High-waterproof moisture-permeable film and preparation method thereof

A waterproof and moisture-permeable membrane, hydrophilic modification technology, applied in the manufacture of rayon, single-component polyester rayon, fiber processing and other directions, can solve the problems of difficult to handle, difficult to biodegrade the waterproof and breathable membrane, to increase the Hydrophilic, good performance, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

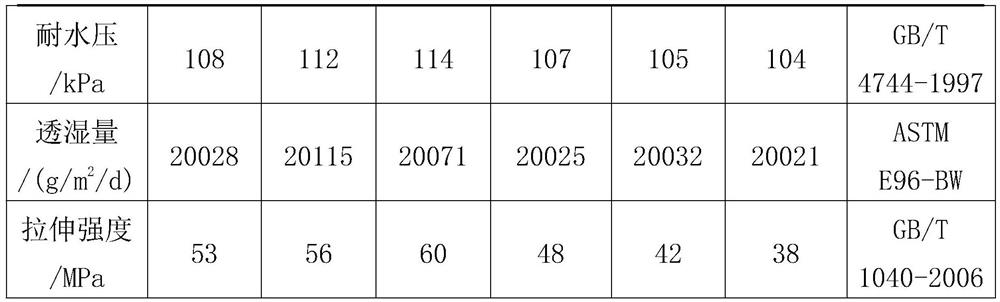

Embodiment 1

[0032] A highly waterproof and moisture-permeable membrane, consisting of the following raw materials in parts by weight: 10 parts of hydrophilic modified polylactic acid, 5 parts of modified carbon nanotubes, 6 parts of polydimethylsiloxane, 0.8 parts of polyvinyl alcohol, organic 90 parts of solvent, the organic solvent is a mixed solvent composed of tetrahydrofuran, ethanol, and petroleum ether, and the mass ratio is 3:2:5.

[0033] The hydrophilic modified polylactic acid is made of polylactic acid and 4-amino-1-butanol, and the specific preparation steps are: dissolving polylactic acid in an ethanol solution, the mass fraction of polylactic acid in the solution is 10%, and then 4-amino-1-butanol was added dropwise, reacted at 60°C for 4h, cooled and placed at -20°C for 12h, suction filtered and freeze-dried to obtain hydrophilic modified polylactic acid. The weight-average molecular weight of the polylactic acid is 1×10 4 , the mass ratio of polylactic acid to 4-amino-1-...

Embodiment 2

[0043] A highly waterproof and moisture-permeable membrane, which is composed of the following raw materials in parts by weight: 15 parts of hydrophilic modified polylactic acid, 6 parts of modified carbon nanotubes, 9 parts of polydimethylsiloxane, 1.2 parts of polyvinyl alcohol, organic 120 parts of solvent, the organic solvent is a mixed solvent composed of tetrahydrofuran, ethanol, and petroleum ether, and the mass ratio is 3:2:5.

[0044] The hydrophilic modified polylactic acid is made of polylactic acid and 4-amino-1-butanol, and the specific preparation steps are: dissolving polylactic acid in an ethanol solution, the mass fraction of polylactic acid in the solution is 10%, and then 4-amino-1-butanol was added dropwise, reacted at 60°C for 6h, cooled and placed at -20°C for 12h, suction filtered and freeze-dried to obtain hydrophilic modified polylactic acid. The weight average molecular weight of described polylactic acid is 5 * 10 4 , the mass ratio of polylactic ac...

Embodiment 3

[0054] A highly waterproof and moisture-permeable membrane, consisting of the following raw materials in parts by weight: 20 parts of hydrophilic modified polylactic acid, 8 parts of modified carbon nanotubes, 12 parts of polydimethylsiloxane, 1.5 parts of polyvinyl alcohol, organic 150 parts of solvent, the organic solvent is a mixed solvent composed of tetrahydrofuran, ethanol, and petroleum ether, and the mass ratio is 3:2:5.

[0055] The hydrophilic modified polylactic acid is made of polylactic acid and 4-amino-1-butanol, and the specific preparation steps are: dissolving polylactic acid in an ethanol solution, the mass fraction of polylactic acid in the solution is 10%, and then 4-amino-1-butanol was added dropwise, reacted at 60°C for 8h, cooled and placed at -20°C for 12h, suction filtered and freeze-dried to obtain hydrophilic modified polylactic acid. The weight-average molecular weight of the polylactic acid is 1×10 5 , the mass ratio of polylactic acid to 4-amino-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com