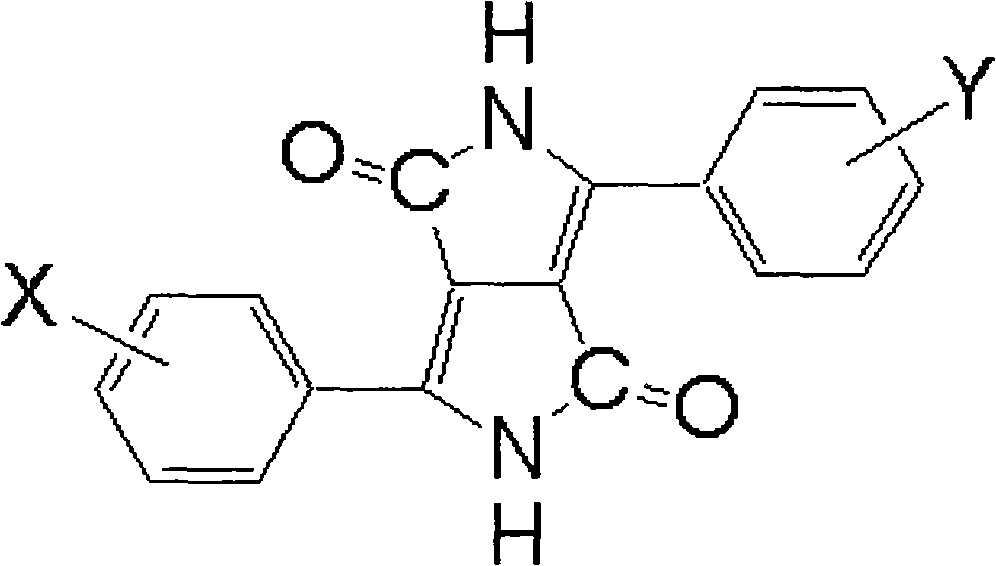

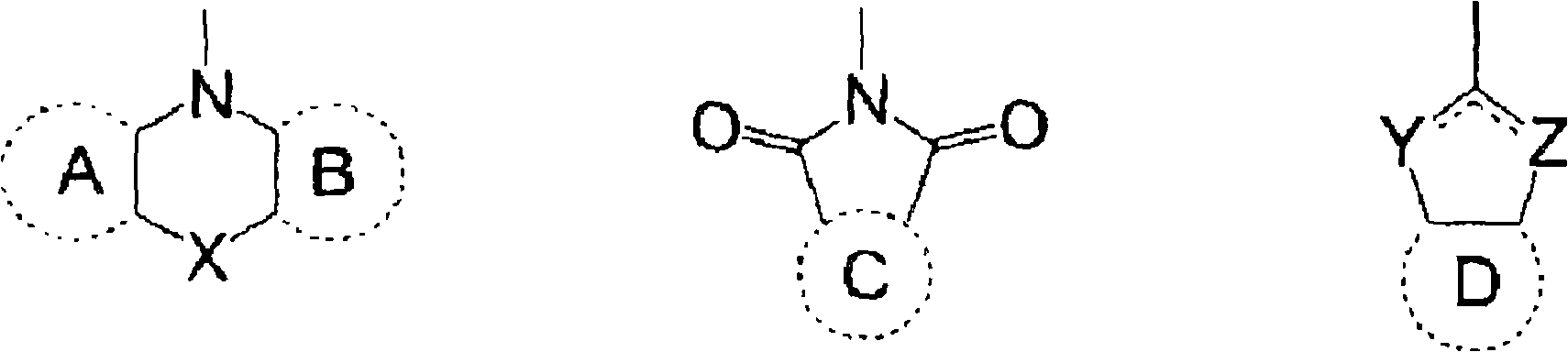

Pigment dispersing composition and manufacturing method thereof, coloured polymerized composition, colour filter and manufacturing method thereof

A technology for pigment dispersion and composition, which is used in optical filters, organic dyes, photosensitive materials for opto-mechanical equipment, etc., can solve problems such as surface dryness, and achieve high contrast and excellent viscosity stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

