Patents

Literature

257 results about "Quinacridone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quinacridone is an organic compound used as a pigment. Numerous derivatives constitute the quinacridone pigment family, which finds extensive use in industrial colorant applications such as robust outdoor paints, inkjet printer ink, tattoo inks, artists' watercolor paints, and color laser printer toner. As pigments, the quinacridones are insoluble. The development of this family of pigments supplanted the alizarin dyes.

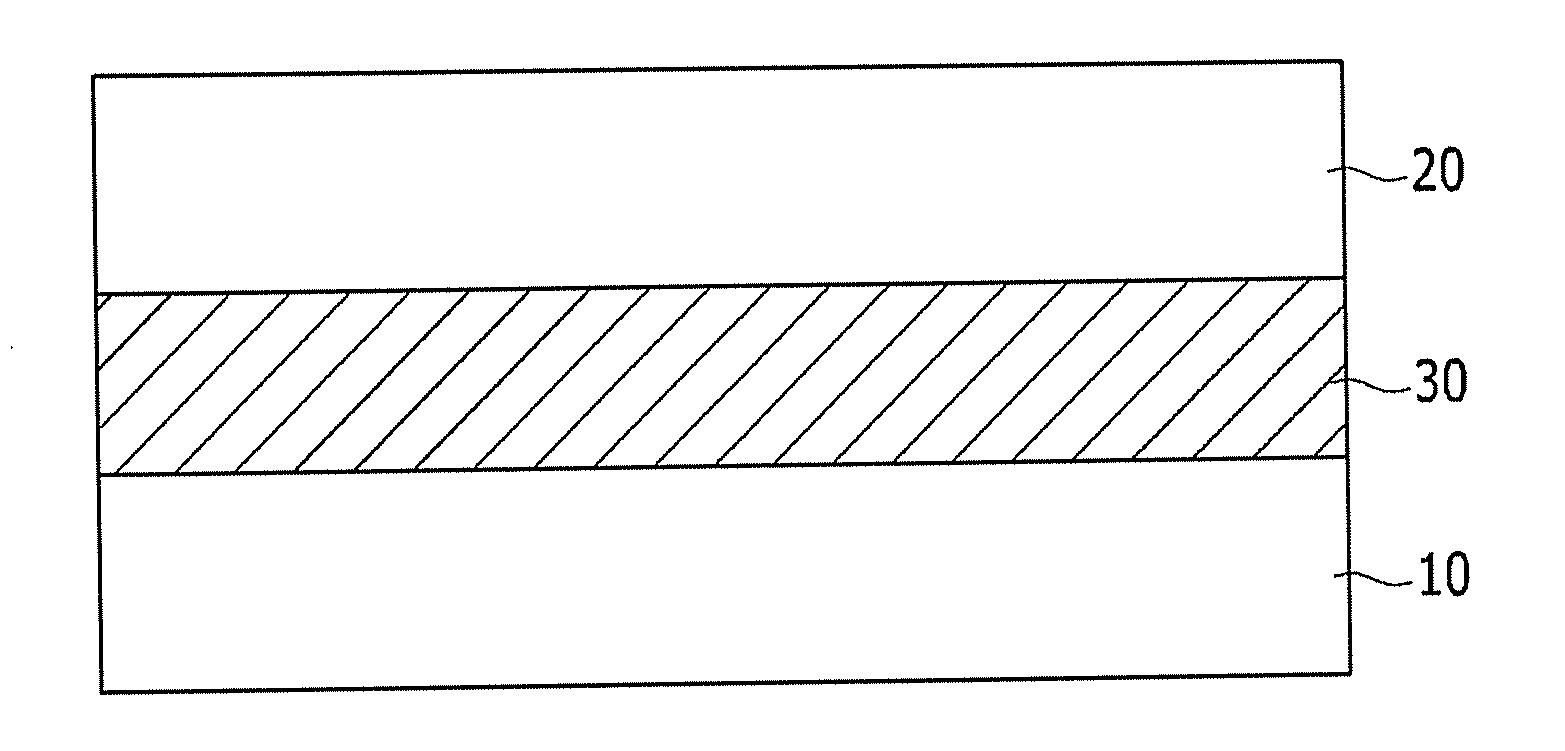

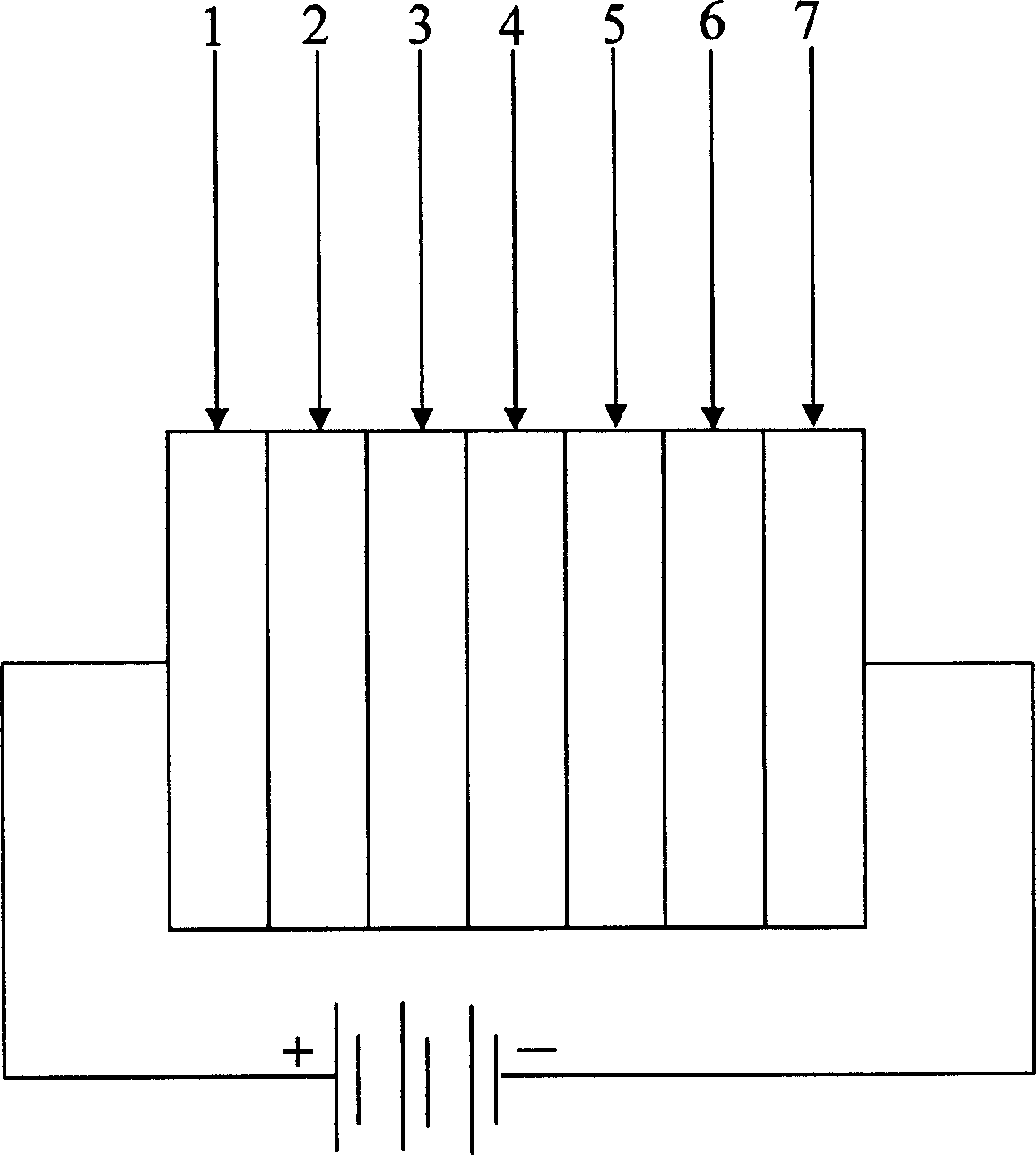

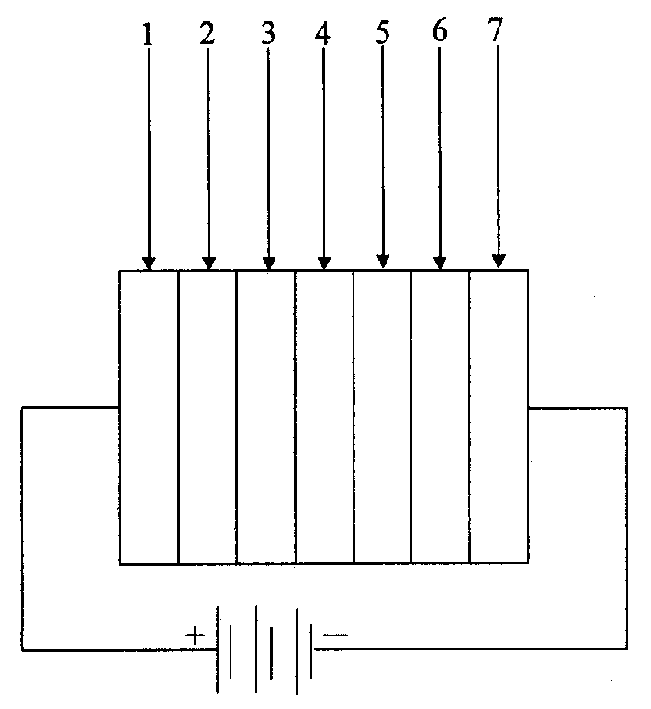

Highly-efficient organic electroluminescent device based on fluorescence doped luminescent layer

ActiveCN104835916AImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionLuminescence

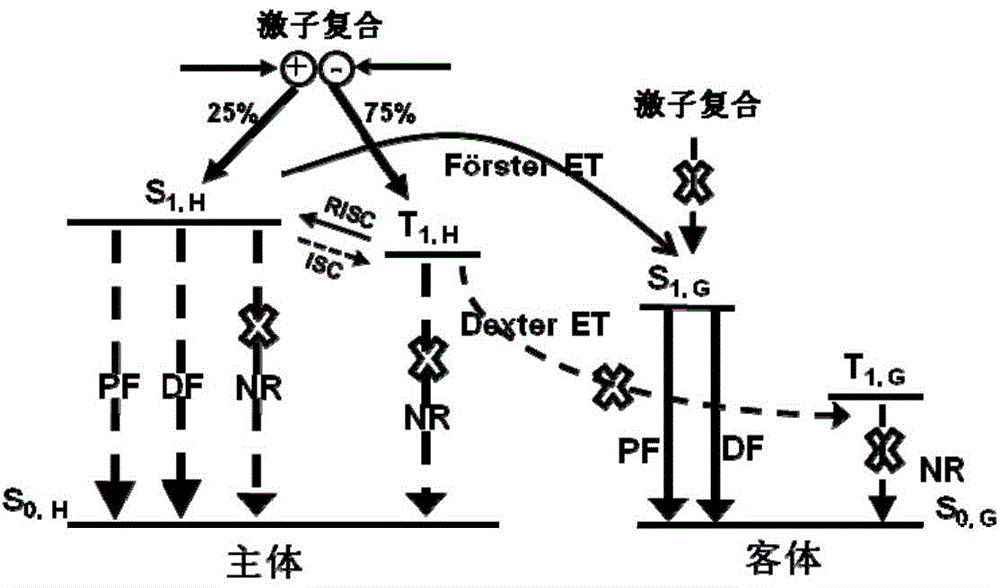

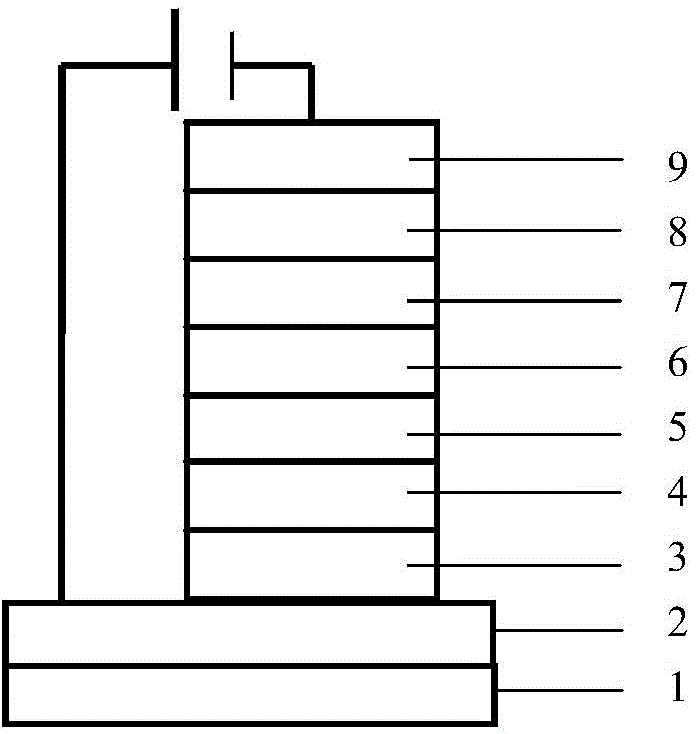

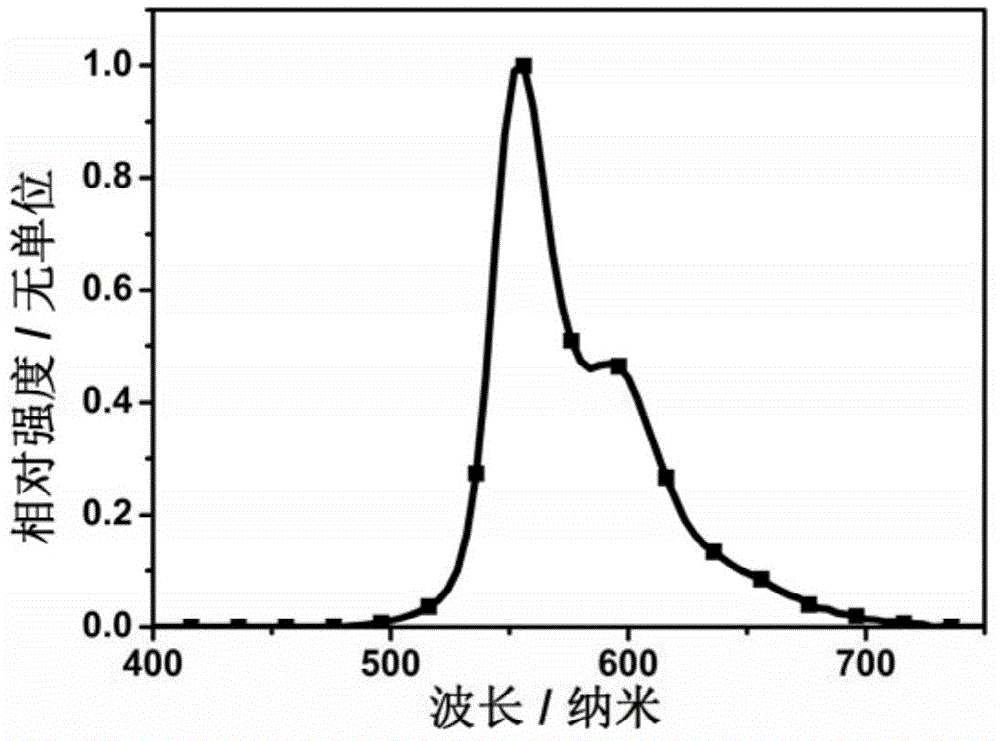

The invention relates to a device structure of an organic light-emitting diode (OLED), and especially relates to a highly-efficient organic electroluminescent device based on a fluorescence doped luminescent layer. The organic electroluminescent device comprises a transparent substrate, a transparent anode, a cavity transmission layer, a first exciton barrier layer, a luminescent layer, a second exciton barrier layer, an electronic transmission layer, an electronic injecting layer and a metal cathode. The luminescent layer is formed by mixing a main body and a guest body. The main body material is organic small molecules whose energy difference between a first kind single heavy excitation state and a triplet excitation state is quite small. The guest body material is dye molecules with high fluorescence efficiency, like quinacridone derivatives. The highly-efficient organic electroluminescent device based on a fluorescence doped luminescent layer is advantageous in that the external quantum efficiency exceeds 5% of theoretic limit efficiency of a conventional fluorescence device, and the luminescence efficiency of a fluorescent OLED device can be effectively improved; the luminescent device of the invention is high in brightness, low in starting voltage, high in efficiency, and low in efficiency roll-off.

Owner:JILIN YUANHE ELECTRONICS MATERIALS CO LTD

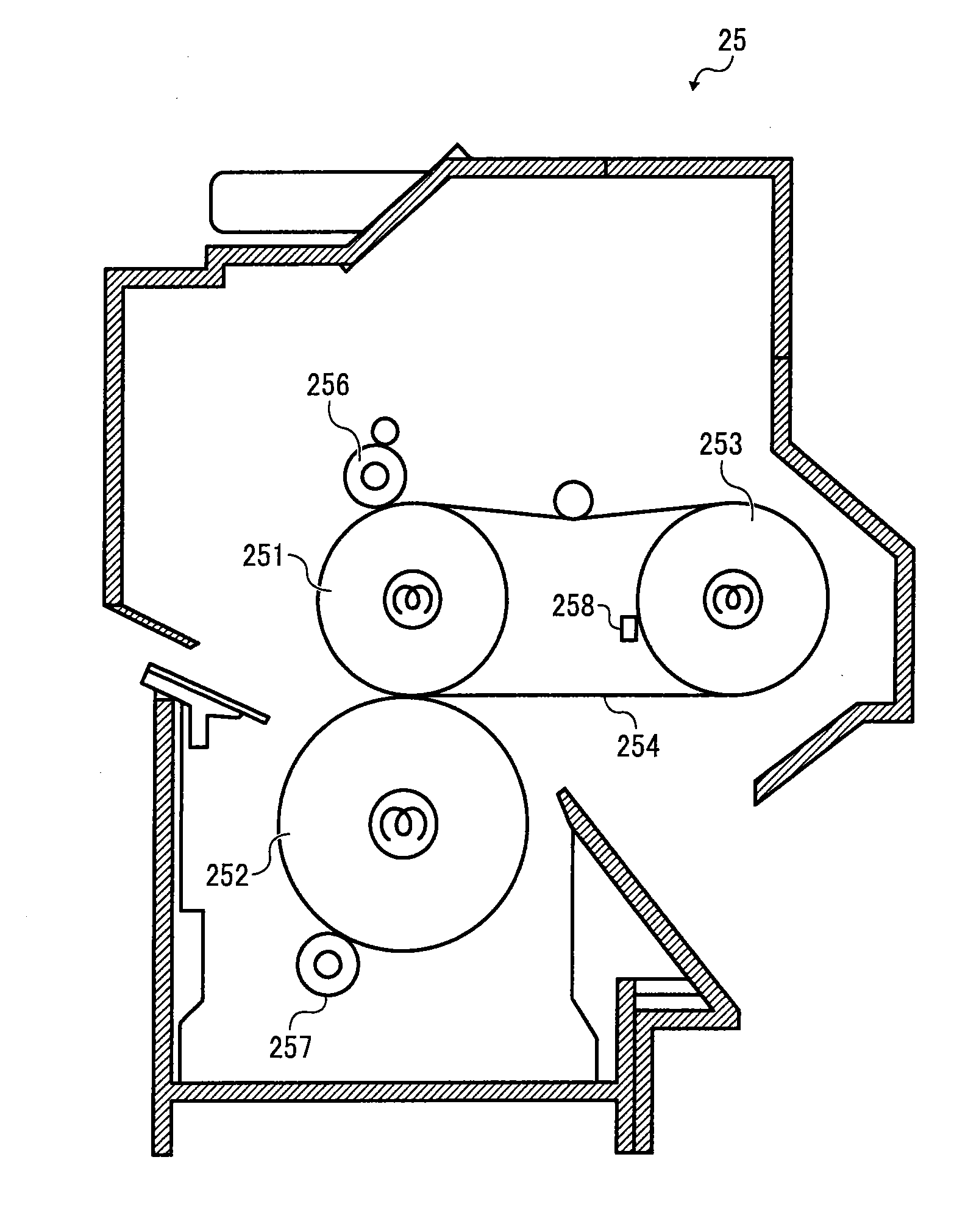

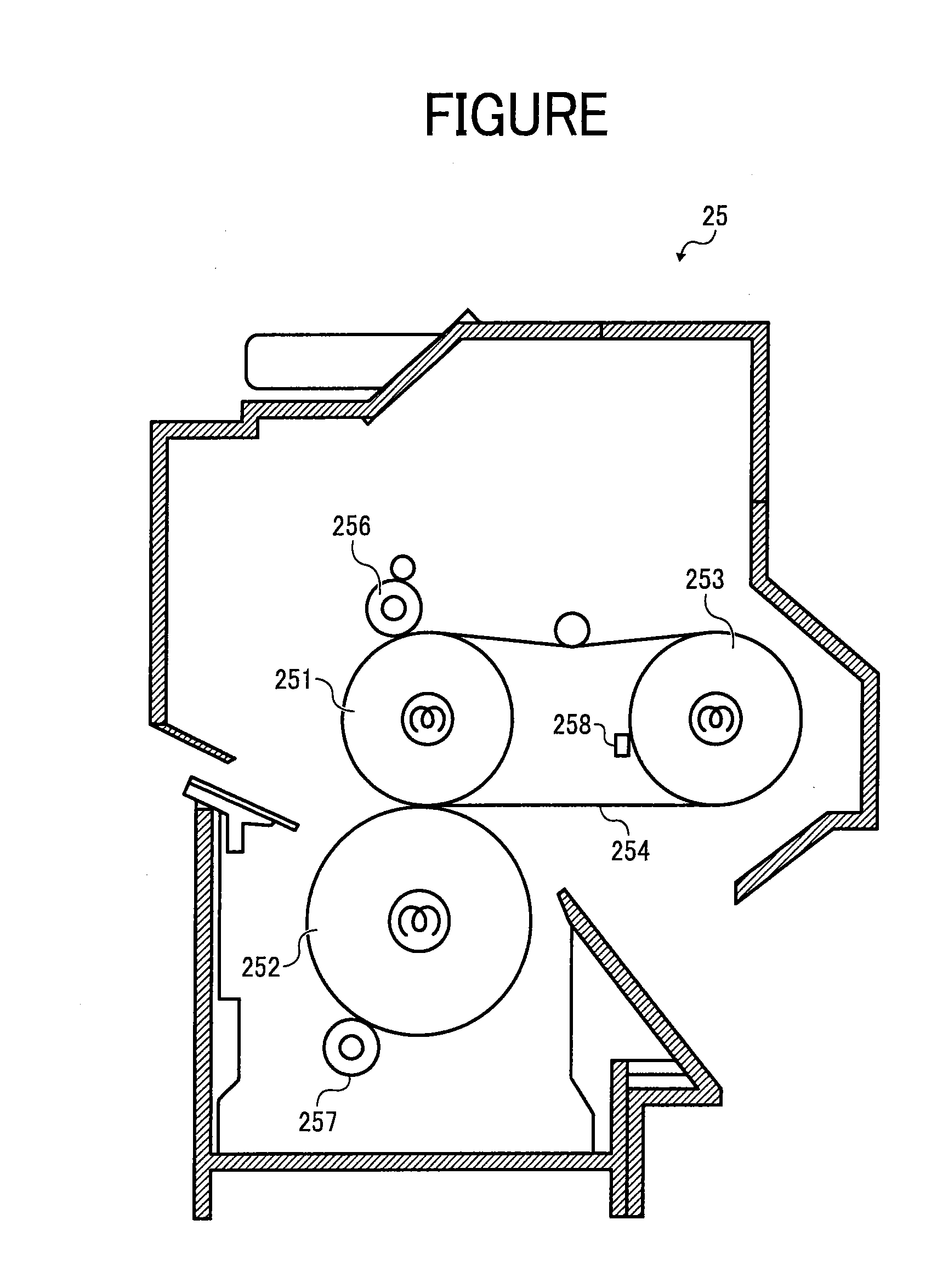

Actinic ray curable composition, image forming method using the same and ink-jet recording apparatus using the same

InactiveUS20050196697A1Improve curing effectStable storageDuplicating/marking methodsPhotomechanical apparatusActinic RaysPhotochemistry

An actinic ray curable composition containing a quinacridone pigment; a dispersant; a cationically polymerizable monomer; a photo acid generator; and a quinacridone derivative.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Magenta recording ink composition, inkjet recording method, and ink recorded matter

InactiveUS20100285287A1Excellent ejection stabilityHigh color saturationMeasurement apparatus componentsLayered productsSolid solutionSolvent

