Gold/titanium dioxide nano-compound and preparation method and application thereof

A nanocomposite, titanium dioxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy aggregation of gold nanoparticles and many active sites , to achieve the effect of simple preparation process, many active sites, and good peroxidase catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

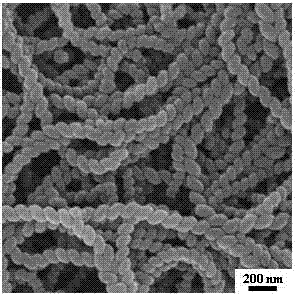

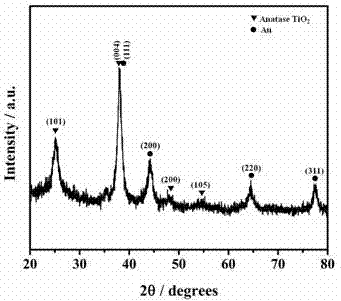

[0036] Prepare gold / titanium dioxide nanocomposite, the steps are as follows:

[0037] 1. Preparation of Helical Carbon Fibers

[0038]Take 1.41 g of potassium sodium tartrate tetrahydrate (i.e. potassium sodium tartrate tetrahydrate) in a 50 mL volumetric flask, add water to prepare a 0.1M potassium sodium tartrate solution for later use. Take 0.85 g of copper chloride dihydrate in a 50 mL volumetric flask, add water to prepare a 0.1M copper chloride solution. All the 50 mL potassium sodium tartrate solution prepared above was transferred to a 500 mL beaker, and under the condition of vigorous stirring, the 50 mL cupric chloride solution prepared above was slowly added dropwise to the potassium sodium tartrate solution, and allowed to stand for 5 After 1 min, it was vacuum filtered to obtain a light blue copper tartrate filter cake. After washing the filter cake with absolute ethanol three times, it was transferred to a 110°C oven for drying for 1h, and then transferred to a...

Embodiment 2

[0047] Prepare gold / titanium dioxide nanocomposite, the steps are as follows:

[0048] 1. Preparation of Helical Carbon Fibers

[0049] With embodiment 1;

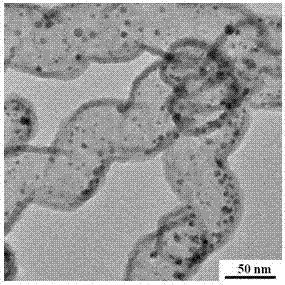

[0050] 2. Preparation of Gold / Carbon Helical Fiber Composite

[0051] Take 5 g of spiral carbon fiber, dissolve it in a beaker filled with 50 mL of absolute ethanol, ultrasonicate for 13 min, and then drop the mixture evenly on the glass slide with a rubber dropper. After natural drying, put the glass slide into the In the HITACHI E-1010 ion sputtering instrument, gold was used as the target material, the control current was 10 mA, and the gold nanoparticles were sputtered for 80 s to obtain the gold-coated carbon helical fiber composite (that is, the gold / carbon helical fiber composite ), the powder on the glass sheet is scraped off, which is the gold / carbon helical fiber composite;

[0052] 3. Preparation of TiO / Au / Carbon Helical Fiber Composite

[0053] Take 5 g of gold / carbon helical fiber composite, dissolve it in...

Embodiment 3

[0057] Prepare gold / titanium dioxide nanocomposite, the steps are as follows:

[0058] 1. Preparation of Helical Carbon Fibers

[0059] With embodiment 1;

[0060] 2. Preparation of Gold / Carbon Helical Fiber Composite

[0061] Take 5 g of spiral carbon fiber, dissolve it in a beaker filled with 50 mL of absolute ethanol, ultrasonicate for 10 min, and then drop the mixture evenly on the glass slide with a rubber dropper. After natural drying, put the glass slide into the In the HITACHI E-1010 ion sputtering instrument, gold was used as the target material, the control current was 10 mA, and the gold nanoparticles were sputtered for 120 s to obtain the gold-coated carbon helical fiber composite (that is, the gold / carbon helical fiber composite ), the powder on the glass sheet is scraped off, which is the gold / carbon helical fiber composite;

[0062] 3. Preparation of TiO / Au / Carbon Helical Fiber Composite

[0063] Take 5 g of the gold / carbon helical fiber composite, dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com