Copper phthalocyanine polymer (at) copper nanowire core-shell nanomaterial and preparation method and application thereof

A core-shell nanomaterial and copper nanowire technology, applied in the field of nanomaterials, can solve the problems of reducing the specific surface area of the catalyst and the electron transport capacity, reducing the catalytic performance, poor conductivity, etc., to enhance the charge transport capacity, improve the conductivity, improve the The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

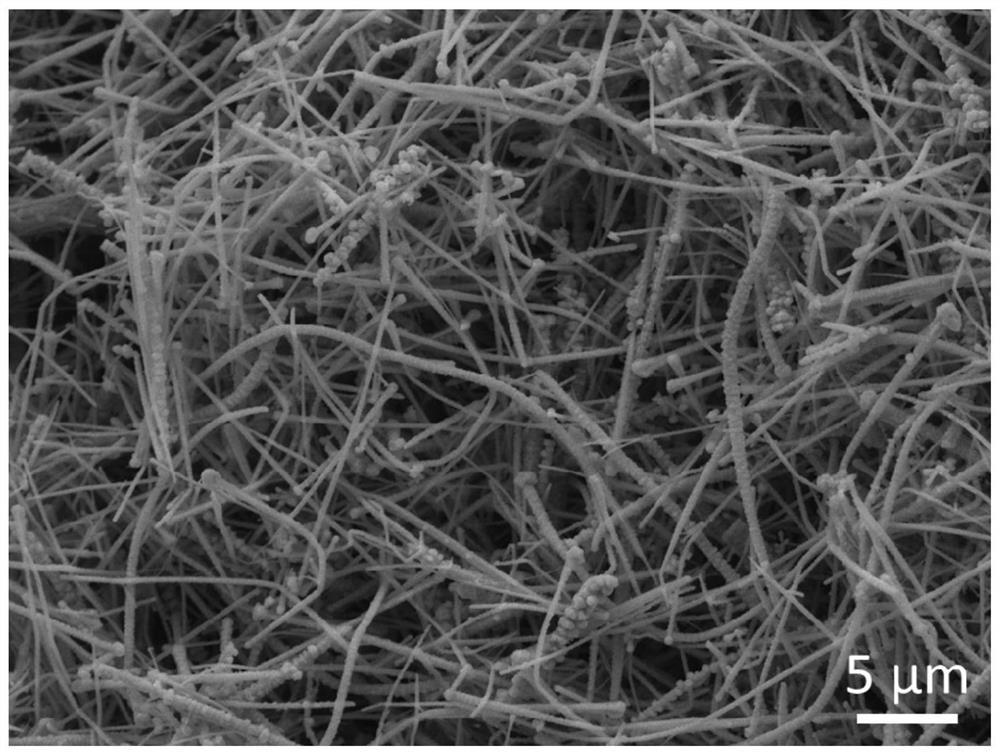

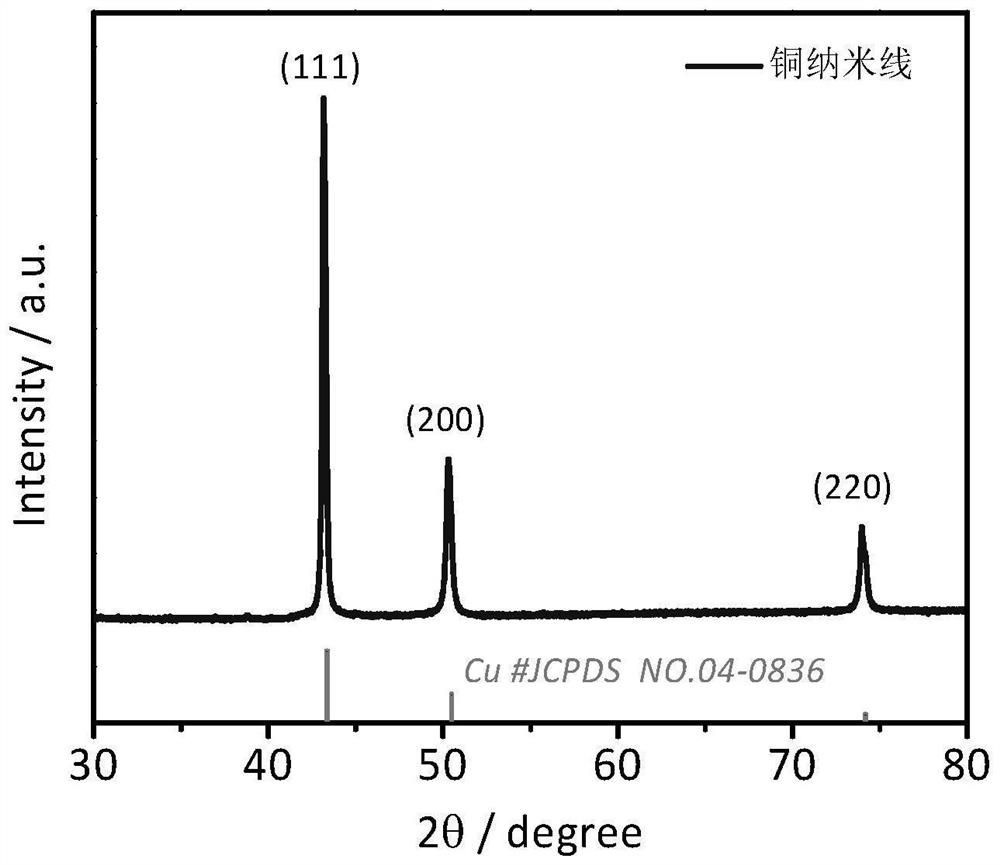

[0042] A preparation method of copper phthalocyanine polymer@copper nanowire core-shell nanomaterial, the steps are as follows:

[0043] (1) Slowly dissolve 250g of sodium hydroxide into 360mL of water, dissolve 0.42g of copper salt into 10mL of water, add the copper salt solution dropwise to the sodium hydroxide solution, and the mixed solution turns blue at this time.

