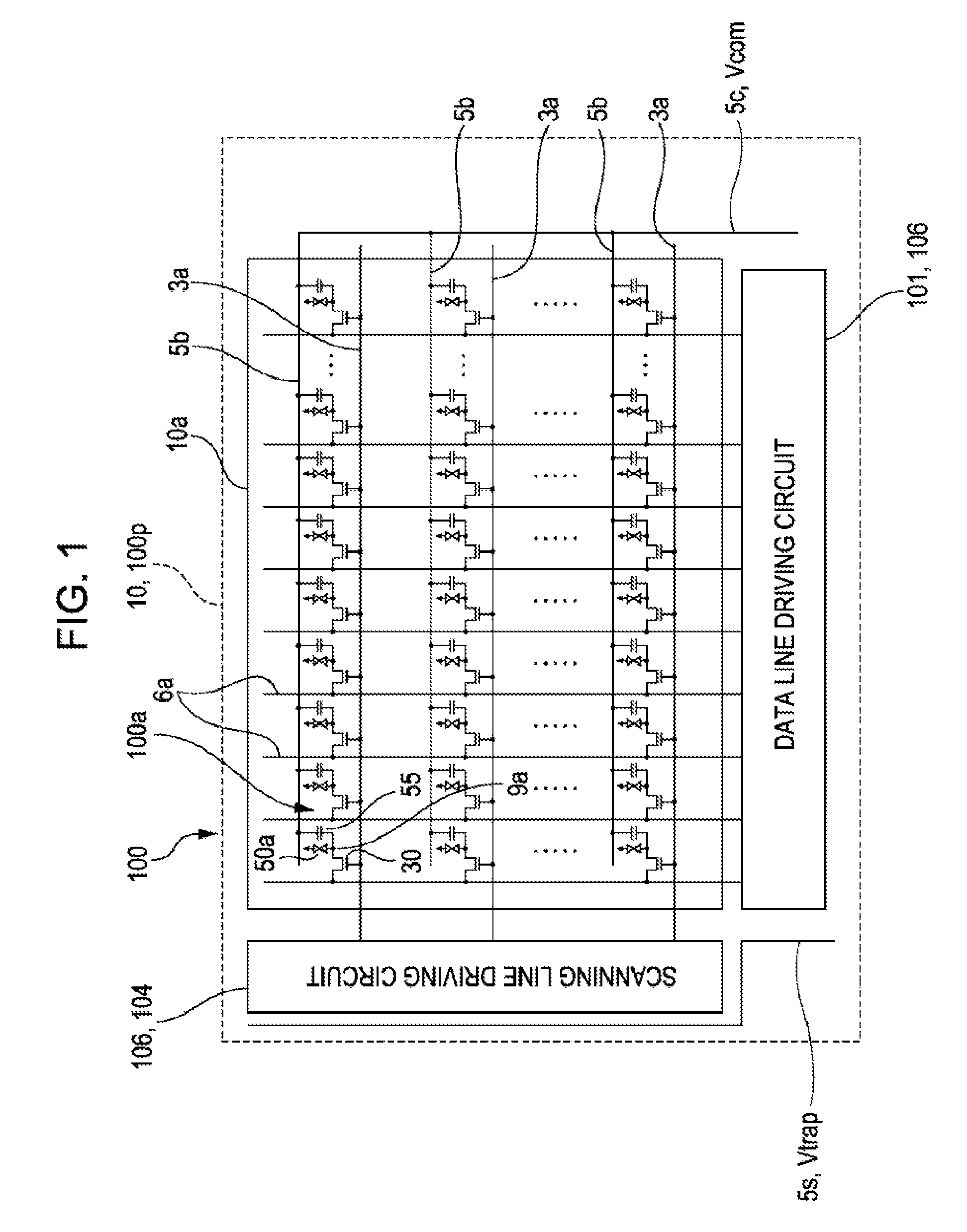

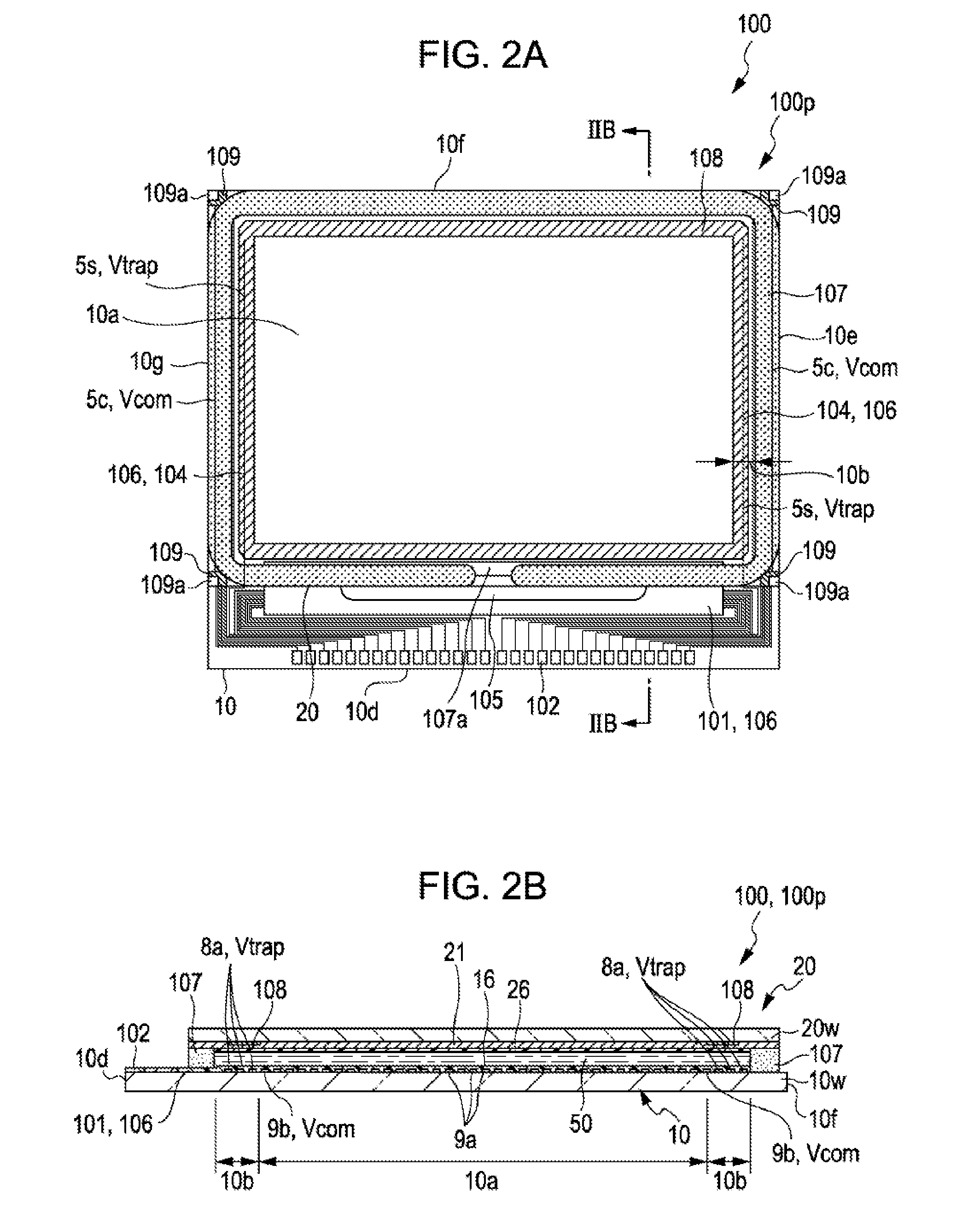

Liquid crystal device and projection-type display apparatus

In an element substrate of a liquid crystal device, in a peripheral region interposed between an image display region and a seal material, a peripheral electrode to which a potential is applied for trapping ionic impurities which is different from a common potential applied to a dummy pixel electrode or the like is formed. In the peripheral electrode, an electrode width of a first portion opposing a sealing material provided at a liquid crystal injection opening of the seal material is set to be greater than electrode widths of the other portions.

Owner:SEIKO EPSON CORP

Disintegratable Zinc Oxide Powder and Method For Producing the Same

InactiveUS20090010971A1Good disintegrationImproves UV protectionCosmetic preparationsMaterial nanotechnologyZinc Acetate DihydrateChemistry

Owner:SHISEIDO CO LTD

Rare earth-aluminum-titanium-boron alloy and preparation method thereof

The invention discloses a preparation method of rare earth-aluminum-titanium-boron alloy. The preparation method comprises the following steps: weighing titanium powder or aluminum-titanium intermediate alloy, boron powder or aluminum-boron intermediate alloy, rare earth metals or rare earth-aluminum intermediate alloy, and aluminum ingot; heating for melting the aluminum ingot, then adding the raw materials for carrying out a reaction, stirring until melt reacts completely, and then refining; carrying out heat preservation and then drossing so as to obtain the rare earth-aluminum-titanium-boron alloy. The rare earth-aluminum-titanium-boron alloy is prepared from the following components by weight percent: 1.0-10.0% of titanium, 0.5-5.0% of boron, 0.1-3.0% of rare earth and the balance ofaluminum. The invention also discloses the rare earth-aluminum-titanium-boron alloy. The preparation method improves the size, morphology and distribution of a TiAl3 phase and TiB2 particles in a refiner, and solves the problem that the TiB2 particles are easy to aggregate.

Owner:BAOTOU RES INST OF RARE EARTHS +1

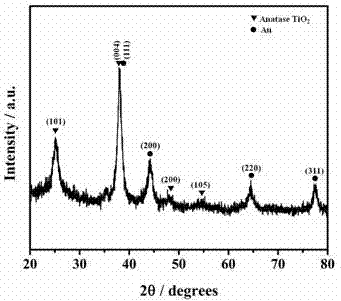

Gold/titanium dioxide nano-compound and preparation method and application thereof

ActiveCN106890638ASimple manufacturing processSolve easy aggregationColor/spectral properties measurementsMetal/metal-oxides/metal-hydroxide catalystsFiberCarbon fibers

The invention discloses a gold / titanium dioxide nano-compound and a preparation method and application thereof.The preparation method comprises the steps that helical carbon fiberis used as a template, gold particles can be sputtered on the surface of carbon fiber through ion sputtering, then a layer of titanium dioxidedeposits through an atomic layer deposition technology, and annealing treatment is conducted on the obtained titanium dioxide / gold / helicalcarbon fiber compound to obtain a product. In the product, the titanium dioxide exists in the form of the hollow helical titanium dioxide fiber, and the gold nano-particles are dispersed in the inner surface of the hollow helical titanium dioxide fiber. The gold / titanium dioxide nano-compound with a hollow helical structure is prepared for the first time, the problem that the gold nano-particles easily aggregate is solved, more active sites exist, the compound has the better peroxide mimic enzyme catalysis activity and overcomes the shortcoming thatnatural enzyme is difficult to extract andis easy to inactivate and degenerate at high temperature, a catalytic temperature range of superoxide mimic enzymeis widened, and the compound has the potential and wide application value in the fields of biological detection, analysis and the like.

