Patents

Literature

720results about How to "Improve reduction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

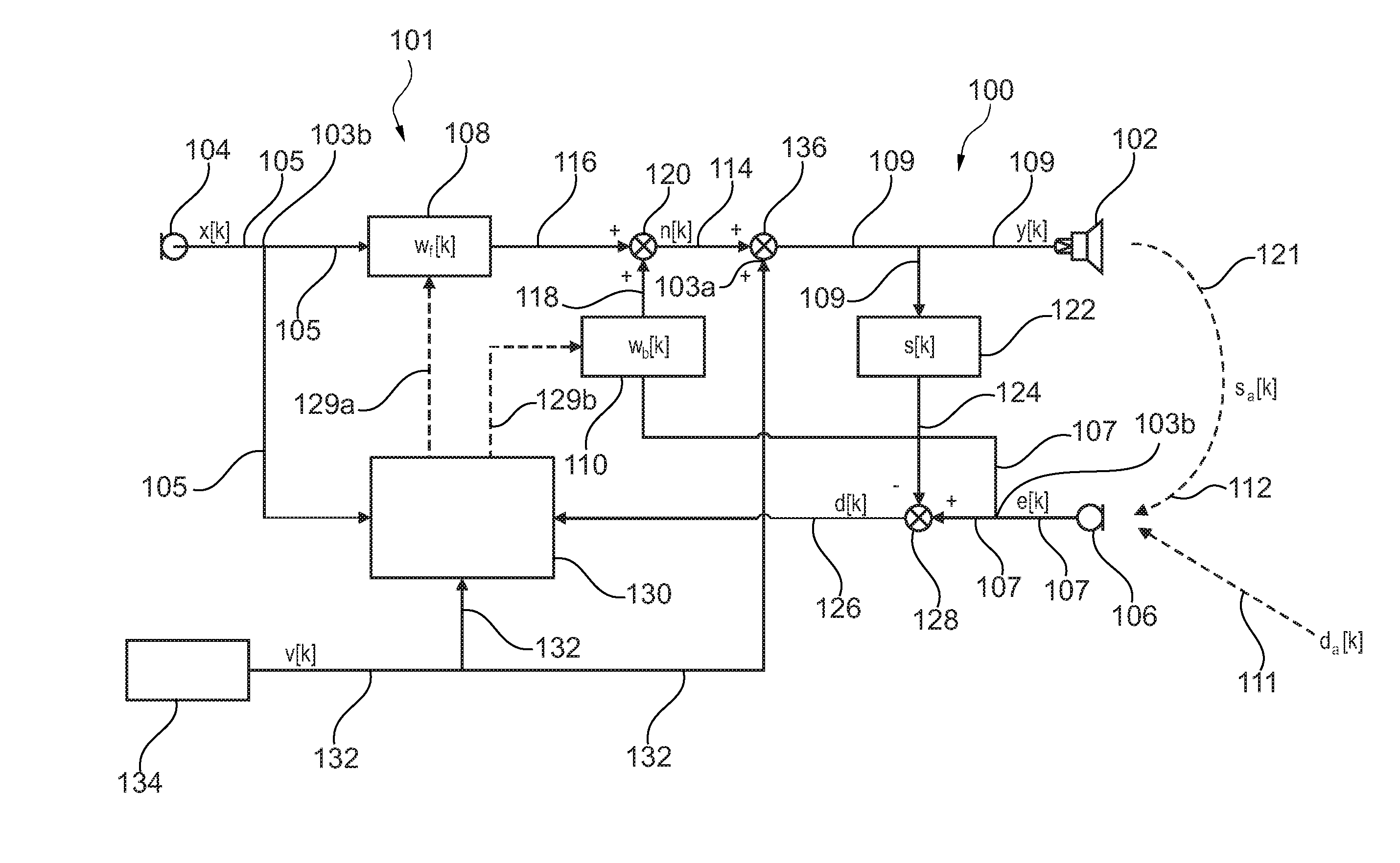

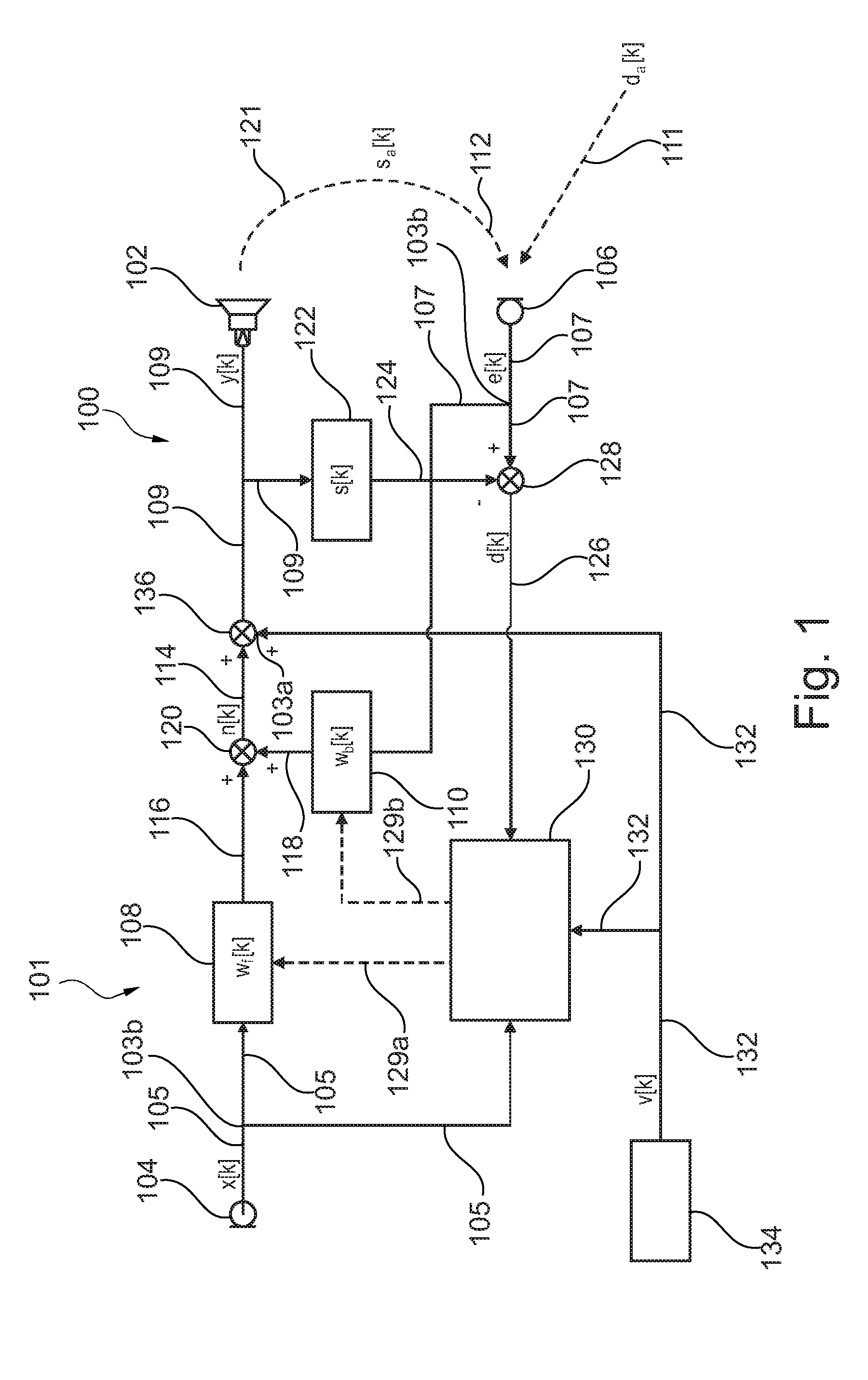

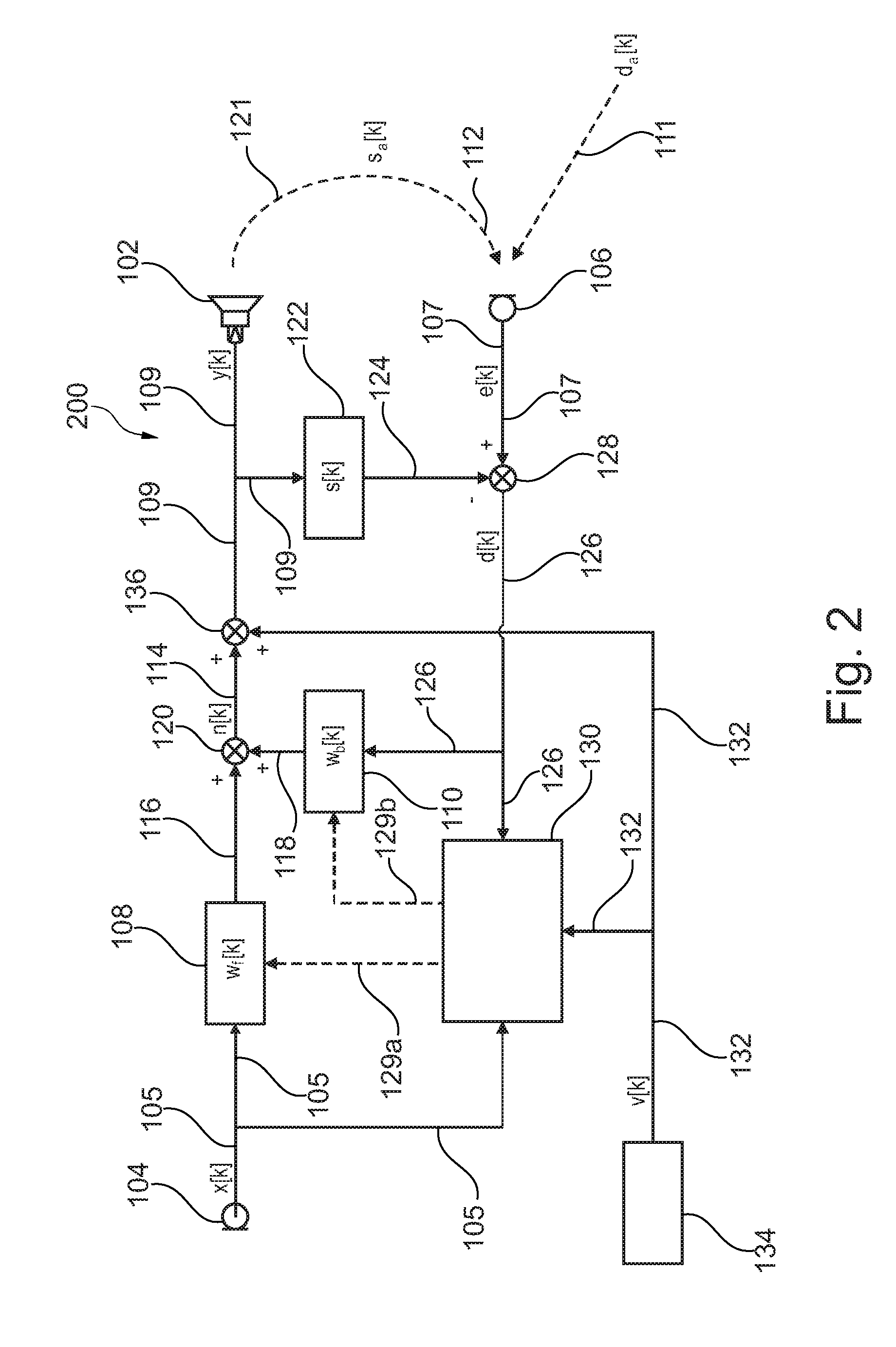

Active noise reduction method using perceptual masking

ActiveUS20110026724A1Improve reduction efficiencyReduce intensityEar treatmentHearing device active noise cancellationEngineeringNoise reduction

A method of active noise reduction is described which comprises receiving an audio signal (132) to be played, receiving a noise signal (105, 107, 116, 118, 126), indicative of ambient noise (111), from at least one microphone (104, 106), and generating a noise cancellation signal (114) depending on both, said audio signal (132) and said noise signal (105, 107, 116, 118, 126).

Owner:NXP BV

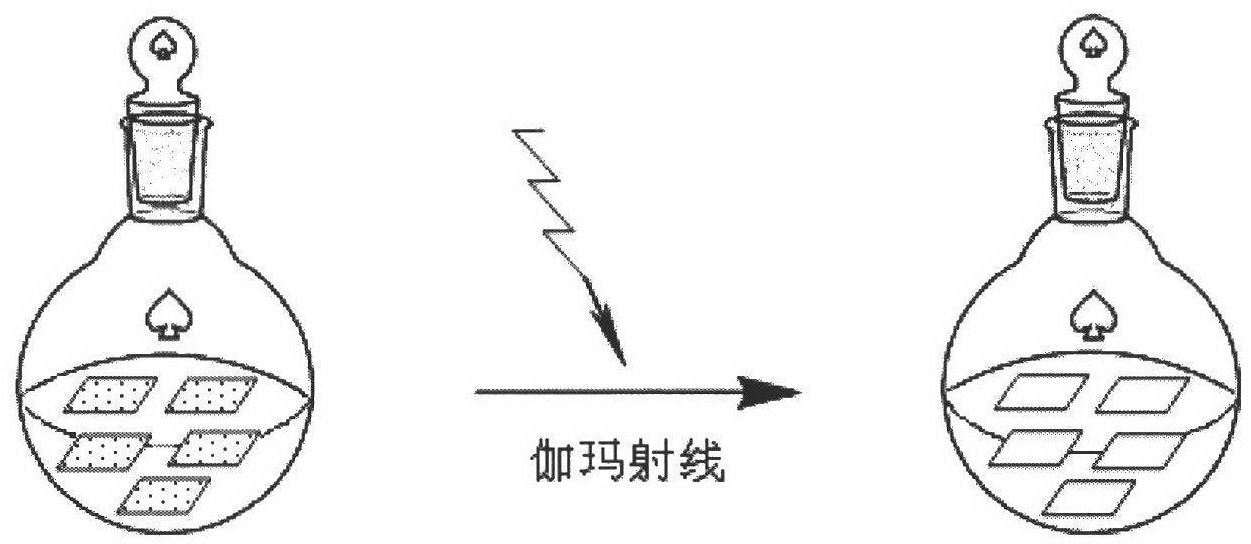

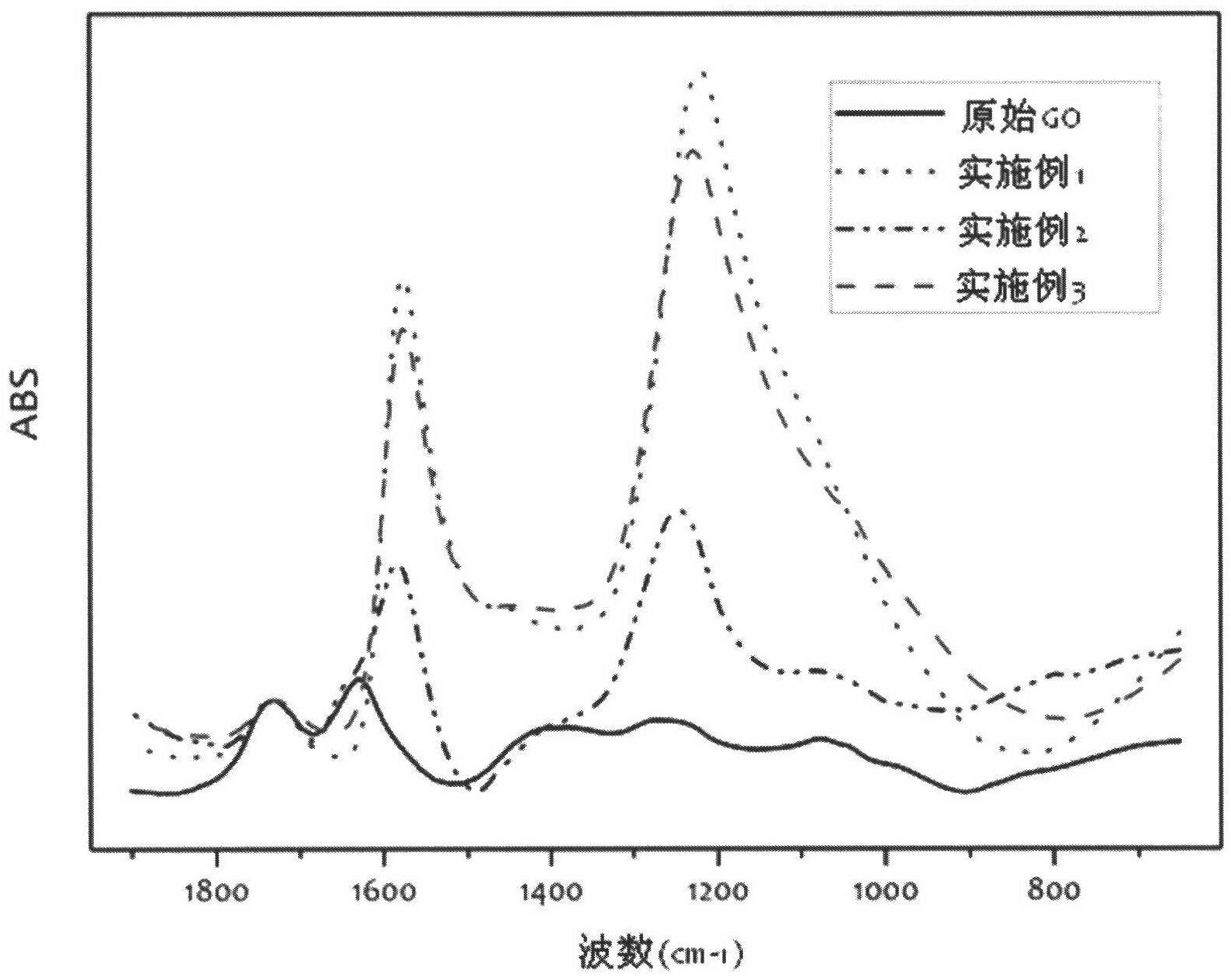

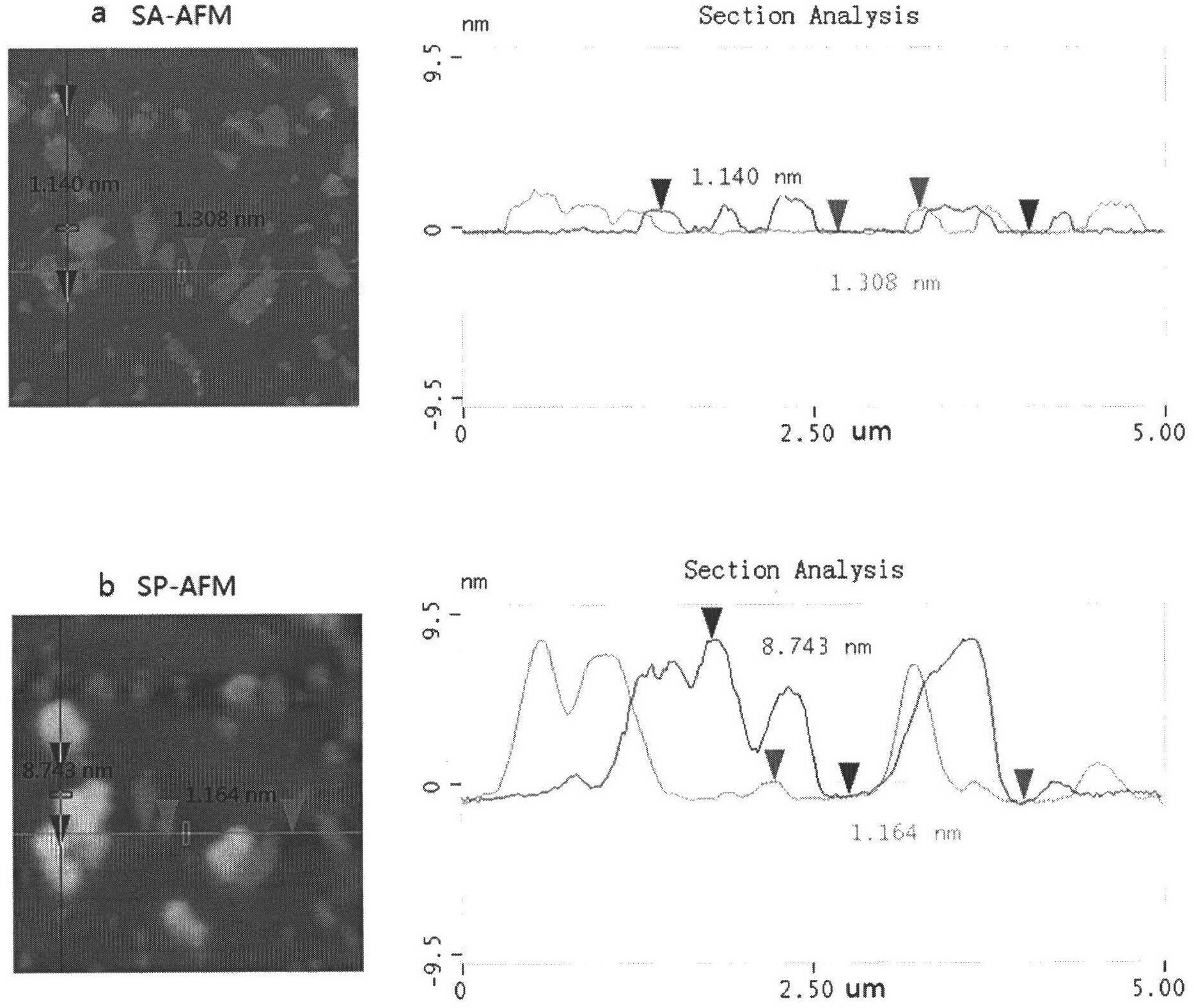

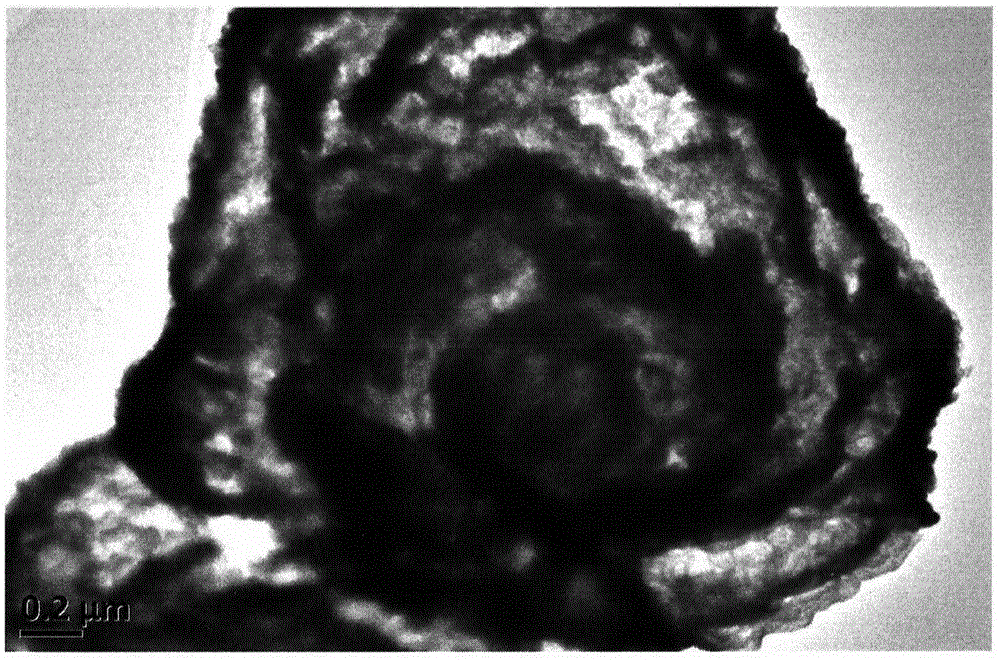

Reduced graphene oxide and preparation method thereof

ActiveCN102408109AIssues that do not involve protectionEasy to prepareEnvironmental resistanceHigh energy

The invention relates to a preparation method of reduced graphene oxide, which comprises the following steps of: mixing reducing agent with water solution of graphene oxide in the absence of oxygen, and carrying out irradiation reduction reaction by high-energy ray irradiation to obtain reduced graphene oxide, wherein the reducing agent is alcohol with one to eight carbon atoms. The invention overcomes the problems on high temperature, toxicity, low efficiency, high energy consumption and the like in the current preparation method of reduced graphene oxide, and a novel, high-efficiency, economical and environment-friendly preparation method of reduced graphene oxide is provided. The method provided by the invention has no need to modify the reduced graphene oxide before grafting, has no need of any special reagent and is simple to operate, which is a method that has wide application range and in particular can realize large scale batch production; and the reduced graphene oxide prepared by the invention has remarkably improved conductivity and broader application field.

Owner:SICHUAN ANDGEM GRAPHENE TECH CO LTD

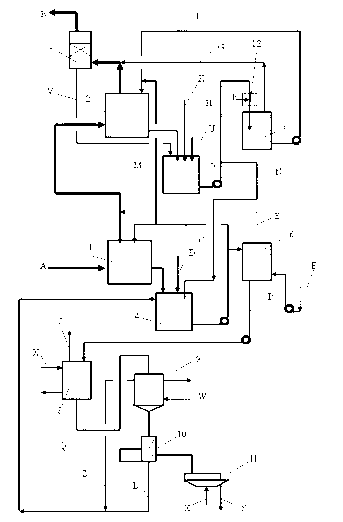

Smoke desulfurization and denitrification integration method and special device thereof

InactiveCN103212281AIncrease the amount of dissolutionIncrease oxidation rateDispersed particle separationAir quality improvementLiquid wasteNitric oxide

The invention discloses a smoke desulfurization and denitrification integration method and a special device thereof. The method is characterized in that a wet-method process is used in one technological system to simultaneously remove sulfur dioxide and nitrogen oxide in the smoke; an ammonium method is used for desulfurization, ammonia water is also used as a desulfurizer of the sulfur dioxide and a neutralizing agent for byproduct nitric acid produced in the denitrification process; an oxidization reduction method is used for the denitrification, a desulfurization byproduct ammonium sulfite or ammonium bisulfite is used as a reducing agent, urea is used as a reducing agent, a quinine-contained hydroxyl compound is used as a catalyst, air is blown into the denitrification circulating liquid so as to provide the dissolving oxygen and the oxidant for the oxidization reaction of the nitrogen oxide; a byproduct ammonium nitrate of the denitrification reaction is placed into the desulfurization liquid so as to recycle the nitrogen ammonium; and ammonia nitrogen chemical fertilizer ammonium sulfate and ammonium nitrate are recycled, and the entire technological flow is free from discharging sulfur-contained or ammonia nitrogen-contained waste liquid out of the system. Due to the adoption of the method, the integration of the desulfurization and the denitrification can be realized, the device is miniaturized, and no waste liquid is discharged in the technological process.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

