Patents

Literature

64results about How to "Reduce scum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

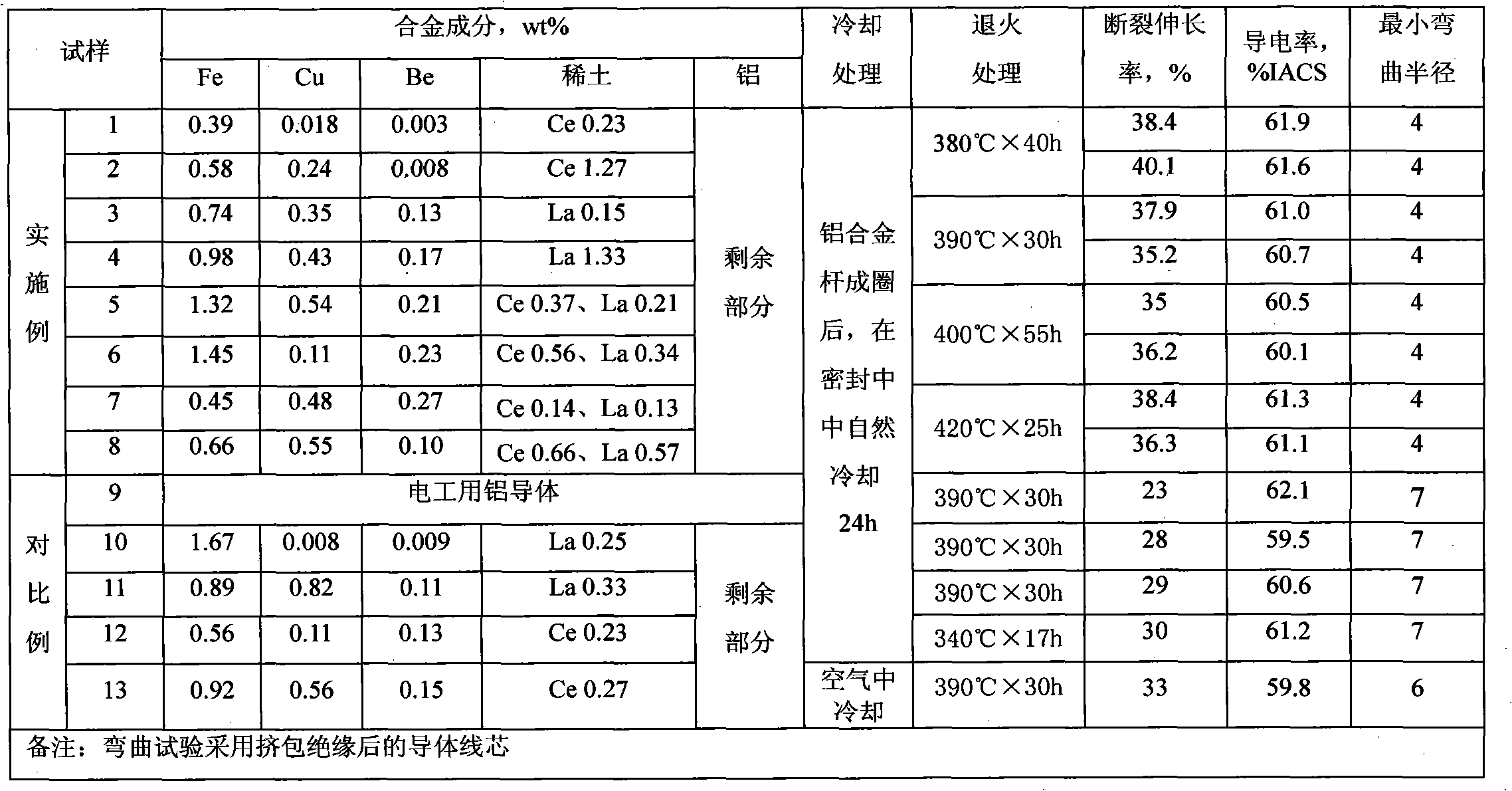

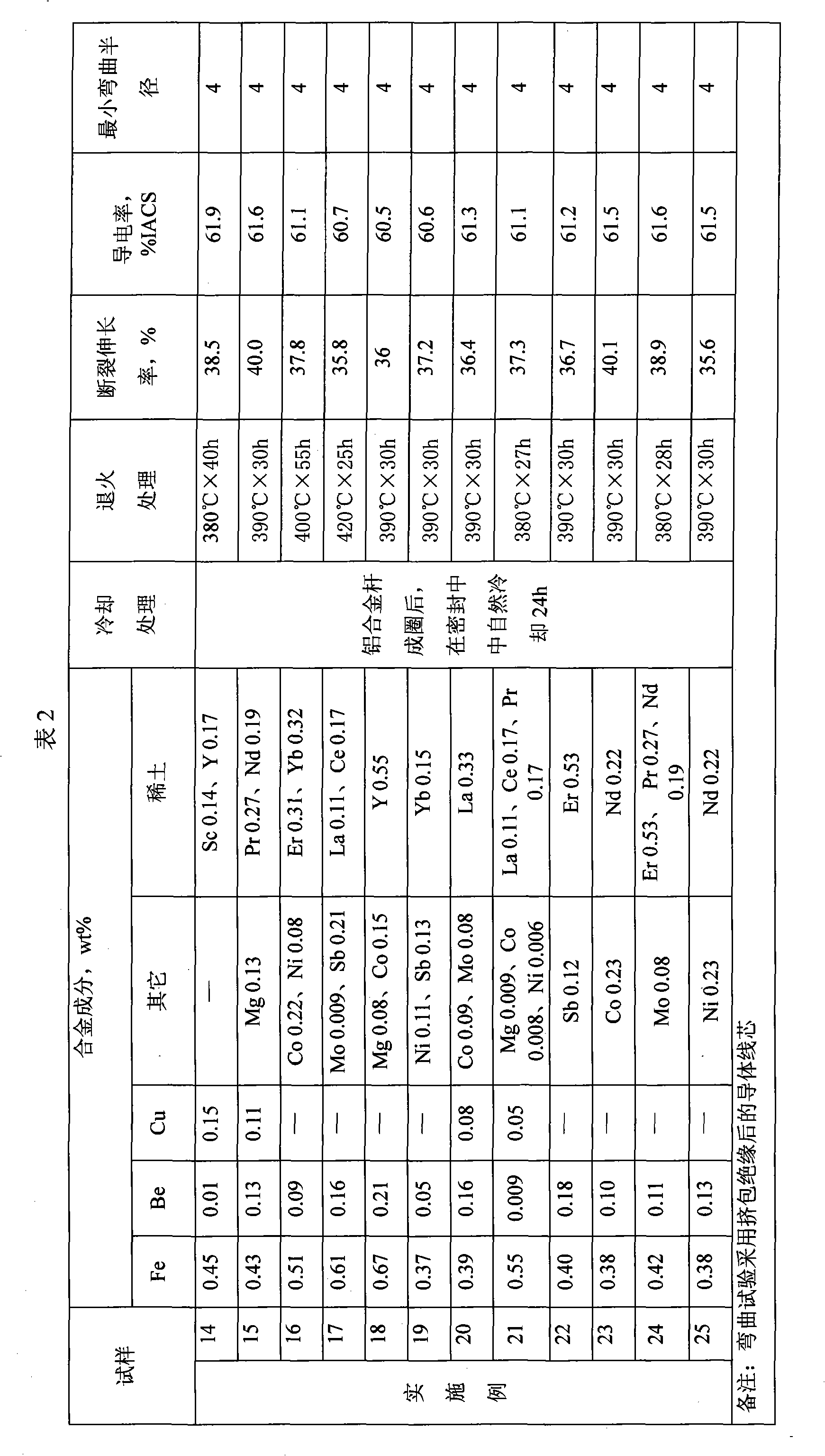