Owner:HAINAN UNIVERSITY

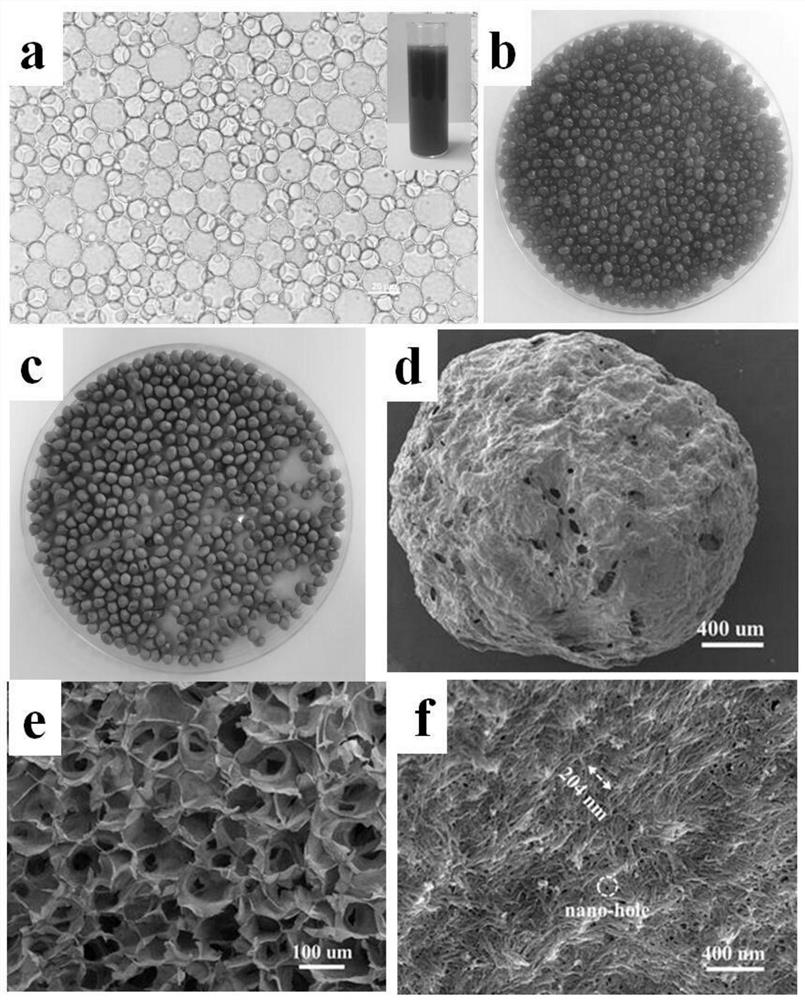

Water-based conductive paint and preparation method thereof

InactiveCN105969009AExcellent ElectricalSolve easy aggregationElectrically-conductive paintsWater basedAcrylic resin

The invention discloses a water-based conductive paint and a preparation method thereof. The water-based conductive paint is prepared from water-based acrylic resin, graphene oxide, acetylene carbon black, titanate, hydrazine hydrate, a thickening agent, a coupling agent, a dispersing agent, a defoaming agent and deionized water. The preparation method includes the steps that graphene oxide is modified with titanate and hydrazine hydrate and then mixed with the other components, high-speed stirring is carried out to prepare a disperse system, and the water-based conductive paint can be obtained. According to the water-based conductive paint and the preparation method thereof, the preparation technology is simple and convenient to implement, the production efficiency is high, and both the production process and the product can meet the requirement for environmental friendliness; the prepared conductive paint is good in compatibility and stability and high in conductive material content, and the resistance of a coating can be reduced to a large extent after film formation.

Owner:WUXI EPIC TECH

Rare earth aluminum-titanium-boron grain refiner and preparation method thereof

The invention discloses a rare earth aluminum-titanium-boron grain refiner and a preparation method thereof. The preparation method comprises the steps that raw materials are weighed, and the raw materials comprise aluminum ingots, potassium fluotitanate, potassium fluoborate, sodium chloride, potassium chloride, cryolite, rare earth oxide or rare earth fluoride and calcium metal; after the raw materials are heated to melt the aluminum ingots, mixed salt of the potassium fluotitanate and the potassium fluoborate is added for reaction; stirring is performed until a melt completely reacts, thenslagging-off is performed after heat preservation, and the sodium chloride, the potassium chloride, the cryolite, the rare earth oxide or rare earth fluoride and the calcium metal are added to react;stirring is performed until the melt completely reacts, then refining is performed, slagging-off is performed after heat preservation, and the rare earth aluminum-titanium-boron grain refiner is obtained after casting, wherein the rare earth aluminum-titanium-boron grain refiner is prepared from the following components in percentage by weight: 1.0% to 10.0% of titanium, 0.5% to 5.0% of boron, 0.1% to 5.0% of rare earth and the balance of aluminum. According to the rare earth aluminum-titanium-boron grain refiner and the preparation method thereof, energy consumption in the preparation processof a rare earth aluminum-titanium-boron alloy can be reduced, the cost is reduced, meanwhile, the sizes, shapes and distribution of TiAl3 and TiB2 particles in the refiner are improved, and the grainrefiner with higher refinement performance is obtained.

Owner:BAOTOU RES INST OF RARE EARTHS +1

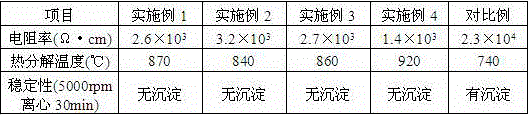

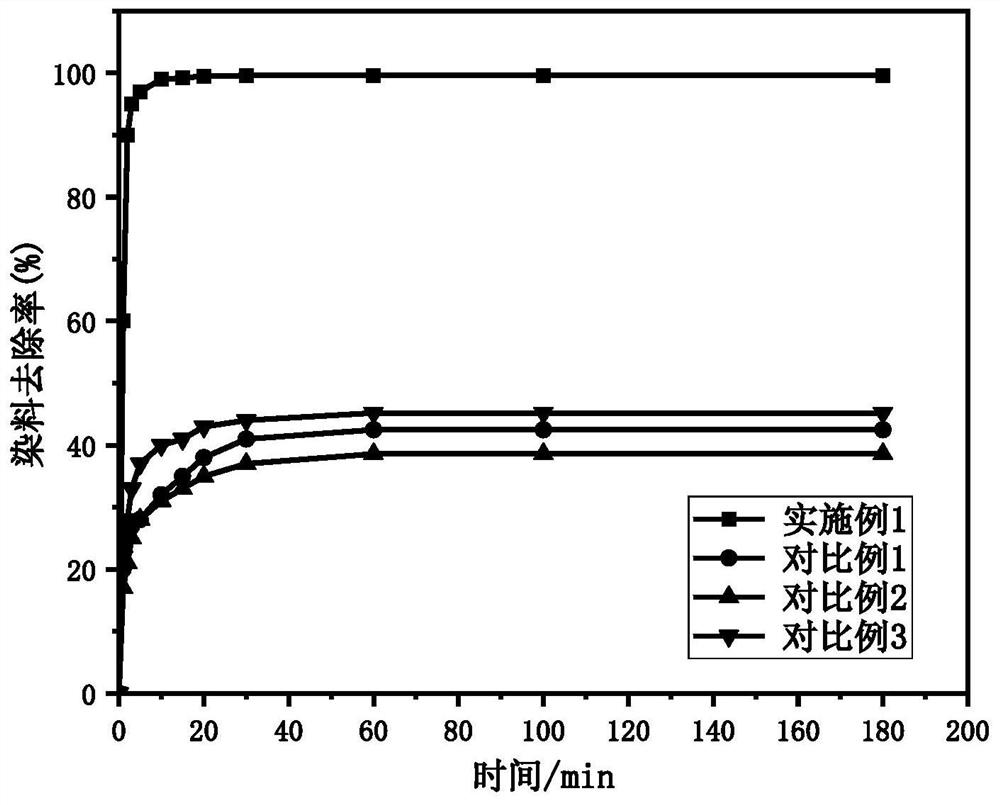

Biomass nanocellulose porous material loaded with nano transition metal oxide on surface, and preparation method thereof

ActiveCN113368838ASolve easy aggregationFully contactedOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic degradationCovalent Interaction

The invention relates to a biomass nanocellulose / nano transition metal oxide porous material, and a preparation method and application thereof. Nano transition metal oxide is loaded on the surface of biomass nanocellulose through non-covalent interaction. The biomass nano cellulose / nano transition metal oxide porous material has both adsorption and catalysis functions, and can be used as a recyclable adsorption and degradation material; when being used as an adsorption catalytic degradation material, the porous material has the advantages of high adsorption catalytic degradation efficiency, environment friendliness, excellent regeneration capacity, easiness in separation, recyclability and no repeated pollution, and has a considerable application prospect.