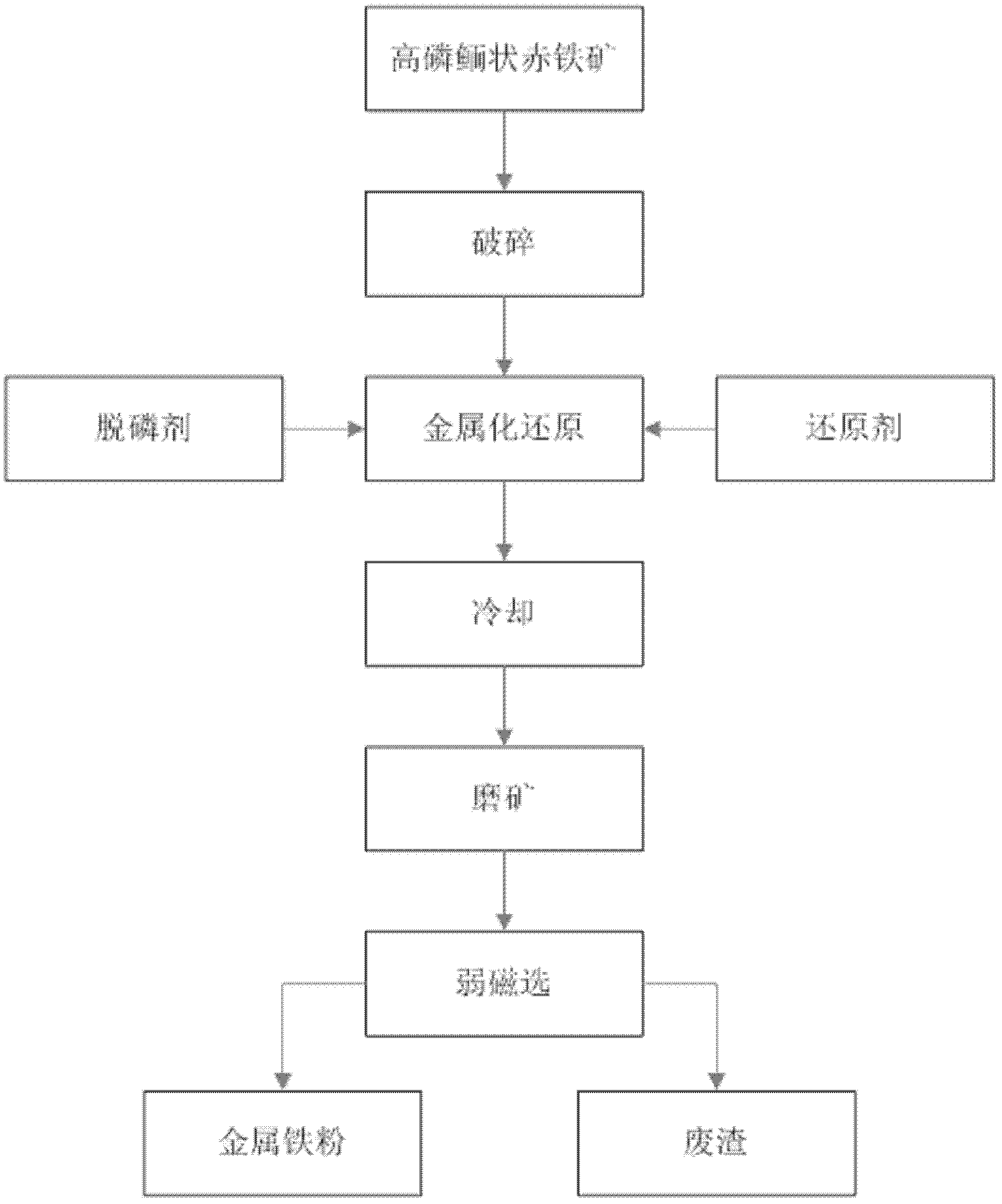

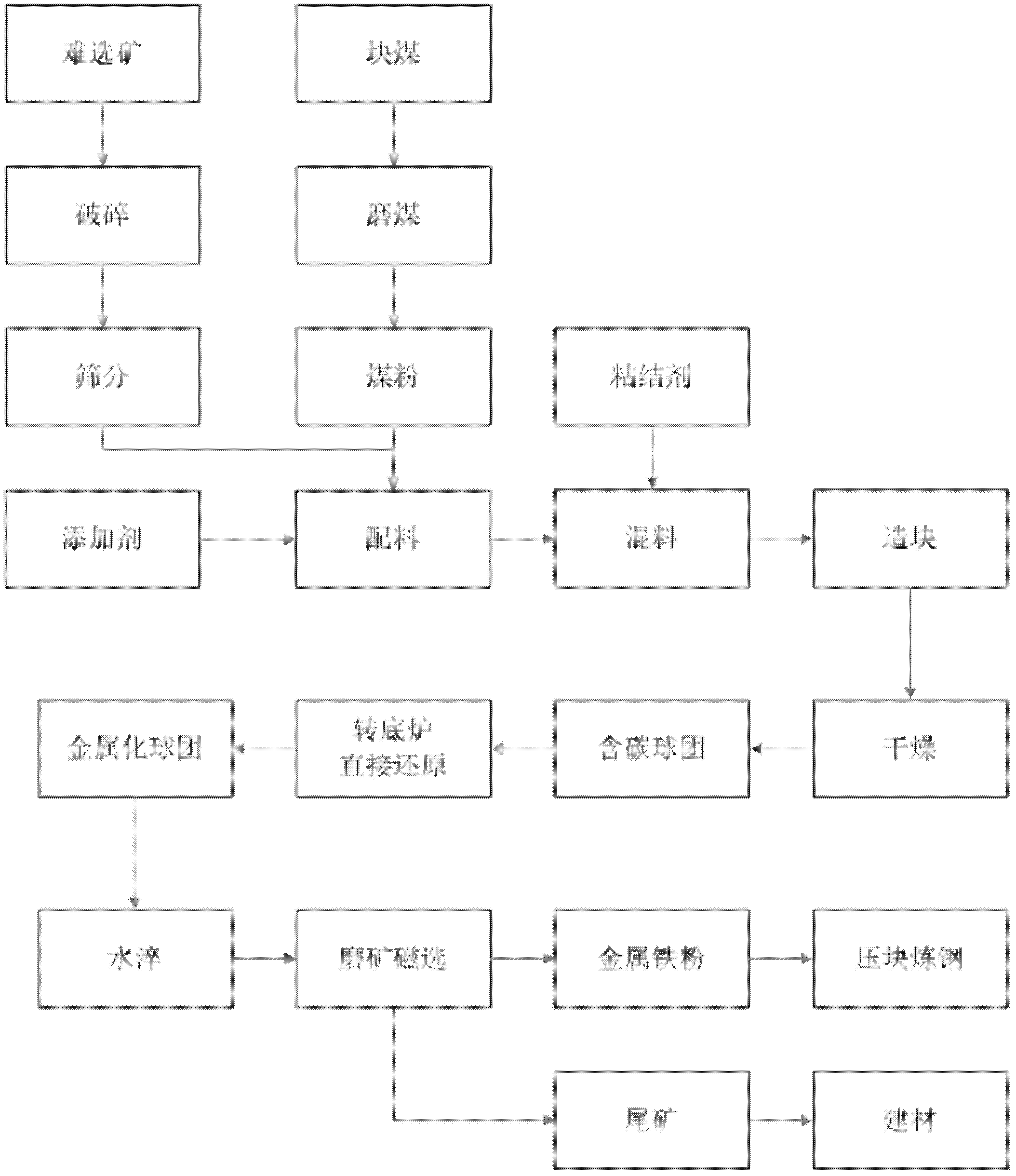

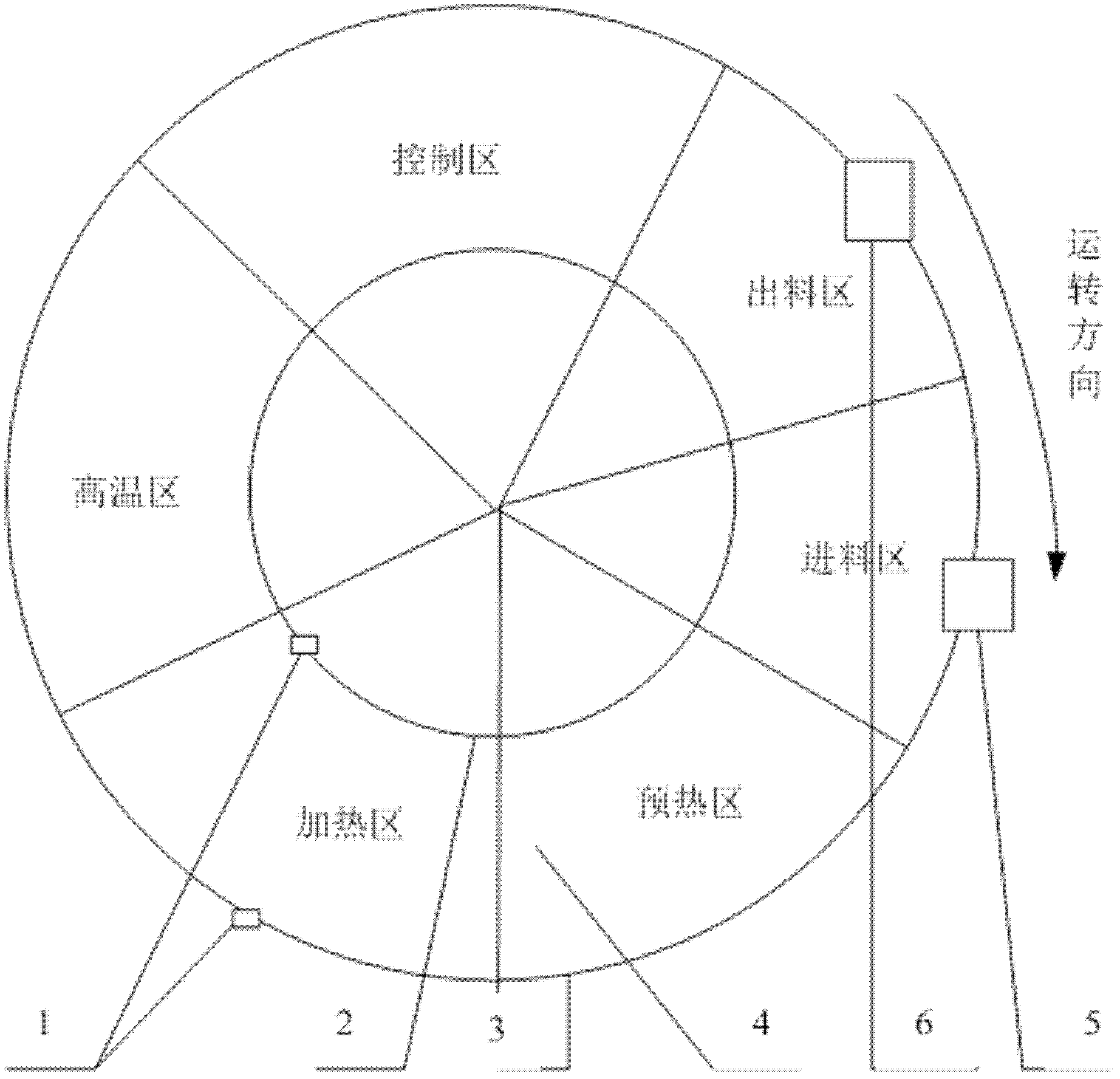

Device and method for treating refractory iron ore

InactiveCN102634621AImprove reduction efficiencyShort recovery timeProcess efficiency improvementCombustionControl area

Owner:SHENWU TECH GRP CO LTD

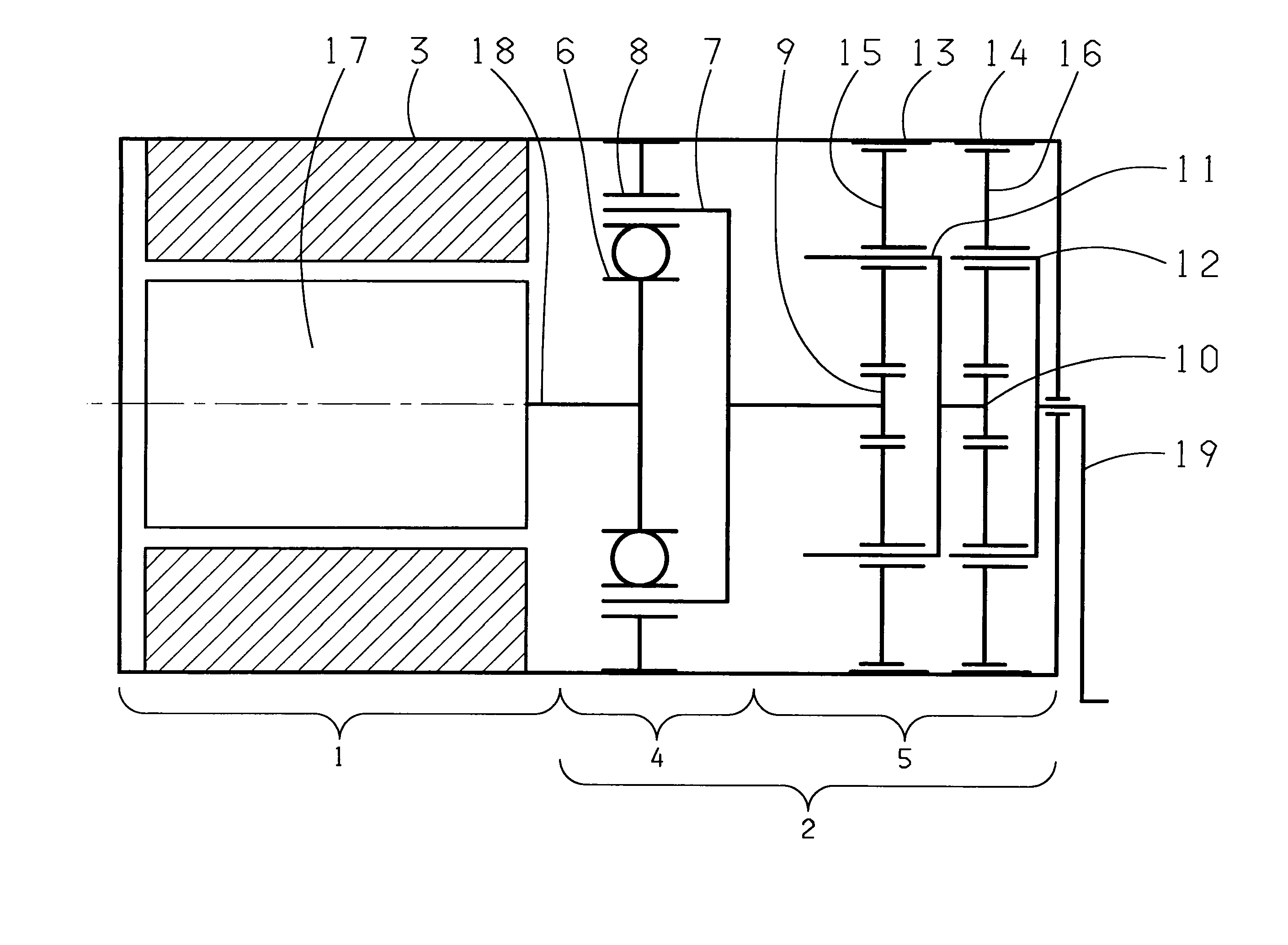

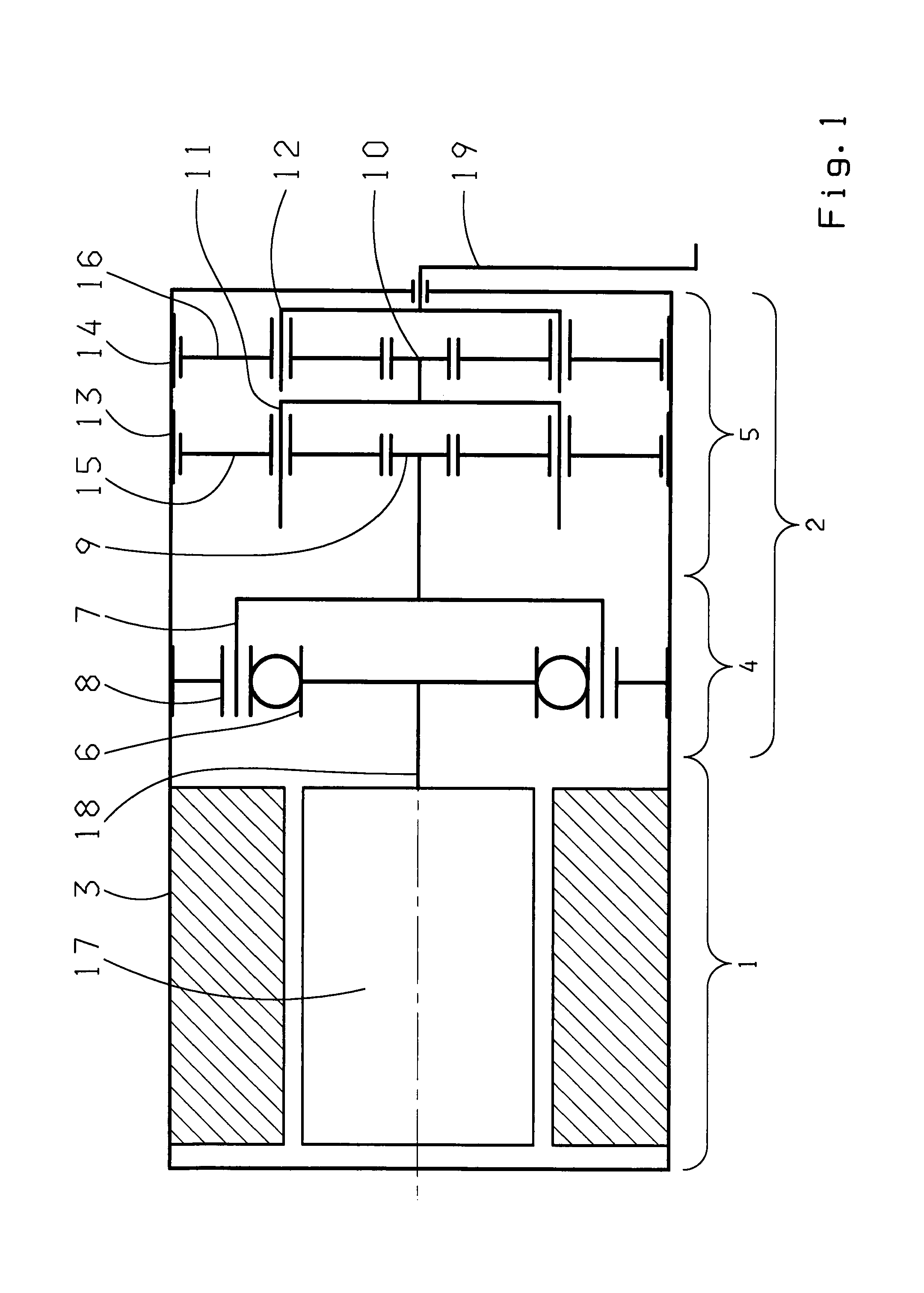

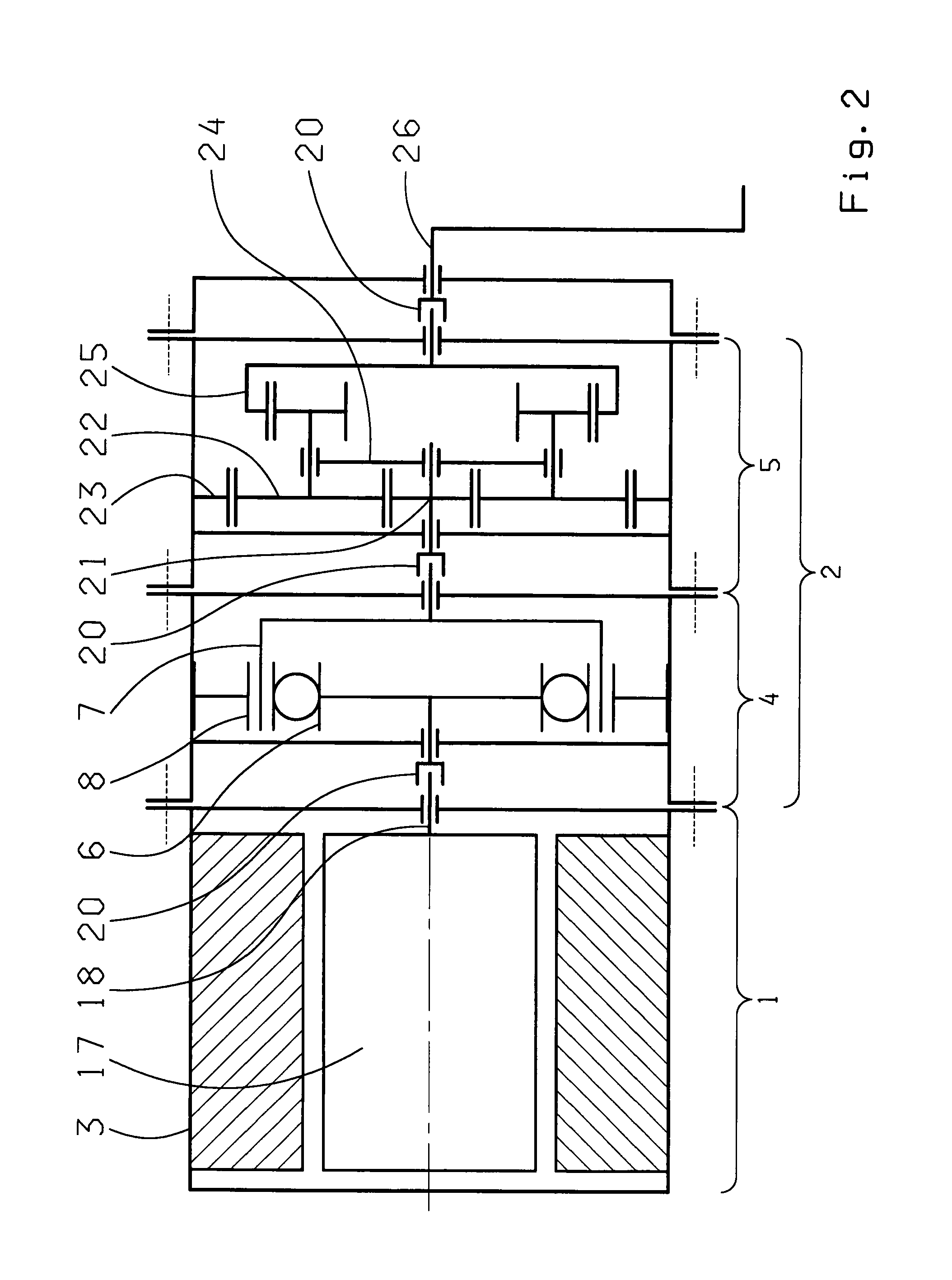

Actuator for generating a rotational positioning movement

InactiveUS20100072725A1Fast positioningIncrease the speed of positioningToothed gearingsInterconnection systemsHarmonicSelf locking

The present invention relates to an actuator for generating a rotational positioning movement, wherein the actuator comprises an electric motor (1) and a reduction gear (2) which consists of two assemblies (4, 5). The first assembly (4) is formed by a gear of the harmonic, cycloid or wobble, type and the second assembly (5) by a gear of the single-step or multistep planetary or Wolfrom type, whereby both assemblies (4, 5) are so tuned to each other, that the reduction gear (2) is not self-locking.

Owner:ZF FRIEDRICHSHAFEN AG

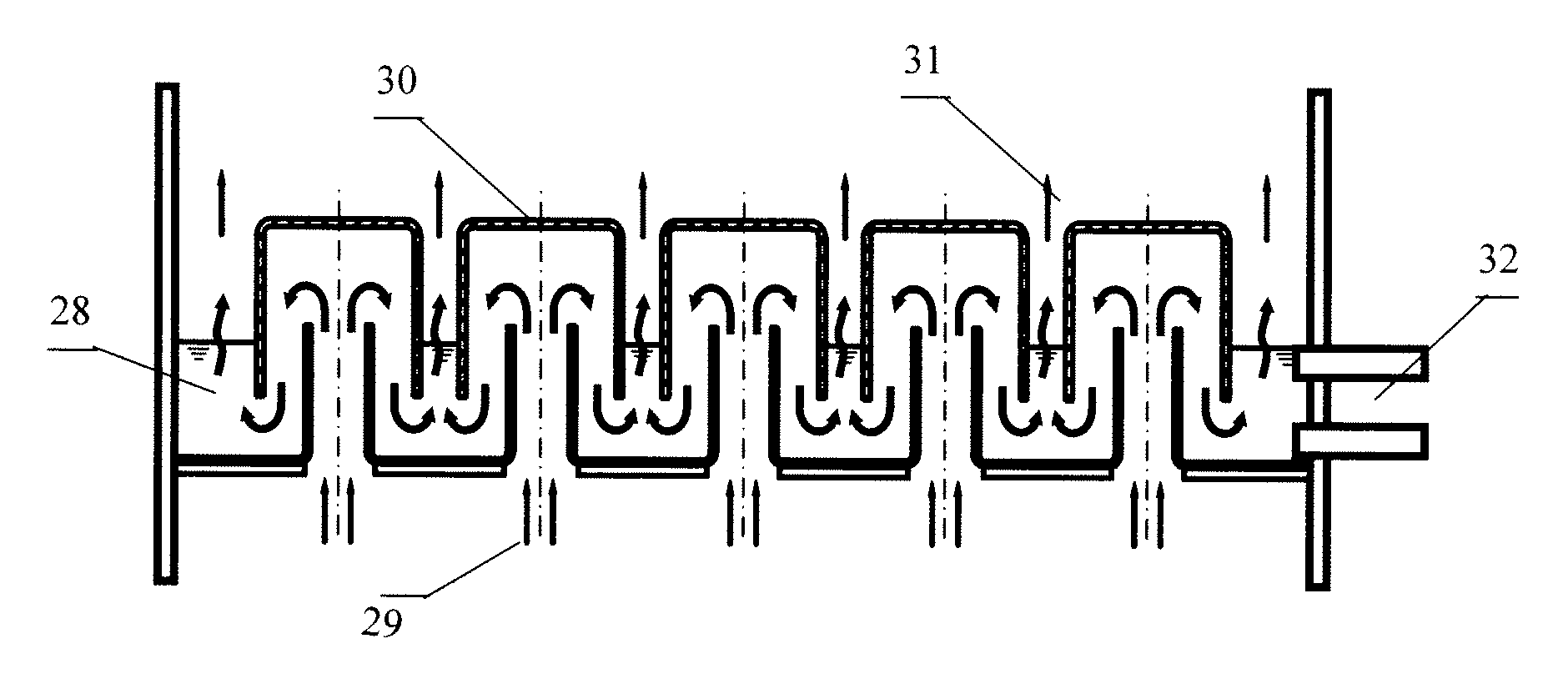

Ship Flue Gas Scrubbing Equipment And Method

InactiveUS20100266472A1Promote resultsOvercomes shortcomingGas treatmentExhaust apparatusFlue gasExhaust fumes

This invention involves a marine ship flue gas scrubbing equipment and scrubbing method. The equipment includes a shell with an upper scrubbing section and a water tank in the lower section. A smoke pipe leads in exhaust gas to an area between the scrubbing section and water tank. Scrubbing seawater is injected through an inlet above the scrubbing section, and a cooler is located along the pathway of the exhaust gas. The method of scrubbing includes leading-in exhaust gas, cooling the exhaust gas, injecting scrubbing seawater, performing scrubbing operation, and discharging clean gas. Embodiments of the invention provide a highly efficient scrubbing equipment and method suitable for high-temperature exhaust gas within a limited usable space. The methods and equipment are highly effective for emission reduction, has low energy consumption, small size, and long life performance.