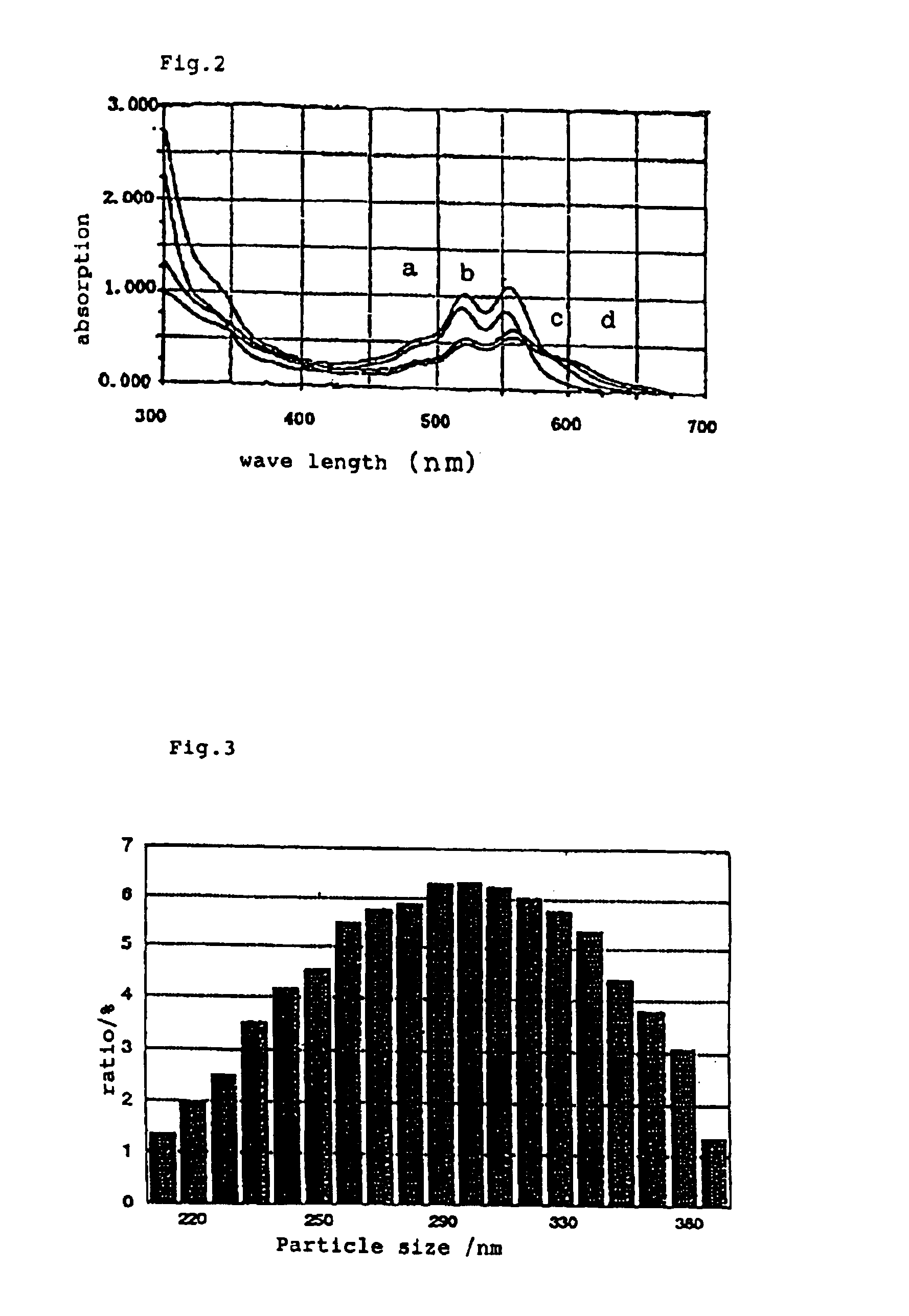

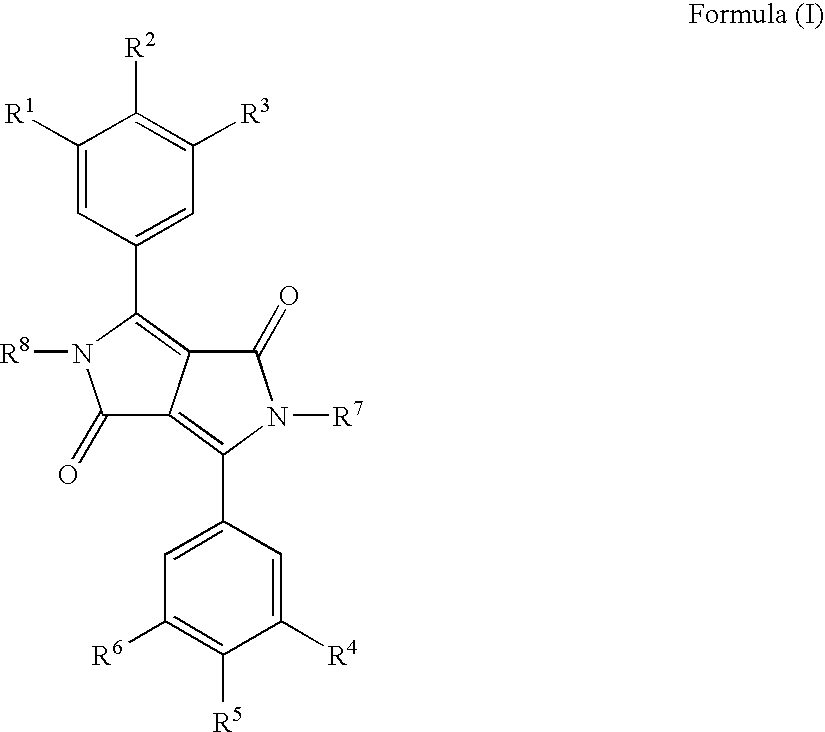

The present invention provides a magenta recording ink composition including at least a solid solution pigment (A) containing quinacridone, a lake pigment (B) having a xanthene structure, an aqueous solvent, and water, wherein the solid solution pigment (A) has visible light absorption peaks at wavelength ranges of from 510 nm to 530 nm and from 540 nm to 560 nm, and a mass ratio (B / A) of the lake pigment (B) to the solid solution pigment (A) falls within the range of 0.1 to 5.

Owner:RICOH KK

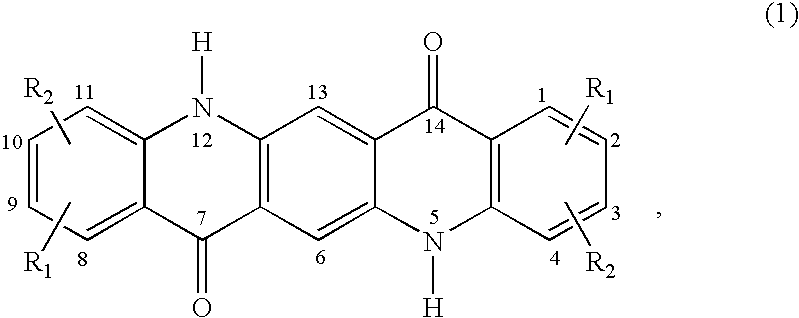

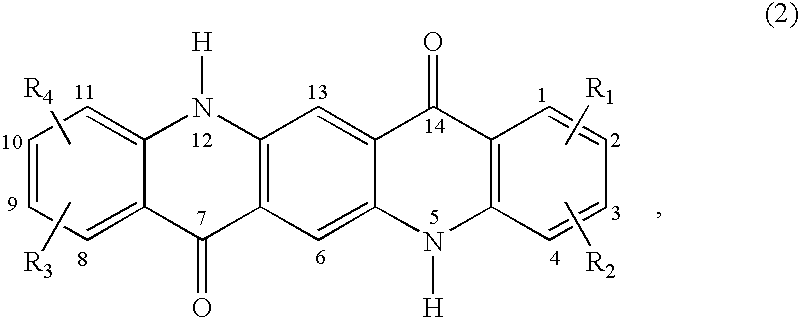

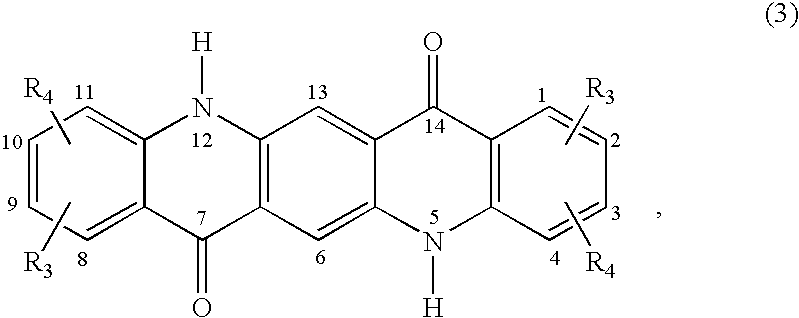

Quinacridone pigment compositions comprising unsymmetrically substituted components

The present invention relates to a novel quinacridone pigment compositions, a process using a mixed amine synthesis for the ultimate production of the compositions and to their use as colorants for pigmenting high molecular weight organic materials.

Owner:CIBA SPECIALTY CHEM CORP

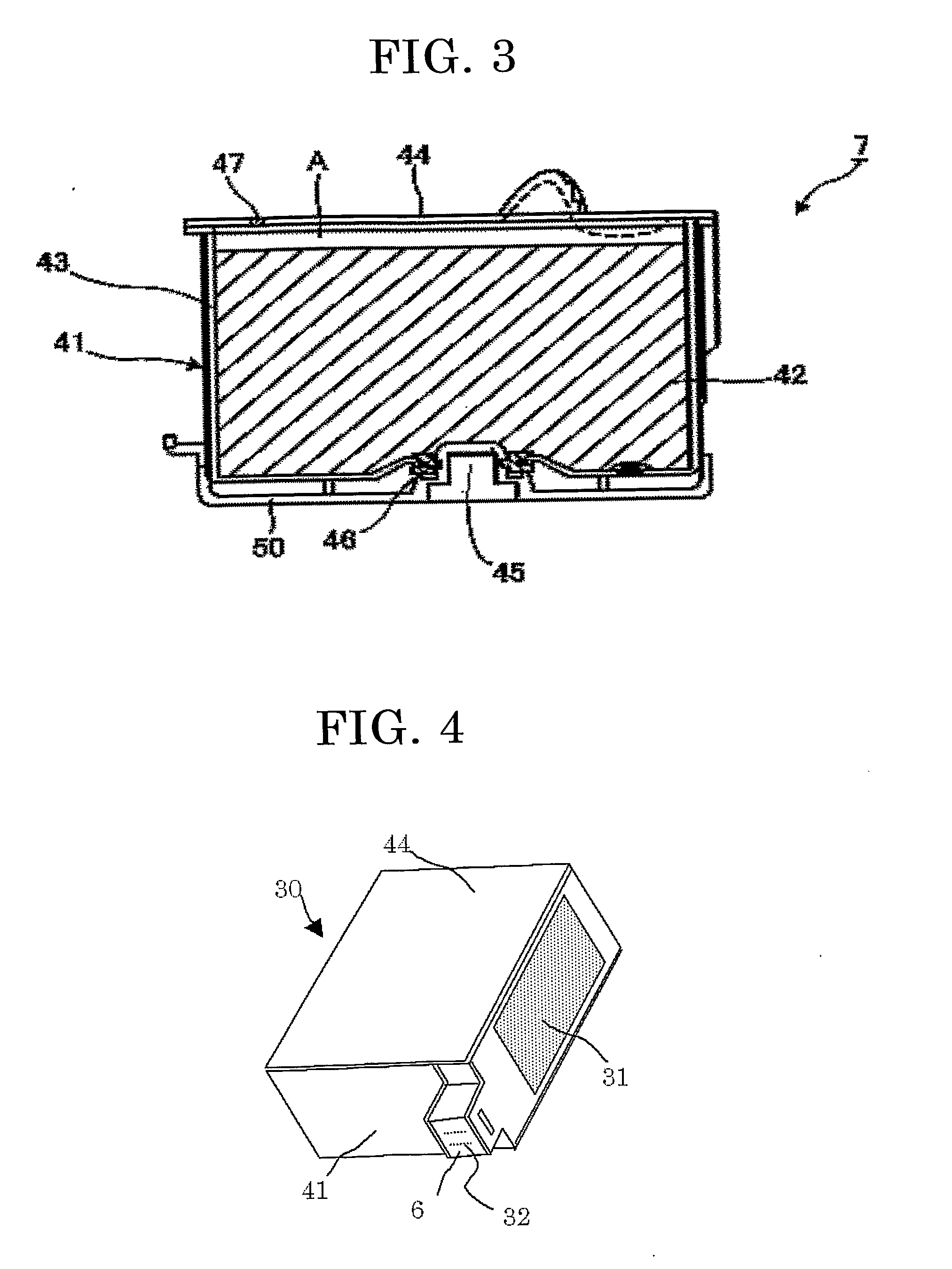

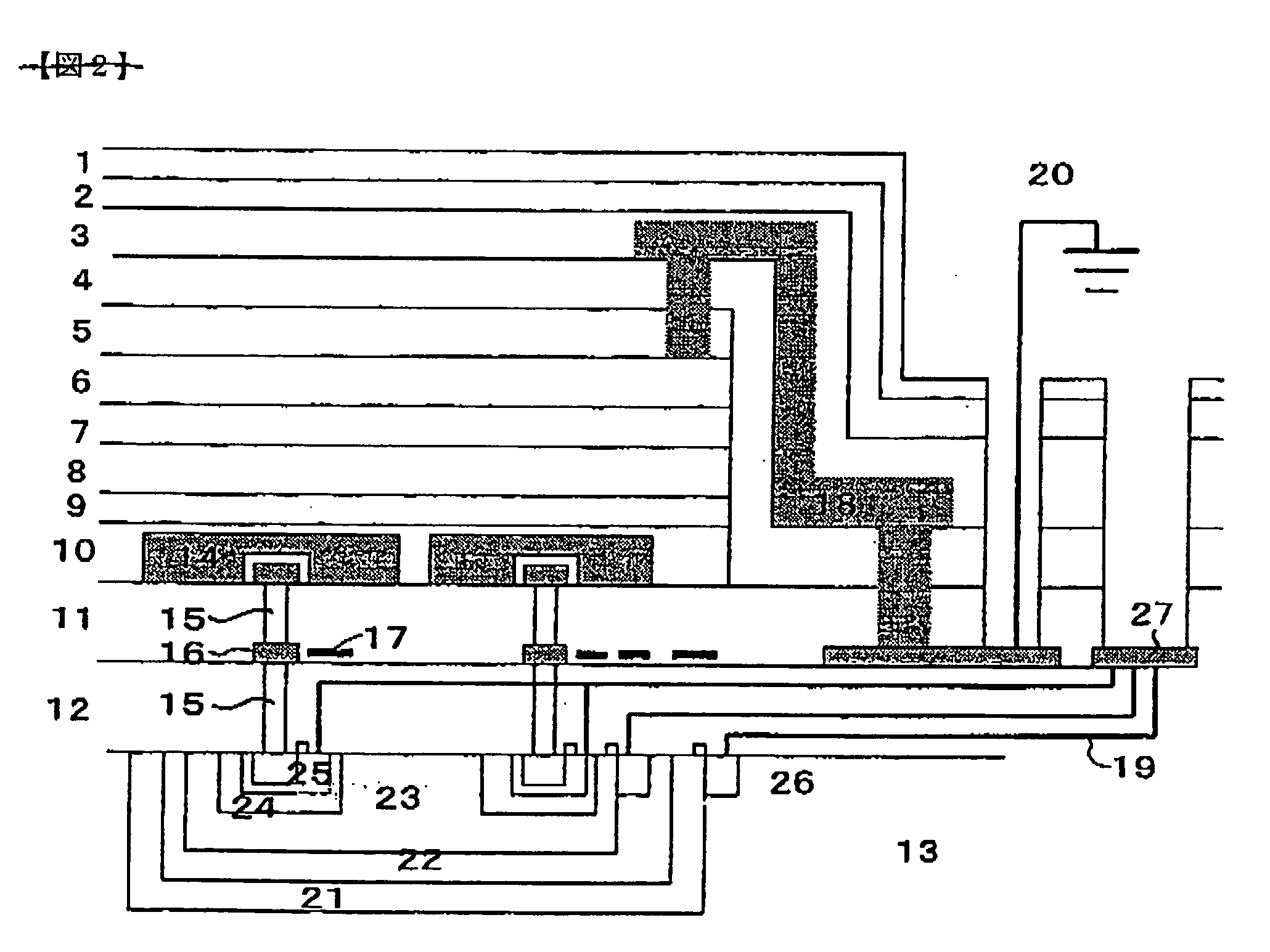

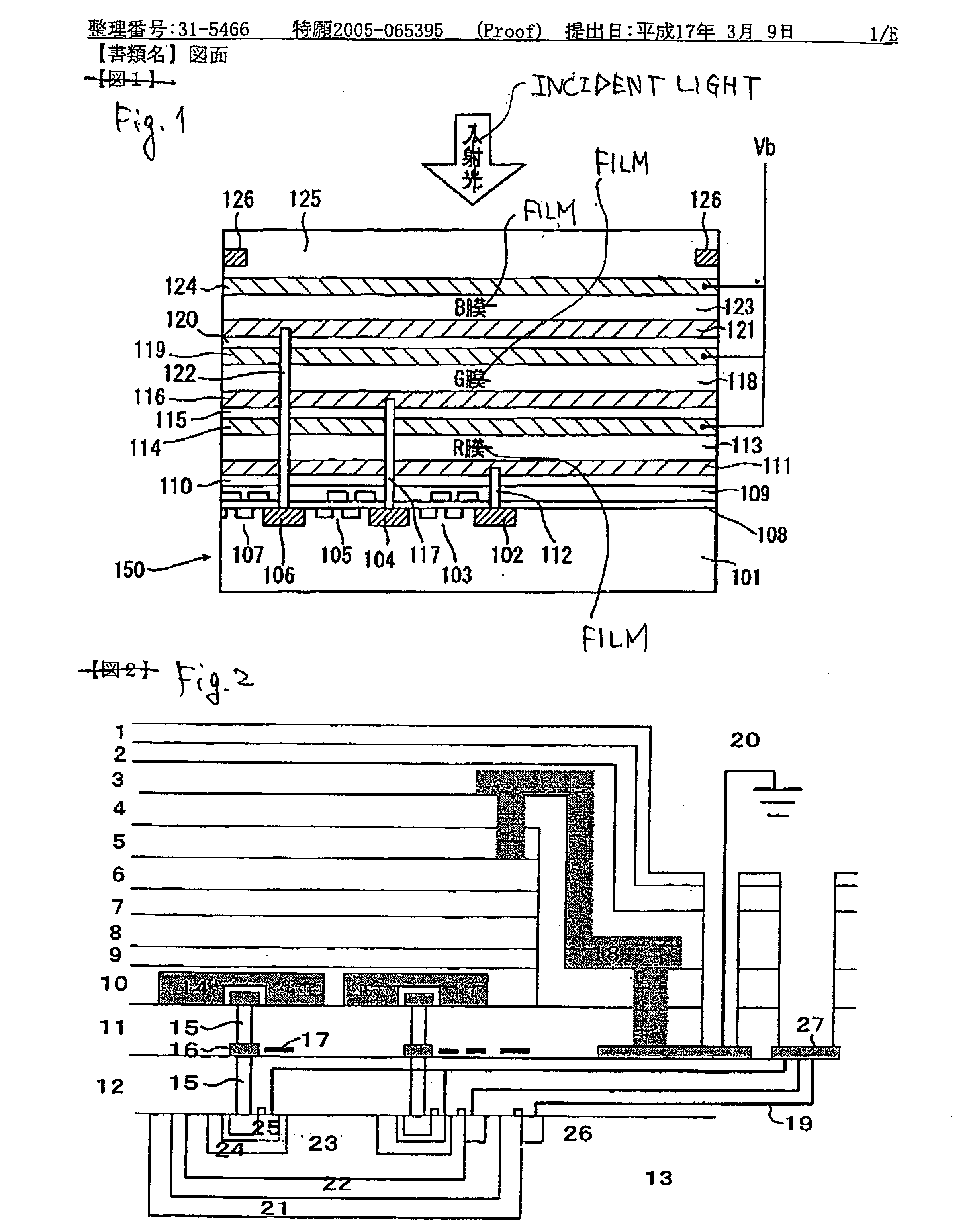

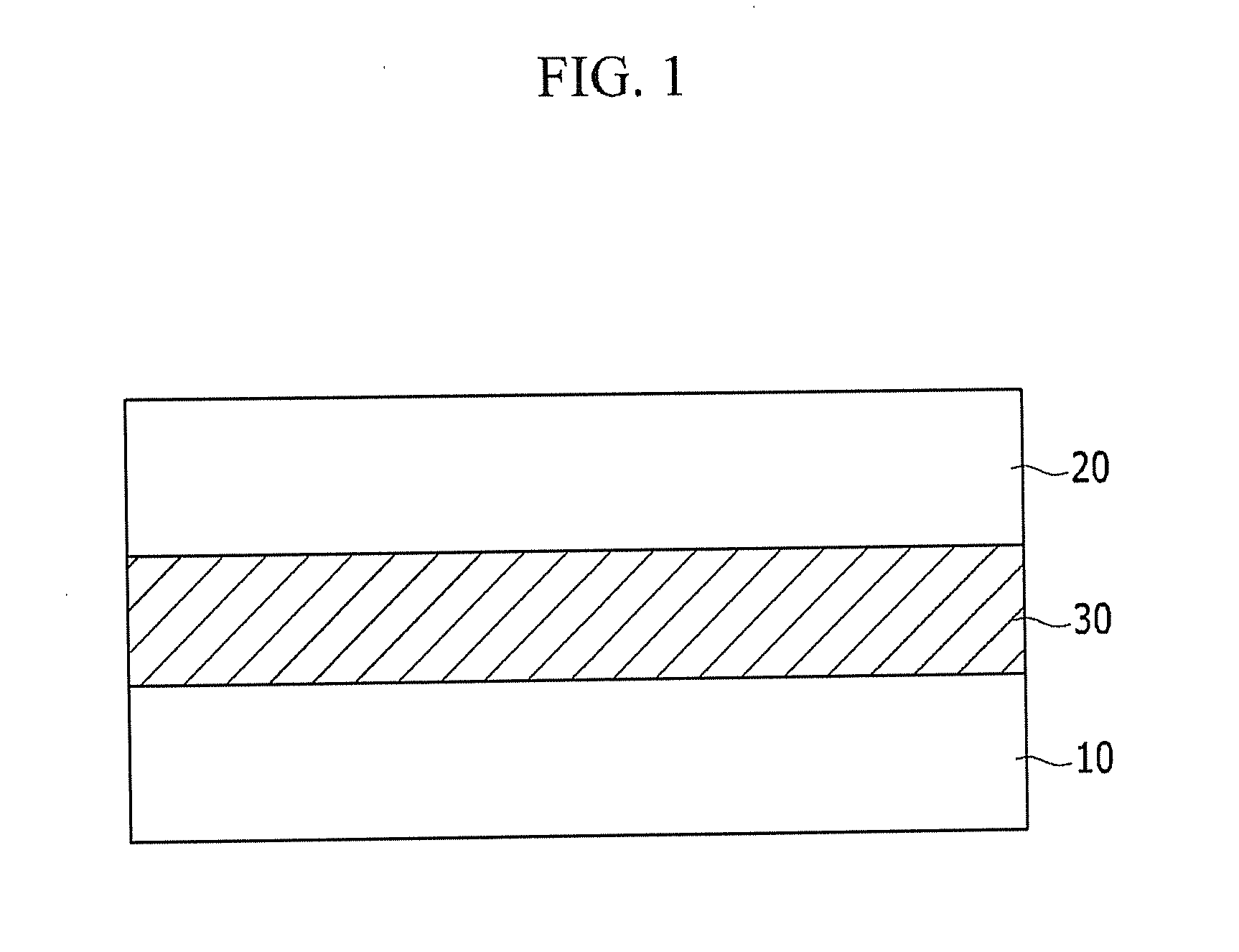

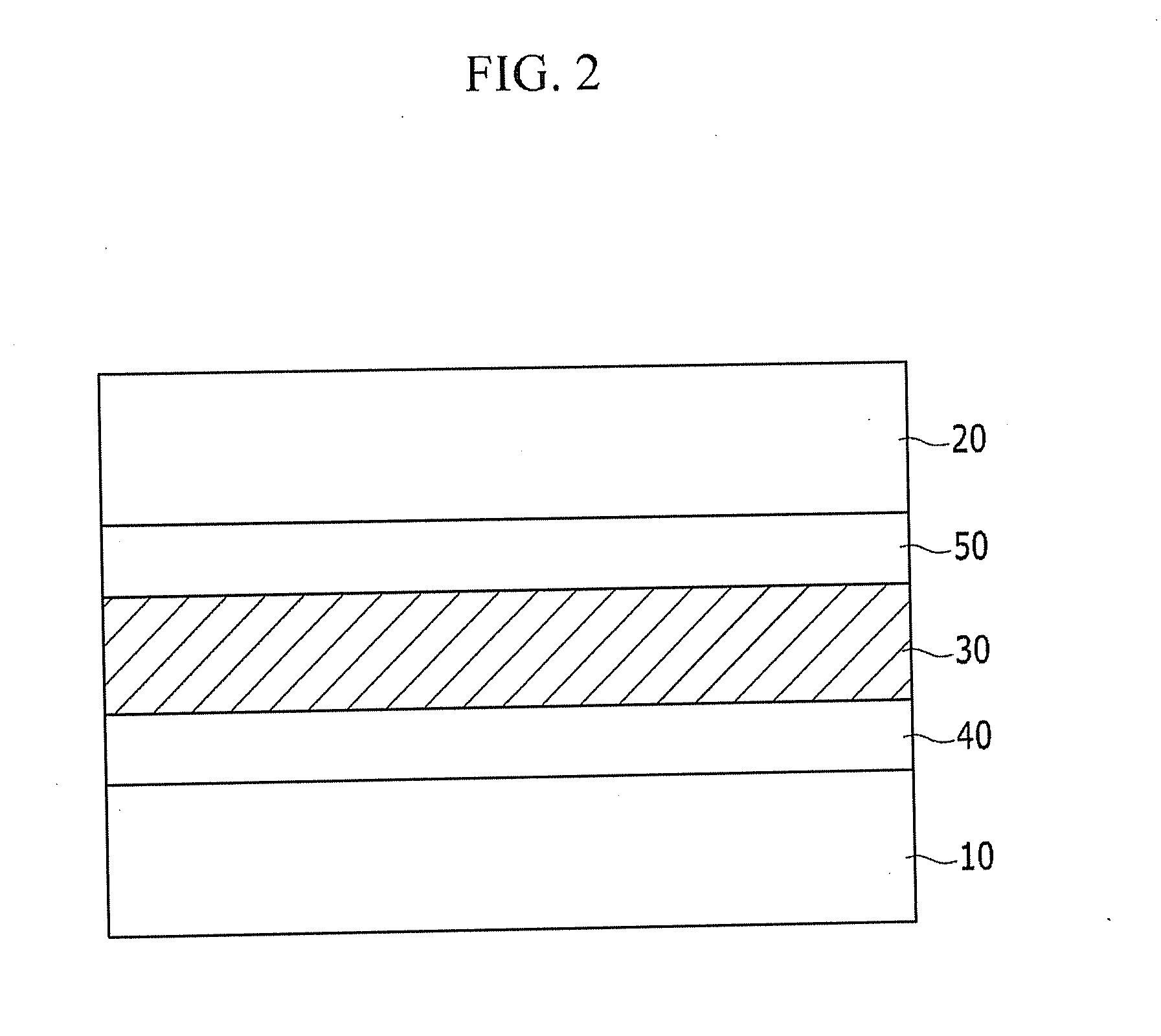

Image pickup device

ActiveUS20060044561A1High Photoelectric Conversion EfficiencyIncreased durabilitySolid-state devicesMaterial analysis by optical meansPhotoelectric conversionQuinazoline

An image pickup device comprises an organic photoelectric conversion film sandwiched between at least two electrodes, wherein the organic photoelectric conversion file comprises a specific quinacridone derivative or a specific quinazoline derivative.