Owner:QINGDAO UNIV OF SCI & TECH

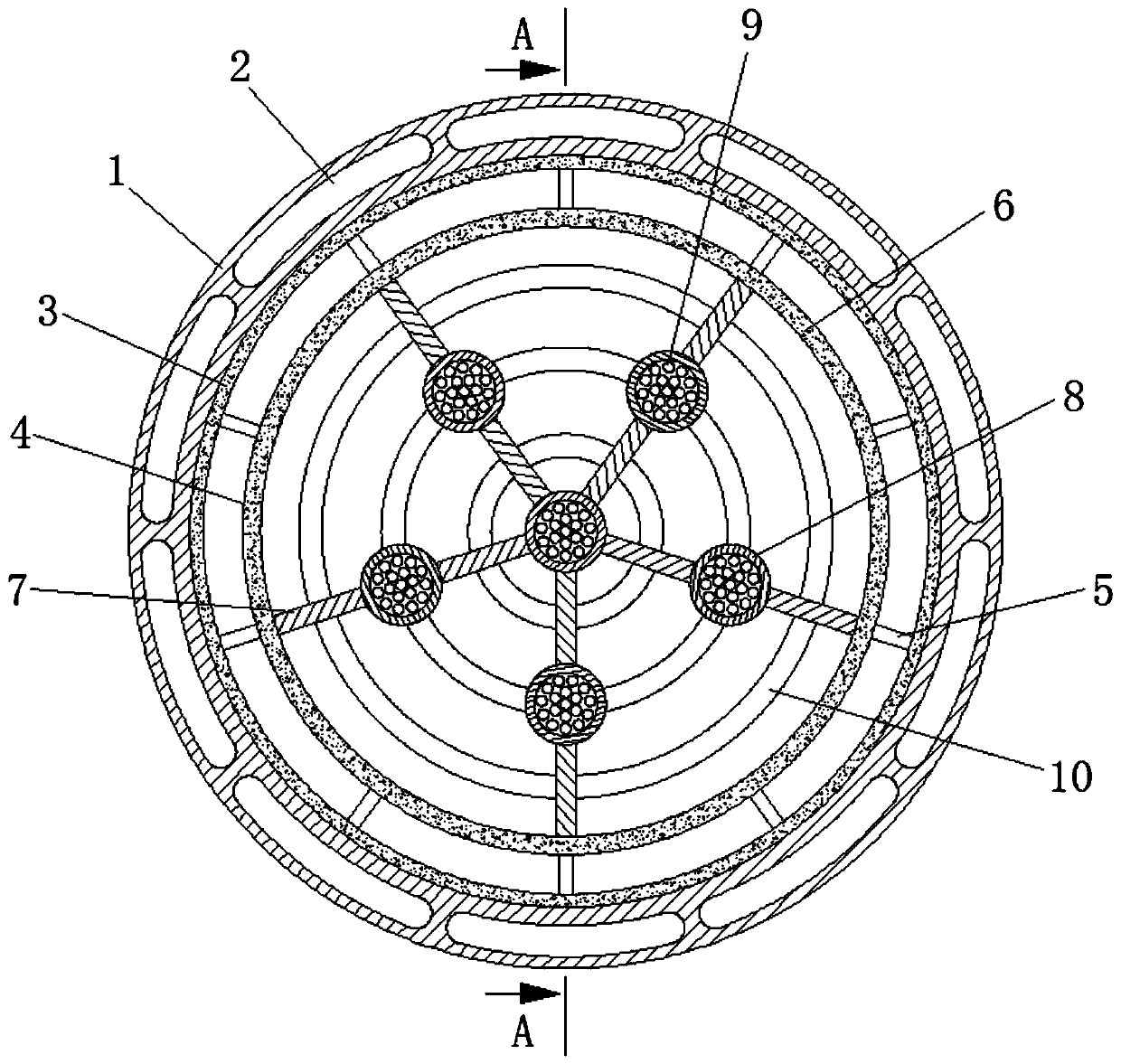

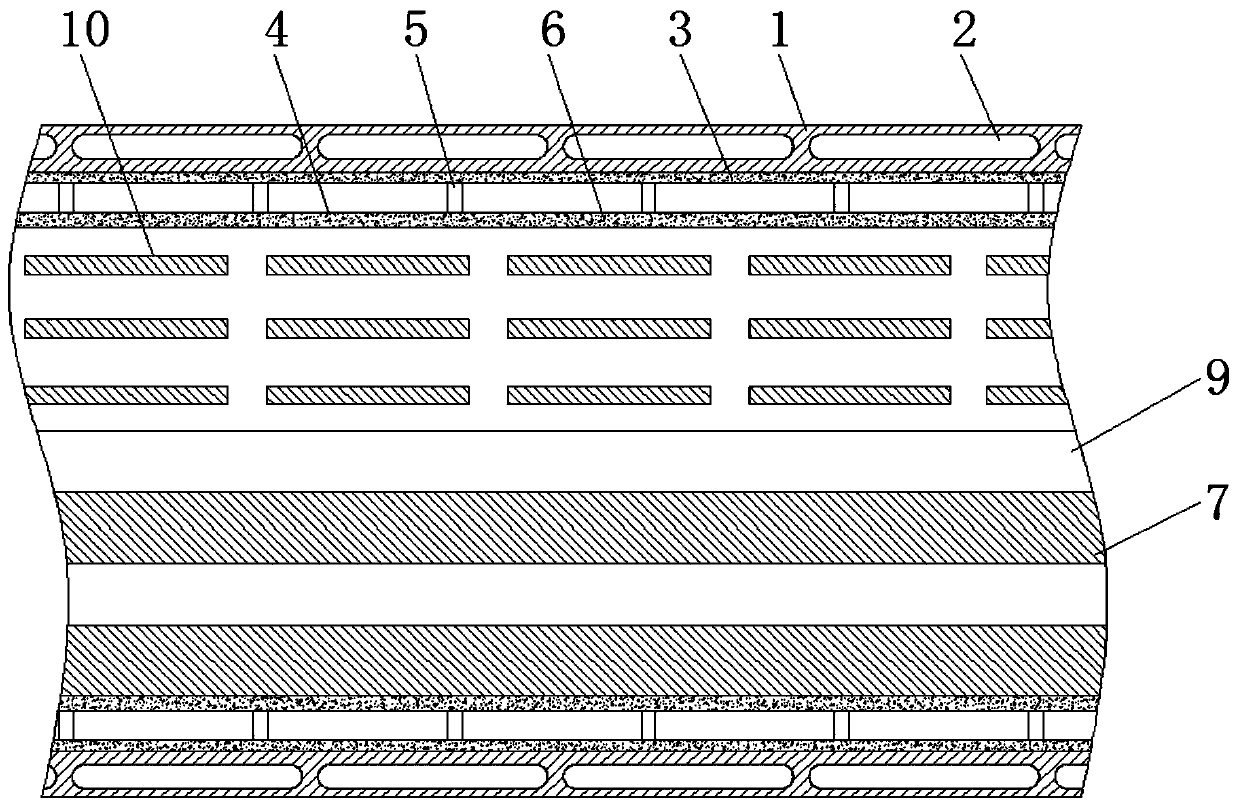

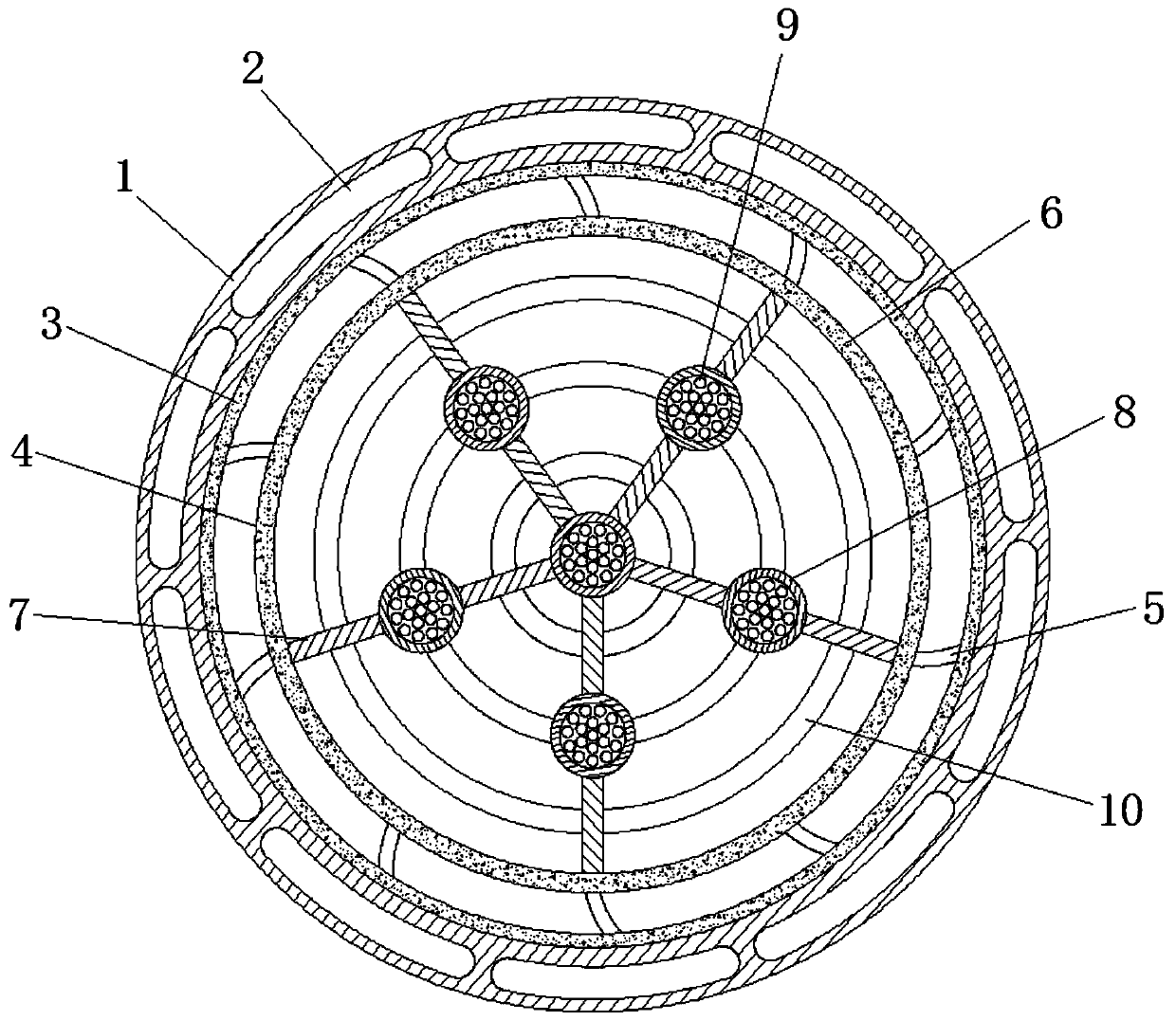

Anti-burn and anti-distortion cable based on flame-retardant inert gas

ActiveCN110942858AReduce feverEvenly dispersedFlexible cablesFlexible conductorsElectric cablesInert gas

The invention provides an anti-burn and anti-distortion cable based on flame-retardant inert gas, and relates to the technical field of cables. The invention discloses an anti-burn and anti-distortioncable based on flame-retardant inert gas. The device comprises an outer package, an inner cavity is formed in the outer package, a first fireproof coating is fixedly installed on the inner side of the outer package, an inner package is fixedly installed in the outer package, a connecting rod is fixedly connected between the inner package and the outer package, and a second fireproof coating is fixedly installed on the periphery of the inner package. The invention discloses an anti-burn and anti-distortion cable based on flame-retardant inert gas. Concentrated heating of internal wires is avoided, torsion generated by twisting can be buffered, the phenomenon that the wires are broken due to long-time excessive twisting is avoided, internal filling materials are saved, the flexibility of the cable is improved, the effect of fire on the cable is relieved, fusing of the internal wires is relieved, and time is bought for cutting off a cable power source.