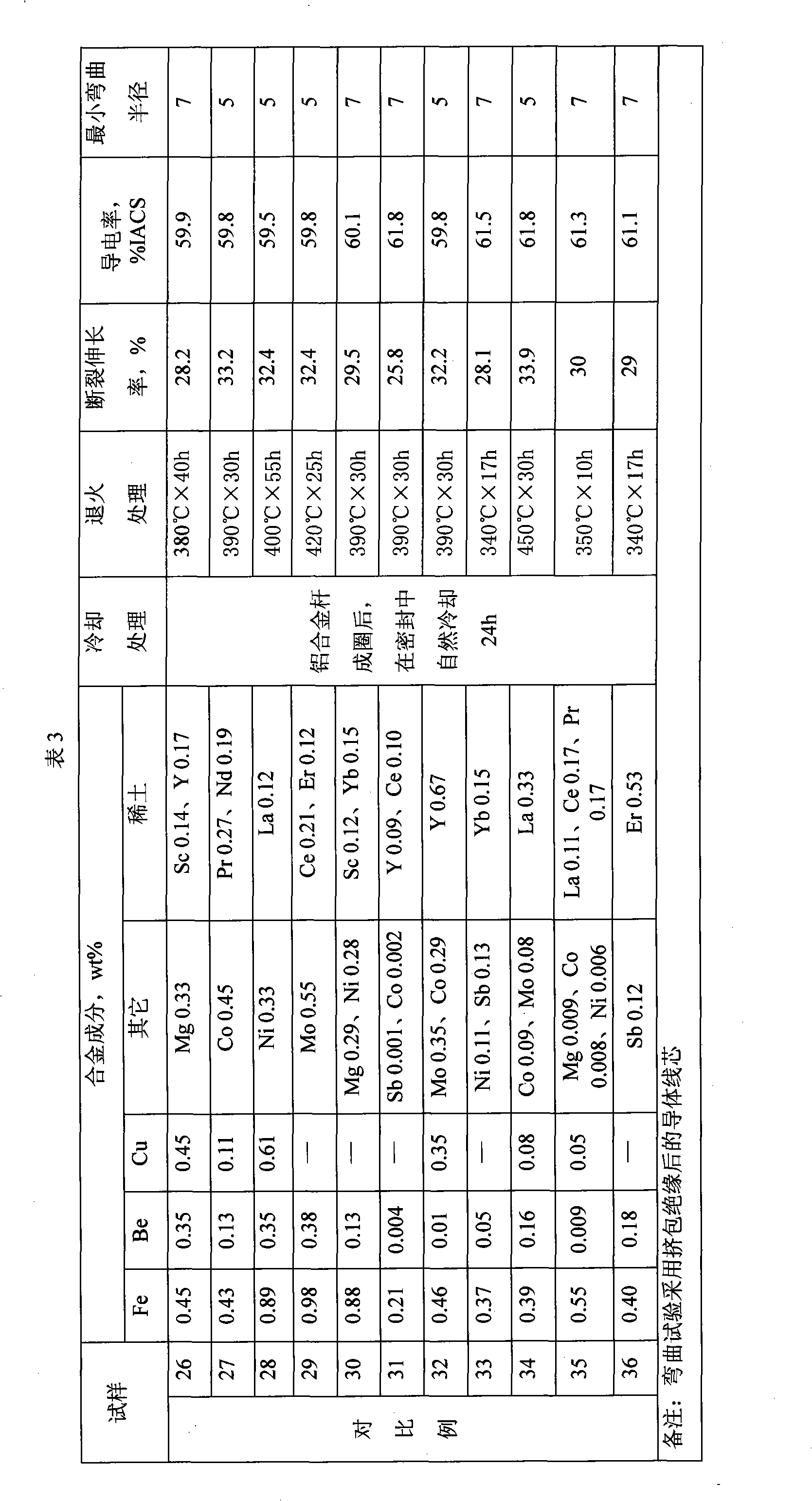

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

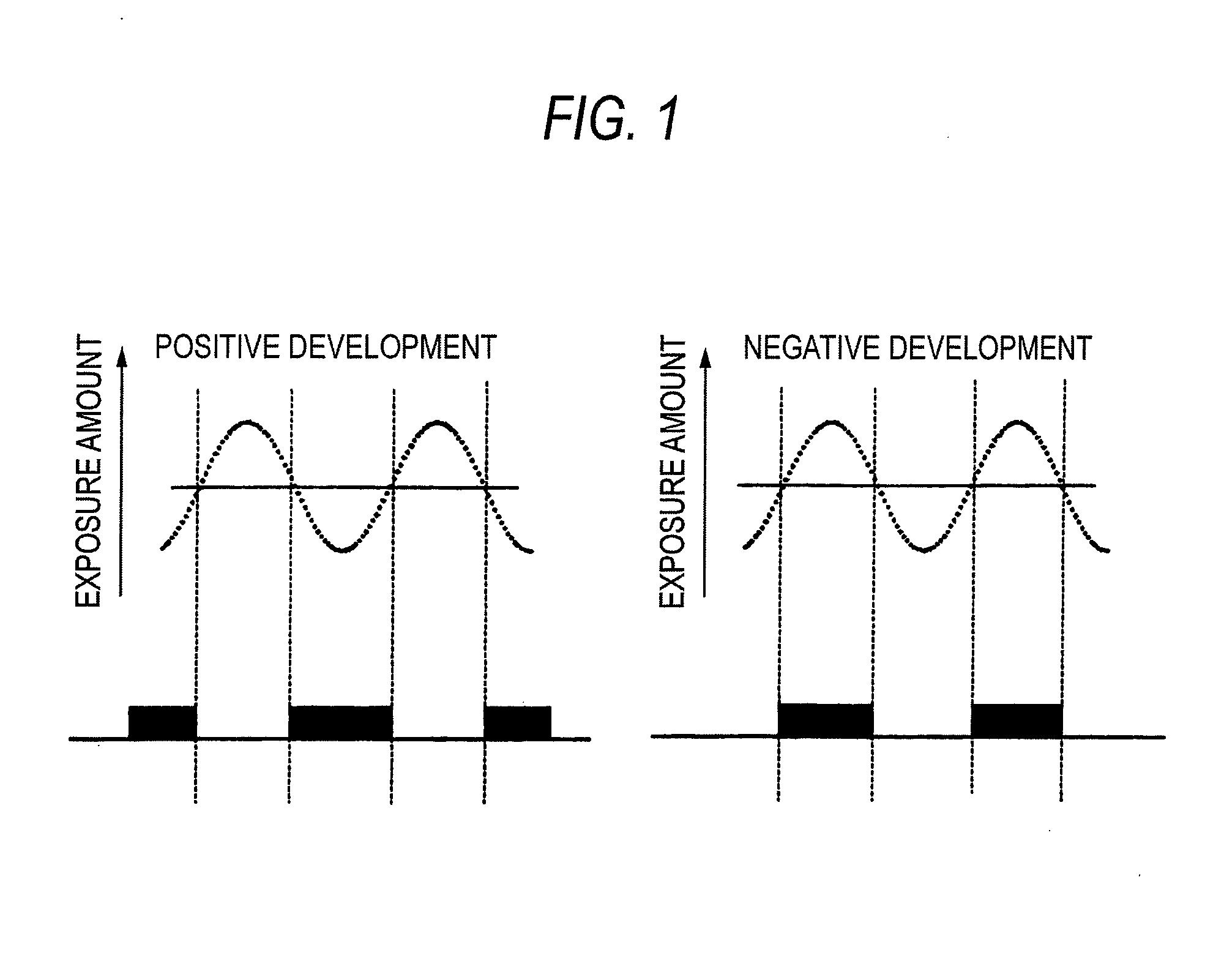

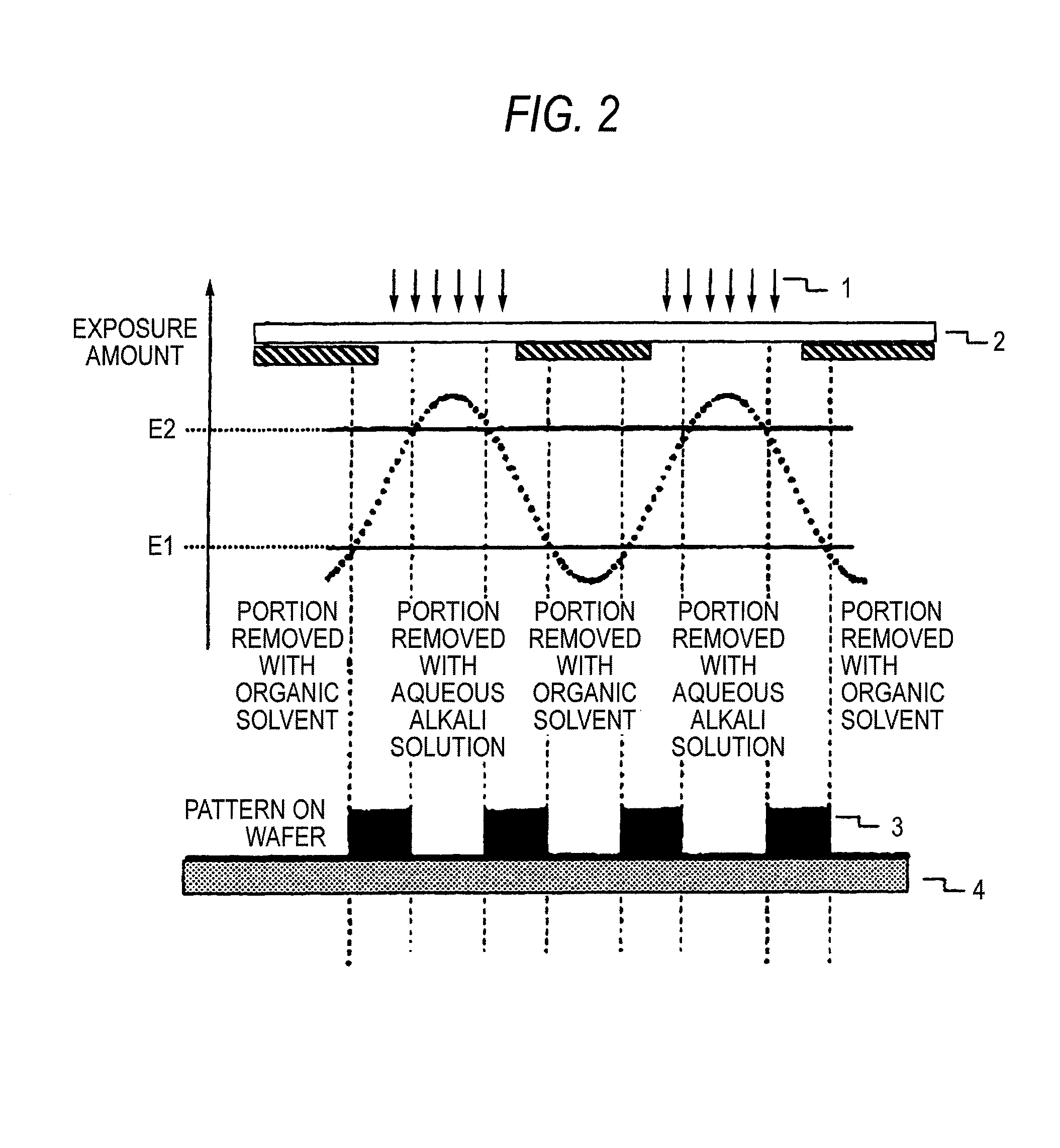

