Patents

Literature

429 results about "Copper phthalocyanine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper Phthalocyanine is a brilliant blue dye with numerous applications in industrial coatings, fine art pigments, textile and paper manufacturing, organic and photovoltaic cells. It is available in both alpha and beta forms.

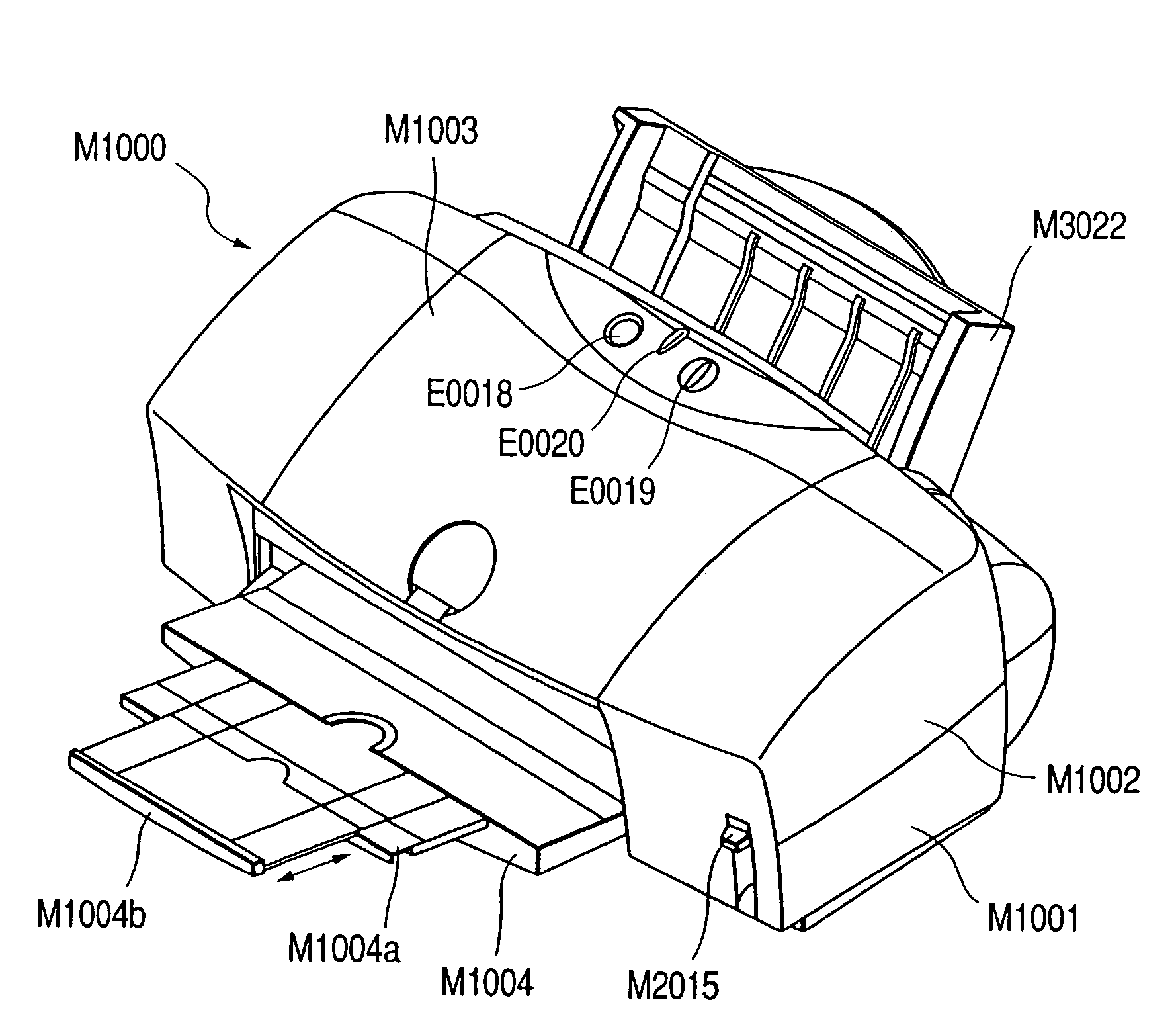

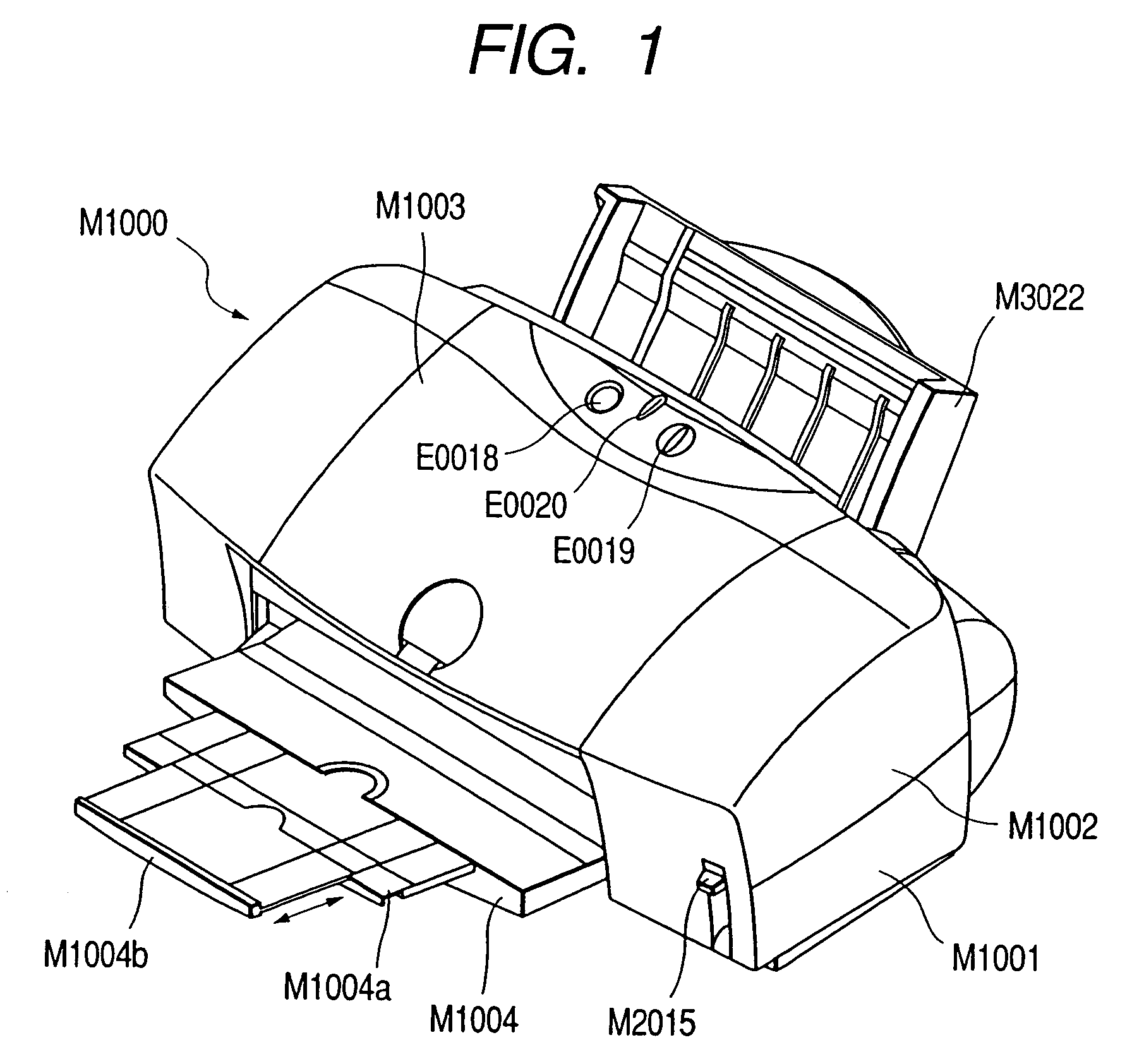

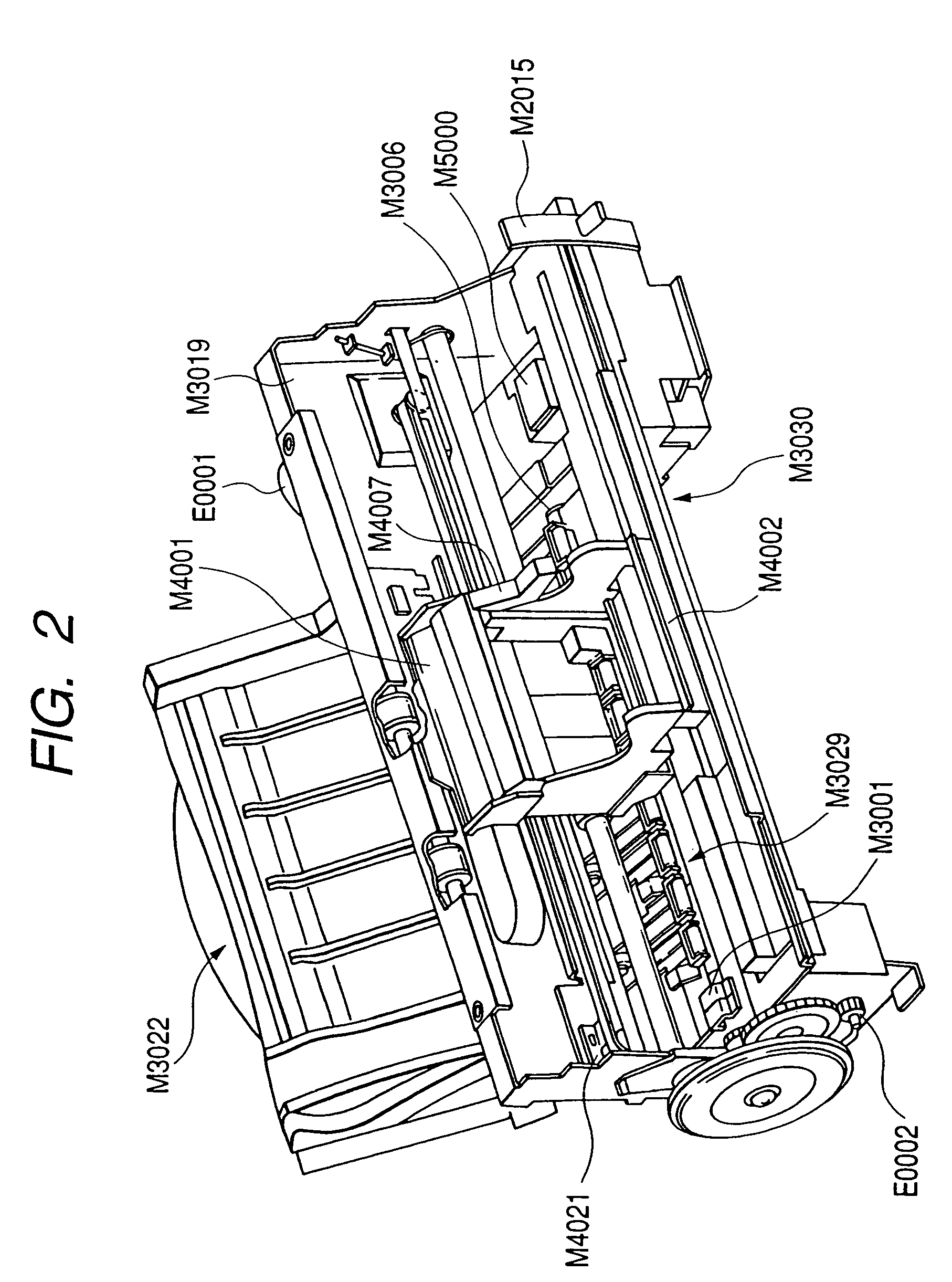

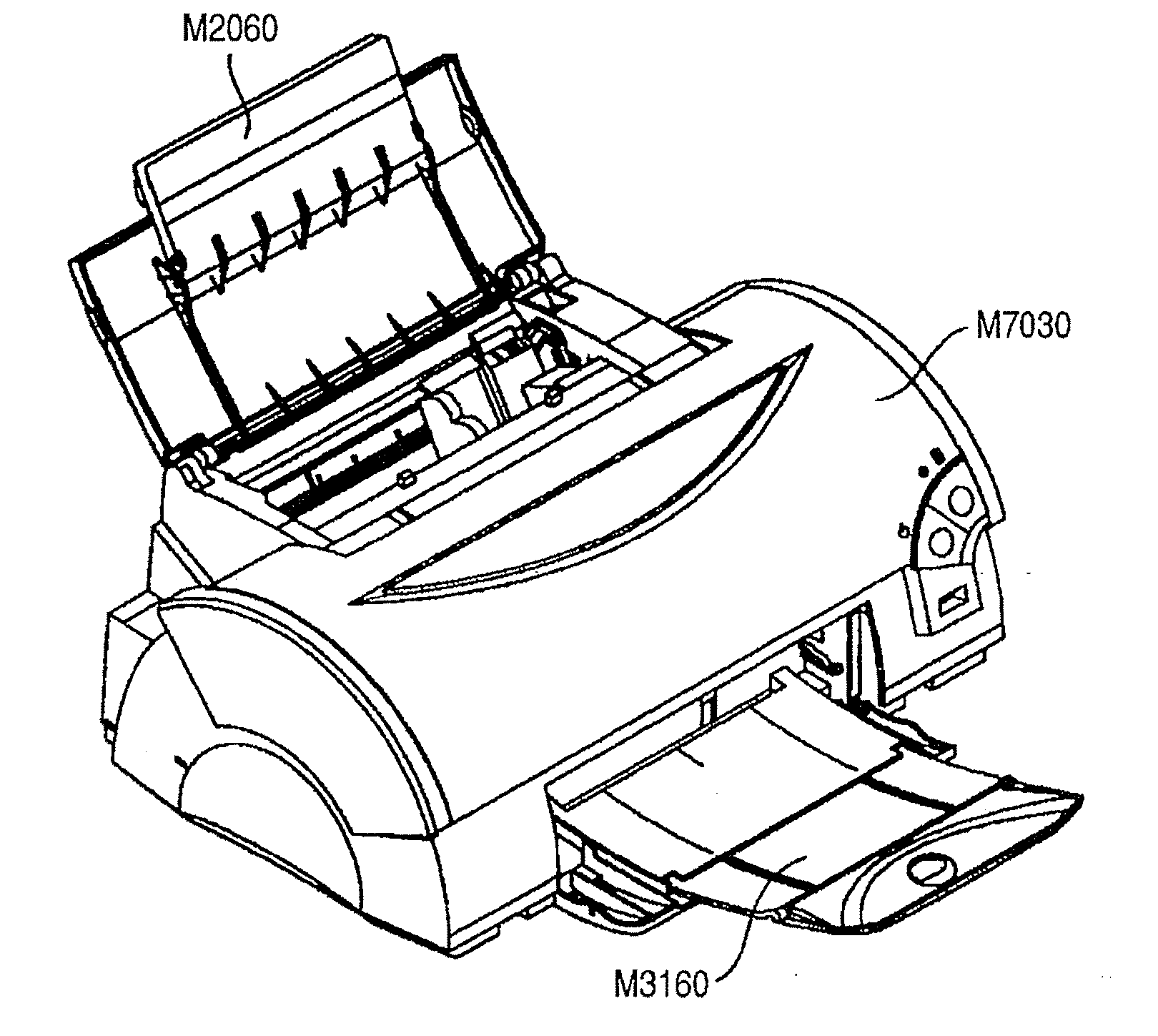

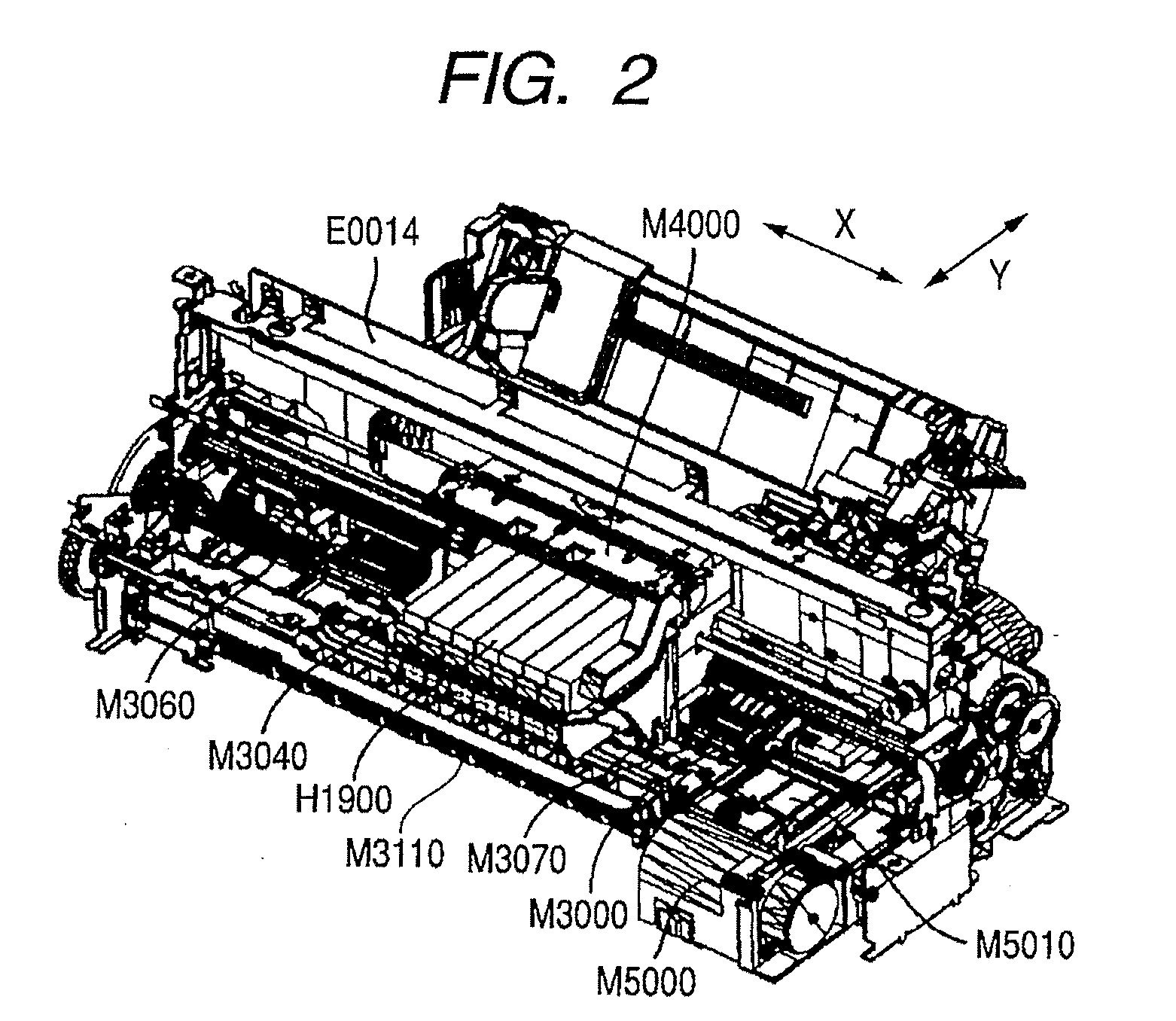