Owner:FUJIFILM CORP +1

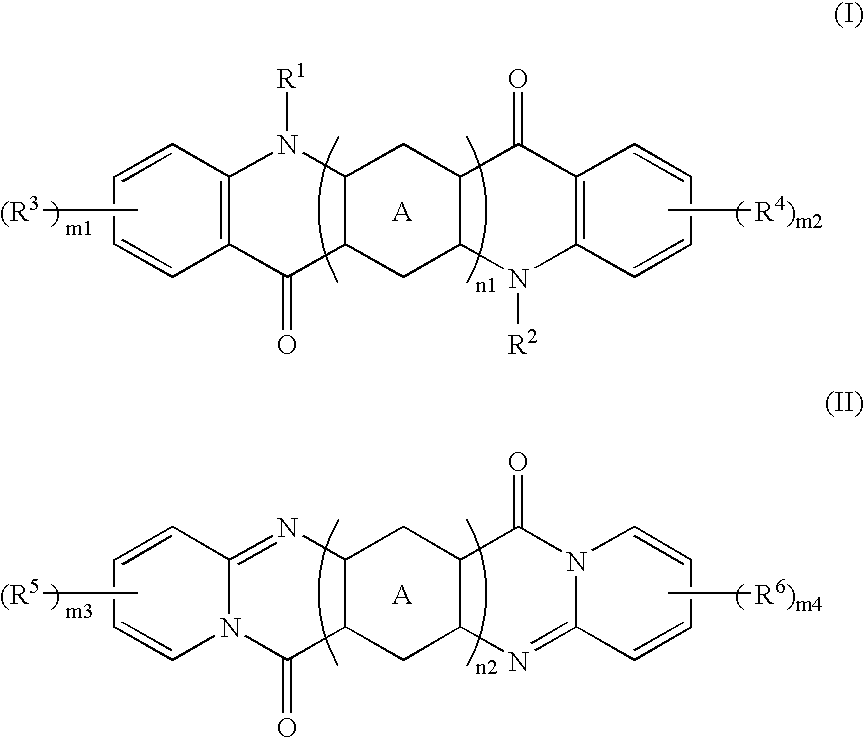

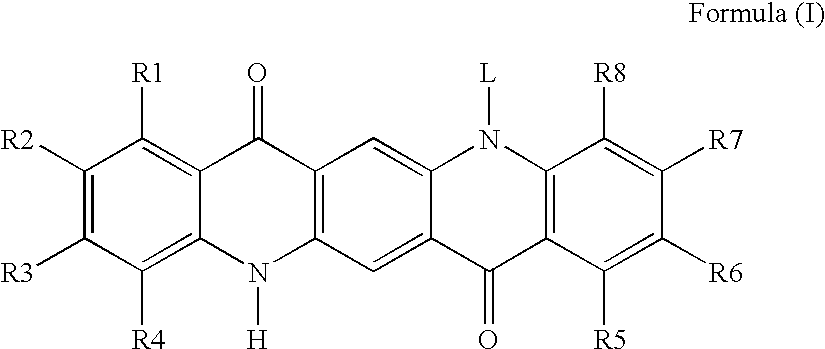

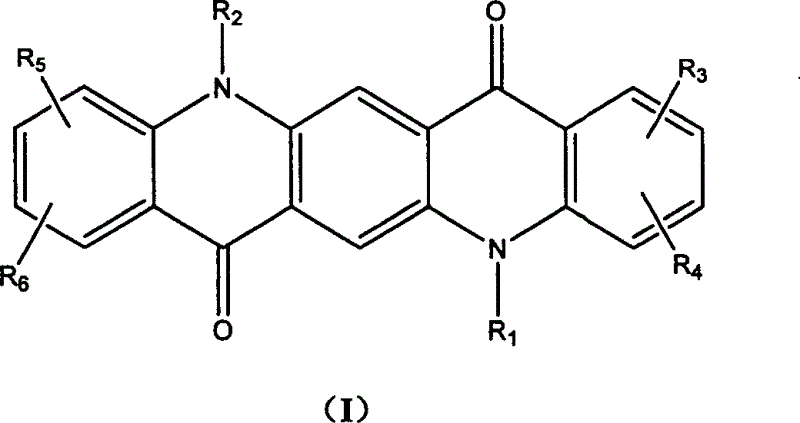

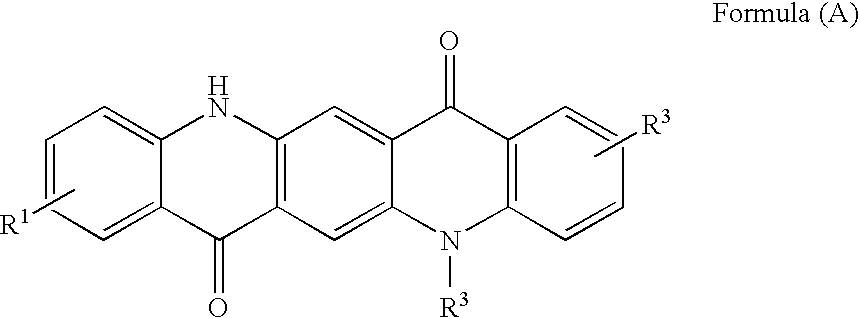

Use of mixed-crystal pigments of the quinacridone series in electrophotographic toners and developers, powder coatings and inkjet inks

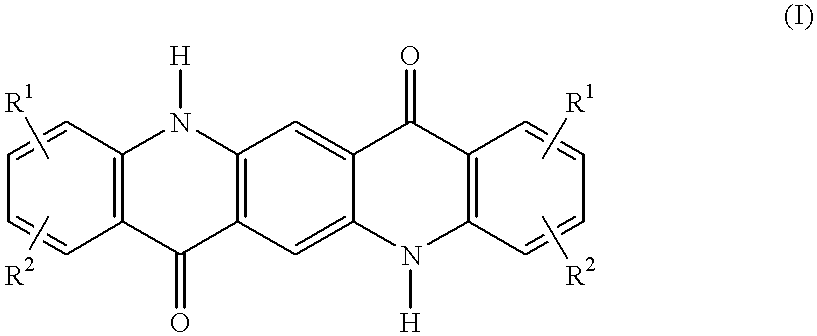

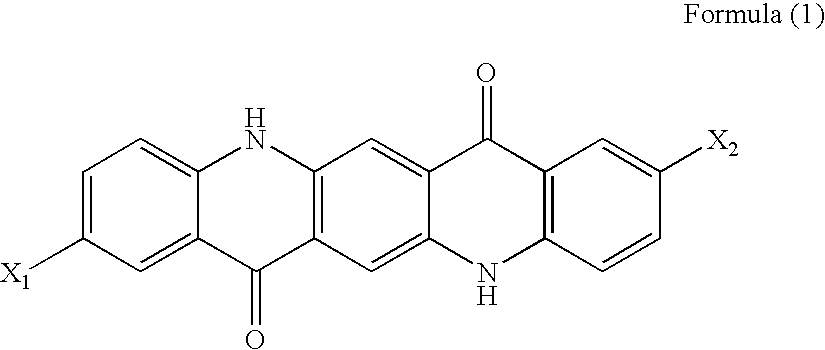

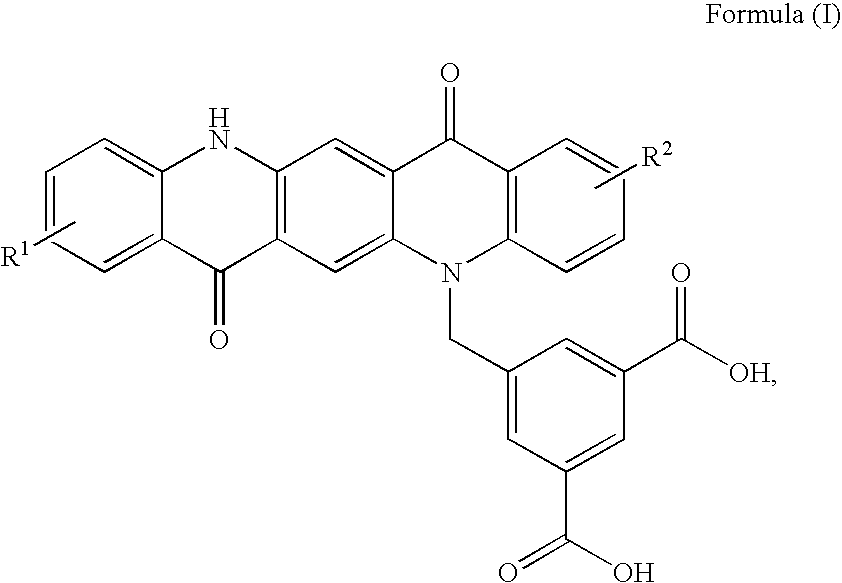

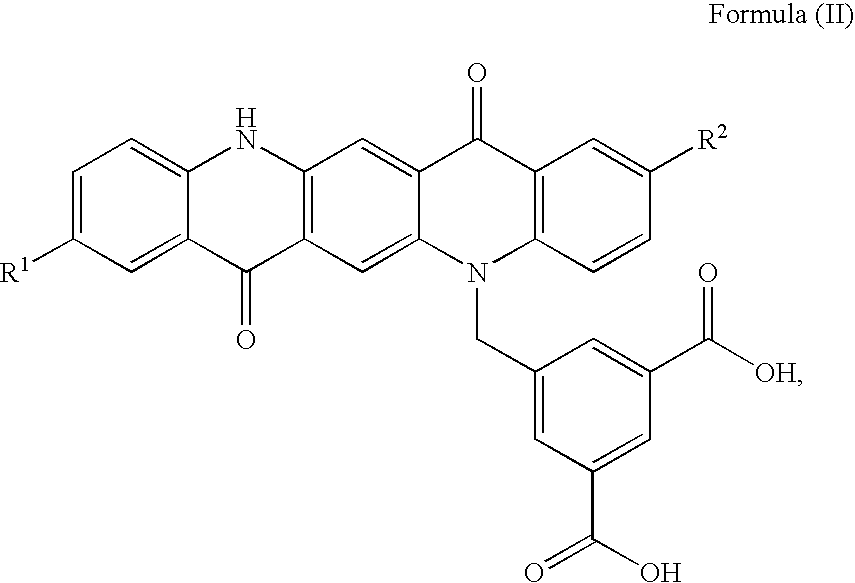

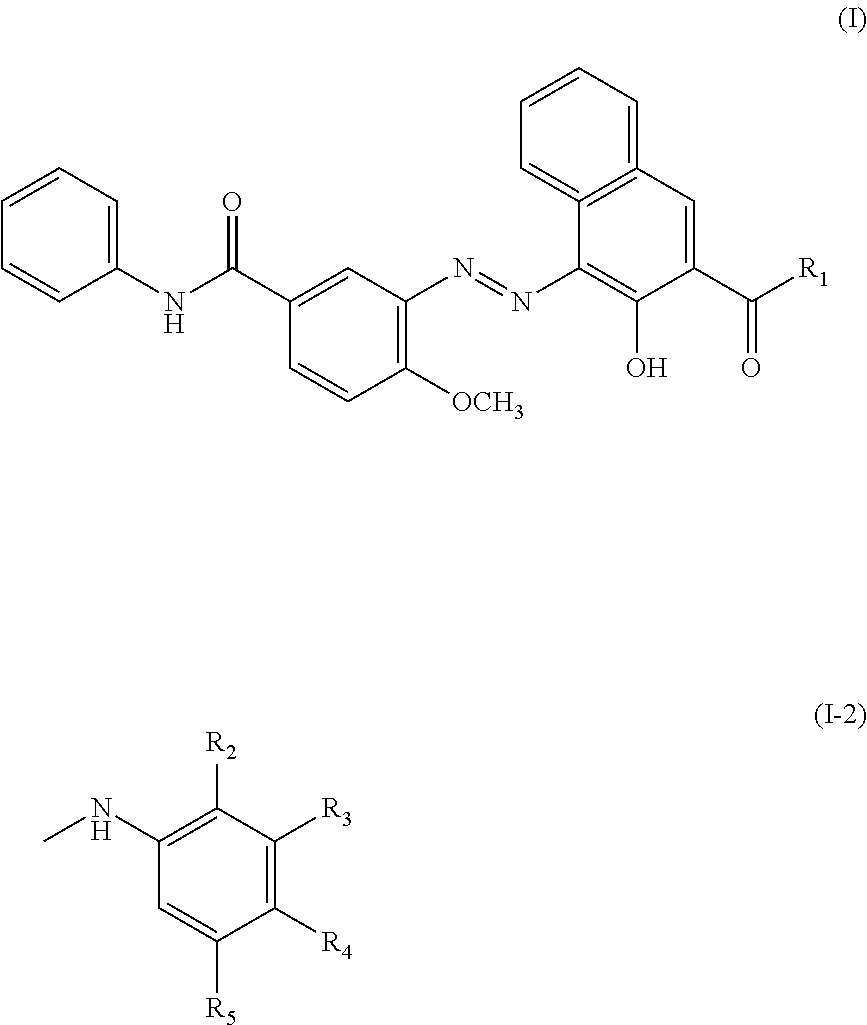

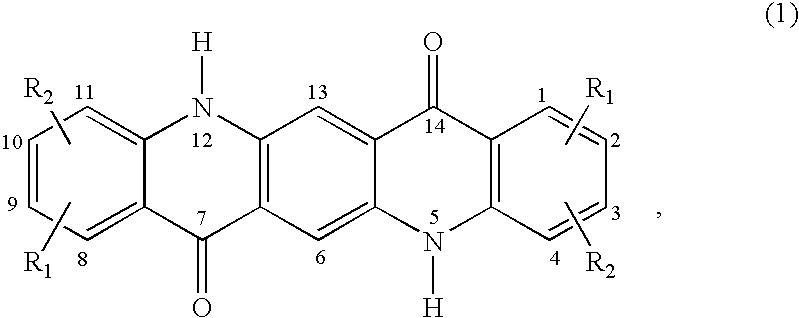

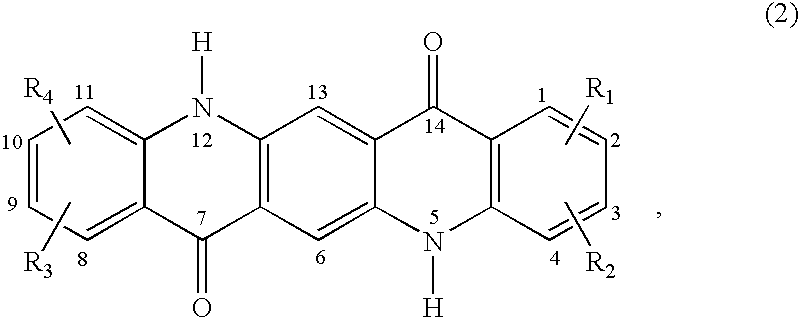

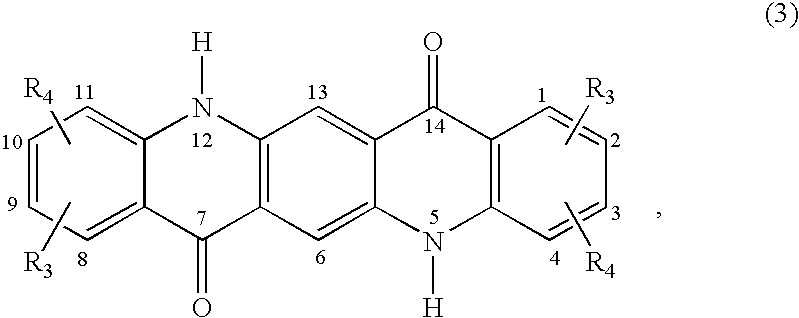

The use of mixed-crystal pigments of the quinacridone series consisting ofa) from 85 to 99% by weight of unsubstituted beta-phase quinacridone of the formula (I)in which R1 and R2 are hydrogen atoms, andb) from 1 to 15% by weight of one or more substituted quinacridones of the formula (I) in which the substituents R1 and R2 are identical or different and are chlorine, bromine or fluorine atoms orC1-C4-alkyl, C1-C4-alkoxy or carboxamido groups, which can be substituted by C1-C6-alkyl groups, and R1 can additionally be hydrogen,as colorants in electrophotographic toners and developers, powder coating materials, inkjet inks, electret fibers, and color filters.

