Preparation method of amino iron-carrying composite modified biochar

A technology of composite modification and biochar, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., to achieve the effect of simple method, excellent adsorption effect and high reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

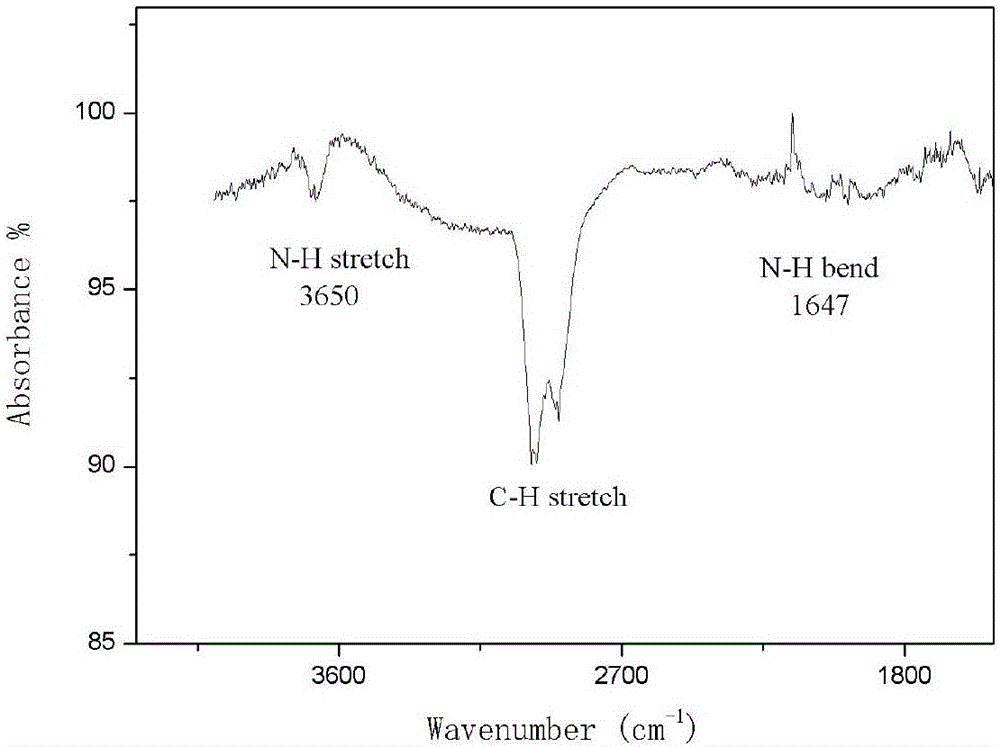

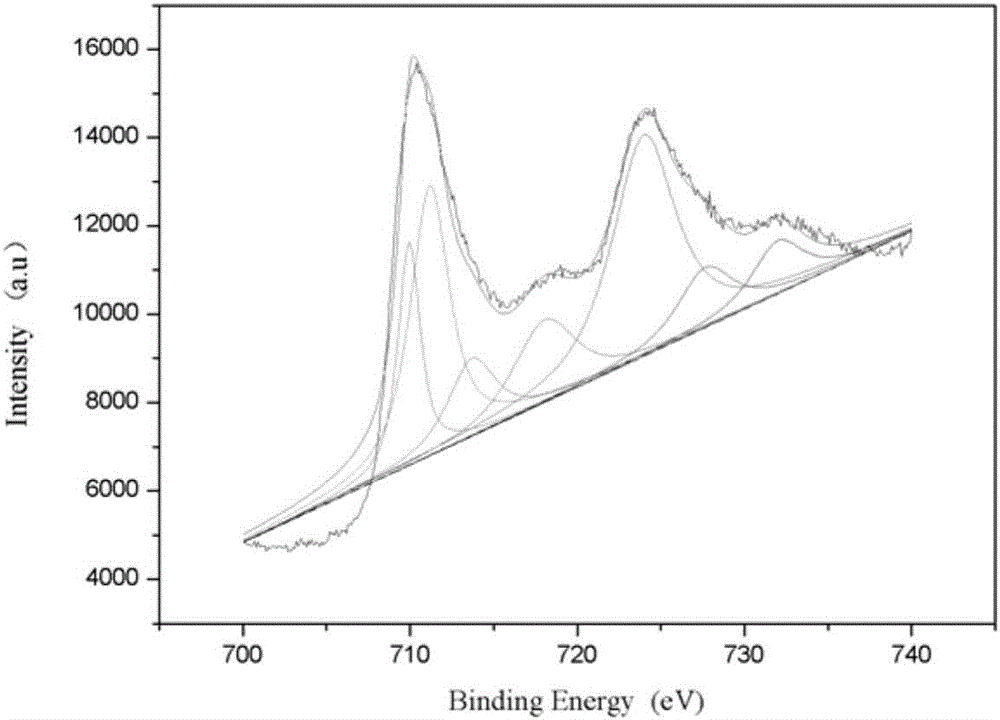

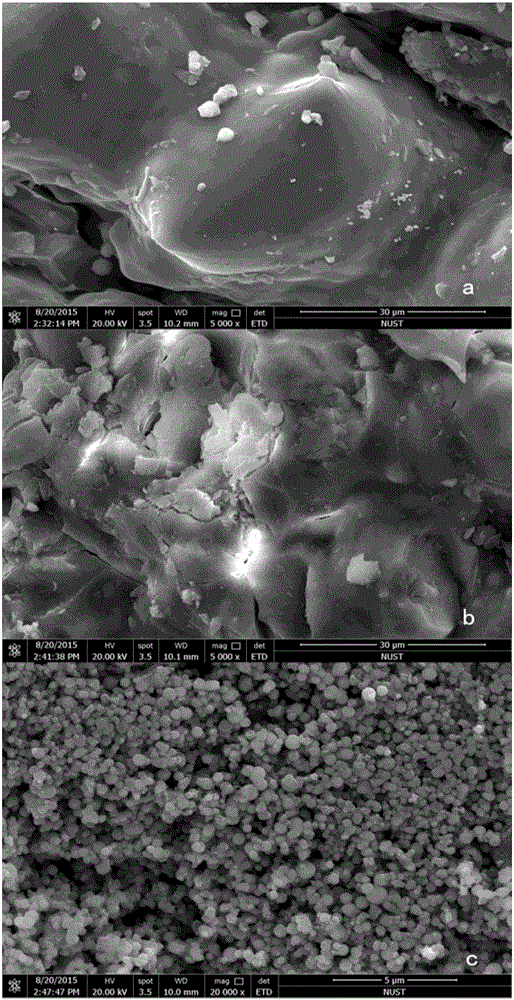

[0022] Example 1: Preparation, characterization and application of amino-supported iron composite modified biochar

[0023] (1) Under the protection of nitrogen, sieve rice husks with a particle size of 40 mesh, place them in a high-temperature muffle furnace, and pyrolyze them at a high temperature of 800 ° C for 3 hours to obtain biochar raw materials;

[0024] (2) Add 50 mL of concentrated sulfuric acid and 50 mL of concentrated nitric acid in the environment of ice bath condensation and reflux, mix well, weigh 6 g of biochar raw material, add it to the mixed acid solution, and stir for 2 hours. After the reaction, use the mixed solution Rinse and filter with ionized water and isopropanol until neutral, and dry the obtained solid in a vacuum oven at 70°C to obtain nitrated biochar;

[0025] (3) Weigh 3 g of dried biochar material and 10 g of solid ferrous sulfate heptahydrate, add them into 150 mL of deionized water and isopropanol mixed solution, add acid dropwise to adjus...

Embodiment 2

[0033] Example 2: Effect of mixed acid mass ratio on the adsorption performance of biochar materials

[0034] (1) Under the protection of nitrogen, sieve rice husks with a particle size of 40 mesh, place them in a high-temperature muffle furnace, and pyrolyze them at a high temperature of 800 ° C for 3 hours to obtain biochar raw materials;