Owner:QINGDAO CABLE

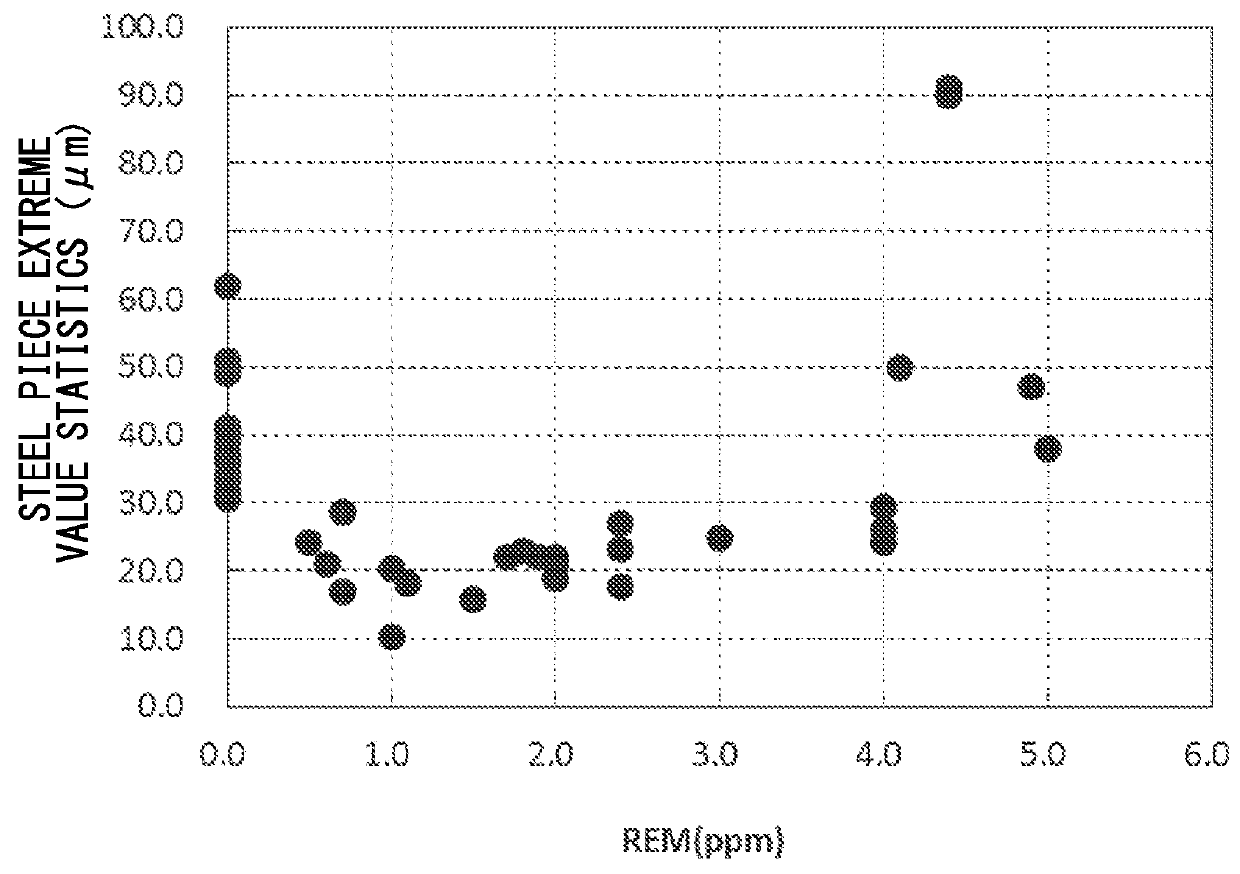

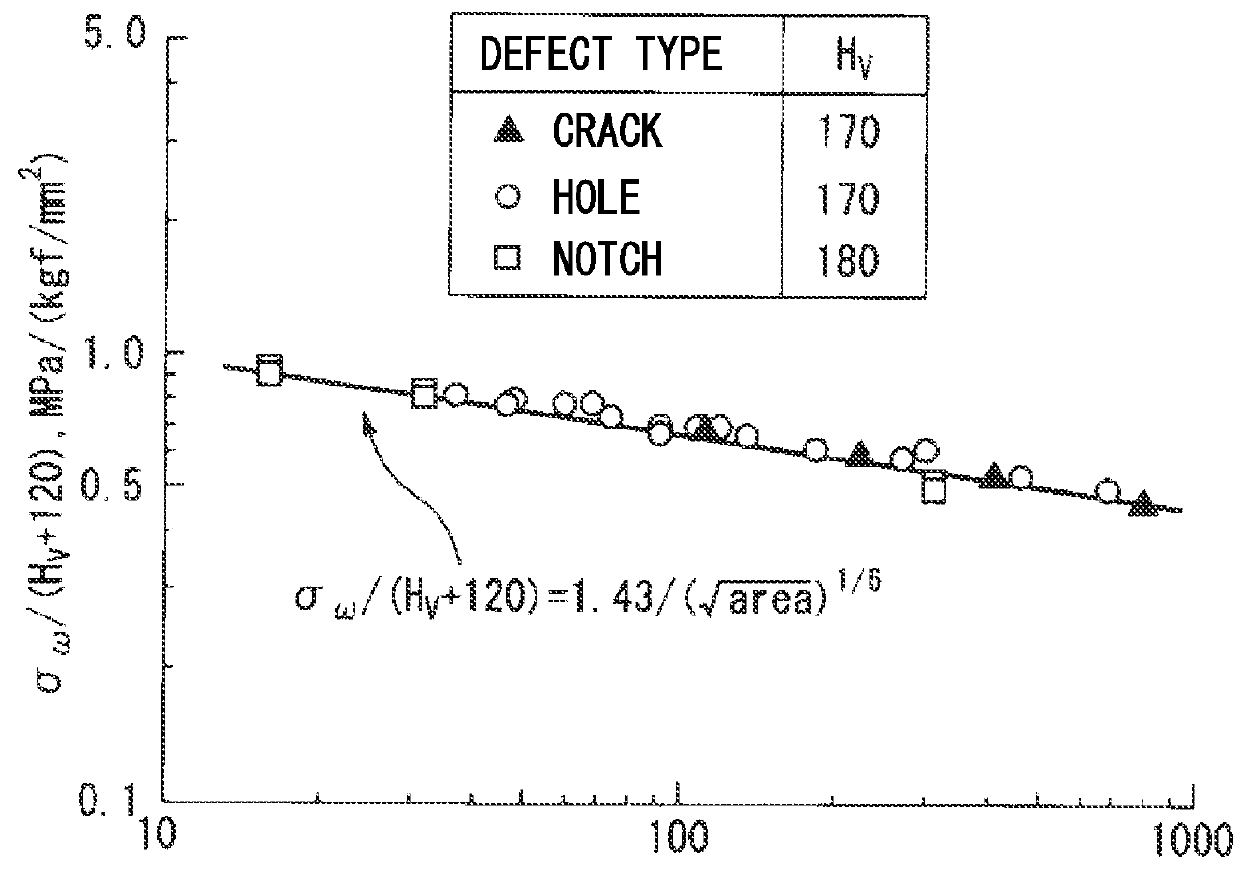

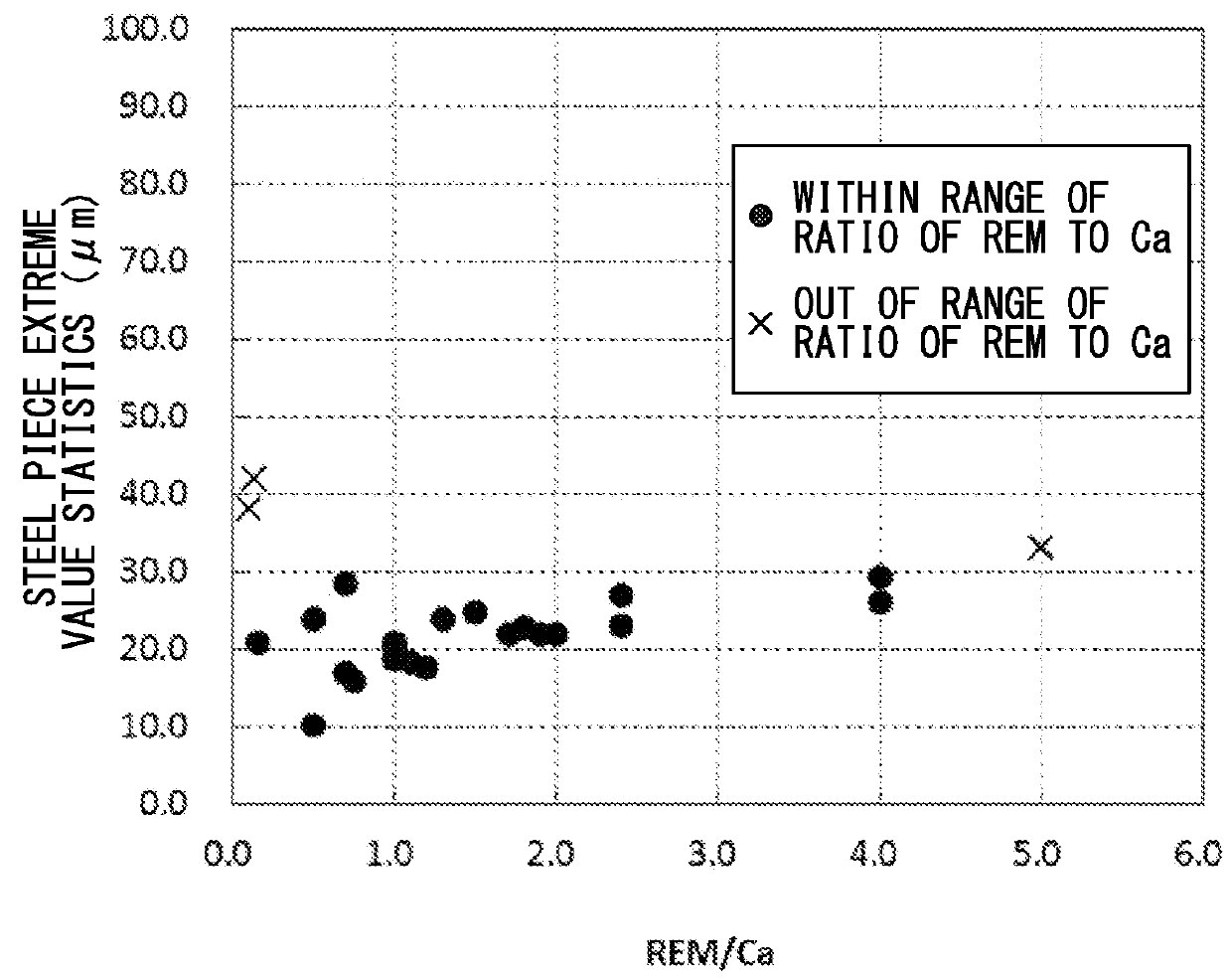

Low-oxygen clean steel and low-oxygen clean steel product

ActiveUS20160053352A1Improve fatigue performanceHigh melting pointRare-earth elementNon-metallic inclusions

Low-oxygen clean steel is provided containing C, Si, Mn, P, and S as chemical components, and further containing, by mass %, 0.005% to 0.20% of Al, greater than 0% to 0.0005% of Ca, 0.00005% to 0.0004% of REM, and greater than 0% to 0.003% of T.O, wherein the REM content, the Ca content, and the T.O content satisfy 0.15≦REM / Ca≦4.00 and Ca / T.O≦0.50, nonmetallic inclusions which have a maximum predicted diameter of 1 μm to 30 μm measured using an extreme value statistical method under the condition in which a prediction area is 30,000 mm2, and contain Al2O3 and REM oxide are dispersed in the steel, an average proportion of the Al2O3 in the nonmetallic inclusions is greater than 50%, the REM is one or two or more of rare-earth elements La, Ce, Pr, and Nd, and the steel is Al-deoxidized steel or Al—Si-deoxidized steel.

Owner:NIPPON STEEL CORP

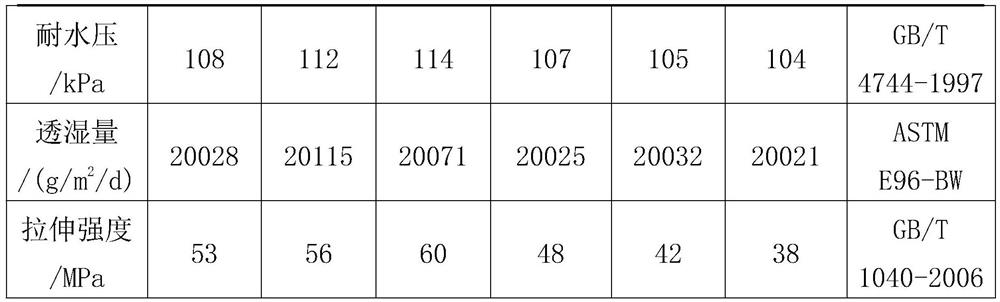

High-waterproof moisture-permeable film and preparation method thereof

PendingCN111778728AImprove performanceAchieve moisture permeabilityFibre typesHeating/cooling textile fabricsPolymer scienceSpinning

The invention relates to the technical field of high polymer materials, and provides a high-waterproof moisture-permeable film and a preparation method thereof. The high-waterproof moisture-permeablefilm is prepared from, by weight, 10-20 parts of hydrophilic modified polylactic acid, 5-8 parts of modified carbon nanotubes, 6-12 parts of polydimethylsiloxane, 0.8-1.5 parts of polyvinyl alcohol and 90-150 parts of an organic solvent. The biodegradable polymer polylactic acid is selected as the raw material, so that the problems that in the prior art, a waterproof breathable film is difficult to biodegrade and difficult to treat after being discarded are solved, and meanwhile, electrostatic spinning and other technical means are combined, so that the prepared film material has excellent waterproof and moisture permeable performance, and the mechanical property is also improved.

Owner:FUJIAN HENGAN HLDG CO LTD +2

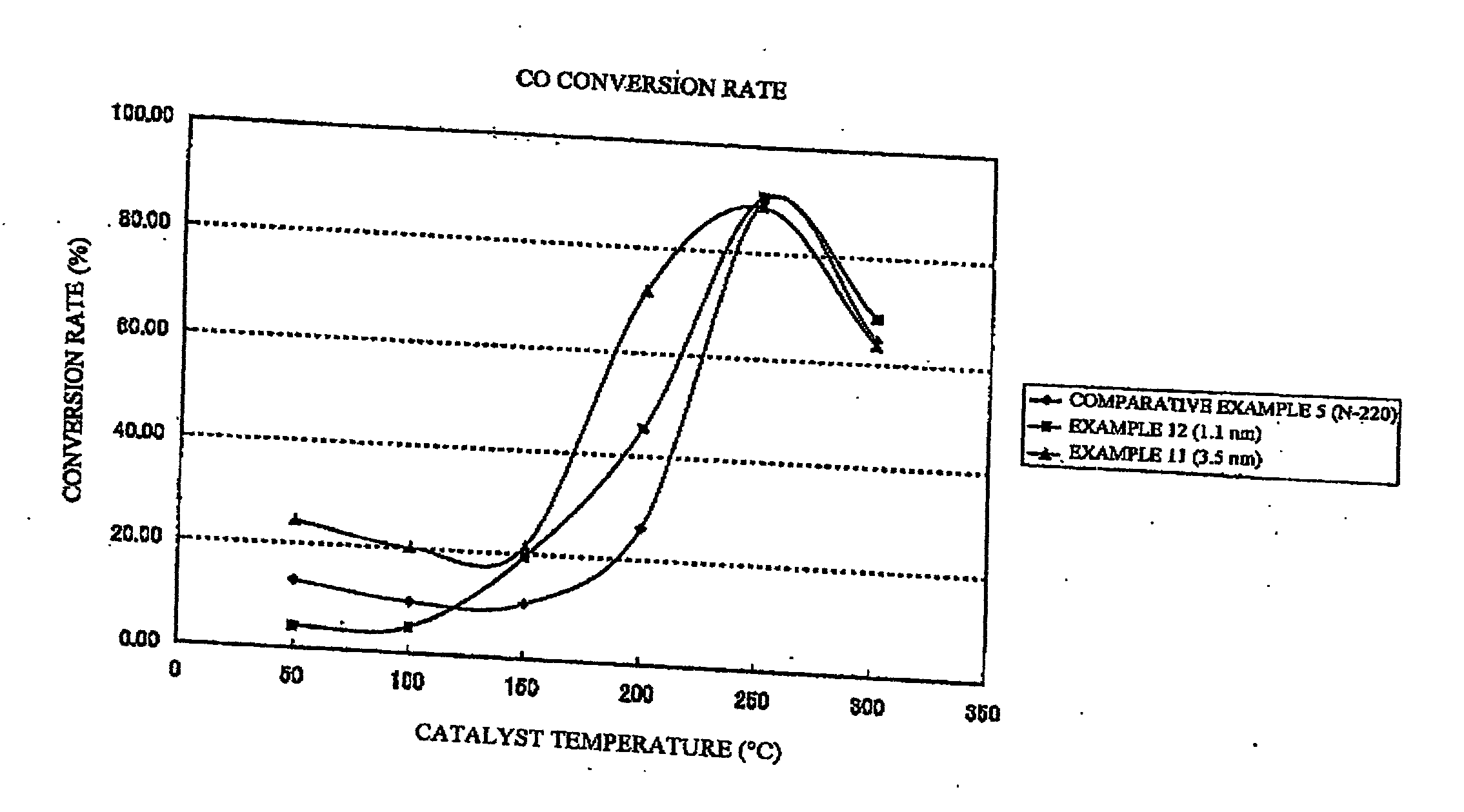

Method for preparing colloidal solution and carrier having colloidal particles fixed on surface thereof, fuel cell cathode, fuel cell anode and method for preparing the same and fuel cell using the same, and low temperature oxidation catalyst, method for preparing the same and fuel cell fuel modifying device using the same

InactiveUS20060144189A1Improve uniformityEasily and strongly fixedMachining electrodesMaterial nanotechnologyFuel cellsOxygen

A method for forming colloidal particles by boiling a solution containing a metal salt and a reducing agent; and a method for preparing a colloidal solution wherein the concentration of the metal salt in the solution is 1×10−4 mol / L or more and less than 4×10−4 mol / L; the equivalent concentration of the reducing agent is four times or more and 20 times or less the equivalent concentration of the metal salt; and the reaction time is 60 minutes or more and 300 minutes or less. A carrier wherein colloidal particles are fixed on the surface of a substrate by applying the colloidal solution prepared by the above-described method. Methods for manufacturing a fuel cell cathode, a fuel cell anode, and a low temperature oxidation catalyst wherein a colloidal solution prepared in the state wherein a solution containing a metal salt and a reducing agent is boiled to remove dissolved oxygen is applied to a substrate and colloidal particles are fixed on the substrate.