Owner:CLARIANT PROD DEUT GMBH

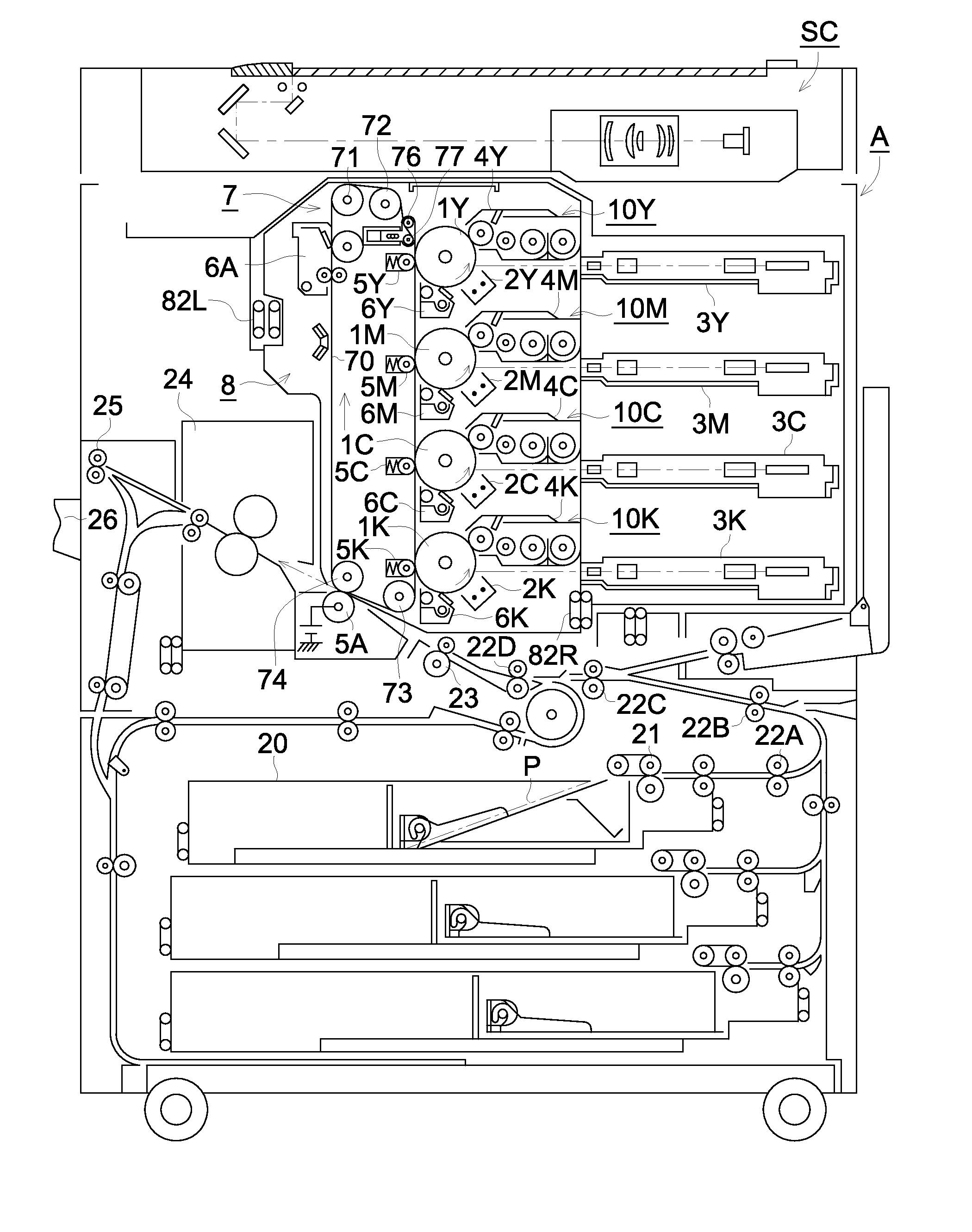

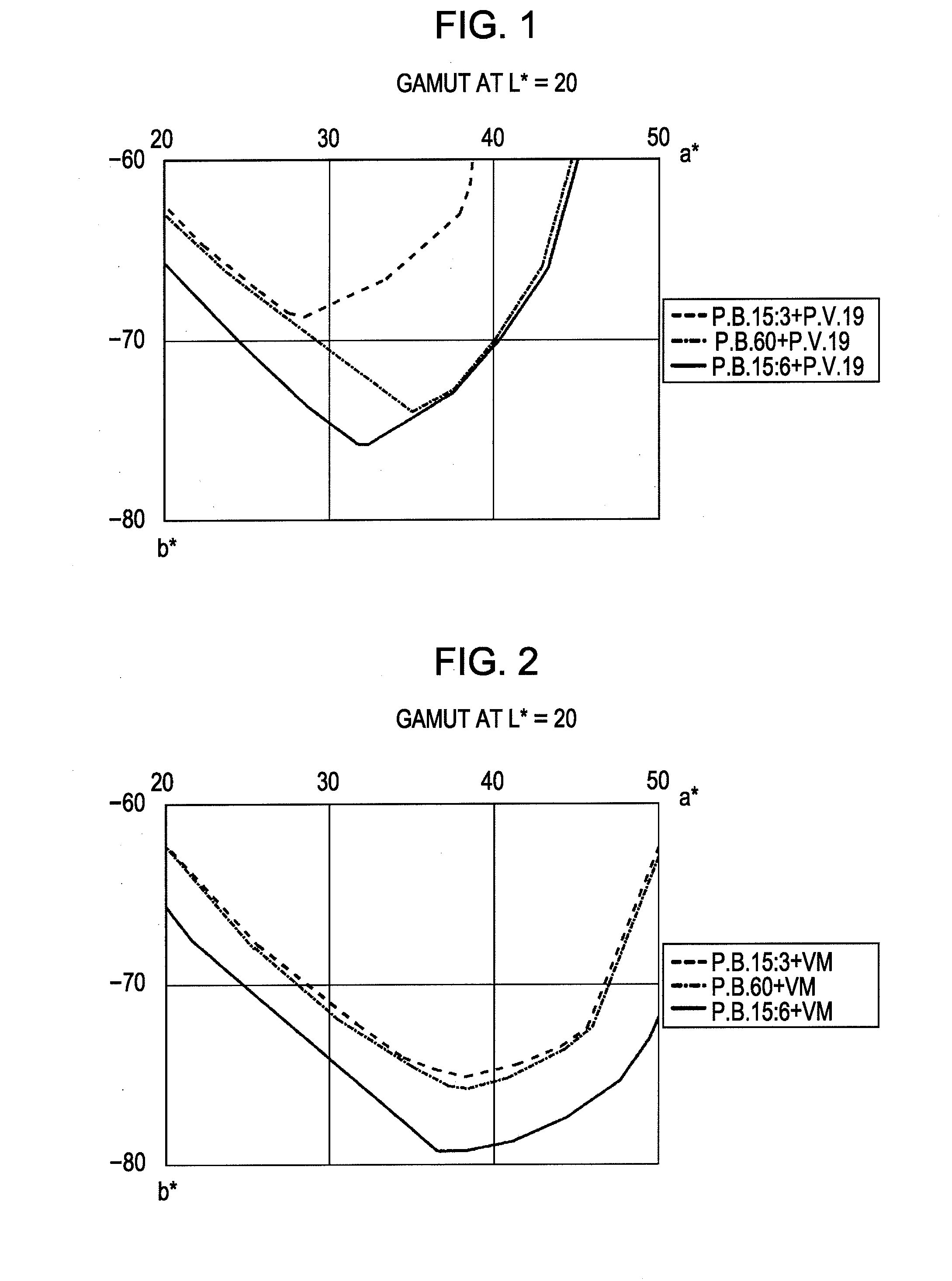

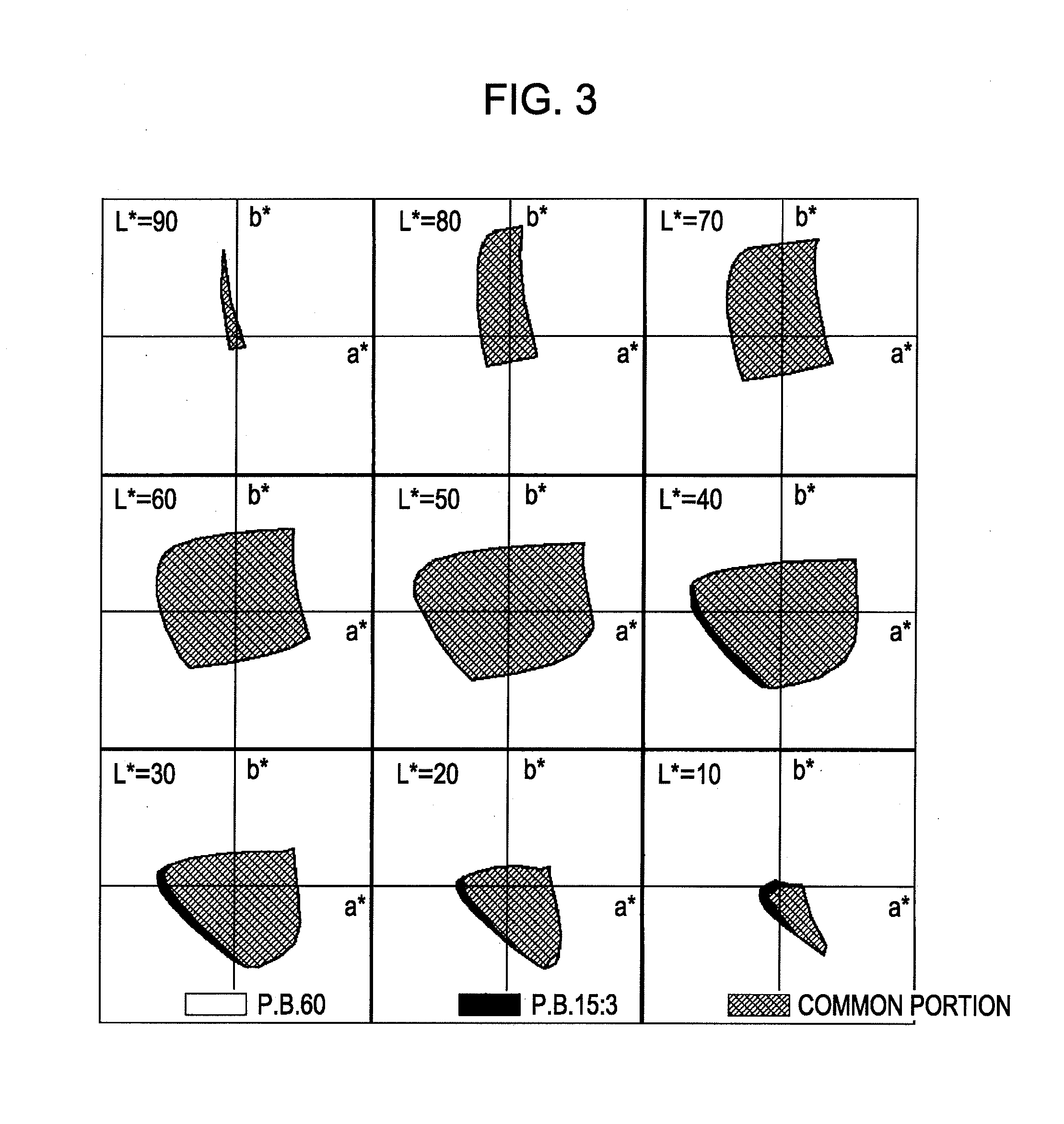

Magenta toner for developing electrostatic images, process for production thereof, developer and image-forming method

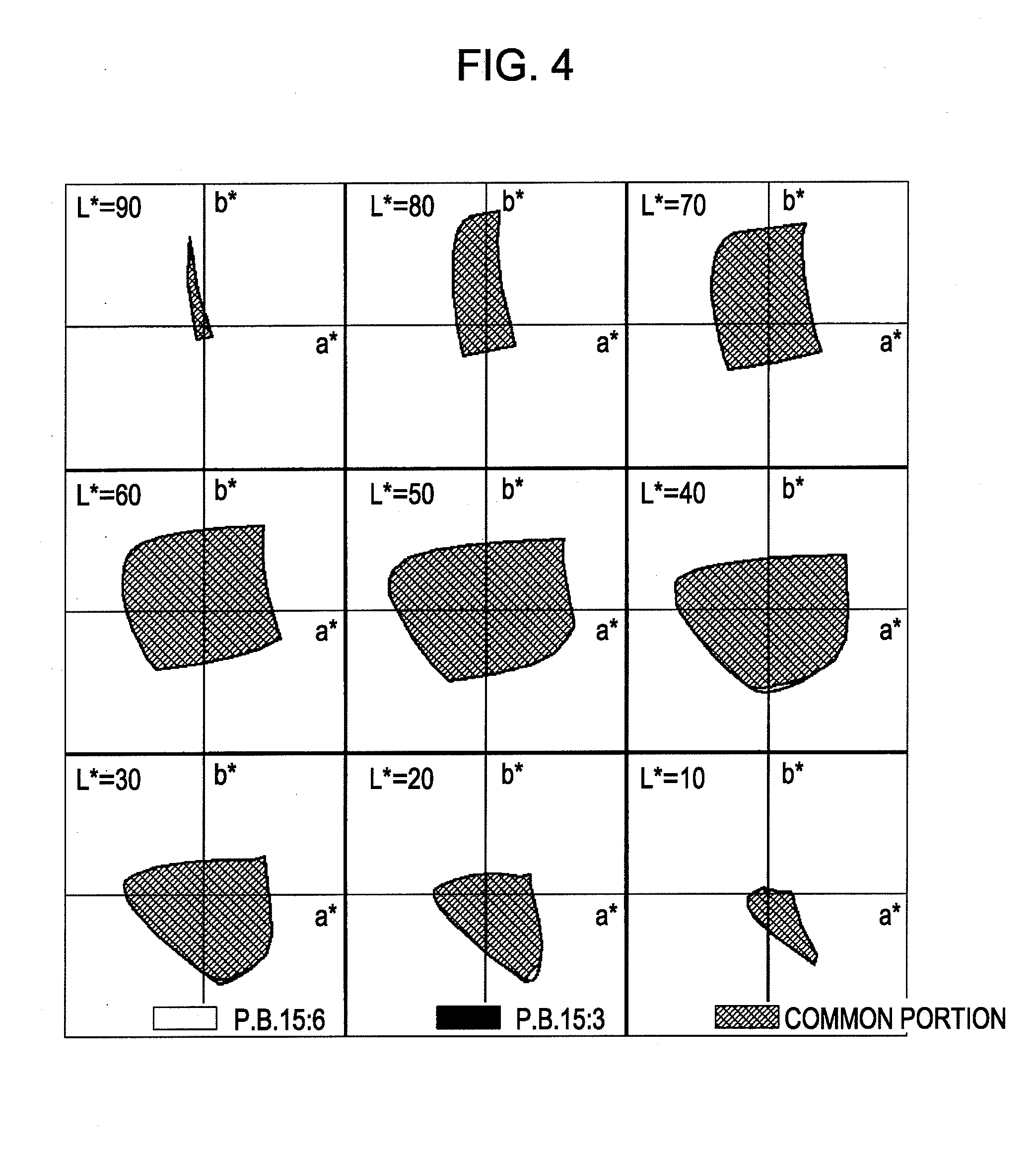

A magenta toner for developing electrostatic images provided which contains a binder resin and a colorant, wherein the colorant includes a mixed crystal of two or more colorants and when a solid patch is fixed on art paper complying with the ISO standard by using this toner, a resulting fixed image color satisfies at least one of the following formulae (b*)<0.85 (a*)−67.92; and (b*)>−7.94(a*)+591.85. The color difference ΔE between the color of the fixed image and the color characterized by L*: 46.6, a*: 75.1 and b*: −4.4 is preferably less than 6. The colorant is preferably a mixed crystal of a quinacridone colorant and a monoazo colorant. Moreover, the invention provides a method for producing the magenta toner, a developer containing the magenta toner, and an image-forming method using the magenta toner.

Owner:FUJIFILM BUSINESS INNOVATION CORP

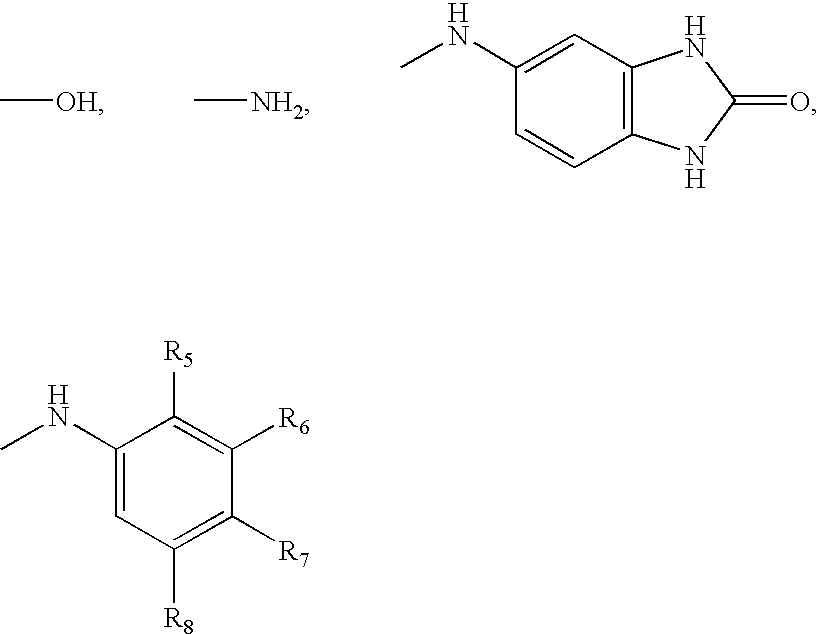

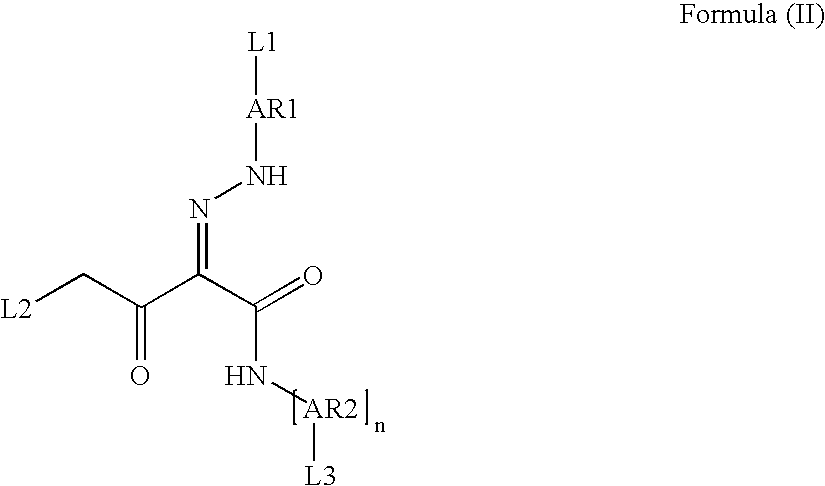

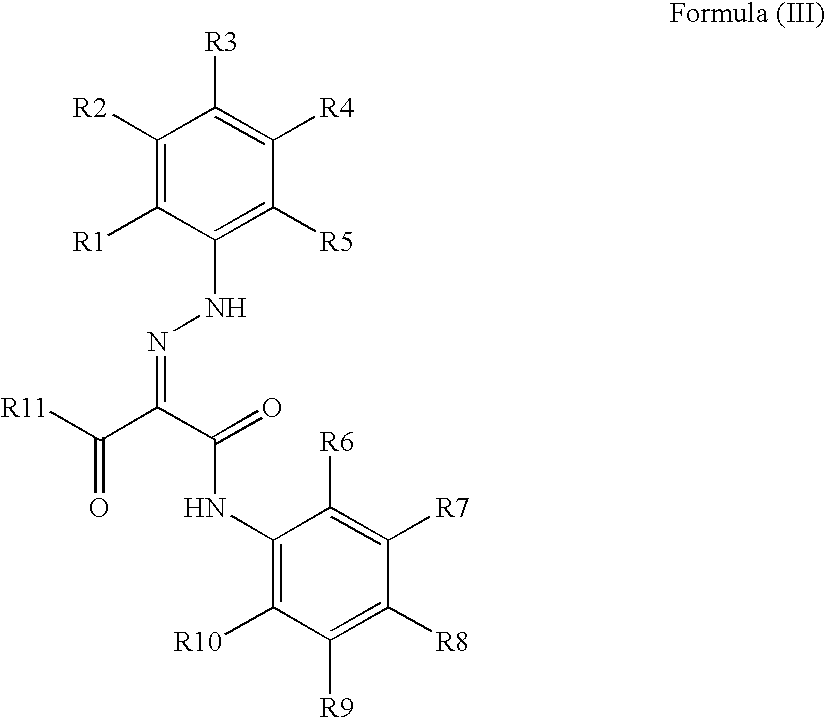

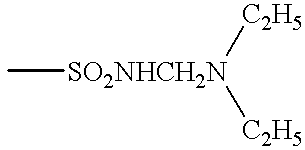

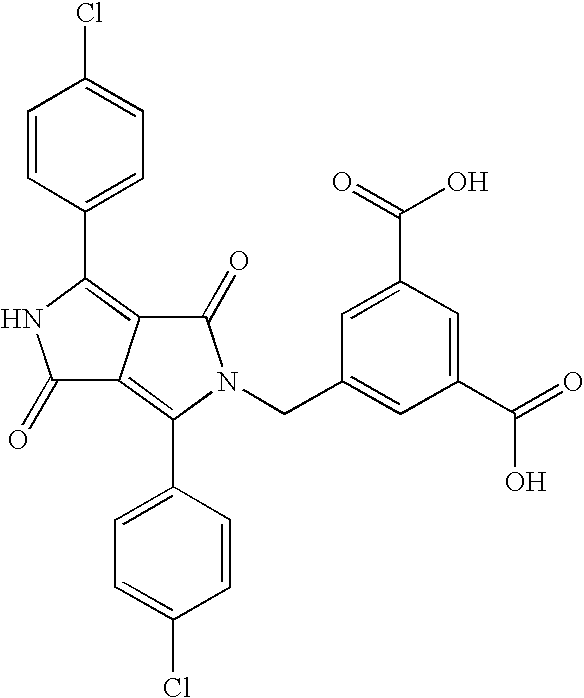

Pigment Dispersions with Polymeric Dispersants Having Pending Chromophore Groups

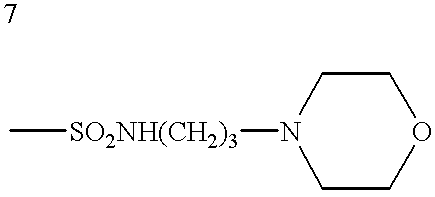

InactiveUS20080227894A1Improve concentrationConsistent Image QualityOrganic chemistryOrganic compound preparationIndigoidineEnd-group

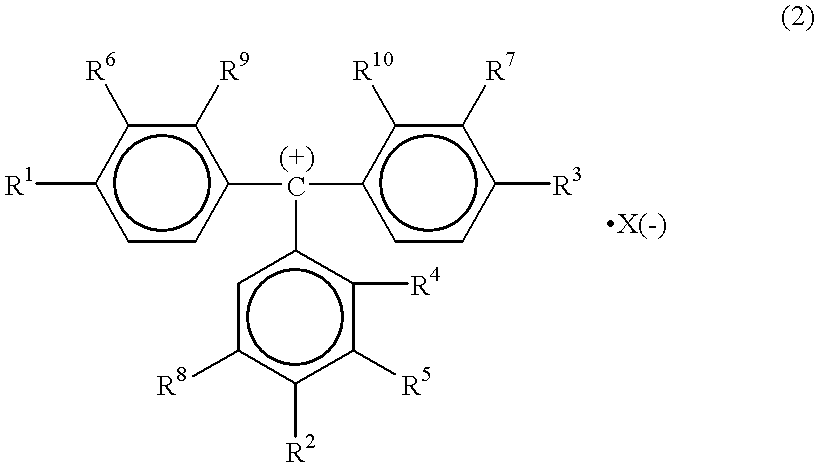

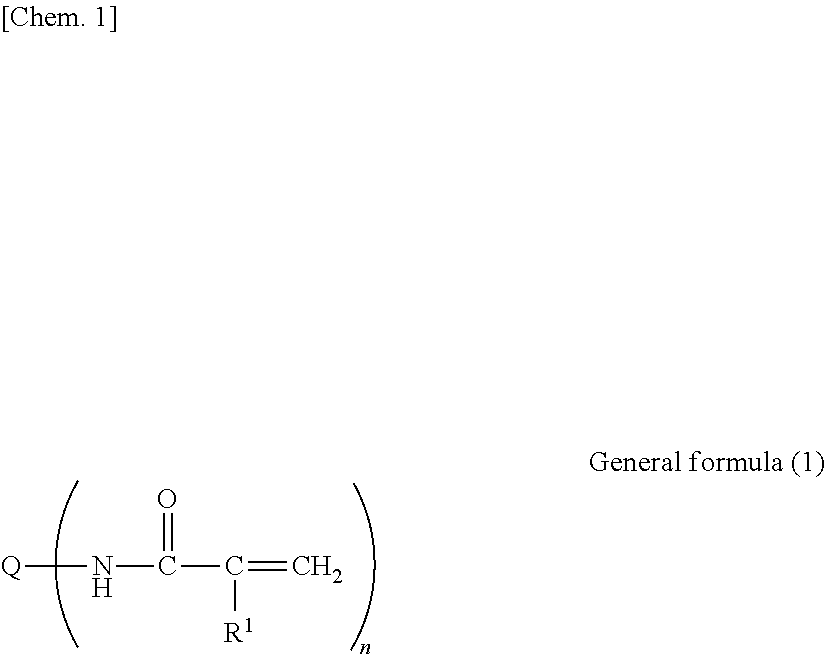

A pigment dispersion comprising a colour pigment and a polymeric dispersant having at least one pending chromophore group covalently bound to the polymeric backbone of the polymeric dispersant through a linking groupwherein the at least one pending chromophore group is a derivative from a colour pigment selected from the group consisting of monoazo pigments, disazo pigments, β-naphtol pigments, naphtol AS pigments, azo pigment lakes, benzimidazolone pigments, disazo condensation pigments, metal complex pigments, isoindolinone pigments, isoindolinine pigments, phthalocyanine pigments, quinacridone pigments, diketopyrrolo-pyrrole pigments, thioindigo pigments, anthraquinone pigments, anthrapyrimidine pigments, indanthrone pigments, flavanthrone pigments, pyranthrone pigments, anthanthrone pigments, isoviolanthrone pigments, aluminium pigment lakes, dioxazine pigments, triarylcarbonium pigments and quinophthalone pigments;the at least one pending chromophore group is a chromophore group occurring as a side group on the polymeric backbone and not a group in the polymeric backbone itself or occurring solely as an end group of the polymeric backbone;the linking group consists of all the atoms between the polymeric backbone and the first atom of the aromatic group by which the pending chromophore group is linked to the polymeric backbone;the polymeric dispersant has a polymeric backbone with a polymerization degree between 5 and 1000; andat most 30% of the monomer units of the polymeric backbone have a pending chromophore group.The pigment dispersion can be advantageously used in inkjet inks.Also disclosed is a method for preparing the pigment dispersion comprising the step of preparing the polymeric dispersant by copolymerizing a monomer already containing the pending chromophore group.

Owner:AGFA NV

Inkjet recording liquid and process for the production thereof

InactiveUS6235099B1High processing temperatureImprove waterproof performanceDuplicating/marking methodsInksWater basedInorganic salts

A water-dispersed inkjet recording liquid excellent in water resistance and transparency and also excellent in the property of ejection from a nozzle, containing, as a colorant, a water-based dispersion of an organic pigment (A) which is at least one member selected from the group consisting of a quinacridone pigment, a benzimidazolone pigment, an insoluble azo pigment, a fuzed azo pigment, a quinophthalone pigment, a naphthol pigment, a perylene pigment and an isoindolinone pigment and has an average particle diameter of 10 to 150 nm (measured by laser scattering), the water-based dispersion of the organic pigment (A) being obtained by mechanically kneading a mixture containing at least three components of the organic pigment (A), a water-soluble inorganic salt (B) in an amount by weight at least three times as large as the amount of the organic pigment (A) and a water-soluble solvent (C) to finely mill the organic pigment (A), and then removing the water-soluble inorganic salt (B) and the water-soluble solvent (C) by washing the kneaded mixture with water, and a process for the production thereof.

Owner:TOYO INK SC HOLD CO LTD

Organic photoelectronic device and image sensor

ActiveUS20130112947A1Improve efficiencyMaterial nanotechnologyOrganic chemistryThiophene derivativesActive layer

An organic photoelectric device may include an anode and a cathode configured to face each other, and an active layer between the anode and cathode, wherein the active layer includes a quinacridone derivative and a thiophene derivative having a cyanovinyl group.