Owner:PENG SIGAN

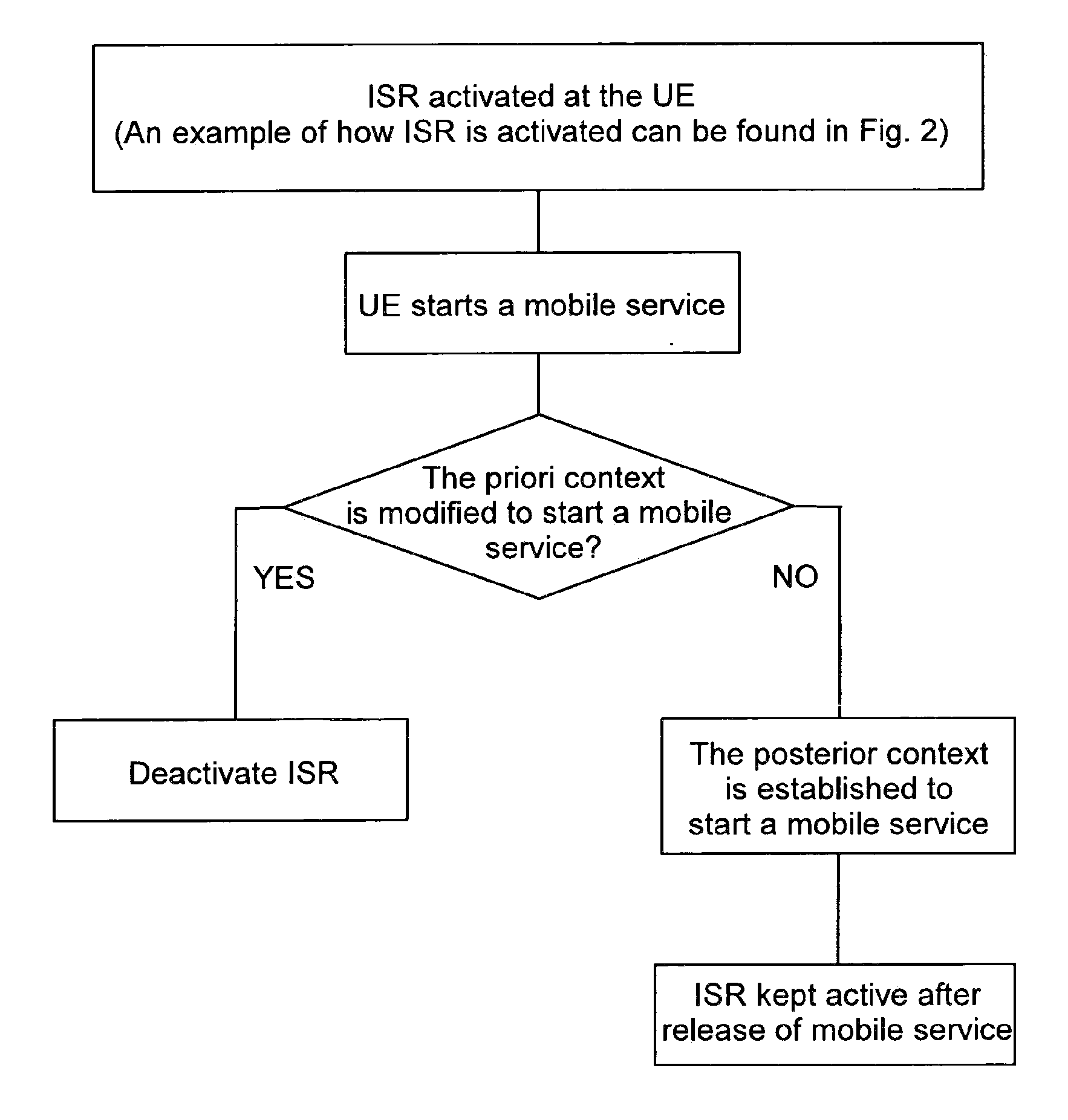

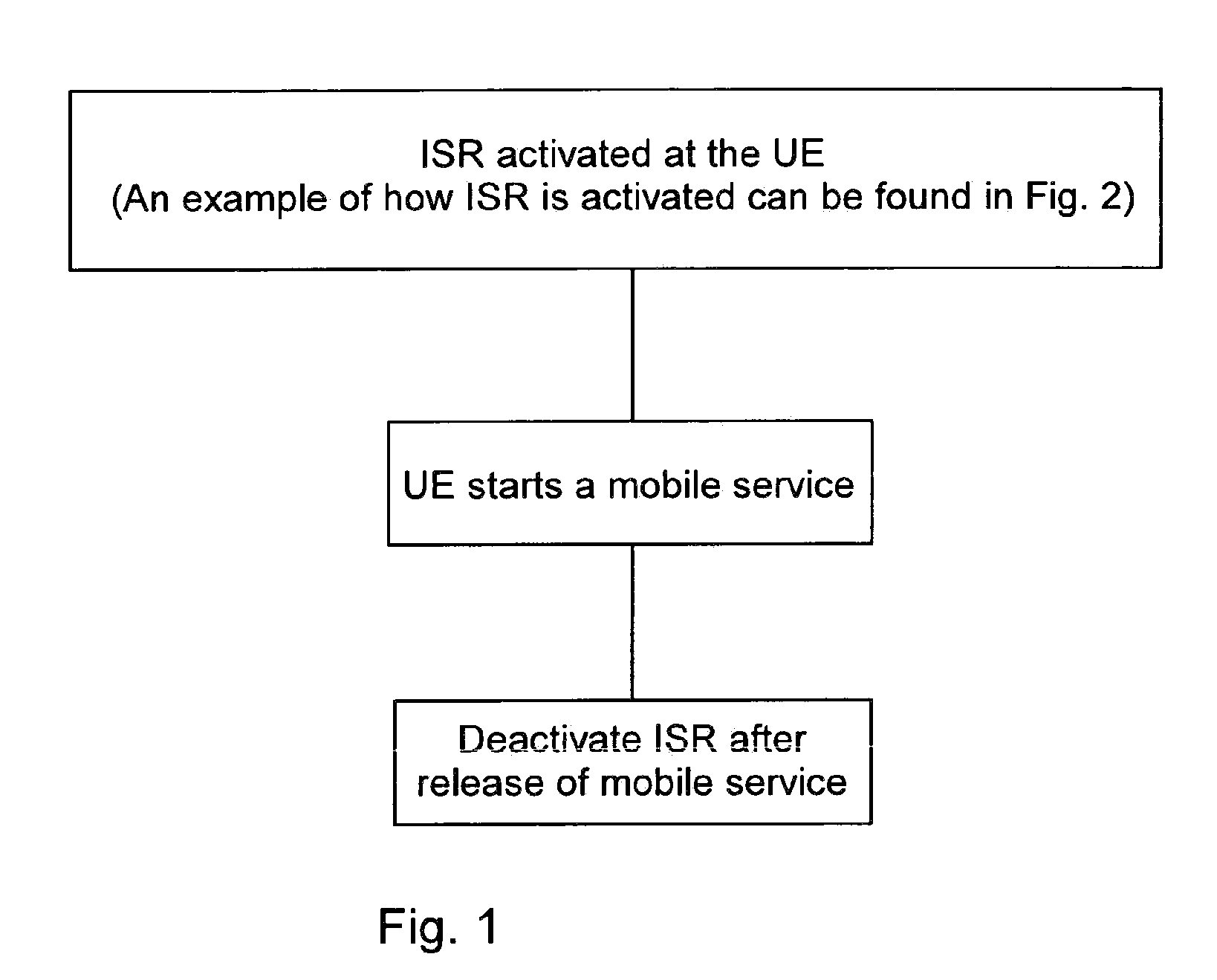

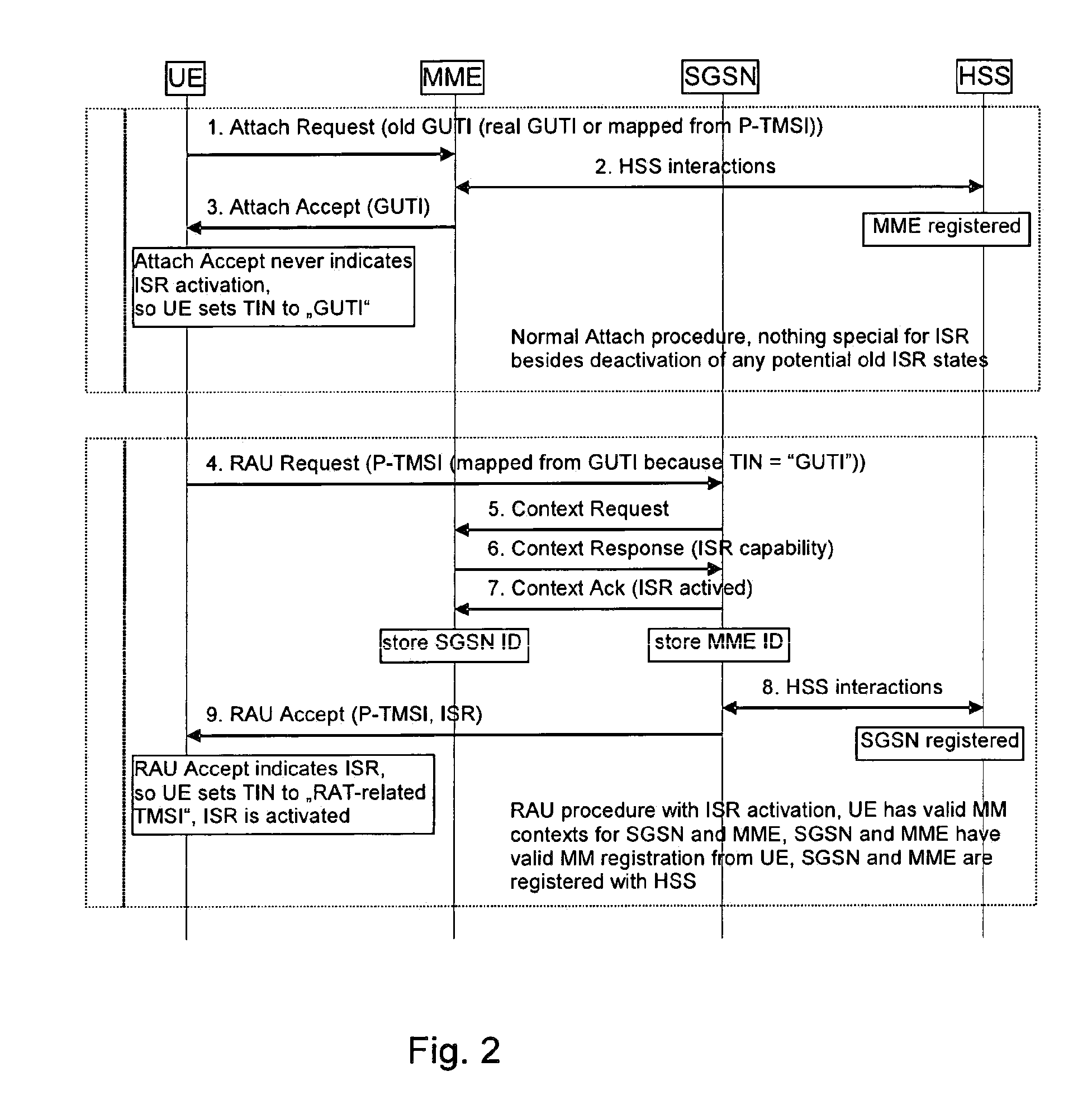

Reducing signalling loads from a mobile network

ActiveUS20110312348A1Improve idlingImprovement of inactive state signalling reduction efficiencyPower managementNetwork traffic/resource managementRadio access technologyTelecommunications network

Method and device for reducing signalling loads from a mobile device to a mobile telecommunications network system due to intersystem changes. The network system comprises a first and second radio access technology having a first and second radio access network and a first and second network core operable to page a mobile device via at least one element each of the first and second radio access technology. When idle or inactive state signalling reduction (“ISR”) is activated at the mobile device, the mobile device stores at least one first EPS bearer context and / or at least one first PDP context. After ISR is activated, at least one second EPS bearer context and / or at least one second PDP context is activated between the mobile device and the respective network. The respective network uses the stored at least one first contexts, or the at least one second contexts.

Owner:VODAFONE HLDG

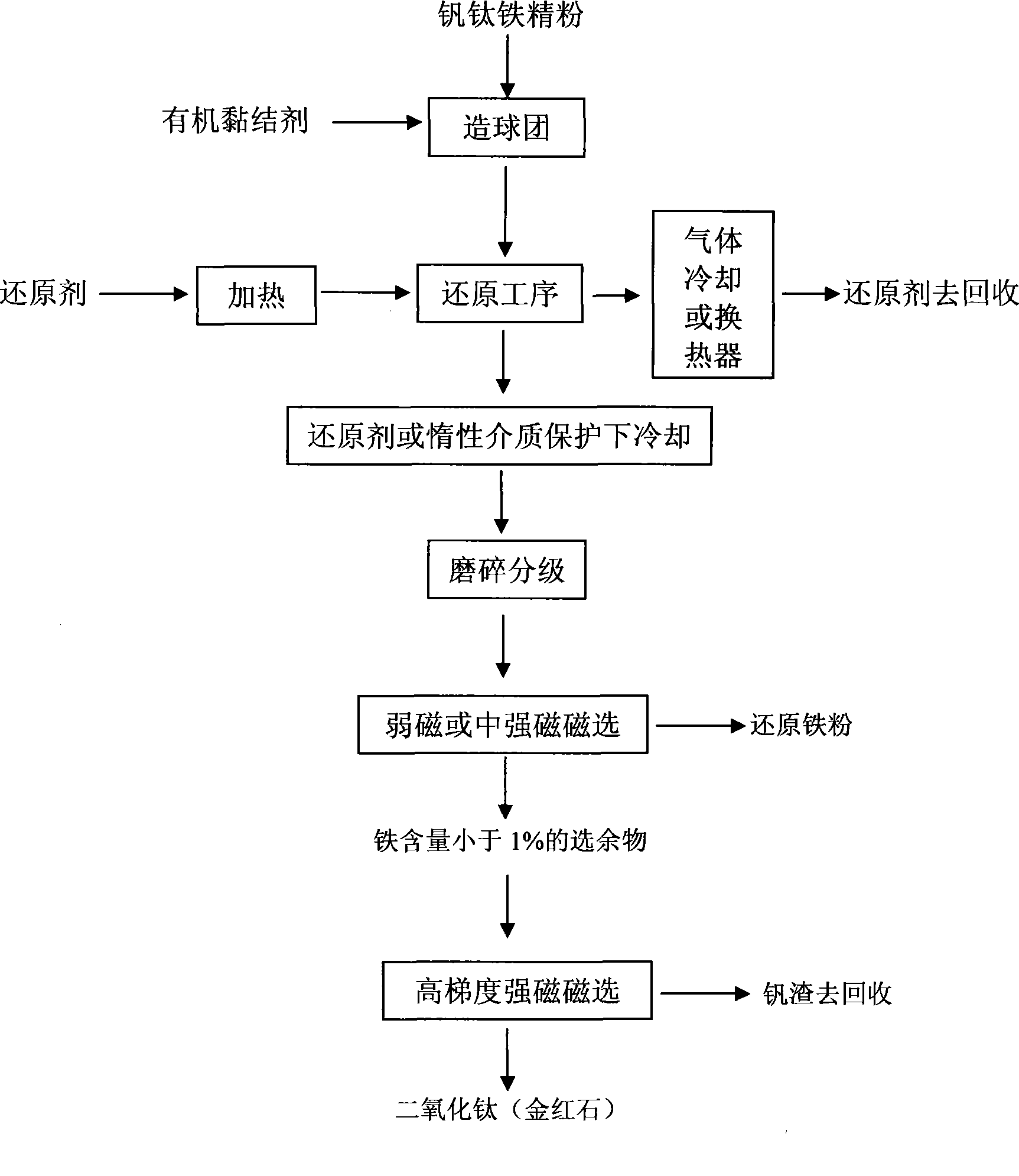

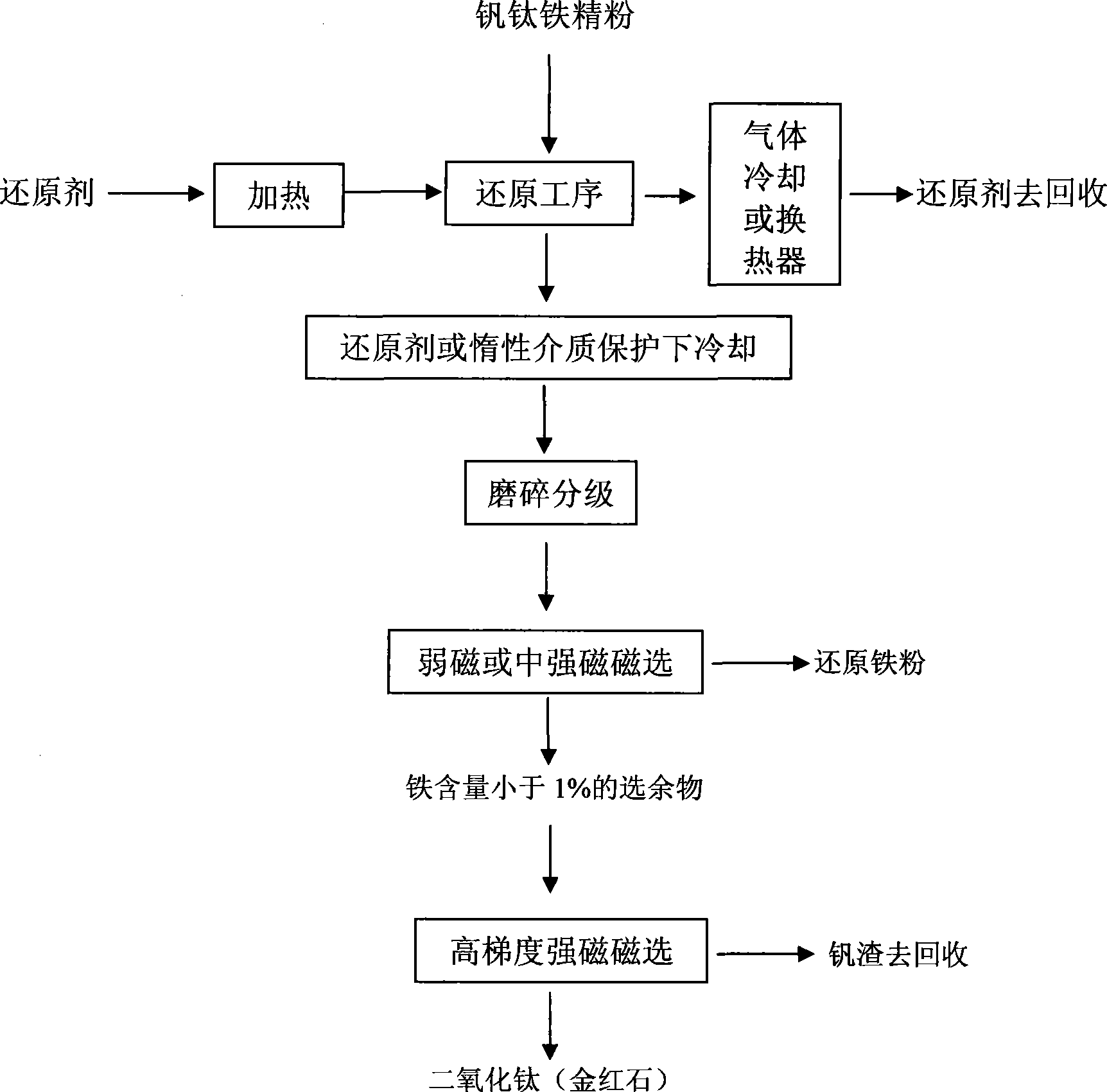

Method for separating V-Ti-Fe concentrate fines

The invention provides a method for separating vanadium-titanium iron fine powder, which comprises the following steps that the vanadium-titanium iron fine powder is sufficiently reduced by a reducing agent under a condition of not less than 500 DEG C, and the reduced vanadium-titanium iron fine powder is grinded and graded; the graded vanadium-titanium iron fine powder is subjected to weak magnetic separation or medium strong magnetic separation, and the magnetic separation object is of high-purity reduced iron powder; the remainders which are subjected to the weak magnetic separation or medium strong magnetic separation are subjected to high-gradient strong magnetic separation; the high-gradient strong magnetic separation object is of titanium dioxide (rutile), and the remainders which are subjected to the high-gradient strong magnetic separation are of high-grade vanadium slag which can be used as raw materials to produce vanadium products; or the remainders which are subjected to the weak magnetic separation or medium strong magnetic separation can also be mixed, roasted and immersed with sodium carbonate, the immersing liquid is acidified by sulfur to produce khaki or read and yellow sedimentation; and the sedimentation is filtered and calcined to obtain vanadium pentoxide products. The method has the characteristics of completely, effectively and economically separating the vanadium-titanium iron fine powder into high-purity reduced iron powder, titanium dioxide and vanadium pentoxide, thereby providing a feasible way for comprehensive utilization of the vanadium-titanium iron fine powder.

Owner:BEIJING BOYUAN HENGSHENG HIGH TECH

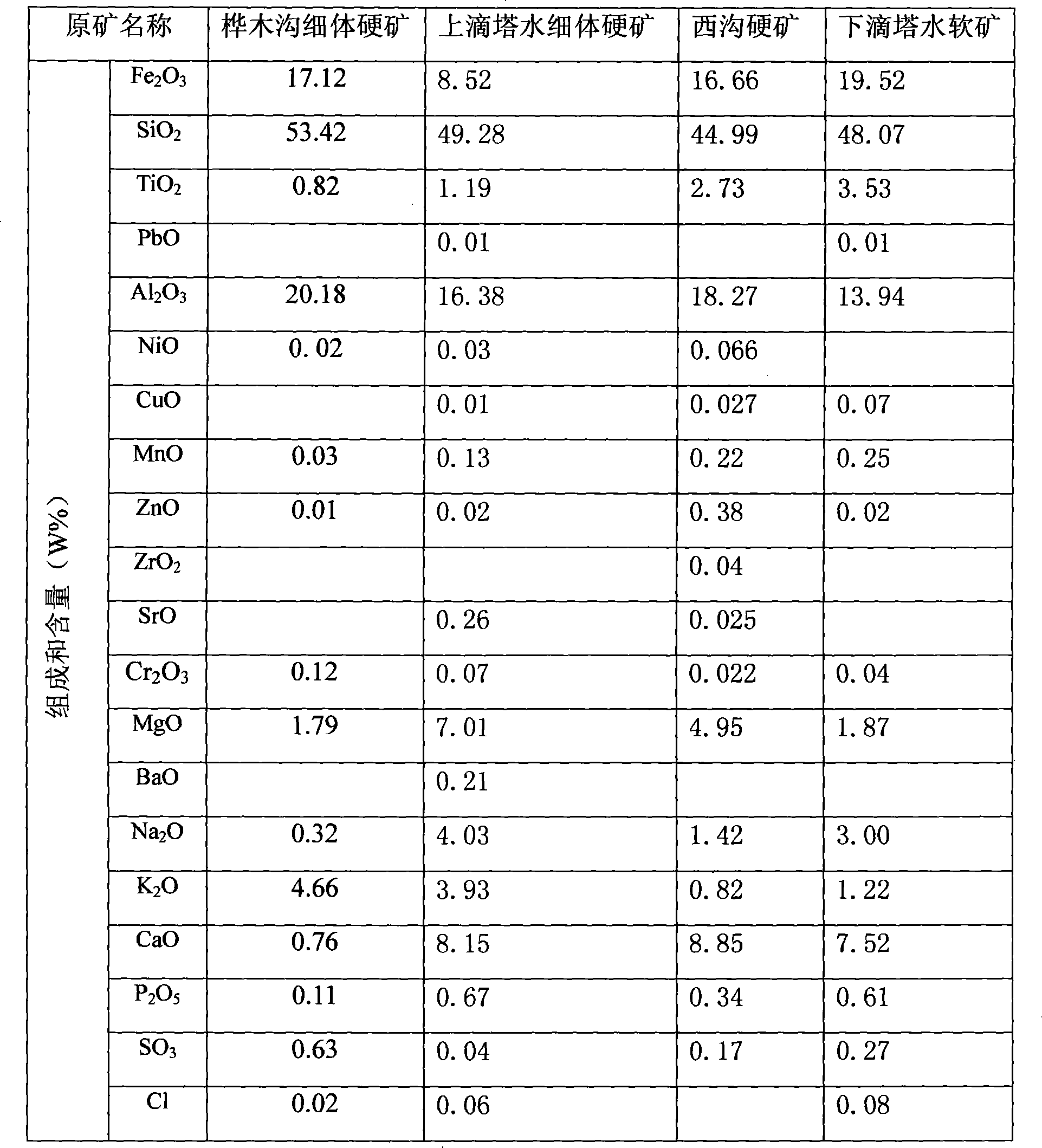

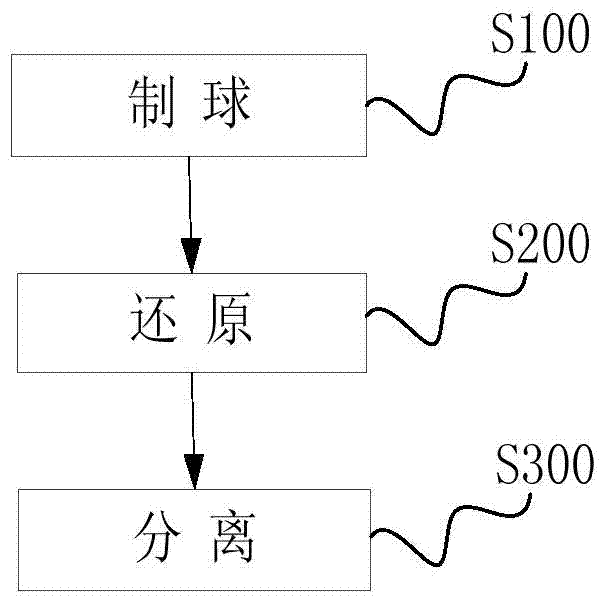

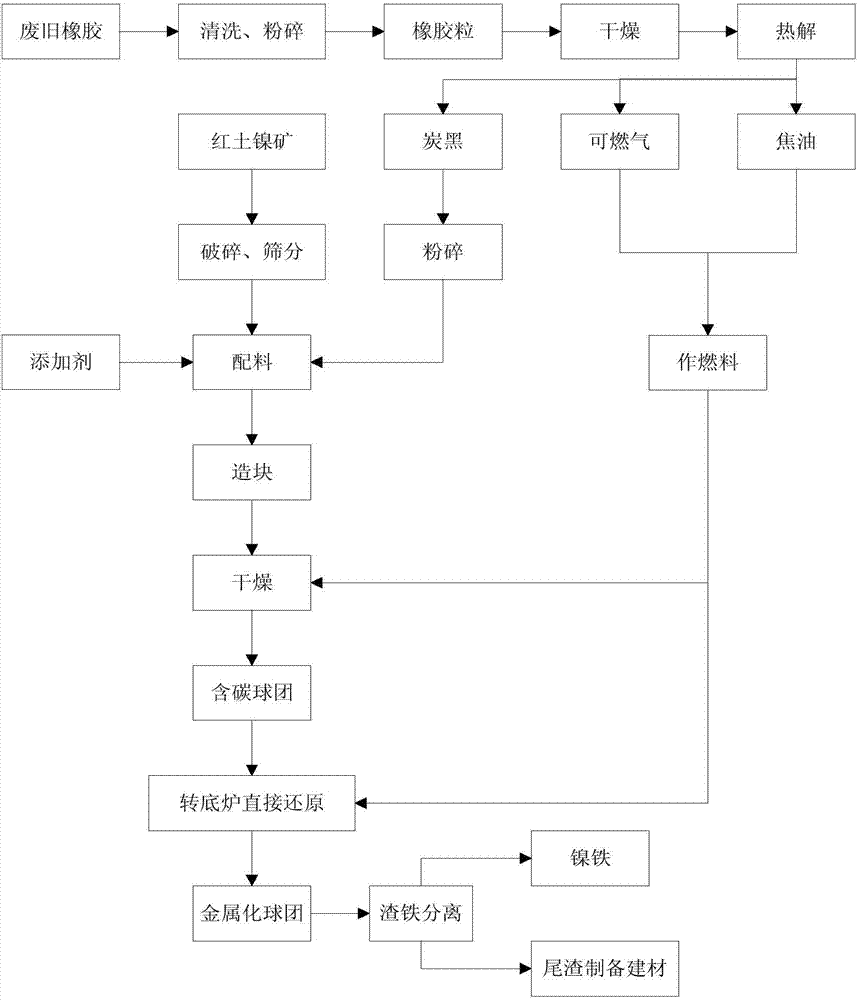

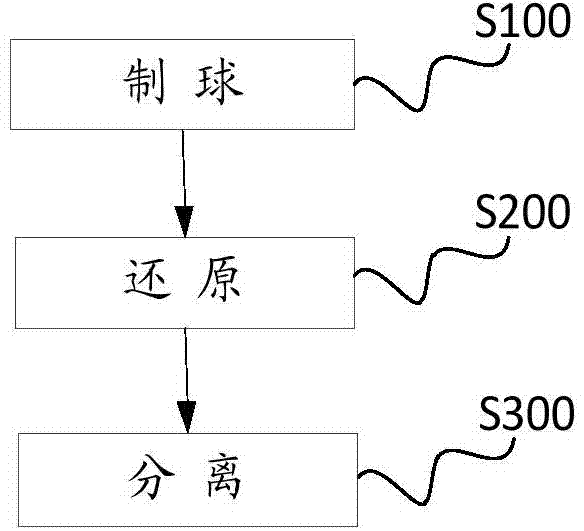

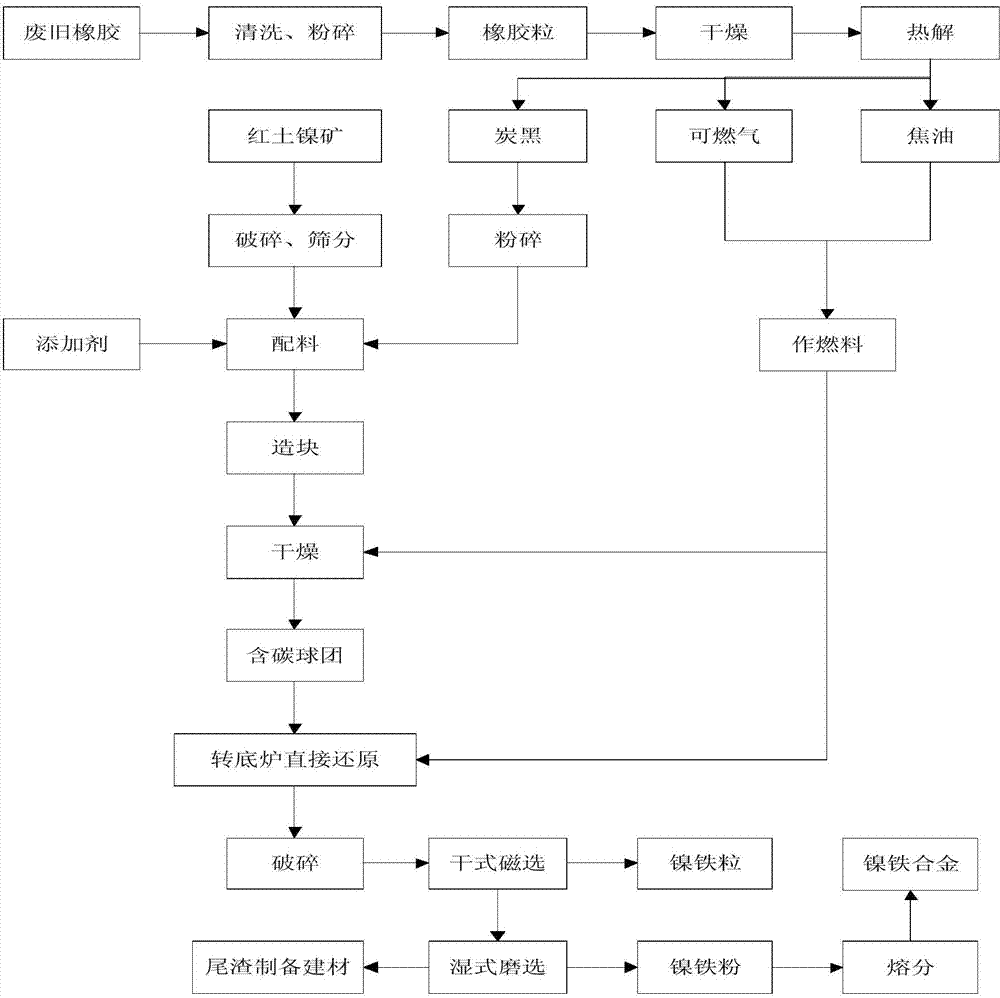

Treatment method of laterite-nickel ore

ActiveCN103667742AEffectively madeImproving the Efficiency of Reduction Roasting Laterite Nickel OreHearth type furnacesSlagHearth

The invention discloses a smelting method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, carbon black and additives; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; and carrying out slag-iron separation on the metalized pellets to obtain nickel iron and tailings. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

