Reused nano-coating structure for sewage treatment and application method thereof

A nano-coating technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low catalytic efficiency, easy to coagulate, difficult to recycle and reuse, and to increase the surface area. , the effect of increasing the amount of holes and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

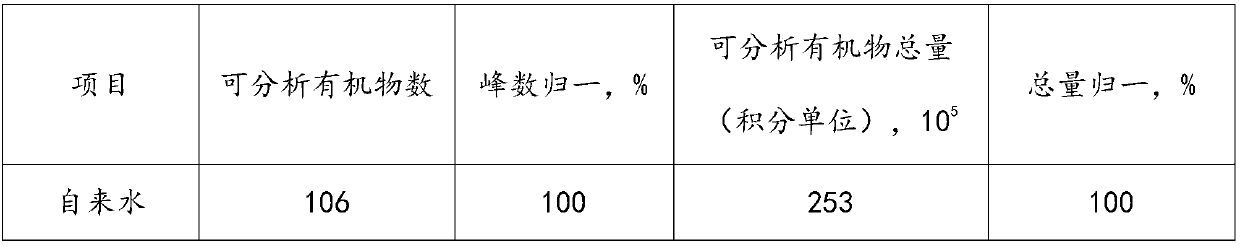

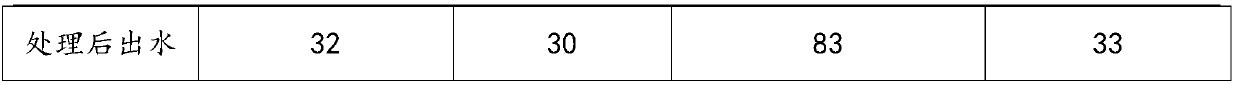

Examples

Embodiment 1

[0057] Step 1, preparation of sulfur-doped nano-titanium dioxide

[0058] ① Add 10 parts of hydroxycellulose to 35 parts of absolute ethanol, continue to stir at a rate of 1000 rpm, and slowly add 8 parts of butyl titanate under stirring, and then add 14 parts of thiourea to obtain a mixed solution A ;

[0059] ② Dissolve hydrochloric acid in deionized water to obtain 35 parts of hydrochloric acid solution with a concentration of 20%, and add 30 parts of absolute ethanol to the hydrochloric acid solution while stirring at a speed of 150 rpm to obtain mixed solution B;

[0060] ③Under stirring at a rate of 150 rpm, slowly add the mixed solution B into the mixed solution A to obtain a transparent sol, age the transparent sol to obtain a gel, and dry the gel;

[0061] ④ Calcining the dried gel at a heating rate of 10°C / min for 2 hours, cooling and grinding to obtain the sulfur-doped nano-titanium dioxide;

[0062] Step 2, preparation of sulfur-doped nano-titanium dioxide modifi...

Embodiment 2

[0078] Step 1, preparation of sulfur-doped nano-titanium dioxide

[0079] ① Add 12 parts of hydroxycellulose to 32 parts of absolute ethanol, continue to stir at a rate of 1000 rpm, and slowly add 10 parts of butyl titanate under stirring, and then add 15 parts of thiourea to obtain a mixed solution A ;

[0080] ② Dissolve hydrochloric acid in deionized water to obtain 40 parts of hydrochloric acid solution with a concentration of 25%, and add 25 parts of absolute ethanol to the hydrochloric acid solution while stirring at a speed of 150 rpm to obtain mixed solution B;

[0081] ③Under stirring at a rate of 150 rpm, slowly add the mixed solution B into the mixed solution A to obtain a transparent sol, age the transparent sol to obtain a gel, and dry the gel;

[0082] ④ Calcining the dried gel at a heating rate of 10°C / min for 2 hours, cooling and grinding to obtain the sulfur-doped nano-titanium dioxide;

[0083] Step 2, preparation of sulfur-doped nano-titanium dioxide modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com