Owner:SAMSUNG ELECTRONICS CO LTD

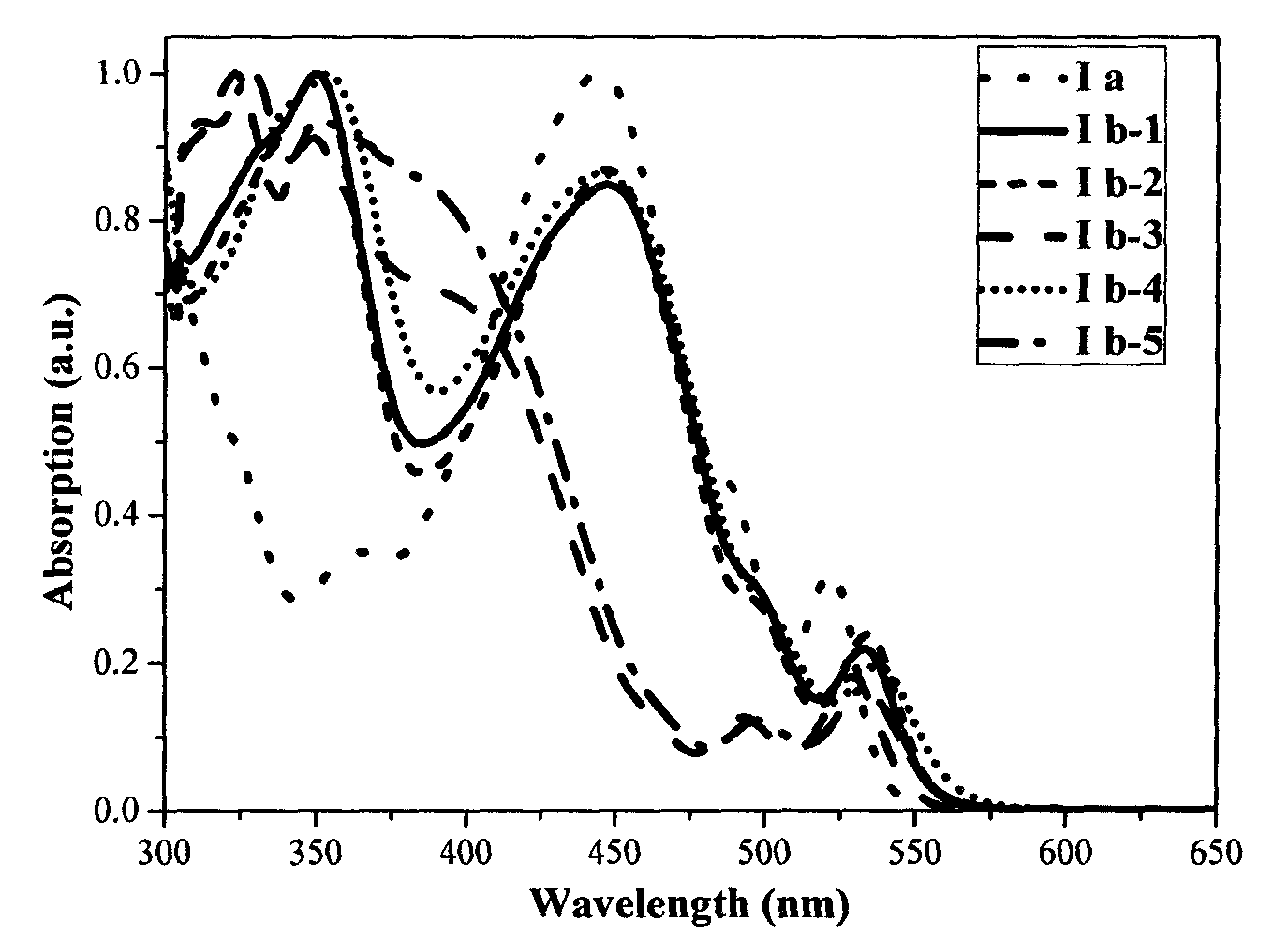

Methods for preparing curable pigment inkjet ink sets

A curable pigment inkjet ink set includes mprg a cyan inkjet ink, a yellow inkjet ink, and a magenta inkjet ink, whereinthe yellow inkjet ink having ABS(Y)500-530<5 and ABS(Y)400-500>60 includes one or more yellow pigments;the cyan inkjet ink includes one or more β-copper phthalocyanine pigments; andthe magenta inkjet ink contains a mixed crystal including a first quinacridone and a second quinacridone in a ratio of the first quinacridone over the second quinacridone such that ABS(M)500-530>20 and ABS(M)500-600>60,ABS(Y)500-530 represents the absorbance of the yellow inkjet ink between 500 and 530 nm in a normalized absorption spectrum of the yellow ink;ABS(M)500-530 represents the absorbance of the magenta inkjet ink between 500 and 530 nm in a normalized absorption spectrum of the magenta ink;ABS(Y)400-500 represents the absorbance of the yellow inkjet ink between 400 and 500 nm in a normalized absorption spectrum of the yellow ink; andABS(M)500-600 represents the absorbance of the magenta inkjet ink between 500 and 600 nm in a normalized absorption spectrum of the magenta ink,wherein ABS(X)WL1-WL2 represents the peak area between the wavelengths WL1 and WL2 calculated by summation of the normalized absorbance values in the range WL1 to WL2 which are obtained by multiplying the absorbance values at each wavelength in the range from 380 to 850 nm by the reciprocal value of the maximum absorbance Amax in the range of 380 to 850 nm using a spectrophotometer with an interval of 1 nm on the ink X diluted in ethyl acetate to a pigment concentration of 40 ppm.

Owner:AGFA NV

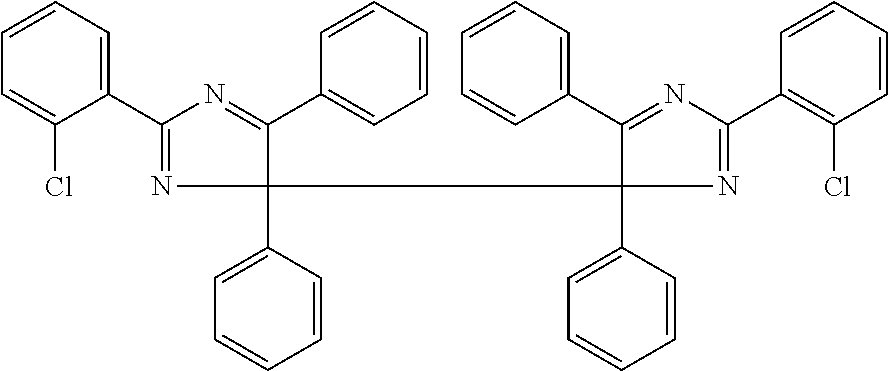

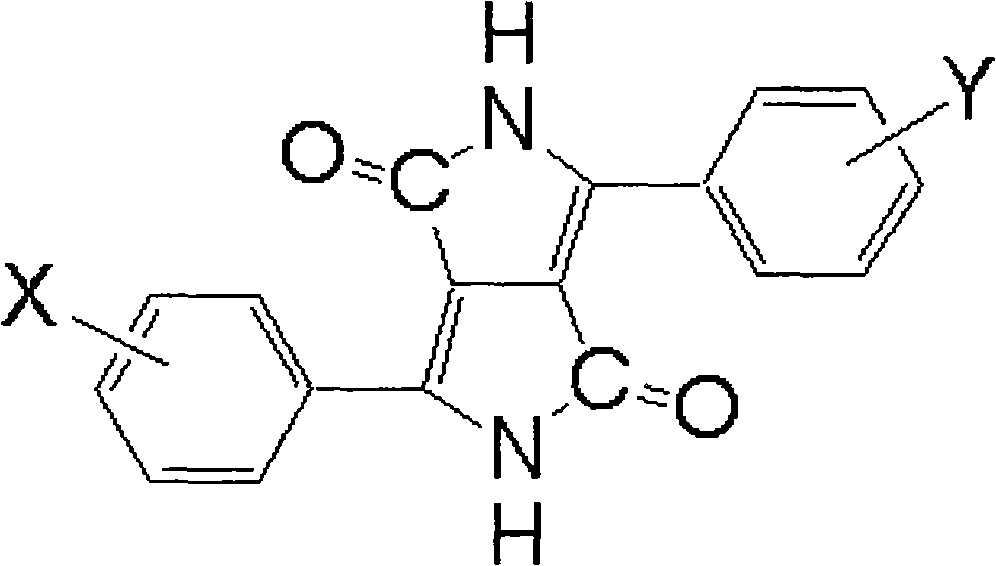

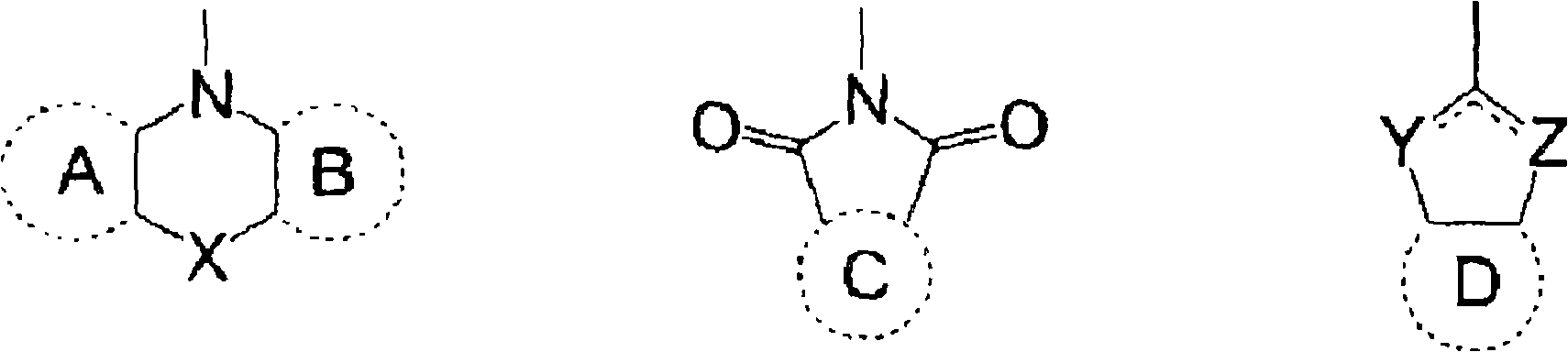

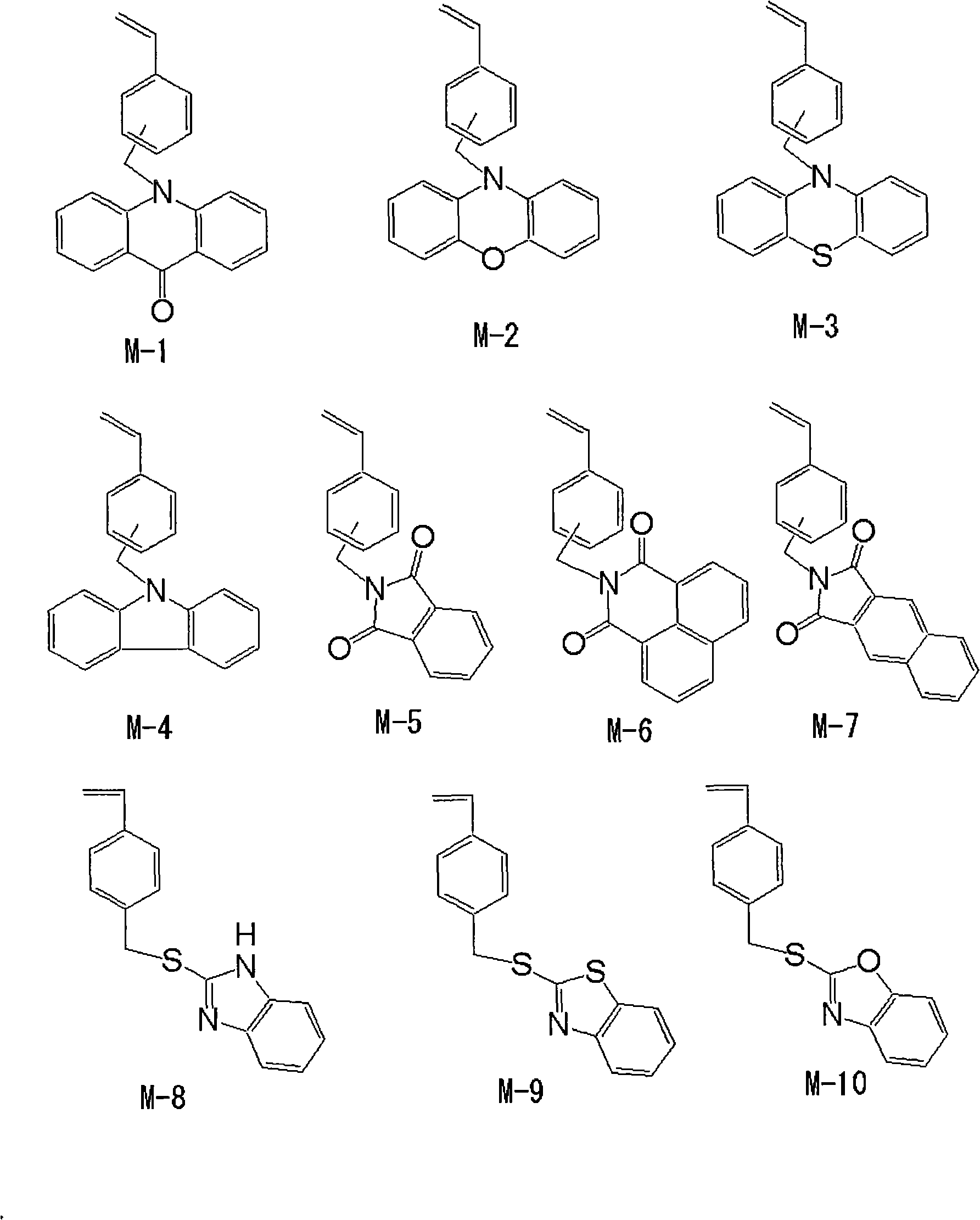

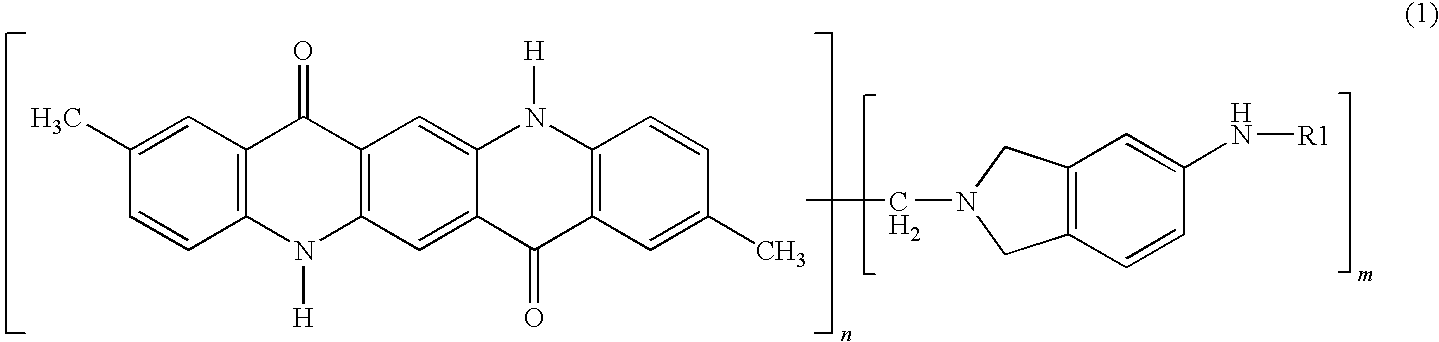

Quinacridone derivant and application in organic electroluminescent device thereof

ActiveCN1482127AIncrease brightnessThe synthesis method is simpleOrganic chemistryElectrical apparatusOrganic electroluminescenceQuinacridone

The present invention relates to organic electroluminescent material, and is especially one kind of quinacridone derivative and its application as electroluminescent material. One series of hexasubstituted quinacridones as novel electroluminescent material for producing high performance organic electroluminescent device is provided. The organic electroluminescent device of the present inventionconsists of glass substrate, positive electrode, negative electrode, carrier implanting layer between the positive electrode and the negative electrode, carrier transmission layer and luminescence layer. The compound of the present invention plays important role in the luminescence layer. The compound of the present invention has simple preparation process, and the luminescent device has high brightness, high efficiency, efficiency less affected by the dope density, low start voltage, long life and other advantages.

Owner:JILIN UNIV

Pigment dispersing composition and manufacturing method thereof, coloured polymerized composition, colour filter and manufacturing method thereof

ActiveCN101555362AImprove dispersion stabilityIncrease contrastOrganic chemistryOptical filtersOrganic solventKetone

The invention provides a pigment dispersing composition and a manufacturing method thereof, coloured polymerized composition, colour filter and manufacturing method thereof. The pigment dispersing composition contains pyrrolo-pyrrole-dione series pigments, 1 to 30 mass parts of phthaloyl imidoalkylated pyrrolo-pyrrole-dione in terms of 100 mass parts of pyrrolo-pyrrole-dione series pigments; 0.1 to 20 mass parts of phthaloyl imidoalkylated quinacridone in terms of 100 mass parts of pyrrolo-pyrrole-dione series pigments and at least an organic solvent.

Owner:FUJIFILM CORP

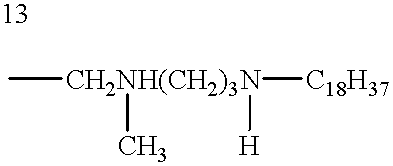

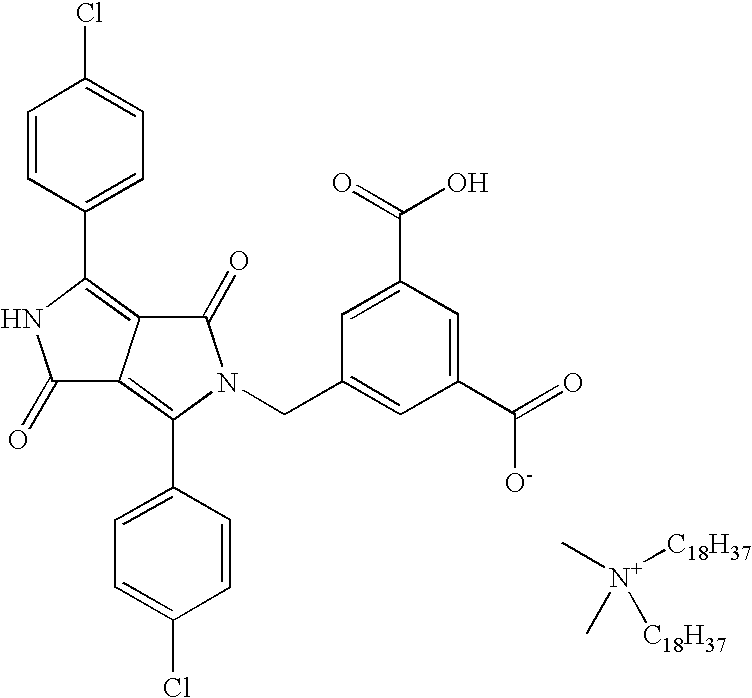

Non-Aqueous Inkjet Inks of Quinacridone Pigments

InactiveUS20080295734A1Quality improvementImprove stabilityInksQuinacridonesMixed crystalQuinacridone

A non-aqueous inkjet ink includes a quinacridone pigment and a dispersion synergist wherein the quinacridone pigment is a mixed crystal including a dimethyl substituted quinacridone and a monomethyl substituted quinacridone and the dispersion synergist includes at least one acid group.

Owner:AGFA NV

Magenta toner

Provided is a magenta toner having a toner particle containing a binder resin, a wax and a colorant, wherein the colorant contains a specific amount of a compound (1), the colorant also contains one or more compounds selected from the group consisting of a naphthol compound, a quinacridone compound and a lake compound thereof in addition to the compound (1), and the binder resin contains a specific amount of a polyester resin.