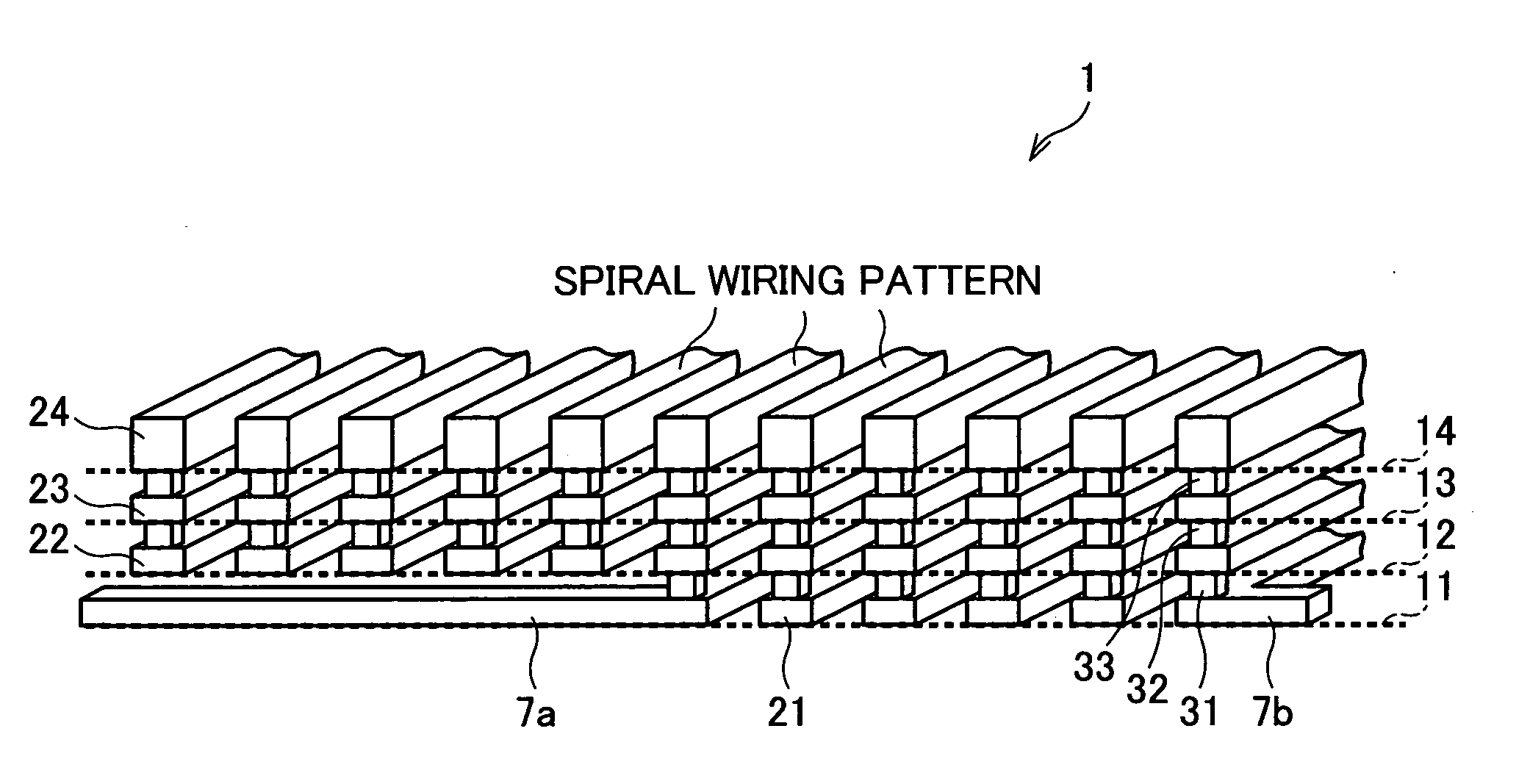

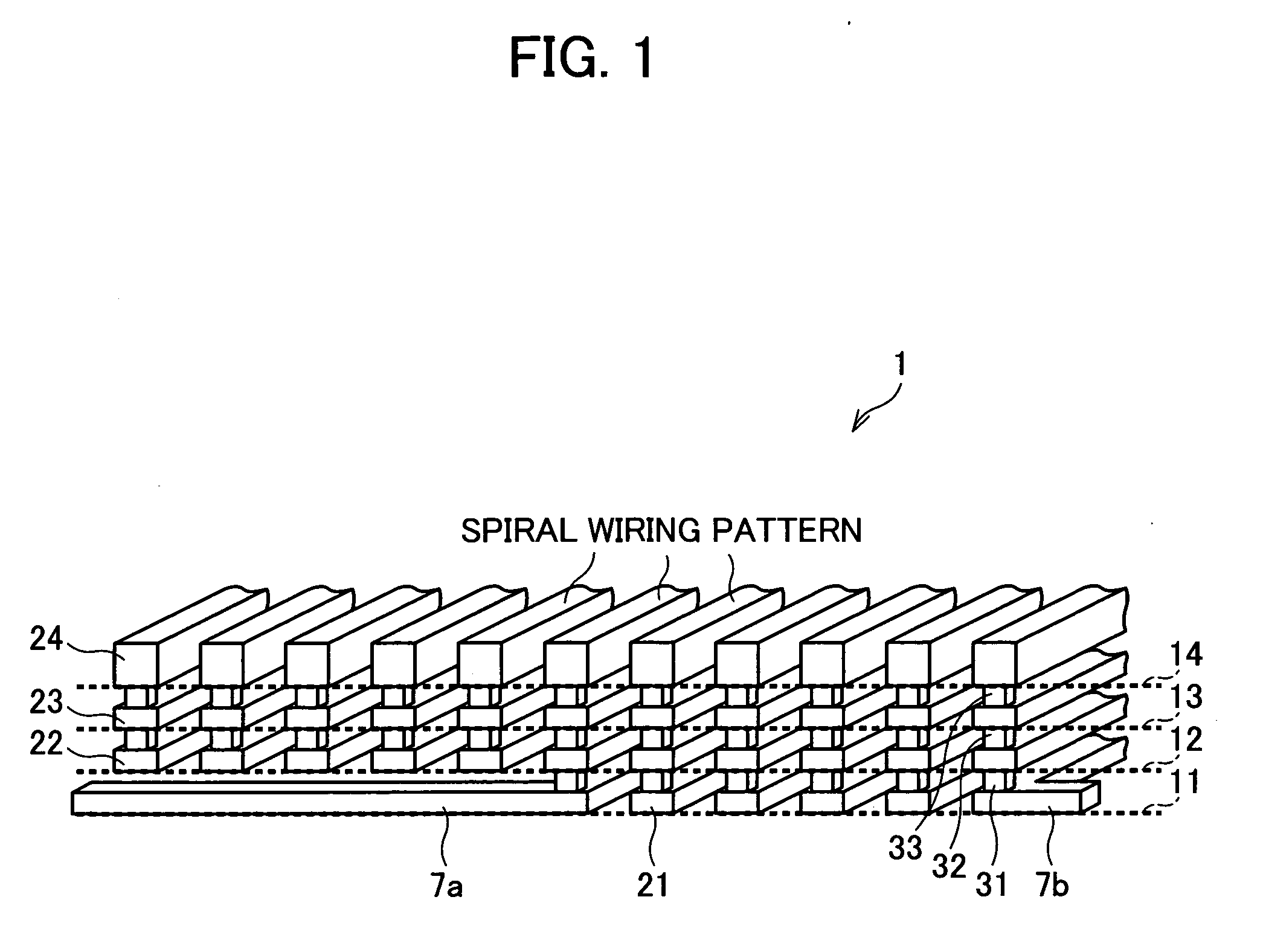

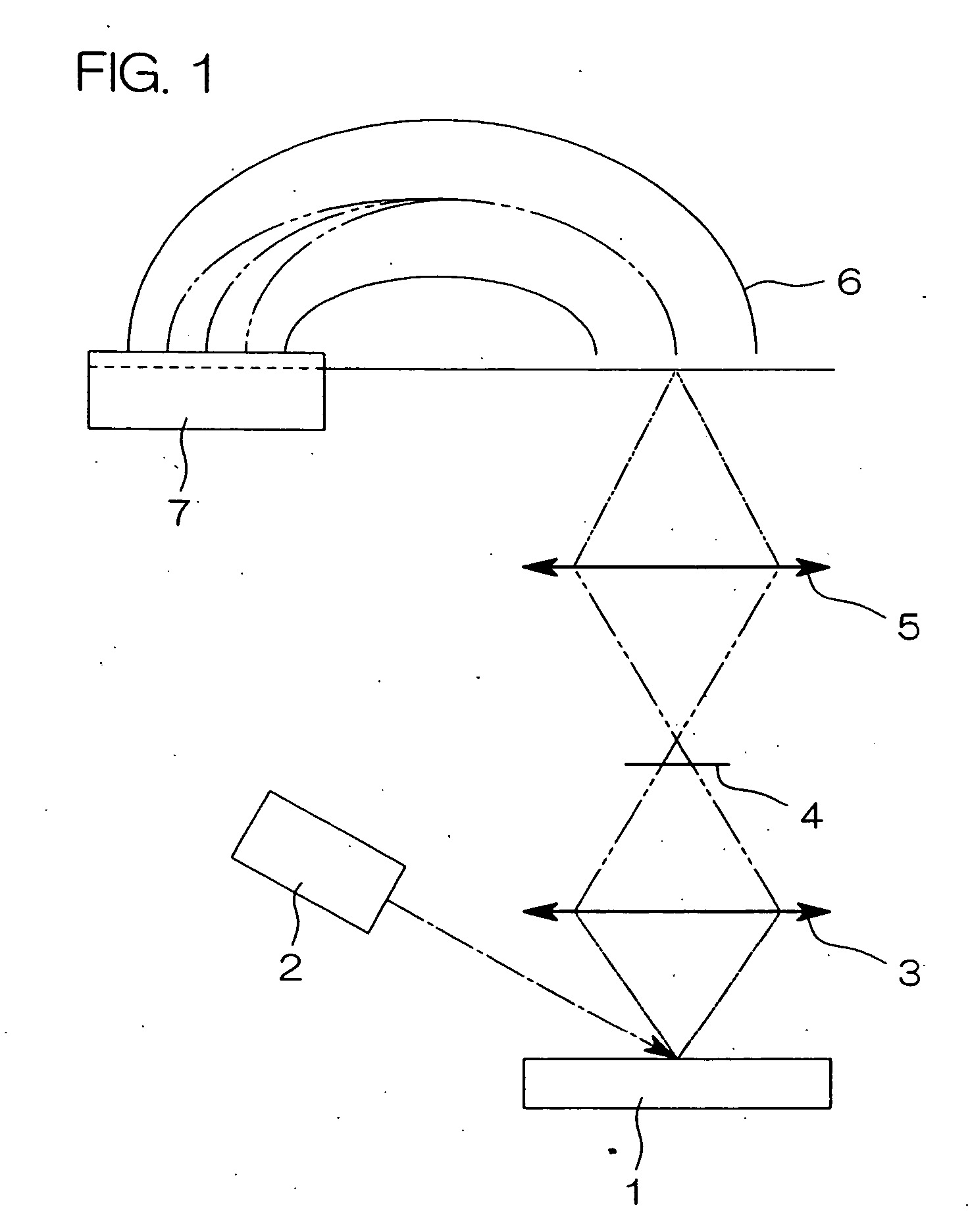

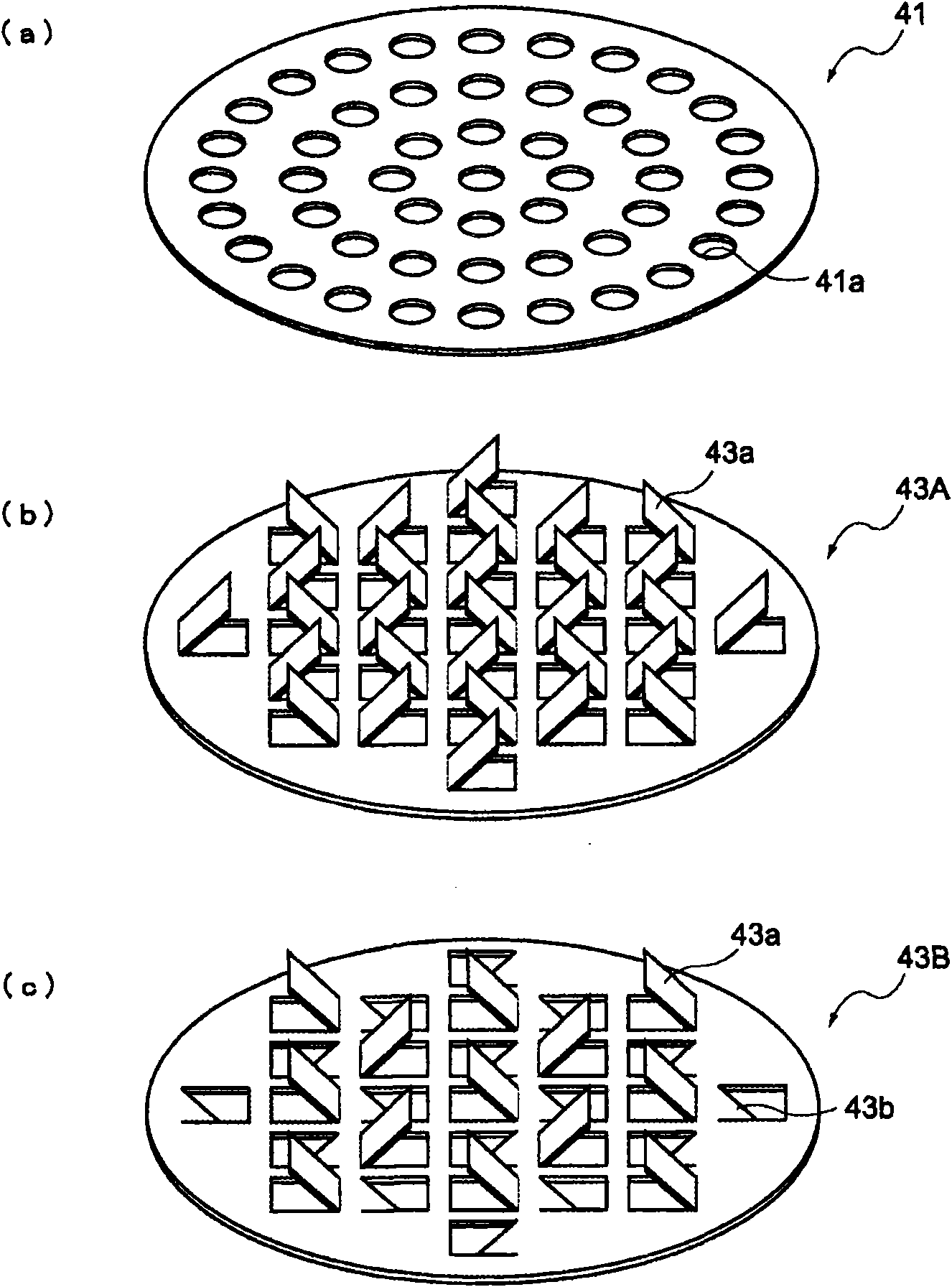

Inductor, resonant circuit, semiconductor integrated circuit, oscillator, and communication apparatus

InactiveUS20060125589A1Increase parasitic capacitanceHigh QTransformers/inductances coils/windings/connectionsOscillations generatorsEngineeringInductor

An inductor of the present invention includes a plurality of insulating layers being stacked and coil patterns respectively provided on predetermined layers of the insulating layers. The coil patterns are provided on at least two of the insulating layers, and electrically connected to each other. With this arrangement, it is possible to improve Q of the inductor without increasing the size of the inductor.

Owner:SHARP KK

Method for synthetically reclaiming iron, vanadium and titanium from vanadium titanium magnet concentrate

InactiveCN101168802ATake advantage ofCannot be efficiently recycledRotary drum furnacesTitanium dioxideRecovery methodMagnetite

The invention relates to a comprehensive recovery method of iron, vanadium and titanium for vanadium and titanium magnetite concentrated ores, in particular to the comprehensive recovery and utilization of the vanadium and titanium magnetite concentrated ore of which the vanadium content is higher. In particular, the invention is vanadium extraction through water immersion after the vanadium and titanium magnetite concentrated ore is performed with sodium activation and sintered, the vanadium product is made from leach solution, the remaining slag is performed with reduction quickly through a rotary furnace after carbon is added, the reduction product is melted through the electric furnace, to segregate the melted iron and the titanium slag, the melted iron is used to make steel, and the titanium slag is used to produce white titanium pigment through a sulfuric acid method titanium white technology. The method of the invention is applied to the refining technology of the vanadium and titanium magnetite concentrated ore, to ensure that the recovery rate of the vanadium and titanium is greatly enhanced, the recovery rate of the total vanadium in the iron concentrated ore can reach more than 80 percent, titanium is fully recovered, and the production of massive blast furnace slag is avoided.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

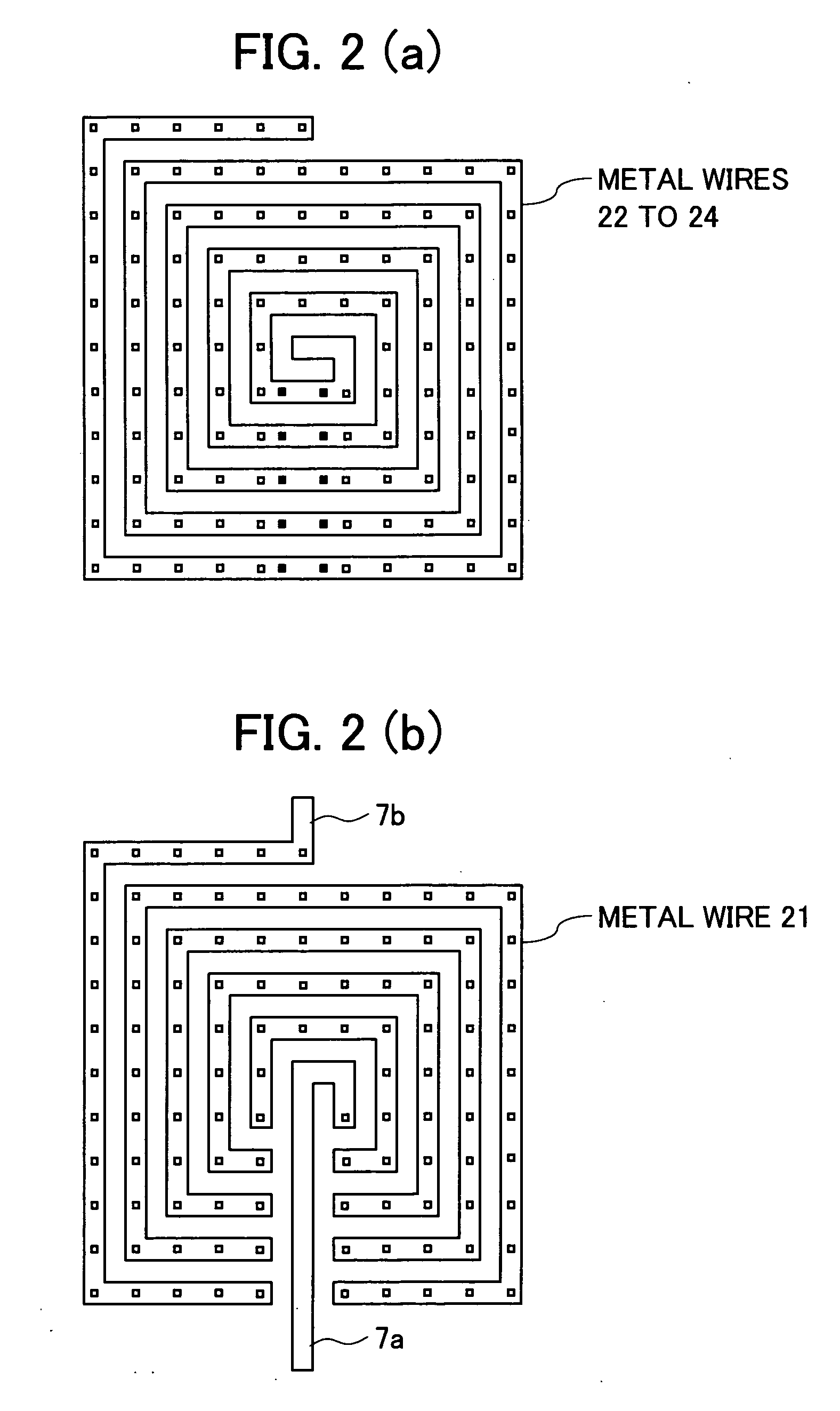

PCB (Printed Circuit Board) copper-containing wastewater treatment method with autocatalytic oxidation as core

ActiveCN103864247ALow costImprove catalytic abilityMultistage water/sewage treatmentProcess efficiency improvementPollutantFenton reaction

The invention discloses a PCB copper-containing wastewater treatment method with autocatalytic oxidation as a core. According to the method, acid copper-containing wastewater is used for regulating pH of alkali copper complex wastewater to be nearly neutral or neutral, zero-valent iron is used for reducing copper ion part in wastewater into new elemental copper which is beneficial for following Fenton reaction, under concerted catalysis action of divalent iron and new elemental copper, high-efficiency Fenton reaction is realized under neutral condition so as to break complex, and then, zero-valent iron is used for reduction to recycle copper ions in wastewater, divalent iron and ferric ions in effluent are removed by an alkali regulation precipitation method, meanwhile, under the effects of flocculation and adsorption of ferric hydroxides, pollutants in water are further removed, copper ion concentration is less than 0.5mg / L and iron ion concentration is less than 10mg / L in final effluent, and biodegradability is good. The method fully uses the copper existing in the system and makes use of catalytic effect of copper while removing the copper, dosage of acid and alkali is remarkably reduced, and salt content of effluent is reduced, and the method has an industrial application value.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

Method for reducing and stabilizing chromium-contaminated soil by chemical-biological coupling

InactiveCN104492802AImprove stabilityReduce leaching concentrationContaminated soil reclamationCouplingSulfate

The invention relates to a method for reducing and stabilizing chromium-contaminated soil by chemical-biological coupling. The method comprises the following steps: mixing chromium-contaminated soil and ferrous sulfate, uniformly stirring, adding water to control the water content, and maintaining until the concentration of hexavalent chromium in the chromium-contaminated oil is reduced to be lower than 500mg / kg to obtain chemically reduced soil; adding a microbial nutrient prepared from honey and soybean cake powder according to a certain proportion into the chemically reduced soil, uniformly stirring, regulating the water content, and isolating air to maintain for over 30 days to obtain the repaired soil. The method provides a new thought for repairing chromium-contaminated soil, has the advantages of low cost, good effect, small chemical reagent dosage, short repairing time, environmental friendliness, simple operation and the like, and has remarkable economic and environmental benefits.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