[0044] (2) Add 3 mL of ethylenediamine dropwise to the blue solution, stir for 5 min, then add 0.3 mL of hydrazine hydrate, at this time the mixed solution appears milky white suspension, stir for 30 min.

[0045] (3) The above mixed solution was reacted at 80° C. for 1.5 h, and then naturally cooled to room temperature.

[0046] (4) The obtained red precipitate was washed three times with a mixed solvent of water and ethanol, and then dried in vacuum to obtain copper nanowire powder.

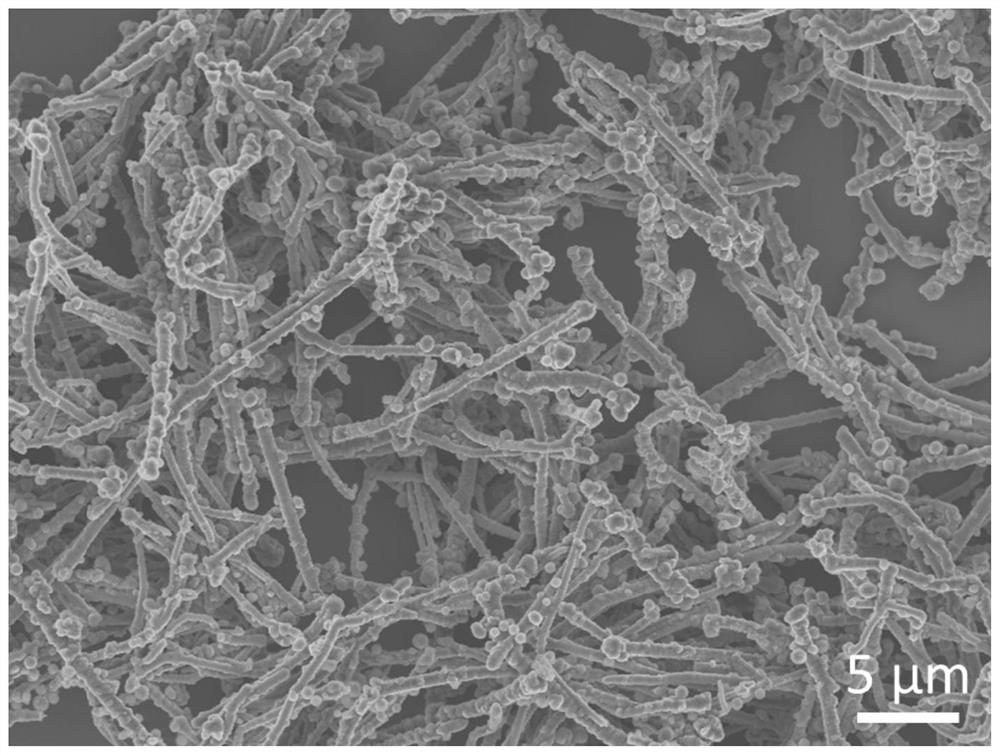

[0047] (5) Disperse 50mg of vacuum-dried copper nanowires in amyl alcohol, add 20mg of tetracyanobenzene and 20mg of 1,8-di...

Embodiment 2

[0058] This embodiment is the same as embodiment 1, the reaction temperature in step (5) is 160 DEG C, and other steps are unchanged.

Embodiment 3

[0060] This embodiment is the same as embodiment 1, the reaction time in step (5) is 200 DEG C, other steps are unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com