Owner:CANON KK

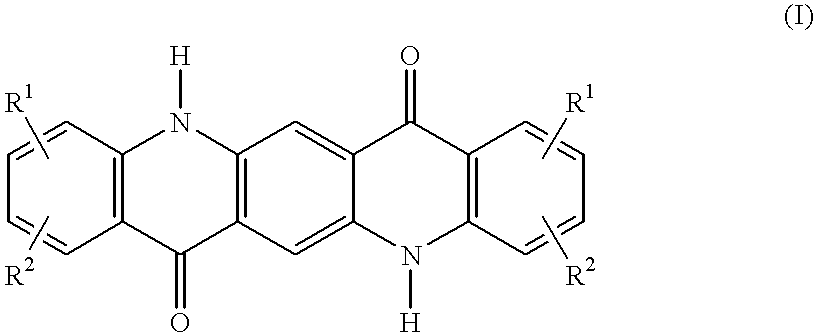

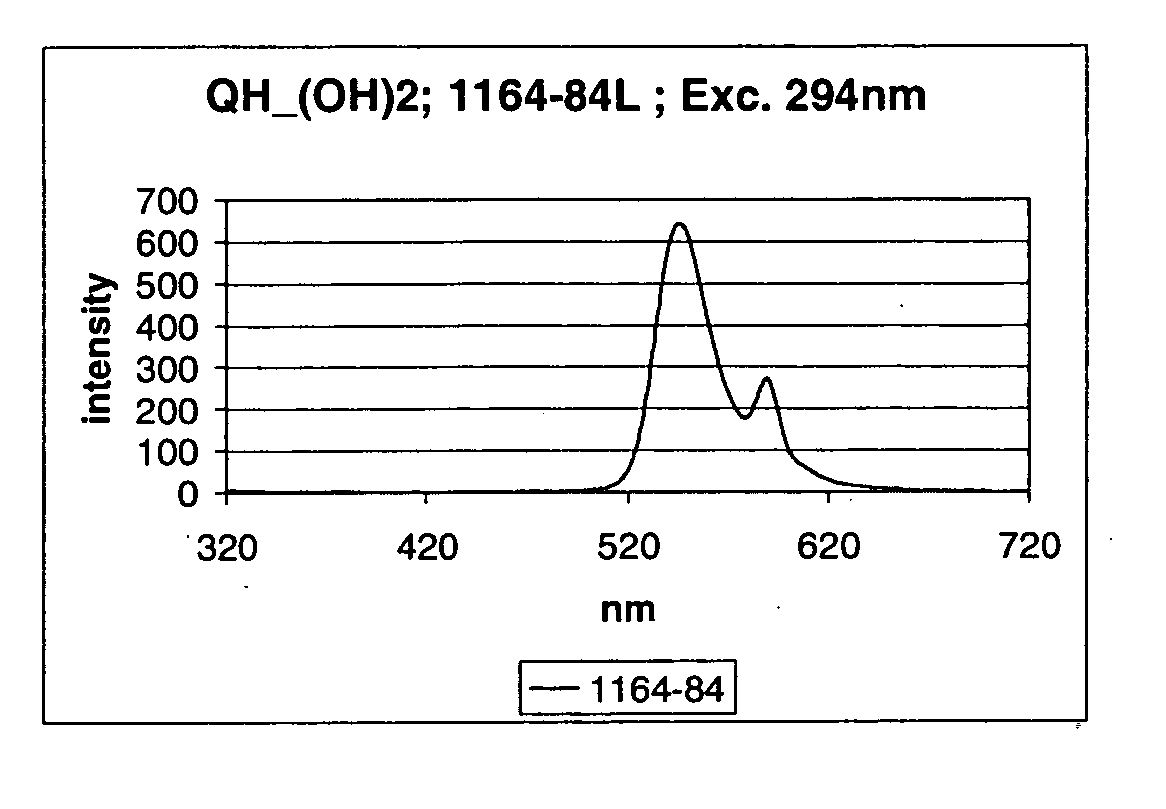

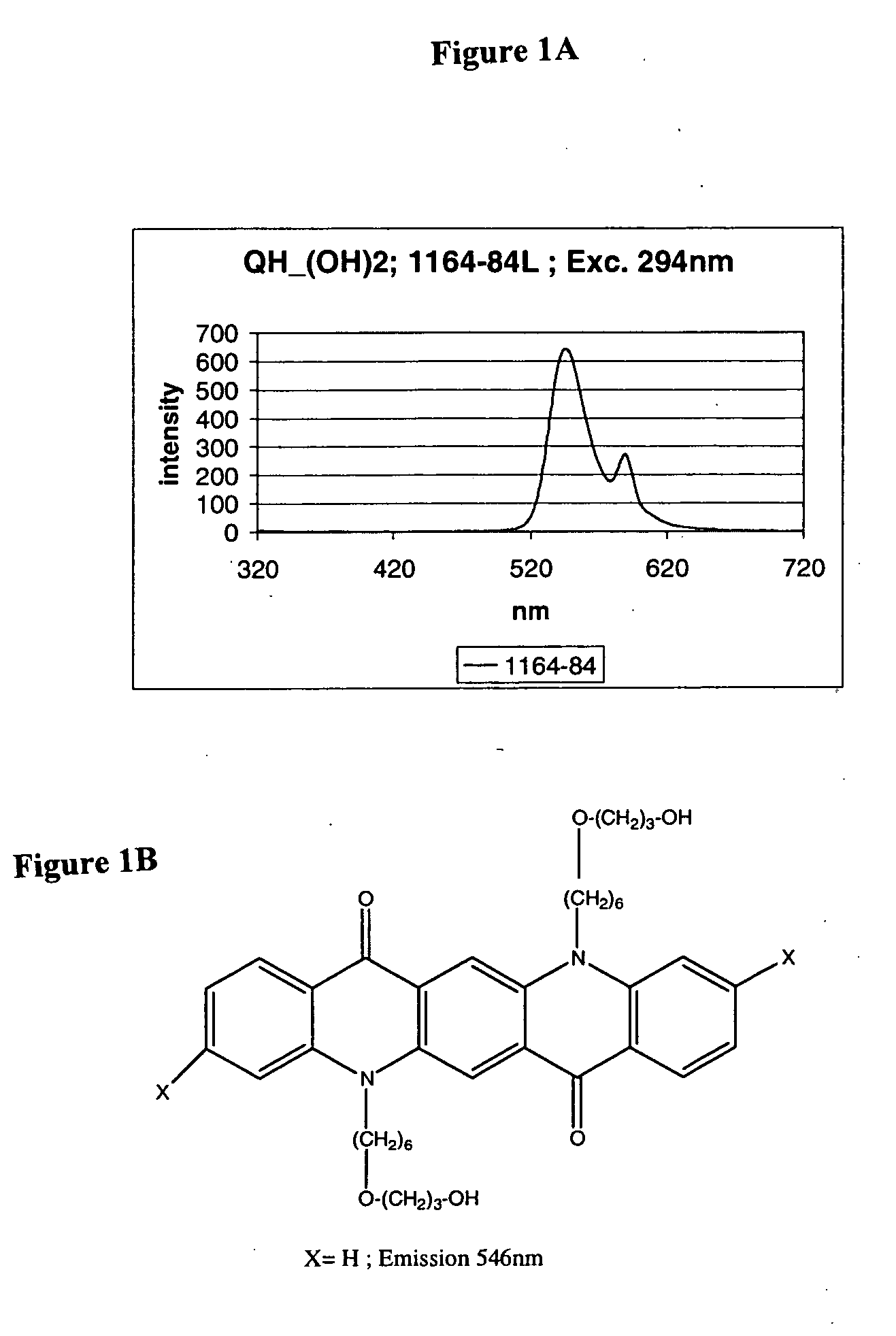

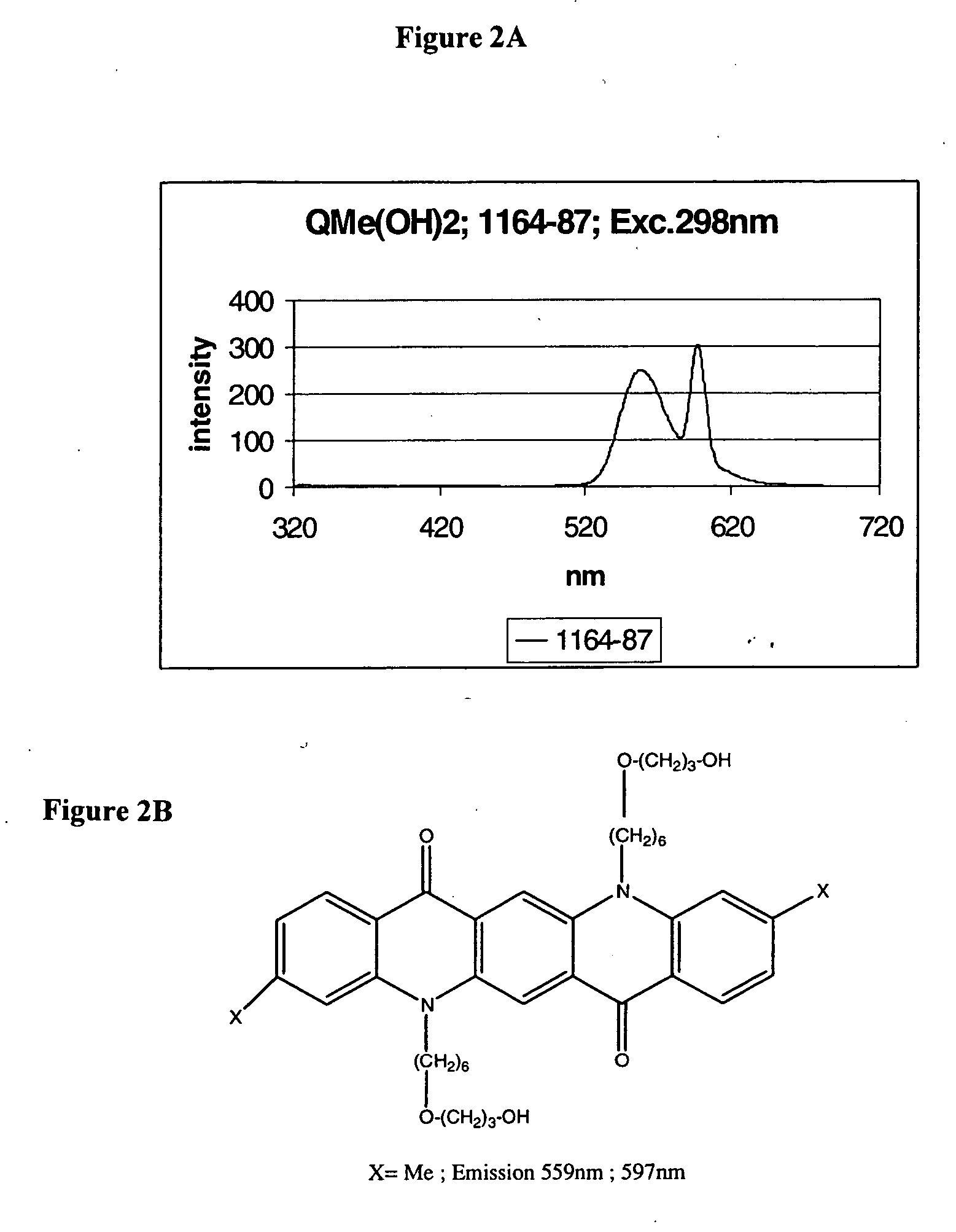

Flourecent quinacridone derivatives

InactiveUS20060240452A1Improve solubilitySugar derivativesGroup 5/15 element organic compoundsOrganic chemistryQuinacridone

The present invention relates to methods and compositions utilizing fluorescent quinacridone derivatives. In particular, the present invention relates to the use of fluorescent quinacridone derivatives for the labeling and detection of riucleic acids. The present invention thus provides improved compositions and methods for labeling biological molecules useful in the detection of nucleic acids and other biological molecules.

Owner:THIRD WAVE TECH

Toner for developing electrostatic image, full color toner kit, and image formation method

ActiveUS20110008720A1High chromaBright color toneDevelopersElectrographic process apparatusImage formationEngineering

Disclosed are a toner for developing an electrostatic image, a full color toner kit and an image formation method, the toner containing at least a resin and a colorant, wherein the colorant comprises a quinacridone pigment having a number average primary particle size of from 30 to 150 nm and having a ratio of a major axis direction length to a minor axis direction length of from 1.0 to 2.0 and Pigment Red 238.

Owner:KONICA MINOLTA BUSINESS TECH INC

Waterborne nanometer universal fat-free colorant and preparation method thereof

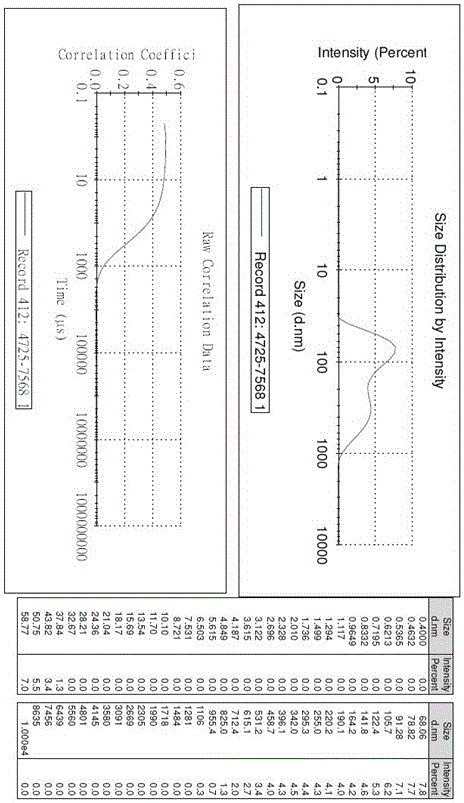

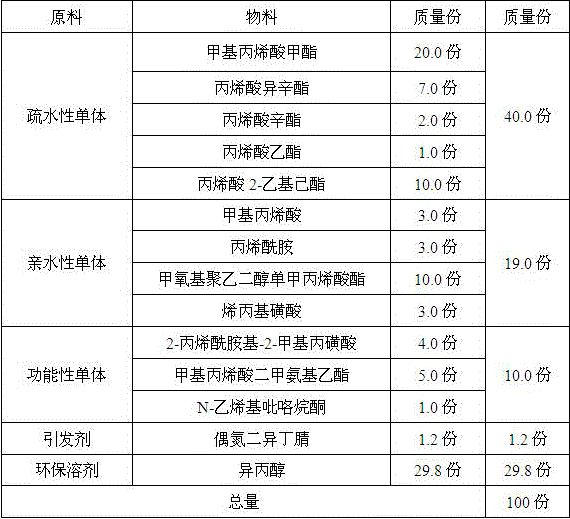

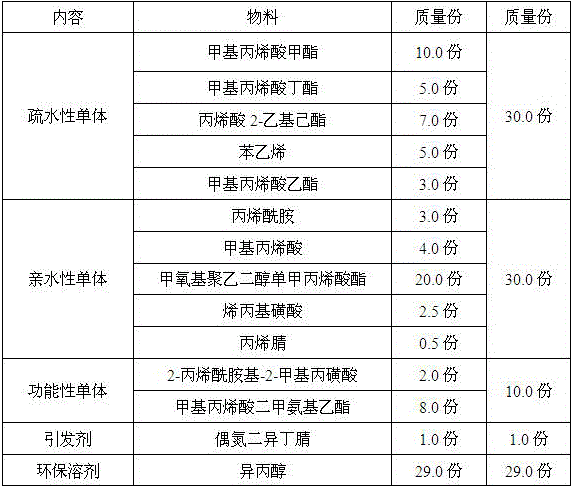

The invention discloses a waterborne nanometer universal fat-free colorant and a preparation method thereof. The colorant is prepared from a dispersing agent and a nanometer universal colorant, wherein the dispersing agent is prepared from a hydrophobic monomer, a hydrophilic monomer, a functional monomer, an initiator and an environment-friendly solvent; the nanometer universal colorant is prepared from a toner, a dispersing agent, a humectant, an defoaming agent, an anti-settling agent, a sterilizing agent and deionized water. The dispersing agent is suitable for various waterborne fat-free colorants, particularly for pigments which are difficult to disperse such as quinacridone; the prepared colorant has high stability, is of nano-grade particle size, has efficient dispersing and anti-flocculating effects, low viscosity and high storage stability, and can be widely applied to waterborne wood lacquer, waterborne metal painting, automobile electrophoretic paint, waterborne plastic colored paint, waterborne textile printing, waterborne screen printing ink and the like.