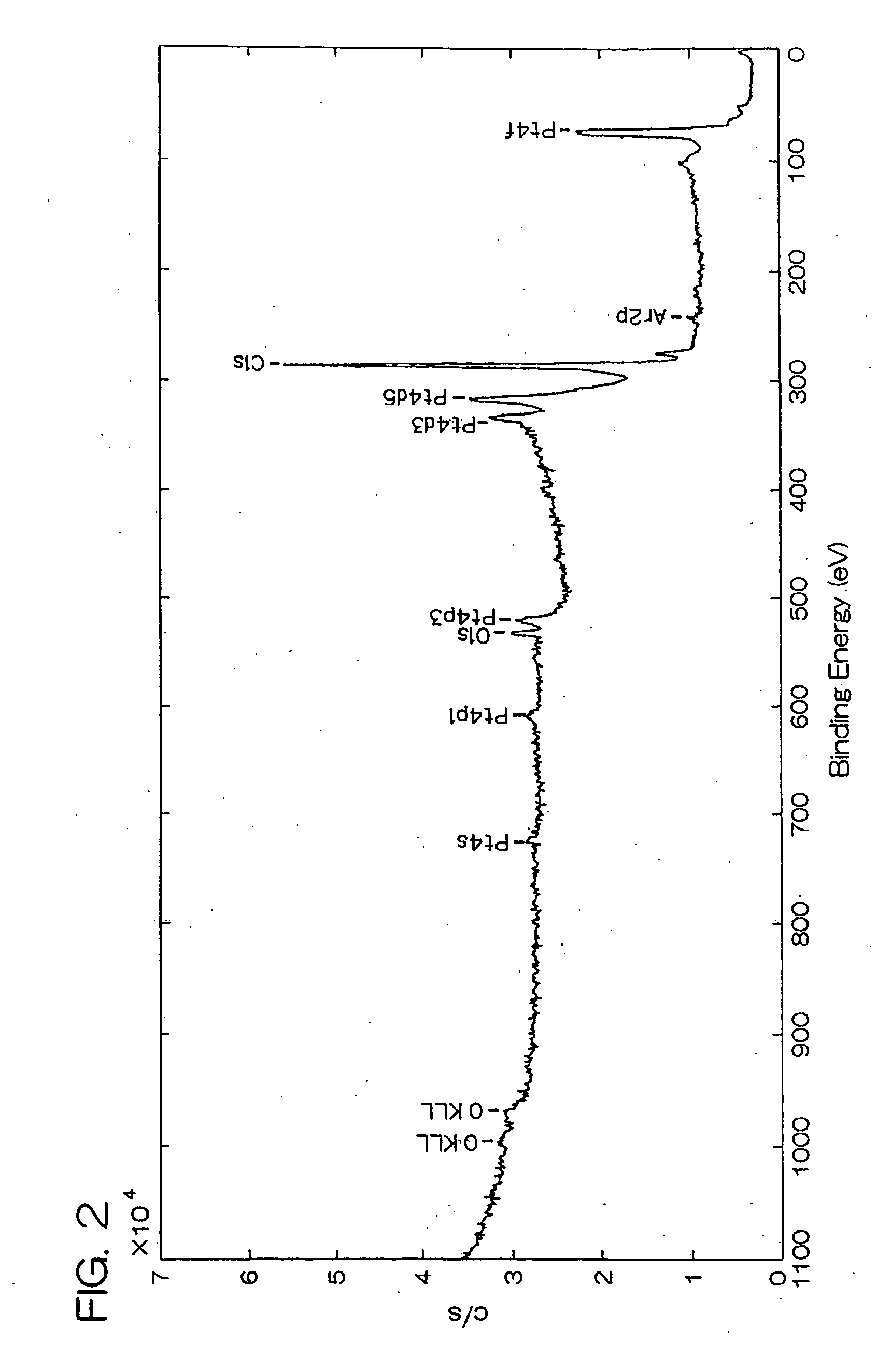

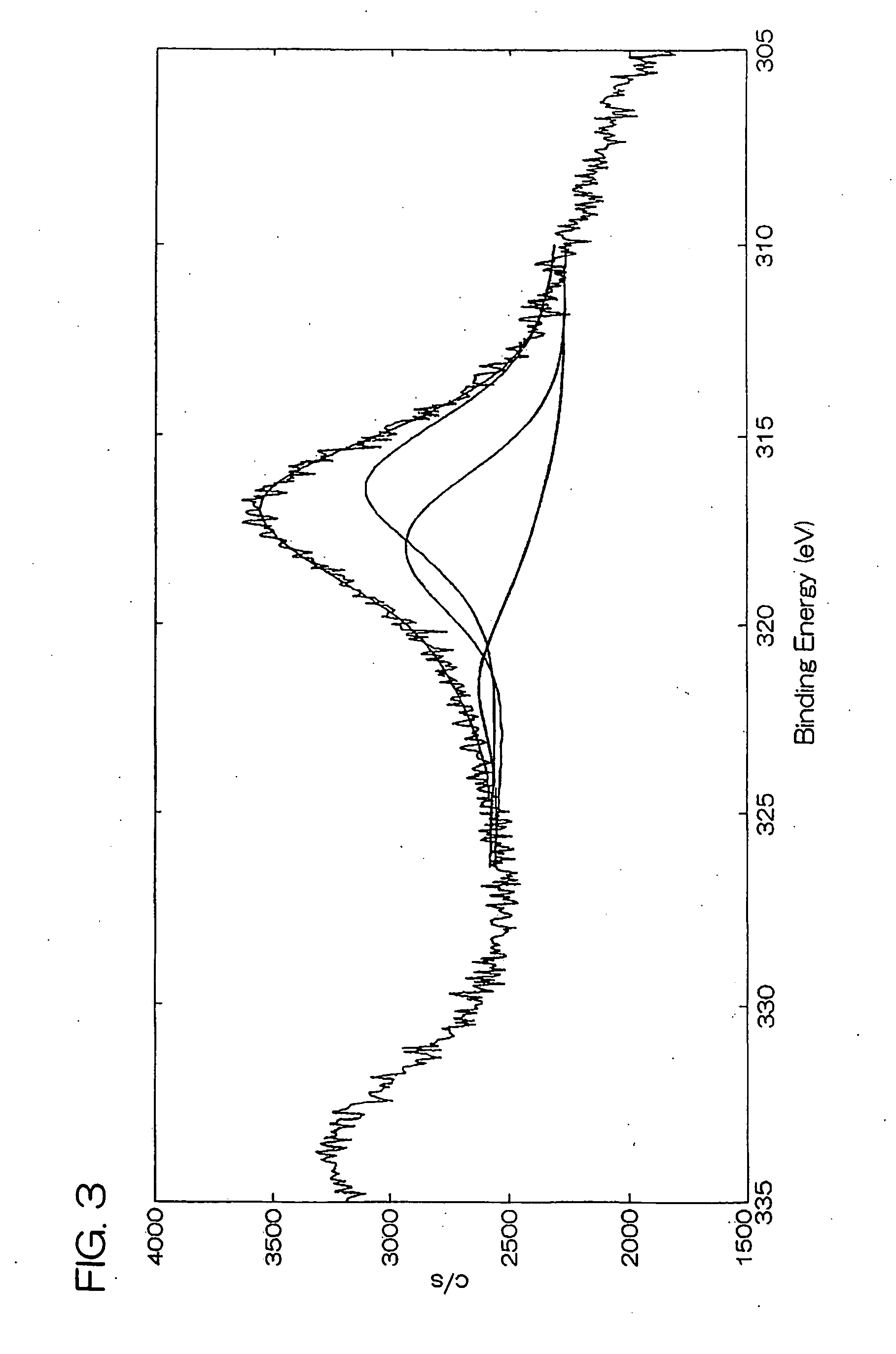

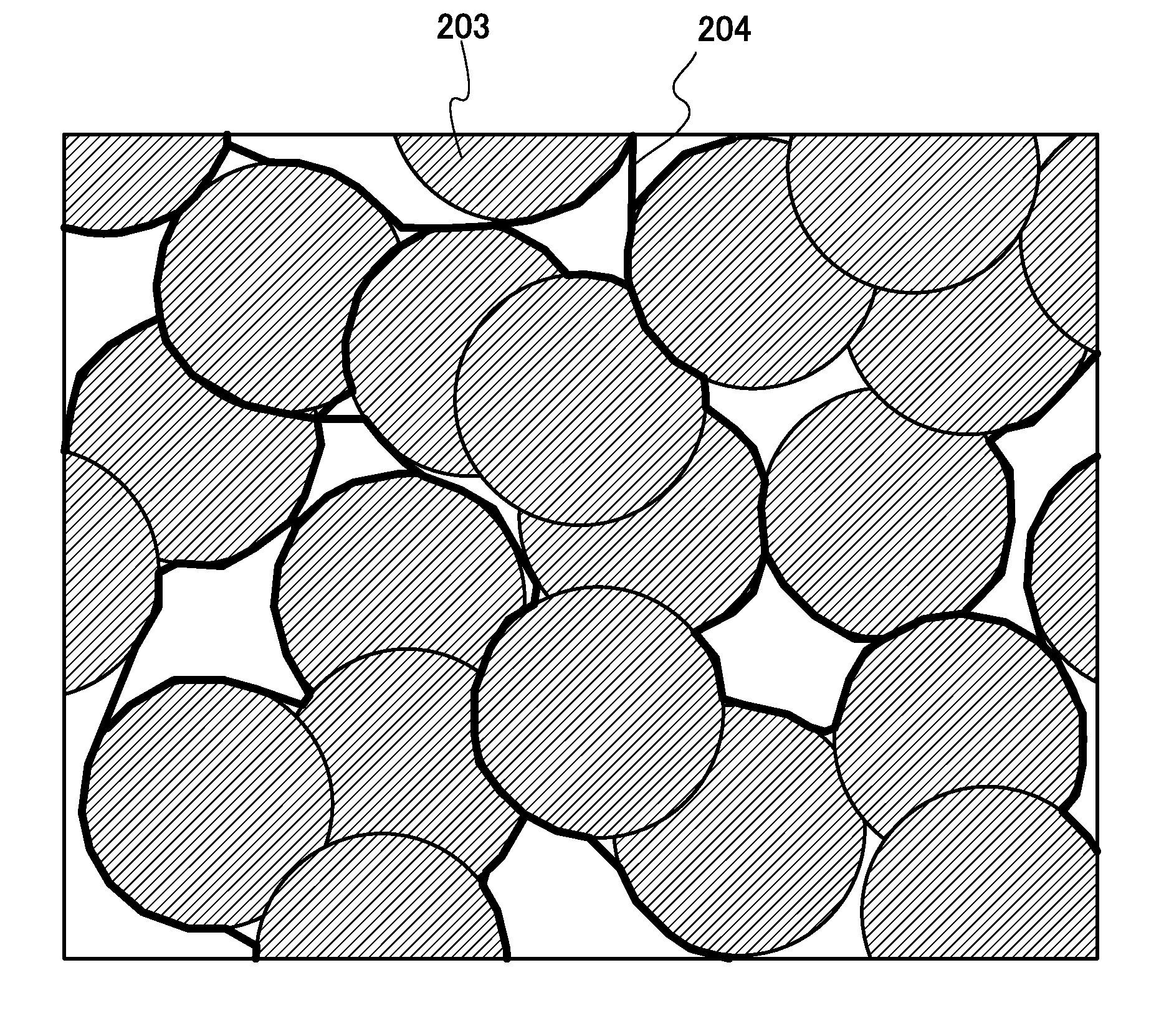

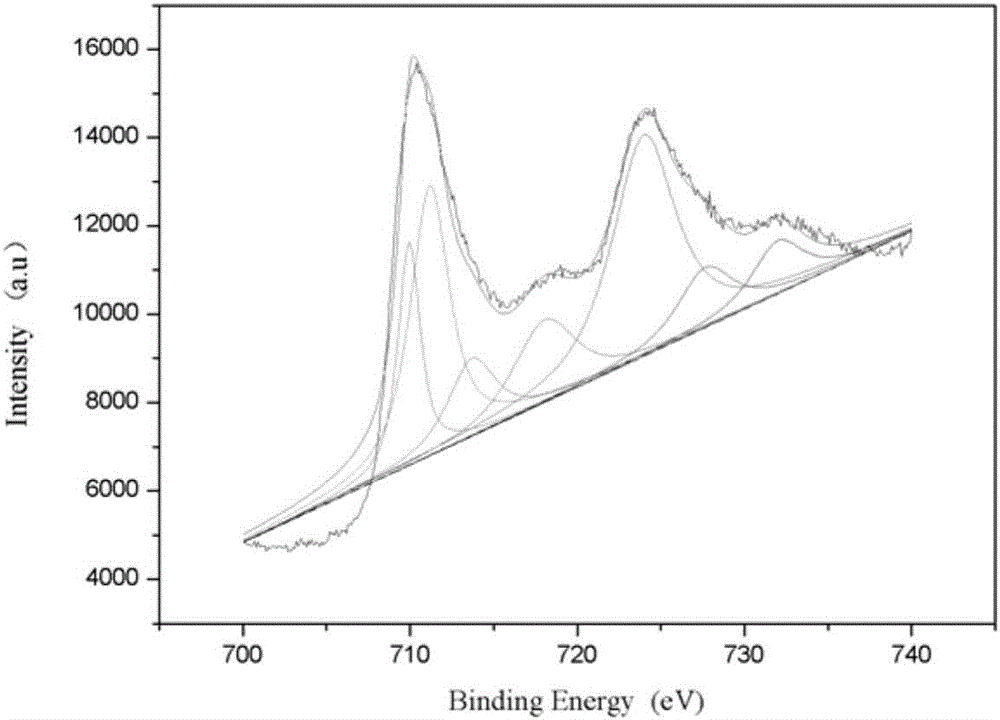

Metal Catalyst and Method for Production Thereof

ActiveUS20070244003A1High catalytic activityHigh catalytic efficiencyCell electrodesCatalyst activation/preparationOxidation stateX-ray

The present invention relates to a metal catalyst containing fine metal particles, characterized in that the fine metal particles have a particle diameter of 3 nm or less and also have a proportion of metallic bond state of 40% or more, which is ascribed by subjecting to waveform separation of a binding energy peak peculiar to the metal as measured by using an X-ray photoelectron spectrometer. The fine metal particles are preferably fine platinum particles. The fine metal particles are preferably supported on the surface of carrier particles by reducing ions of metal to be deposited through the action of a reducing agent in a reaction system of a liquid phase containing the carrier particles dispersed therein, thereby to deposit the metal on the surface of carrier particles in the form of fine particles. The proportion of metallic bond state of the fine metal particles is adjusted within the above range by reducing after deposition thereby to decrease the oxidation state.

Owner:SUMITOMO ELECTRIC IND LTD

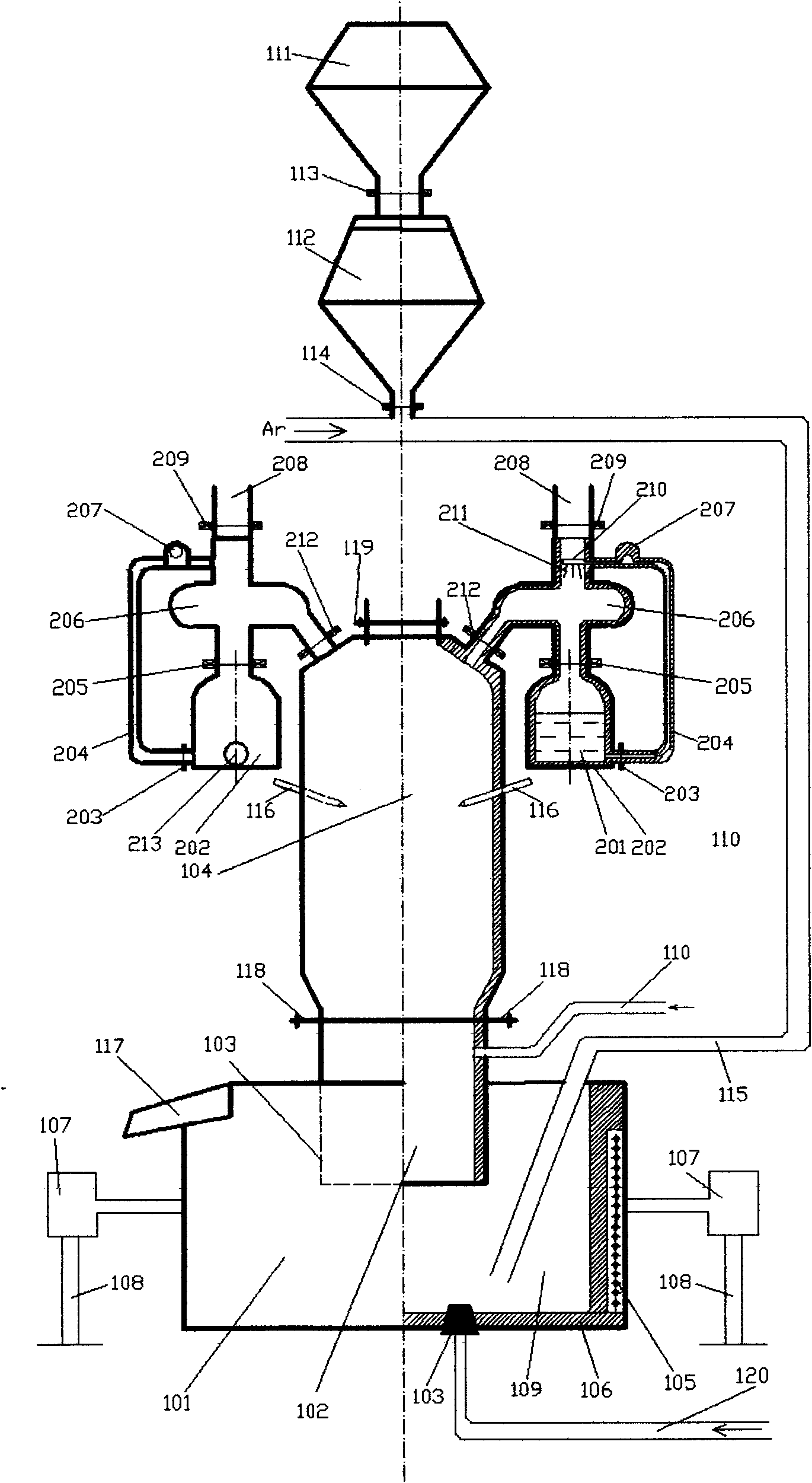

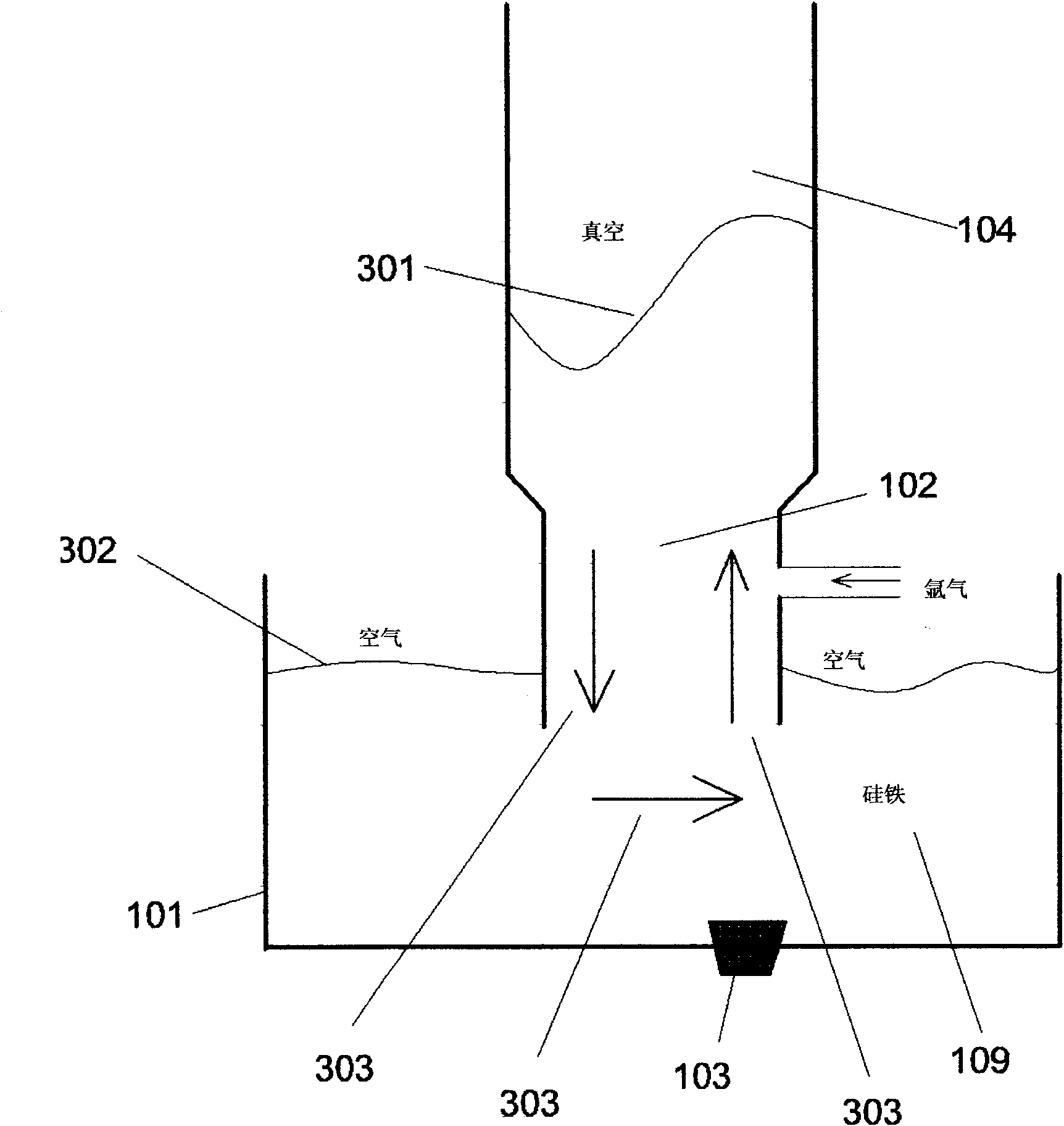

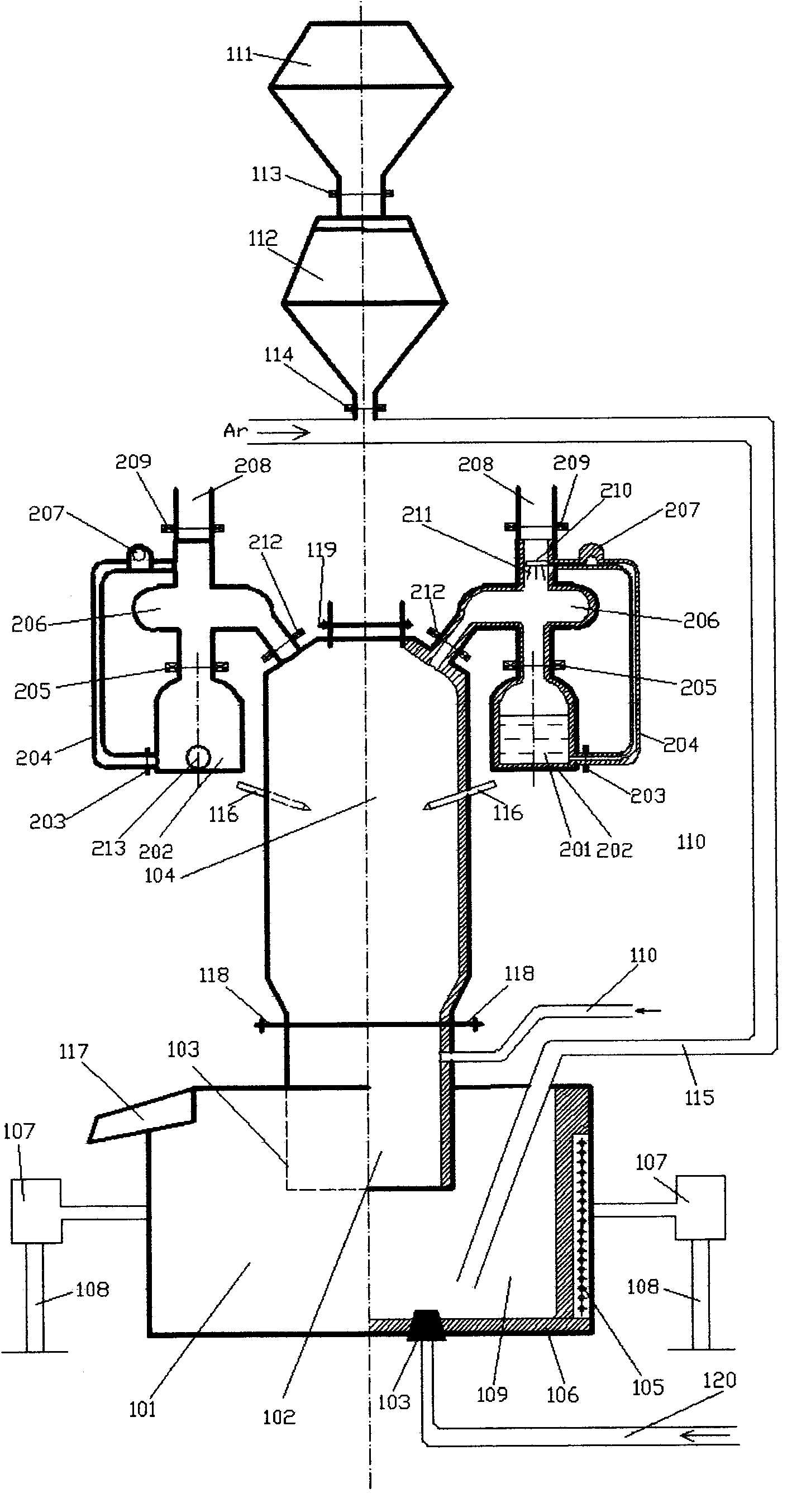

Single-dip pipe silicon iron bath vacuum circulated magnesium-smelting device and method

The invention discloses single-dip pipe silicon iron bath vacuum circulated magnesium-smelting device and method. The device comprises an induction furnace (101), a vacuum reaction chamber (104), a single dip pipe (102) and an argon blowing pipe (110) with a side wall communicated with guided flows; and besides, the device also comprises a magnesium steam condenser (206), a magnesium liquid spray thrower (210), a magnesium liquid storer (202) and magnesium mining powder conveying and spraying devices (111)-(115), wherein the magnesium steam condenser (206), the magnesium liquid spray thrower (210) and the magnesium liquid storer (202) are communicated. The method comprises the following steps of: preparing silicon iron liquid with the silicon content of 30%-65% and the temperature of 1,350-1,600 DEG C, making the mixtures of the silicon iron liquid and magnesium mining powder blown into the silicon iron liquid annularly flow between a vacuum reaction device and the induction furnace at the vacuum degree of 350 Pa-10,000 Pa for reaction to generate magnesium steam, carrying out condensation and magnesium liquid spraying to the magnesium steam to generate magnesium liquid, making the magnesium liquid flow into a storing device, and then pouring magnesium ingots. The device has the advantages of energy saving, low consumption, high productivity and the like.

