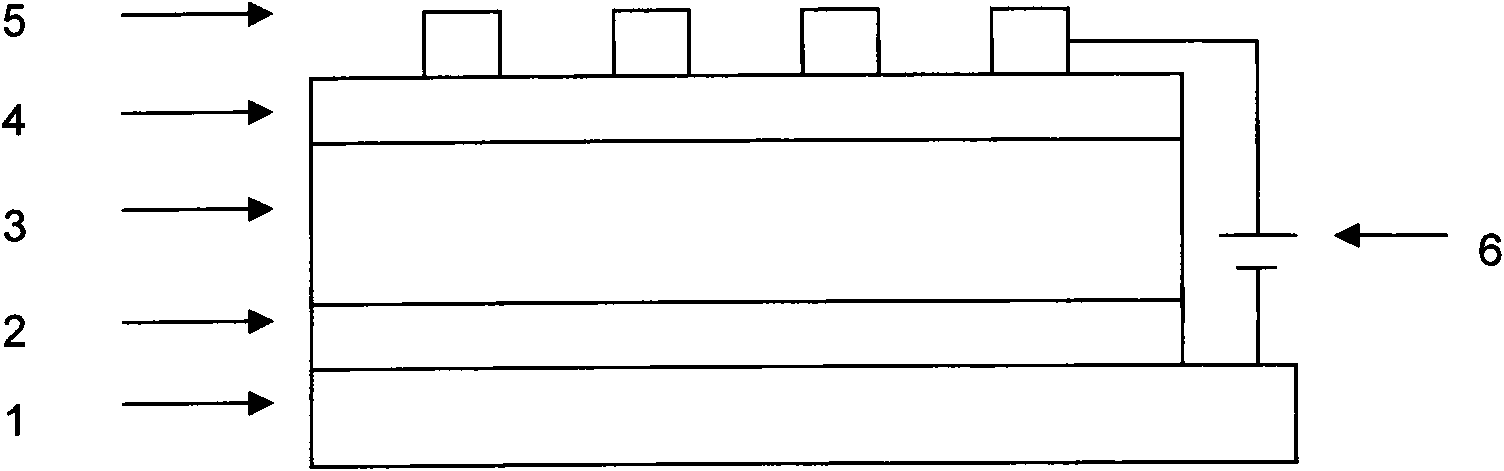

Reciprocal form structure polymer solar cell and preparation method thereof

A technology of structural polymers and solar cells, which is applied in the field of polymer solar cells, can solve the problems of increased surface roughness of ITO, increased device series resistance, and decreased energy conversion efficiency, so as to simplify the pre-processing process, reduce series resistance, The effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