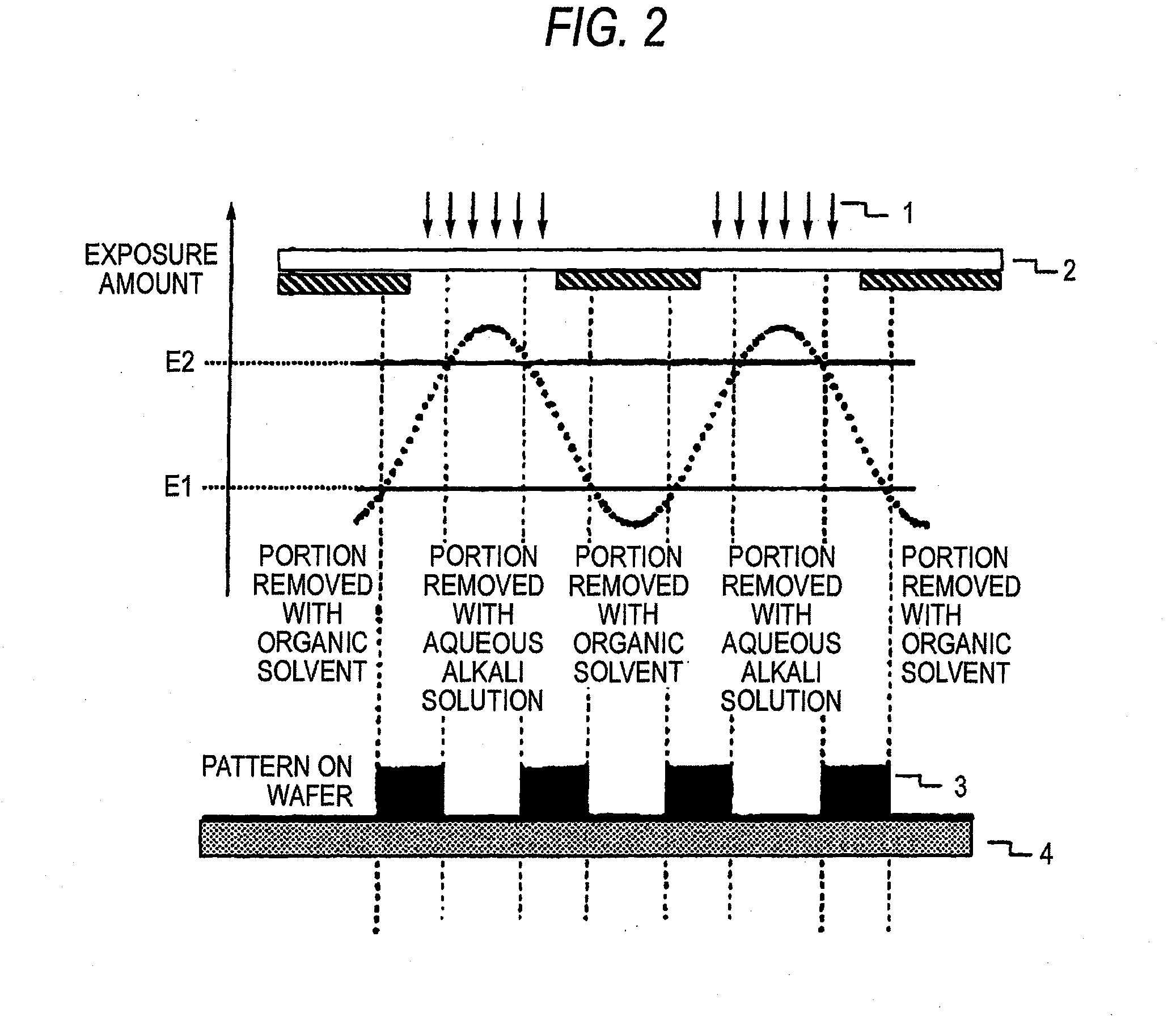

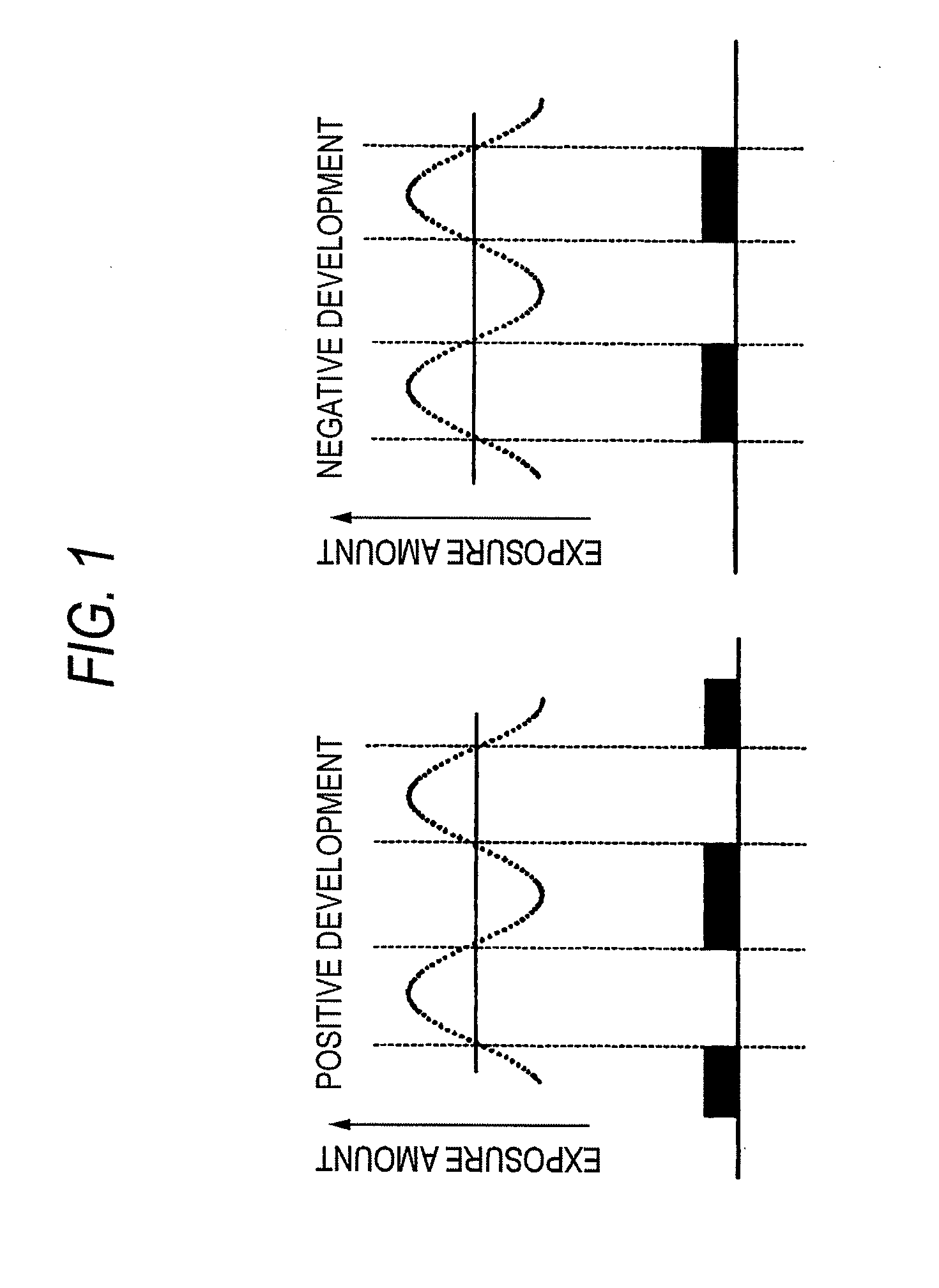

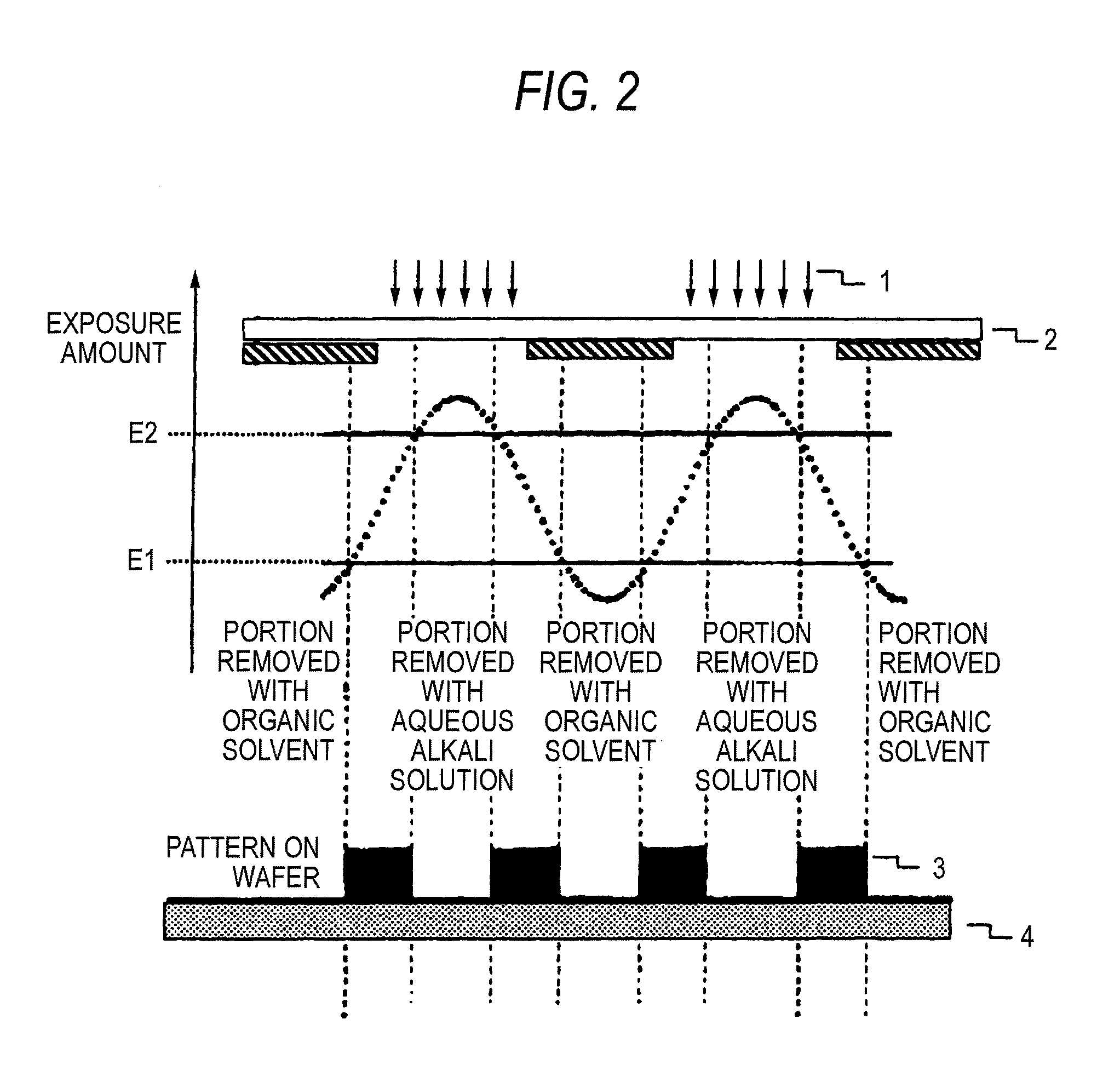

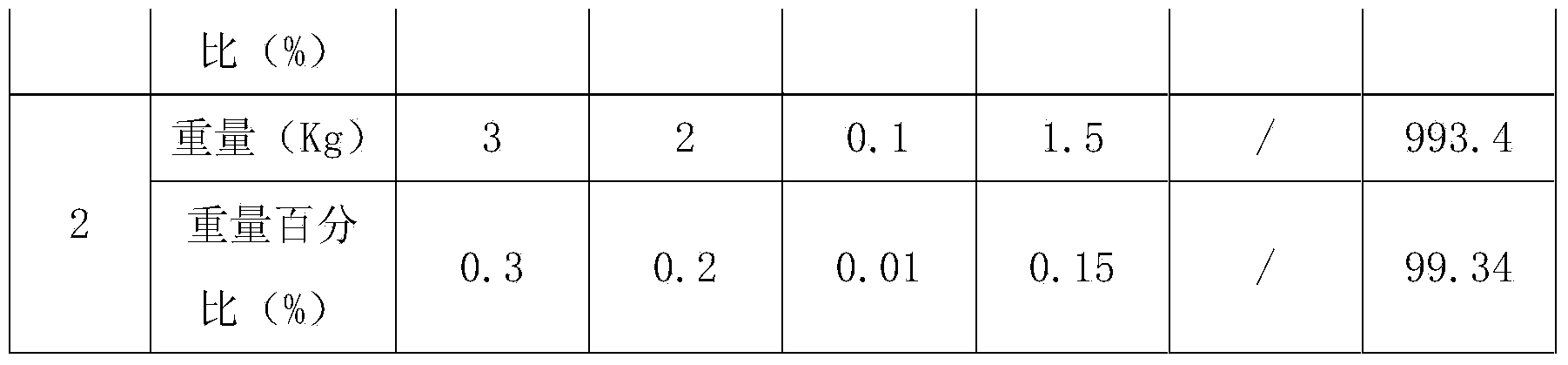

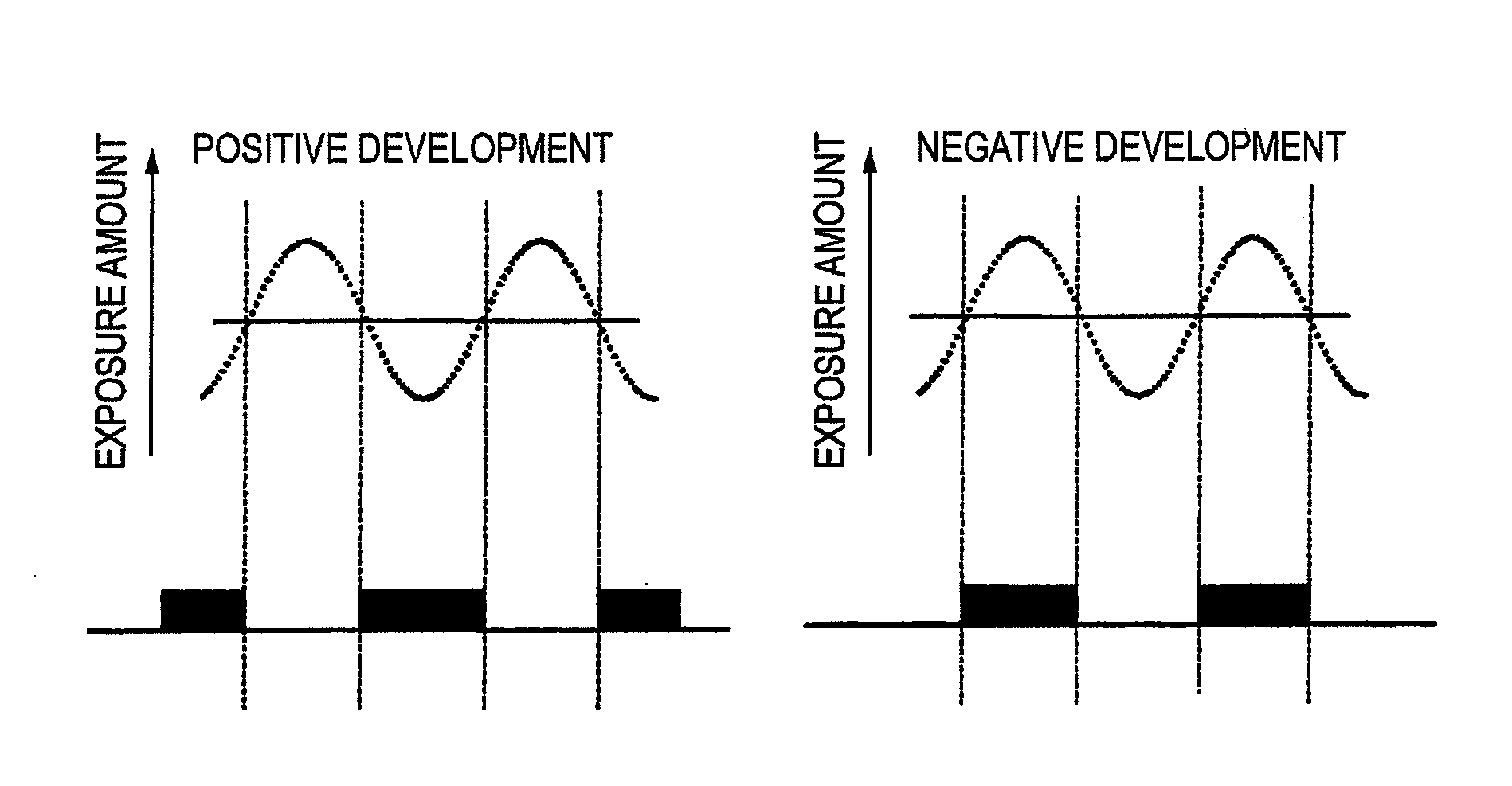