Owner:杭州吉幔铁氢能科技有限公司

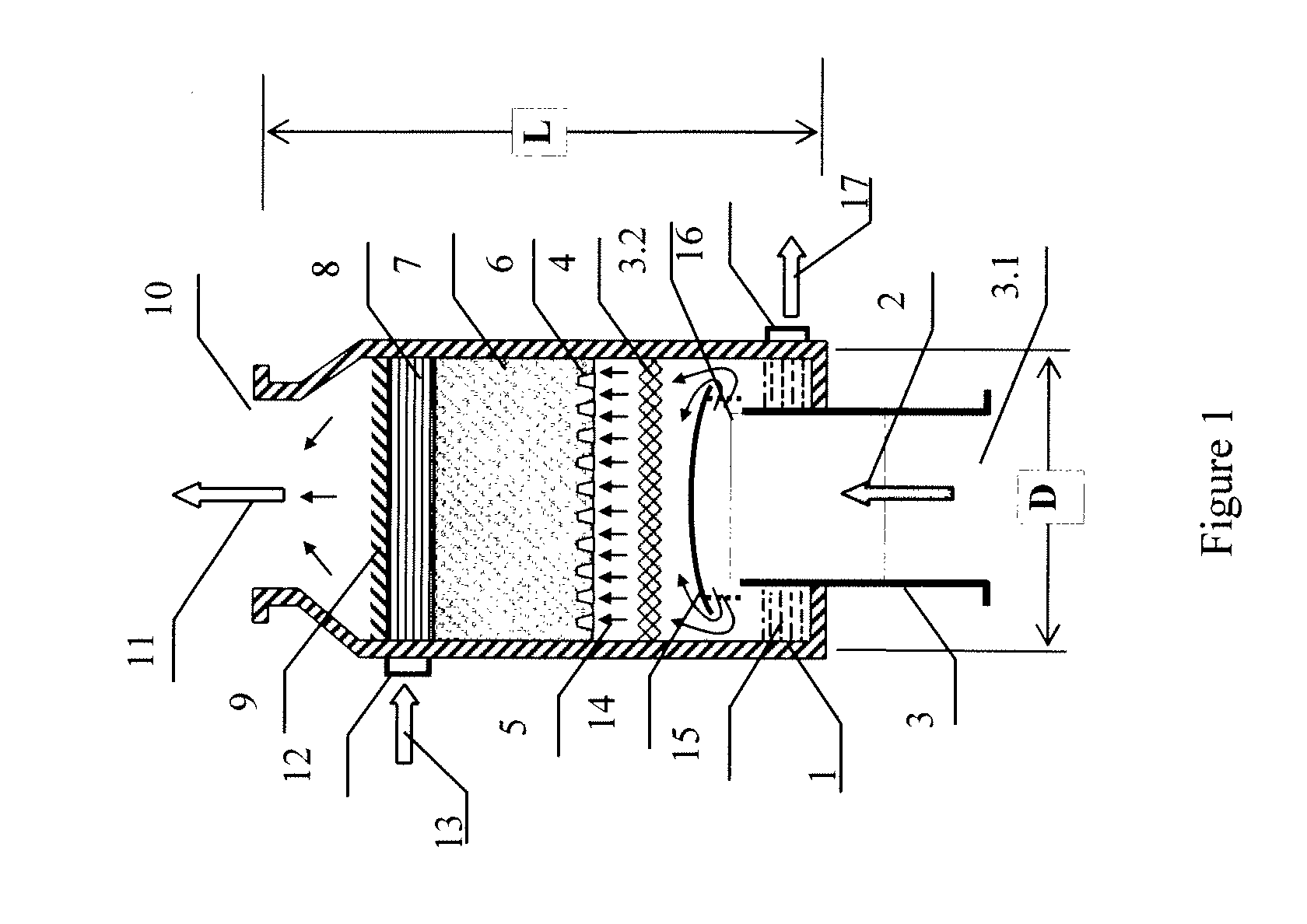

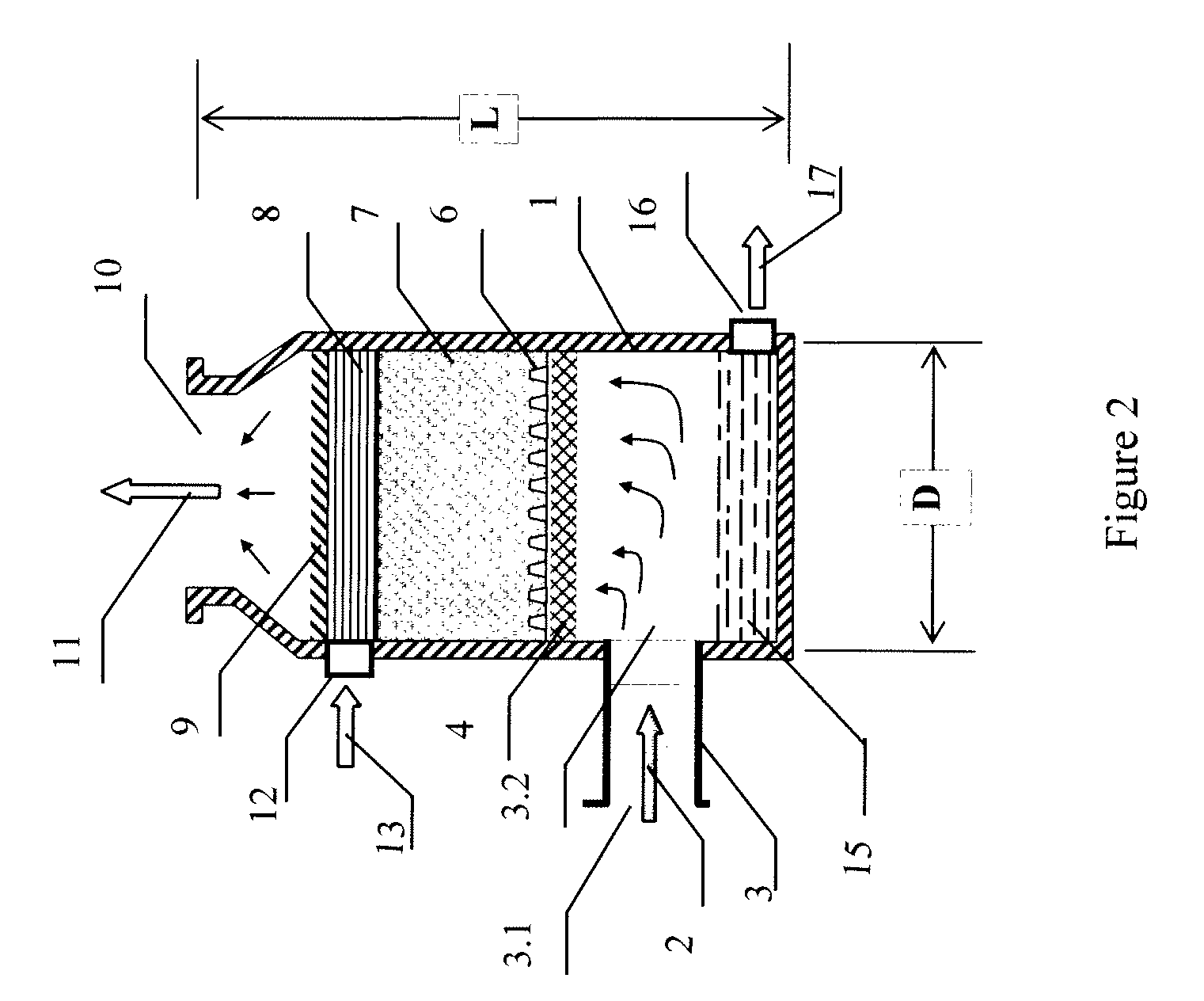

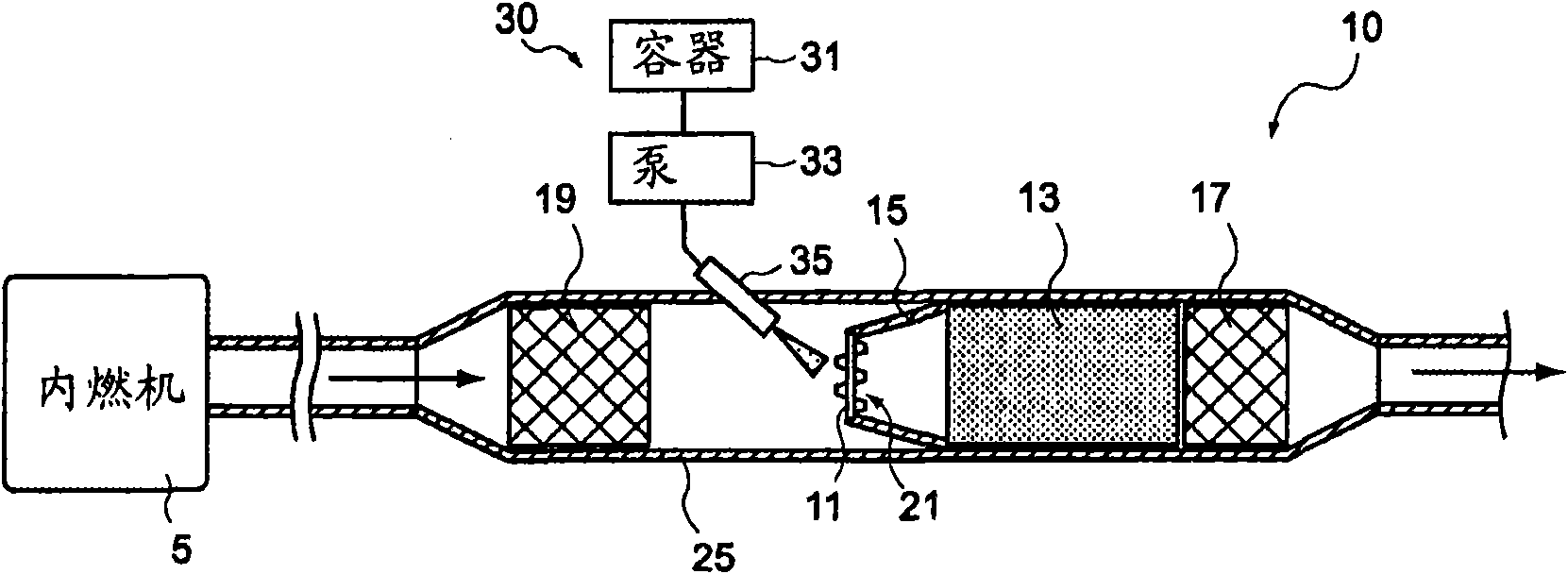

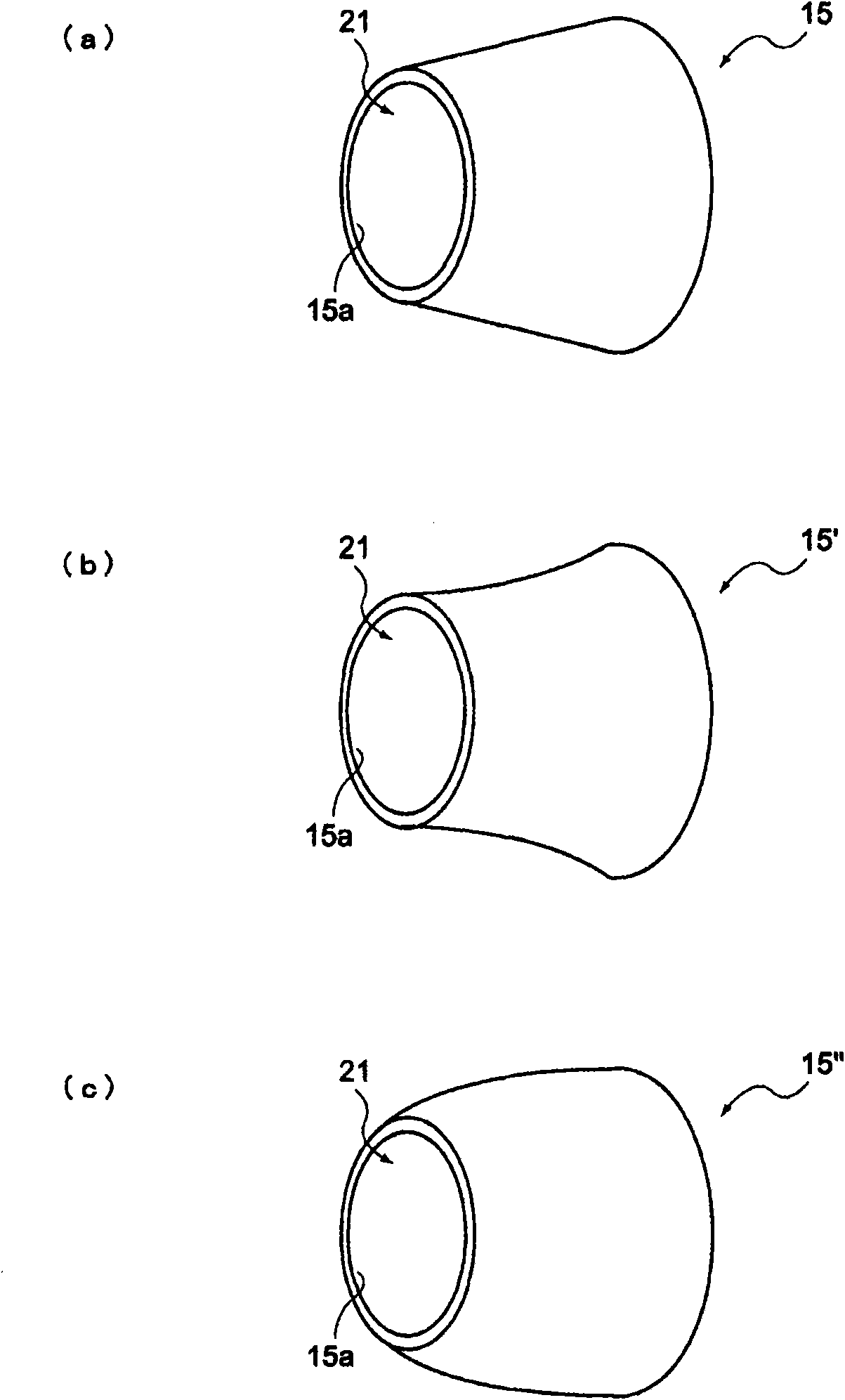

Exhaust gas purification apparatus for internal combustion engine

InactiveCN101627190AImprove reduction efficiencyIncrease flow rateInternal combustion piston enginesFlow mixersExternal combustion enginePulp and paper industry

This invention provides an exhaust gas purification apparatus for an internal combustion engine, which can realize the flow of an exhaust gas with a reducing agent uniformly dispersed therein into an NOx catalyst disposed on the downstream side of the exhaust gas purification apparatus. The exhaust gas purification apparatus for an internal combustion engine comprises an NOx catalyst disposed in an exhaust path in the internal combustion engine and a reducing agent jetting part for injecting a reducing agent into the exhaust path on the upstream side of the NOx catalyst. The exhaust gas purification apparatus is characterized in that a throttle part is provided at a position on the downstream side of the reducing agent jetting part in its reducing agent jetting position and on the upstream side of the NOx catalyst so that the sectional area of the flow path in the throttle part is smaller than the sectional area of the exhaust path and the sectional area of the NOx catalyst and the throttle part comprises means for diffusing the reducing agent.

Owner:BOSCH CORP

Treatment method of laterite-nickel ore

The invention discloses a treatment method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, a reducer and additives to obtain laterite-nickel ore pellets; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; carrying out crushing and dry magnetic separation on the metalized pellets to obtain nickel iron granules and first tailings; and carrying out wet grinding and wet magnetic separation on the first tailings to obtain nickel iron powder and second tailings, wherein the reducer is carbon black prepared from rubber. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

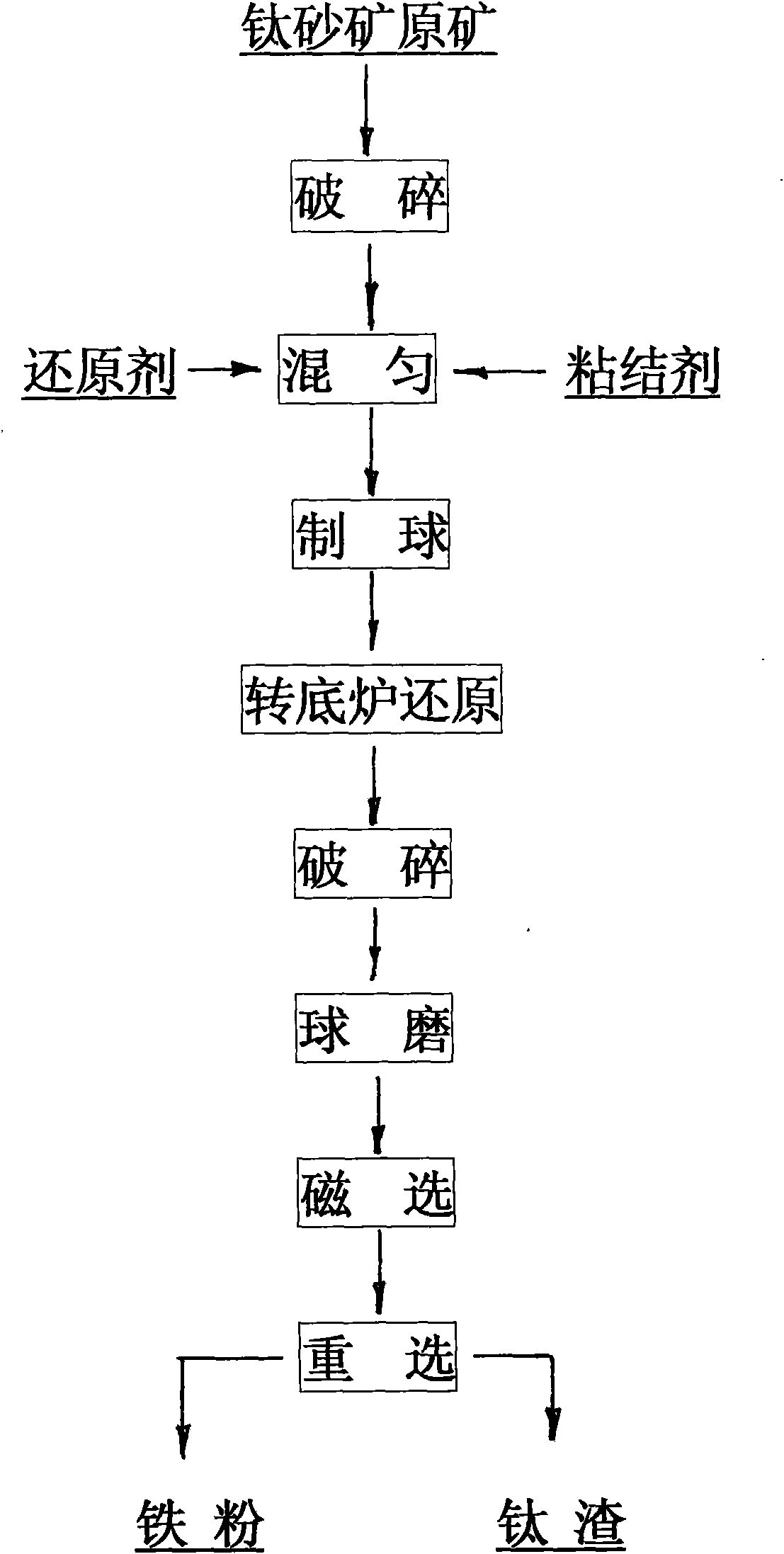

Method for producing ferrous powder and co-production titanium slag by rapidly reducing titanium placer pellets by rotary hearth furnace

InactiveCN101565768AAbandon distracting serious problemsImprove controllabilityRotary drum furnacesWet separationIron powderHearth

The invention discloses a method for producing ferrous powder and co-production titanium slag by rapidly reducing titanium placer pellets by a rotary hearth furnace, which comprises the following steps of: thinning titanium placer which is then added with a certain proportions of carbonaceous reducing agent, adhesive and concentrate ore and evenly mixing the materials; making pellets with the diameter of 10-40mm by a pellet forming machine; drying the pellets for 4-6 hours at the temperature of 200-500 DEG C and rapidly reducing the pellets in the rotary hearth furnace with the reducing temperature of 1200-1350 DEG C and the reducing time of 20-120min; crashing the pellets after being reduced; and then carrying out ball milling to the crashed pellets according to the grinding ore concentration of 50-80 percent, the ball milling time of 0.5-1.5h and the grinding ore fineness of 80-90 percent of -200 meshes; and after ball milling, carrying out magnetic separation and reelecting to obtain concentrate ore ferrous powder and tailing titanium slag, wherein the magnetic separation strength is 1000-4000 gausses. The invention adopts a method for rapidly reducing titanium placer pellets at the high temperature by the rotary hearth furnace, not only has even furnace temperature field, but also can quicken the reducing reaction speed, shorten the reducing time, improve the reducing efficiency and control the reducing temperature and atmosphere simultaneously.

Owner:KUNMING INST OF PRECIOUS METALS

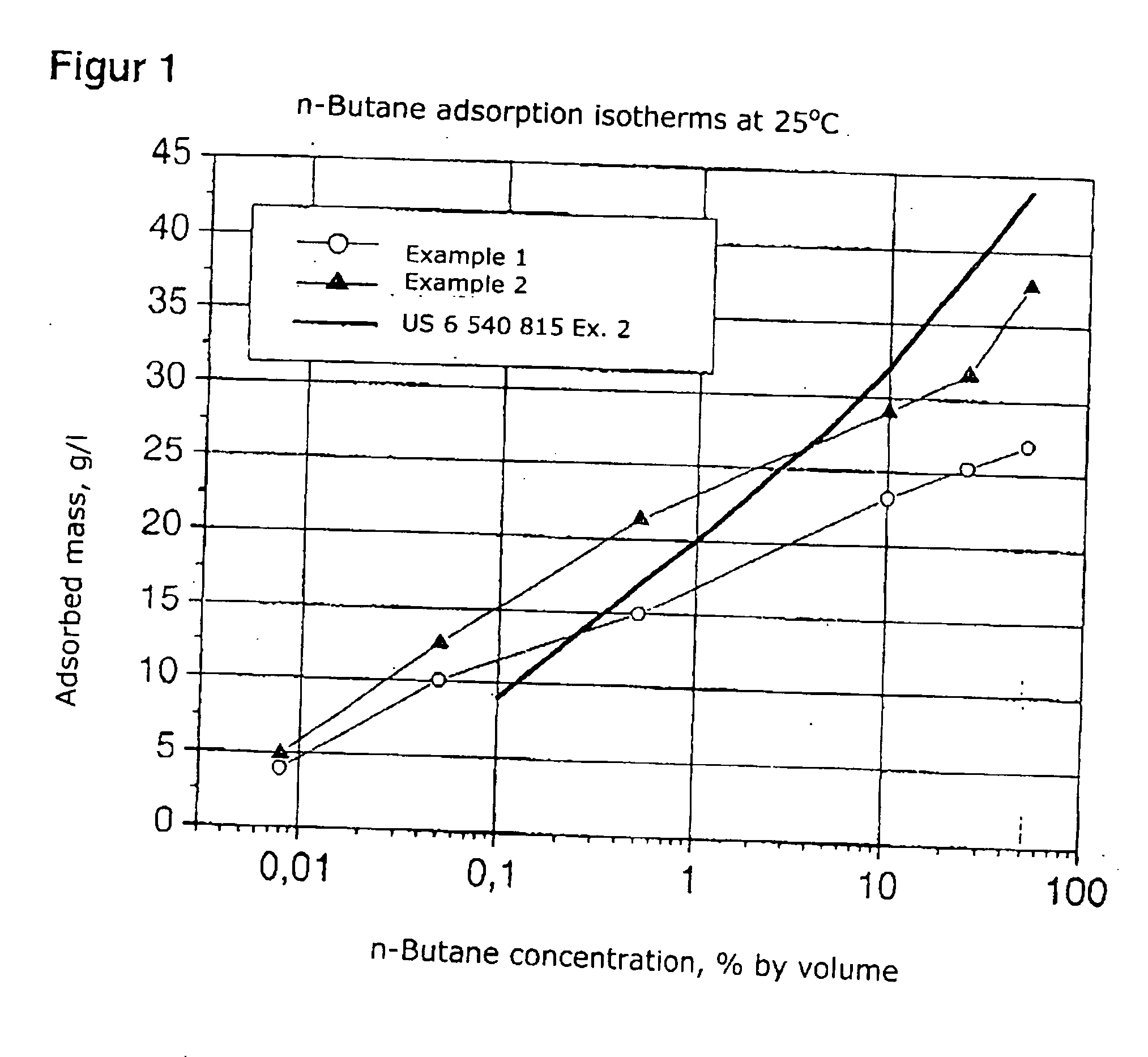

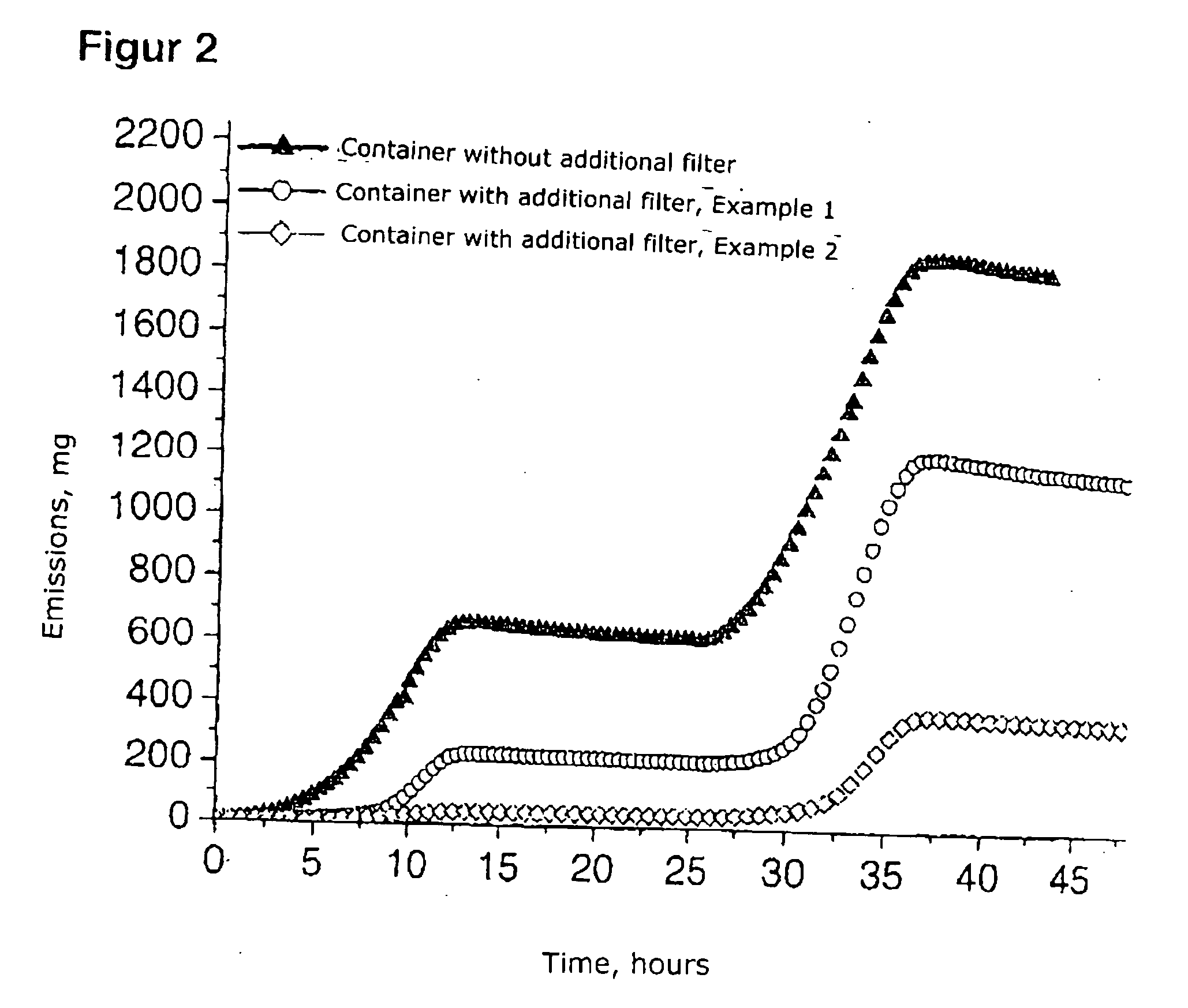

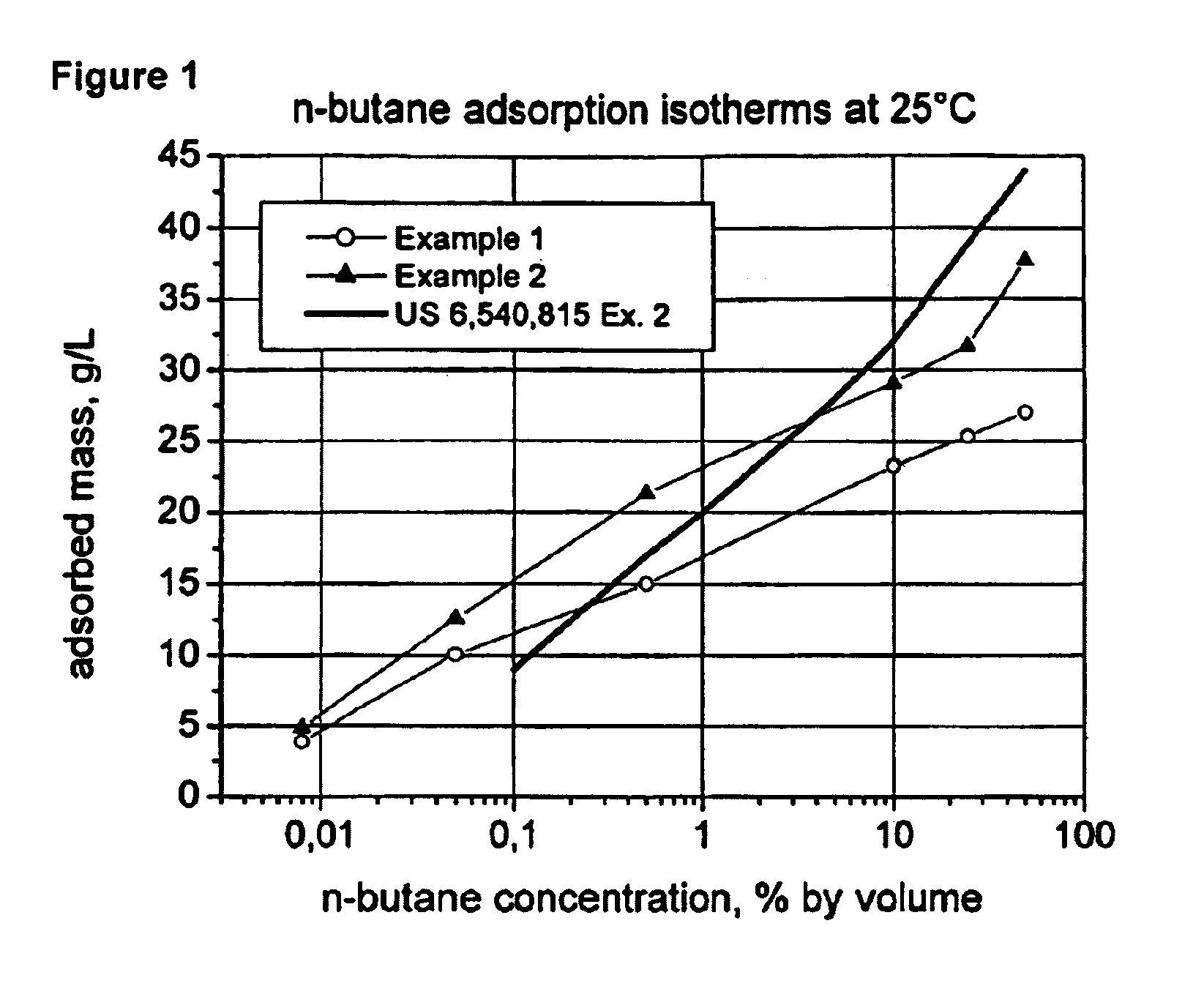

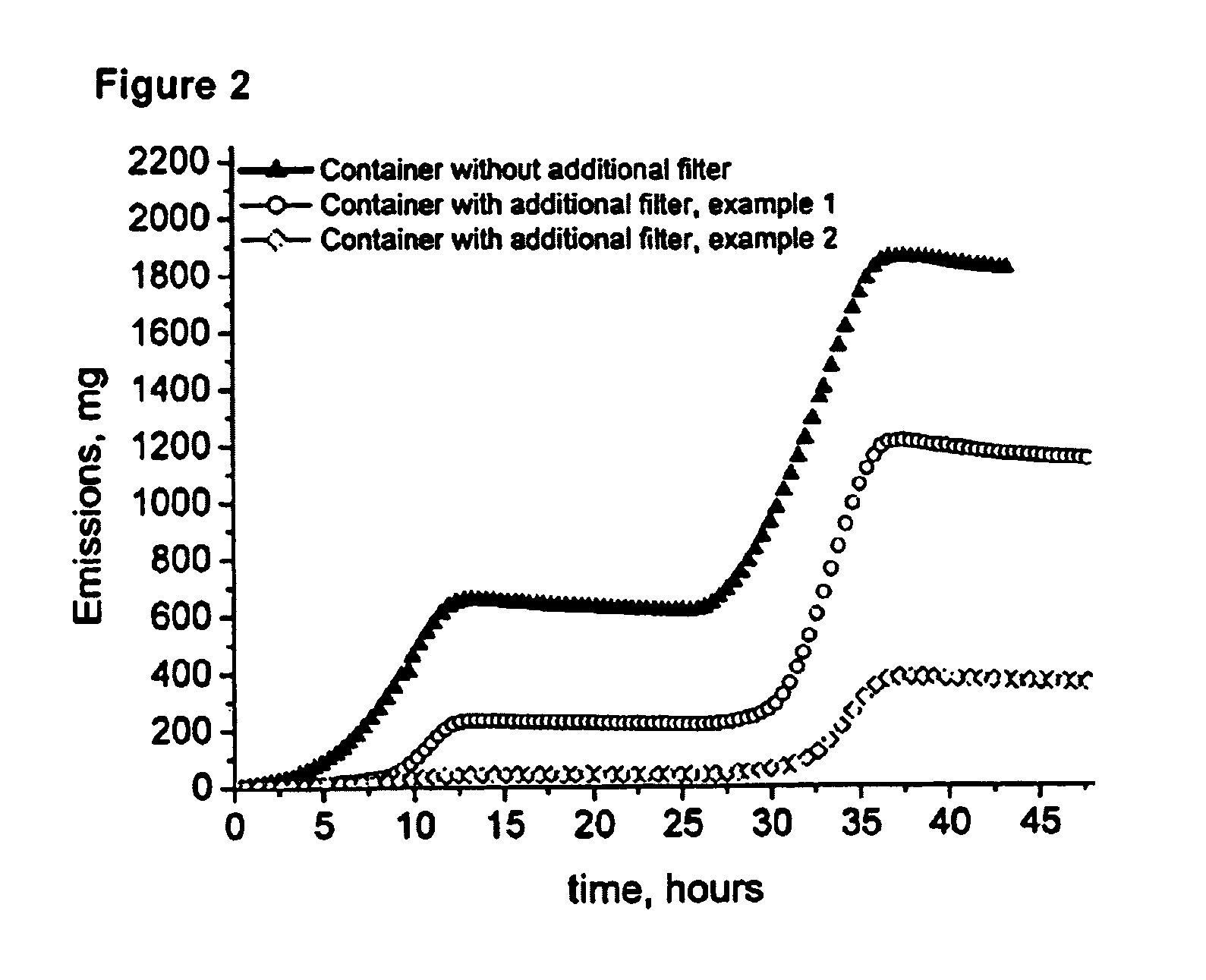

Fuel tank venting system and an additional filter element therefor

ActiveUS20050132888A1Improve reduction efficiencyReduction of level of hydrocarbonGas treatmentNon-fuel substance addition to fuelActivated carbon filtrationSorbent