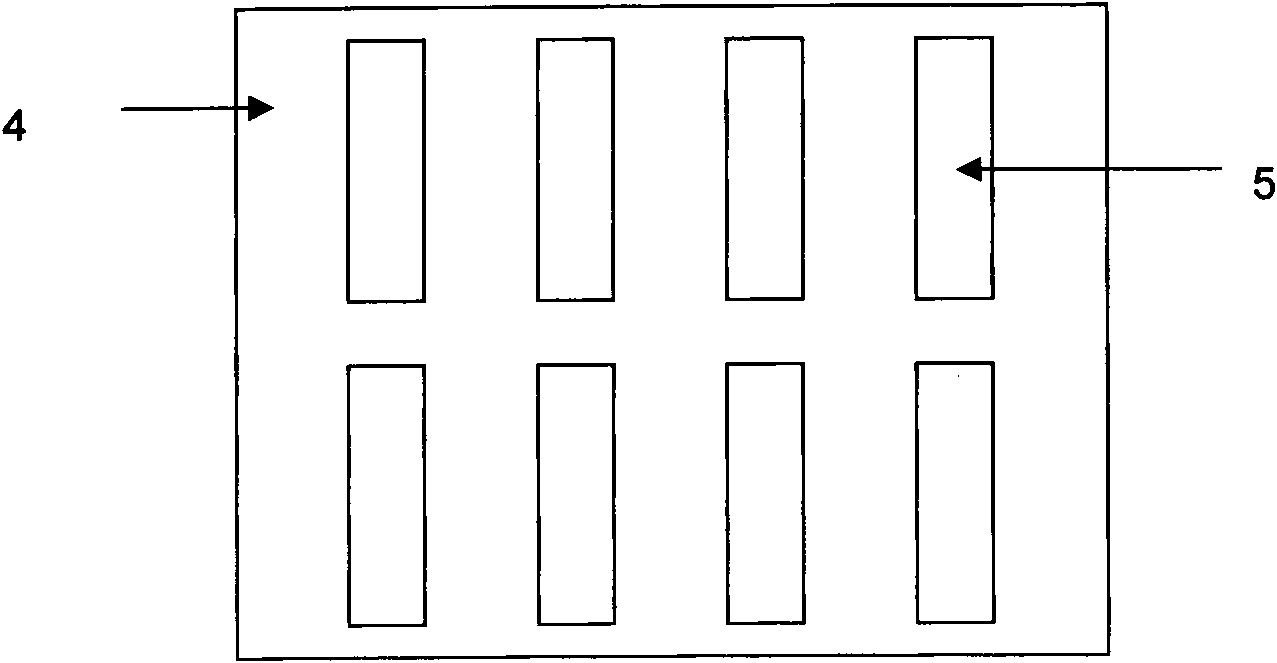

Method used

Image

Examples

Embodiment 1

[0028] A.

[0029] Cut 15mm x 20mm ITO glass and put it into a beaker. Use acetone, ethanol, and deionized water to ultrasonically clean them for 15 minutes. After cleaning, dry them with dry nitrogen and place them in a petri dish.

[0030] B.

[0031] 1) Put 10ml of Ti(OC 4 h 9 ) 4 Add dropwise to 90ml of absolute ethanol under vigorous stirring, then add dropwise 10ml of glacial acetic acid, and stir for 30 minutes to obtain a uniform and transparent light yellow solution; then add 10ml of acetylacetone (Tianjin Chemical Reagent Factory), and stir for 30 minutes. 10ml of deionized water was slowly added dropwise to the above solution at a rate of 2ml / min, and the stirring was continued for 1h to obtain a uniform and transparent light yellow sol, which was left to age for 7 hours.

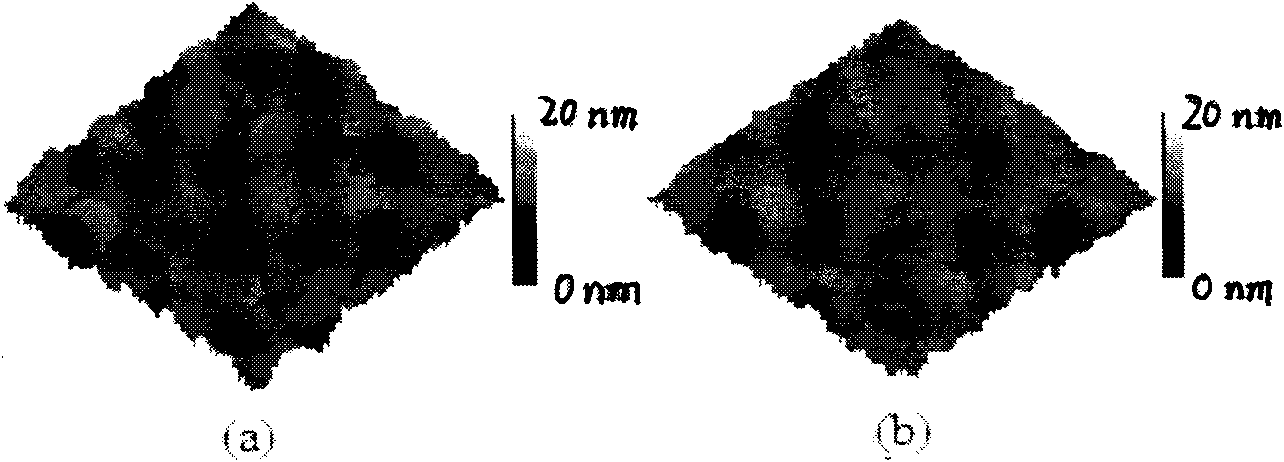

[0032] 2) Prepare TiO from the aged sol on cleaned and dried ITO glass 2 Thin film, the thickness of film is 30nm, and the method for making thin film adopts spin-coating, and rotation spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com