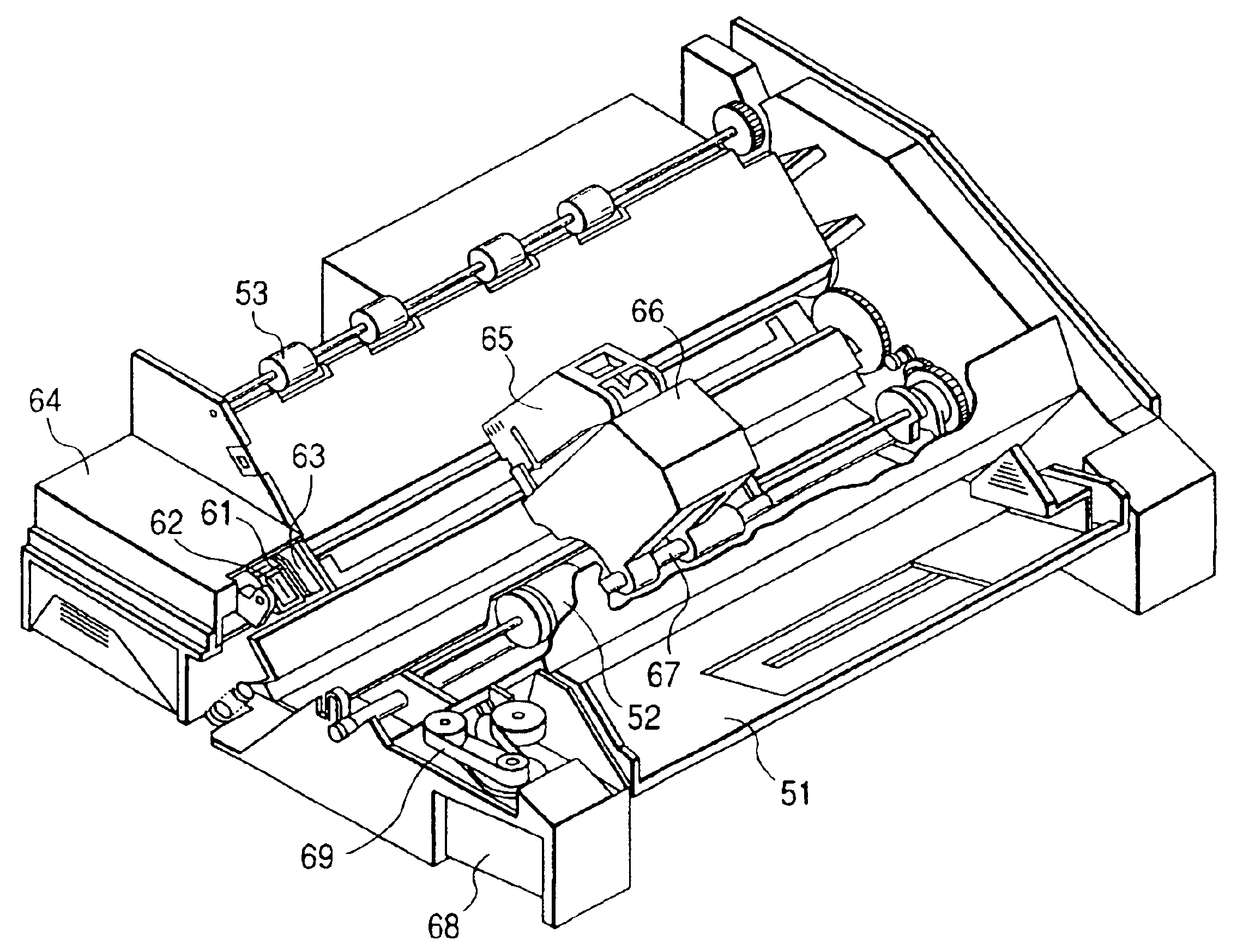

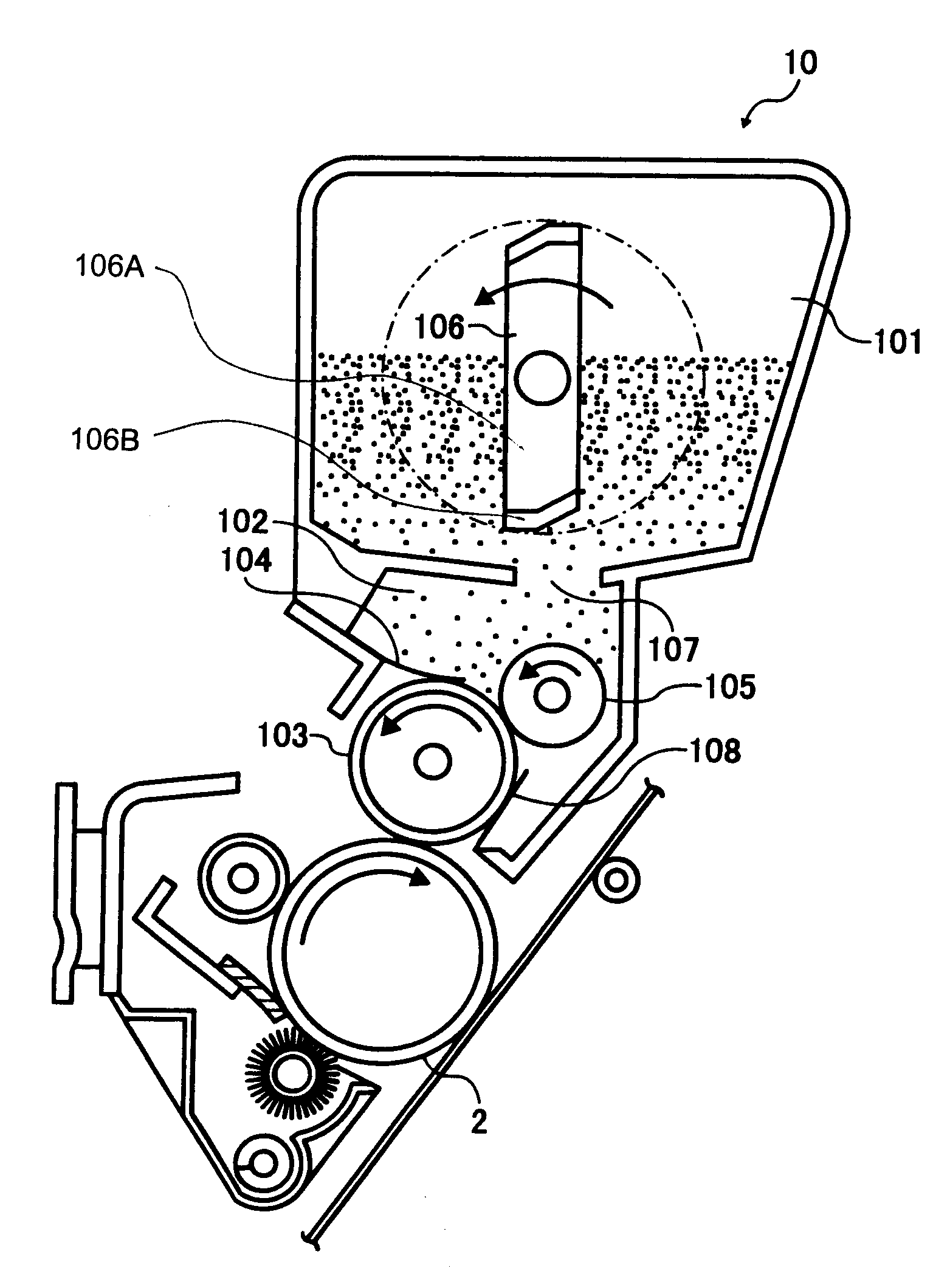

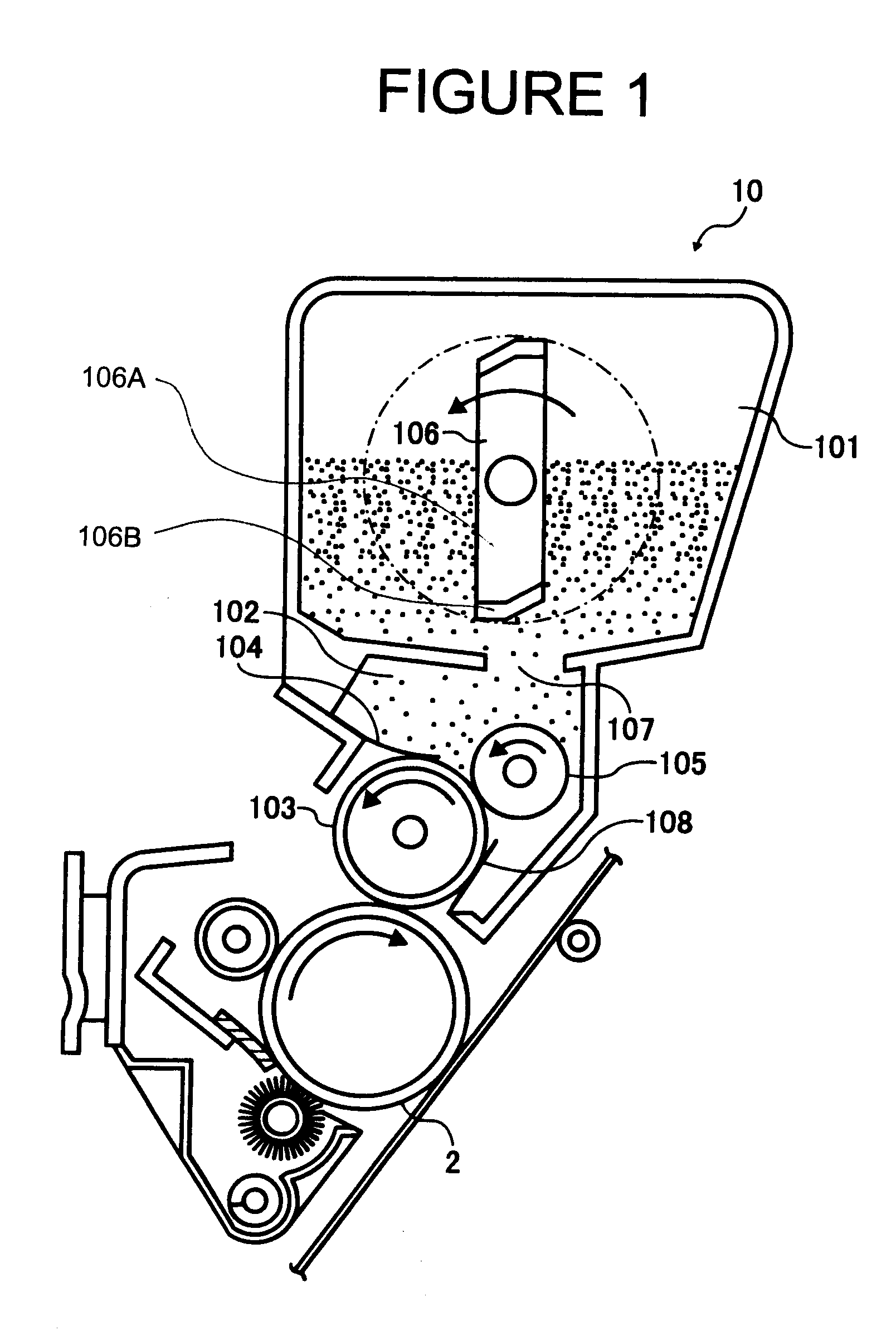

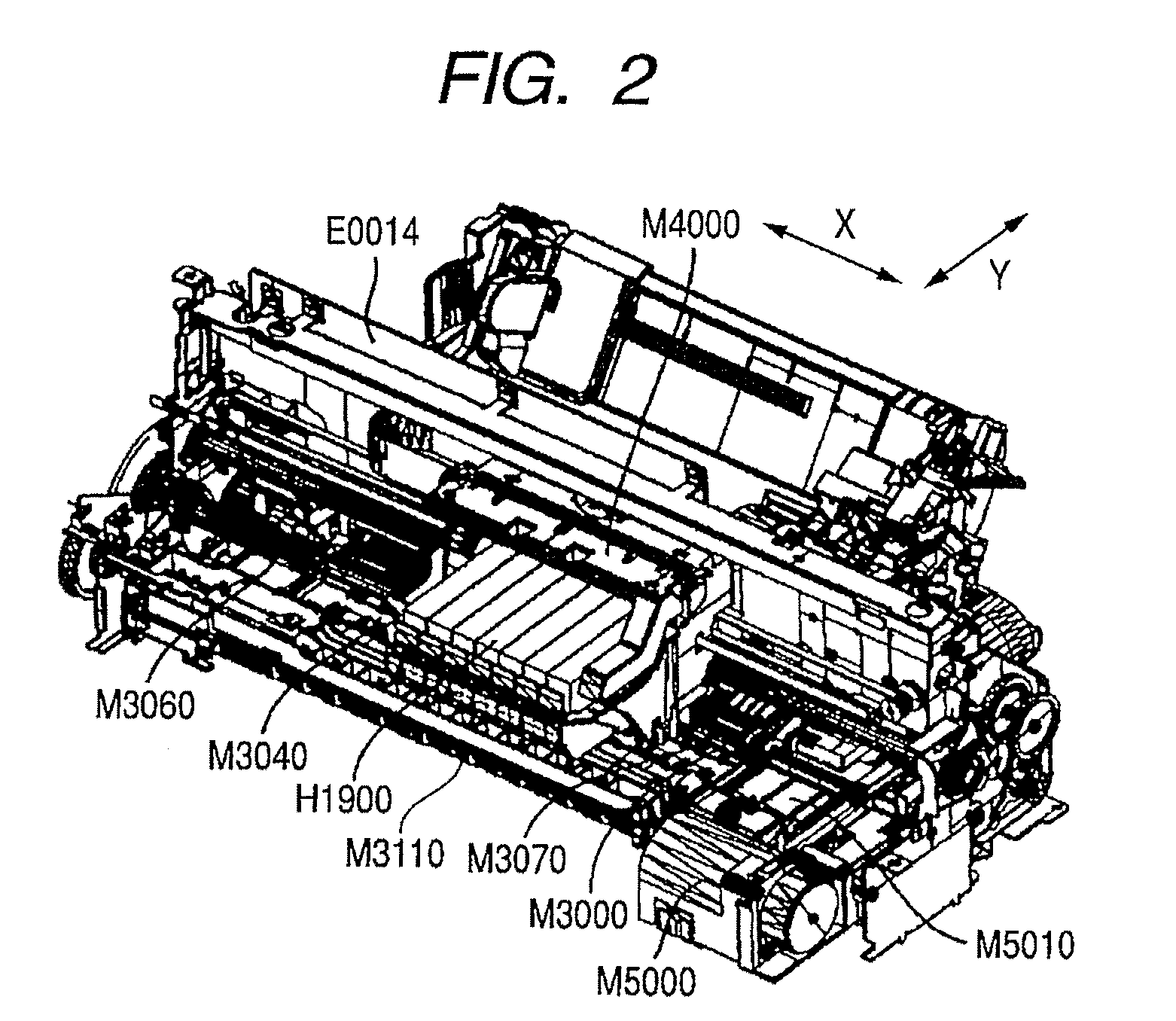

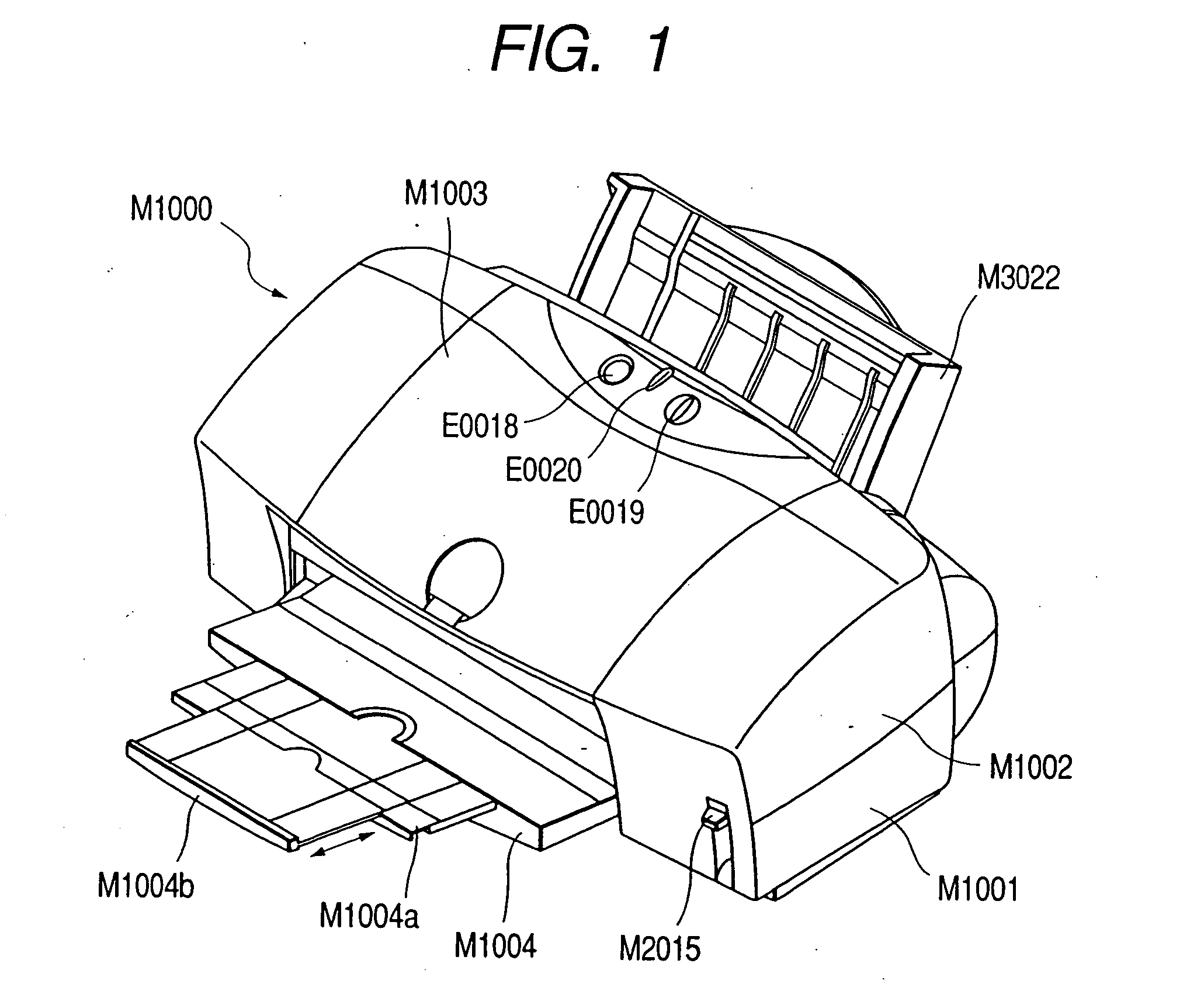

Ink jet recording ink, ink jet recording method, ink cartridge, and ink jet recording apparatus

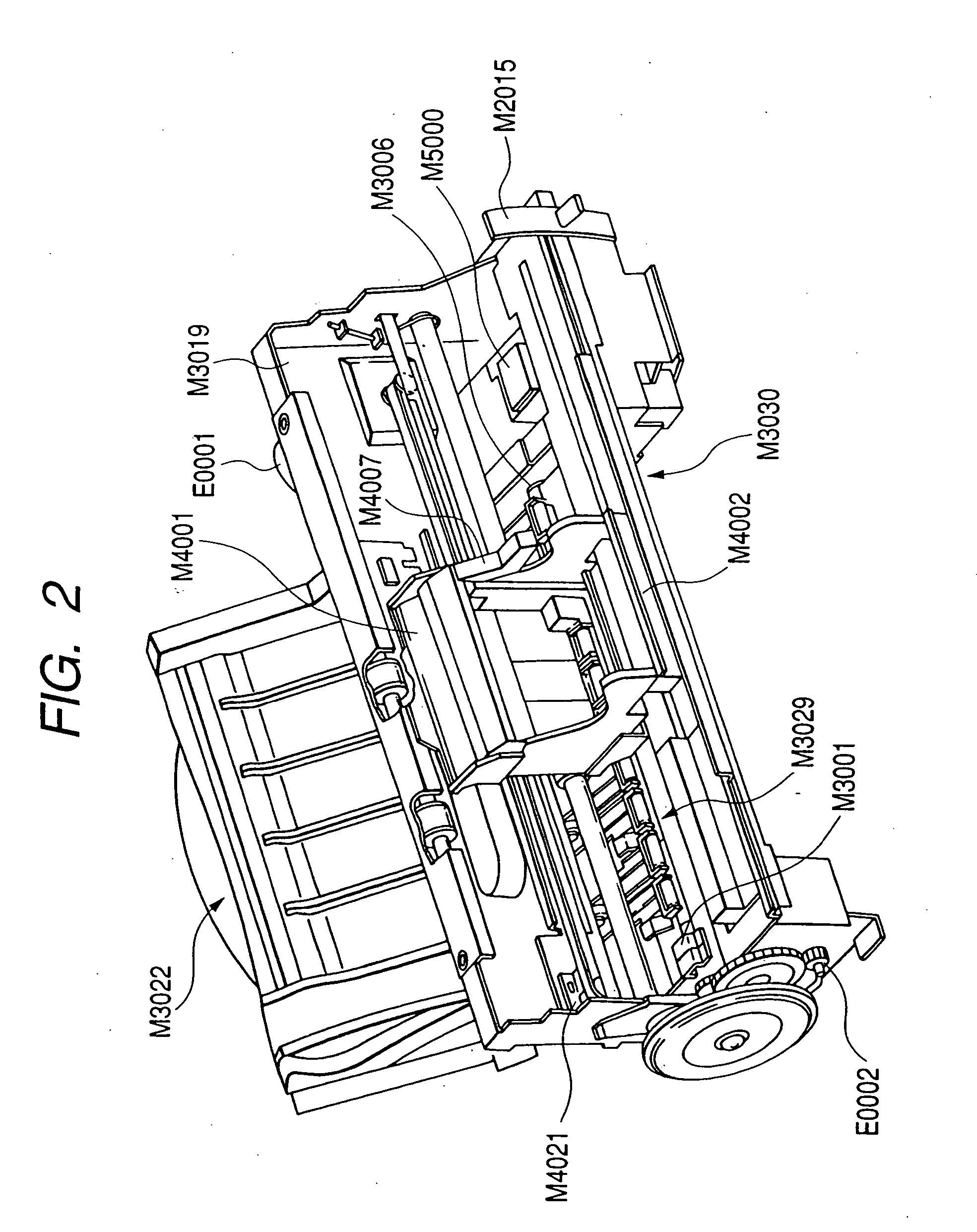

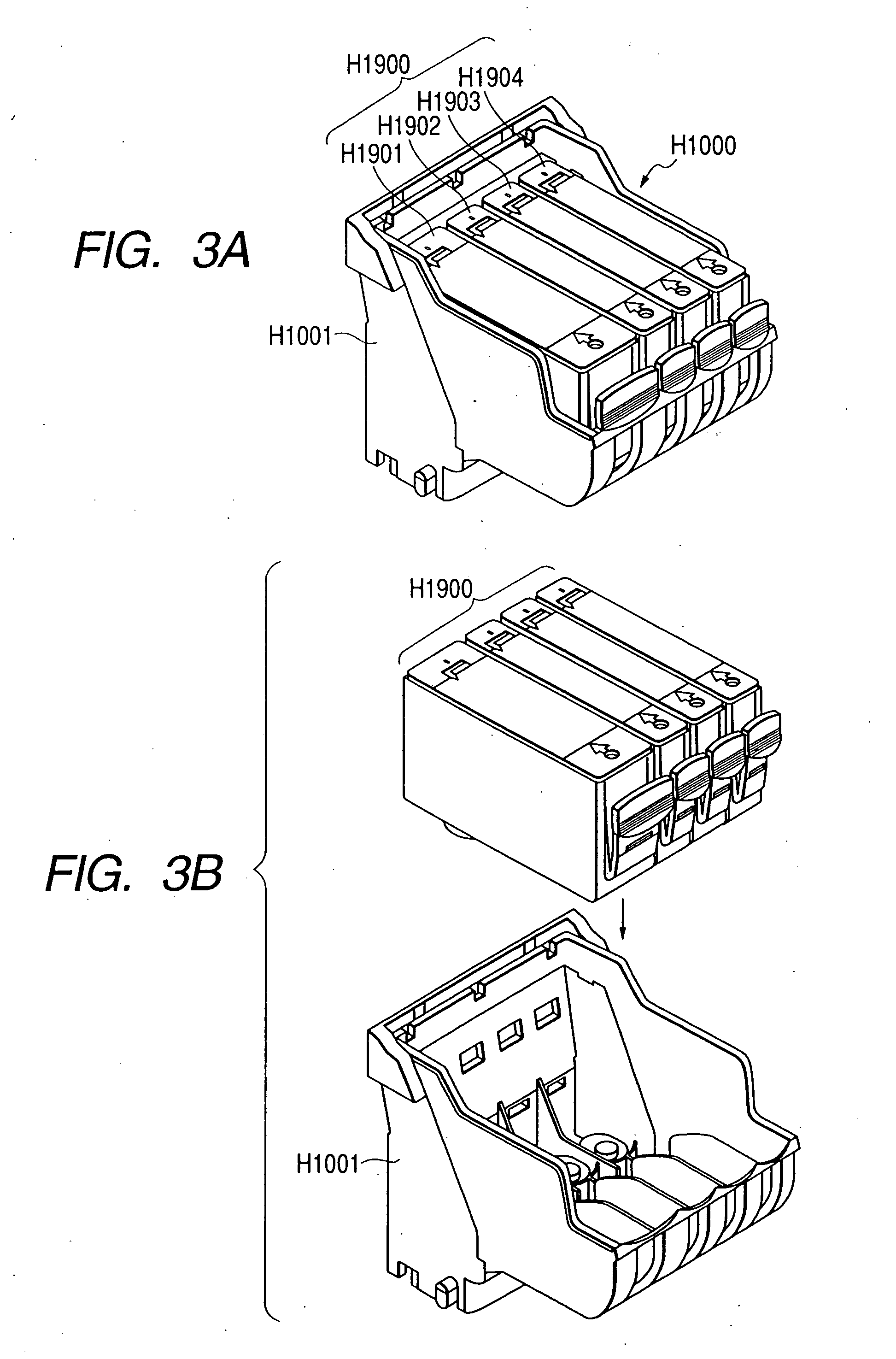

InactiveUS7244299B2Preventing bronzingGood weather resistanceMonoazo dyesMeasurement apparatus componentsPhthalocyanineMechanical engineering