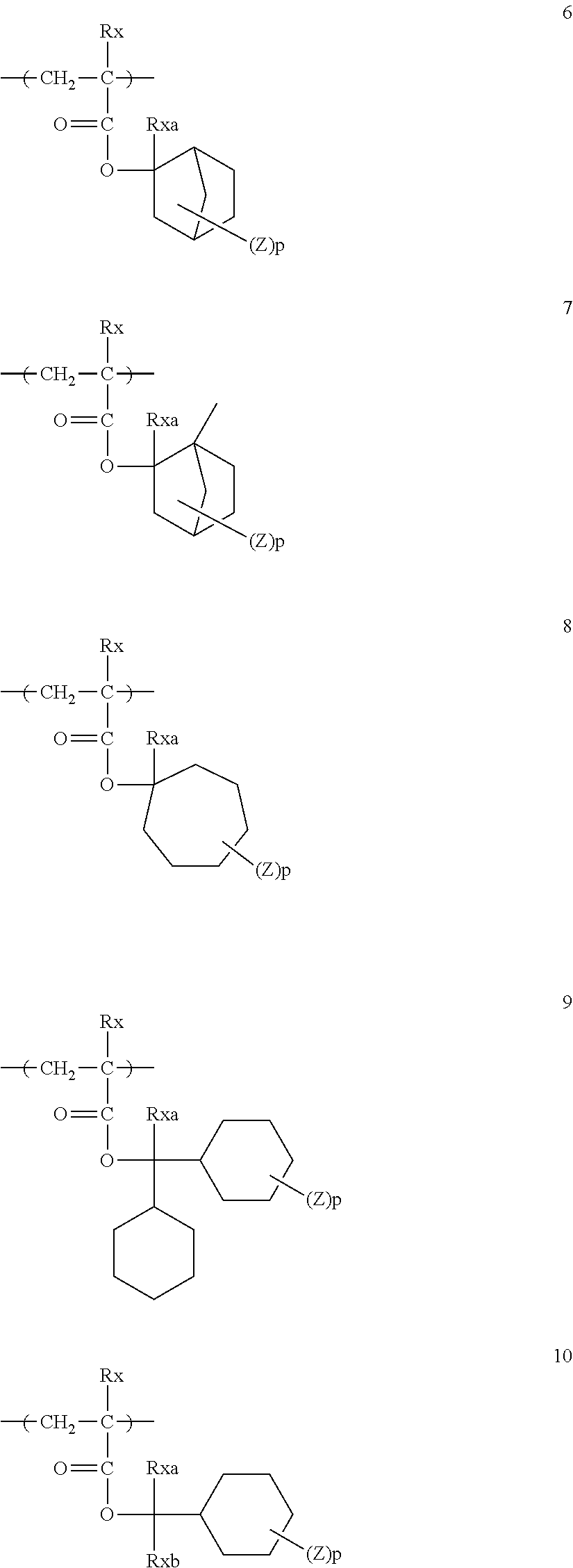

Method of forming patterns

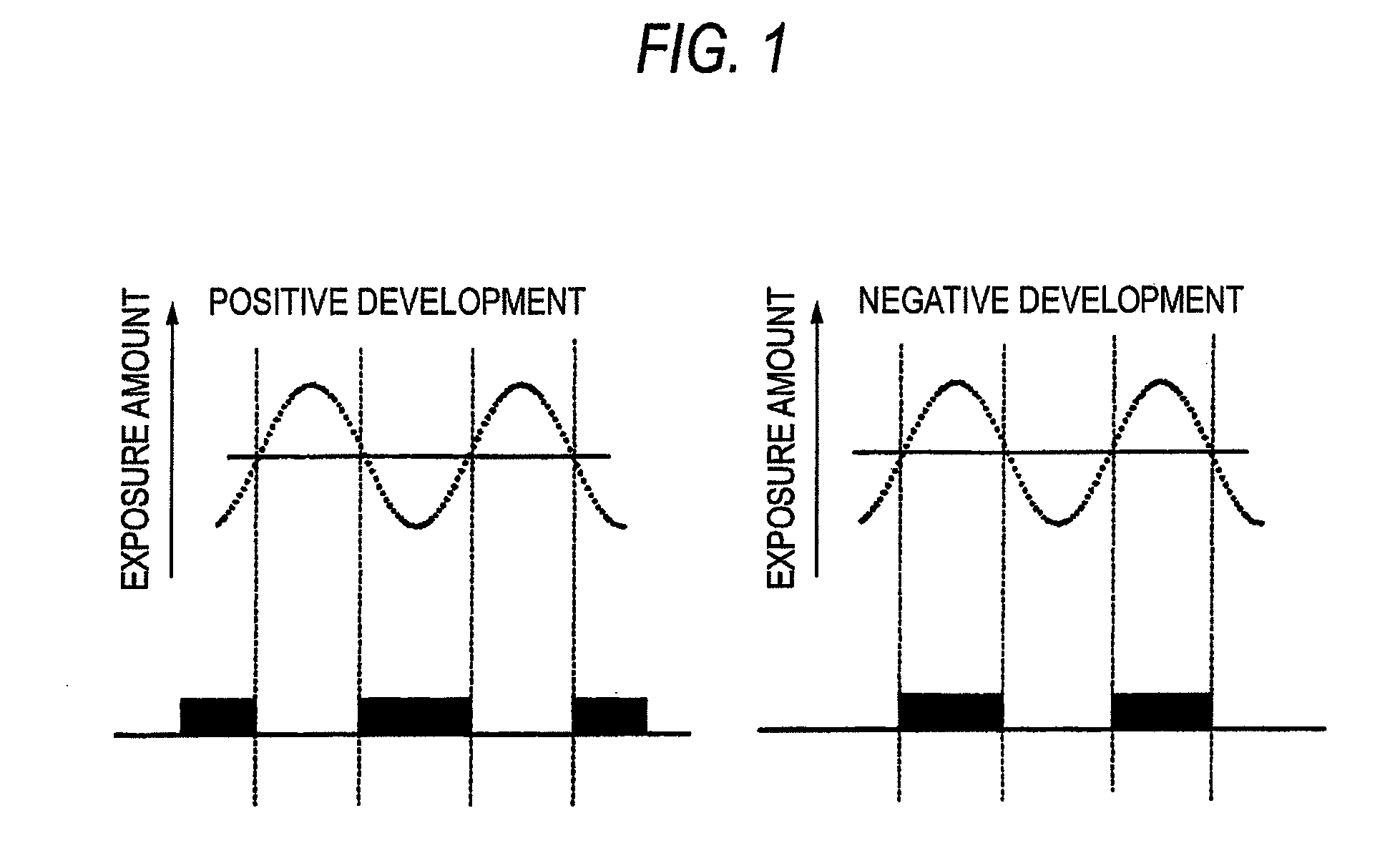

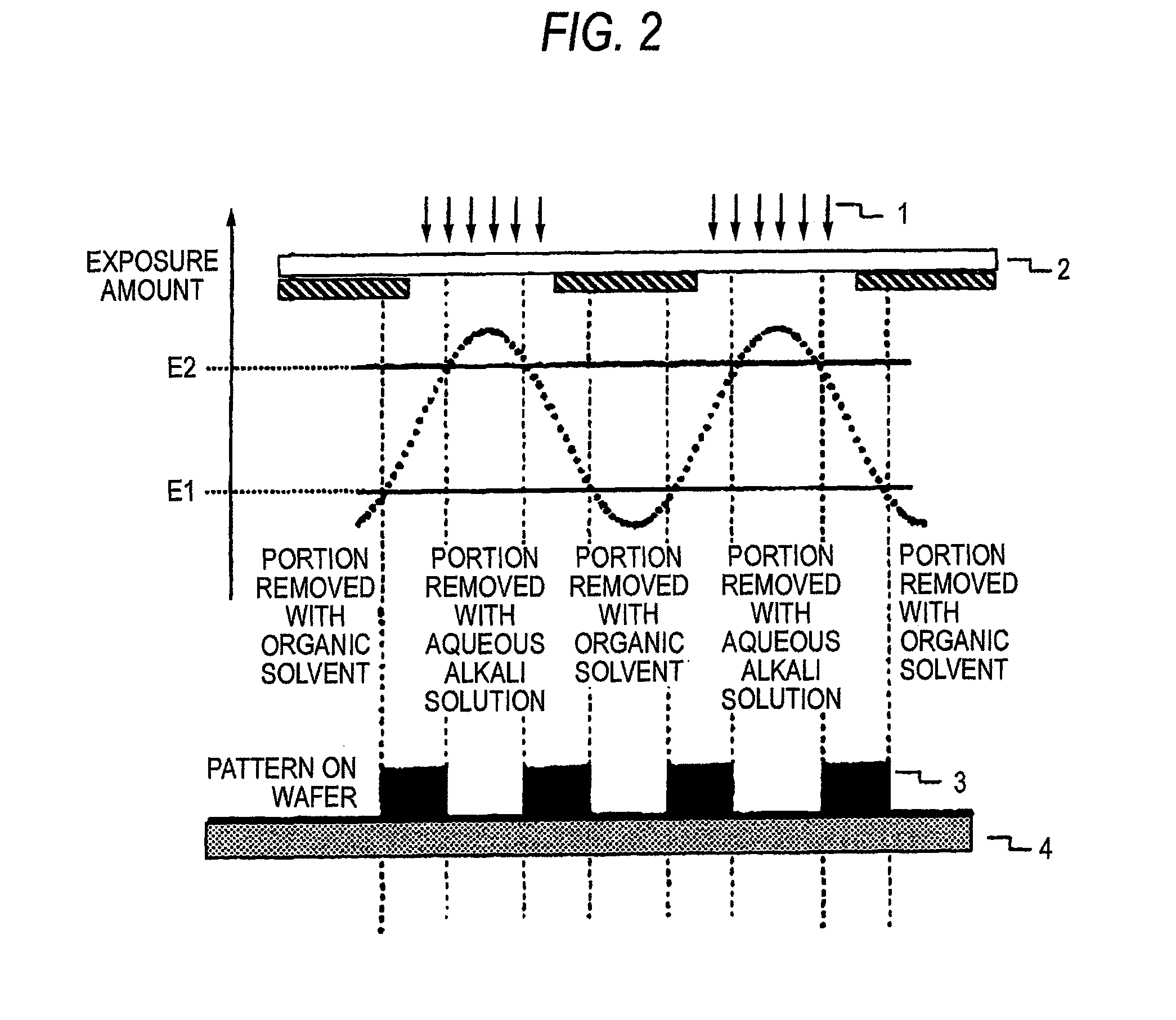

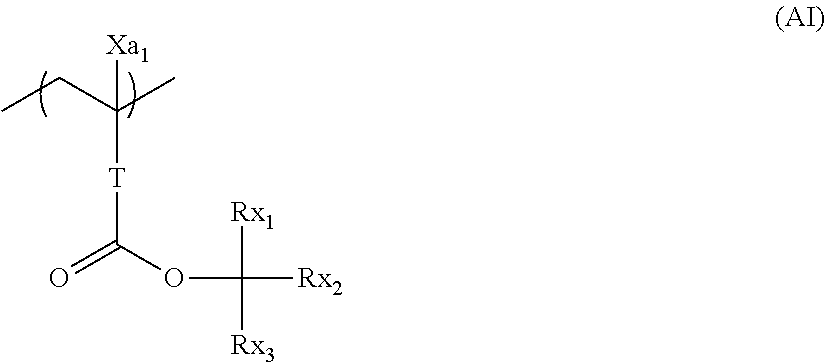