[0035] (2) Add 40mL of concentrated sulfuric acid and 40mL of concentrated nitric acid in the environment of ice bath condensation and reflux, mix well, and prepare 60mL of concentrated sulfuric acid and concentrated nitric acid in the same environment, each weighing 6g of biochar raw materials, adding into the mixed acid solution and stirred for 2 hours. After the reaction, the mixed solution was washed and filtered with deionized water and isopropanol until neutral, and the obtained solid was dried in a vacuum oven at 70°C to obtain nitrated biological carbon;

[0036] (3) Weigh 3g of dried biochar material and 10g of solid ferrous sul...

Embodiment 3

[0038] Example 3: Effects of pyrolysis temperature and holding time on the adsorption performance of biochar materials

[0039] (1) Under the protection of nitrogen, sieve rice husks with a particle size of 40 mesh, place them in a high-temperature muffle furnace, and pyrolyze them at 1000°C for 3 hours, 800°C for 3 hours, and 600°C. 5 hours, obtained biochar materials obtained by different pyrolysis temperatures and holding times;

[0040] (2) Add 50 mL of concentrated sulfuric acid and 50 mL of concentrated nitric acid in the environment of ice bath condensation and reflux, mix well, weigh 6 g of biochar raw materials respectively, add them to the mixed acid solution, and stir for 2 hours. After the reaction is completed, use the mixed solution with Rinse and filter with deionized water and isopropanol until neutral, and dry the obtained solid in a vacuum oven at 70°C to obtain nitrated biochar;

[0041] (3) Weigh 3g of dried biochar material and 10g of solid ferrous sulfat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com