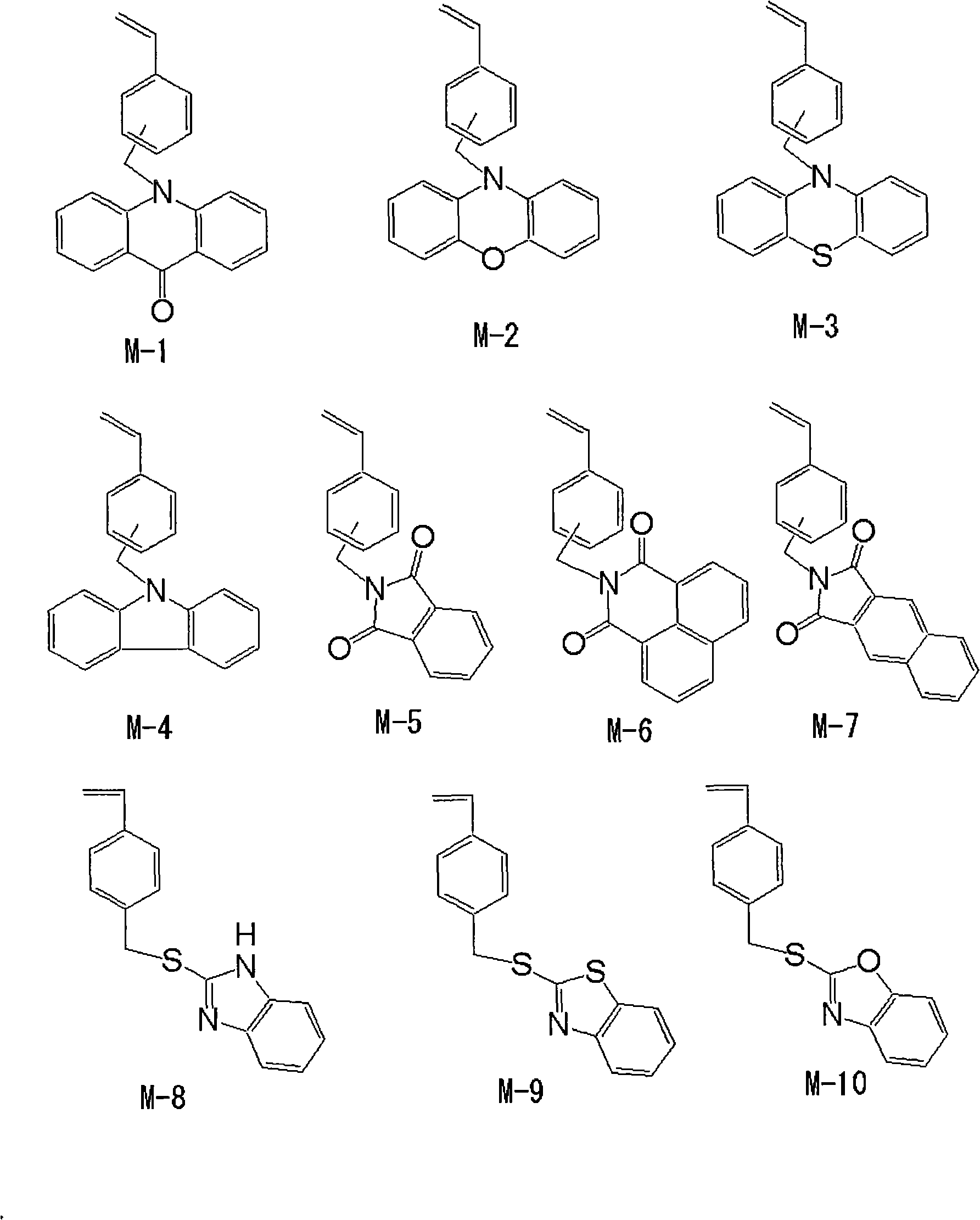

[0596] (manufacturing method of processing pigment using salt grinding)

[0597] In the present invention (A) diketopyrrolopyrrole pigment, 50 g of Ilgafoared BT-CF (manufactured by Ciba Japan Co., Ltd., Pigment Red 254), 500 g of sodium chloride (average particle diameter: 10 μm) , and 150 g of diethylene glycol (manufactured by Tokyo Chemical Industry Co., Ltd.), which is a water-soluble organic solvent, were put into a stainless steel 1-gallon kneader (manufactured by Inoue Seisakusho Co., Ltd.), and kneaded at 50° C. for 10 hours.

[0598] Next, 25 g of the resin A solution (solid content: 30% by mass) synthesized as above was added to the mixture and mixed, and the mixture was poured into about 3 liters of hot water, and mixed at a high speed while heating to about 70°C. Machine stirring for about 1 hour to make a slurry. Then, filtering and washing with water were performed to remove sodium chloride and the solvent, and drying was performed in a hot air oven at 60° C. f...

Embodiment 2

[0620]

[0621] Using the pigment dispersion composition obtained in Example 1 above, a colored polymerizable composition of the following composition (2) was prepared.

[0622] In addition, the red pigment dispersion composition A and the yellow pigment dispersion composition A were prepared as follows.

[0623] (red pigment dispersion composition A)

[0624] In the production method of the above-mentioned processed pigment, it was carried out in the same manner as in Example 1, except that "Red Pigment ("Cromofutal Red A2B" manufactured by Chiba Japan Co., Ltd.: PR177)" was used instead of "Ilga Foal Red BT-CF". Salt grinding was performed to obtain a treated pigment having a primary average particle diameter of 28 nm. Then, using the obtained processed pigment, except having used "pigment derivative (5)" instead of "pigment derivative (1)", it carried out similarly to Example 1, and obtained the red pigment dispersion composition A.

[0625] In addition, the yellow pigm...

Embodiment 3

[0650] Salt grinding was performed in the same manner as in Example 1, except that 0.8 g of the pigment derivative (1) was further added when performing salt grinding in Example 1, to obtain a processed pigment. The average primary particle diameter of the obtained treated pigment was 26 nm. Then, a red pigment dispersion composition was obtained in the same manner as in Example 1 using the obtained treated pigment. Furthermore, after obtaining the red coloring polymeric composition similarly to Example 2, the evaluation similar to Example 2 was performed. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average primary particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com