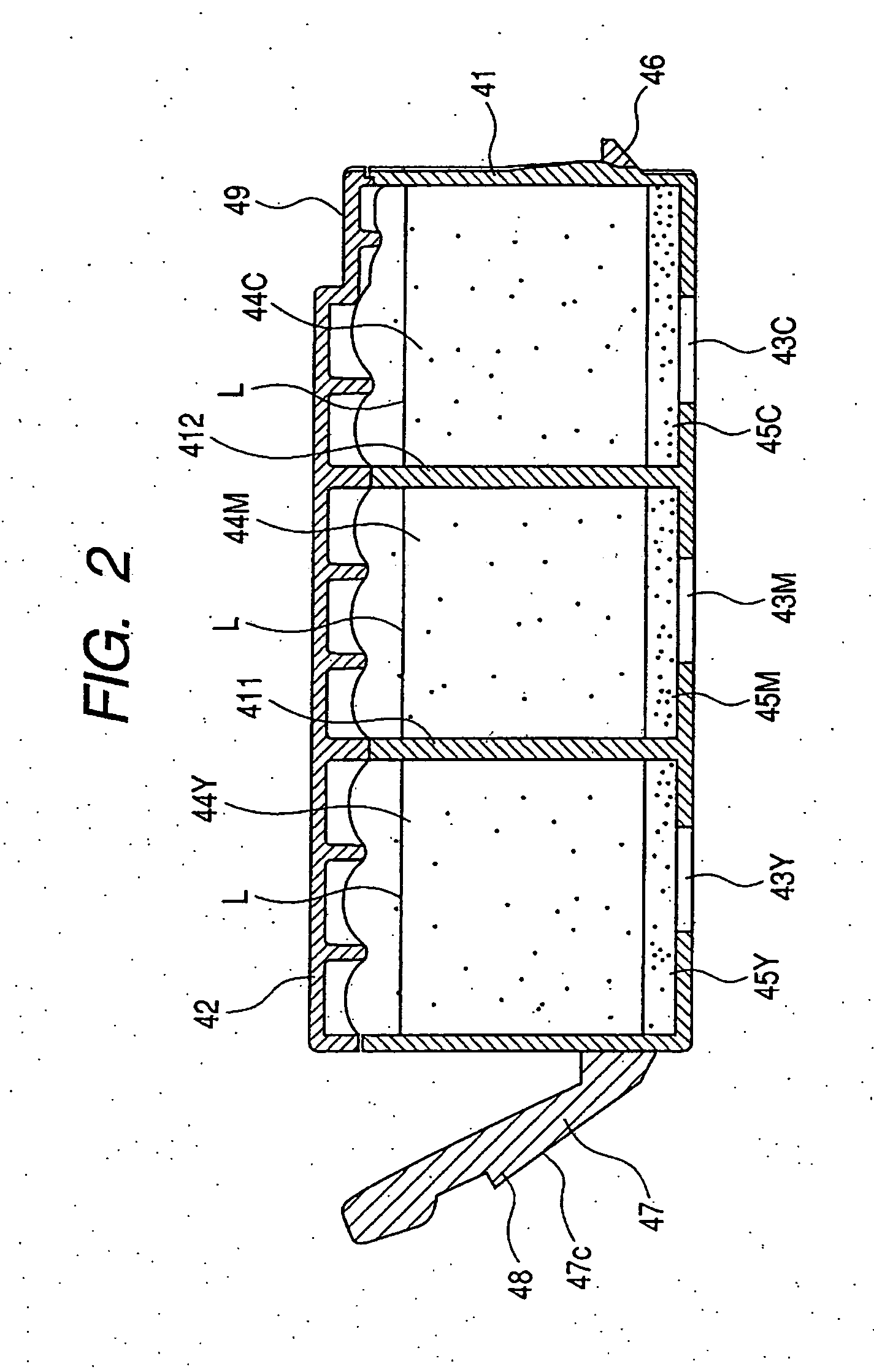

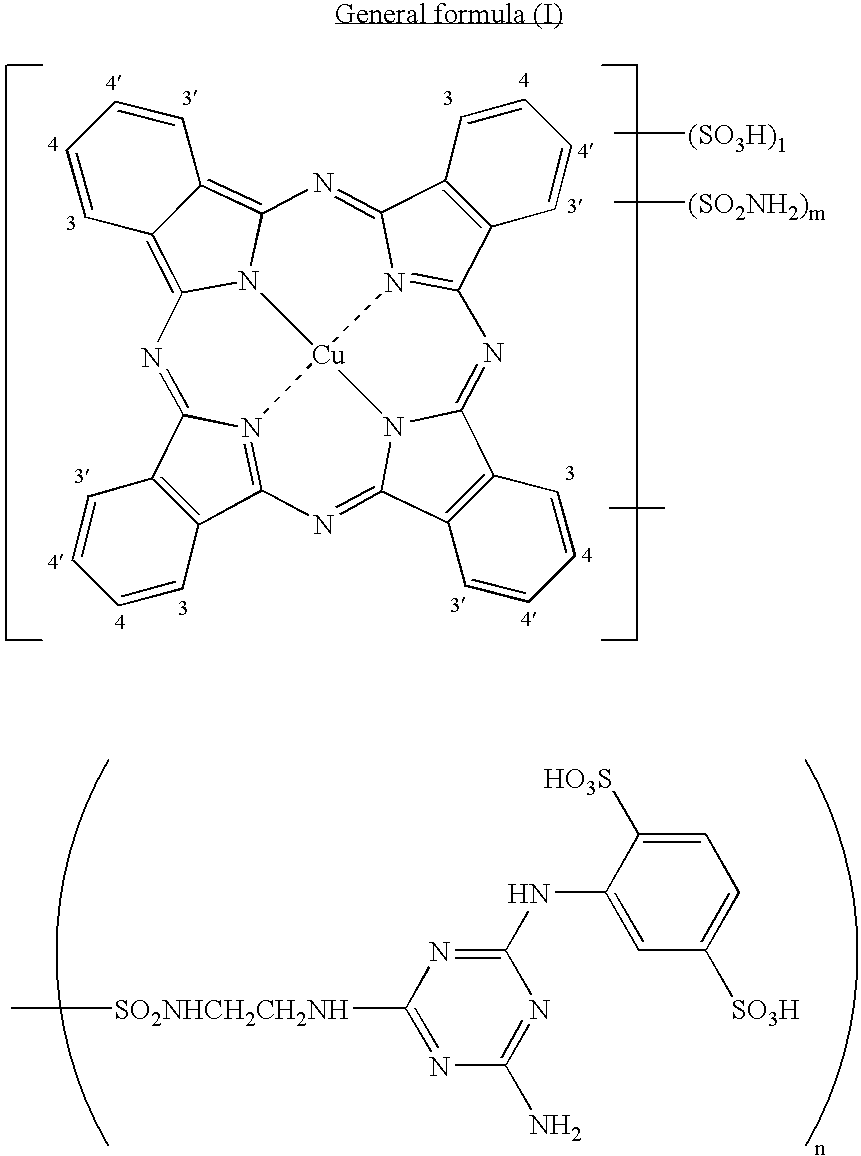

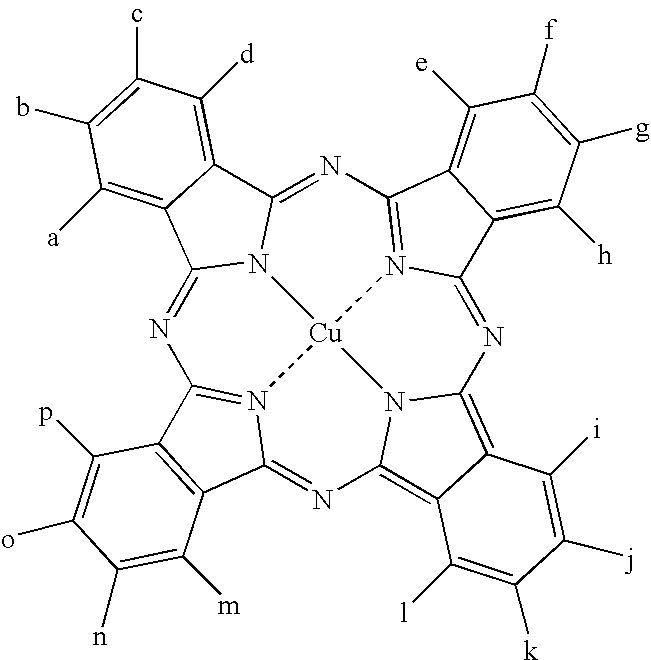

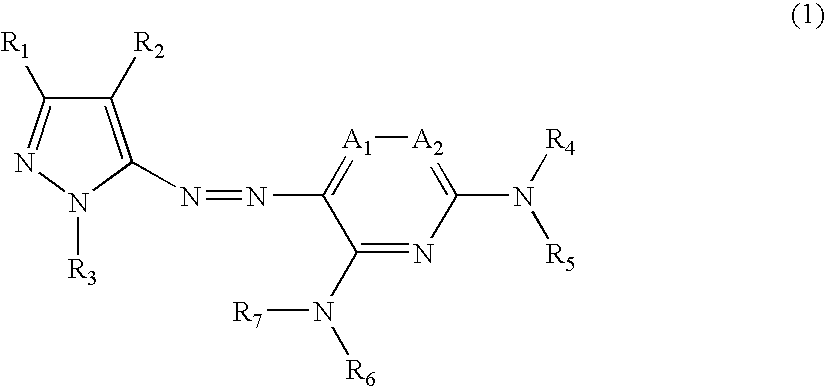

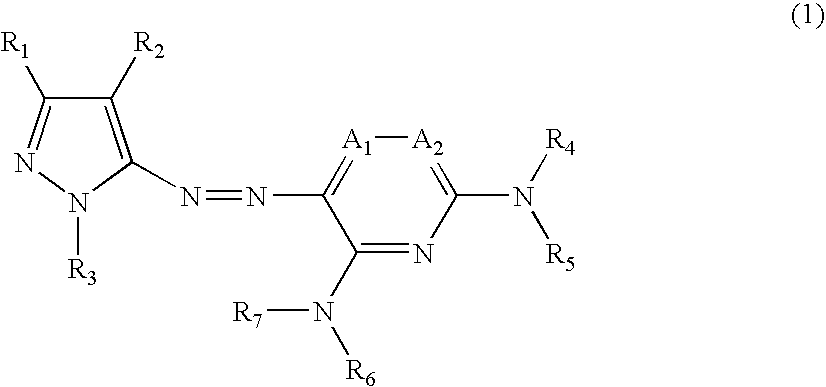

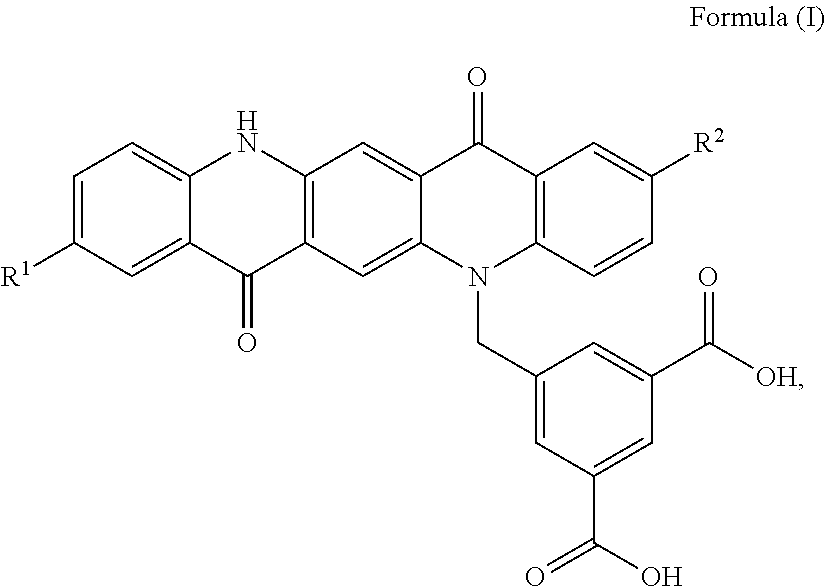

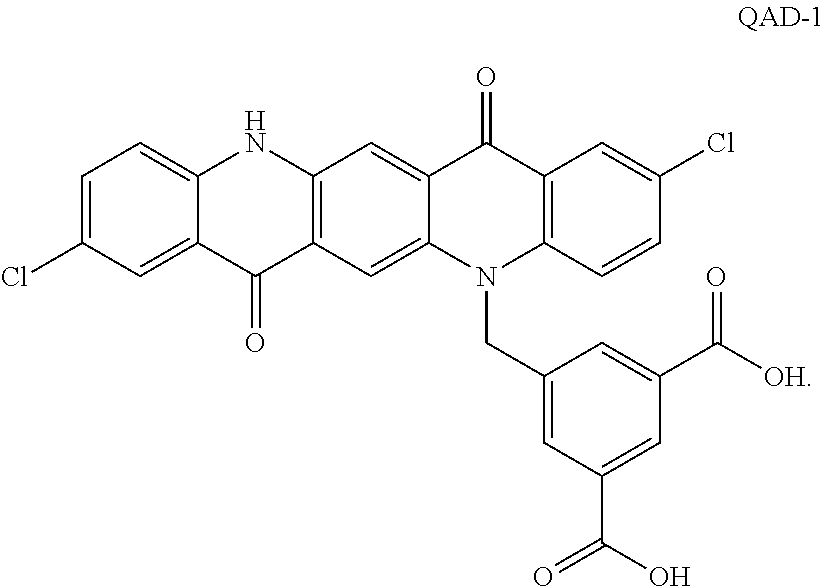

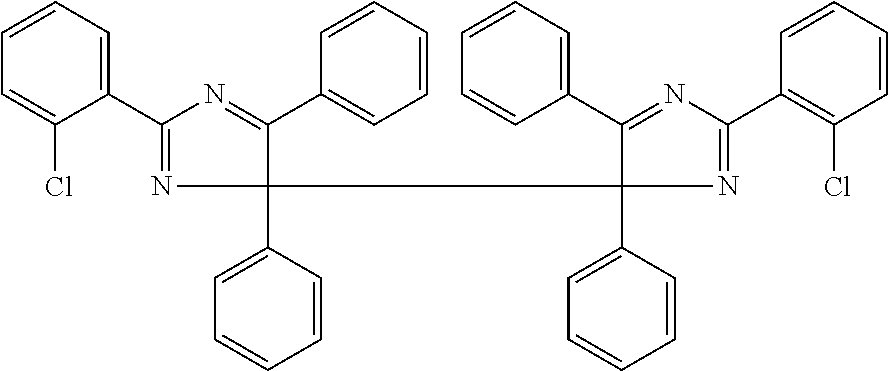

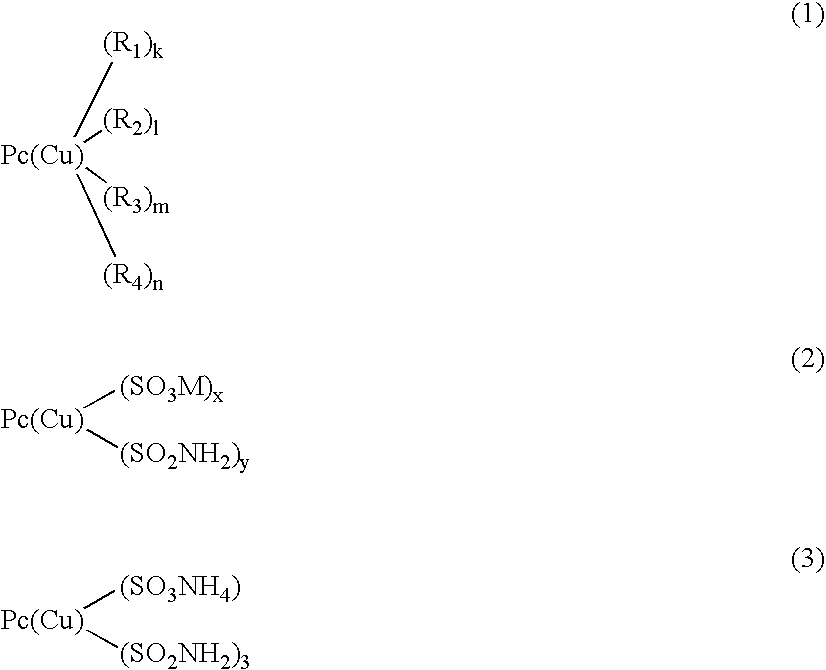

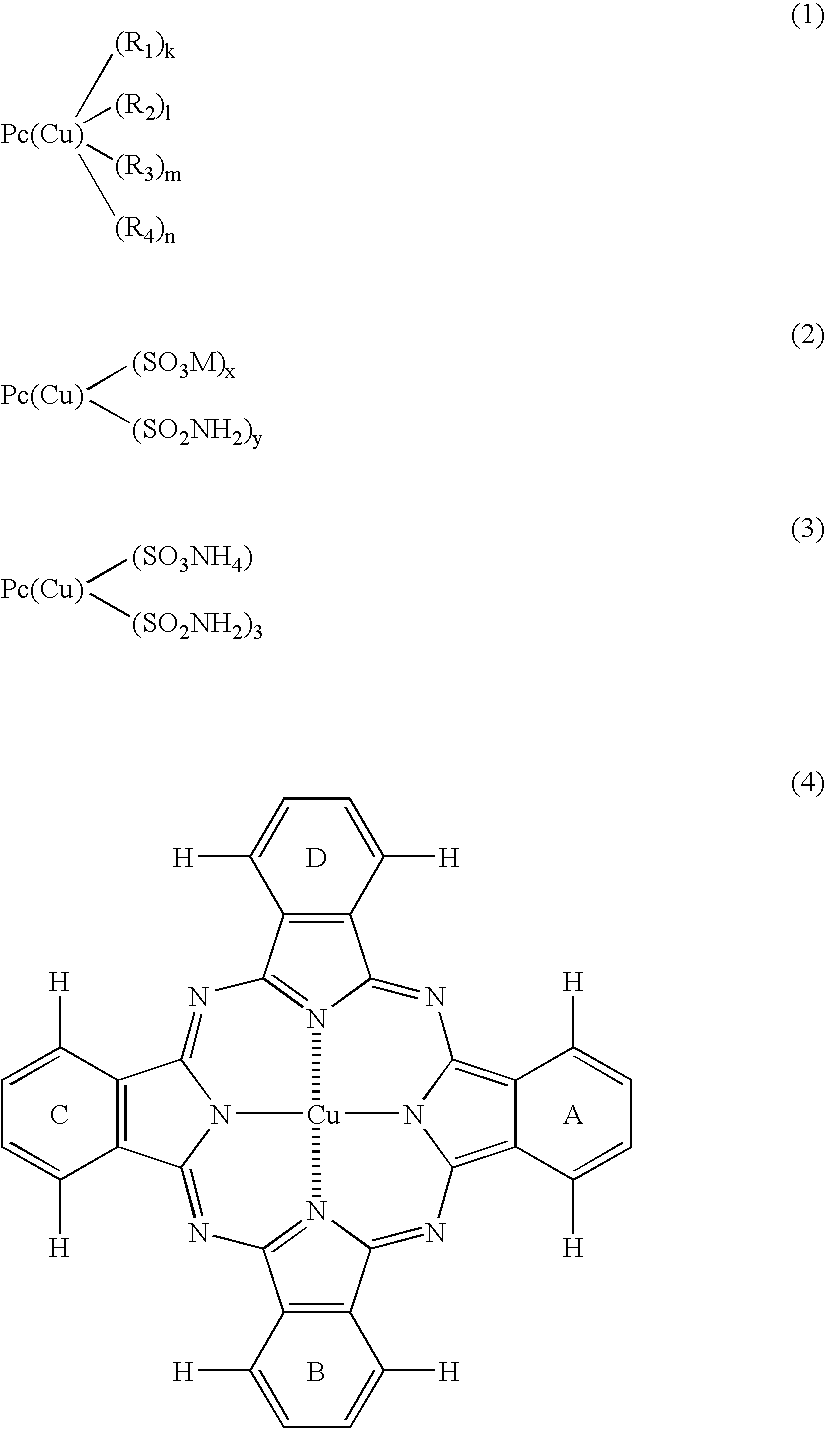

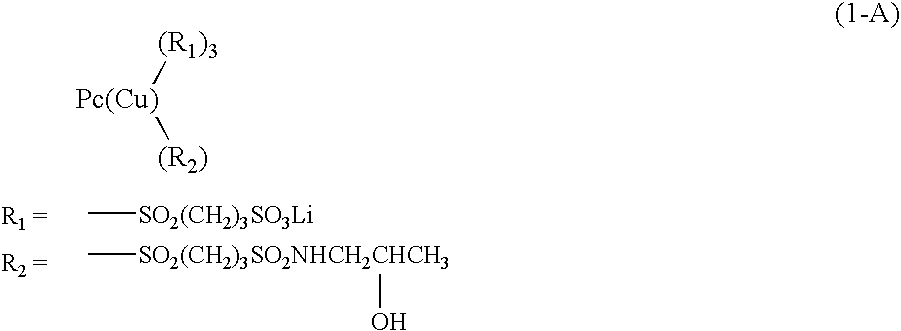

An ink jet recording ink comprising at least a copper phthalocyanine dye represented by the following general formula (1) and a compound represented by the following general formula (2):

Owner:CANON KK

Ink jet ink, method for producing ink jet ink, ink jet recording method and ink cartridge

InactiveUS20060137570A1Excellent developabilityIncreased durabilityMeasurement apparatus componentsDuplicating/marking methodsChemical compoundPhthalocyanine

An ink jet ink includes at least a coloring material. The coloring material is composed of at least one selected from the group consisting of C.I. Acid Blue 9 and a compound having a copper phthalocyanine structure, and a compound represented by the following general formula (I) or a salt thereof.

Owner:CANON KK

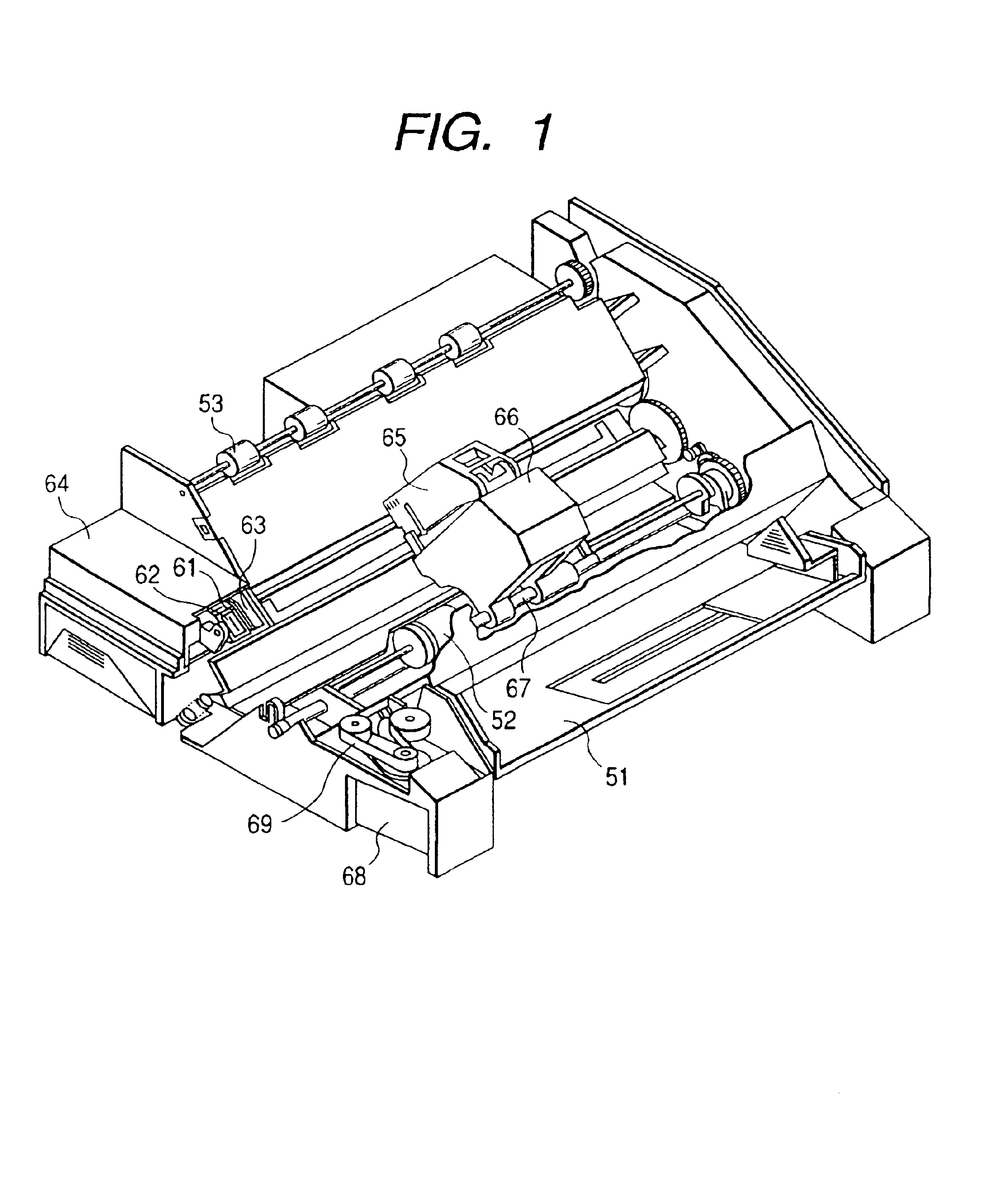

Aqueous ink, ink-jet recording method, ink cartridge, recording unit and ink jet recording apparatus

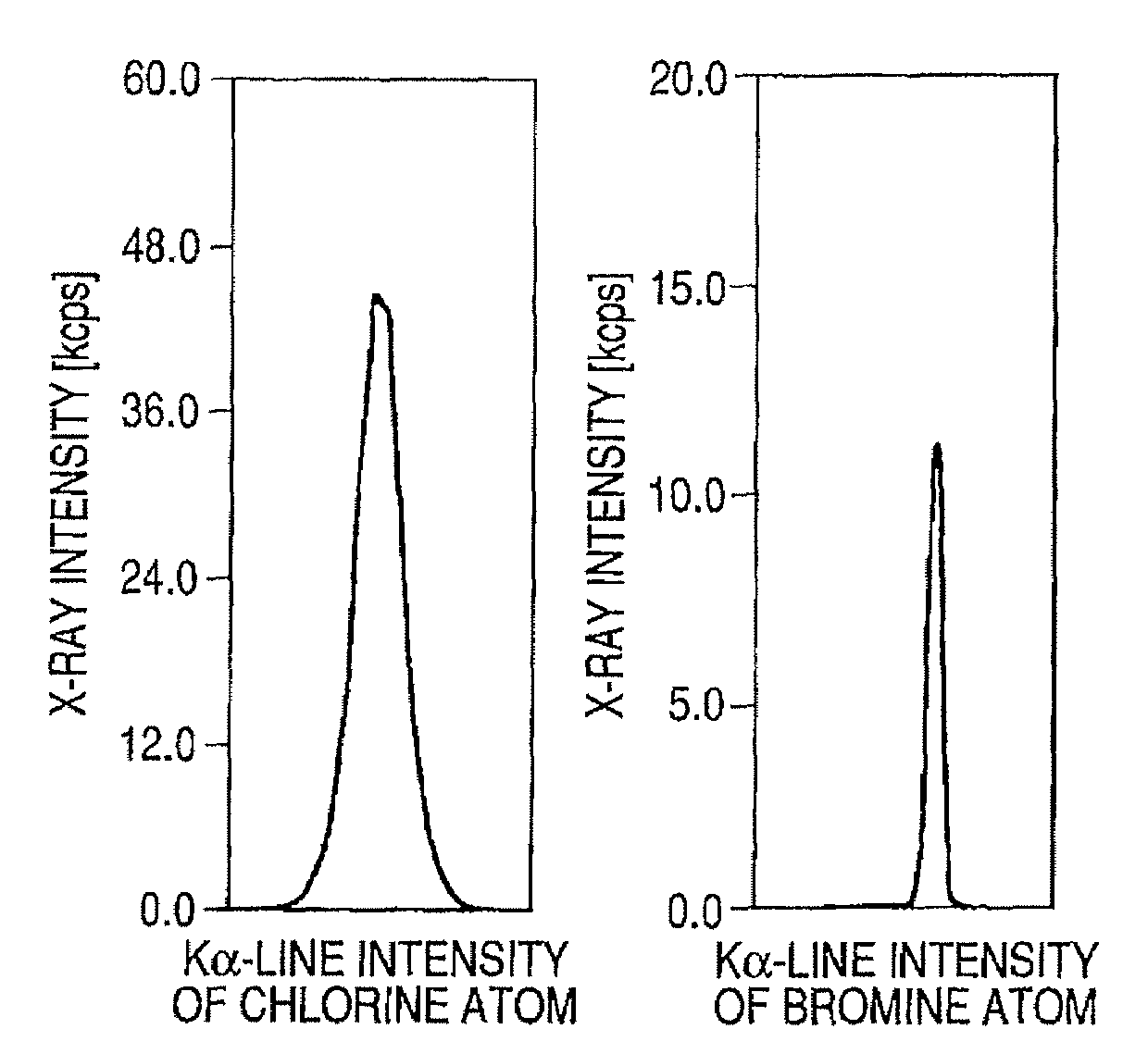

InactiveUS20070188572A1Excellent ejection stabilityGood storage stabilityMeasurement apparatus componentsInksBrominePhthalocyanine

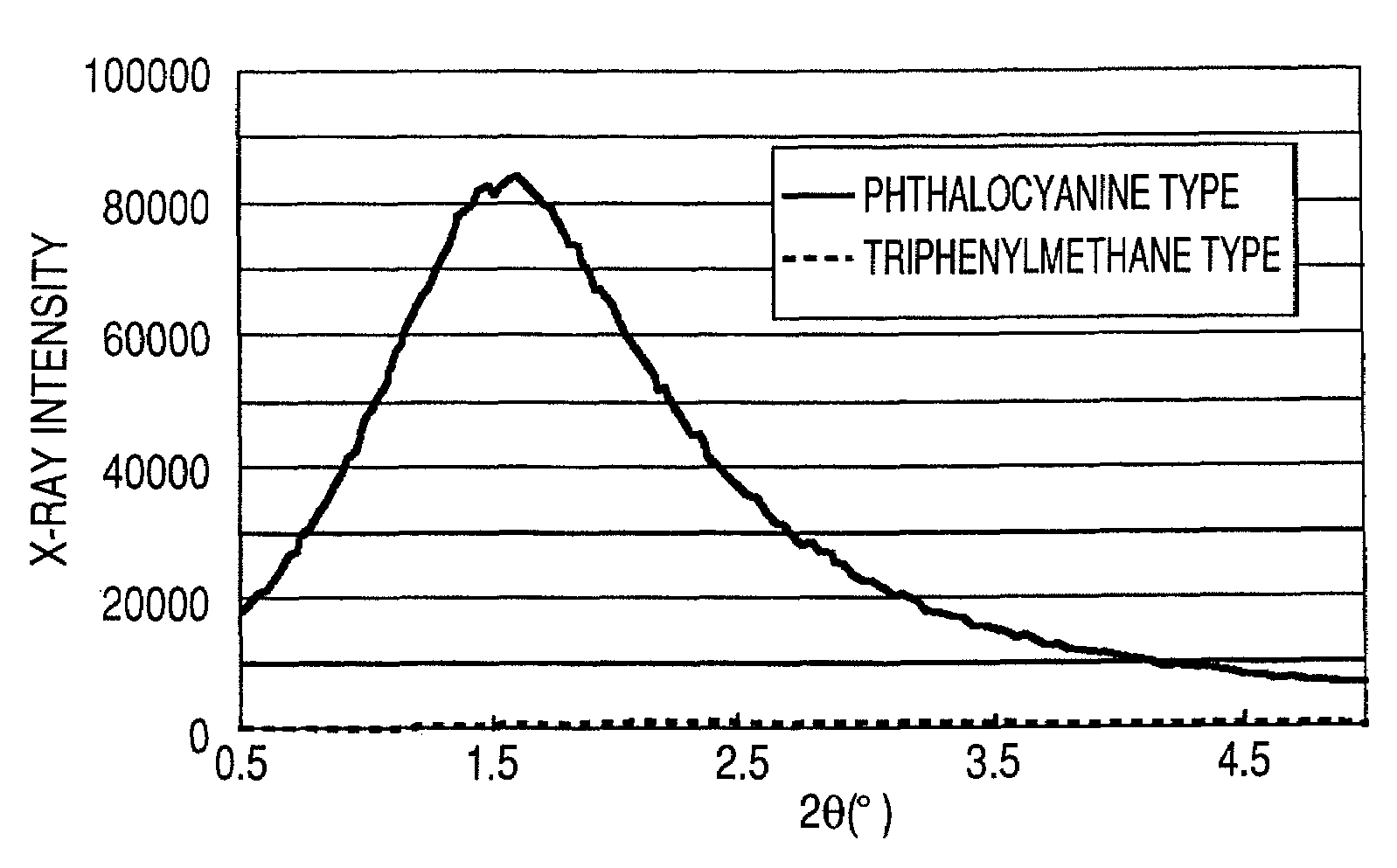

An aqueous ink to be used in an ink jet recording containing a green pigment having a copper phthalocyanine skeleton, wherein a proportion of the Kα-line intensity of a chlorine atom to the Kα-line intensity of a bromine atom obtained by subjecting the green pigment to X-ray fluorescence analysis is 3.3 or more to 10.0 or less.

Owner:CANON KK

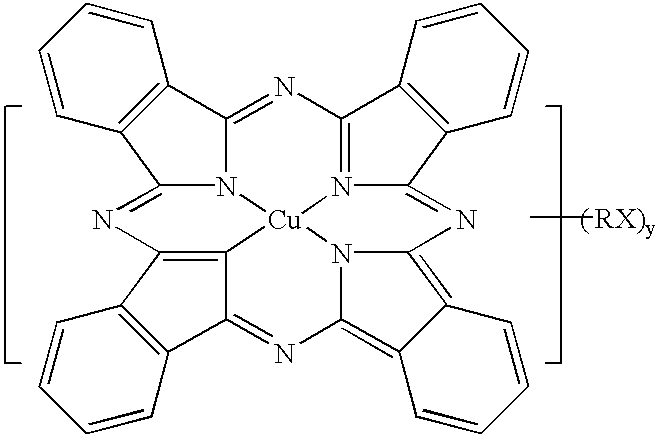

Cyan dye mixture, water-based cyan ink composition, and method of ink-jet recording

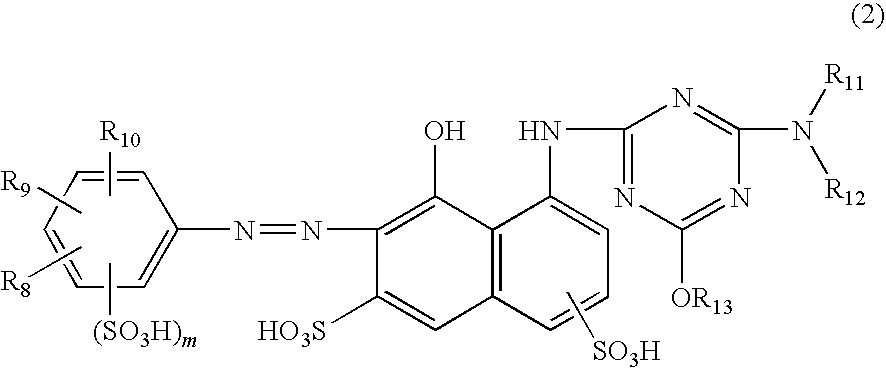

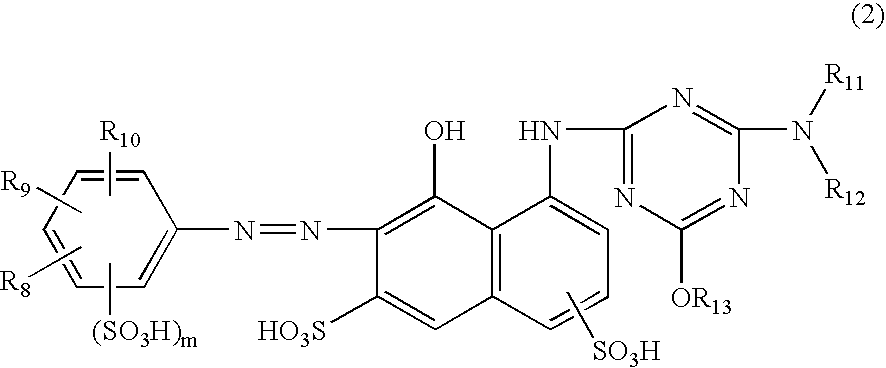

The present invention relates to a cyan dye mixture, an ink composition containing the mixture and a method of ink-jet recording with the ink composition. The print obtained by the method is characterized by discoloring or fading little even when allowed to stand in a well ventilated shade or in an ozone gas. The cyan dye mixture comprises compounds which are obtained by chlorosulfonating, as a starting material, copper phthalocyanine or a sulfonated copper phthalocyanine and then aminating the chlorosulfonation product with an aminating agent used in an amount of at least 2.5 mol per mol of the starting material, and which are represented by the following formula (1): wherein M represents a proton, alkali metal ion, alkaline earth metal ion, onium ion of an organic amine, or ammonium ion; m is an integer of 1 to 4; and n is an integer of 0 to 3; provided that m+n is an integer of 1 to 4.