Owner:NIPPON SHEET GLASS CO LTD

Diamond abrasive recovery method

ActiveUS9868187B2High puritySolve easy aggregationSedimentation separationWater/sewage treatment by flocculation/precipitationInorganic saltsRecovery method

A diamond abrasive recovery method in which diamond abrasive is recovered from polishing material slurry including diamond abrasive used for polishing a polishing target mainly composed of silicon. The method comprises (1) recovering polishing material slurry including the used diamond abrasive; (2) adding inorganic salt including a metallic element which is to be a divalent or trivalent cation to the recovered polishing material slurry to aggregate the diamond abrasive and separating a supernatant liquid from a diamond abrasive included dispersion medium; and (3) extracting diamond abrasive from the separated diamond abrasive included dispersion medium using a low polarity dispersion medium.

Owner:KONICA MINOLTA INC

Rapid drying device for stainless steel machining process

InactiveCN113280606AImprove scalabilityEffective protectionDrying gas arrangementsDrying chambers/containersStructural engineeringAir knife

The invention discloses a rapid drying device for the stainless steel machining process. The rapid drying device comprises a box body, a feeding port and a discharging port are fixedly formed in the middles of the left side and the right side of the box body correspondingly, supporting plates are fixedly arranged at the upper ends and the lower ends of the feeding port and the discharging port correspondingly, and first carrier rollers are fixedly installed outside the supporting plates; and a visual window is fixedly arranged in the middle of the front end of the box body, second carrier rollers are movably installed in the middle of the interior of the box body, drying air knives are fixedly installed at the rear ends of the second carrier rollers, the drying air knives are fixedly connected to a forked air duct, and a heat exchanger is fixedly connected to the left end of the forked air duct. When the rapid drying device is used, a stainless steel band is firstly put into the box body from the feeding port, under the action of the first carrier rollers, the plate band is preliminarily positioned, a draught fan is started, the plate band is gradually and completely fed into the box body, the plate band sequentially penetrates through the four sets of second carrier rollers, the drying air knives blow air from the position above the plate band and the position below the plate band, and all-directional drying of the stainless steel band is effectively guaranteed.

Owner:江苏鑫泽不锈钢制品有限公司

Bi-component corrosion-prevention and coagulation-prevention modified epoxy zinc-rich coating

InactiveCN110305560ASolve easy aggregationImprove stabilityAnti-corrosive paintsEpoxy resin coatingsChemistryCardanol

The invention relates to the technical field of epoxy zinc-rich coating preparation and discloses bi-component corrosion-prevention and coagulation-prevention modified epoxy zinc-rich coating. In theformula, the bi-component corrosion-prevention and coagulation-prevention modified epoxy zinc-rich coating is prepared from experimental raw materials such as a curing agent and an anti-settling agent, and a modified mannich amide curing agent prepared from cardanol-phenol mixed modified ethanediamine is used. According to the bi-component corrosion-prevention and coagulation-prevention modified epoxy zinc-rich coating, a mixture of gel amorphous silica, the mannich amide curing agent and organic bentonite is used as the ternary mixed anti-settling agent, wherein the mannich amide curing agentserves as a carrier of zinc powder, the problem that the zinc powder is prone to coagulation in liquid coating is well solved, a mixture of propylene glycol monomethyl ether and dipropylene glycol methyl ether is used as a mixed co-solvent, the stability of the metal zinc powder in the liquid coating is improved, a mixture of elementary zinc and zinc hydroxide is used as the metal zinc powder, and the protecting principle of a metal zinc powder sacrificial anode is utilized to obtain excellent corrosion-prevention performance.

Owner:嘉兴瑛蔓贸易有限公司

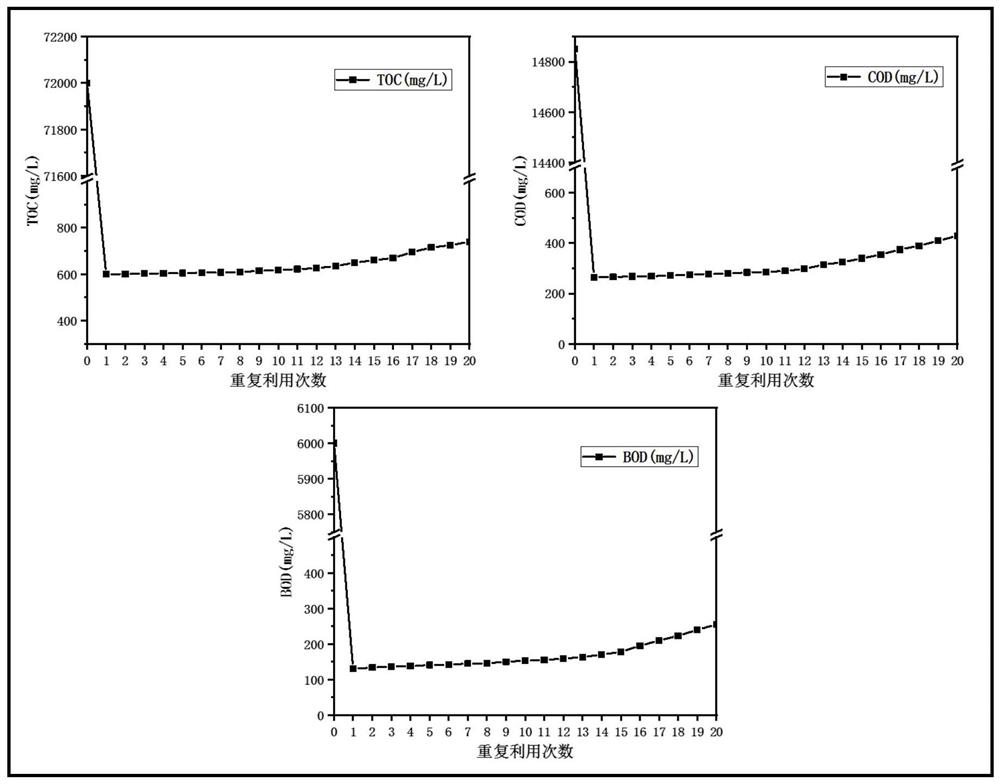

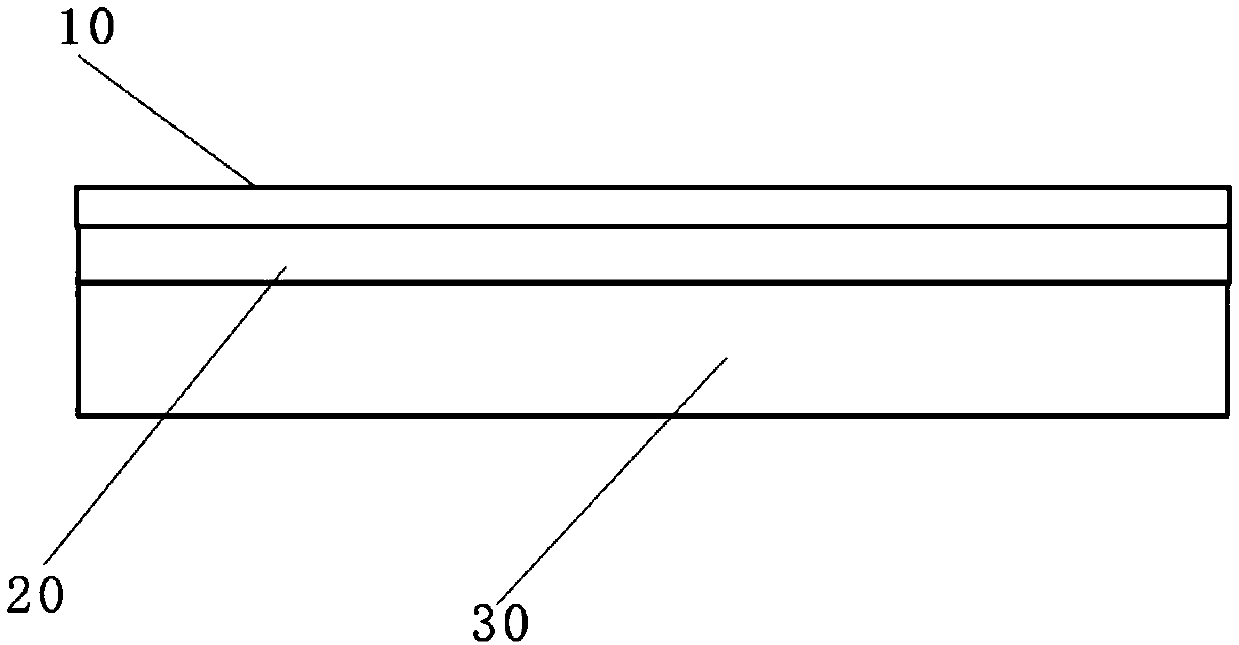

Reused nano-coating structure for sewage treatment and application method thereof

ActiveCN108676486AReduce utilizationImprove photocatalytic activityWater/sewage treatmentPolyurea/polyurethane coatingsPlasma electrolytic oxidationSulfur

The invention provides a reused nano-coating structure for sewage treatment and an application method thereof. The nano-coating structure is obtained through preparing sulfur-doped nano titanium dioxide, preparing a modified coating material by using the obtained sulfur-doped nano titanium dioxide, preparing an aluminum-alloy micro-arc-oxidated film, and coating the micro-arc-oxidated film with the obtained modified coating material. The reused nano-coating structure for sewage treatment, provided by the invention, has the advantages of high catalytic degradation efficiency, easiness in recovery and reuse and can be recycled repeatedly by a special application method.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

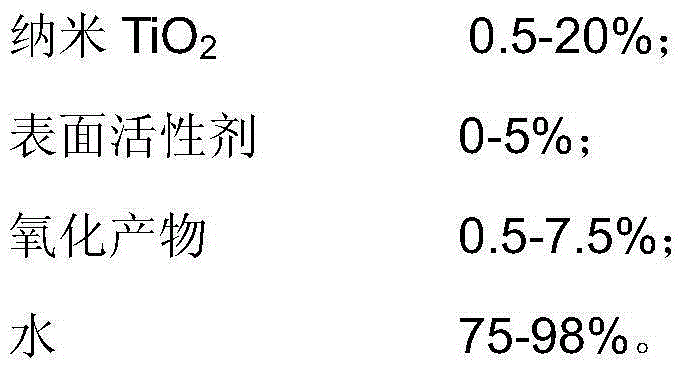

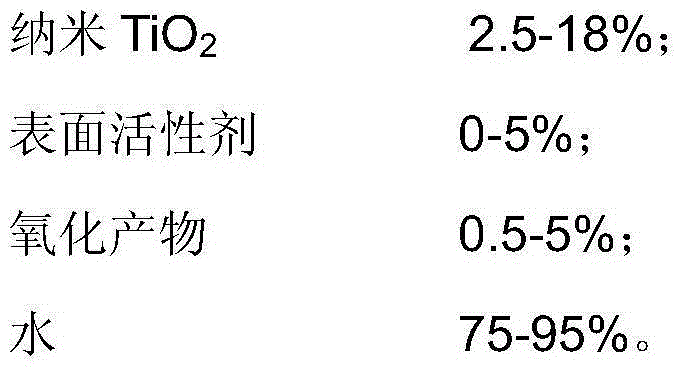

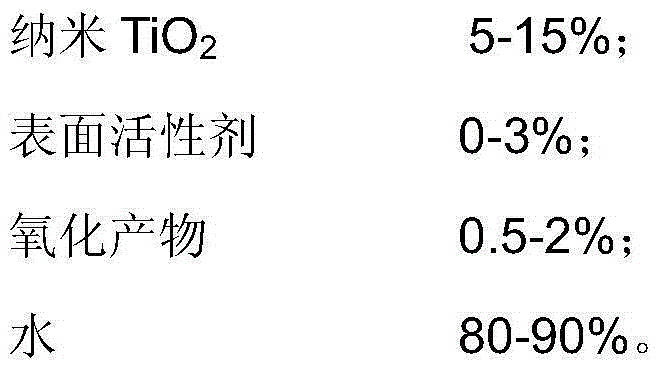

Preparation method of nano TiO2 photocatalyst particles

ActiveCN106277044ASolve easy aggregationOvercomes the disadvantage of functioning under UV light conditionsMaterial nanotechnologyPhysical/chemical process catalystsWater bathsUltraviolet lights

The invention provides a preparation method of nano TiO2 photocatalyst particles. The method comprises the following steps: (1) neutralizing precipitation process; (2) dispersion process; (3) oxidative transformation process; (4) curing process. The method not only solves the problem of easy aggregation of the nano TiO2 photocatalyst particles, enables the product particle sizes to be small, enables the average particle size to be less than 30nm and enables the product to be higher in concentration, but also has a good formaldehyde degradation function under the condition of visible light and overcomes the defect that the traditional photocatalyst works only under the condition of ultraviolet light, thus being wider in application scope. The preparation method does not need high-temperature calcination or water-bath heating, is low in requirements for equipment, simple in technological process and easy to operate and control; furthermore, the preparation method can use general industrial grade raw materials, thus being economical and reasonable in cost; therefore, the method has very high market competitiveness and is easy in realization of large-scale industrialization.