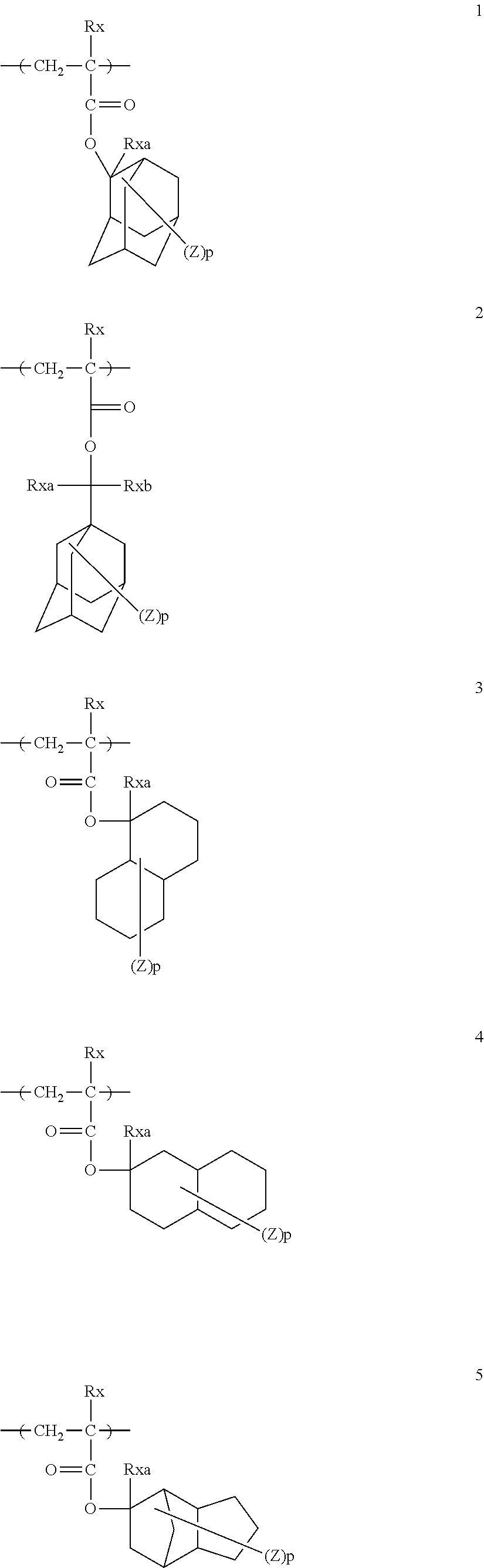

ActiveUS20080318171A1Enhanced in-plane uniformity of line widthReduced line edge roughnessPhotosensitive materialsPhoto-taking processesActinic RaysRadiation exposure