Owner:NIPPON KAYAKU CO LTD

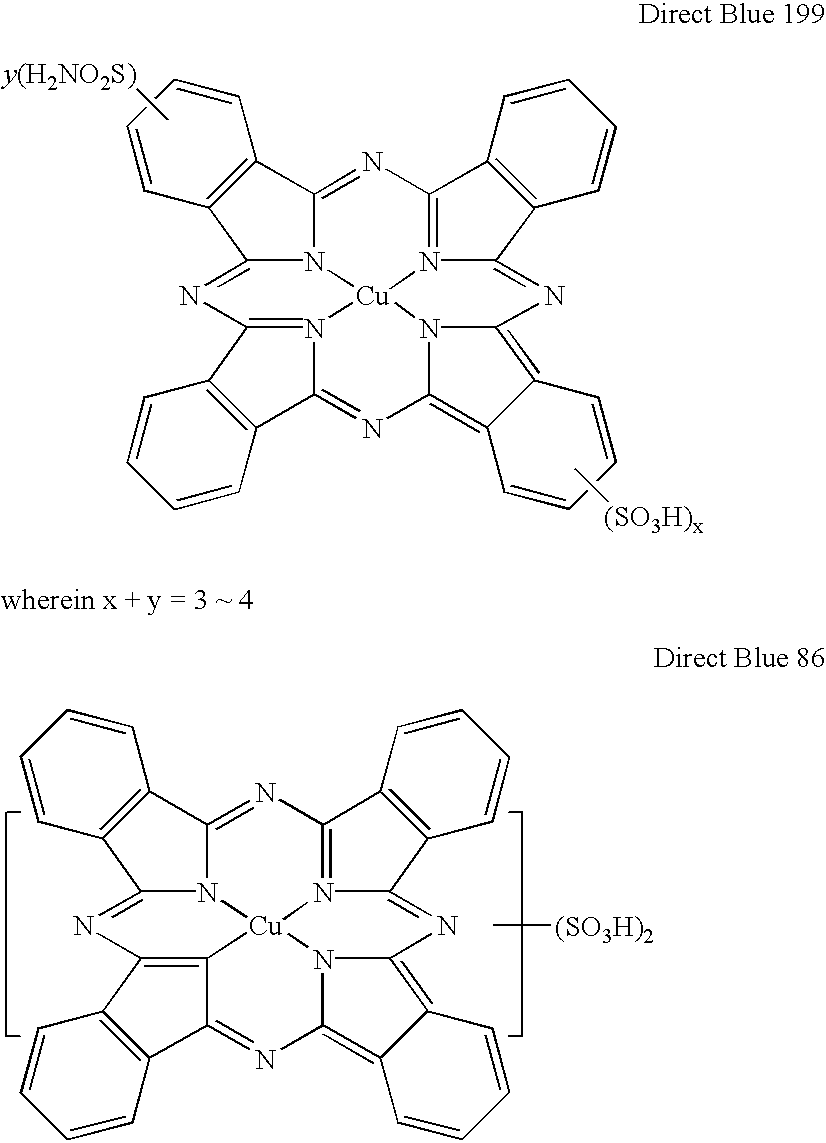

Aqueous ink, ink jet recording method, ink tank recording unit and ink jet recording apparatus

InactiveUS6976755B2Gas resistance can be improvedExcellent gas resistanceMeasurement apparatus componentsInksCopper phthalocyanineVapor pressure

An aqueous ink comprises a phthalocyanine dye represented by a general formula (I) and an aqueous medium, wherein the phthalocyanine dye does not contain a component of x+y=2 but at least contains components of x+y=3 and x+y=4, the content of the component of x+y=4 is larger than the content of the component of x+y=3, and the aqueous medium contains an amine compound having a vapor pressure of 0.01 mmHg or higher at 20-25° C.: wherein CuPc represents a copper phthalocyanine residue; x represents 1, 2, 3 or 4 and y represent 0, 1, 2 or 3.

Owner:CANON KK

Ink, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

ActiveUS7611571B2Excellent ozone resistancePreferable color toneMeasurement apparatus componentsInksPhthalocyanineCopper

An ink having a cyan color is provided which can form images excellent in ozone resistance in such a high level as to exceed anticipation and having a preferable color tone. The ink includes at least two coloring materials of a first coloring material and a second coloring material, wherein the first coloring material is a compound having a copper phthalocyanine skeleton with a specific structure and the second coloring material is a compound having a copper phthalocyanine skeleton with a specific structure that is different from the first coloring material.

Owner:CANON KK

Ink, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

ActiveUS20080274286A1Excellent ozone resistancePreferable color toneMeasurement apparatus componentsInksPhthalocyanineCopper

An ink having a cyan color is provided which can form images excellent in ozone resistance in such a high level as to exceed anticipation and having a preferable color tone. The ink includes at least two coloring materials of a first coloring material and a second coloring material, wherein the first coloring material is a compound having a copper phthalocyanine skeleton with a specific structure and the second coloring material is a compound having a copper phthalocyanine skeleton with a specific structure that is different from the first coloring material.

Owner:CANON KK

Ink jet ink, method for producing ink jet ink, ink jet recording method and ink cartridge

InactiveUS7282090B2Excellent developabilityIncreased durabilityMeasurement apparatus componentsDuplicating/marking methodsChemical compoundPhthalocyanine

An ink jet ink includes at least a coloring material. The coloring material is composed of at least one selected from the group consisting of C.I. Acid Blue 9 and a compound having a copper phthalocyanine structure, and a compound represented by the following general formula (I) or a salt thereof

Owner:CANON KK

Full-color toner kit, process cartridge, and image forming method

A full-color toner kit including yellow, magenta, and cyan toners each including a benzimidazolone, a naphthol, and a copper phthalocyanine colorants, respectively, and resins (A) and (B) each of which having a polyester skeleton and containing a wax, and a resin (C) having a polyester skeleton and containing no wax. Each of the toners has a softening point of from 125° C. to 135° C. The following relationships are satisfied: Ts(A)<Ts(B), Ay+5≦Am≦Ay+15, and Ac+5≦Am≦Ac+15, wherein Ts(A) and Ts(B) (° C.) each represent softening points of the resin (A) and (B), respectively, and Ay, Am, and Ac each represent ratios (% by weight) of the amount of the resin (A) to total amount of the resins (A) and (B) in the yellow, magenta, cyan toners, respectively.

Owner:RICOH KK

Water-base ink and ink set using the same

Owner:SEIKO EPSON CORP

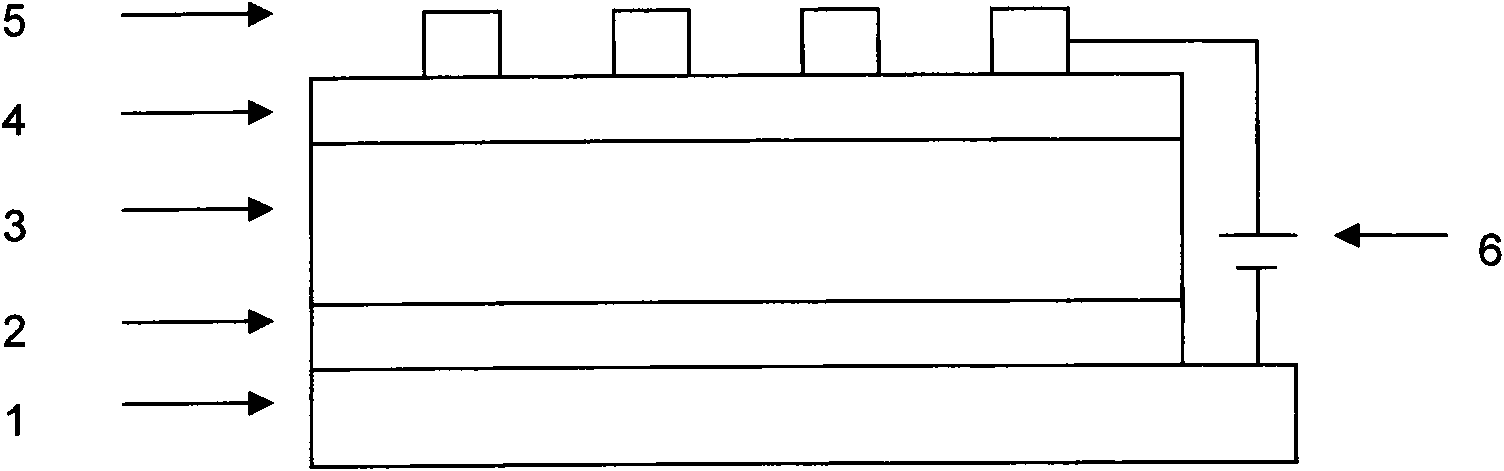

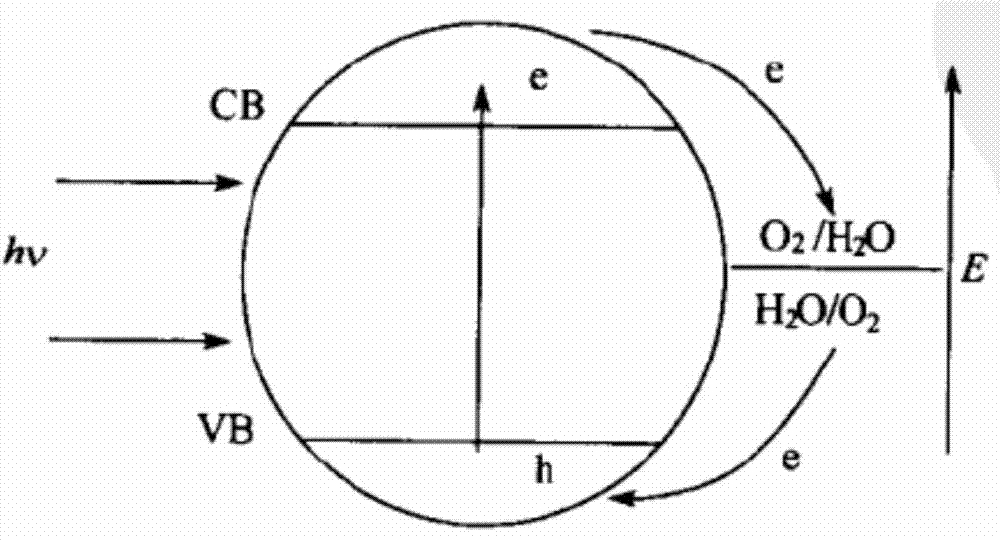

Reciprocal form structure polymer solar cell and preparation method thereof

InactiveCN101577313AAvoid priceLow priceSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionEvaporation

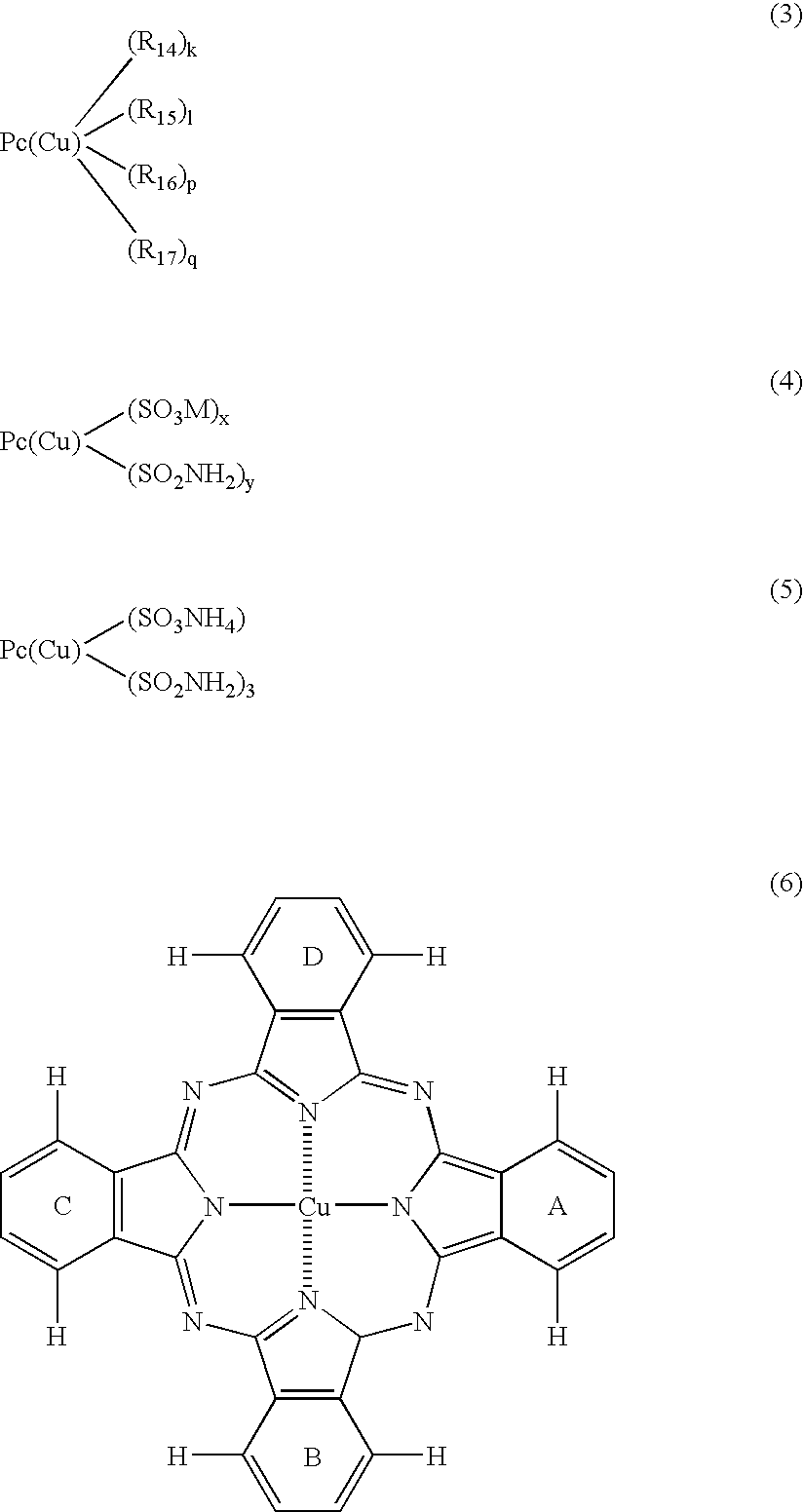

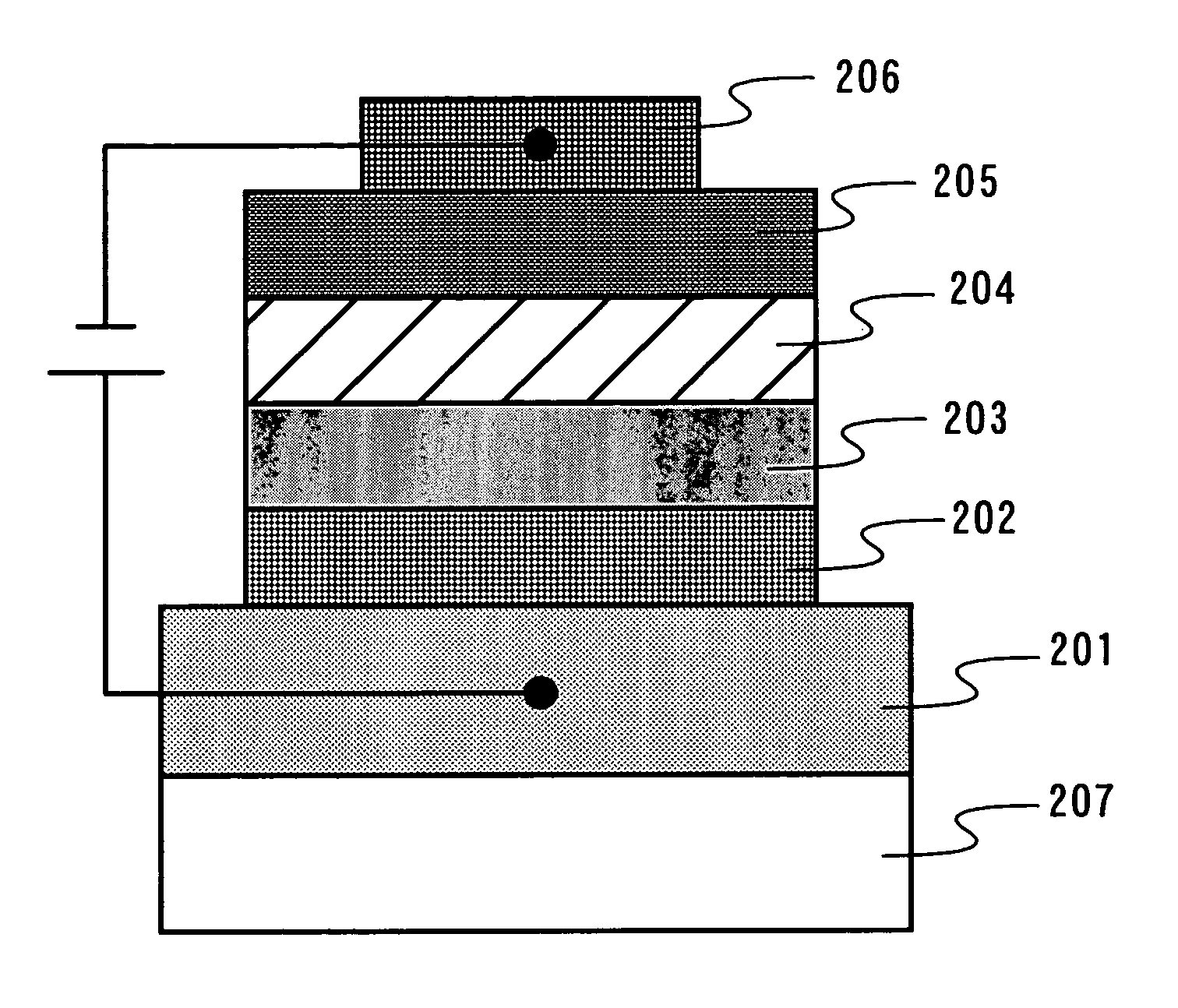

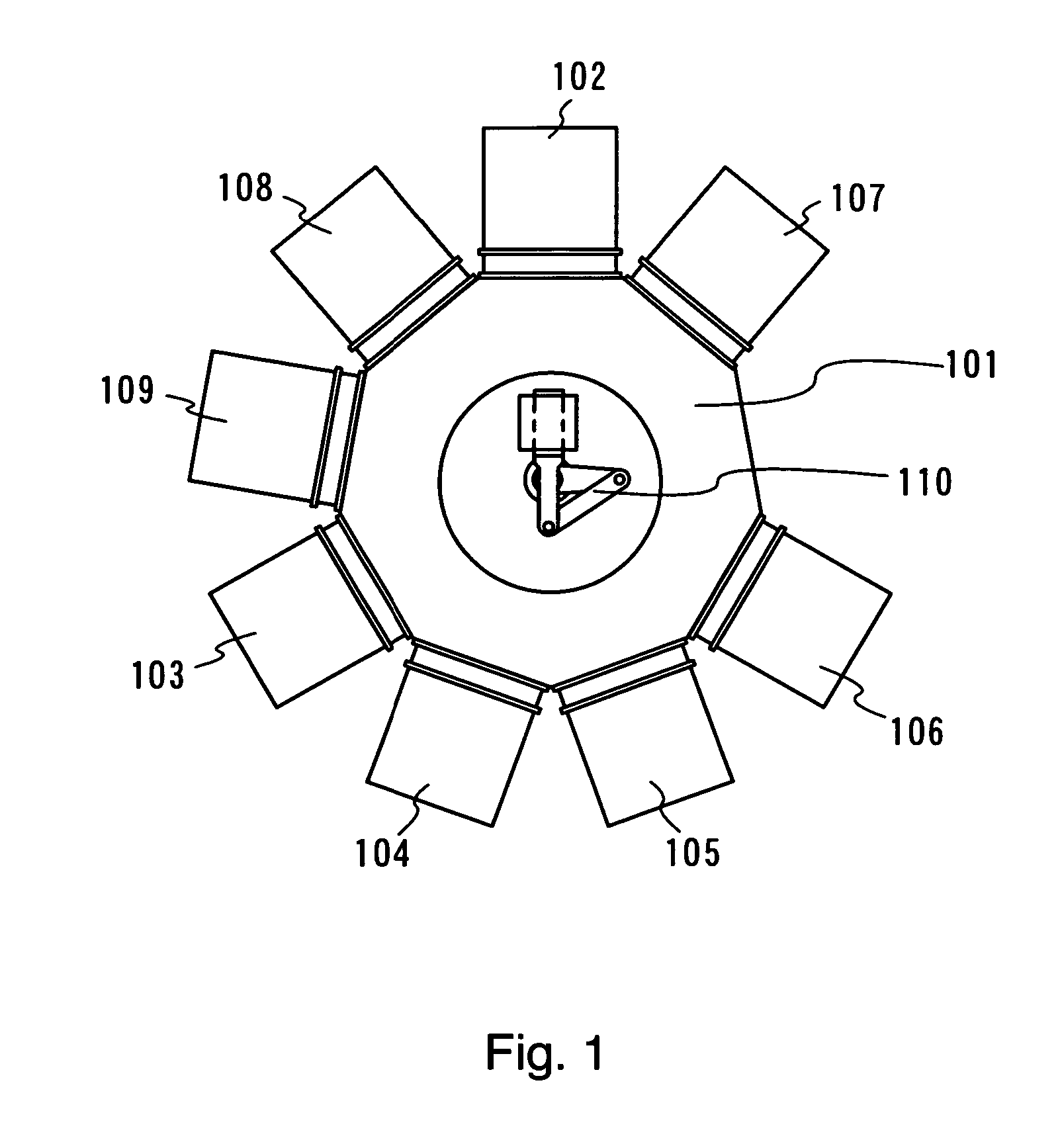

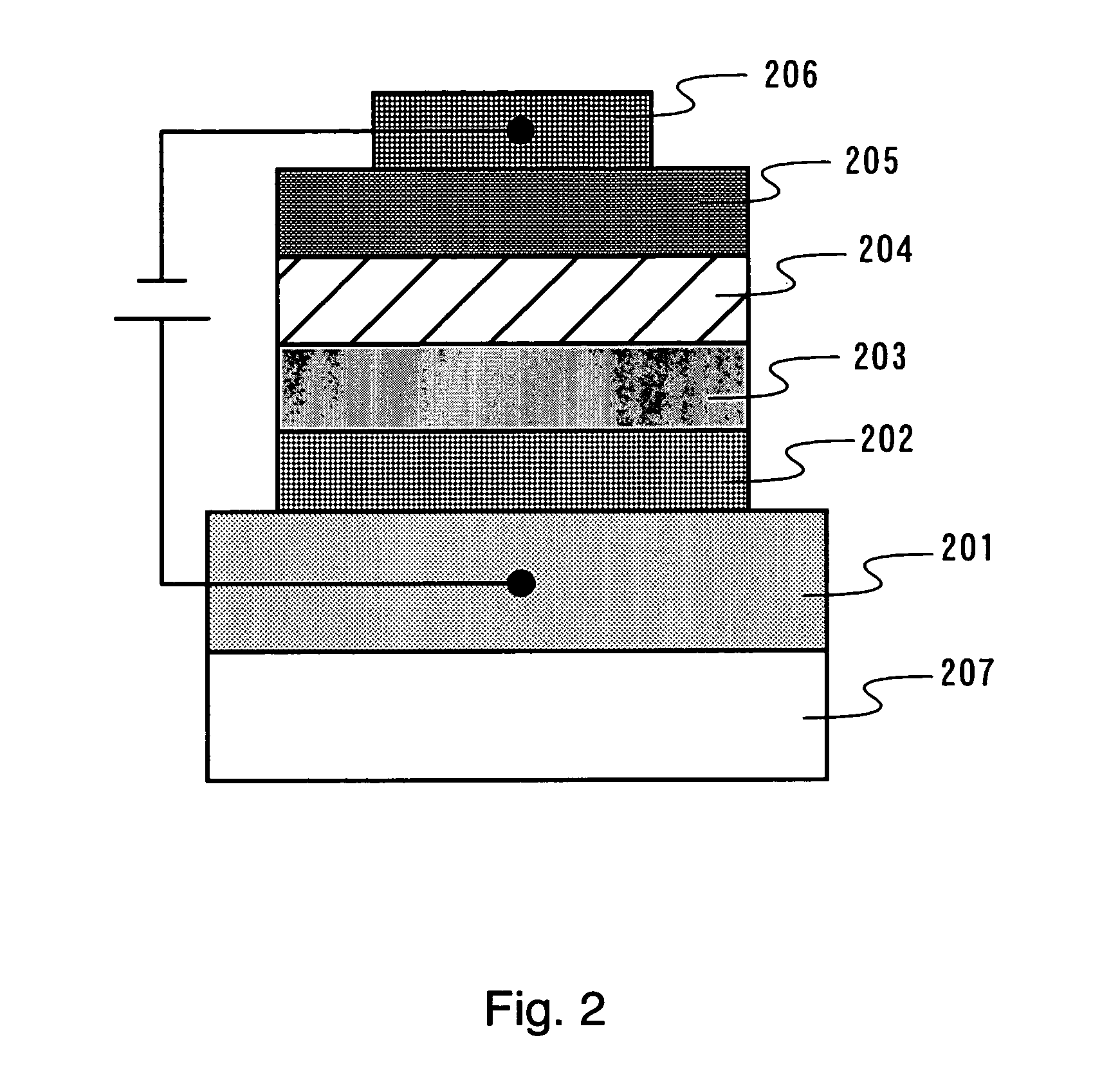

The invention belongs to the technical field of polymer solar cells and particularly relates to a reciprocal form electrode polymer solar cell using TiO2 as an electronic transmission layer, CuPc as a cavity transmission layer and a preparation method thereof. The method includes the steps of: using sol-gel technology to grow a layer of uniform and compact nanocrystal titanium dioxide (TiO2) film on an ITO glass substrate, then spin-coating a layer of P3HT:PCBM solution dissolved by dichlorobenzene, after annealing, using thermal evaporation to grow a layer of CuPc with certain thickness and finally evaporating Au electrode. The polymer solar cell prepared by utilizing the method solves two problems of the traditional polymer solar cell, namely that the mixed solution of 3, 4-EDOT and polystyrolsulfon acid corrode the surface of ITO glass, and the excessive thinness of cathode buffer layer LiF causes the operating process to be difficult to be controlled accurately.