Owner:SHANGHAI REFRESH AIR TECH

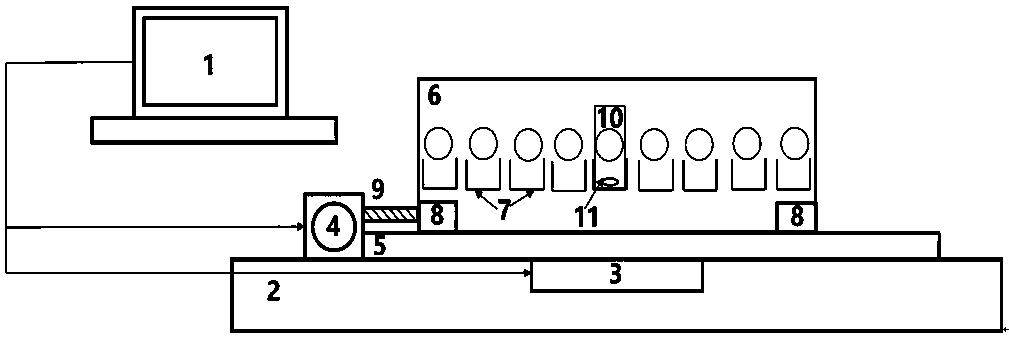

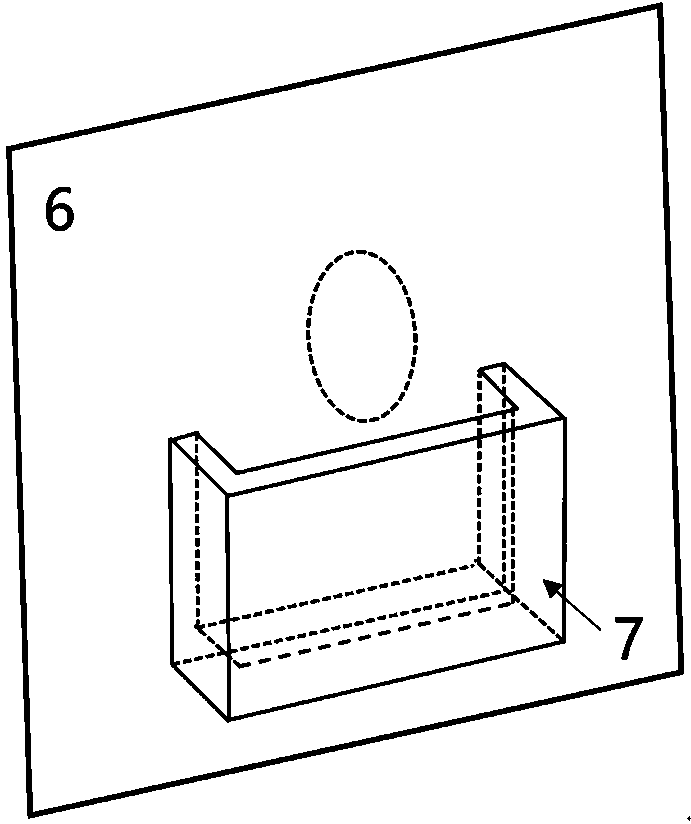

In-situ stirring and continuous sampling device of small-angle neutron scattering spectrometer

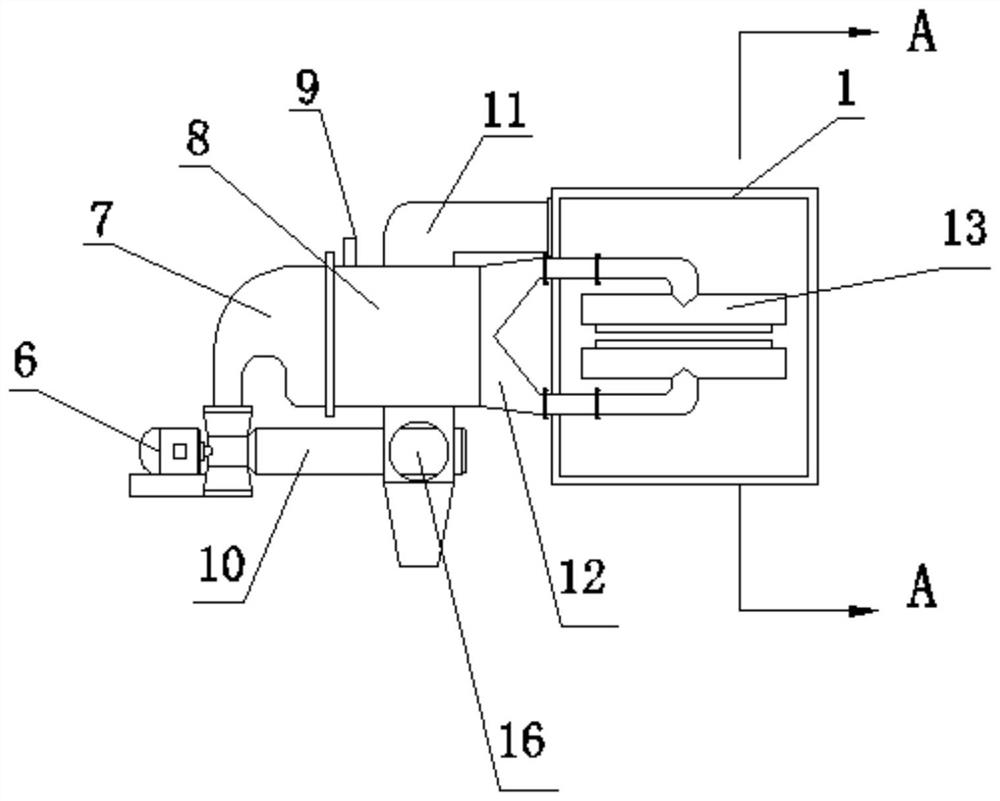

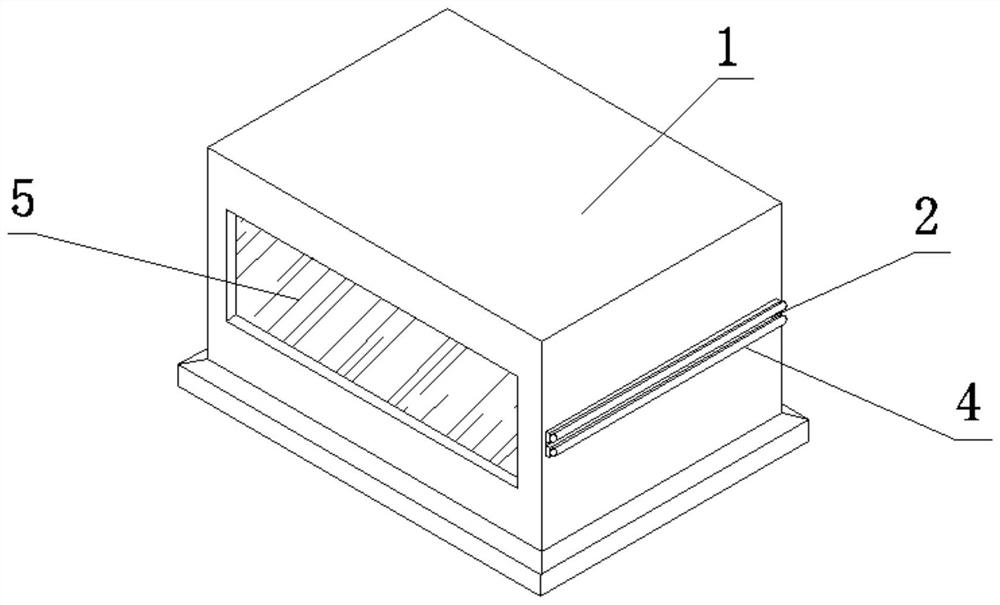

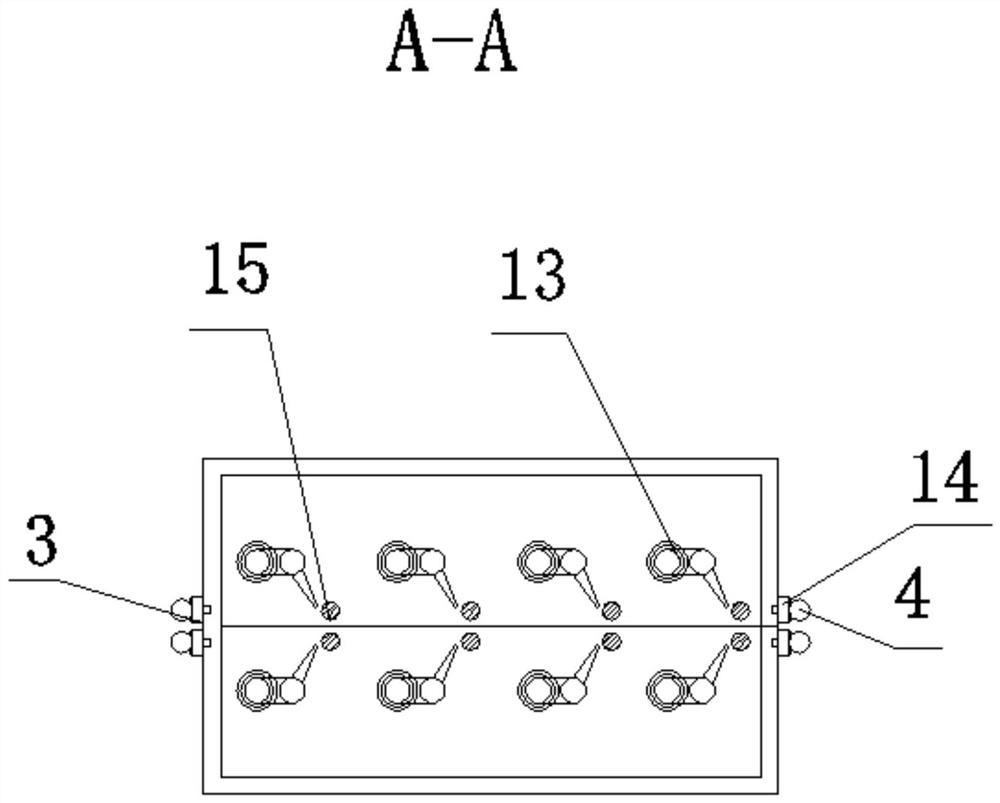

PendingCN110632106AEnsure safetySolve weak scattered signalMaterial analysis using wave/particle radiationCuvetteMagnetic stirrer

The invention discloses an in-situ stirring and continuous sampling device applicable to a small-angle neutron scattering spectrometer. In the device, a sample plate welded with a cuvette pool and with a neutron incident hole is driven to move in a timing and positioning way by a servo motor controlled by a computer so as to achieve the purpose of automatic and continuous sampling. A cuvette loaded with a sample and a magnetic stirrer is placed in the cuvette pool, a magnetic stirring device is controlled to drive the magnetic stirrer to continuously stir at different rotational speeds by thecomputer, so that continuous stirring of a sample is achieved as well as automatic and continuous sampling is achieved. With the in-situ stirring and continuous sampling device provided by the technical scheme of the invention,in-situ structure evolution test of colloid with small-angle neutron easy to coagulate and settle down and particle dispersion sample can be achieved; and moreover, the in-situ stirring and continuous sampling device has the advantages of settling prevention, displacement accuracy, automation, labor saving and the like, is simple to install and easy to disassemble and isapplicable to microstructure evaluation test of systems easy to coagulate such as the colloid and the particle dispersion system in small-angle neutron scattering research.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

