Waterborne nanometer universal fat-free colorant and preparation method thereof

A nano and color paste technology, applied in the direction of pigment paste, etc., can solve the problems of high odor, environmental and operator harm, excessive VOC, etc., and achieve the effect of simple raw materials, good stability and low viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

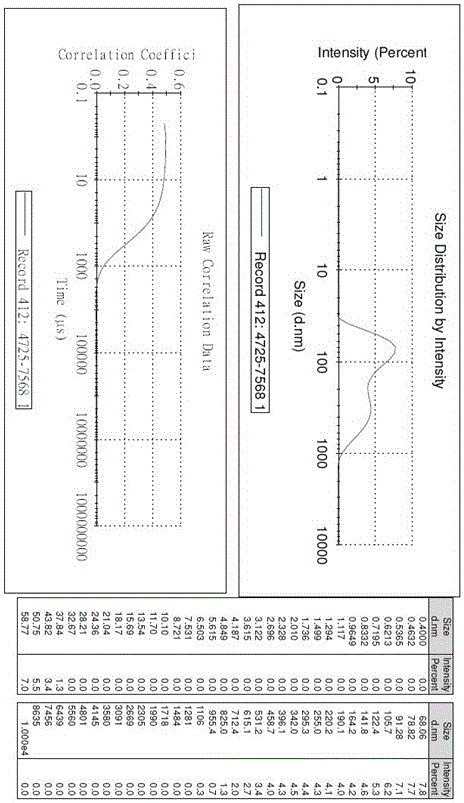

Image

Examples

Embodiment 1

[0031] A water-based nano-universal fat-free color paste, which consists of two parts: the synthesis of a dispersant and the preparation of a nano-universal color paste;

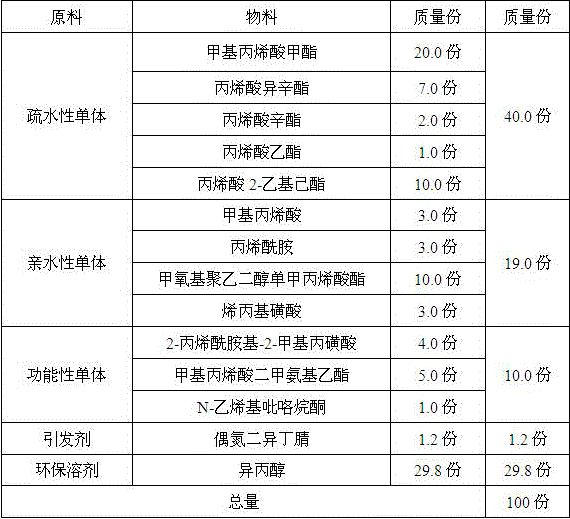

[0032] The dispersant is prepared from the raw materials in parts by mass shown in Table 1: Table 1: The specific material ratio of the dispersant

[0033]

[0034] Described nano universal color paste is prepared from the raw materials of the mass parts shown in table 2:

[0035] Table 2

[0036]

[0037] The preparation method comprises the steps of:

[0038] (1) Dissolve hydrophobic monomers, hydrophilic monomers, and functional monomers in 80% environmentally friendly solvents to form a monomer mixture, add 20% of the volume of the monomer mixture to the reactor, stir and heat up At 60°C, use two constant pressure separatory funnels to add the initiator solution (the initiator is dissolved in the remaining 20% environmentally friendly solvent) and the remaining monomer mixture dropwise. After 2...

Embodiment 2

[0041] A water-based nano-universal fat-free color paste, which consists of two parts: the synthesis of a dispersant and the preparation of a nano-universal color paste;

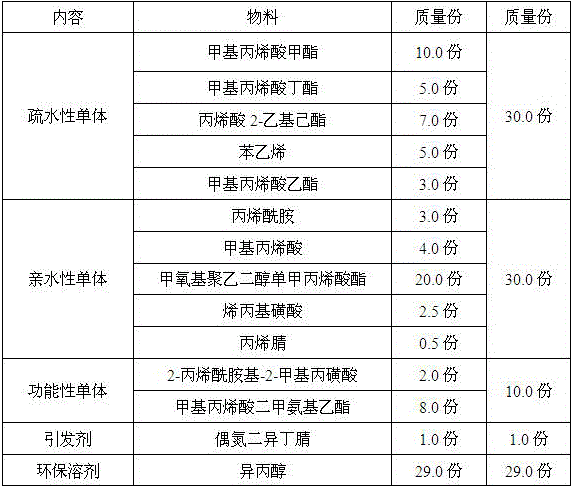

[0042] Dispersants are prepared from the raw materials in Table 3:

[0043] Table 3: Specific material ratio of dispersant

[0044]

[0045] Described nano universal color paste is prepared from the raw materials of the mass parts shown in table 4:

[0046] Table 4

[0047]

[0048] The preparation method is different from Example 1 in that: in step (1), the temperature of the monomer solution is raised to 65° C., the initiator solution is added dropwise in 1 hour, and the reaction is kept for 5 hours.

Embodiment 3

[0050] A water-based nano-universal fat-free color paste, which consists of two parts: the synthesis of a dispersant and the preparation of a nano-universal color paste;

[0051] The dispersant is prepared from the raw materials in Table 5: Table 5: The specific material ratio of the dispersant

[0052]

[0053] Described nano universal color paste is prepared from the raw material of the mass parts shown in table 6: table 6

[0054]

[0055] The preparation method is different from Example 1 in that: in step (1), the temperature of the monomer solution is raised to 50° C., the initiator solution is added dropwise in 2 hours, and the reaction is kept for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com