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

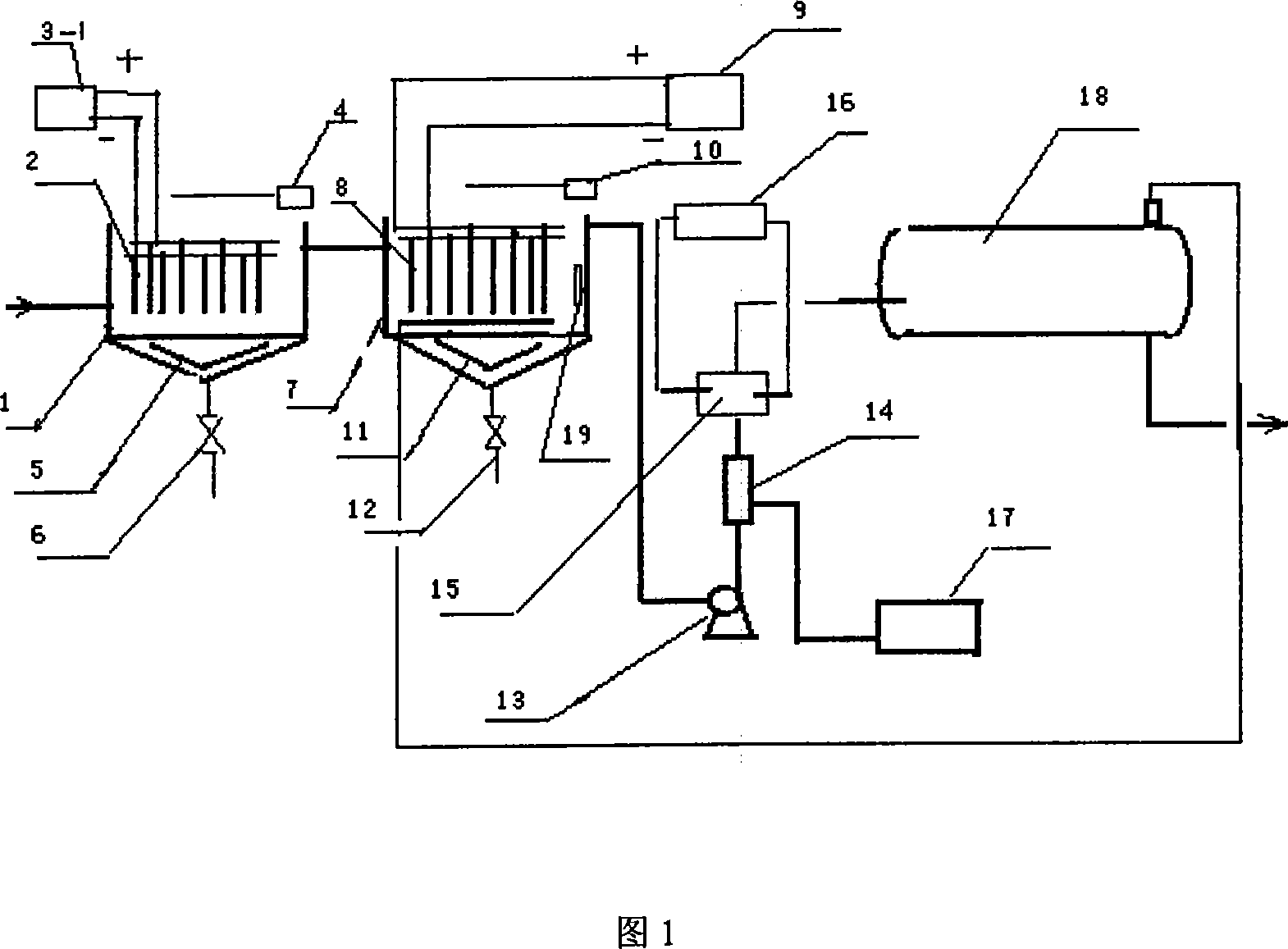

Apparatus for treating sewage containing oil, and processing technique

InactiveCN101050040ASolve processing problemsAdaptableWaste water treatment from quariesFatty/oily/floating substances removal devicesSmall footprintPetroleum

This invention discloses apparatus and process for treating oil-containing wastewater. The apparatus is composed of an electric flocculation tank, an electric floatation tank, an ozone- and ultrasonic-enhanced oxidation device, and a reaction tank. Electric flocculation and electric floatation are adopted to remove oil and suspended substances. Ozone- and ultrasonic-enhanced oxidation is adopted to remove COD by degrading organic matters. The process has such advantages as stable operation, no need for chemical reagents, small floor area, and high automation. Treated oil-containing wastewater is qualified for discharge.

Owner:UNIV OF SCI & TECH BEIJING

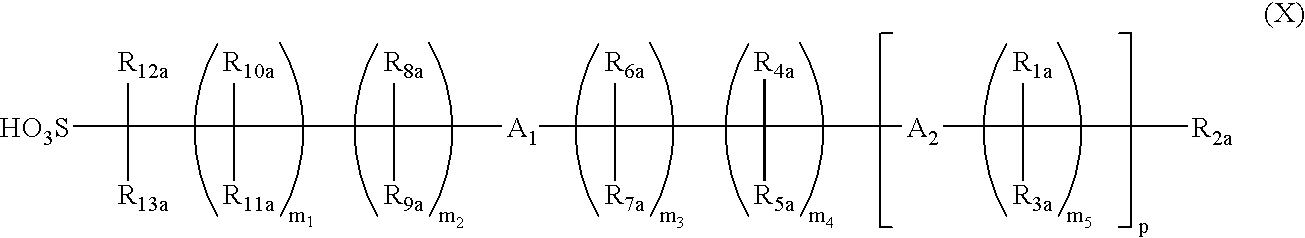

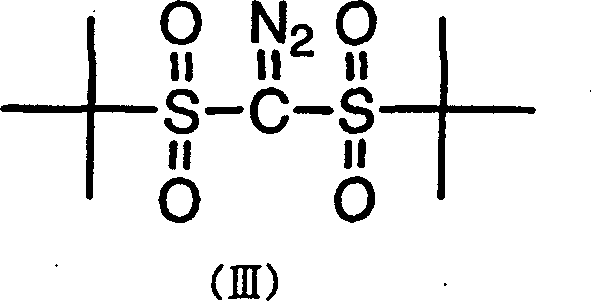

Positive photosensitive composition

InactiveUS20070003871A1High resolutionIncrease exposureOrganic chemistryOrganic compound preparationActinic RaysPhotochemistry

Owner:FUJIFILM CORP

Method for reducing malodor with Bacillus subtilis Kubota

PCT No. PCT / JP97 / 00778 Sec. 371 Date Sep. 5, 1997 Sec. 102(e) Date Sep. 5, 1997 PCT Filed Mar. 12, 1997 PCT Pub. No. WO97 / 33487 PCT Pub. Date Sep. 18, 1997The present invention relates to an oral composition containing Bacillus subtilis Kubota FERM BP-5847 for animals. The oral administration of Bacillus subtilis Kubota FERM BP-5847 can deodorize feces and urine from livestock, poultry, fish and the like and also suppresses the occurrence of diarrhea.