Owner:JILIN UNIV

Aqueous ink, ink-jet recording method, ink cartridge, recording unit and ink jet recording apparatus

InactiveUS7381257B2Improve stabilityImprove color balanceMeasurement apparatus componentsInksBrominePhthalocyanine

An aqueous ink to be used in an ink jet recording containing a green pigment having a copper phthalocyanine skeleton, wherein a proportion of the Kα-line intensity of a chlorine atom to the Kα-line intensity of a bromine atom obtained by subjecting the green pigment to X-ray fluorescence analysis is 3.3 or more to 10.0 or less.

Owner:CANON KK

Ink set for ink-jet recording

ActiveUS7713343B2Uniform processImprove featuresMonoazo dyesDuplicating/marking methodsMagentaPhotochemistry

An ink set for ink-jet recording is formed from a yellow ink in which C. I. Direct Yellow 132 and C. I. Direct Yellow 86 are employed, a magenta ink in which a specific pyrazolylazopyridine-based (or pyrazolylazopyrazine-based) dye and another specific dye are employed, and a cyan ink in which two specific types of copper phthalocyanine-based dyes are employed.

Owner:BROTHER KOGYO KK

Ink Set for Ink-Jet Recording

ActiveUS20070186806A1Excellent ejection stabilityGood storage stabilityMonoazo dyesDuplicating/marking methodsMagentaPhotochemistry

An ink set for ink-jet recording is formed from a yellow ink in which C. I. Direct Yellow 132 and C. I. Direct Yellow 86 are employed, a magenta ink in which a specific pyrazolylazopyridine-based (or pyrazolylazopyrazine-based) dye and another specific dye are employed, and a cyan ink in which two specific types of copper phthalocyanine-based dyes are employed.

Owner:BROTHER KOGYO KK

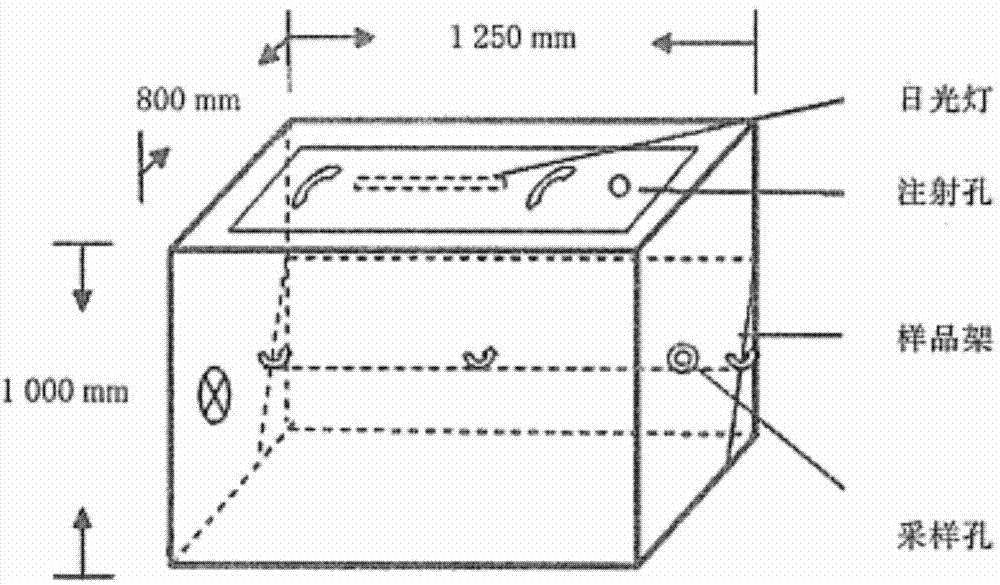

Air purification lacquer and preparation method thereof

The invention relates to an air purification lacquer and a preparation method thereof. The air purification lacquer is prepared by taking a water-based acrylic emulsion as an adhesive, taking 5A molecular sieve powder and an active carbon fiber as adsorbents and microelectrodes, taking nano-titanium dioxide as a photoelectric conversion agent, taking nano silver as a doping agent, taking copper phthalocyanine as a photosensitizer, taking a silane coupling agent and an organic silicon hydrophobing agent as hydrophobic modifying agents, taking quartz sand as an aggregate, taking tourmaline as a negative ion accelerating agent and taking citric acid as a pH value regulating agent. The air purification lacquer disclosed by the invention has similar photosynthetic functions of absorbing harmful substances for 24 hours day and night and decomposing the harmful substances under light irradiation at daytime and similar plant functions of releasing negative ions to air, so that dust is increased in granule diameter due to the effect of electrostatic attraction so as to accelerate sedimentation.

Owner:人民非物质文化传播有限公司

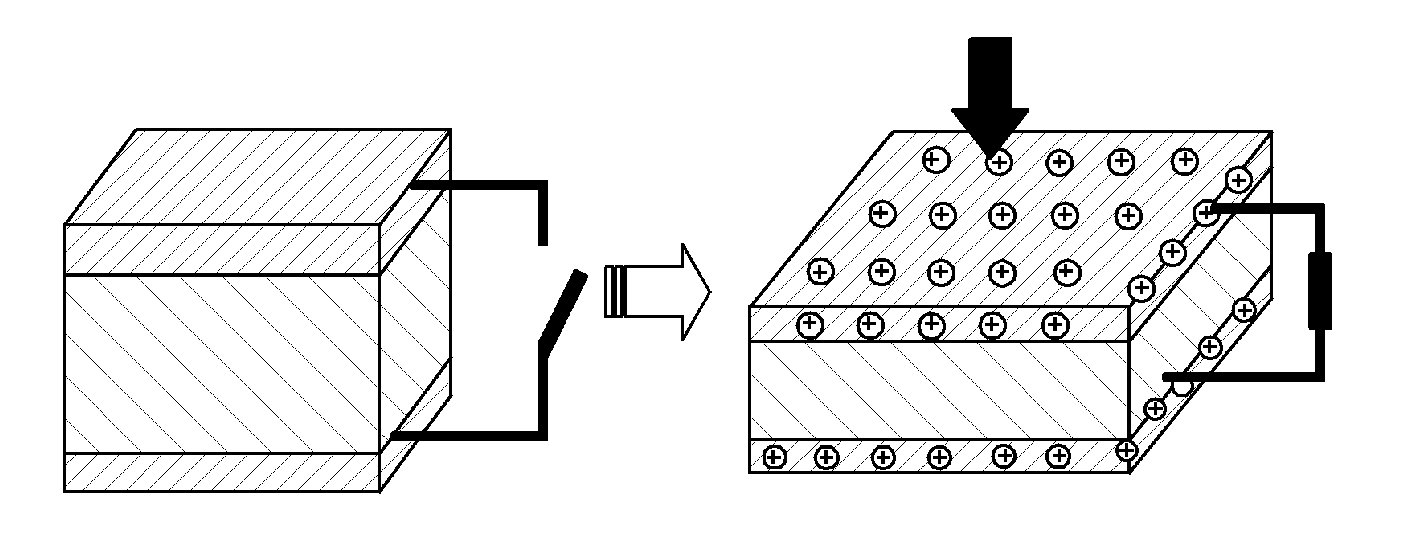

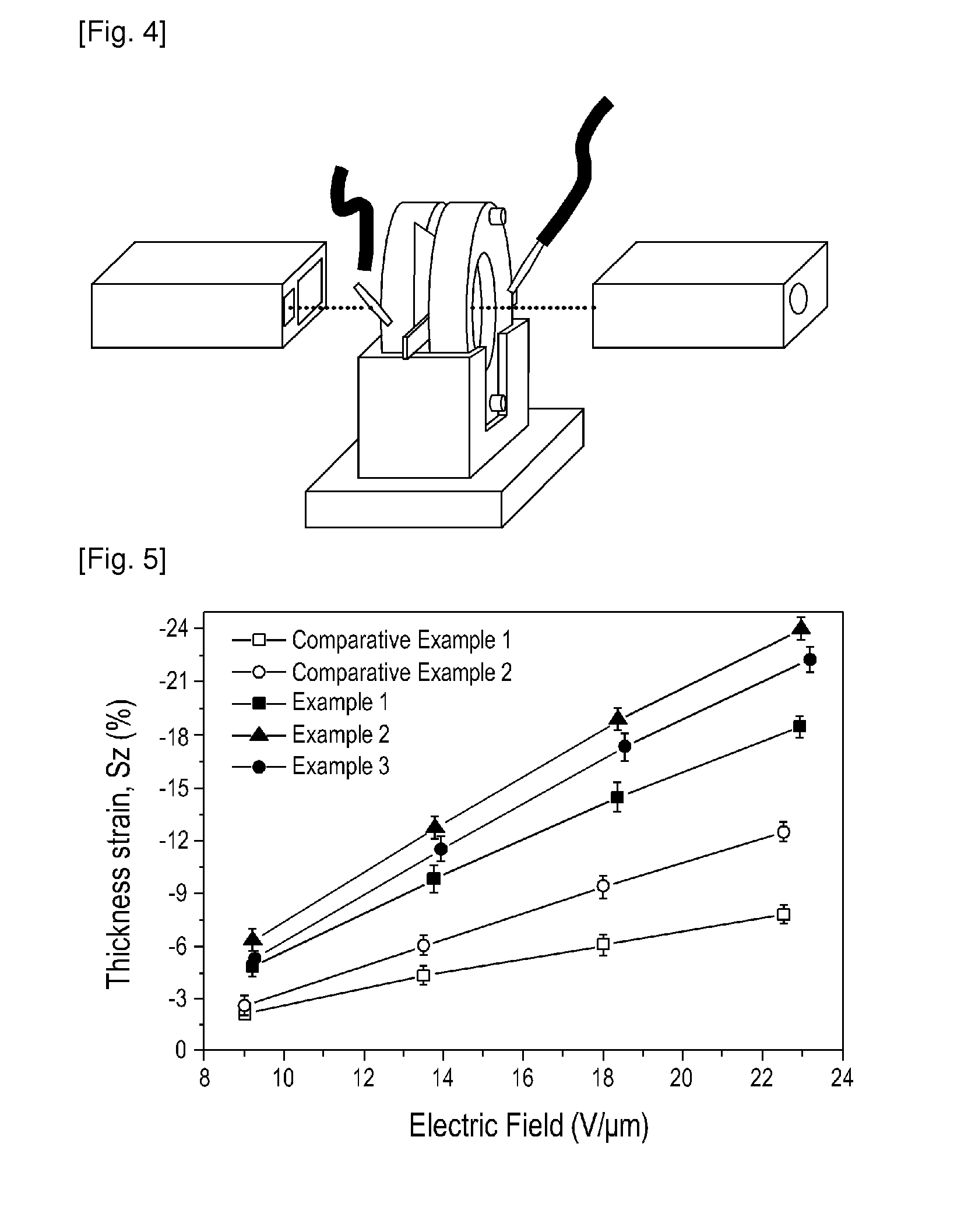

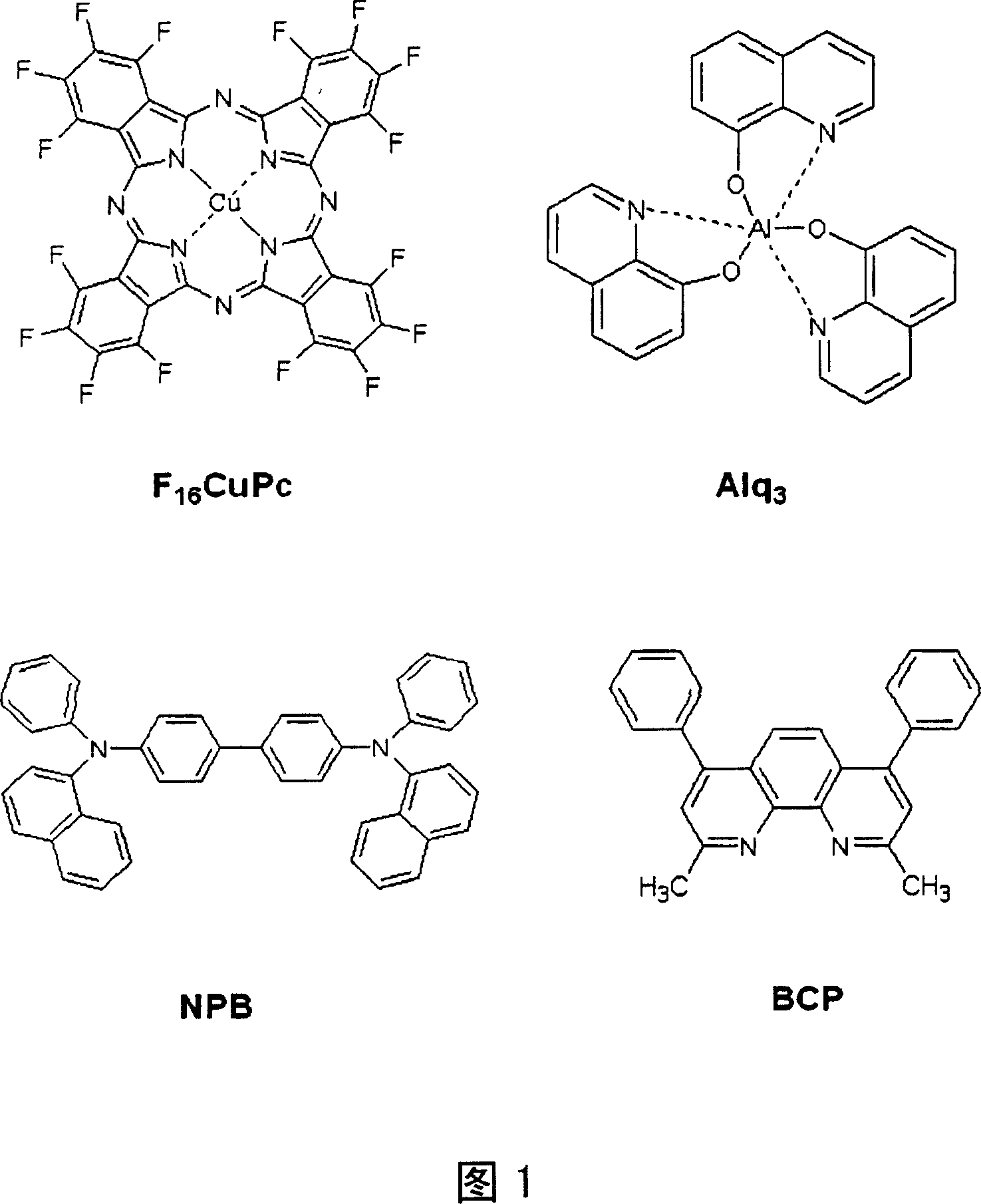

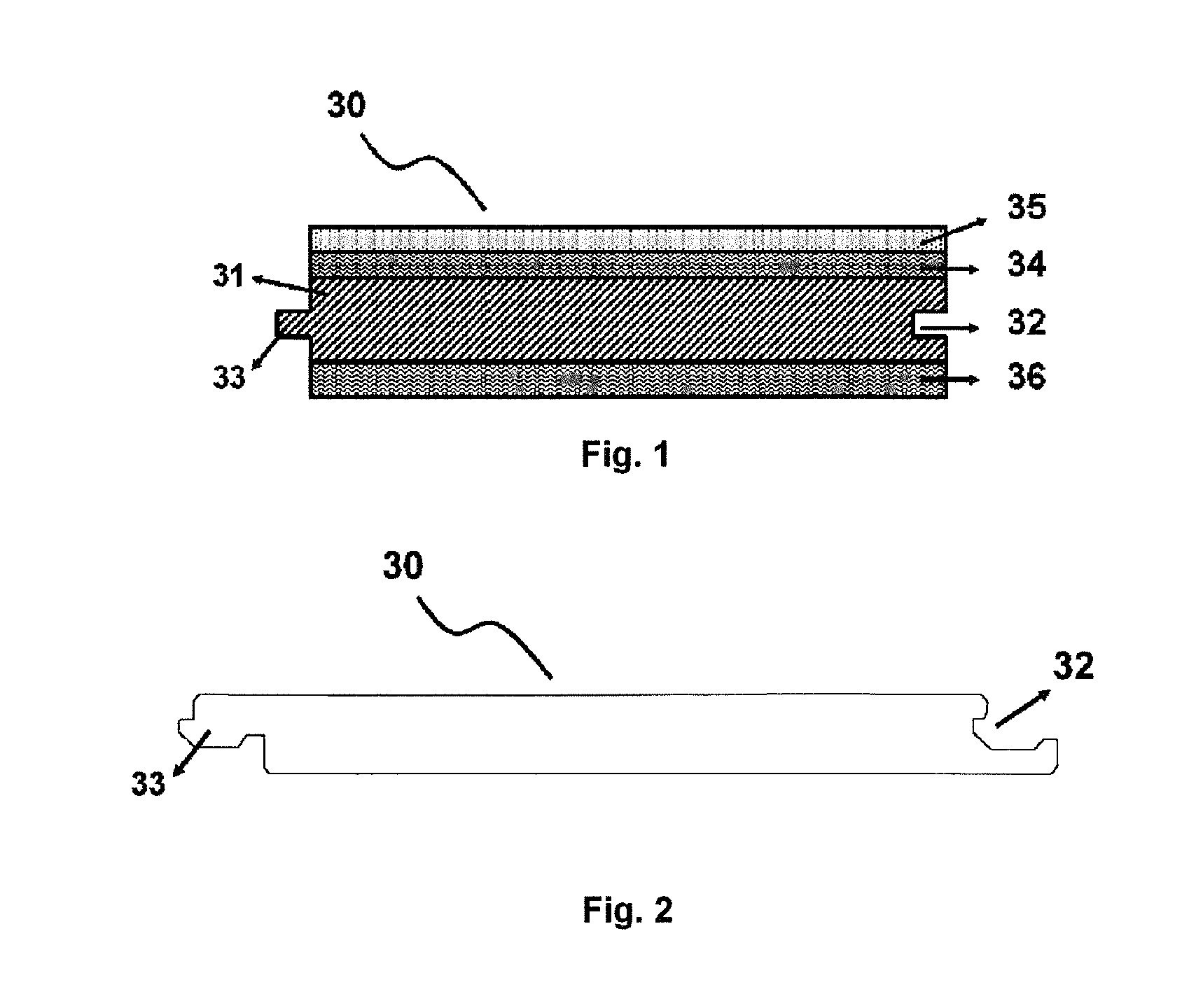

Dielectric elastomer composites and actuators using the same

InactiveUS20130049530A1Improve propertiesEnhancing dispersibility of fillerPiezoelectric/electrostrictive device manufacture/assemblyNanotechnologyPolymer scienceBarium titanate

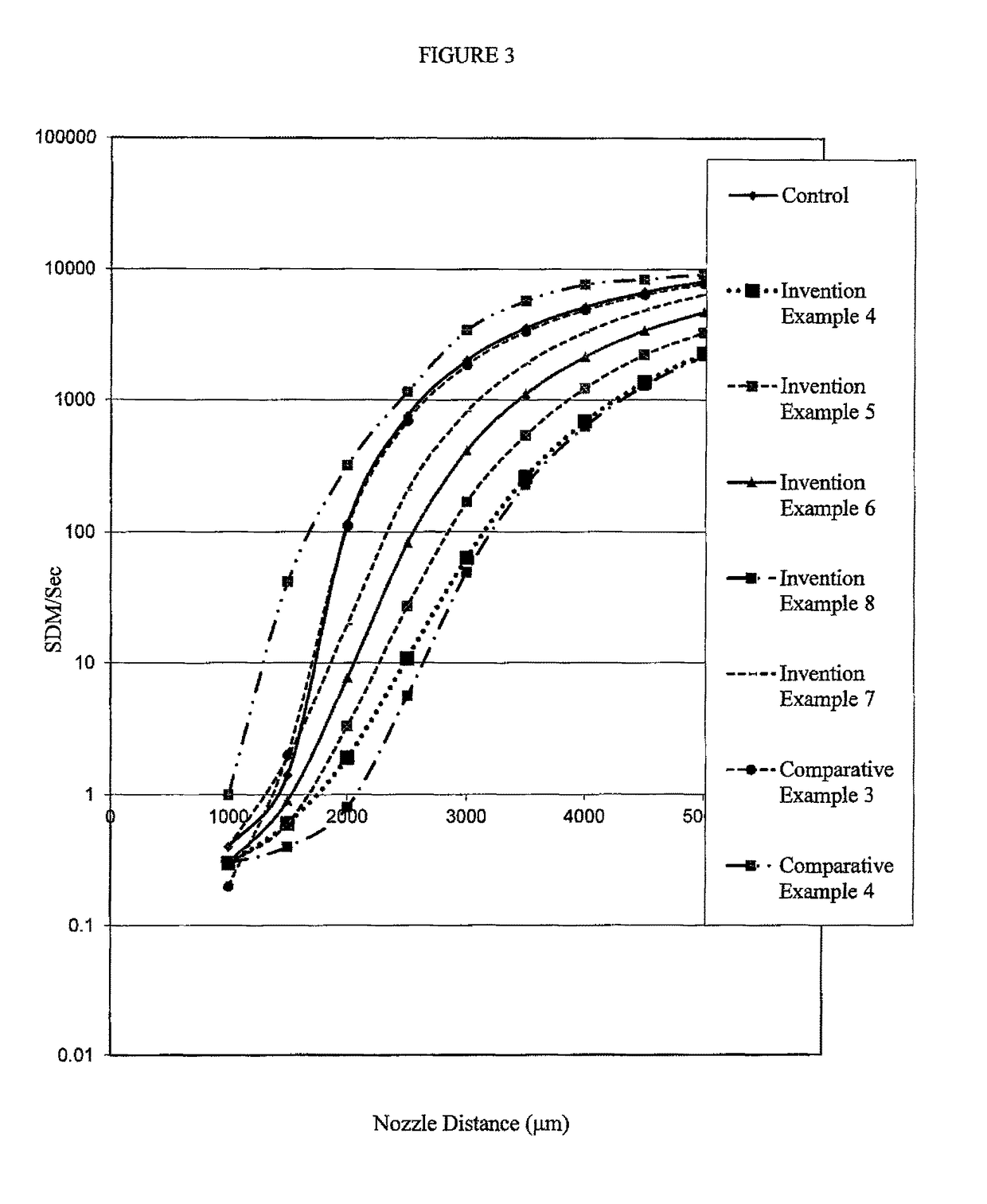

The present invention relates to an actuator which is one of the energy conversion devices, and is characterized by improving the ability to convert electrical energy into mechanical energy by way of using a dielectric elastomer composite comprising a filler with an efficient dispersibility. In case of using a conventional resilient dielectric layer, there was a problem in that the operating voltage is high, while advantageously exhibiting a fast response and a high strain. The present invention can provide dielectric elastomer composite actuators that show excellent electromechanical conversion properties, by adding a dispersing agent such as a pyrene derivative or a polymeric compound having an amine end group when preparing the composite wherein carbon-based conductive fillers such as carbon blacks, single-walled carbon nanotubes (SWCNTs), double-walled carbon nanotubes (DWCNTs), multi-walled carbon nanotubes (MWCNTs) and graphenes, or high dielectric fillers such as copper phthalo-cyanine (CuPc), MOFs (metal organic frameworks) and barium titanate (BaTiO3) are comprised in a thermoplastic resilient dielectric layer to enhance the dispersibility of the fillers.