Owner:JIANGSU LYNWON TECH CO LTD

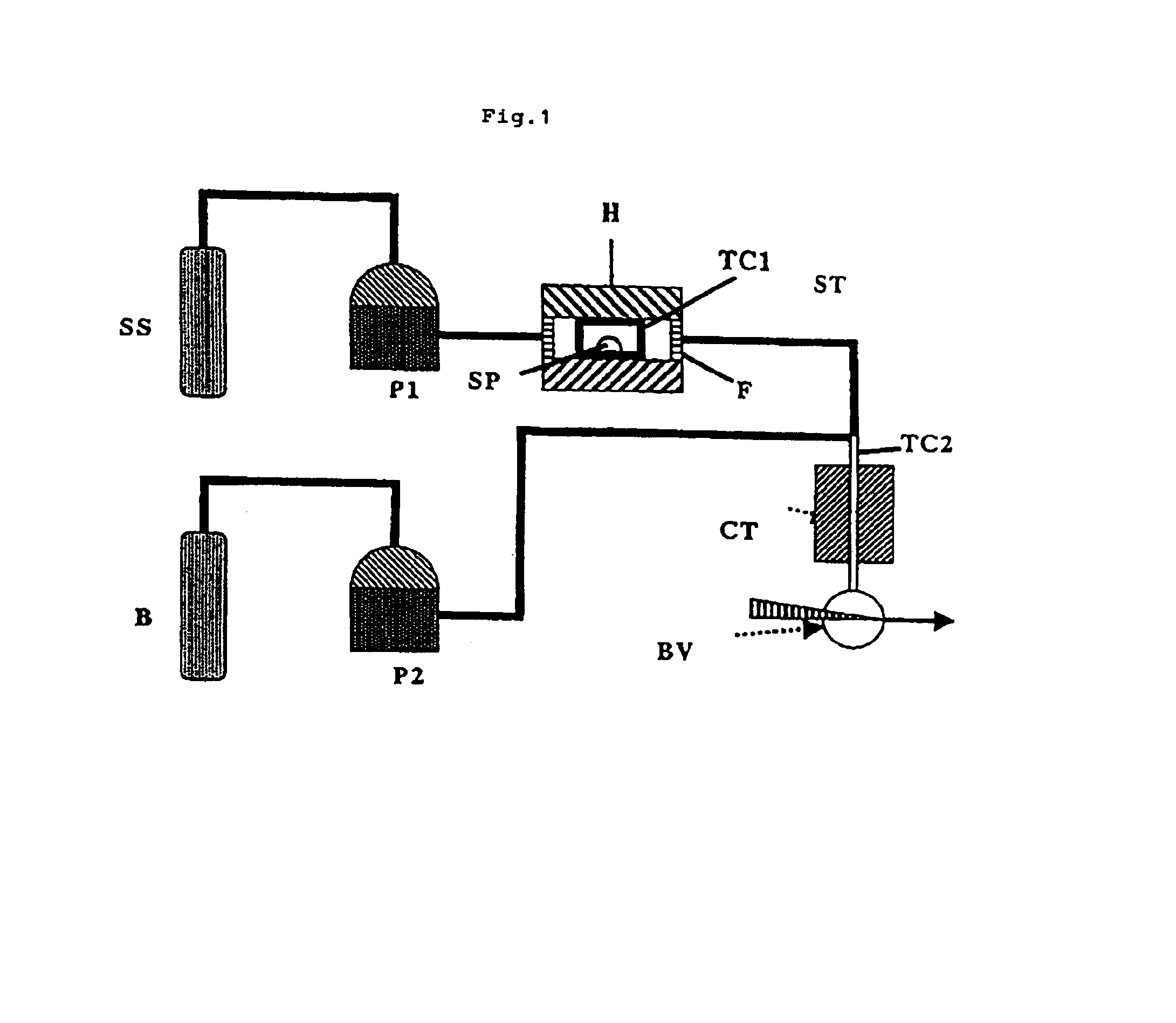

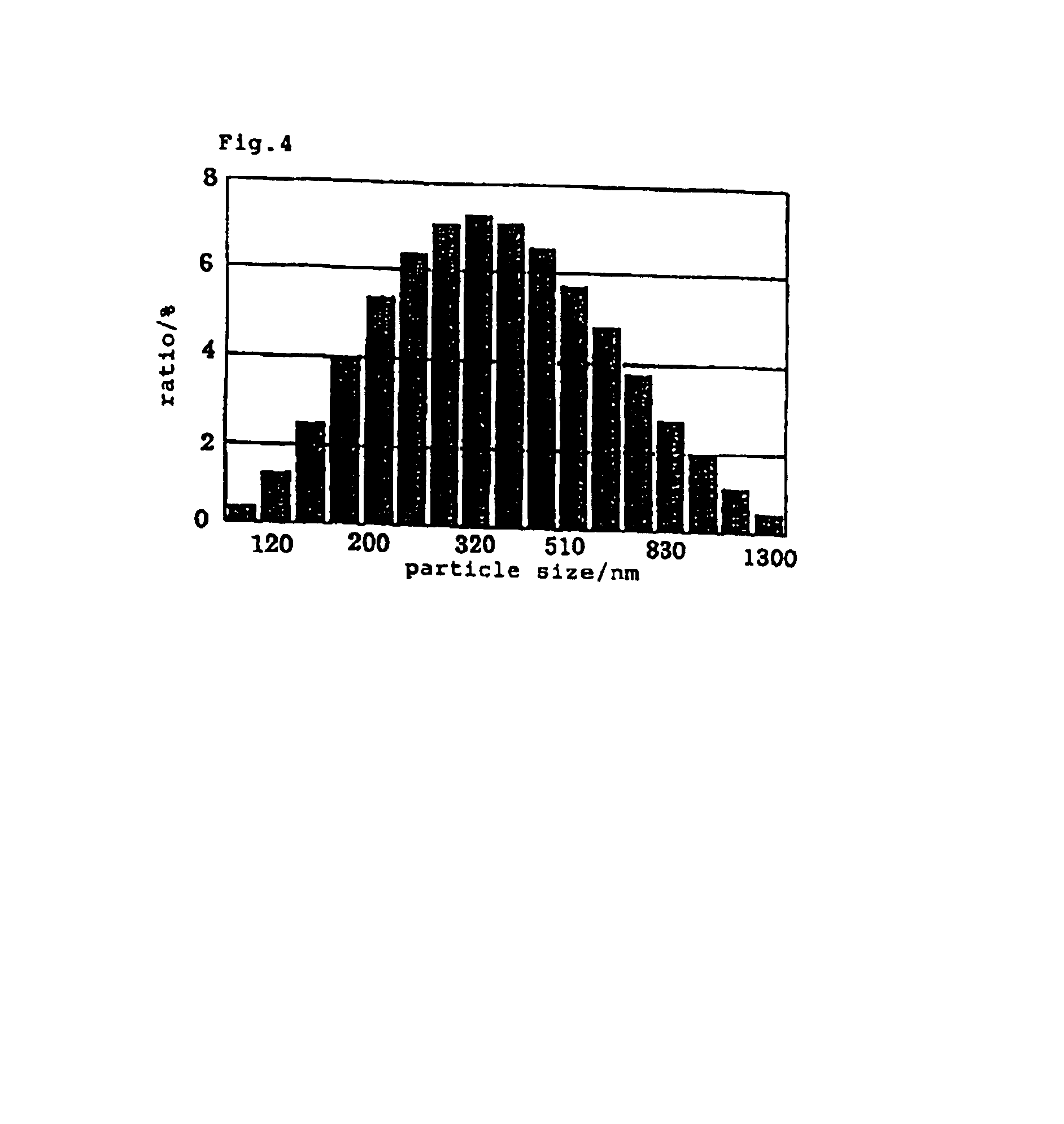

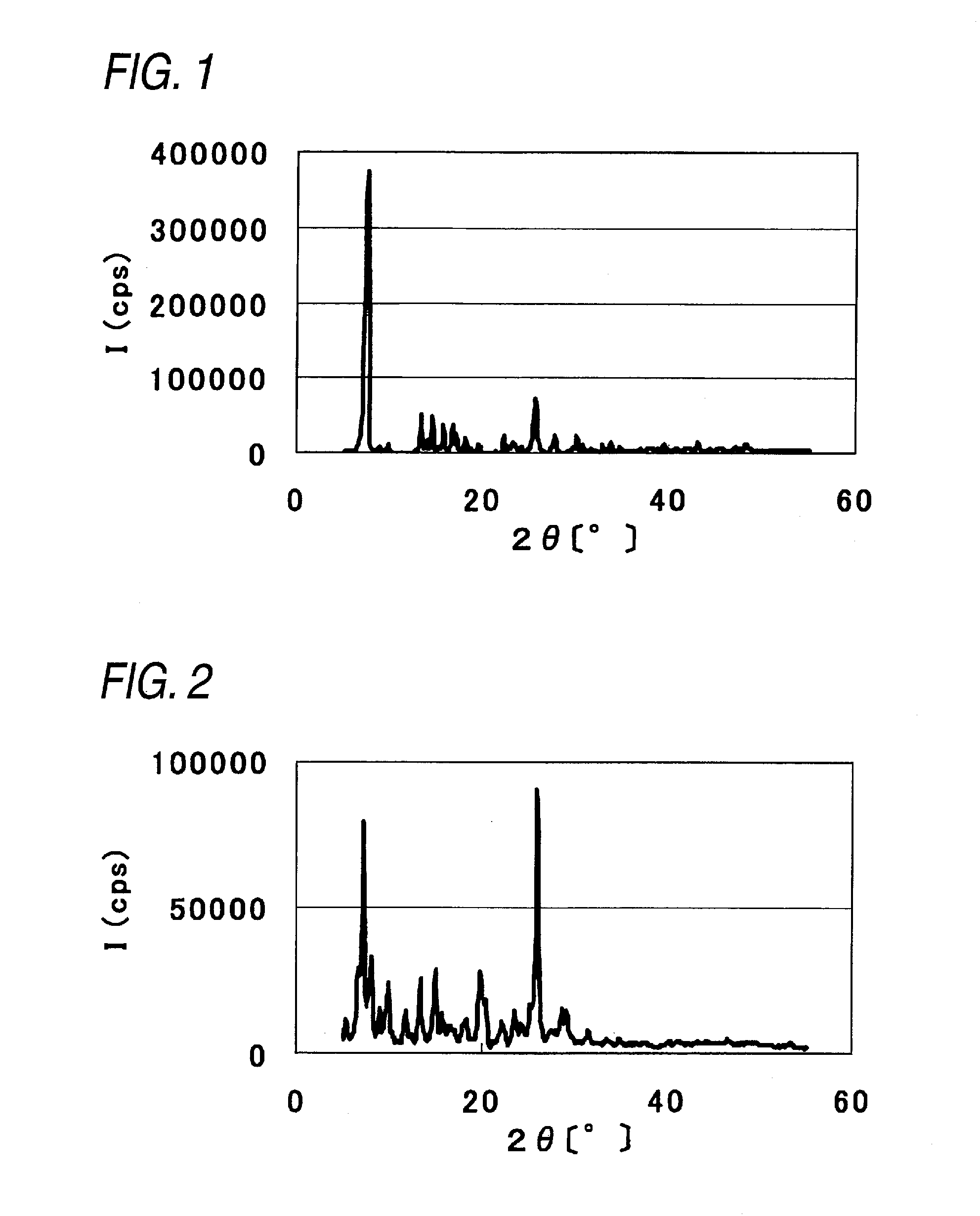

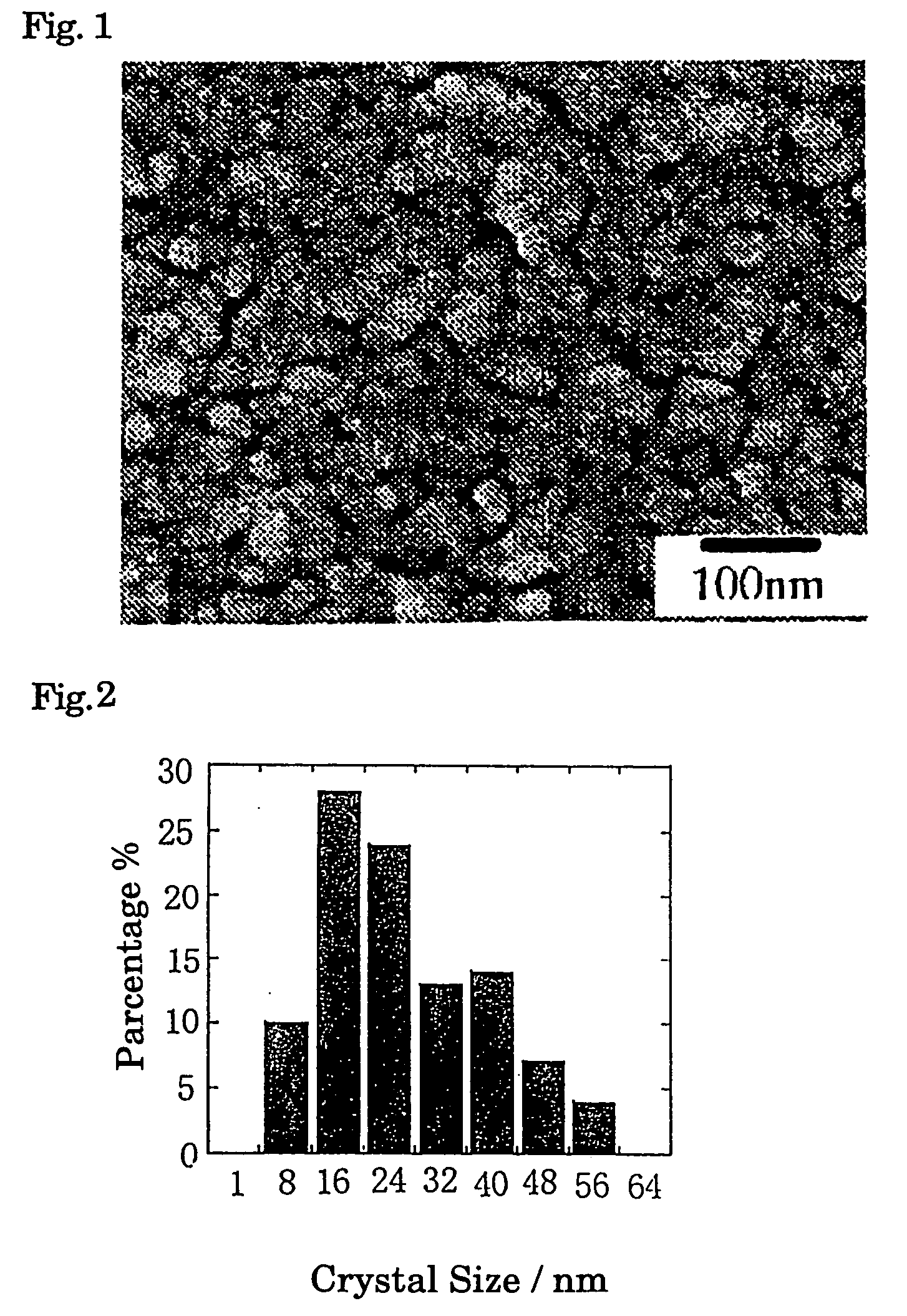

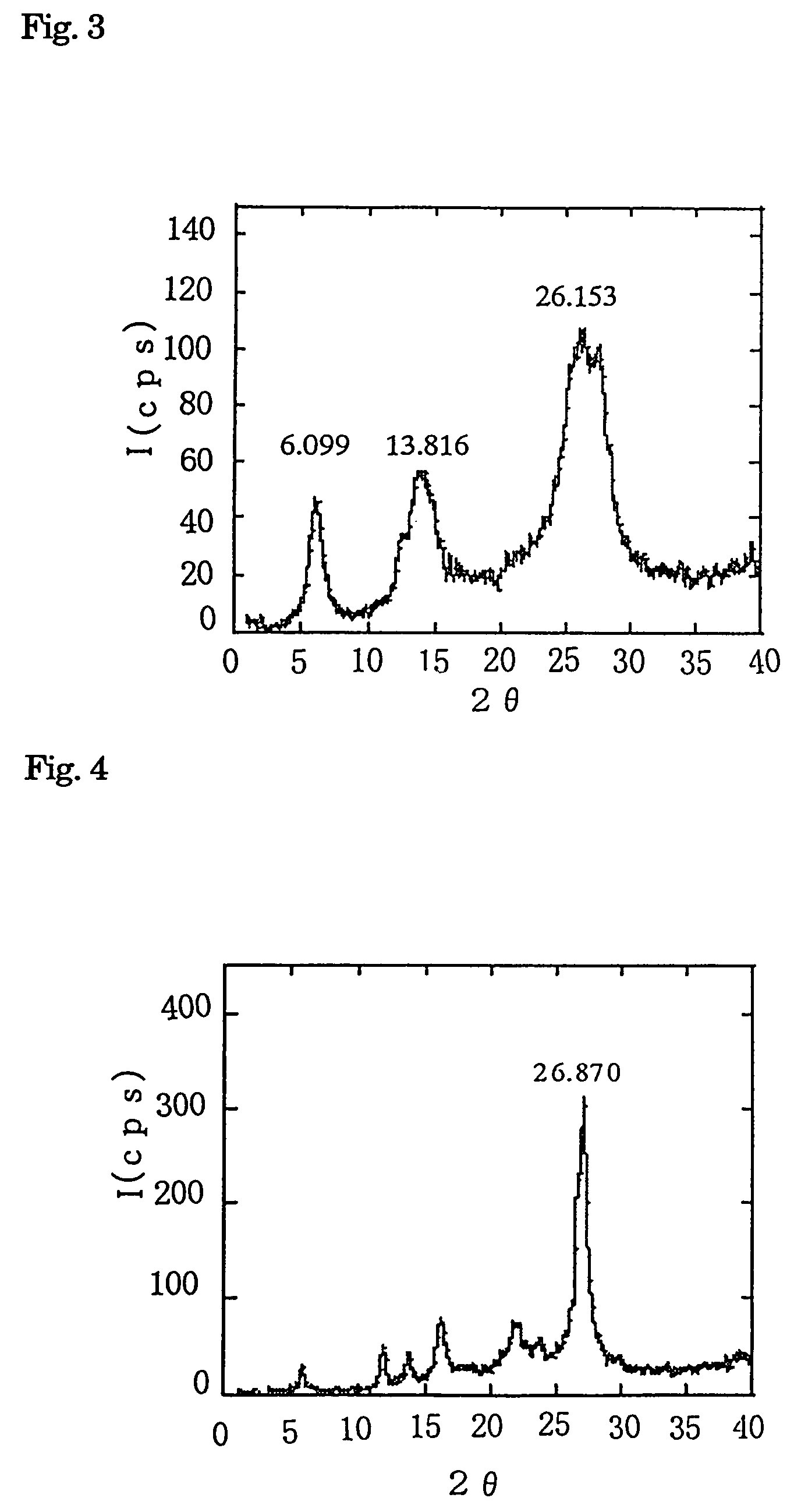

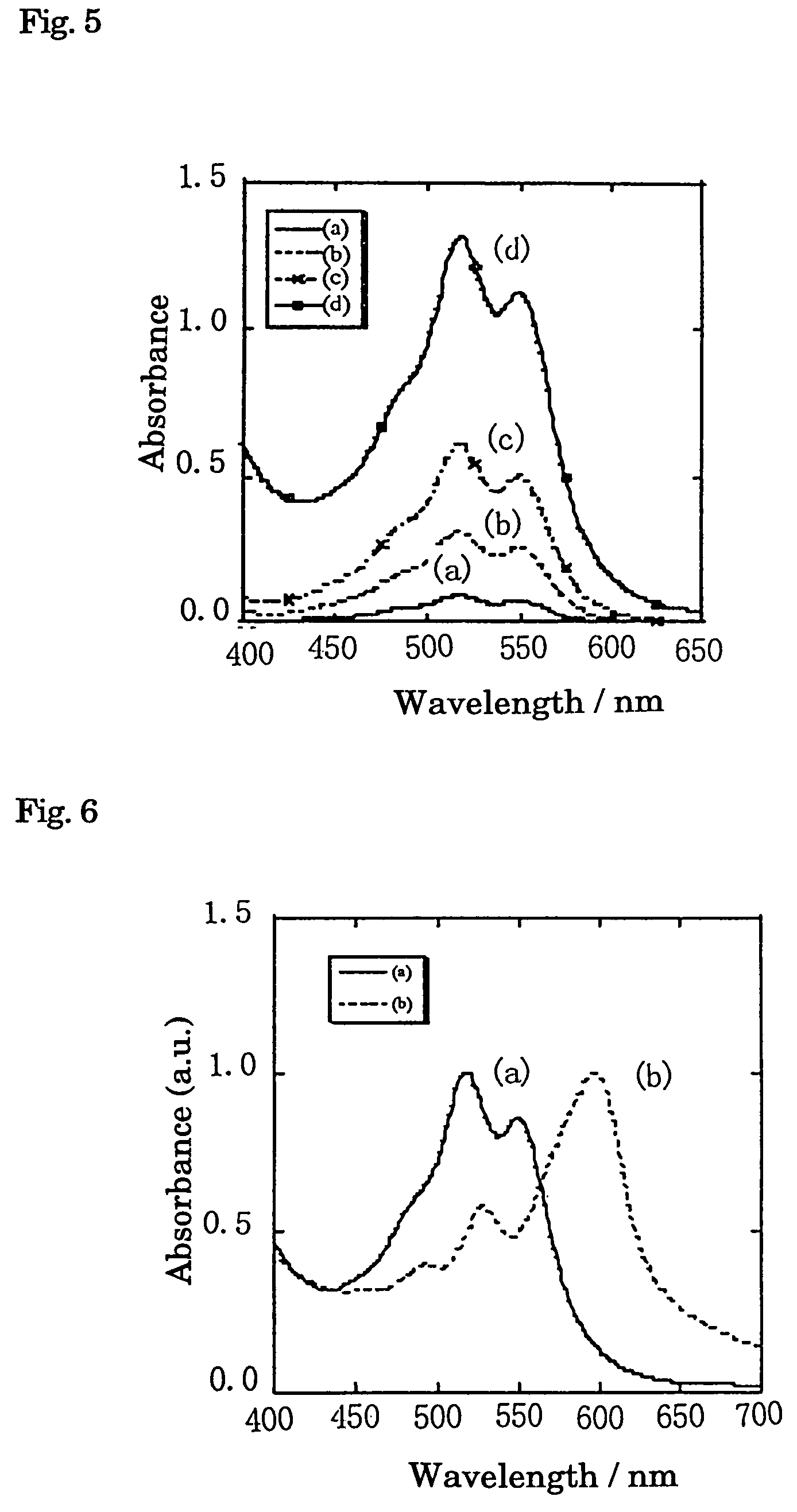

Process for producing quinacridone pigment microcrystals

The method for preparation quinacridone pigment nanocrystals with sub micrometer to nanometer in average size comprising, supplying supercritical or semi-critical liquid, which dissolves quinacridone pigment, into a specimen tube (ST) composing a reactor possessing a filter of desired opening to the upper stream side and to the down stream side in which quinacridone pigment is set up, flowing out the supercritical or semi-critical liquid in which quinacridone pigment is dissolved from said reactor to a mixing apparatus to which coolant is supplied, and by selecting the kind of supercritical of semi-critical liquid and combination of conditions e.g. supplying speed of each liquids, temperature of the liquid and the reacting pressure.

Owner:JAPAN SCI & TECH CORP

Magenta toner and developer

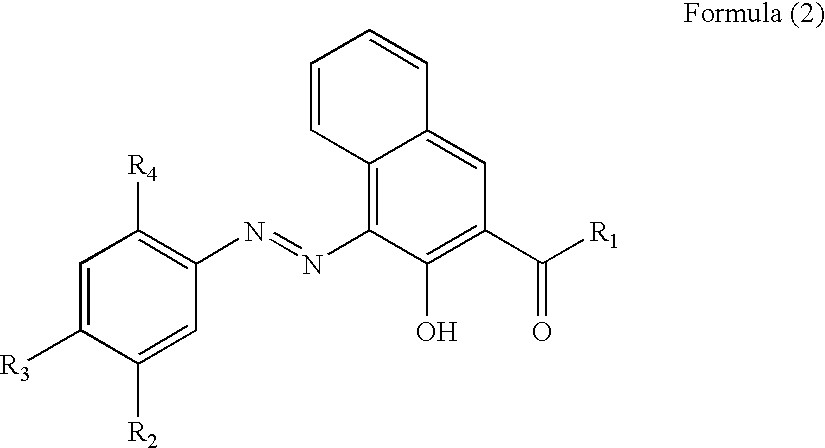

A magenta toner, produced by a method including suspending an oily liquid comprising a binder resin and a colorant in an aqueous medium, wherein the colorant comprises a naphthol pigment and a quinacridone pigment, and the quinacridone pigment comprises a pigment having a specific formula.

Owner:RICOH KK

Method for forming multilayer coated film

A method for forming a multilayer coated film on an object includes steps (1) to (3) below. A first colored coating material is applied to the object, thereby forming a first colored coated film (step (1)). The first colored coating material includes an iron-oxide-coated aluminum pigment and a quinacridone pigment and has a light reflectance property at specific wavelengths. A second colored coating material is applied to the first colored coated film, thereby forming a second colored coated film (step (2)). The second colored coating material includes a perylene pigment and has a specific hue. A clear coating material is applied to the second colored coated film (step (3)). A color difference ΔE between the first colored coated film and the multilayer coated film is in a range of 20 to 30.

Owner:KANSAI PAINT CO LTD +1

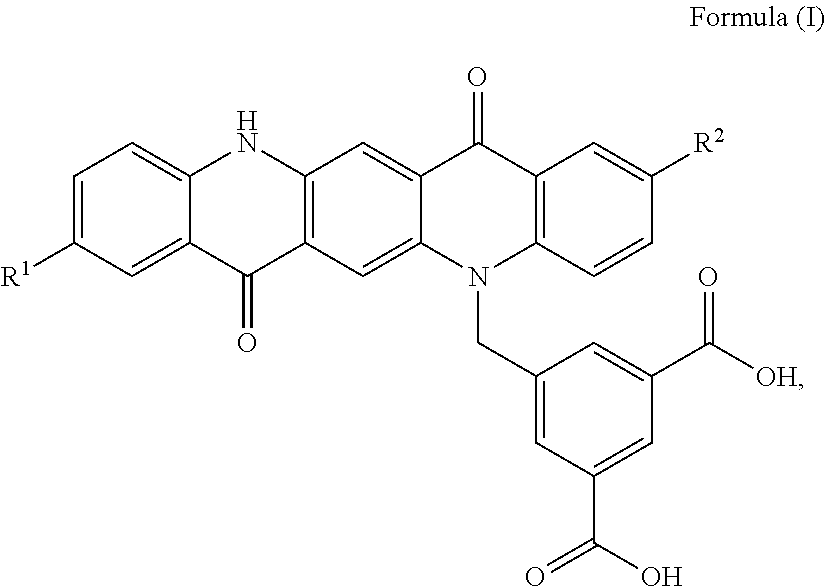

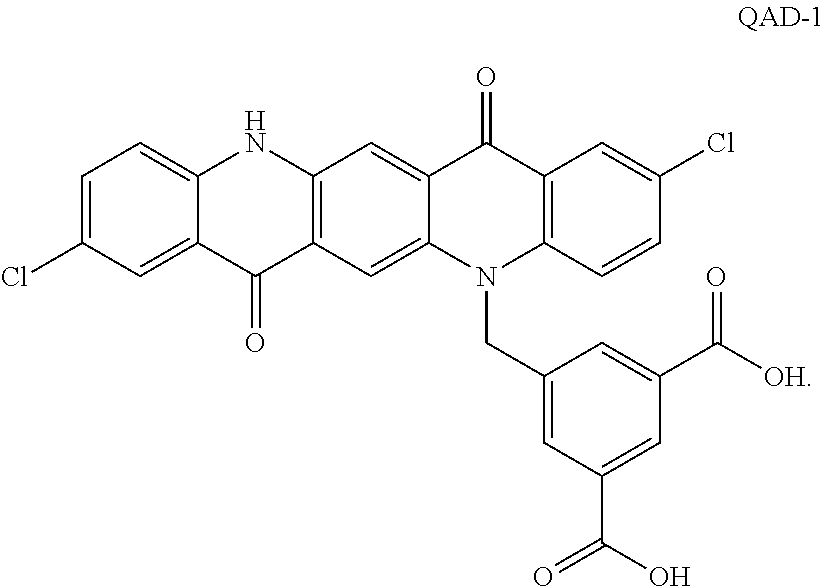

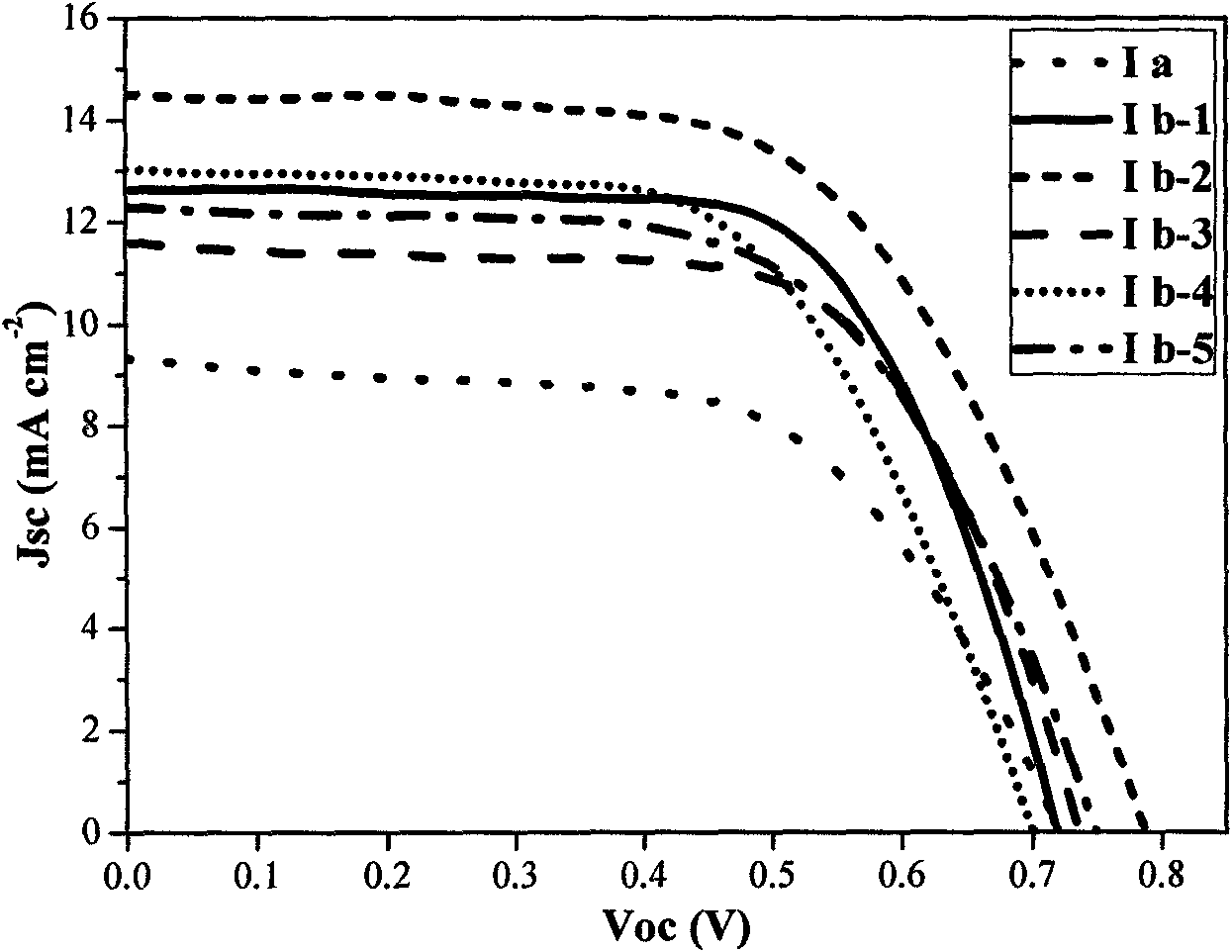

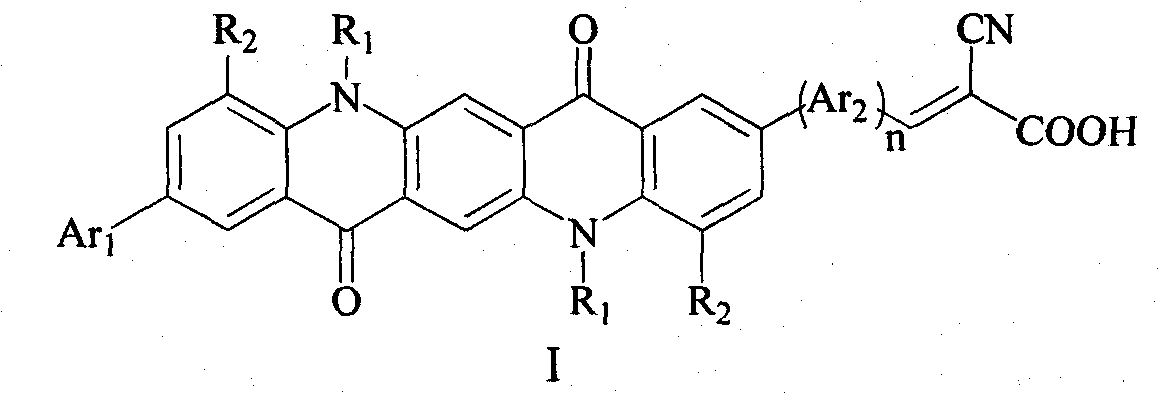

Quinacridone derivatives and uses thereof

The invention relates to a quinacridone derivative and application thereof. The quinacridone derivative is obtained by subjecting quinacridone (matrix) to chemical modification (connection with electron-donating groups and electron-withdrawing groups of triphenylamine). In the quinacridone derivative which contains donor-acceptor electronic groups and is designed and prepared in the invention, electrons are easier to transfer in an excitation state, so that the quinacridone derivative achieves the performance of effectively converting optical energy into electric energy and can be used as a photosensitizer for a dye-sensitized nanocrystal solar cell. Experiments show that the quinacridone derivative provided by the invention has favorable photosensitization property.

Owner:EAST CHINA UNIV OF SCI & TECH

Liquid pressure transfer ink, liquid pressure transfer film, liquid pressure transfer article and liquid pressure transfer method

InactiveUS6551392B1Effectively prevent disarrangementEffectively prevent blurringLayered productsDecorative surface effectsWeather resistanceColor printing

A pattern-transferring film having a print pattern provided on an upper surface thereof is floated on a liquid surface within a transferring bath and an objective body is immersed into a liquid within the transferring bath together with the pattern transferring film under a liquid pressure so as to transfer the print pattern onto the objective body. An ink set of at least blue, yellow and red inks is used for printing the pattern on the pattern-transferring film. Each of the printing inks comprises at least a resin ingredient and a pigment including color pigments. The color pigment for the blue ink is a phthalocyanine blue, the color pigment for the yellow ink is an isoindolinone yellow and the color pigment for the red ink is a quinacridone red. The ink set may include one or both of a white ink and a black ink. The color pigment for the white ink is a titanium white and the color pigment for the black ink is a carbon black. All the five color printing inks have a weather resistance of more than 3000 hours on a weather resistance test by a JIS based sunshine weather meter and therefore a color tone of the transferred pattern obtained by using these printing inks is balanced and the pattern transferred article having such a transferred pattern has the same weather resistance, which causes the article to have its life span maintained.