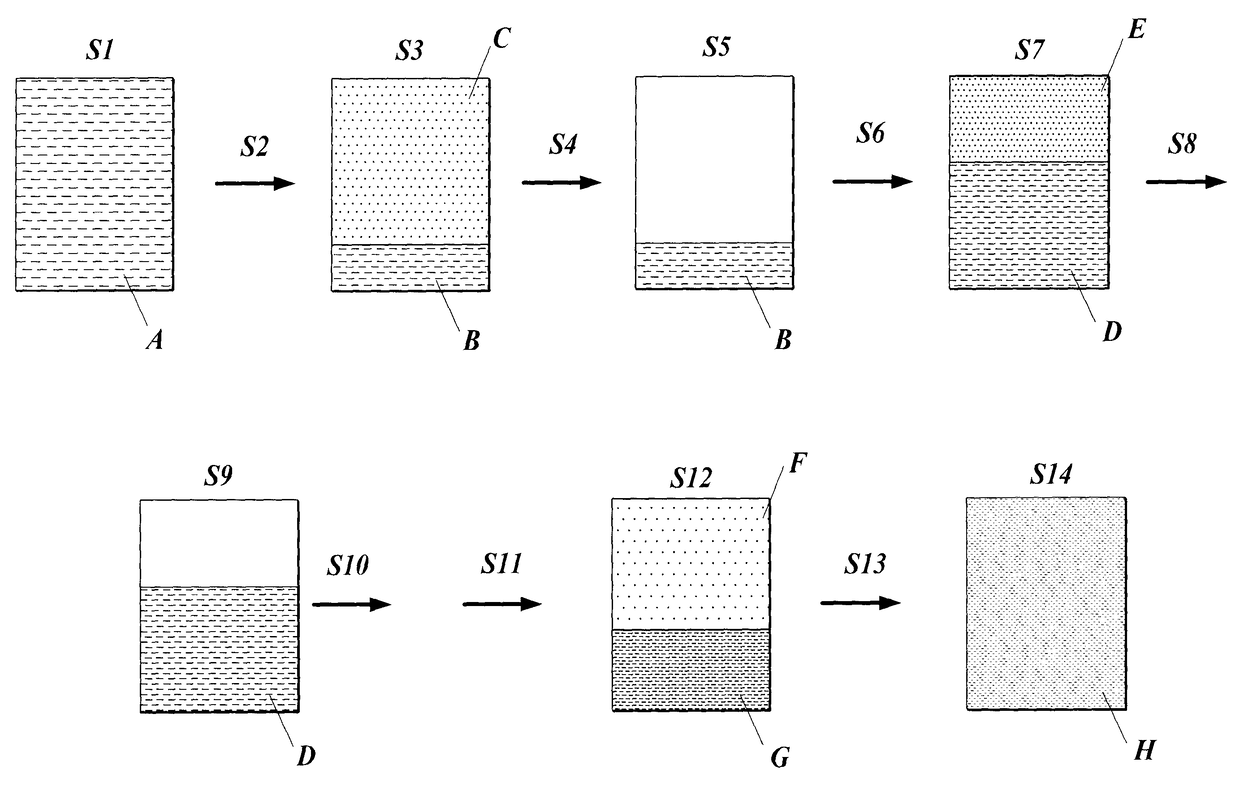

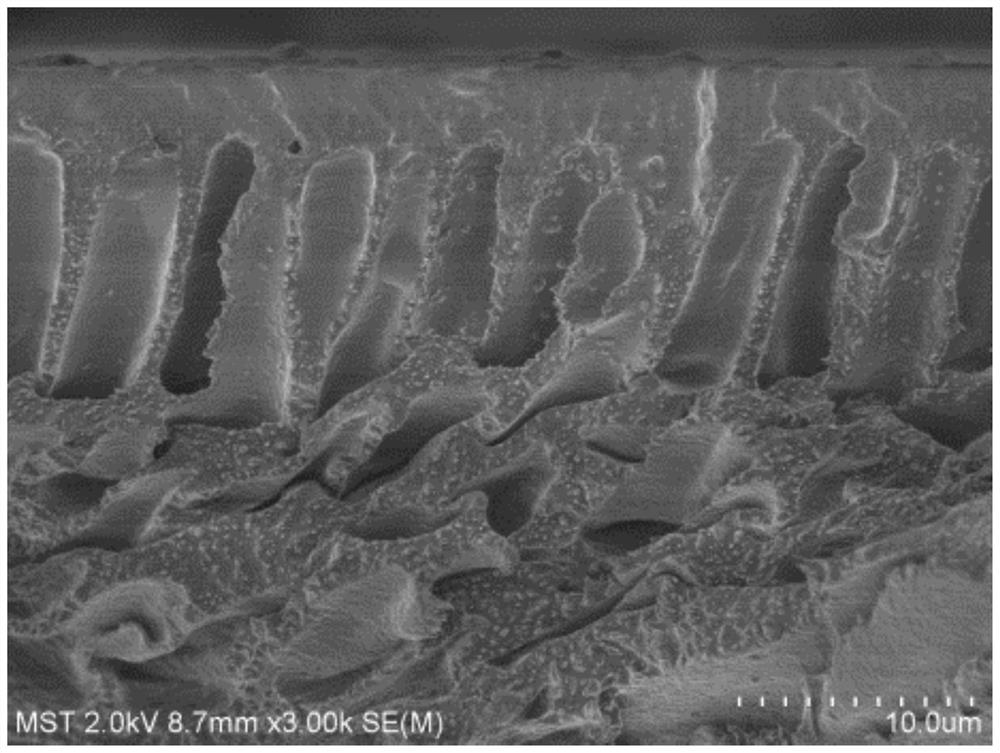

ZIF-8/PDMS mixed matrix pervaporation membrane as well as preparation method and application thereof

The invention discloses a ZIF-8 / PDMS mixed matrix pervaporation membrane as well as a preparation method and application thereof. The preparation method comprises the following steps of dissolving zinc nitrate hexahydrate and 2-methylimidazole in a solvent, uniformly mixing, and standing to obtain a ZIF-8 precursor solution, penetrating through a PVDF membrane through a suction filtration method to obtain a PVDF membrane I with preset ZIF-8 seed crystals, placing a zinc nitrate hexahydrate solution and a 2-methylimidazole solution on the two sides of the PVDF membrane with the preset ZIF-8 seed crystal respectively through a diffusion method for diffusion crystallization, then taking out the membrane, washing and drying, and acquiring a PVDF substrate membrane II with ZIF-8 crystals, mixing PDMS and a cross-linking agent to obtain a suspension liquid, then adding dibutyltin dilaurate into the suspension liquid, and stirring the mixture to be uniform to obtain a membrane coating liquid, and uniformly coating the PVDF substrate membrane II with the ZIF-8 crystals with the membrane coating liquid, cross-linking at normal temperature, and drying to obtain the PVDF / ZIF-8 composite membrane. The ZIF-8 is loaded on the surface and in pore channels of the PVDF membrane by using a preset seed crystal-pair diffusion growth method, and the PVDF membrane is coated with PDMS to prepare a sandwich structure, so that the problem that the ZIF-8 is easy to aggregate in the PDMS membrane is solved.

Owner:NANJING UNIV OF TECH

Preparation method of rare earth aluminum titanium boron grain refiner

The invention discloses a preparation method of a rare earth aluminum-titanium-boron grain refiner. The raw materials are weighed, and the raw materials include: aluminum ingots, potassium fluorotitanate, potassium fluoroborate, sodium chloride, potassium chloride, cryolite, and Rare earth oxides or rare earth fluorides and metal calcium; after the raw materials are heated and melted aluminum ingots, the mixed salt of potassium fluorotitanate and potassium fluoroborate is added to react; after stirring until the melt reaction is complete, keep warm and remove slag, add sodium chloride, chlorine Potassium chloride, cryolite, and rare earth oxides or rare earth fluorides and calcium metal are reacted; stirring until the melt is completely reacted, refining, slag removal after heat preservation, and casting to obtain rare earth aluminum titanium boron grain refiner; rare earth aluminum The titanium-boron grain refiner is calculated by weight percentage, including: 1.0-10.0% of titanium, 0.5-5.0% of boron, 0.1-5.0% of rare earth, and the balance is aluminum. The invention can reduce the energy consumption in the preparation process of the rare earth aluminum titanium boron alloy, reduce the cost, and improve the TiAl in the refiner at the same time 3 、TiB 2 The size, shape and distribution of particles can be used to obtain a grain refiner with higher refinement performance.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Liquid crystal device and projection-type display apparatus

In an element substrate of a liquid crystal device, in a peripheral region interposed between an image display region and a seal material, a peripheral electrode to which a potential is applied for trapping ionic impurities which is different from a common potential applied to a dummy pixel electrode or the like is formed. In the peripheral electrode, an electrode width of a first portion opposing a sealing material provided at a liquid crystal injection opening of the seal material is set to be greater than electrode widths of the other portions.

Owner:SEIKO EPSON CORP

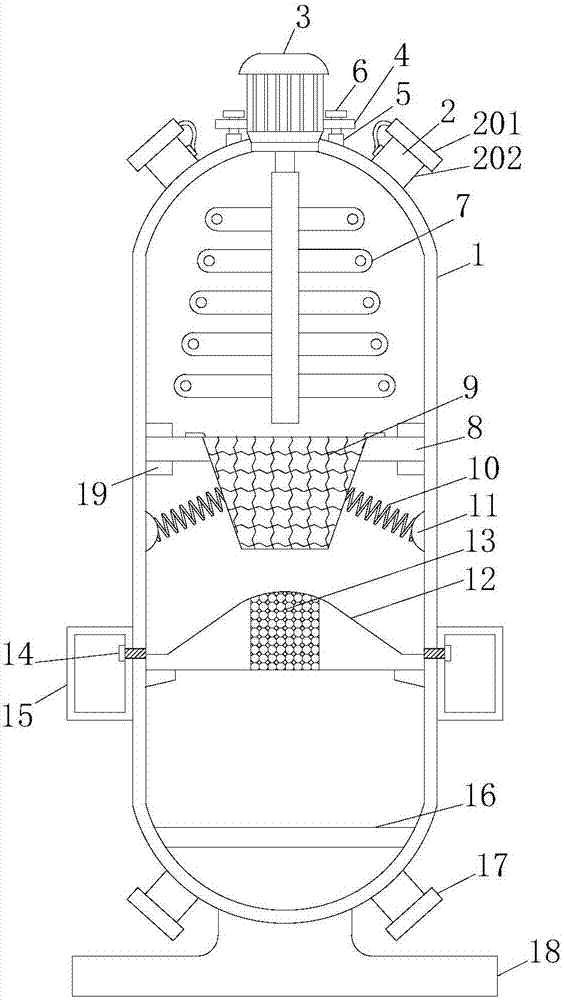

PP soaking tank with filtering function

InactiveCN107308832AWith filter functionSolve easy aggregationTransportation and packagingRotary stirring mixersEngineeringImpurity

The invention discloses a PP soaking tank with a filtering function. The PP soaking tank comprises a tank body, a feeding device is fixedly mounted on each of the two sides of the top of the tank body, a motor is mounted at the top of the tank body, a supporting plate is mounted on each of the left side and the right side of the motor, locking bolts are in threaded connection with the supporting plates, the bottoms of the locking bolts are in threaded connection into threaded sleeves, and the bottoms of the threaded sleeves are welded at the top of the tank body. The PP soaking tank disclosed by the invention has the beneficial effects that through arranging the motor, stirring shafts, a transverse plate, a soaking bag, springs, a flow division table, a filtering tank, piston sleeves, collecting boxes and a precipitation plate, chemical raw materials are poured into the tank body through feeding pipes; the chemical raw materials after being filtered for two times finally precipitate on the precipitation plate and are finally filtered through filtering holes in the precipitation plate, so that impurities in the chemical raw materials are filtered; and finally, the chemical raw materials are discharged through discharging pipes, so that the problem of easy impurity gathering of an existing PP soaking tank is solved.