Owner:KOREA INST OF SCI & TECH

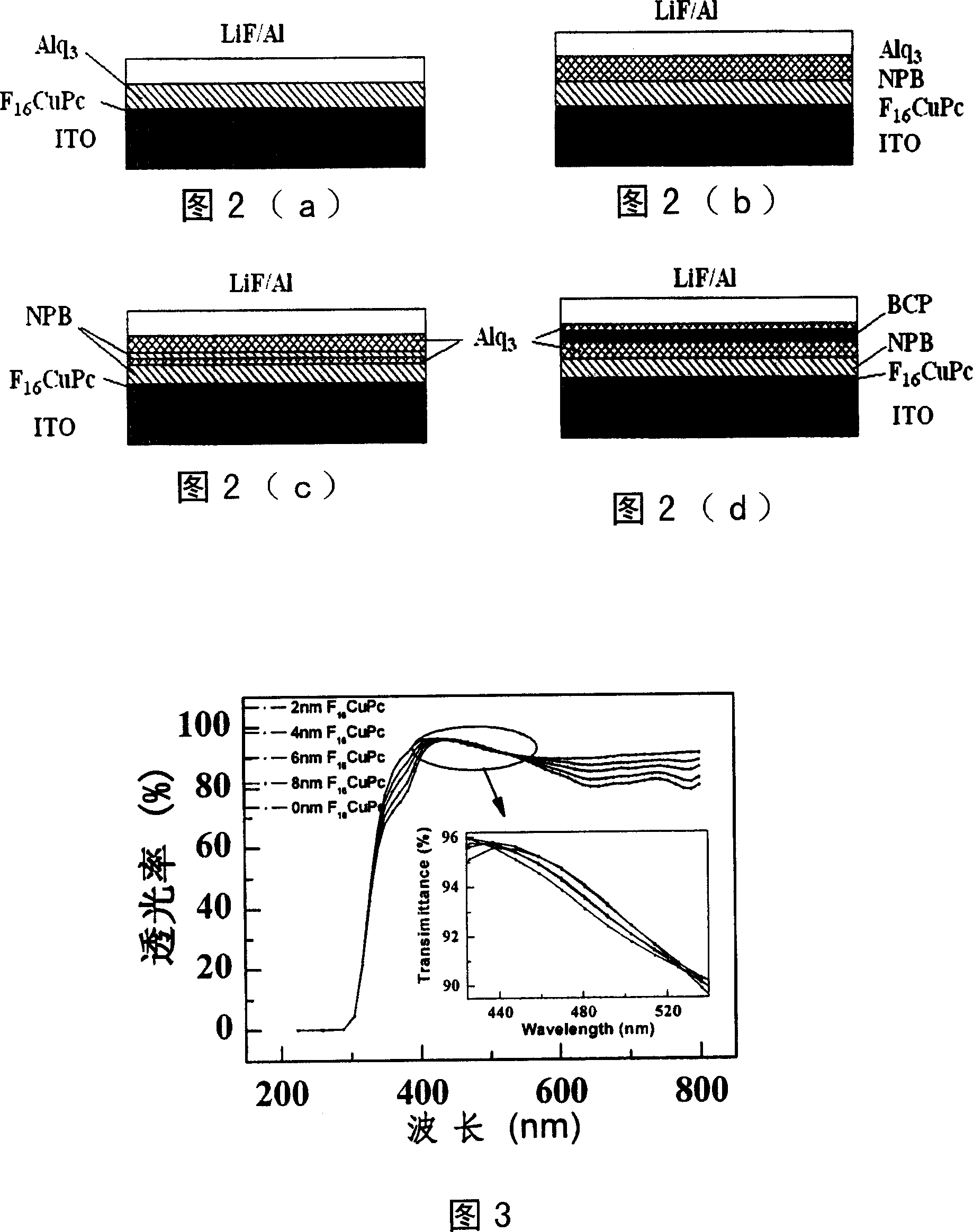

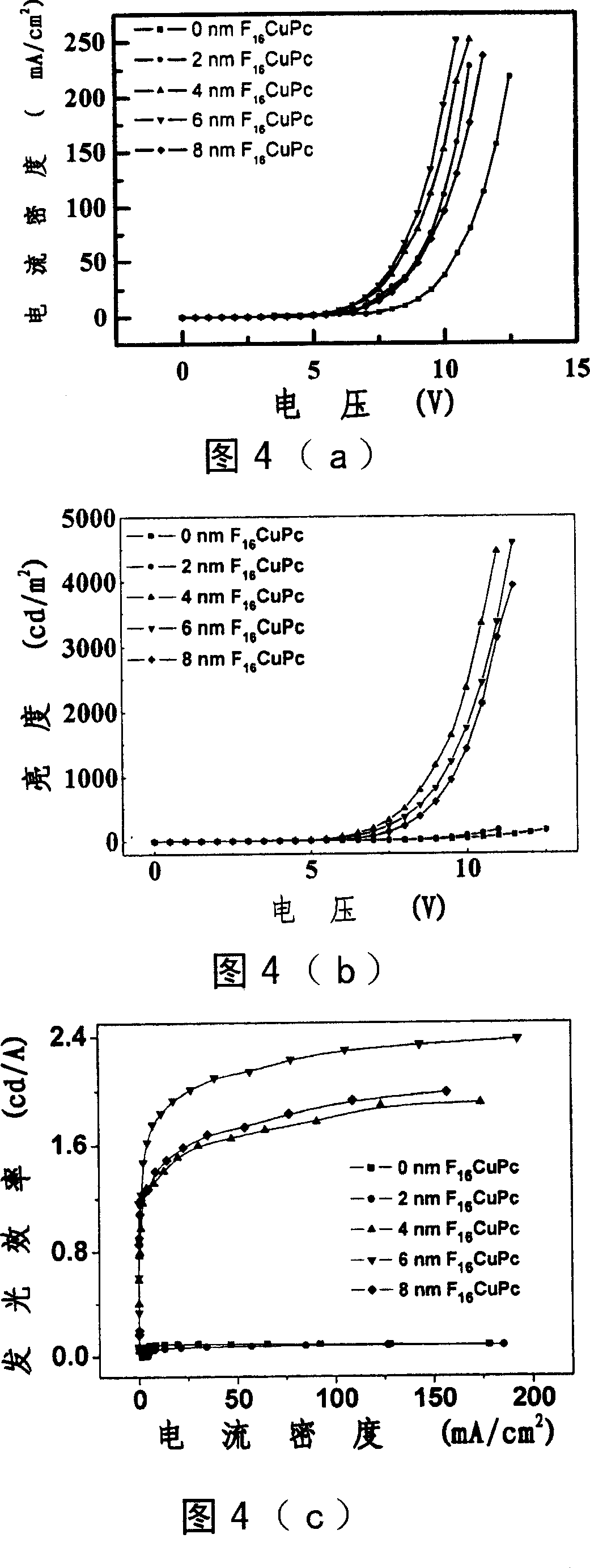

Organic LED based on anode modification

InactiveCN1983664ALower turn-on voltageImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmGreen-light

The invention is concerned with the organic light emitter diode based on anode decoration, it is: deposits forced electronic molecular layer formed by hexadeca fluoro copper phthalocyanine on the indium tin oxide anode of the organic light emitter diode in order to forming the full dipole layer, constructs each function layer of the organic light emitter diode respectively on the forced electronic molecular layer, at least one of the function layer is with organic film and cathode. The invention is low cast, high light effect and lower operating voltage. The invention is also concerned with the decoration method of the organic light emitter diode based on anode decoration, that is simple operation, can use for several parts structure and with high light-admitting quality especially for blue and green light.

Owner:INST OF CHEM CHINESE ACAD OF SCI

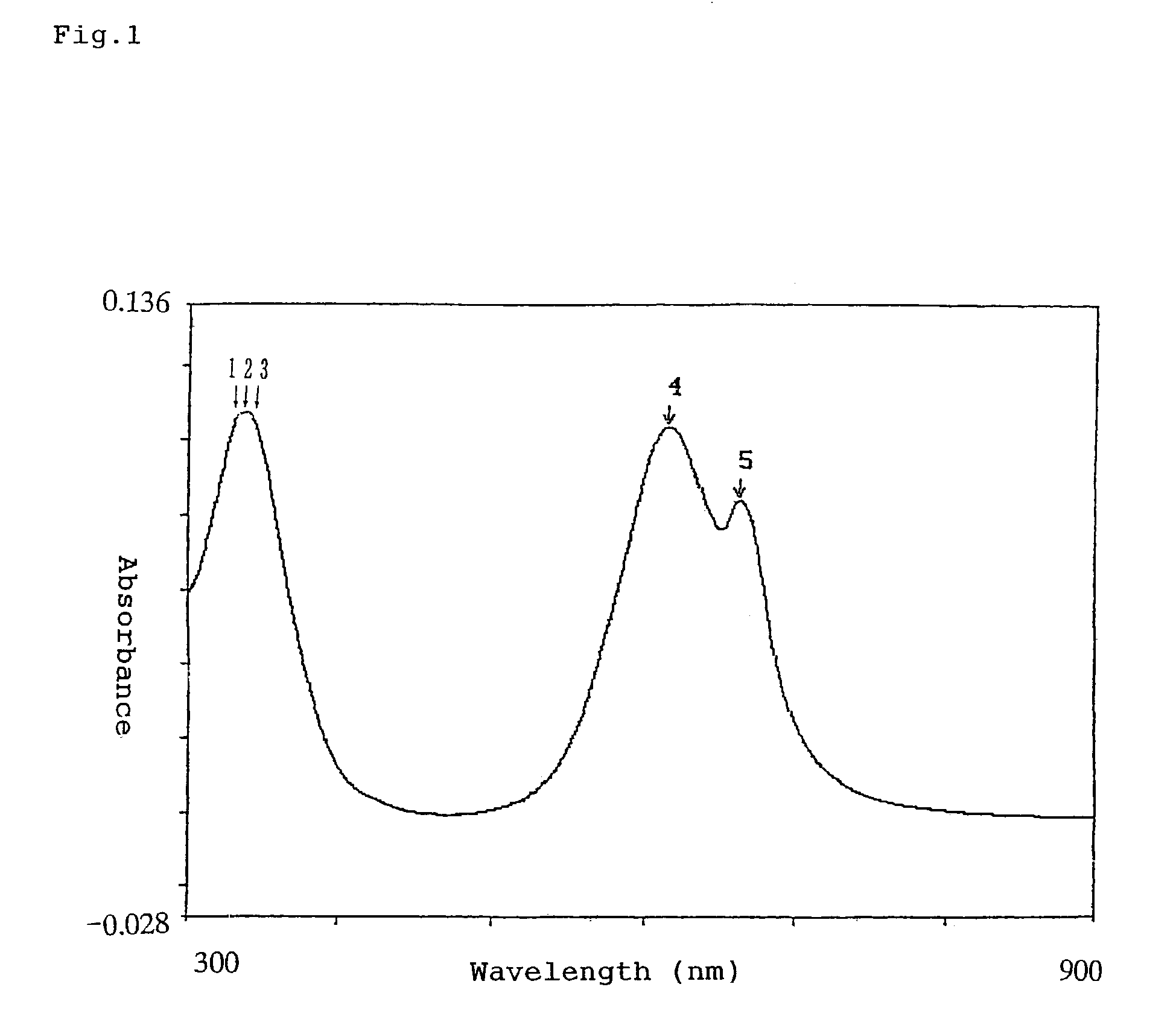

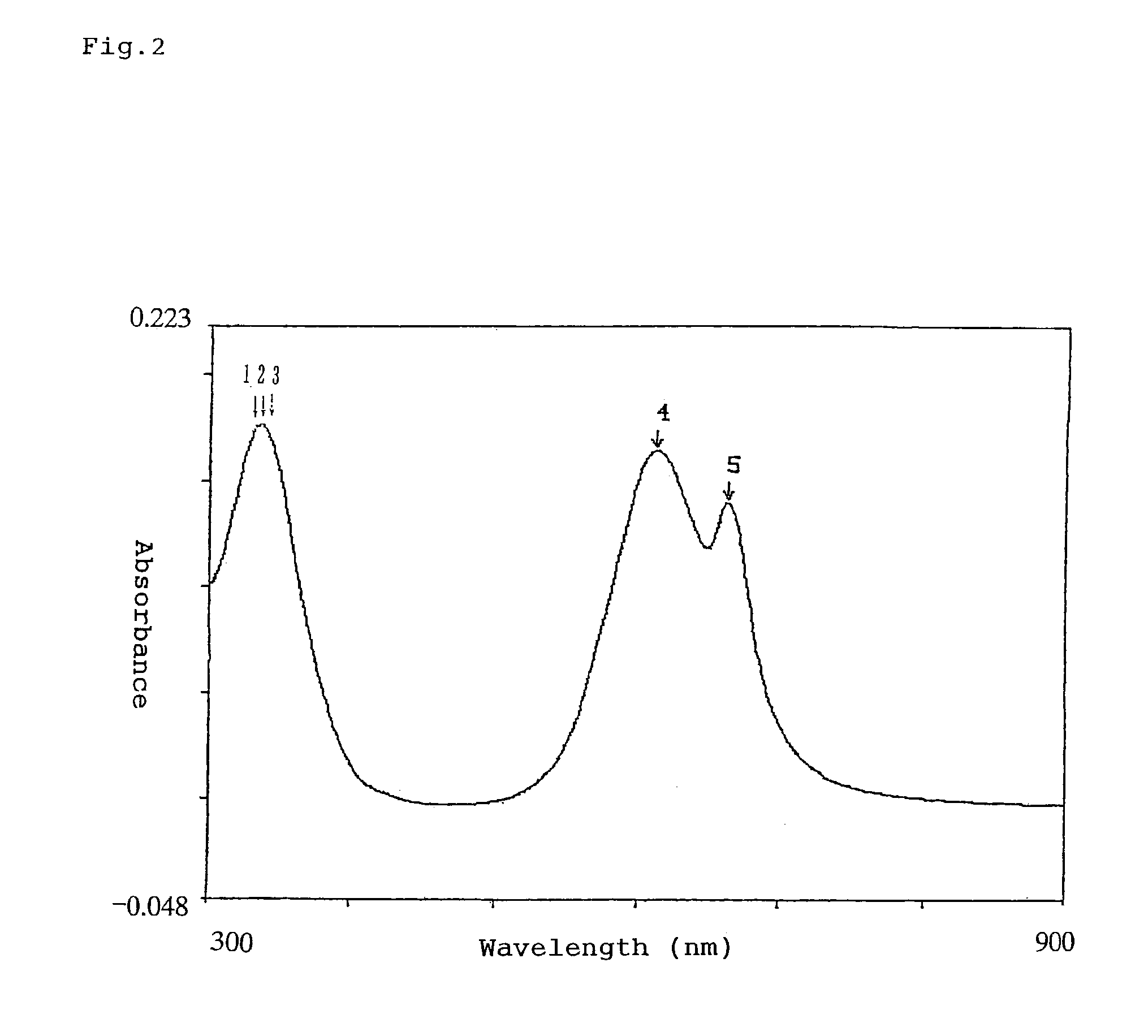

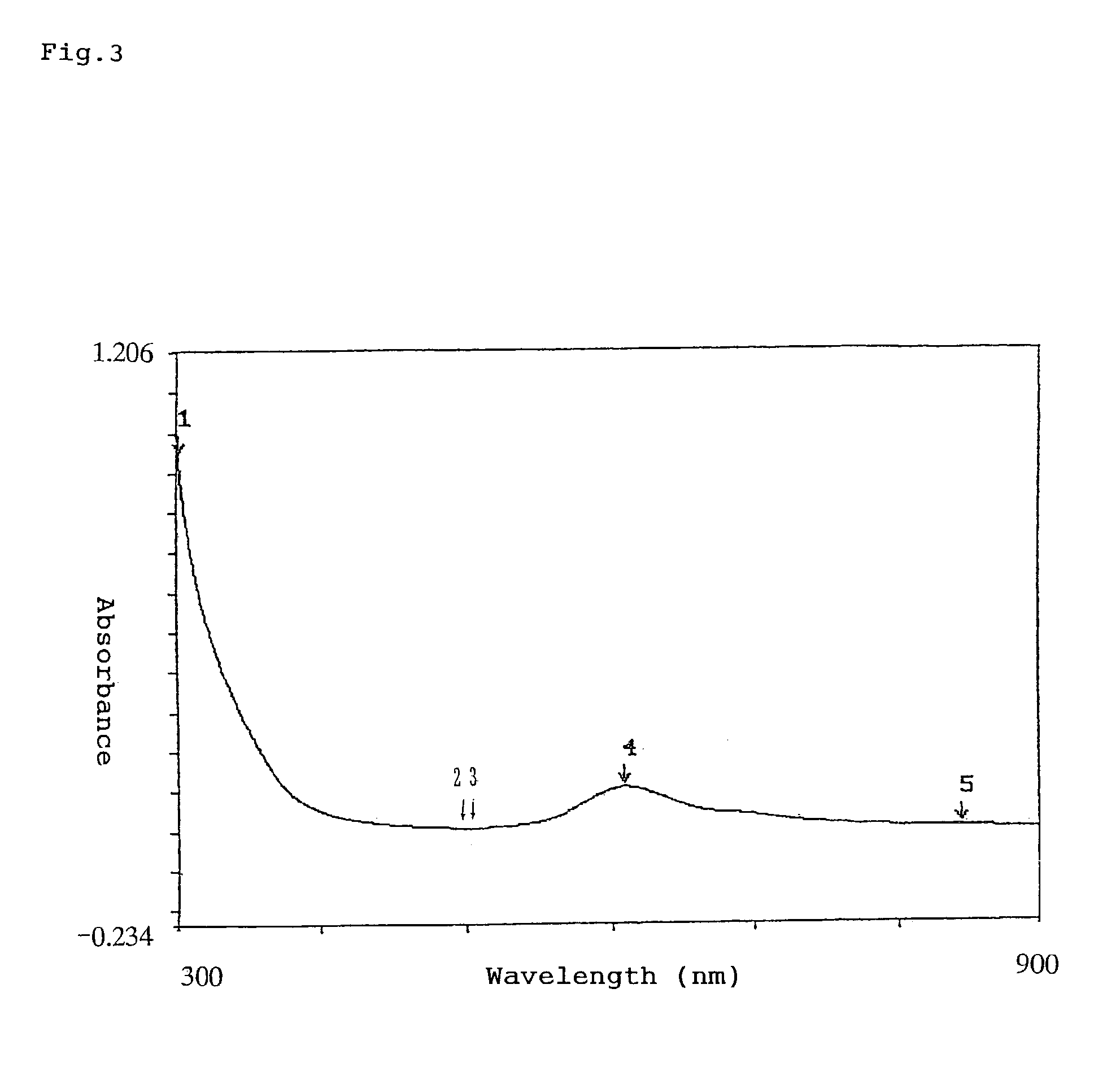

Methods for preparing curable pigment inkjet ink sets

A curable pigment inkjet ink set includes mprg a cyan inkjet ink, a yellow inkjet ink, and a magenta inkjet ink, whereinthe yellow inkjet ink having ABS(Y)500-530<5 and ABS(Y)400-500>60 includes one or more yellow pigments;the cyan inkjet ink includes one or more β-copper phthalocyanine pigments; andthe magenta inkjet ink contains a mixed crystal including a first quinacridone and a second quinacridone in a ratio of the first quinacridone over the second quinacridone such that ABS(M)500-530>20 and ABS(M)500-600>60,ABS(Y)500-530 represents the absorbance of the yellow inkjet ink between 500 and 530 nm in a normalized absorption spectrum of the yellow ink;ABS(M)500-530 represents the absorbance of the magenta inkjet ink between 500 and 530 nm in a normalized absorption spectrum of the magenta ink;ABS(Y)400-500 represents the absorbance of the yellow inkjet ink between 400 and 500 nm in a normalized absorption spectrum of the yellow ink; andABS(M)500-600 represents the absorbance of the magenta inkjet ink between 500 and 600 nm in a normalized absorption spectrum of the magenta ink,wherein ABS(X)WL1-WL2 represents the peak area between the wavelengths WL1 and WL2 calculated by summation of the normalized absorbance values in the range WL1 to WL2 which are obtained by multiplying the absorbance values at each wavelength in the range from 380 to 850 nm by the reciprocal value of the maximum absorbance Amax in the range of 380 to 850 nm using a spectrophotometer with an interval of 1 nm on the ink X diluted in ethyl acetate to a pigment concentration of 40 ppm.

Owner:AGFA NV

Ink jet recording ink, ink jet recording method, ink cartridge, and ink jet recording apparatus

InactiveUS20060011097A1Good weather resistanceExcellent ejection stabilityMonoazo dyesMeasurement apparatus componentsPolymer chemistryCopper phthalocyanine

An ink jet recording ink comprising at least a copper phthalocyanine dye represented by the following general formula (1) and a compound represented by the following general formula (2):

Owner:CANON KK

Cyan ink for ink-jet recording

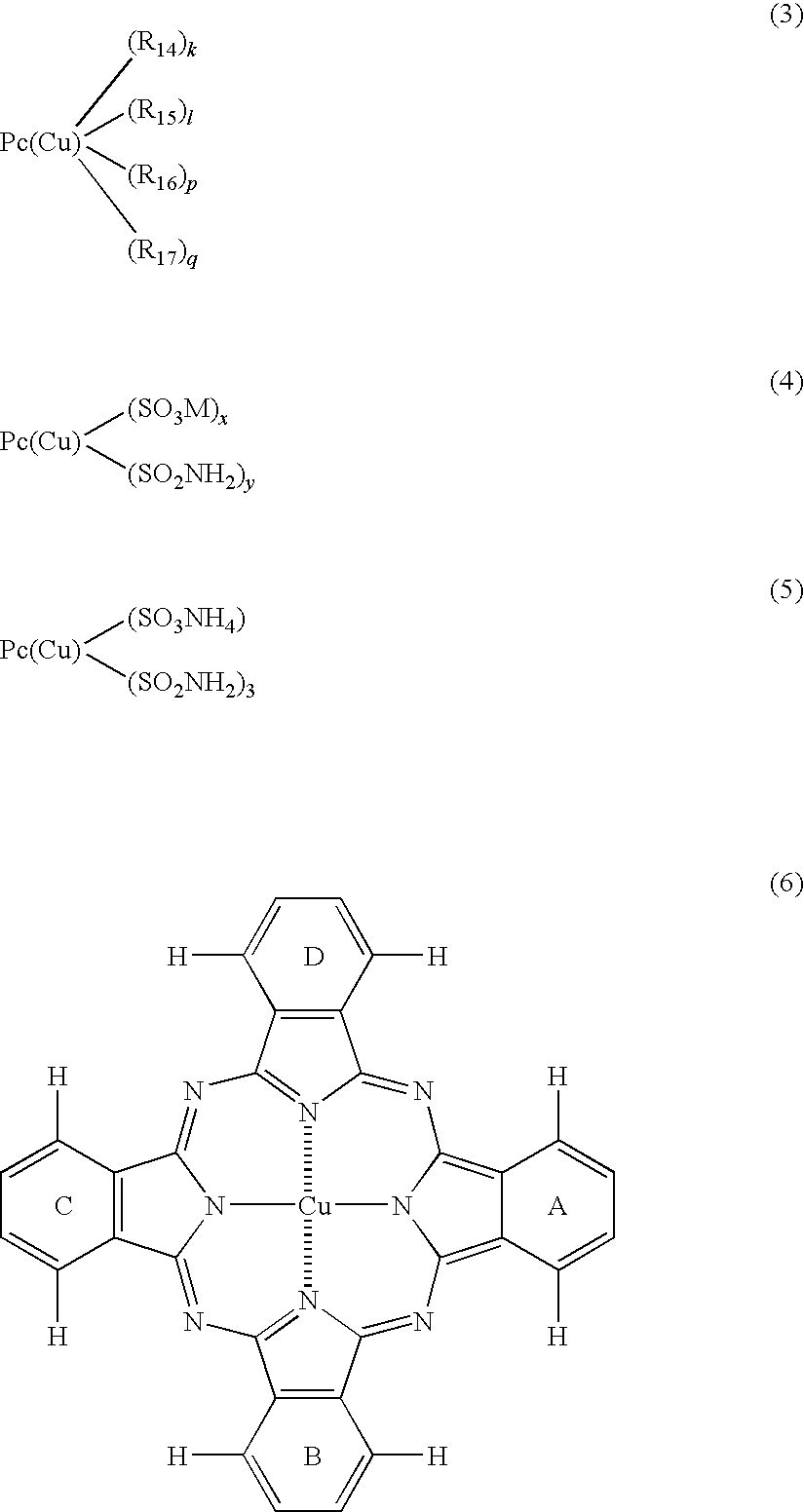

A cyan ink for ink-jet recording contains a coloring agent, water and a water soluble organic solvent. Different types of dyes are employed as the coloring agent. In particular, a dye represented by the general formula (1) is used together with at least one dye selected from the group consisting of a dye represented by the general formula (2), a dye represented by the general formula (3) and C. I. Direct Blue 86. In the formulas, Pc(Cu) is a copper phthalocyanine nucleus.