Owner:TAICA

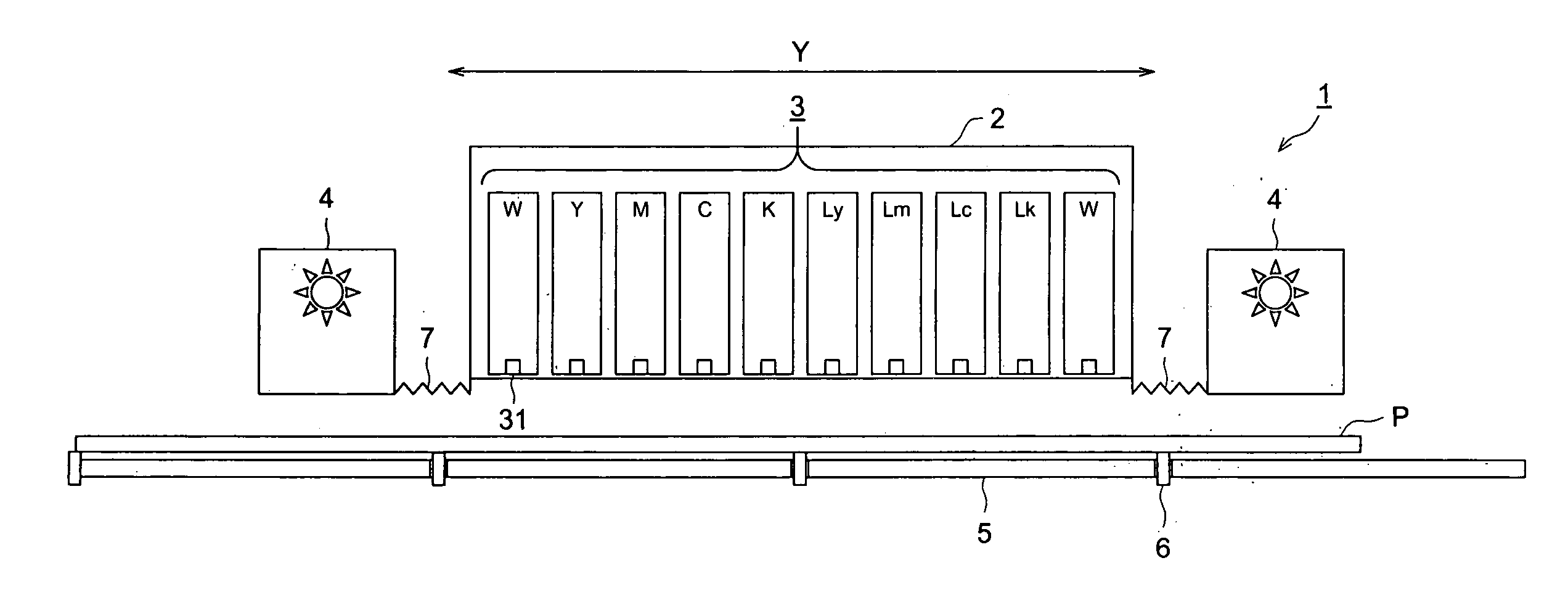

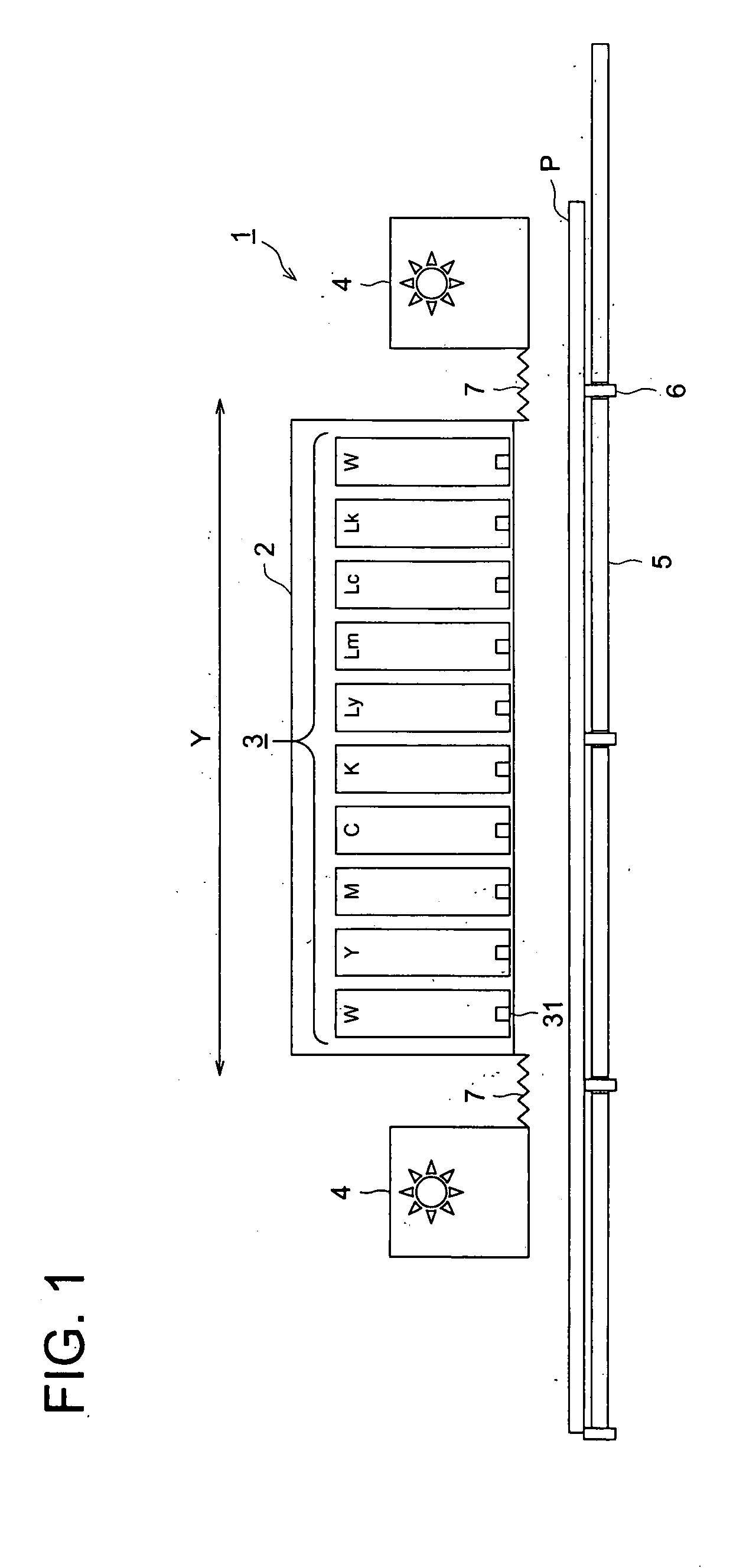

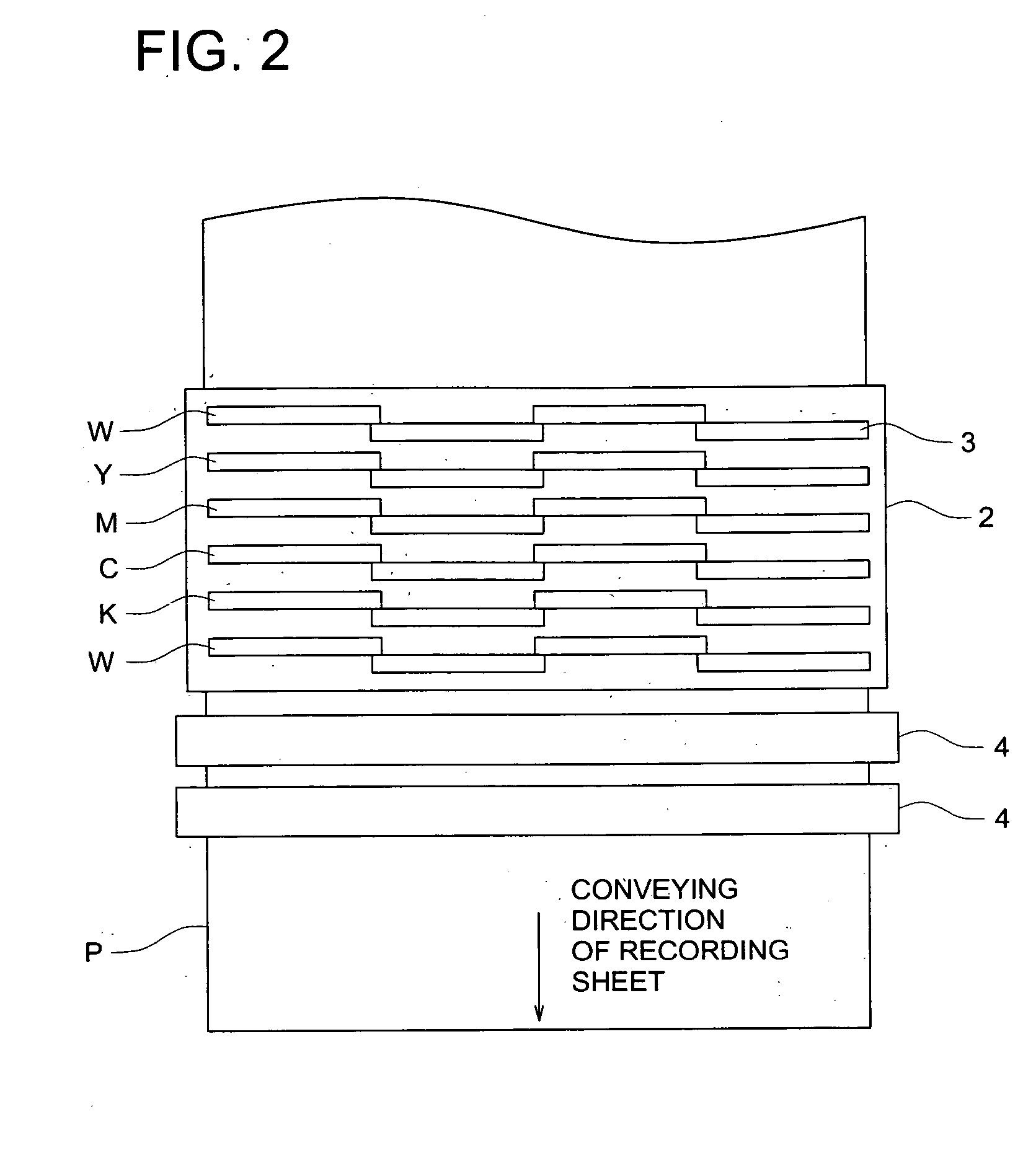

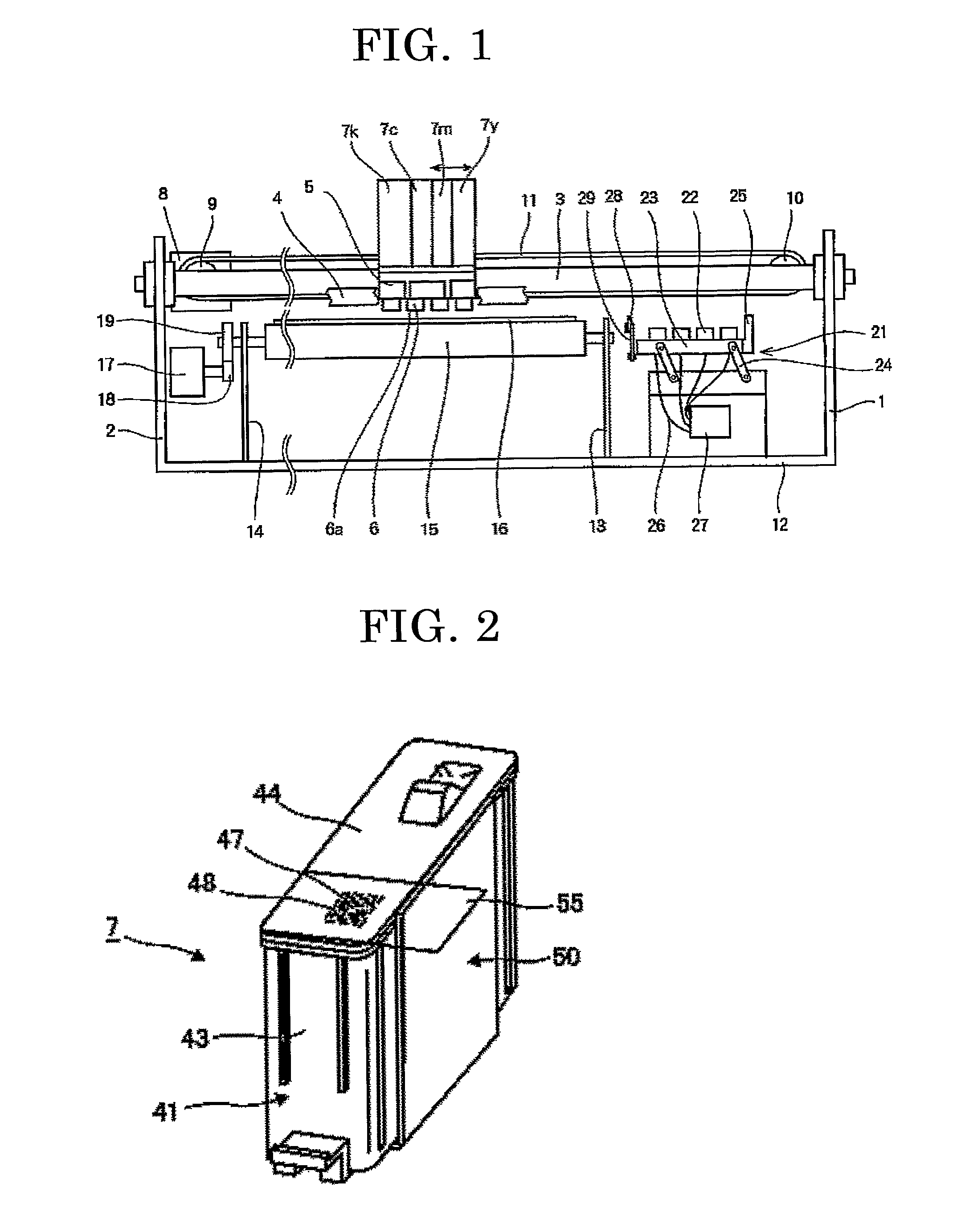

Ink set, recording apparatus, and recording method

InactiveUS20100212543A1Increase graininessHigh color reproductionMeasurement apparatus componentsDuplicating/marking methodsSolid solutionMagenta

An ink set includes a cyan ink composition containing C. I. Pigment Blue 15:6 as a pigment; a magenta ink composition containing a quinacridone pigment selected from the group consisting of C. I. Pigment Violet 19, C. I. Pigment Red 122, C. I. Pigment Red 202, and C. I. Pigment Red 209 or a quinacridone solid solution pigment composed of at least two selected from the group; a yellow ink composition containing a pigment selected from the group consisting of C. I. Pigment Yellow 74, C. I. Pigment Yellow 213, and C. I. Pigment Yellow 185; a light magenta ink composition containing a quinacridone pigment selected from the group consisting of C. I. Pigment Violet 19, C. I. Pigment Red 122, C. I. Pigment Red 202, and C. I. Pigment Red 209 or a quinacridone solid solution pigment composed of at least two selected from the group at a pigment concentration lower than that of the magenta ink composition; and a light cyan ink composition containing C. I. Pigment Blue 15:3 as a pigment at a pigment concentration lower than that of the cyan ink composition.

Owner:SEIKO EPSON CORP

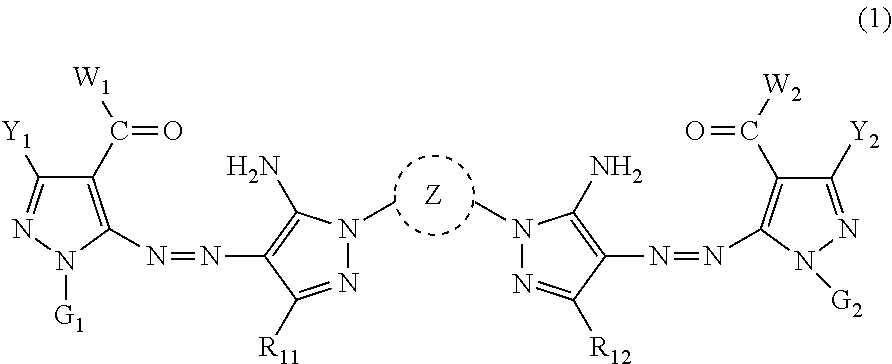

Ink set, recorded material and printed material

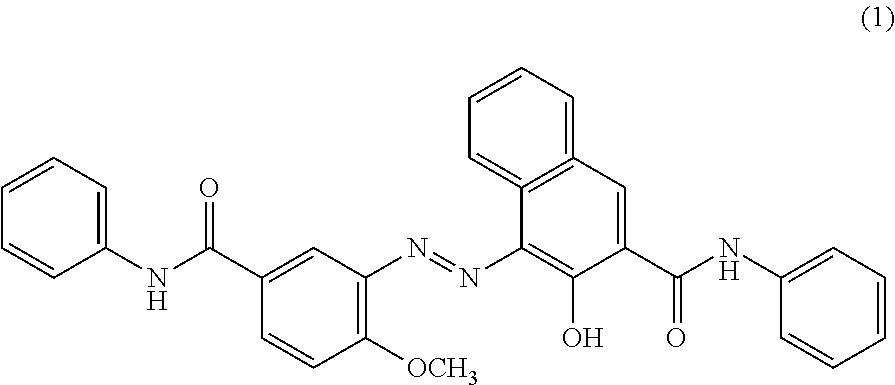

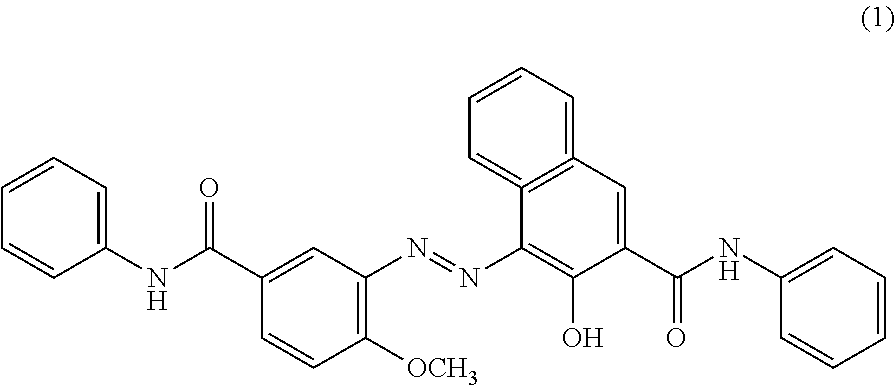

InactiveUS20110300344A1High tinting strengthLight fastnessDisazo dyesDecorative surface effectsArylHydrogen

An ink set is provided, the ink set including a yellow ink composition; and at least one of a magenta ink composition and a cyan ink composition, wherein a colorant of the yellow ink composition contains an azo pigment represented by formula (1), its tautomer, or a salt or hydrate thereof, the magenta ink composition contains at least one pigment selected from quinacridone pigments, and the cyan ink composition contains at least one pigment selected from phthalocyanine pigments:wherein Z represents atoms necessary to complete a 5- to 8-membered nitrogen-containing heterocycle; Y1, Y2, R11 and R12 each represents a hydrogen or a substituent; G1 and G2 each represents a hydrogen, an alkyl group, an aralkyl group, an alkenyl group, an alkynyl group, an aryl group or a heterocyclic group; and W1 and W2 each represents an alkoxy group, an amino group, an alkyl group or an aryl group.

Owner:FUJIFILM CORP

Process for producing pigment nanoparticle

InactiveUS7192477B2Efficient methodRemarkable effectFatty acid chemical modificationCrystallization separationOrganic solventNanoparticle

The process for producing highly concentrated nanometer-size fine particles of an organic pigment, which comprises dissolving the organic pigment in an amide solvent, especially an organic solvent comprising at least 50 vol % 1-methyl-2-pyrrodinone, and pouring the resultant organic pigment solution with stirring into a poor solvent which is not compatible with the organic pigment. The pigment may be a quinacridone pigment, phthalocyanine pigment etc. Any atmospheric pressure to a sub-critical and / or supercritical state can be employed as the production conditions.

Owner:JAPAN SCI & TECH CORP

Non-Aqueous Pigment Dispersions Using Dispersion Synergists

InactiveUS20090048375A1Quality improvementImprove stabilityInksDiketopyrrolopyrrole dyesPolymer chemistryQuinacridone

A non-aqueous pigment dispersion including a diketopyrrolo-pyrrole pigment, a polymeric dispersant and a dispersion synergist in a dispersion medium wherein the dispersion synergist is a quinacridone derivative containing at least one acidic group or a salt thereof.

Owner:AGFA NV

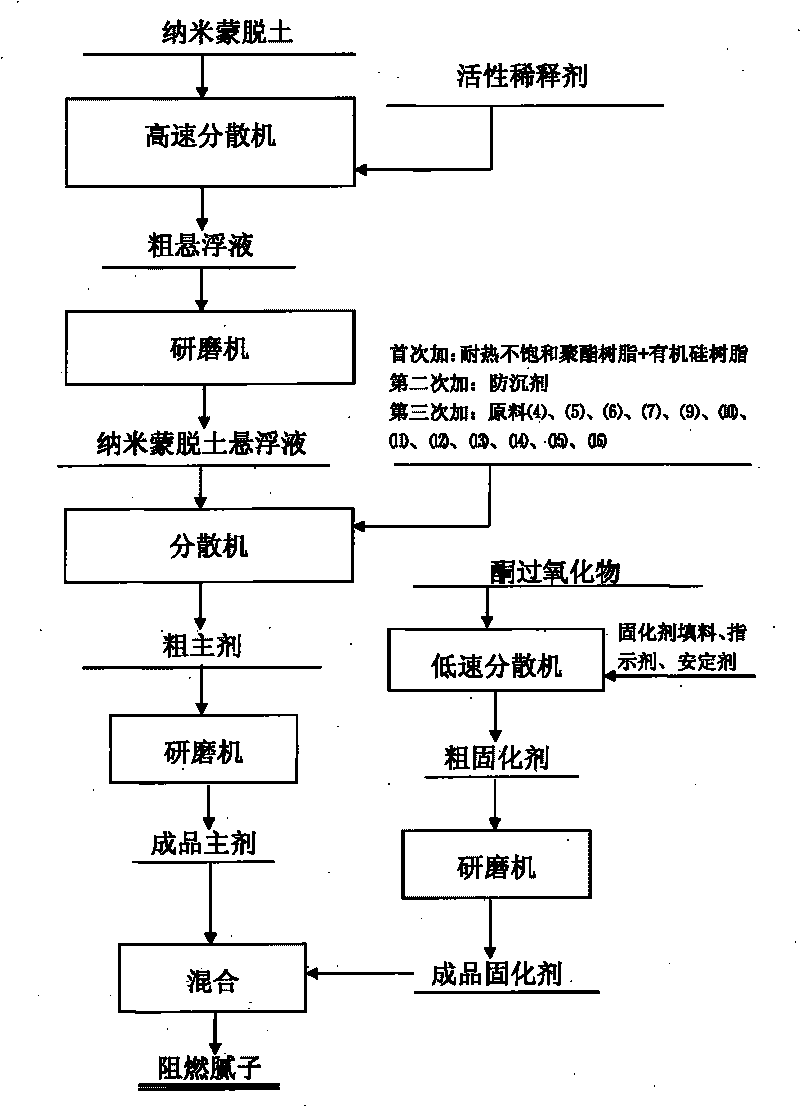

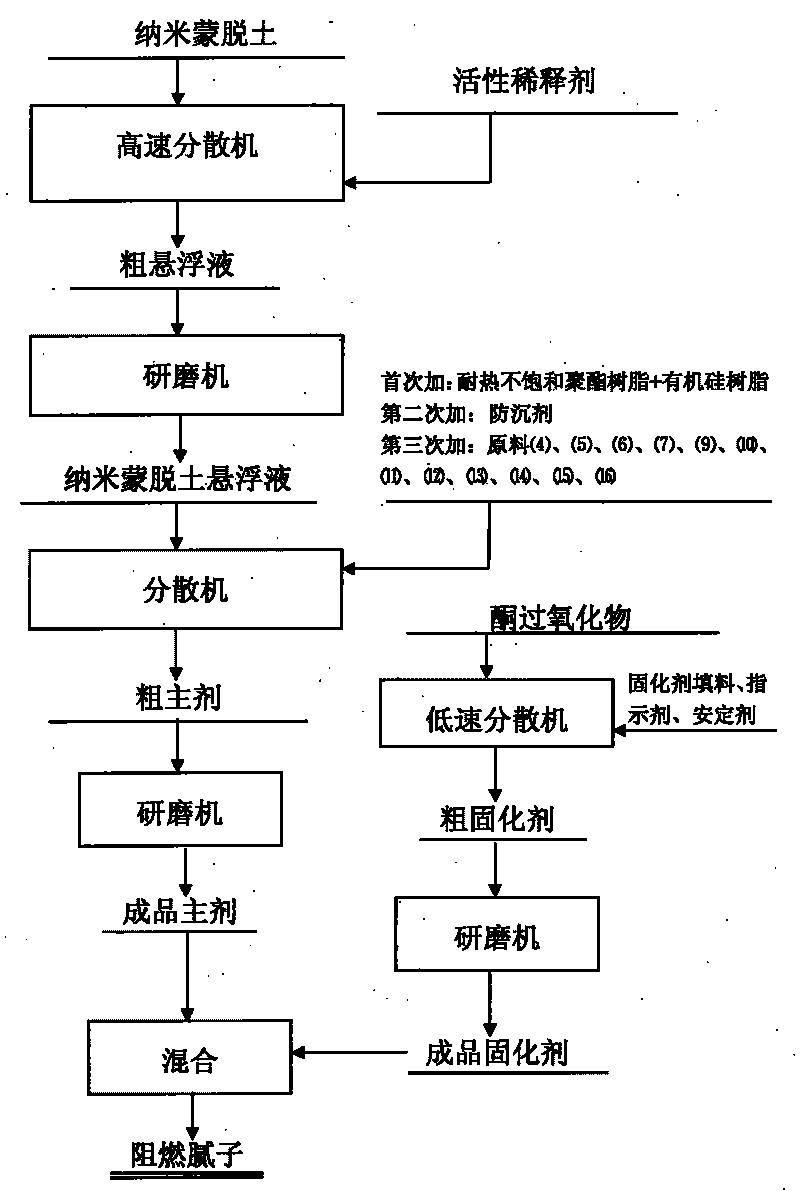

Flame-retarding lacquer putty and preparation method thereof

InactiveCN101696331AImprove heat resistanceImprove air drynessFilling pastesDimethylaniline N-oxideLacquer

Owner:ZHUZHOU HUALIAN HI TECH

Quinacridone pigment compositions comprising unsymmetrically substituted components

The present invention relates to a novel quinacridone pigment compositions, a process using a mixed amine synthesis for the ultimate production of the compositions and to their use as colorants for pigmenting high molecular weight organic materials.

Owner:CIBA SPECIALTY CHEM CORP

Ink composition, ink set, and image forming method

InactiveUS20130050355A1Improve stabilityImprove adhesionDuplicating/marking methodsInksCross-linkWater soluble

An ink composition having excellent ink stability over time and image adhesion to a recording medium is provided.The ink composition of the present invention includes: cross-linked particles containing a quinacridone solid solution pigment including at least two types of quinacridone-based compound; a water-soluble polymerizable compound; a polymerization initiator; and water.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com