Owner:HELSA AUTOMOTIVE GMBH & CO KG

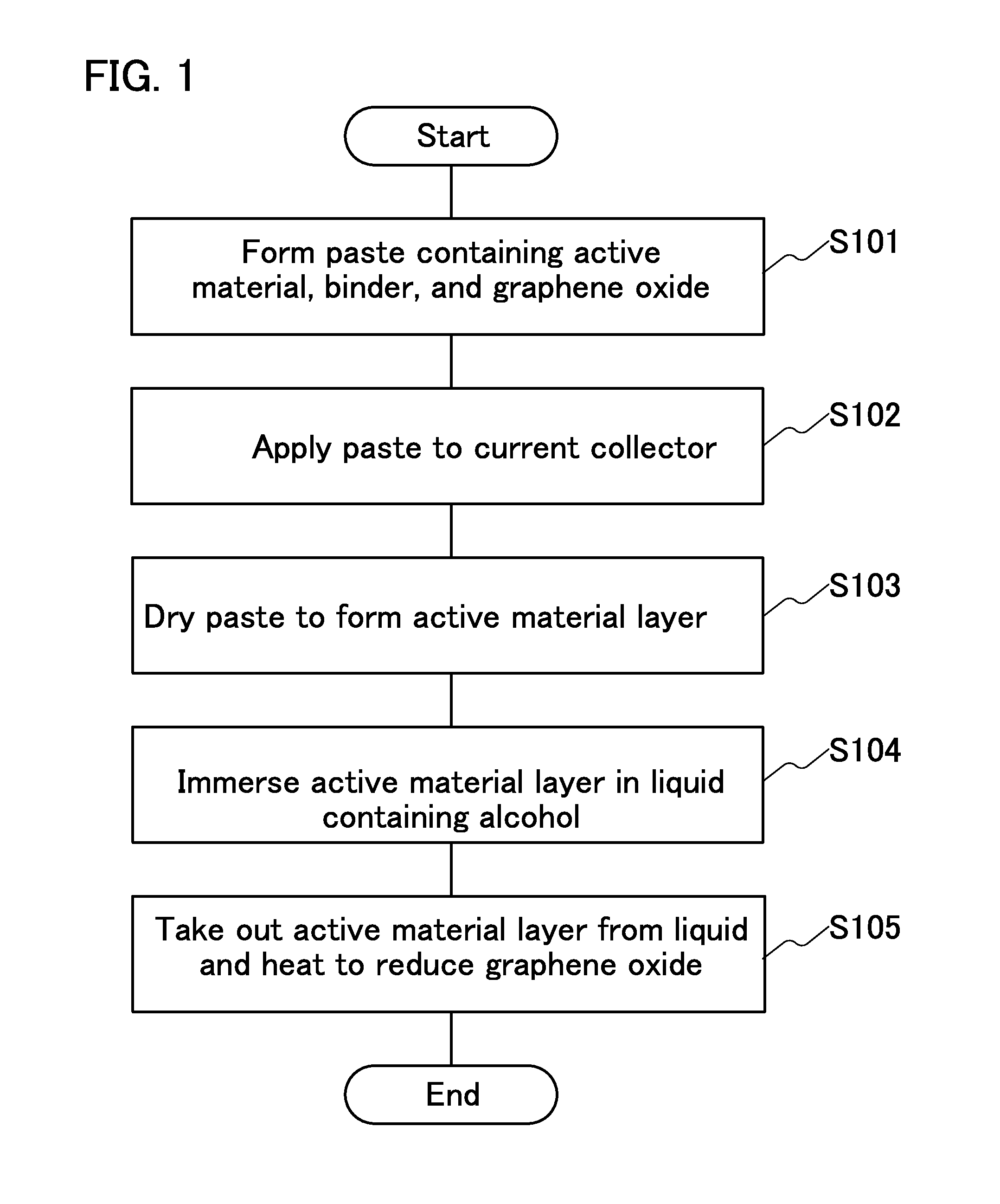

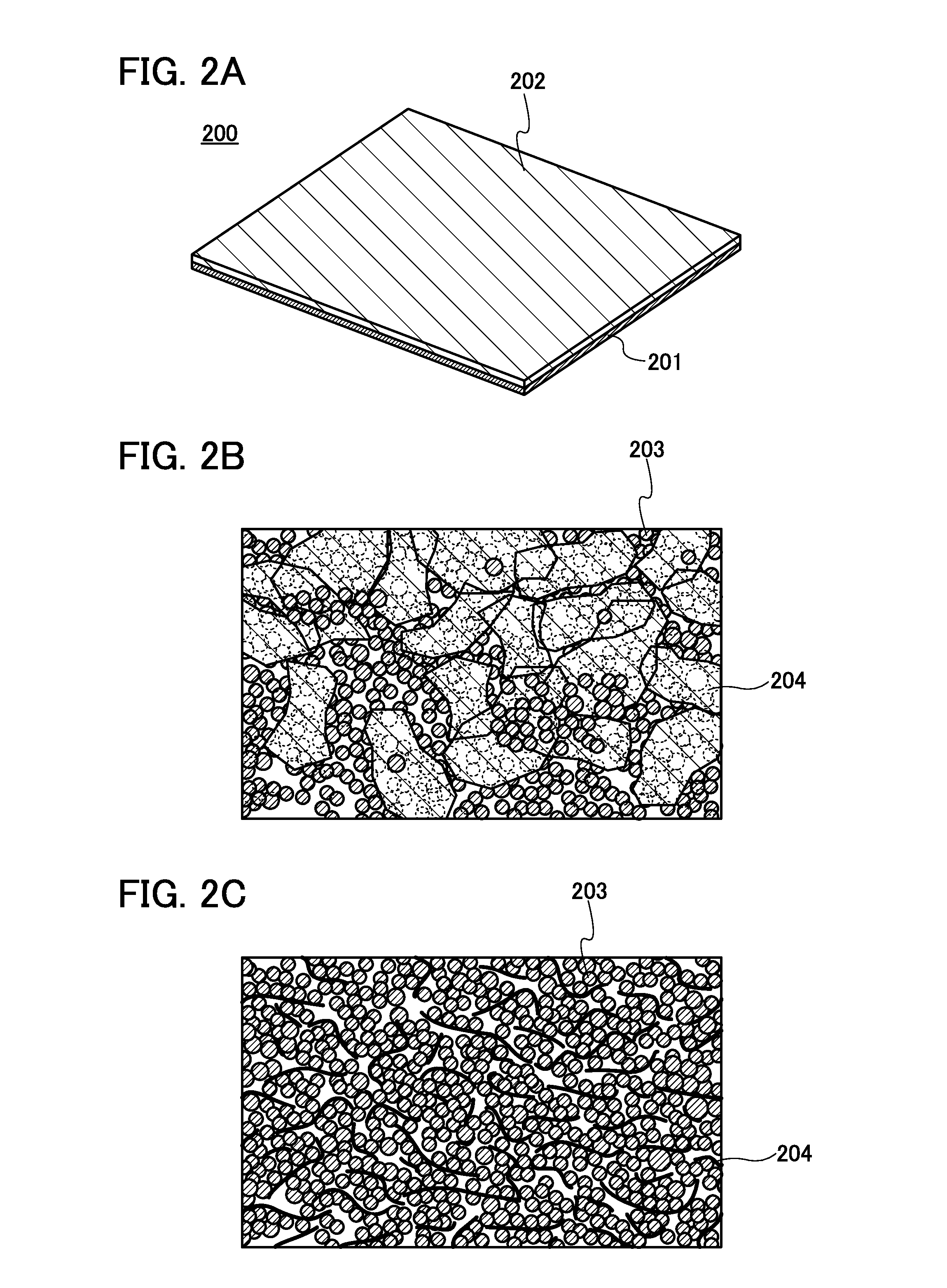

Storage battery electrode, manufacturing method thereof, storage battery, and electronic device

ActiveUS20160118646A1Increase storage capacityGraphene oxide can be sufficiently reducedElectrochemical processing of electrodesElectrode thermal treatmentAlcoholSolvent

In manufacture of a storage battery electrode containing graphene as a conductive additive, the efficiency of reduction of graphene oxide is reduced with high efficiency under mild conditions, and cycle characteristics and rate characteristics of a storage battery are improved. Provided is a manufacturing method of a storage battery electrode. In the manufacturing method, a paste containing an active material, a binder, graphene oxide, and a solvent is formed; the paste is applied to a current collector and the solvent contained in the paste is evaporated to form an active material layer; the active material layer is immersed in a liquid containing alcohol; and the active material layer is taken out from the liquid and heated so that the graphene oxide is reduced.

Owner:SEMICON ENERGY LAB CO LTD

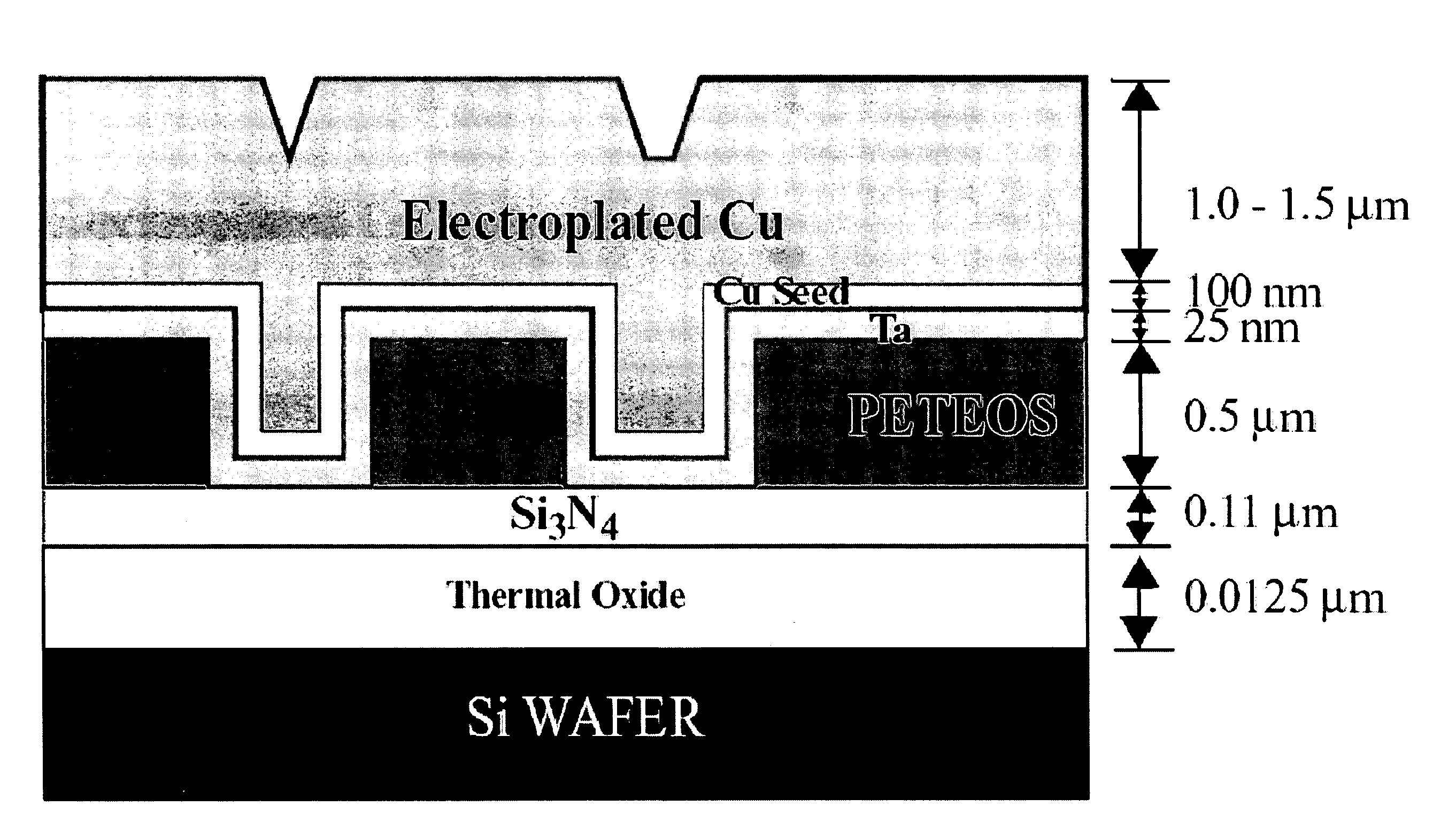

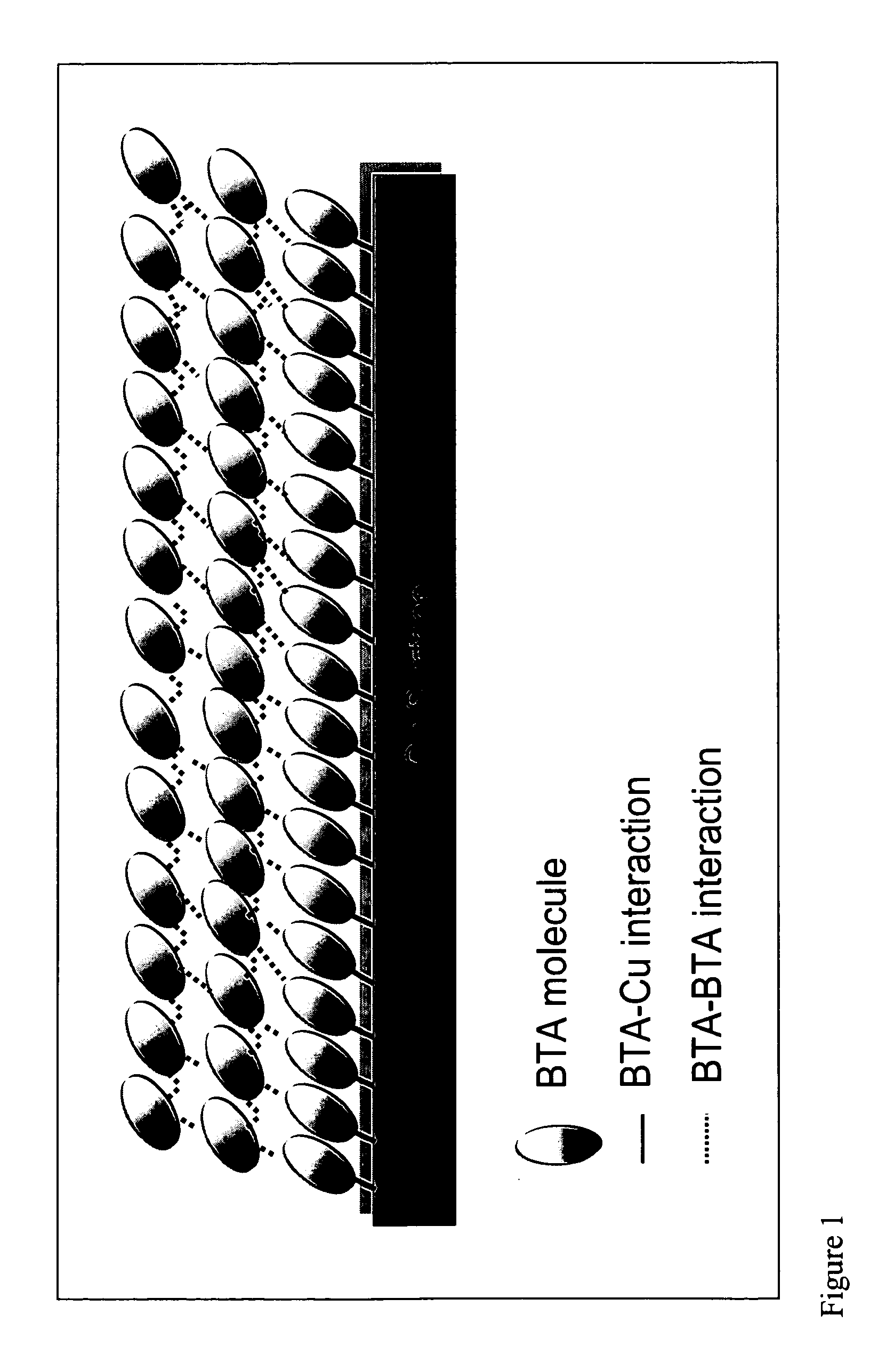

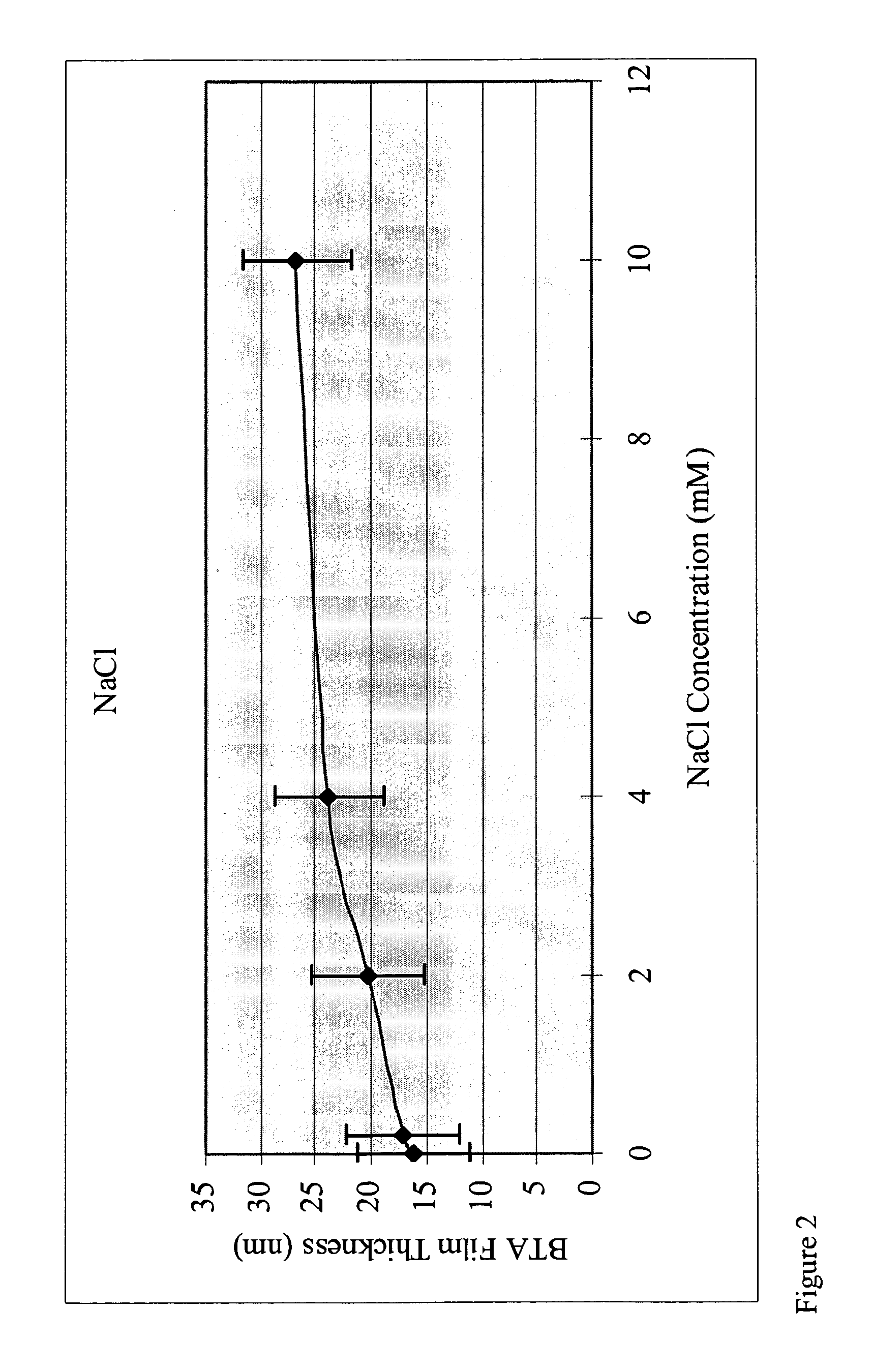

Controlling passivating film properties using colloidal particles, polyelectrolytes, and ionic additives for copper chemical mechanical planarization

InactiveUS20100178768A1Increase static etch rateLower static etch ratePigmenting treatmentOther chemical processesSlurryCopper

The present invention provides for a copper CMP slurry composition which comprises a complexing agent, an oxidizer, an abrasive and a passivating agent. The present invention also provides for a method of chemical mechanical planarization of a copper conductive structure which comprises administering the copper CMP slurry composition during the planarization process.

Owner:BASF AG

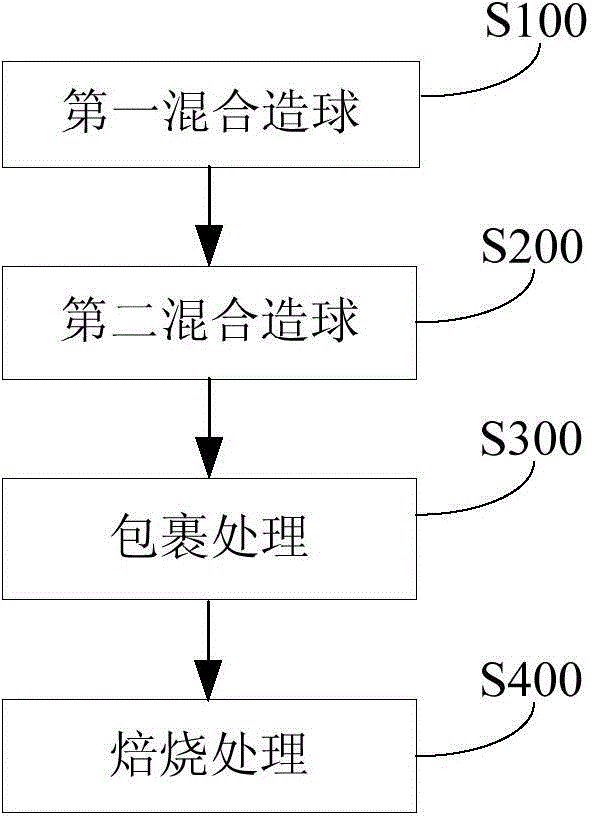

Method for improving metallization rate of metallurgical slag pellet

The invention discloses a method for improving the metallization rate of a metallurgical slag pellet. The method comprises the following steps: (1) mixing a carbonic substance with an adhesive for pelletizing for the first time to obtain a carbonic pellet; (2) mixing the carbonic pellet with a mixture containing metallurgical slag, a reducing agent, the adhesive and an additive for pelletizing for the second time to obtain the metallurgical slag pellet with the carbonic pellet serving as a core; (3) wrapping the metallurgical slag pellet to form a high-temperature-resistant layer on the surface of the metallurgical slag pellet; and (4) roasting the metallurgical slag pellet with the high-temperature-resistant layer to obtain a metalized pellet. According to the method, the metallization rate of the metallurgical slag pellet can be remarkably improved, so that a product with higher iron level and higher recovery rate is obtained favorably in the subsequent treatment process.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

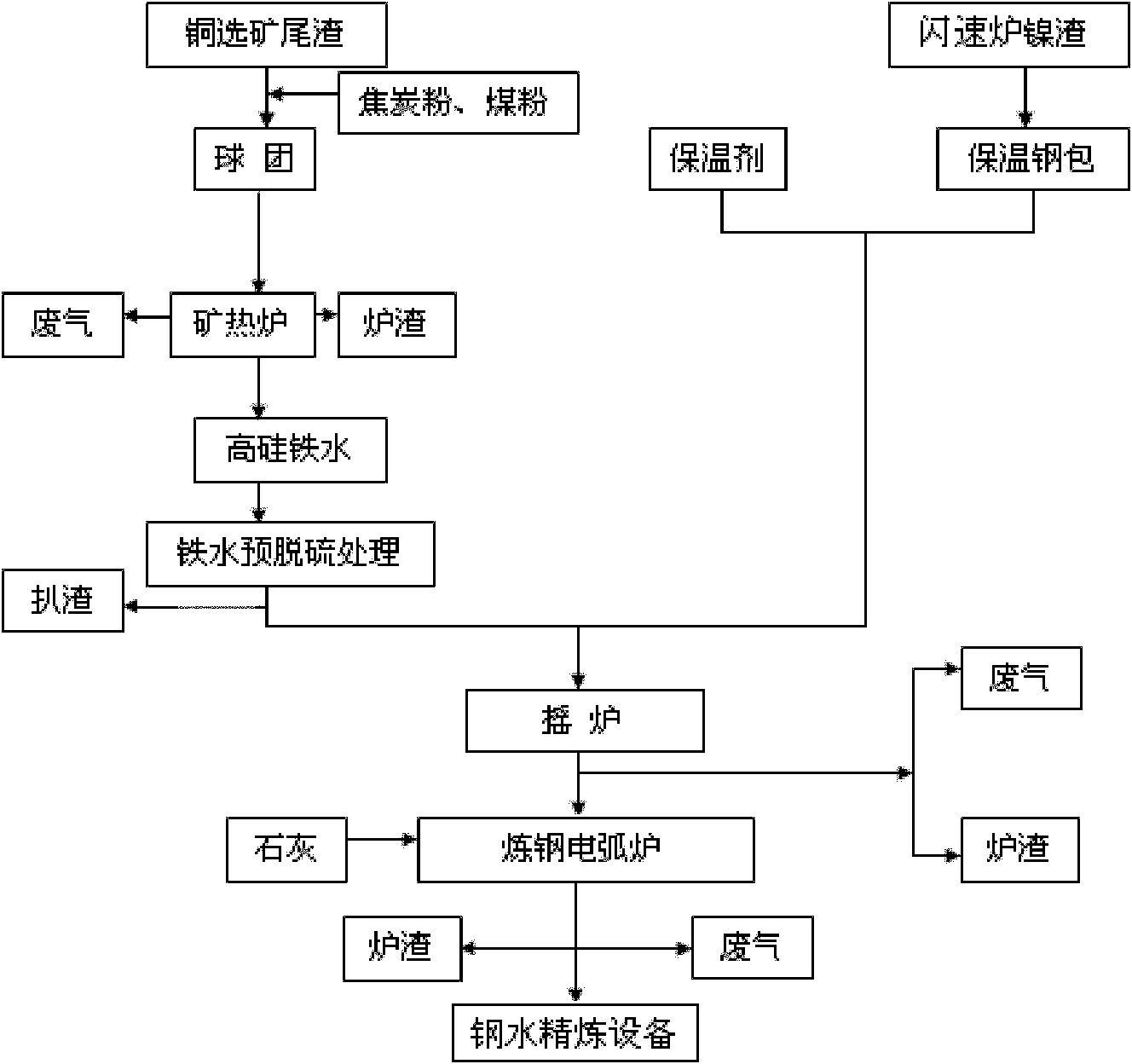

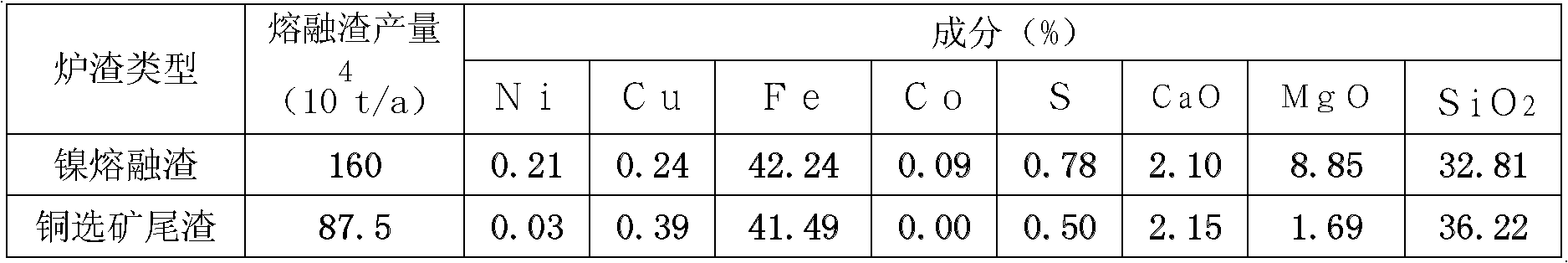

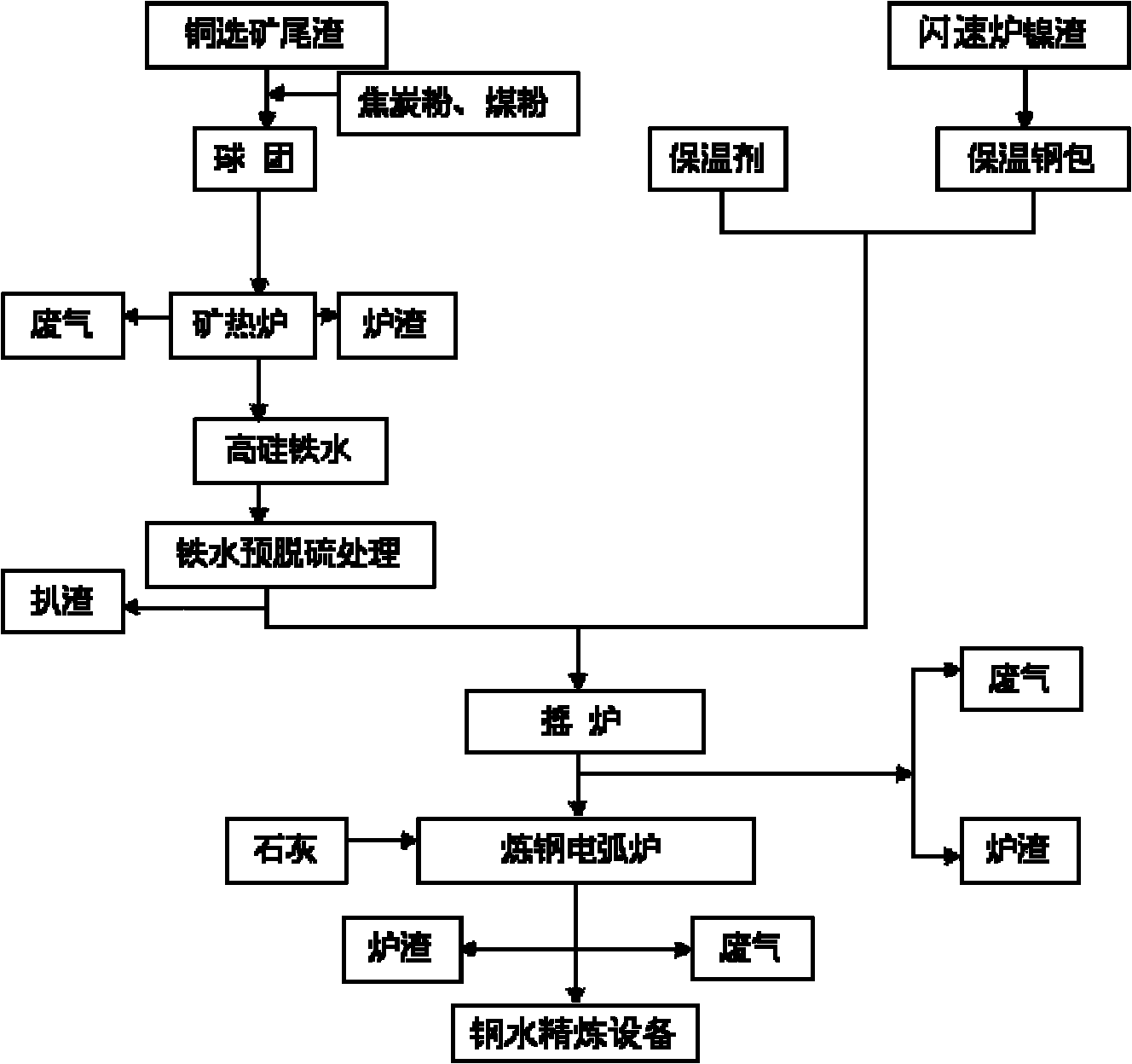

Iron extracting and steelmaking process for comprehensively treating copper ore tailing and nickel molten slag