Owner:BROTHER KOGYO KK

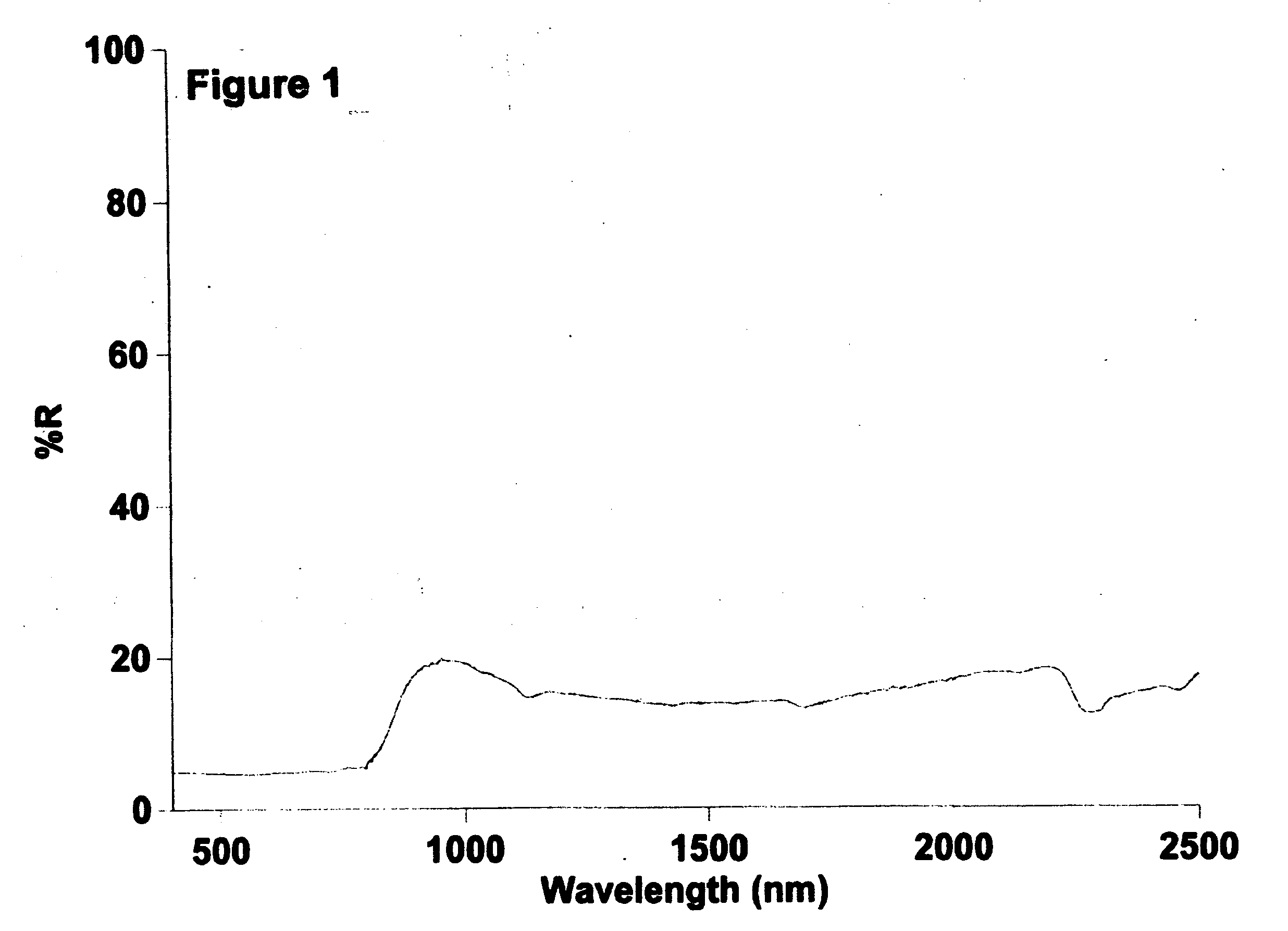

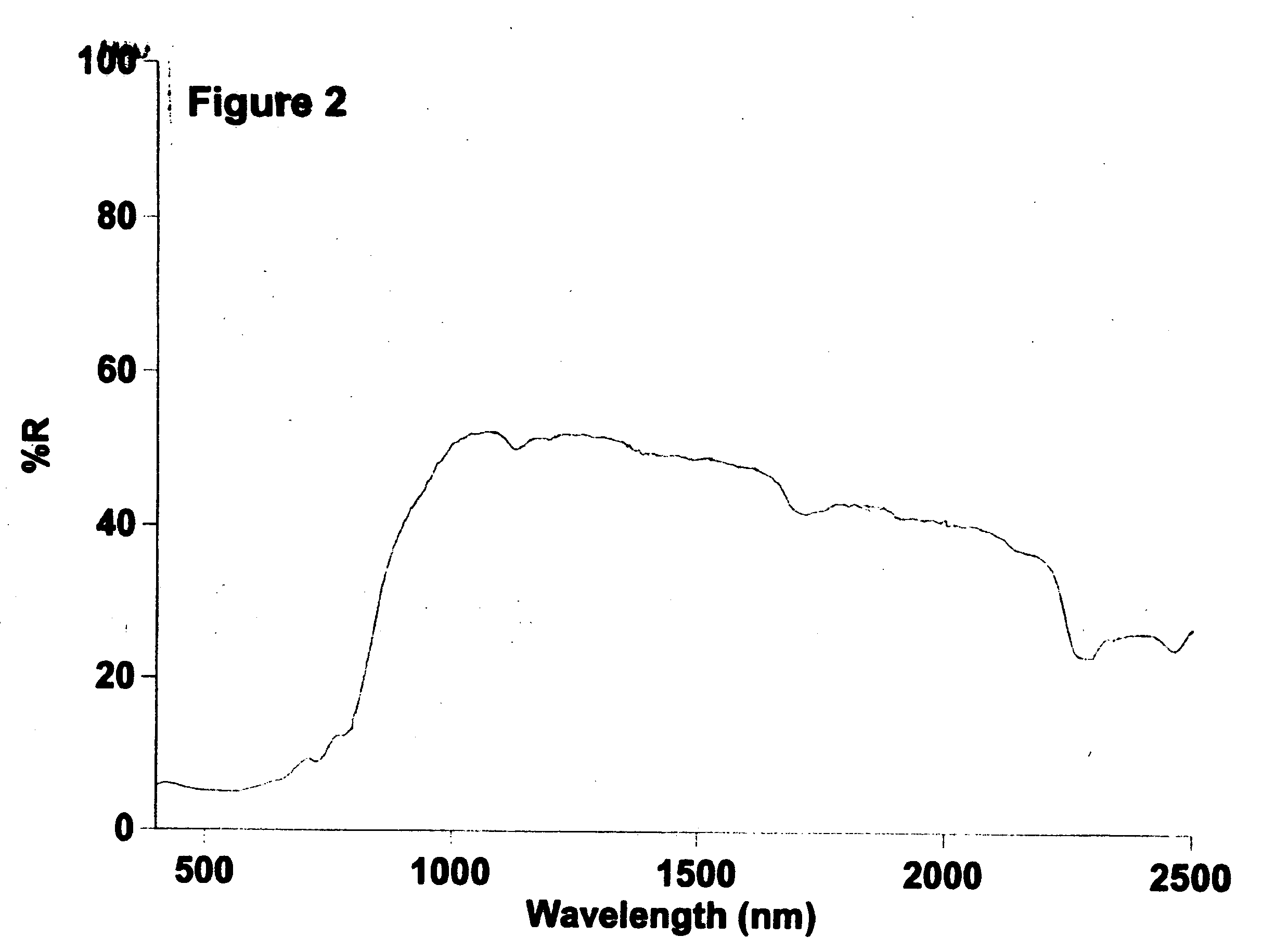

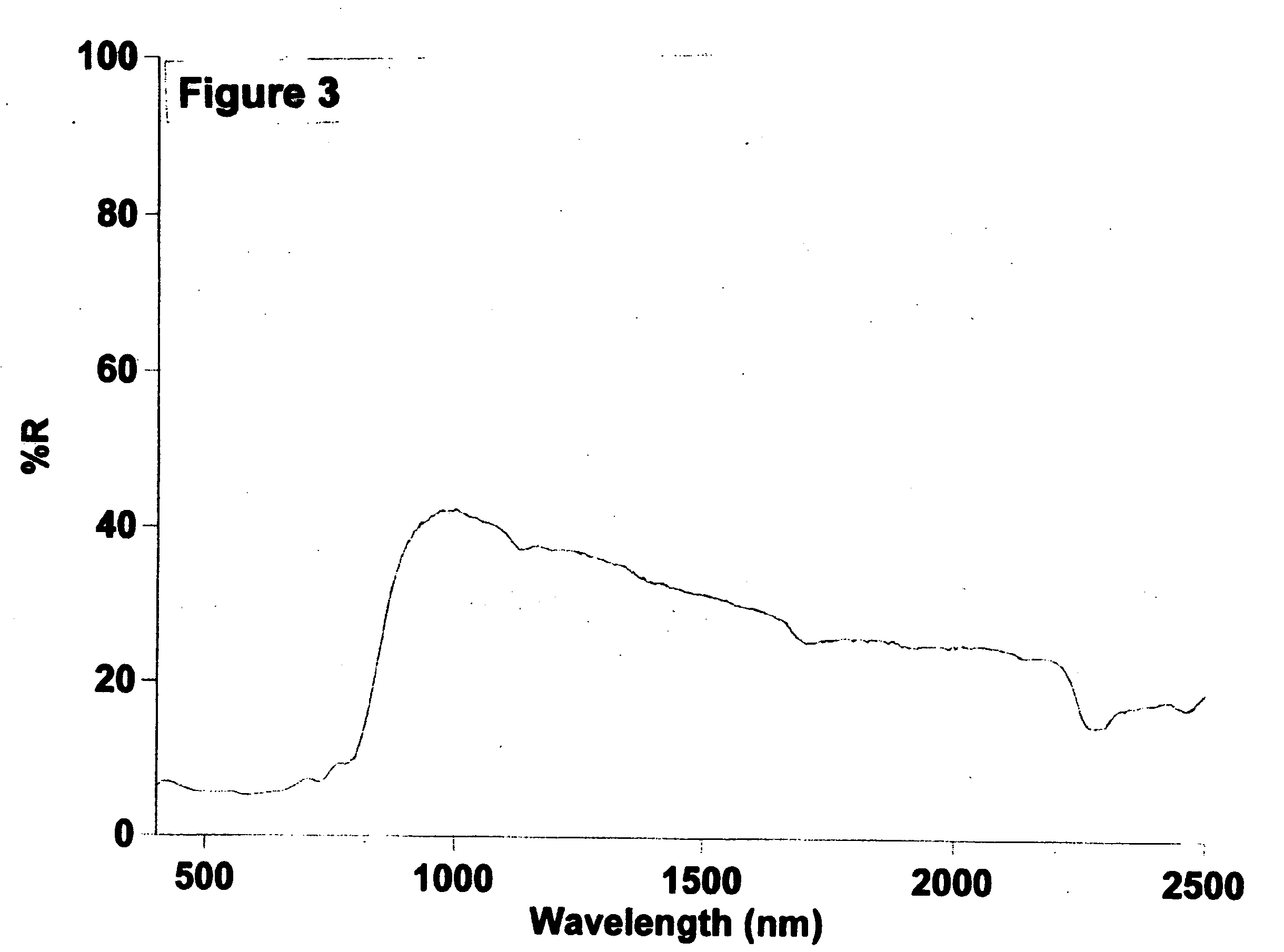

IR reflective pigment compositions

The present invention relates to IR reflective black pigment compositions comprising a halogenated copper phthalocyanine such as C.I. Pigment Green 7 and a perylenetetracarboxylic acid diimide such as C.I. Pigment Violet 29. The compositions are characterized by an IR reflection spectrum with a positive slope in the wavelength range between 800 and 900 nm when incorporated as coloring agents in coatings or plastics. The inventive IR reflective black pigment compositions are useful for coloring high molecular weight materials like coatings, inks and plastics.

Owner:CIBA SPECIALTY CHEM CORP

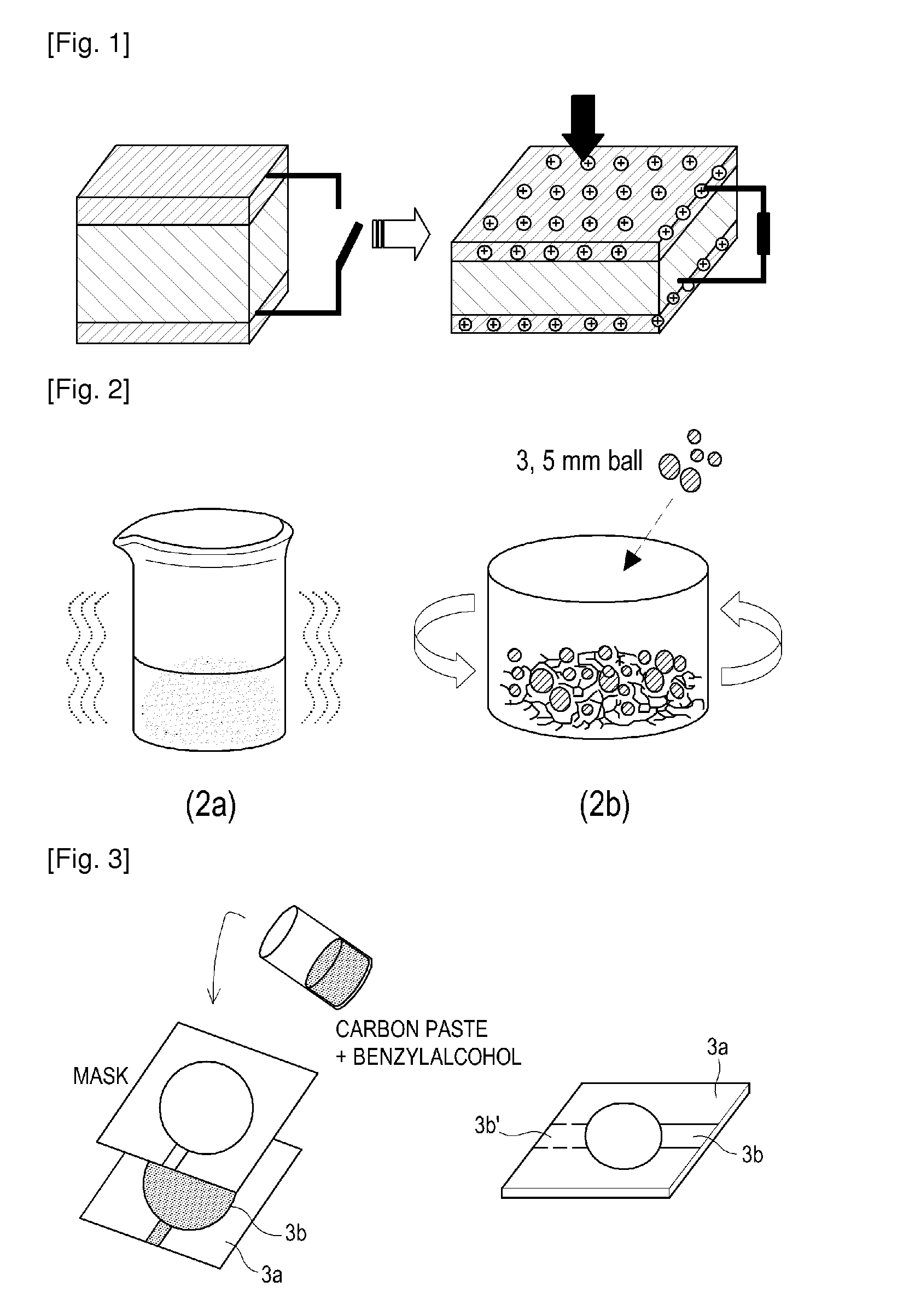

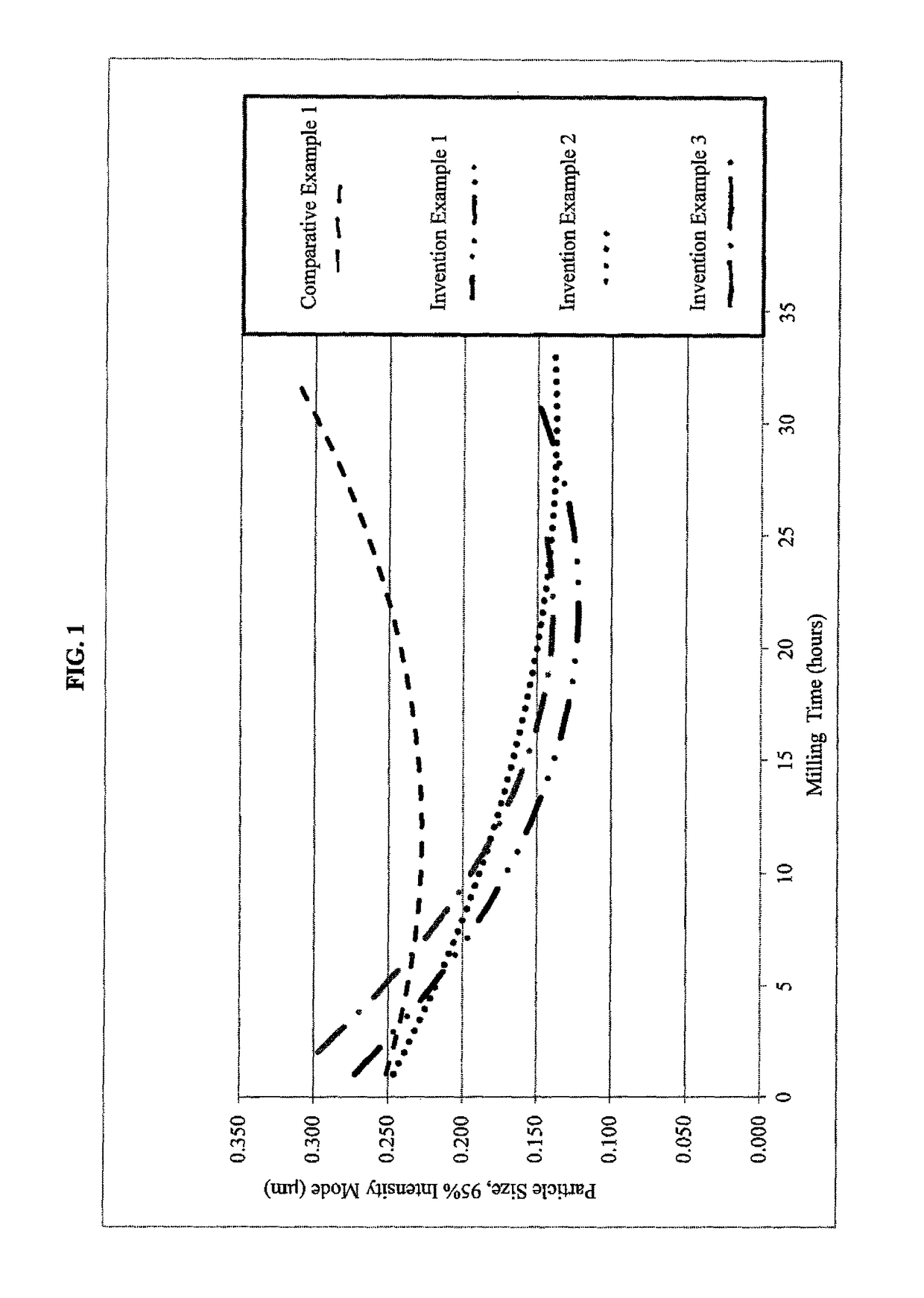

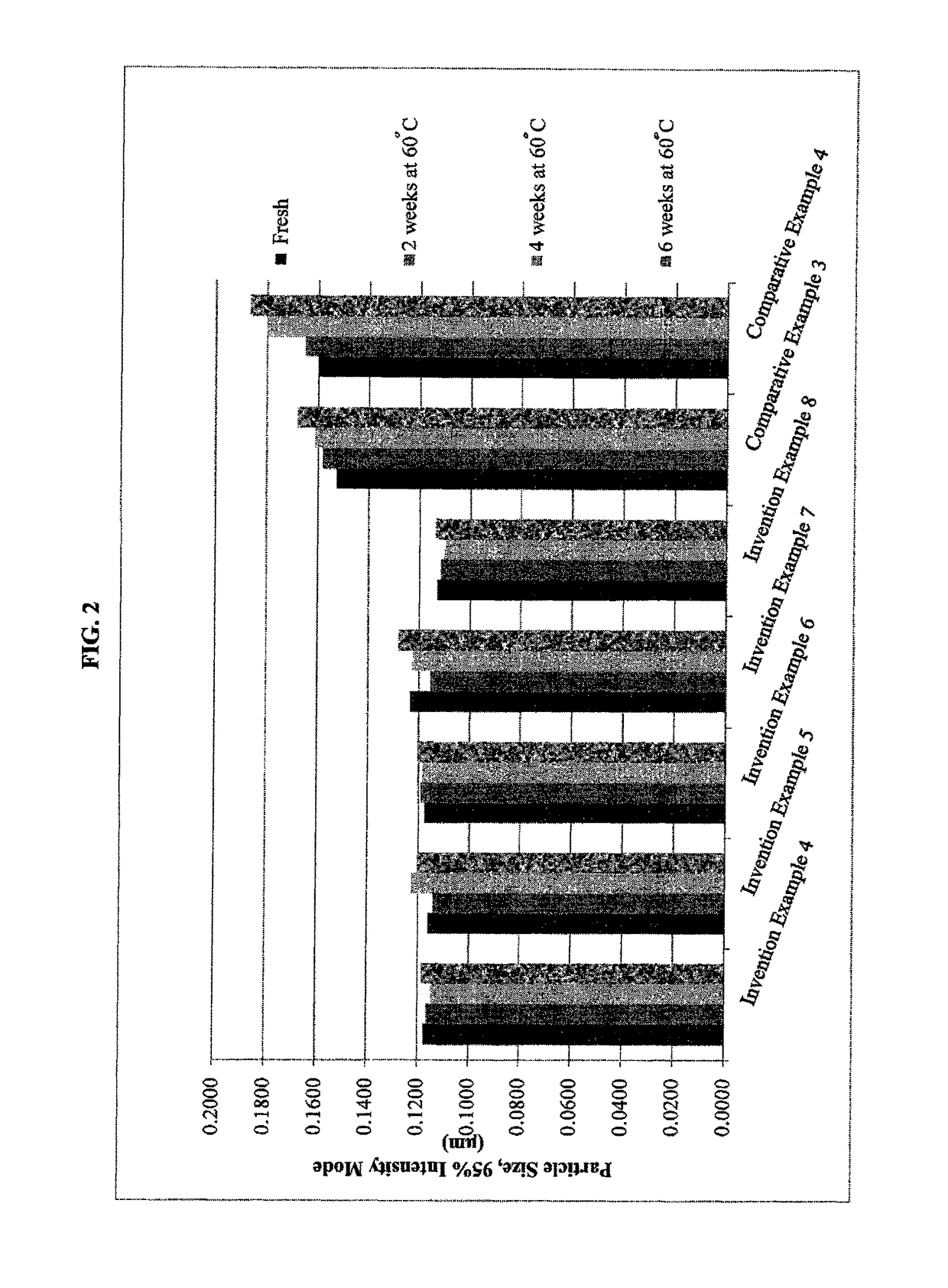

Method of producing an ink composition for offset printing

InactiveUS20120238675A1High tinting strengthExcellent color brightnessOrganic dyesPetroleum resinCopper

The present invention provides a method of producing an ink composition for offset printing with use of a crude copper phthalocyanine pigment and / or an active crude copper phthalocyanine pigment and without use of a pigment dispersion resin that requires additional cost, to produce an ink composition which provides a highly tinted and bright image. The method includes the steps of: premixing a premix component through stirring so as to obtain a pigment mixture, the premix component containing a crude copper phthalocyanine pigment and / or an active crude copper phthalocyanine pigment, at least one binder resin selected from the group consisting of a rosin-modified phenolic resin, a rosin-modified maleic acid resin, a petroleum resin, and an alkyd resin, and an oil component; grinding and milling the pigment mixture obtained by the premixing, using a bead mill with grinding media of beads each having a size of 0.1 mm or larger and smaller than 1.5 mm, at a temperature within the range of 0° to 180° C., thereby obtaining a pigment dispersion; and further adding the binder resin and / or the oil component to the pigment dispersion and stirring the resulting dispersion, wherein the method satisfies the conditions that (1) the pigment mixture contains 5 to 40% by mass of the crude copper phthalocyanine pigment and / or the active crude copper phthalocyanine pigment, (2) the pigment mixture contains 5 to 500 parts by mass of the binder resin, for each 100 parts by mass of the crude copper phthalocyanine pigment and / or the active crude copper phthalocyanine pigment, and (3) the pigment mixture has a viscosity of 0.001 to 20 Pa·s at the temperature of the grinding and milling.