Owner:KUBOTA TOYOAKI

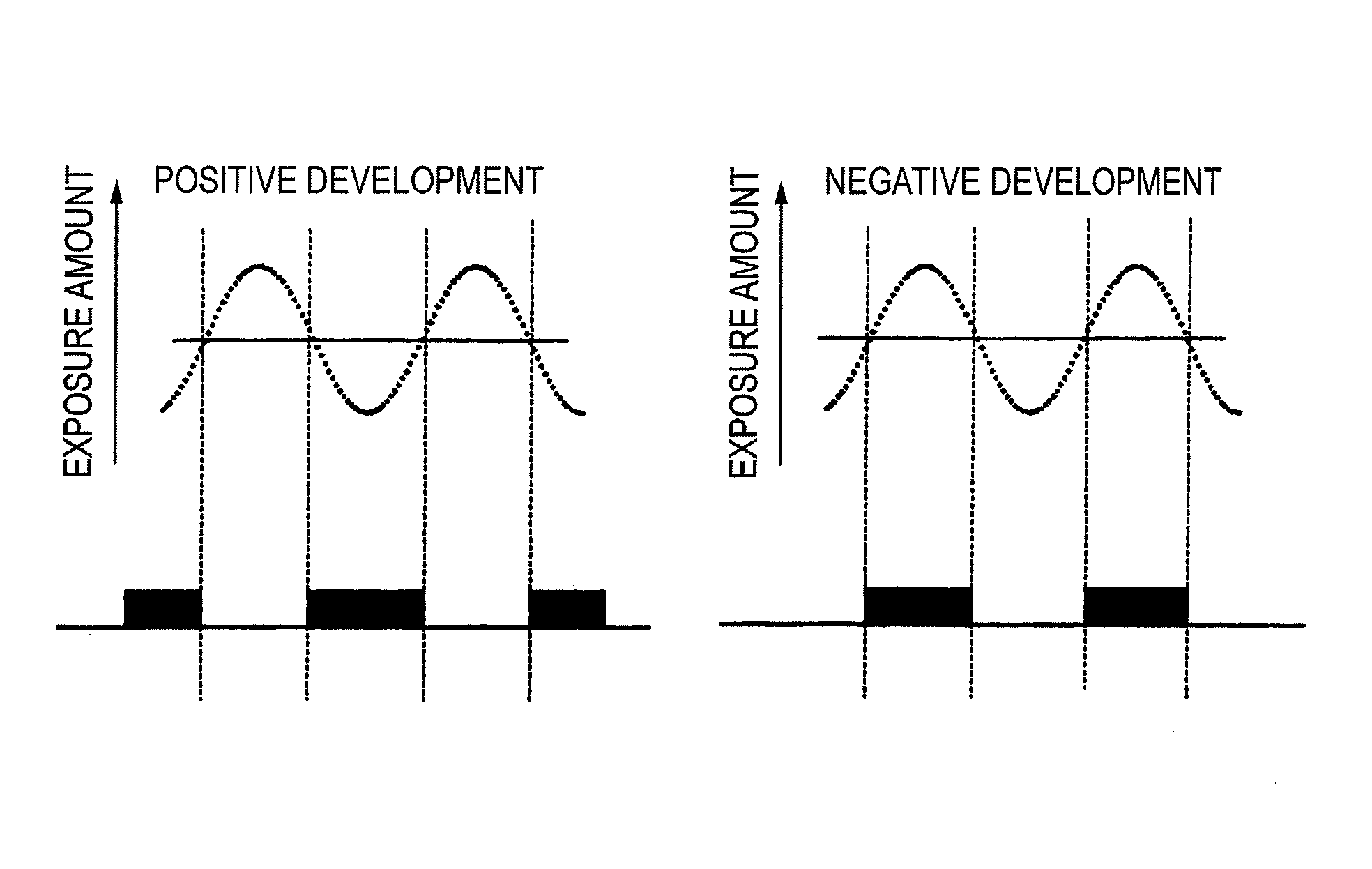

Method of forming patterns

ActiveUS20120135355A1Enhanced in-plane uniformity of line widthReduced line edge roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusActinic RaysFluence