InactiveCN102051428AGood reduction kinetics conditionsImprove smelting efficiencySteelmakingProcess equipment

The invention discloses an iron extracting and steelmaking process for treating copper ore tailing and nickel molten slag by an ore heating furnace, a shaking furnace, a steelmaking electric arc furnace and a refining furnace. The iron extracting and steelmaking process comprises the following steps of: (1) uniformly mixing copper ore tailing and a carbonaceous reducing agent and granulating into pellet lump ore; (2) charging the pellet lump ore into the ore heating furnace and smelting to obtain silicon-contained molten iron; (3) desulfurating and deslagging the silicon-contained molten iron to obtain low-sulphur-silicon molten iron or confirming whether sulphur is removed according to the sulphur content of the silicon-contained molten iron; (4) transporting the nickel molten slag to an iron extracting station in a heat preserving way; (5) charging the nickel molten slag into the shaking furnace, adding lime and low-sulphur-silicon molten iron, mixing and stirring to obtain reduced molten iron; and (6) conveying the reduced molten iron into the electric arc furnace and adding lime for desulfurating, decarbonizing and dephosphorizing to obtain molten steel. The process reasonably utilizes the components of the copper ore tailing, fully recovers valuable metals in the copper ore tailing and the nickel molten slag, achieves the aim of comprehensive utilization, has reasonable design, is convenient for mastering and construction and is suitable for industrialized application.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

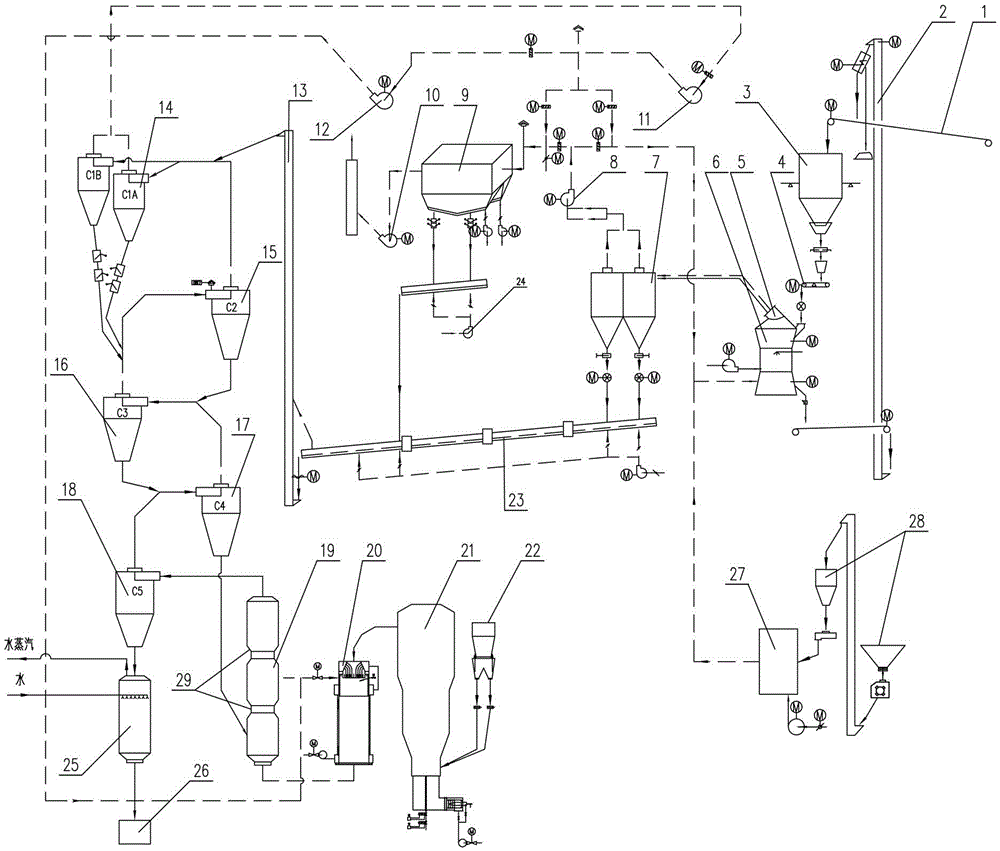

Preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore

The invention relates to the production techniques of iron ore concentrate of refractory ore, in particular to a preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore. The method comprises the following steps that firstly, the crushed iron ore is ground into fine ore; then the fine ore is subjected to low-temperature roasting, and during the low-temperature roasting, the fine ore is made to be in a roasting system to be preheated and roasted; the roasted ore enters a cooling system to be cooled; and then the cooled roasted ore is subjected to size mixing and sent to a magnetic separation system to be separated, and high-grade iron ore concentrate is obtained through separation. According to the method, the process is simple, the temperature and air flow are distributed uniformly, control is easy, the automation degree is high, the number of operation components of equipment is small, refractory siderite and limonite can be treated, the magnetizing roast efficiency of the refractory iron ore is high, heat is substantially recycled during roasting, the roasted ore is stable in quality and high in magnetic separation efficiency, and the technical indexes that the grade of the iron ore concentrate is larger than 60%, and the iron recycling rate is larger than 85% can be achieved.

Owner:湖北华方装备有限公司

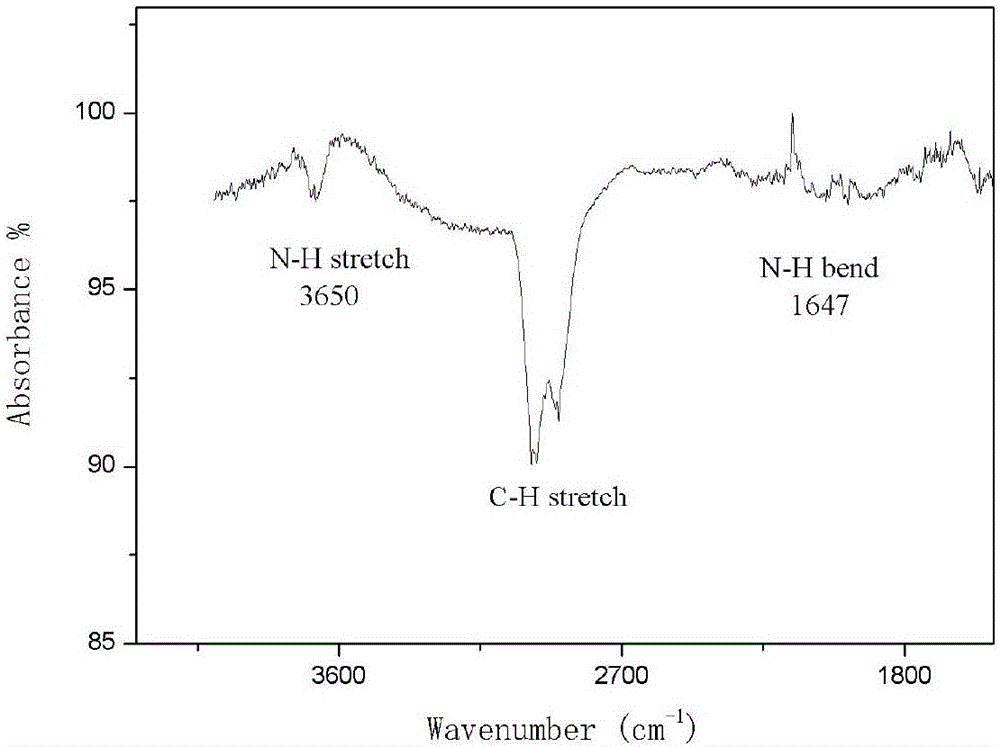

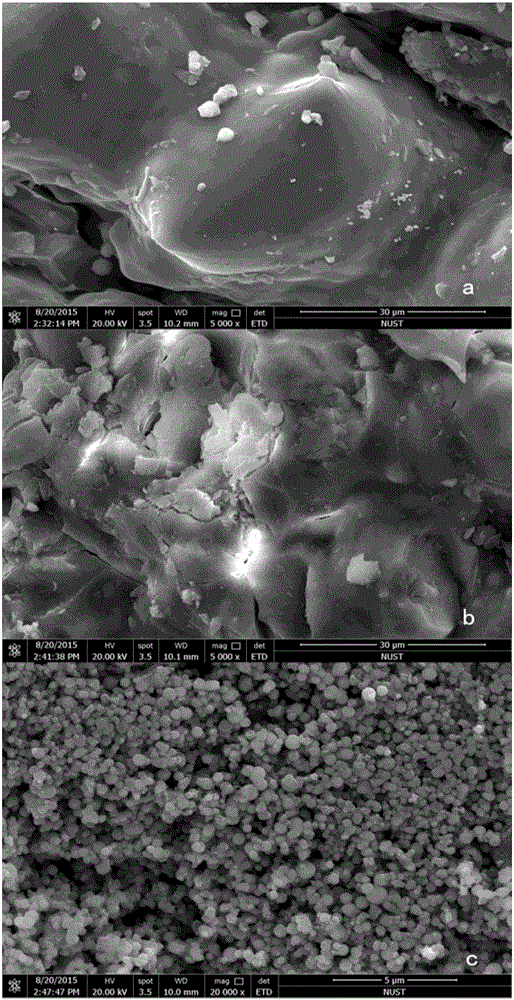

Preparation method of amino iron-carrying composite modified biochar

InactiveCN106378094ARealize composite modification of aminated ironImprove reduction efficiencyOther chemical processesWater contaminantsWastewaterOxygen

The invention discloses a preparation method of amino iron-carrying composite modified biochar. The method comprises the following steps: carrying out pyrolysis on the raw material crop straws under oxygen-free conditions to obtain a biochar material, carrying out nitro modification on the biochar, adding iron ions and a reducer in the absence of air, stirring at normal temperature, reducing the nitro on the biochar surface into amino by a one-step reduction process, and reducing the iron ions into zero-valent iron and attaching the zero-valent iron onto the biochar surface. The aminated iron-carrying composite modified biochar material has the advantages of favorable stability, high separability, environment friendliness and energy saving. The biochar material modified by the method uses heavy-metal-copper-ion-containing heavy metal wastewater as the adsorption object, has favorable adsorption and removal effects, and thus, has important application value in copper-ion-containing industrial sewage treatment.

Owner:NANJING UNIV OF SCI & TECH

Fuel tank venting system and an additional filter element therefor

ActiveUS7186291B2Lower Level RequirementsImprove reduction efficiencyGas treatmentNon-fuel substance addition to fuelSorbentActivated carbon filtration

Owner:HELSA AUTOMOTIVE GMBH & CO KG

Molten metal anti-oxidation reducing agent, preparation method and application thereof

InactiveCN101532130AReduce scumSpeed up the flowMetallic material coating processesO-Phosphoric AcidPhytic acid

The invention relates to a molten metal anti-oxidation reducing agent and a preparation method and application thereof. The molten metal anti-oxidation reducing agent comprises the following main compositions in portion by weight: 51.19 to 91.19 portions of nonylphenol polyoxyethylene ether, 3 to 15 portions of organic amine, 0.3 to 5 portions of phosphoric acid and 0.5 to 8 portions of phytic acid; the anti-oxidation reducing agent can further comprise essence in proper amount; and the molten metal anti-oxidation reducing agent is water-soluble oily liquid. The reducing agent has no flash point, does not splash when being added into molten metal and can automatically and rapidly diffuse; the molten metal anti-oxidation reducing agent is lighter than molten metal liquid and can overspread the whole flowing liquid level to isolate air and effectively prevent oxidation; contained active substances and organic or inorganic acid can disperse the inner gravitation of oxidized metal scruff, and actively scatter an inner structure of the oxidized metal scruff to reduce useful metal out; the reduction efficiency is 95 percent or so; cost performance is high; the residual scruff is little, soluble in water and convenient to clean; and the molten metal anti-oxidation reducing agent is convenient to maintain equipment.

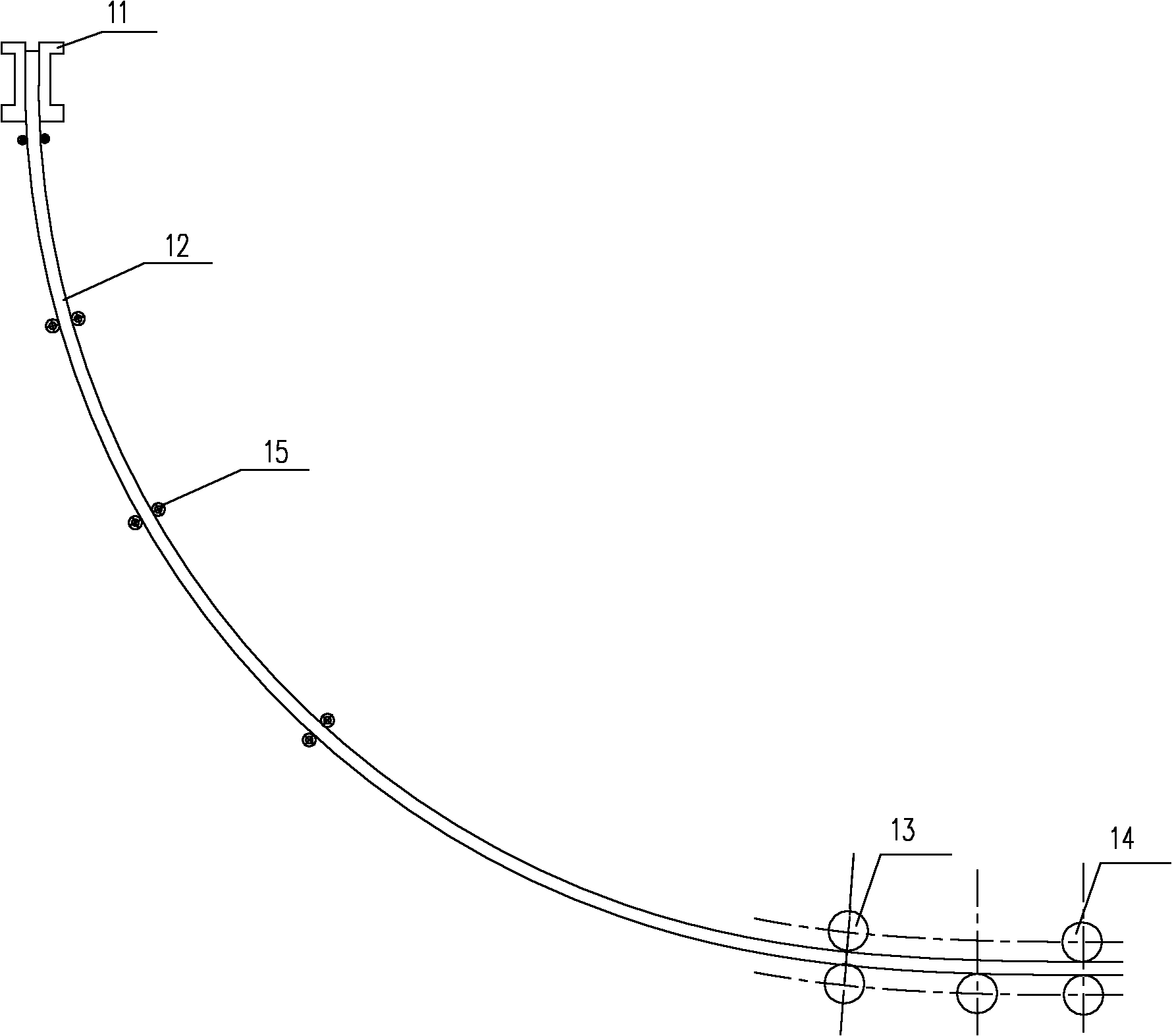

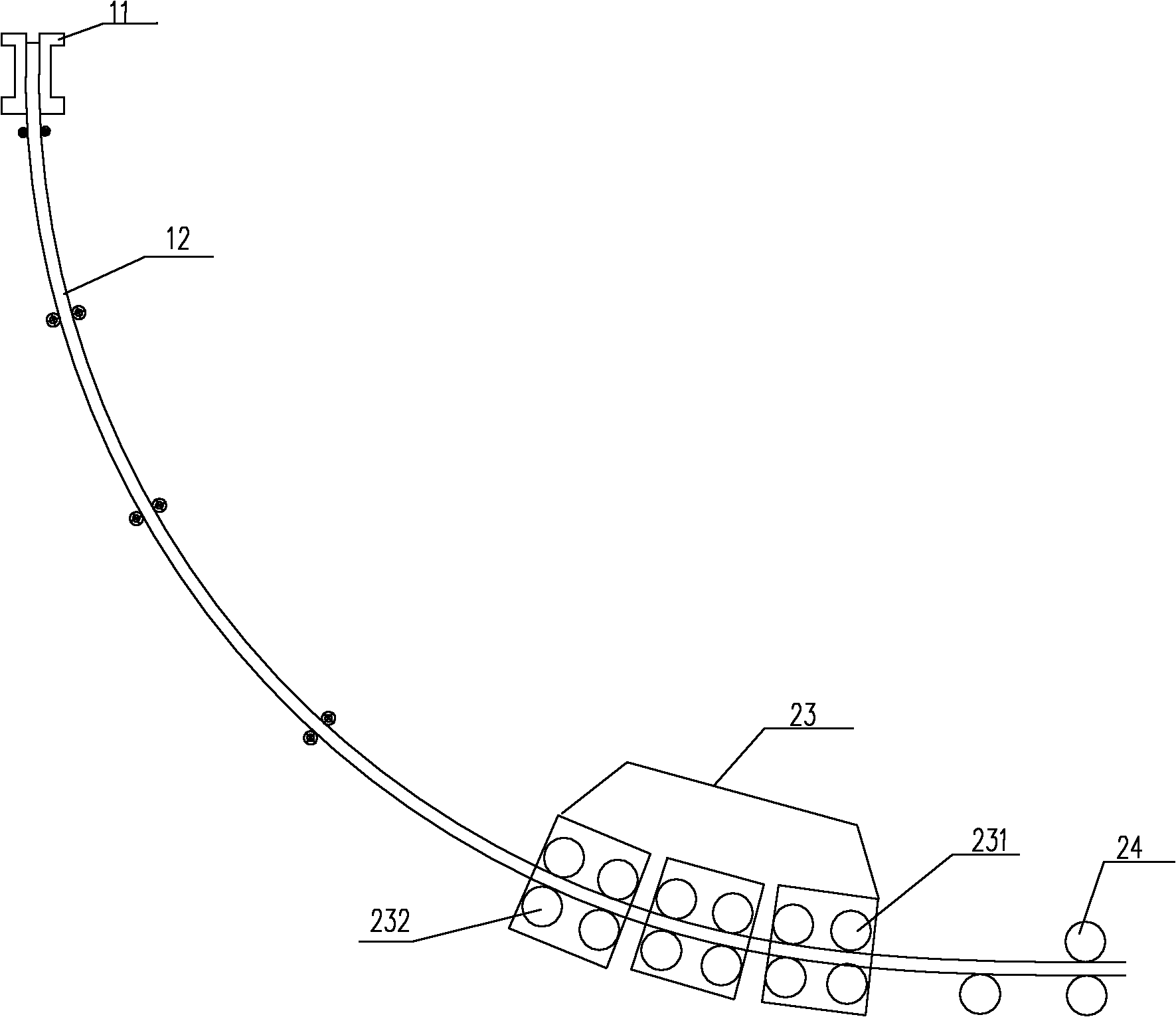

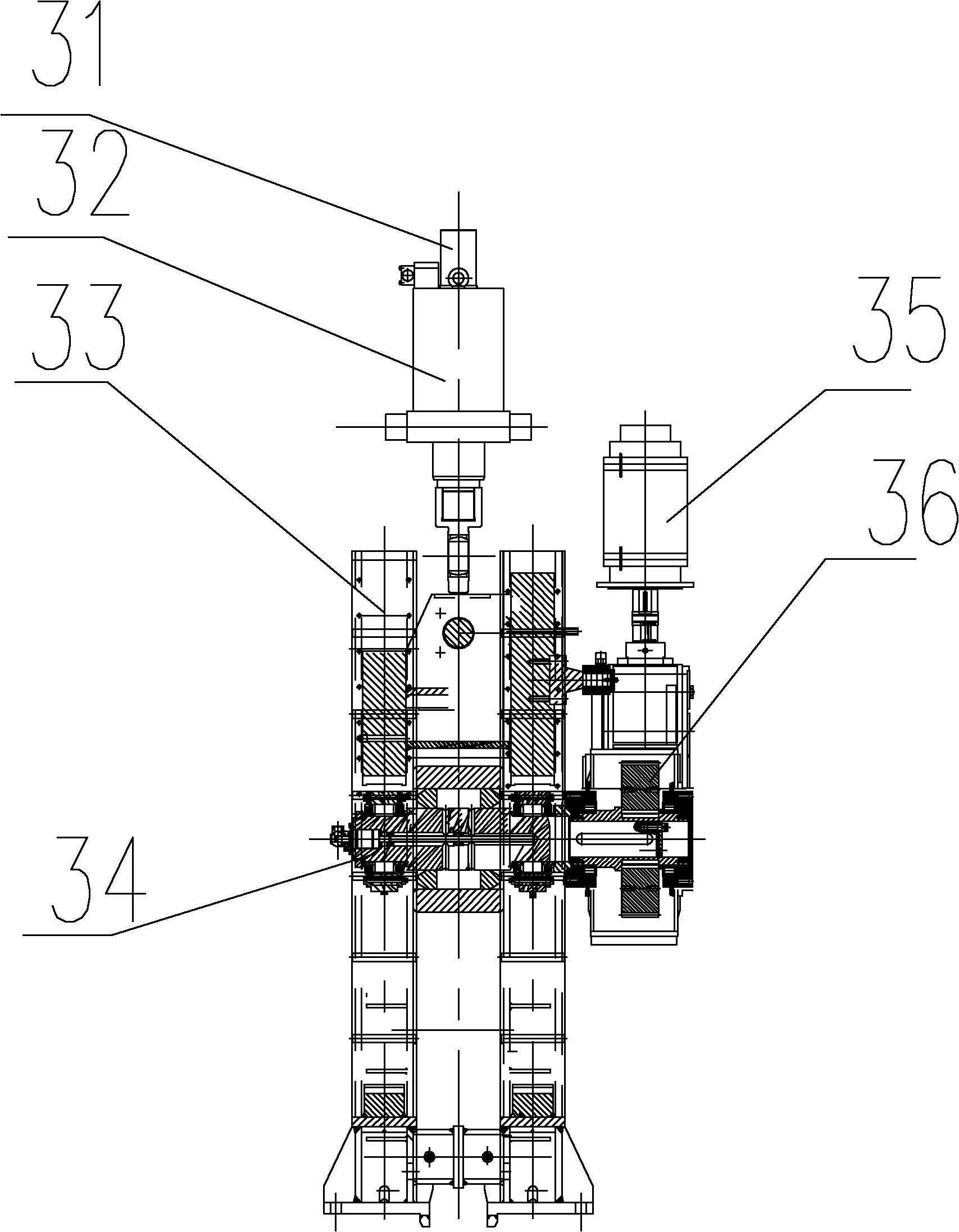

Continuous casting machine and small square billet soft reduction device

The invention relates to a small square billet continuous casting machine comprising a crystallizer, a strand support roller bed, a soft reduction device and a tension leveler, wherein the soft reduction device is arranged in a solidification tail end area of casting blanks and comprises at least one group of reduction units; each group of reduction units is a reduction system consisting of two pairs of upper compression rollers and lower compression rollers; the size of a roller gap formed between the upper compression roller and the lower compression rollers corresponds to the specificationof the small square billets; and the length of the reducable interval of the soft reduction device is matched with the length of the solidification tail end area of the small square billets. The invention also relates to the soft reduction device of the small square billet continuous casting machine. The invention can improve the density inside the square billets, so that the phenomena of center porosity and center segregation of the small square billets can be effectively controlled.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

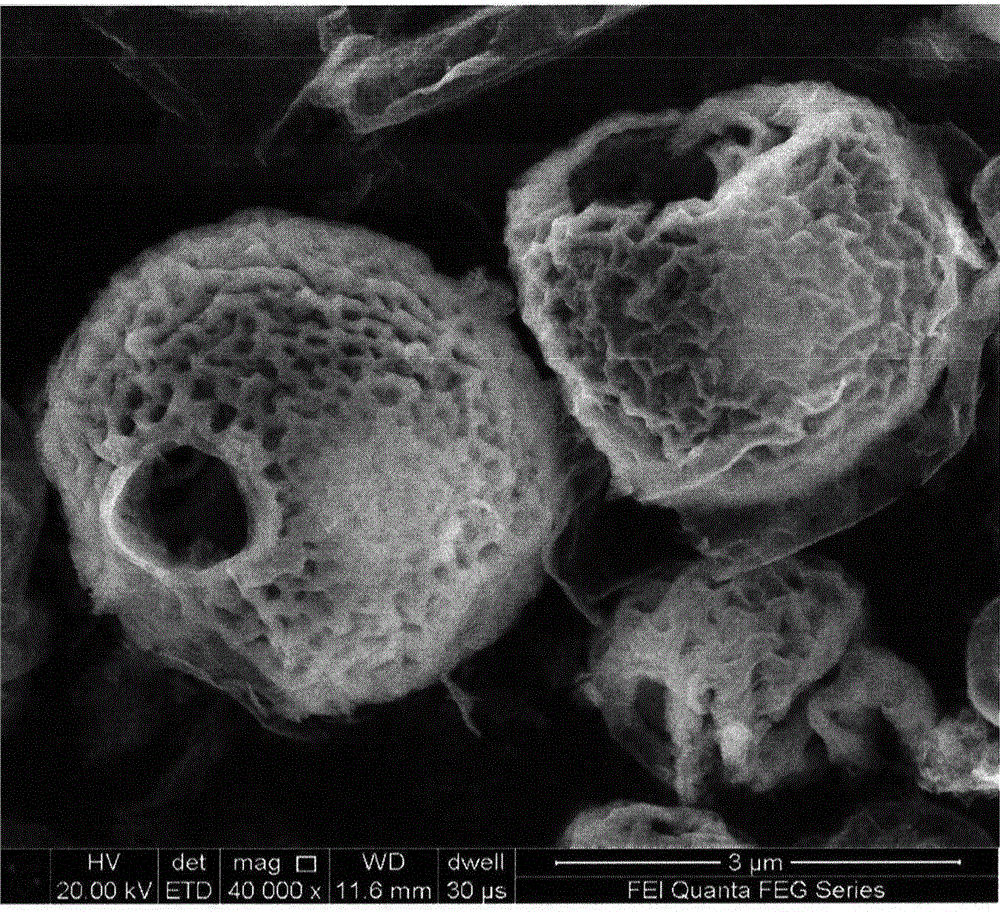

Manganese-cerium composite oxide low-temperature denitration catalyst with hollow multi-shell microsphere structure

InactiveCN104857950AUnique structureIncrease contact timeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsComposite oxideMulti shell

The invention provides a manganese-cerium composite oxide low-temperature denitration catalyst with a hollow multi-shell microsphere structure, which belongs to the technical field of catalytic treatment of flue gas. The catalyst is characterized in that the catalyst is composite oxide of MnOx and CeO2 and has the hollow multi-shell microsphere structure, and the diameters of microspheres are in a range of 1 to 3 [mu]m; annular cavities are located among spherical shells, so a hollow multi-shell structure is formed, which enables the catalyst to have a great specific surface area, as great as 110 to 190 m<2> / g; MnOx and CeO2 are uniformly distributed and in a mol ratio of Mn to Mn+Ce of 0.2 to 0.7; and MnOx is composed of Mn2O3 and MnO2. The catalyst has good selective catalytic reduction performance at a low temperature; the denitration efficiency of the catalyst reaches more than 95% when reaction temperature is 180 DEG C and reaction space velocity is 36000 per hour; and the catalyst is applicable to treatment of nitrogen oxides in flue gas of fire coal and has wide application prospects.

Owner:XI AN JIAOTONG UNIV

Treatment method for slag adjustment before slag splashing protection of converters

InactiveCN102392097AImprove fire and corrosion resistanceGuaranteed lifeManufacturing convertersSteelmakingConverters

The invention belongs to the technical field of steel making and provides a treatment method for slag adjustment before slag splashing protection of converters, which is used for solving the existing problems of bad slag hanging effect in high iron oxide type slag splashing protection after high-temperature steel tapping and short lining life. The method provided by the invention is characterized in that: coke powder, magnesite and titanium white are used as slag adjustment agents; the coke powder is capable of decreasing the ferric oxide in residual slag and reacting with the titanium white to generated titanium carbide with high melting point; and the titanium carbide acts synergistically with the magnesite to increase the viscosity and the melting temperature of the slag. Therefore, by using the invention, the adherence stability and high temperature and slag steel erosion resistance of the slag on furnace walls can be markedly improved, the slag splashing protection effect can be improved and the lining life of the converters can be greatly prolonged.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com