Owner:黄石万鑫塑胶有限公司

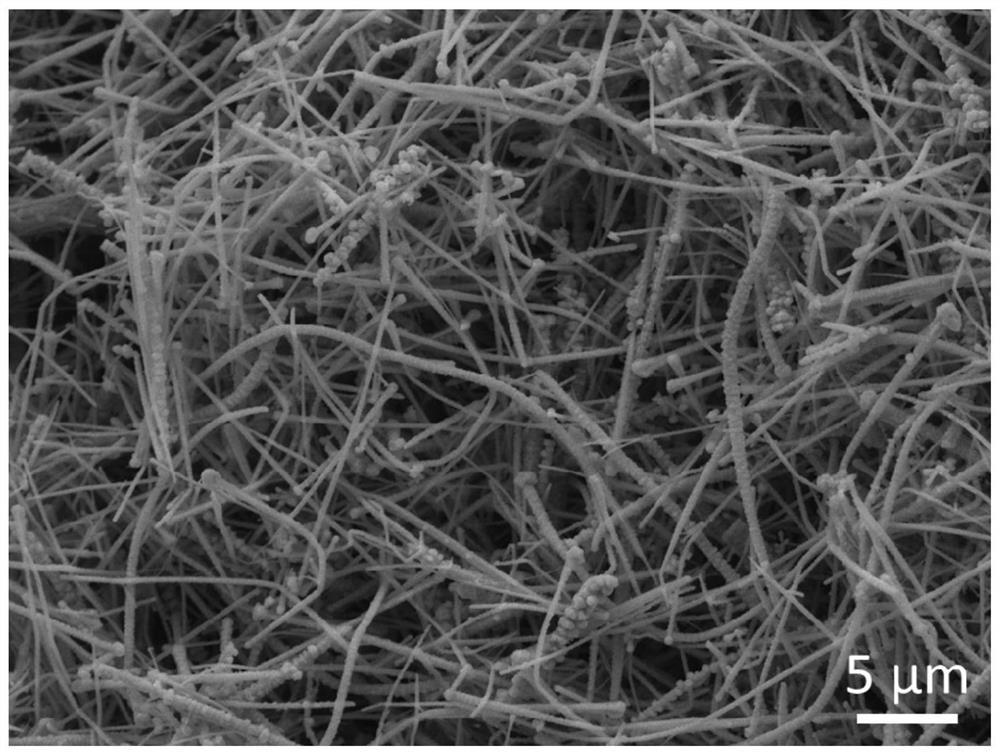

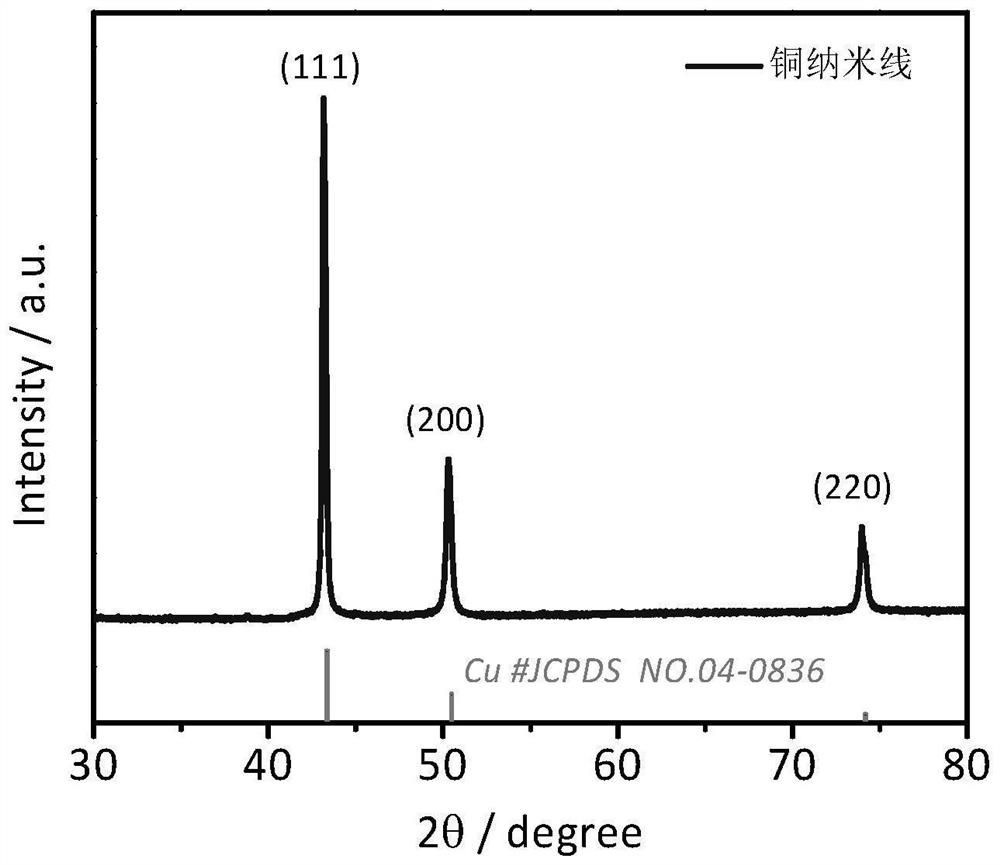

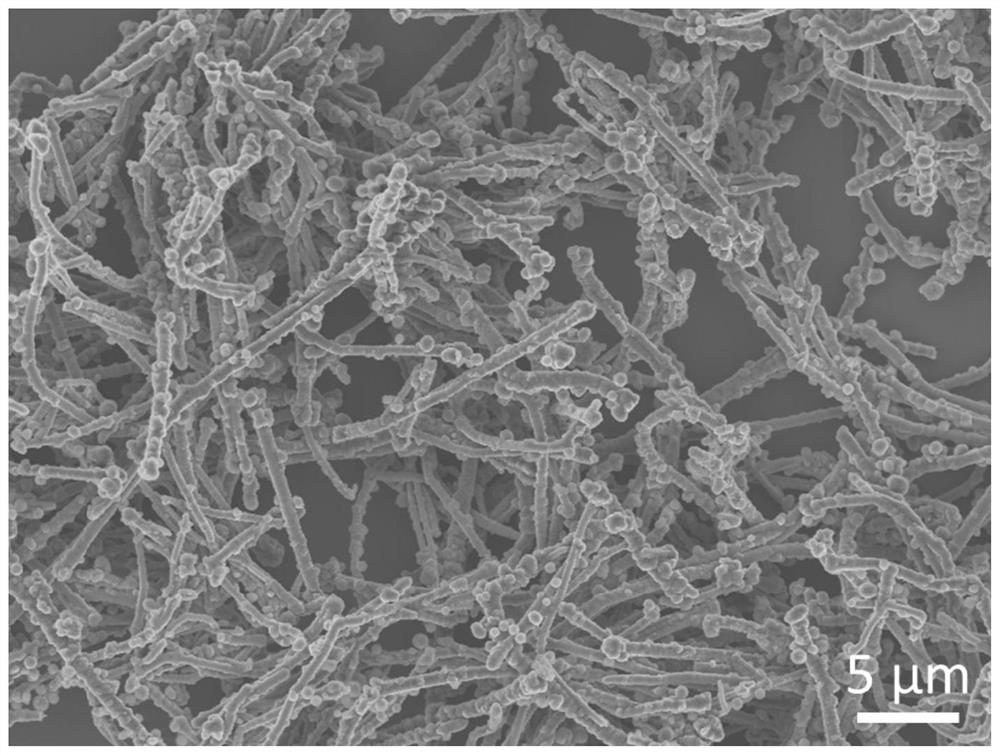

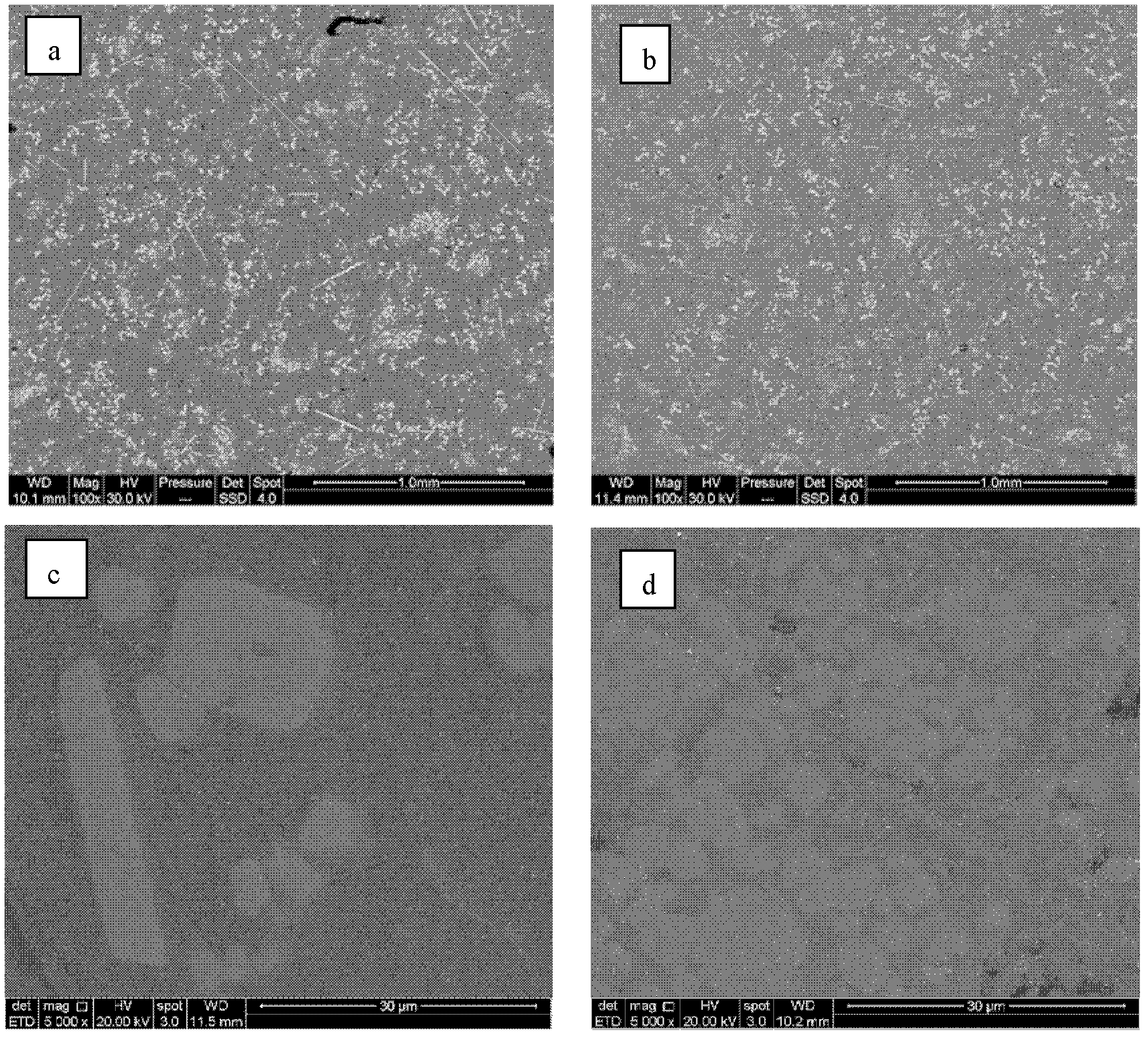

Copper phthalocyanine polymer (at) copper nanowire core-shell nanomaterial and preparation method and application thereof

ActiveCN114427104AGood dispersionSolve easy aggregationElectrolytic organic productionElectrodesPtru catalystPhthalocyanine

The invention belongs to a copper phthalocyanine polymer and copper nanowire core-shell nano material in the field of electrochemical carbon dioxide reduction of a nano material catalyst technology, and a preparation method and application thereof. According to the copper phthalocyanine polymer and copper nanowire core-shell nano material disclosed by the invention, a copper nanowire is used as a copper source and a carrier, and a core-shell structure with the copper nanowire as a core and the copper phthalocyanine polymer as a shell is formed. The preparation method comprises the following steps: firstly, synthesizing a copper nanowire through a hydrothermal method, then putting the copper nanowire into a microwave reactor, enabling copper on the surface of the copper nanowire to be coordinated with a cyano group, and forming a two-dimensional cross-linked network copper phthalocyanine polymer on the surface of the copper nanowire as a template, thereby forming the copper phthalocyanine polymer-copper nanowire core-shell nano material. The method can be applied to electrochemical CO2 reduction.

Owner:SHENZHEN INST OF ADVANCED TECH

Al-Ti-B-Er refiner and preparation method thereof

The invention discloses an Al-Ti-B-Er refiner and a preparation method thereof and belongs to the technical field of refiners. The Al-Ti-B-Er refiner comprises the following components in weight percentage: 3.0-10.0 percent of Ti, 0.6-2 percent of B, 0.1-0.3 percent of Er and the balance of Al, wherein the weight ratio of the Ti to the B is 5 / 1. The phase composition comprises alpha-Al, TiAl3, TiB2, Al3Er and AlErTi. The preparation method comprises the following steps of: weighing boron (B) powder, titanium (Ti) powder, aluminum (Al) powder, an Al-Er intermediate alloy and an aluminum ingot as required, wherein the weight ratio of the titanium (Ti) powder to the boron (B) powder is 5, the molar ratio of the aluminum (Al) powder to the titanium (Ti) powder is 2.5-3.0, and the purity of the aluminum ingot is 99.9 percent; evenly mixing the Ti, the Al with the B; putting in a mould; pressing into a block; heating to melt the aluminum ingot; covering by kryocide; pressing in the Al-Er intermediate alloy; standing; heating a melt; pressing in the block; performing stirring reaction; pressing in C2Cl6 for refining; drossing and pouring. According to the Al-Ti-B-Er refiner disclosed by the invention, the problem that the TiB2 can be easily gathered is solved, and the refining efficiency is increased.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com