Owner:SAKATA INX +1

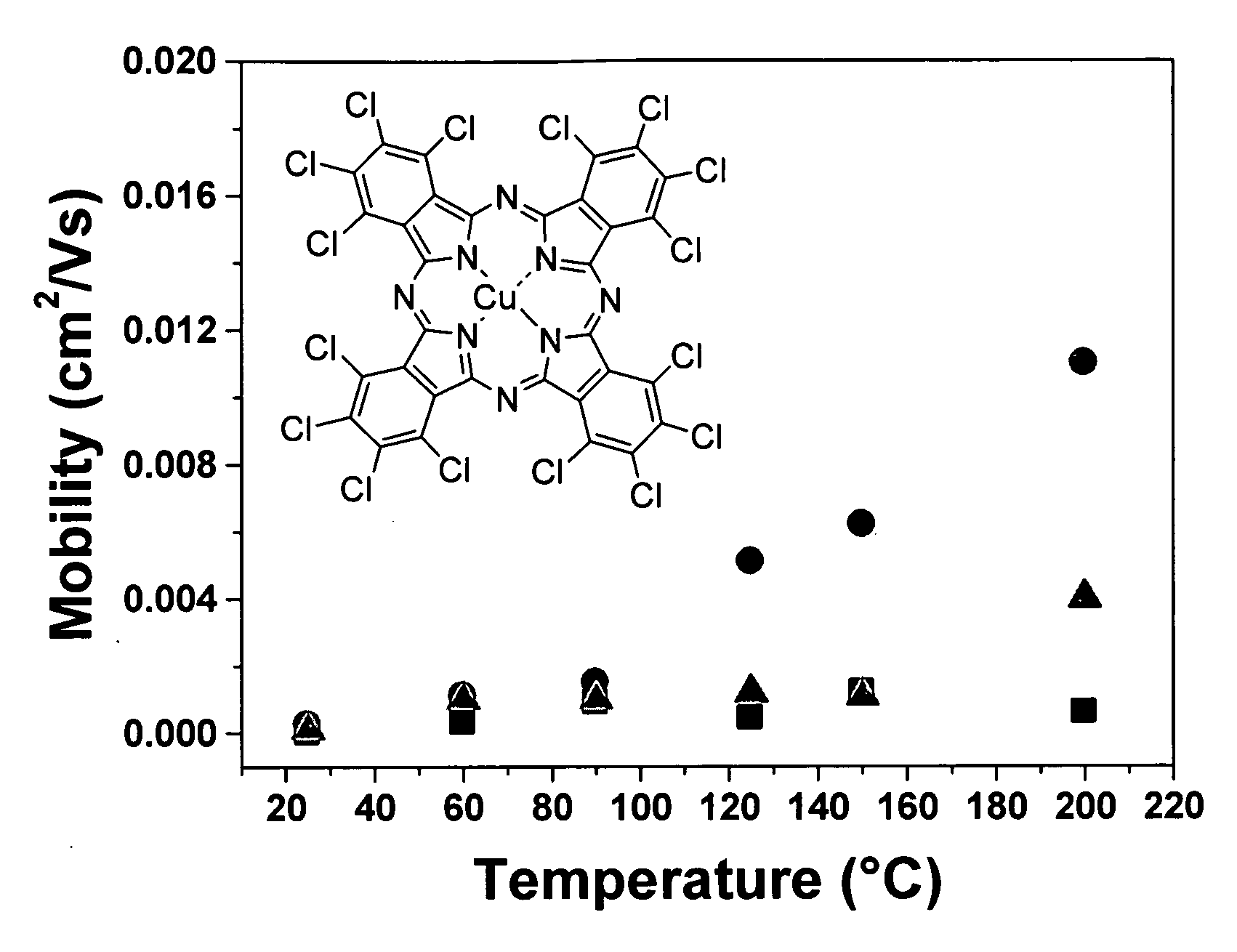

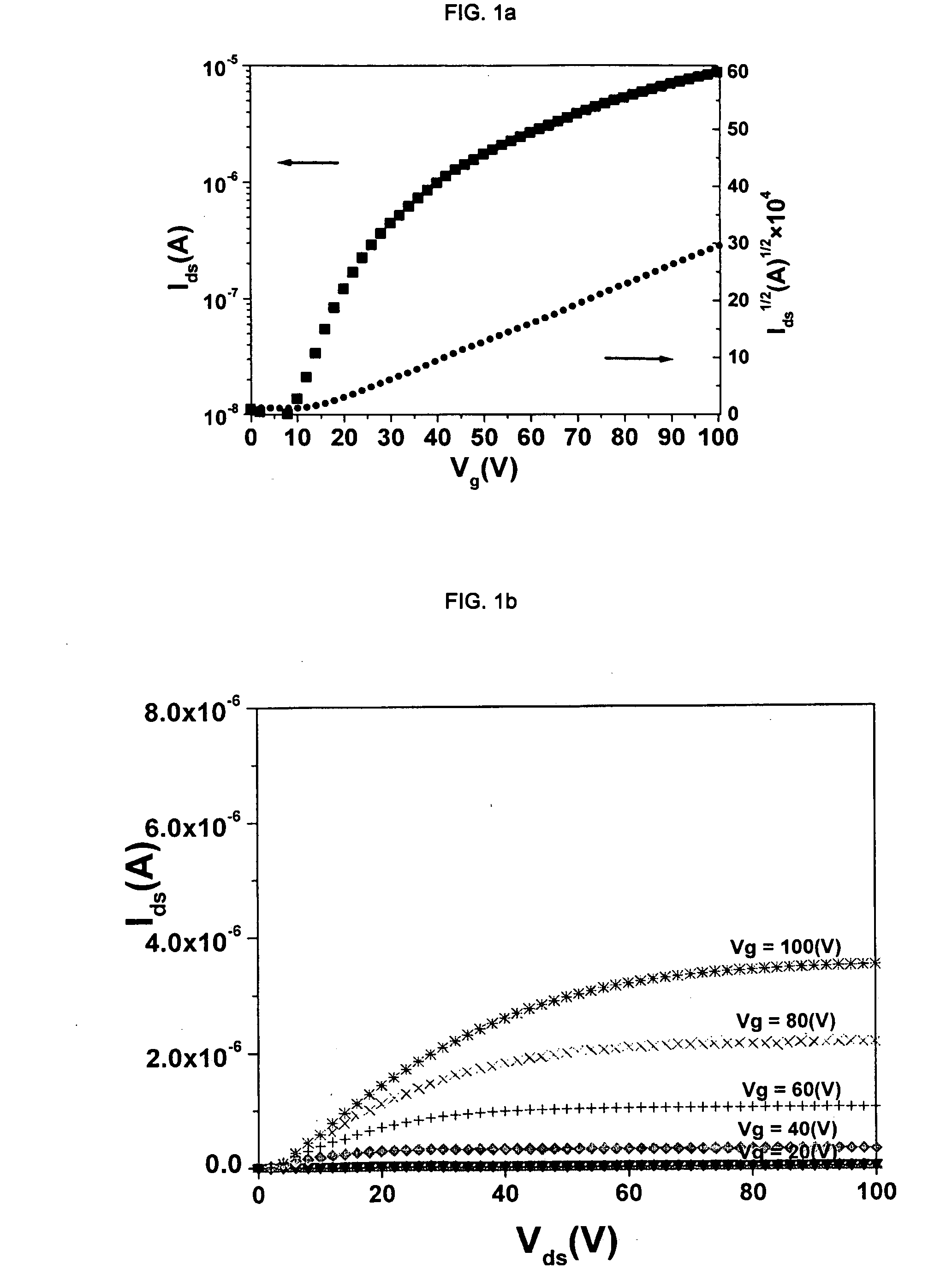

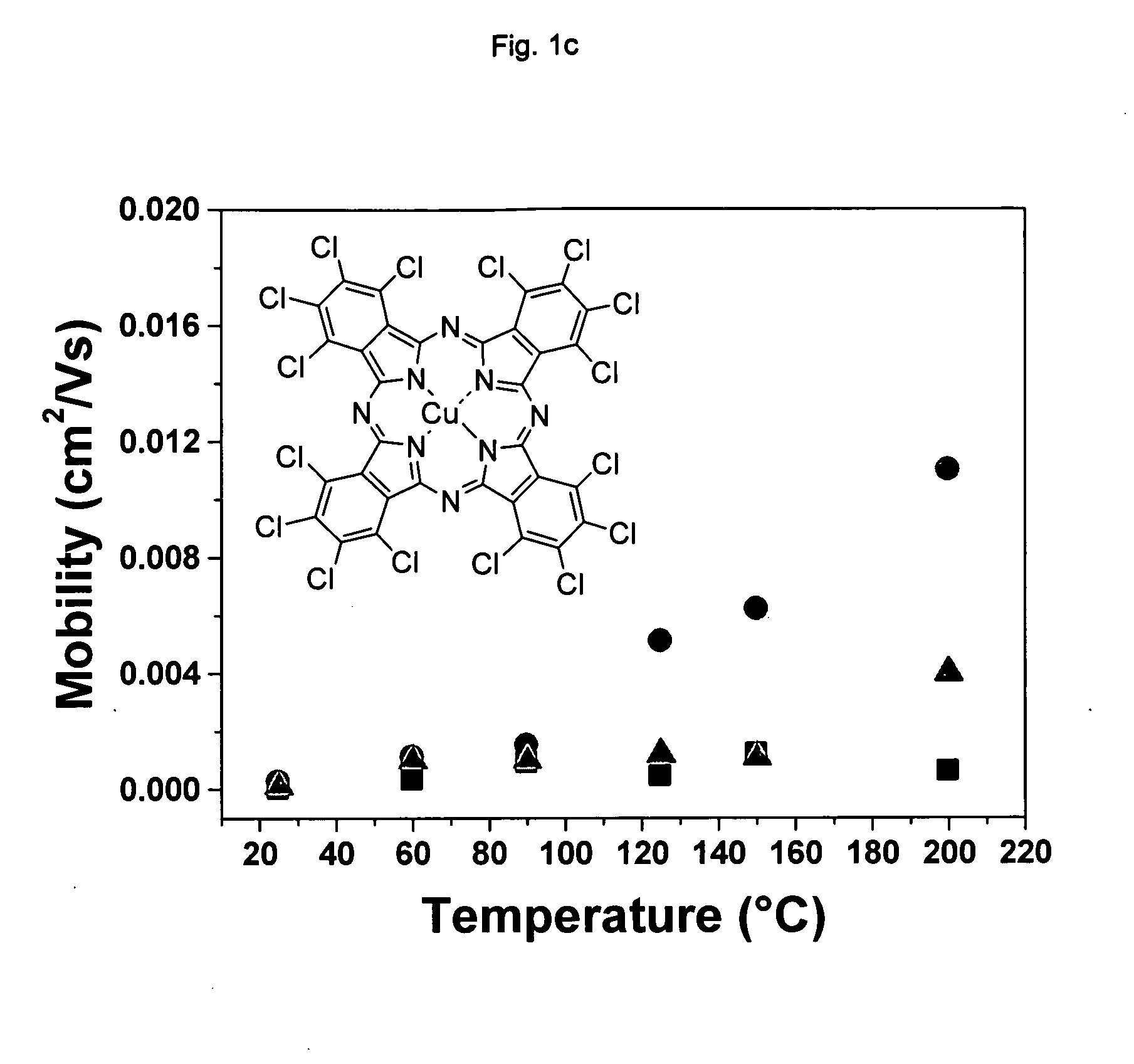

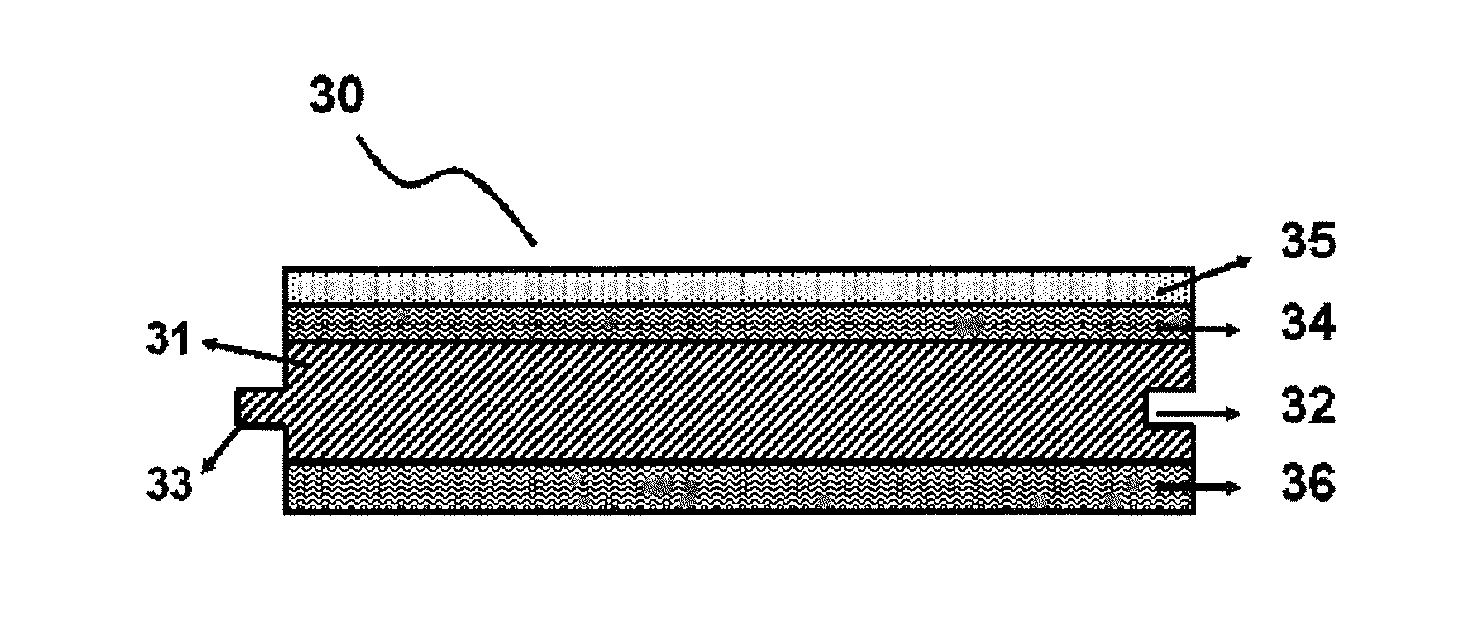

Use of chlorinated copper phthalocyanines as air-stable n-channel organic semiconductors

InactiveUS20080009092A1Rich varietyFinal product manufactureSolid-state devicesOrganic semiconductorCopper

The present invention relates to the use of chlorinated copper phthalocyanines as air-stable n-type organic semiconductors.

Owner:BASF AG +1

Manufacturing of decorative surfaces by inkjet

ActiveUS20160214395A1Excellent metamerismDuplicating/marking methodsSpecial ornamental structuresCopper phthalocyanineCarbon black

A method for manufacturing decorative surfaces includes the steps of a) inkjet printing a colour pattern on a paper substrate with one or more aqueous inkjet inks of an aqueous inkjet ink set; and thereafter b) impregnating the paper substrate with a thermosetting resin, wherein the aqueous inkjet ink set includes a cyan aqueous inkjet ink containing a copper phthalocyanine pigment; a red aqueous inkjet ink containing a pigment C.I Pigment Red 254 or a mixed crystal thereof; a yellow aqueous inkjet ink containing a pigment C.I Pigment Yellow 151 or a mixed crystal thereof; and a black aqueous inkjet ink containing a carbon black pigment; with the proviso that the aqueous inkjet inks do not include a polymer latex binder; and that the paper substrate includes one or more ink receiving layers for improving the image quality of the aqueous inkjet inks jetted thereon.

Owner:AGFA NV

Aqueous green pigment dispersions and inkjet compositions

ActiveUS9828513B2High color reproductionImprove color gamutInksQuinacridonesPigment dispersionCopper

Owner:EASTMAN KODAK CO

Preparation method and application of nanometer pigment microcapsule

InactiveCN102847497AElectronegativityImprove surface propertiesInksMicroballoon preparationIn situ polymerizationComputer printing

The invention discloses a preparation method and an application of a nanometer pigment microcapsule. The preparation method comprises the following steps: preparing pigment pre-dispersion liquid, that is, mixing copper phthalocyanine pigment with a dispersant I, adding zirconium beads into the mixed solution, performing ball milling dispersion, adding a microcapsule wall material monomer and a dispersant II into the dispersion liquid, continuing ball milling dispersion for 1-2 hours, and separating the zirconium beads to obtain the pigment pre-dispersion liquid; adding an initiator into the pigment pre-dispersion liquid, performing an in-situ polymerization reaction to obtain the nanometer pigment microcapsule stably dispersed in an aqueous solution. The nanometer pigment microcapsule is applicable to ink-jet ink for printers and aqueous pigment ink for ball pens. The preparation method of the invention is relatively simple; the prepared nanometer pigment microcapsule not only improves pigment surface characteristics, but also has certain electronegativity, which provides good dispersion stability and excellent comprehensive application performance for the prepared aqueous ink.

Owner:TIANJIN UNIV

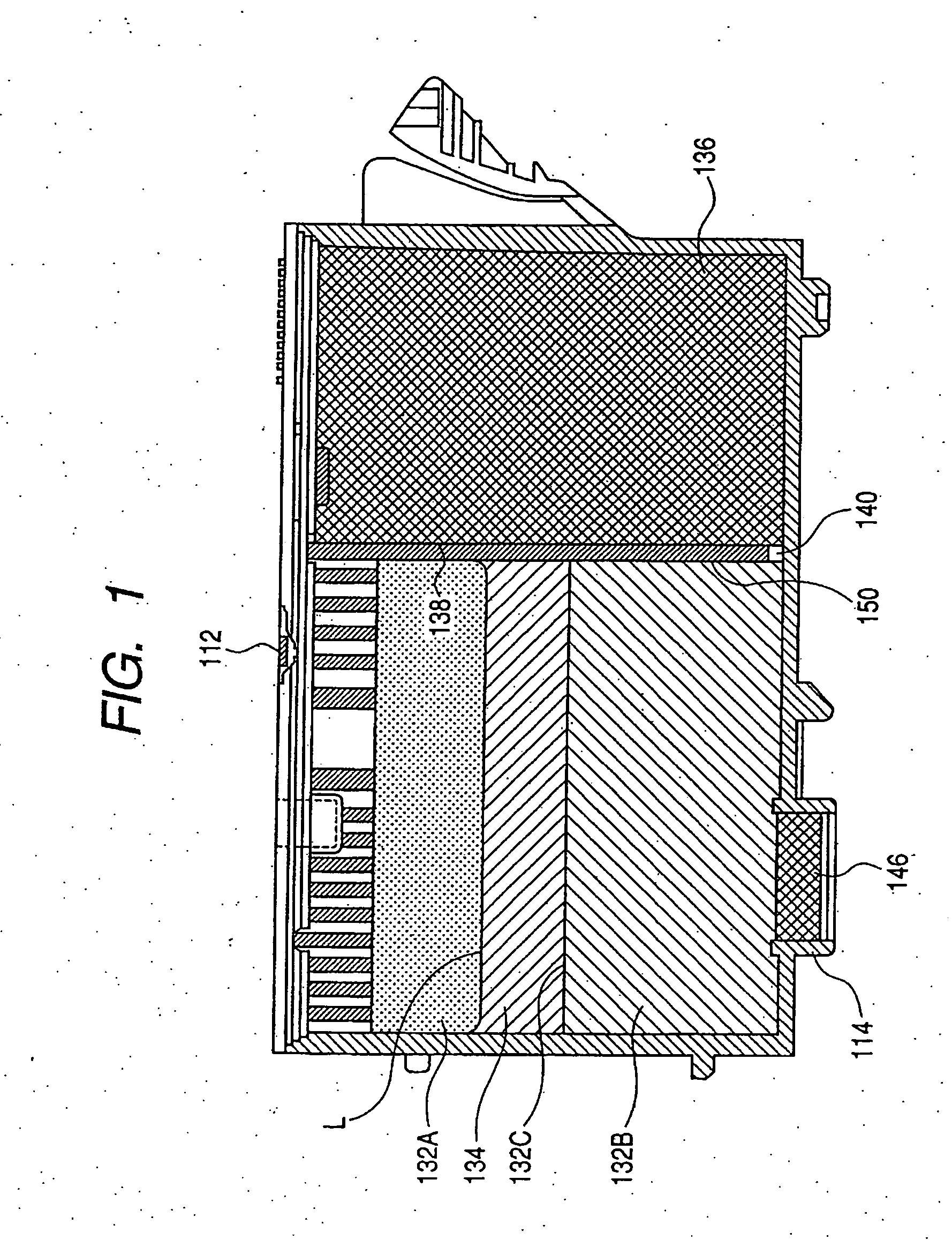

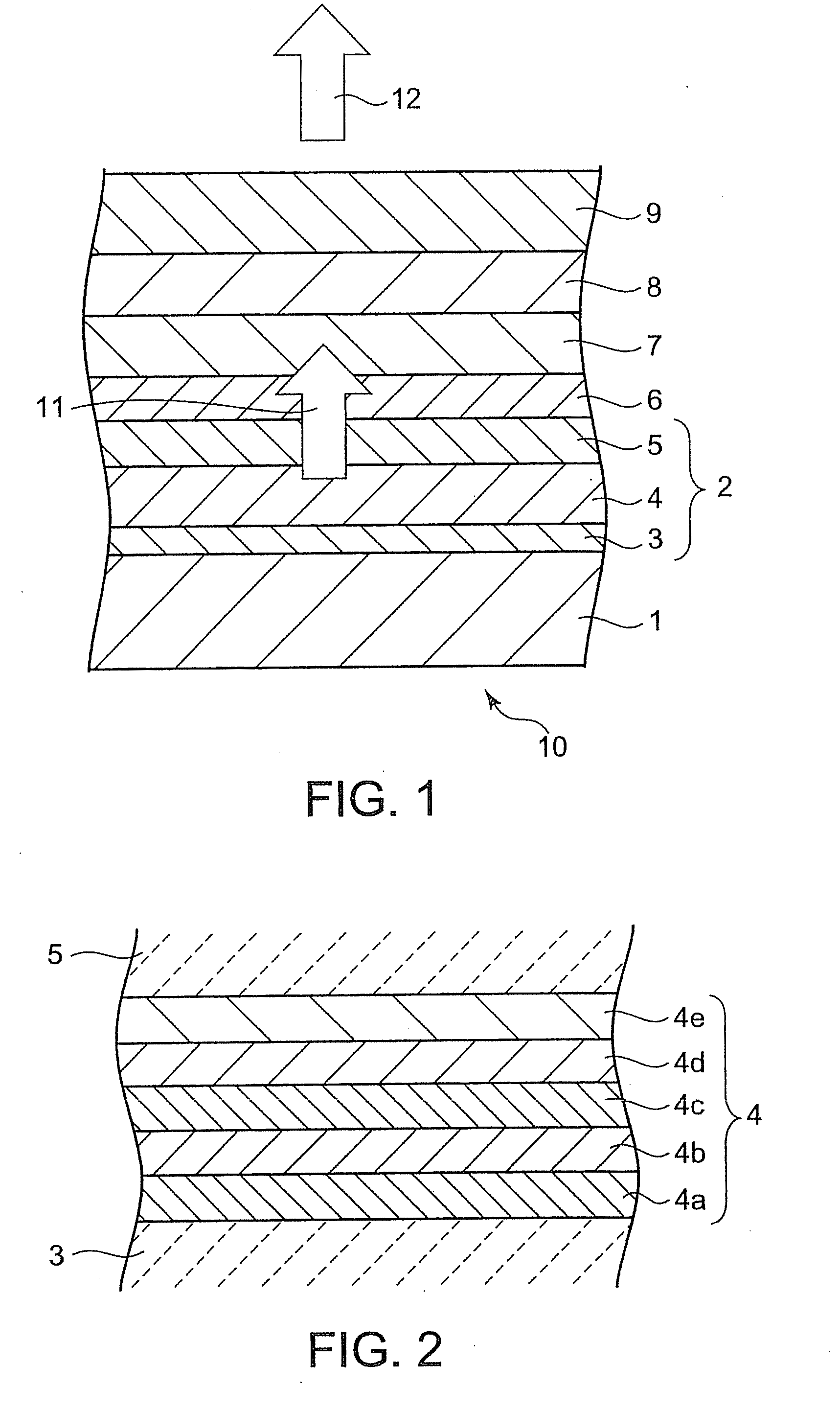

Light emitting element and method for manufacturing the same

InactiveUS7059928B2Alleviates deterioration of luminanceDeterioration of luminance is smallMultiplex communicationElectroluminescent light sourcesPhthalocyanineOrganic compound

In order to provide a light emitting device and an electronic equipment which suppress luminance deterioration, and have long life, the invention does not form an organic compound layer which is composed of a hole injection layer, a hole transport layer, a light emitting layer, an electron transport layer, an electron injection layer and so on, and electrodes in vacuum-through, as in a conventional vacuum deposition method, but after a hole injection layer, which comprises phthalocyanine, is formed, it is exposed to gas atmosphere. In particular, copper phthalocyanine is exposed to oxygen atmosphere. By this method, provided is an organic light emitting element which has long life, and by using the above-described organic light emitting element, a light emitting device and an electronic equipment are fabricated.

Owner:SEMICON ENERGY LAB CO LTD

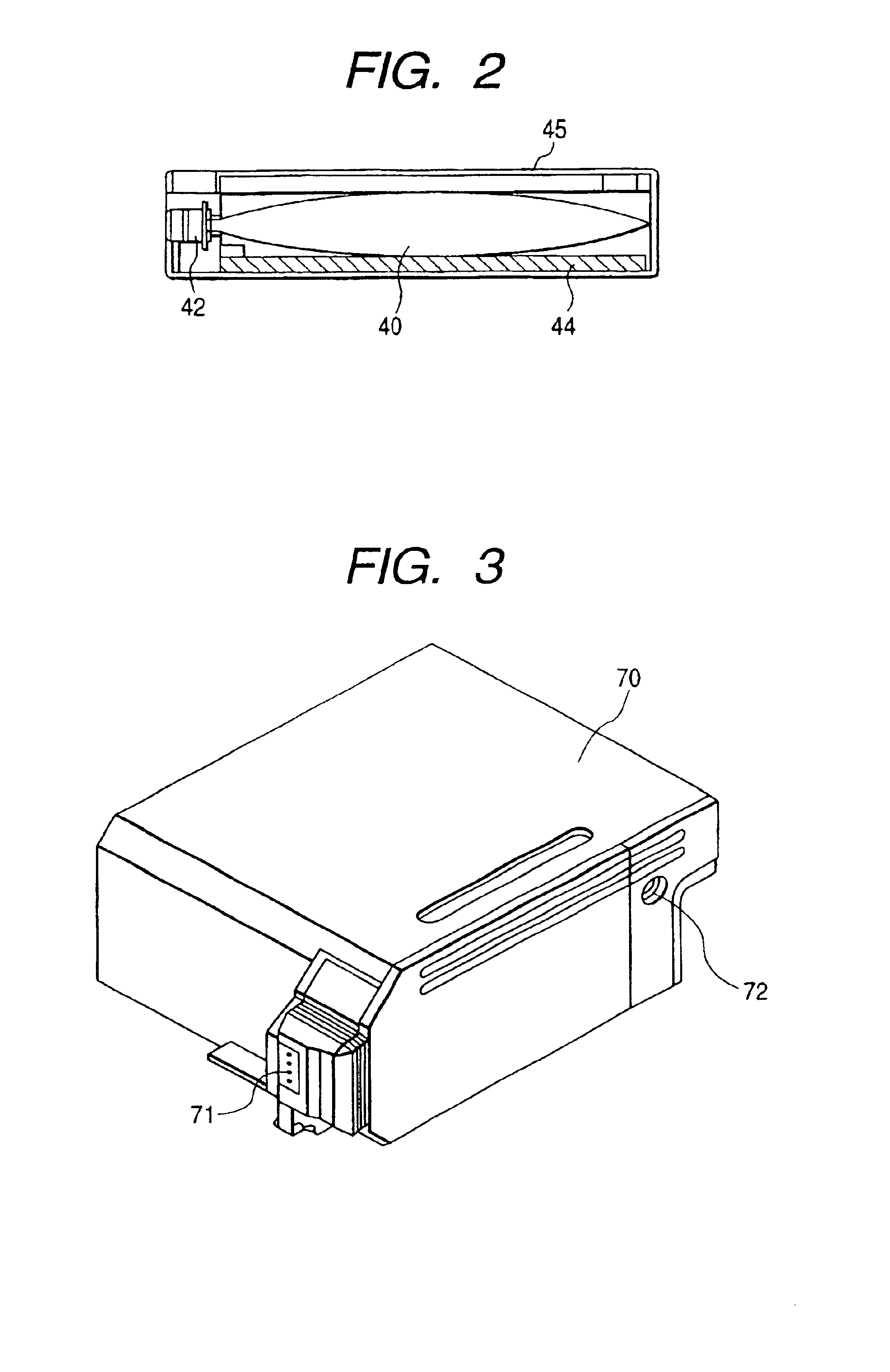

Ink jet ink, method of producing ink jet ink, ink jet recording method, ink cartridge, and cyan ink

InactiveUS7601210B2Good colorQuality improvementMeasurement apparatus componentsInksOrganic solventEngineering

Owner:CANON KK

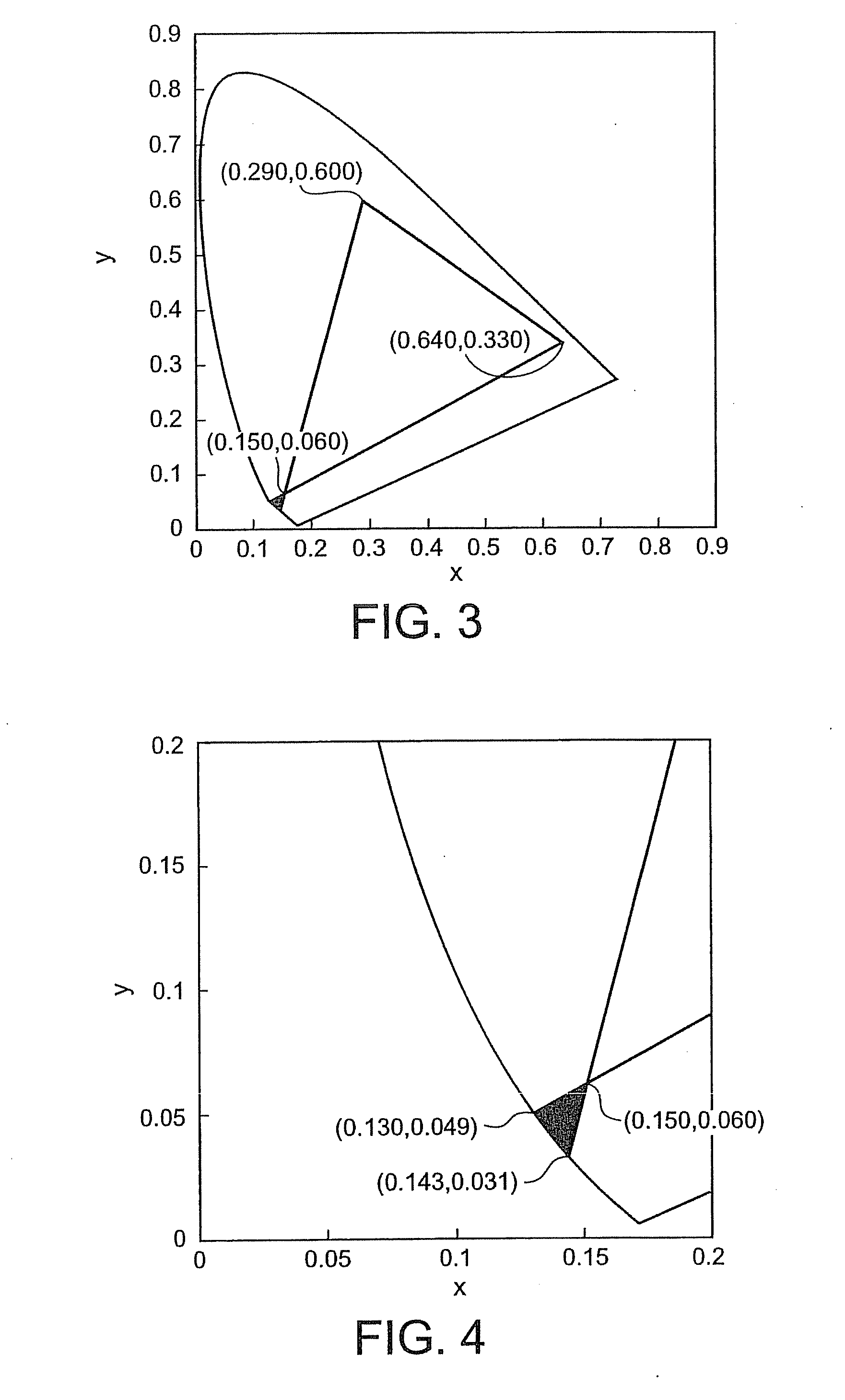

Organic el device, color filter, and organic el display

ActiveUS20100244011A1Excellent color reproduction rangePoor heat resistanceElectroluminescent light sourcesSolid-state devicesColor gelCopper

An organic EL device includes an organic EL emitter (2) that emits blue light and a blue color filter (8B) through which the light emitted from the organic EL emitter passes. The blue color filter contains a coloring material selected from the group consisting of a triarylmethane dye, a lake pigment, a copper-phthalocyanine pigment, and a mixture of a copper-phthalocyanine pigment and a dioxazine pigment. The chromaticity of the light, the light that has passed through the blue color filter after emitted from the organic EL emitter, is in the range defined by lines connecting three chromaticity coordinates (0.150, 0.060), (0.143, 0.031), and (0.130, 0.049) on the CIE chromaticity diagram.

Owner:DAI NIPPON PRINTING CO LTD

Cyan dye set and ink-jet ink composition with high water-fastness

A cyan dye set and ink-jet ink composition with high water-fastness. The cyan dye set is suitable for use in ink-jet printing and includes Acid Blue 90 dye and at least one copper phthalocyanine type blue dye. The cyan dye set has good water-fastness and exhibits improved printing quality when applied in ink-jet printing.

Owner:BENQ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com