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

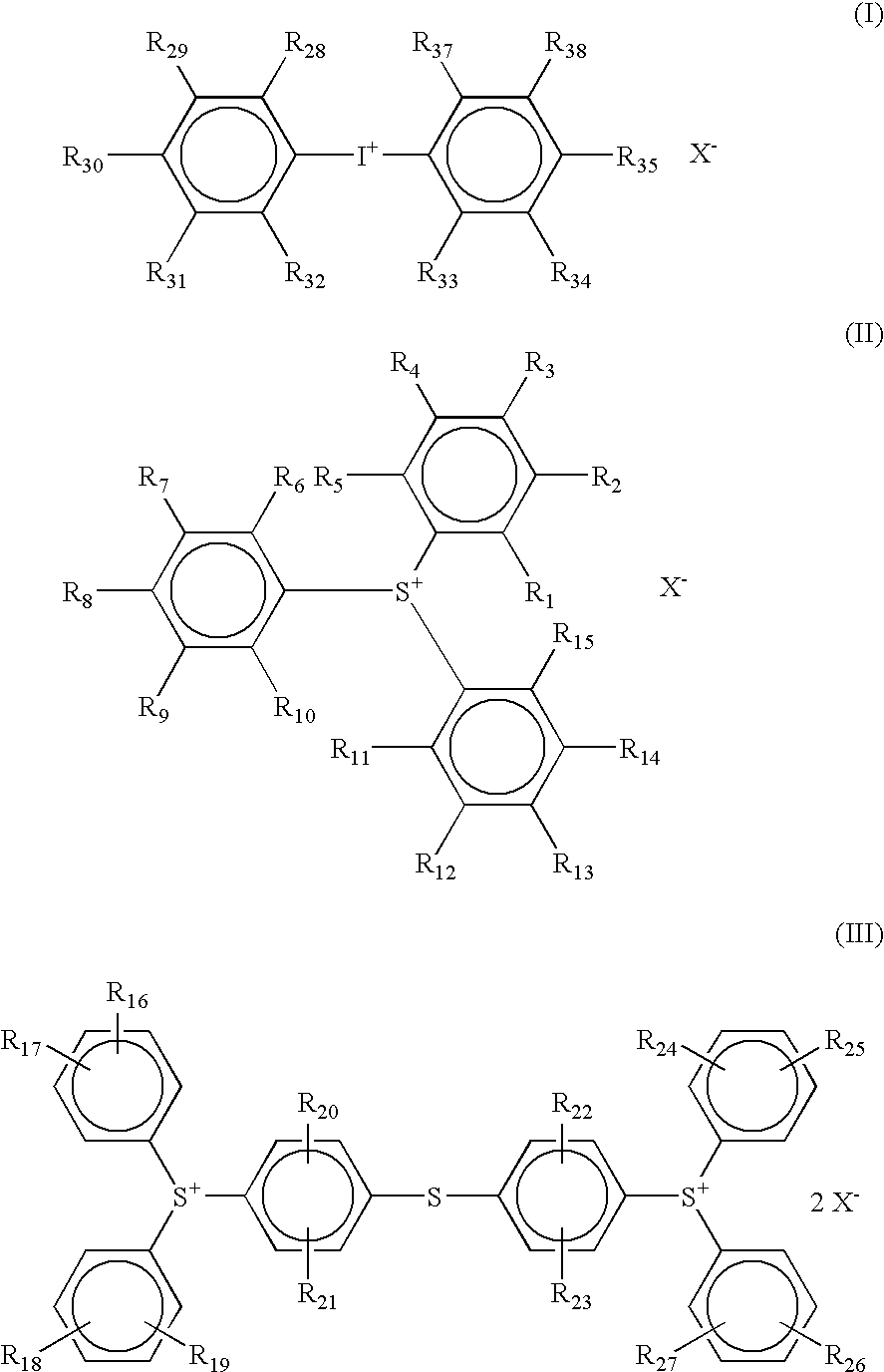

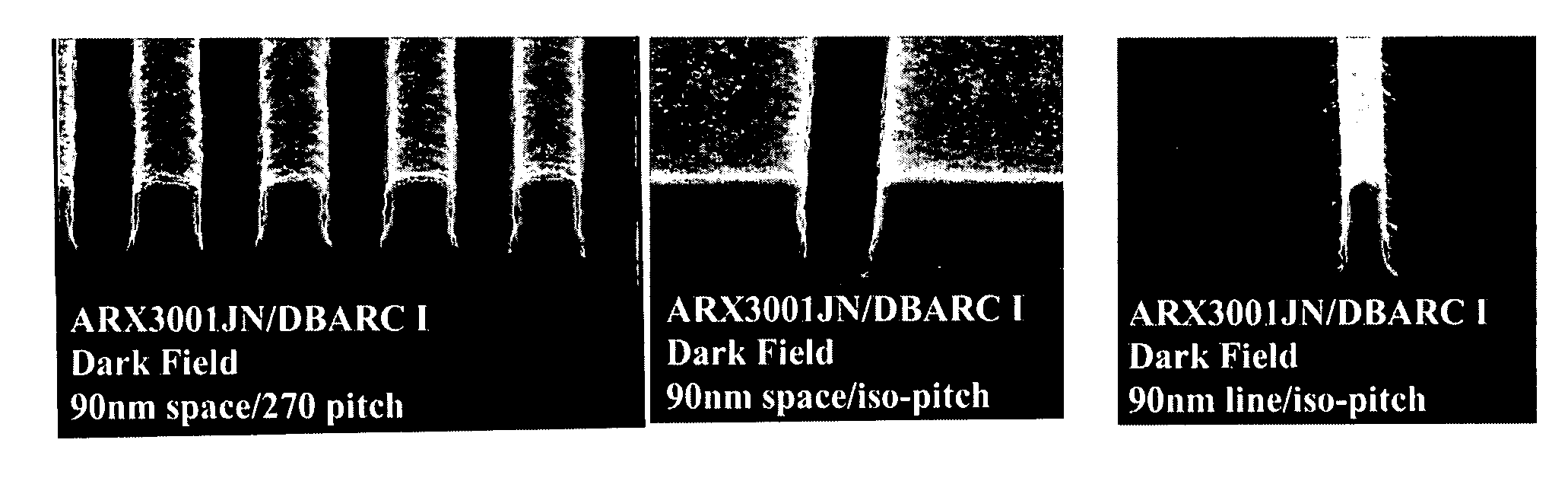

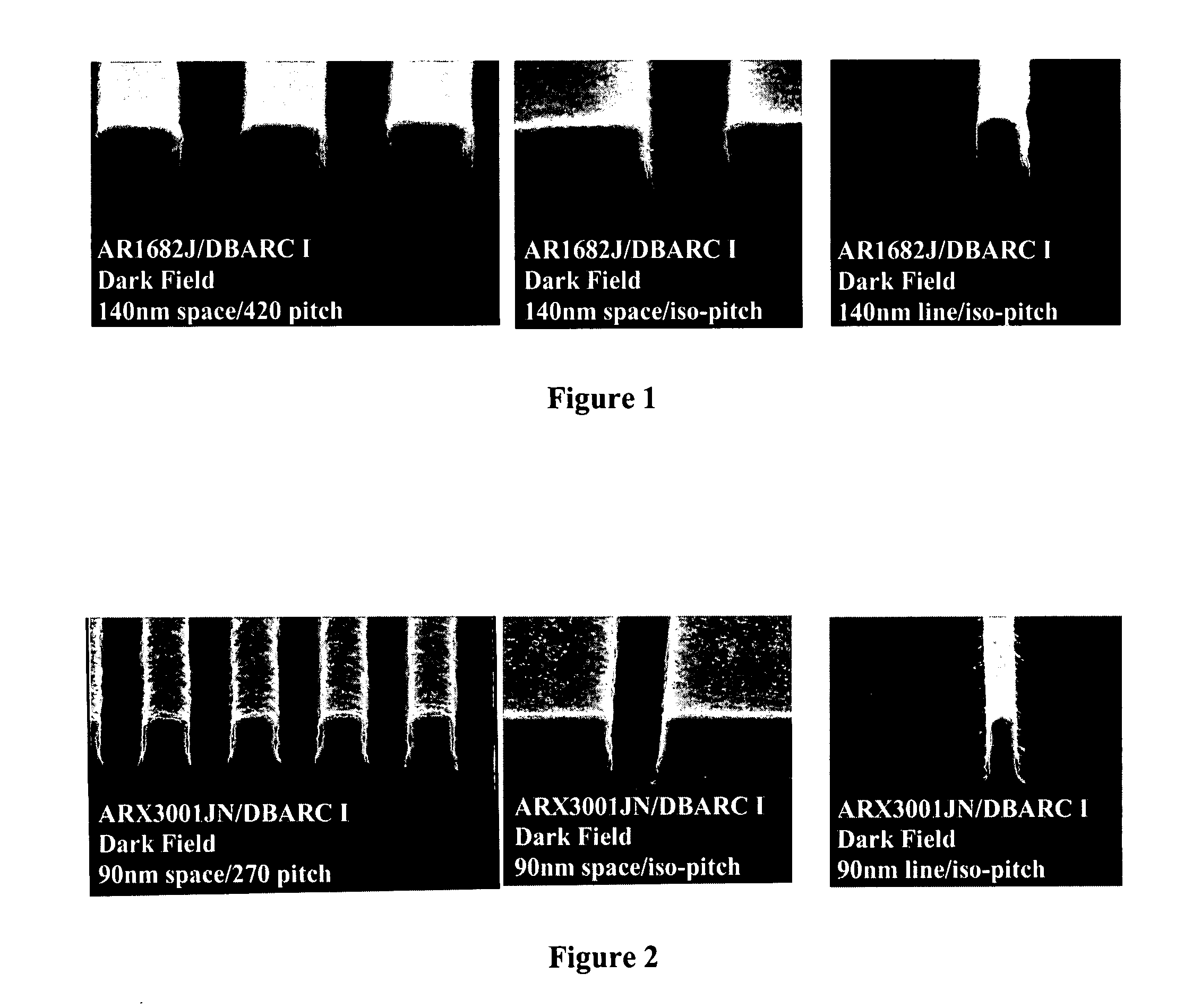

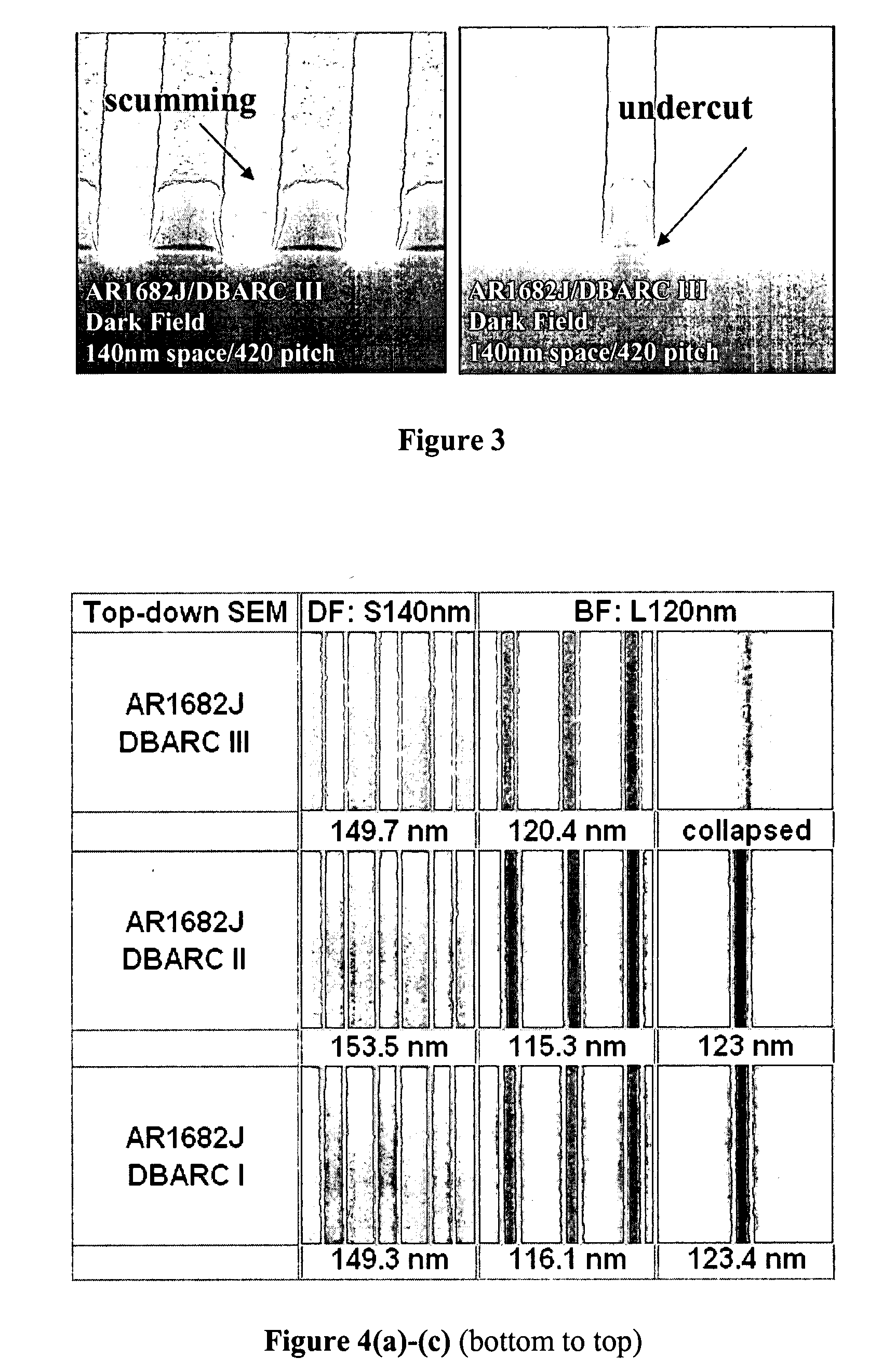

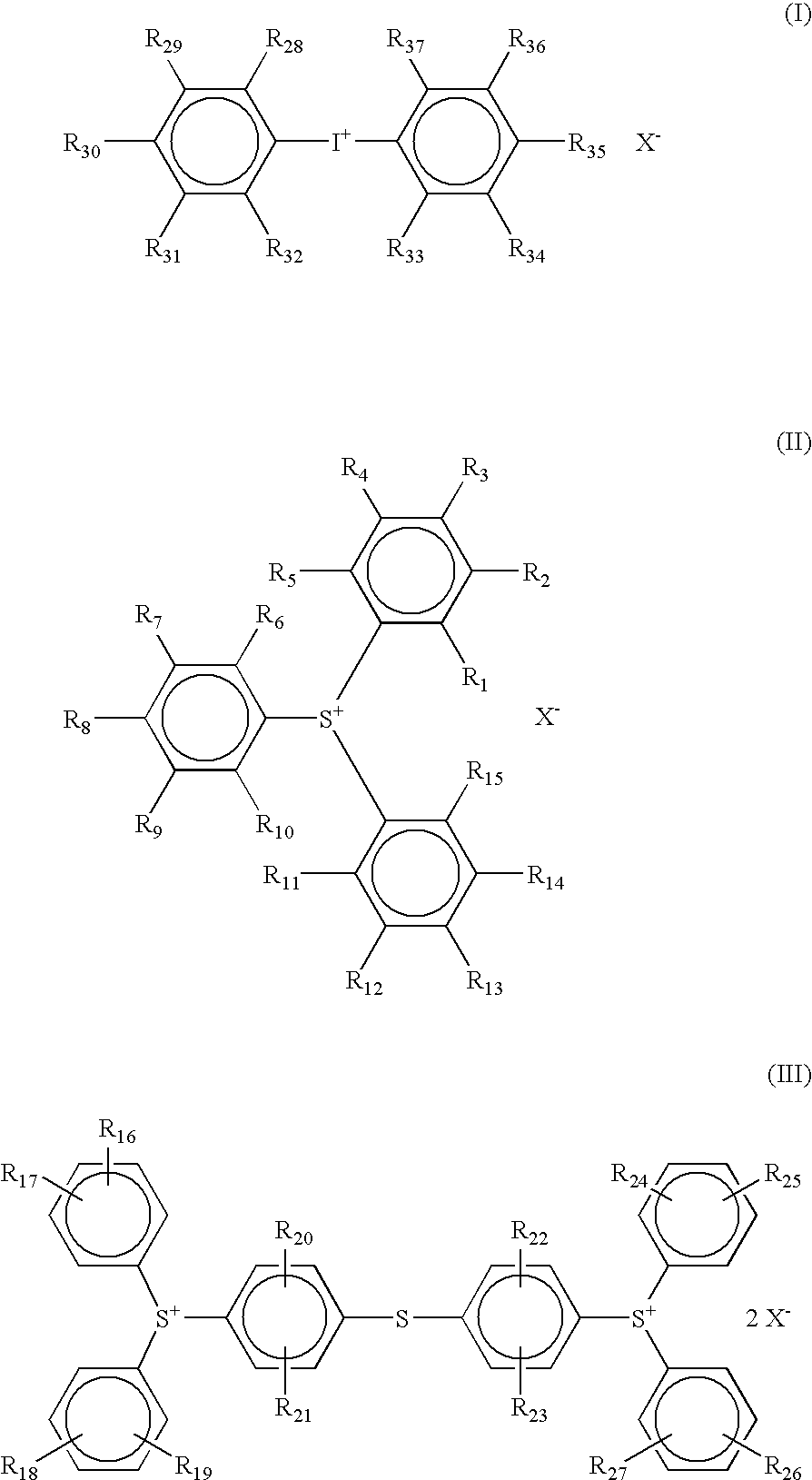

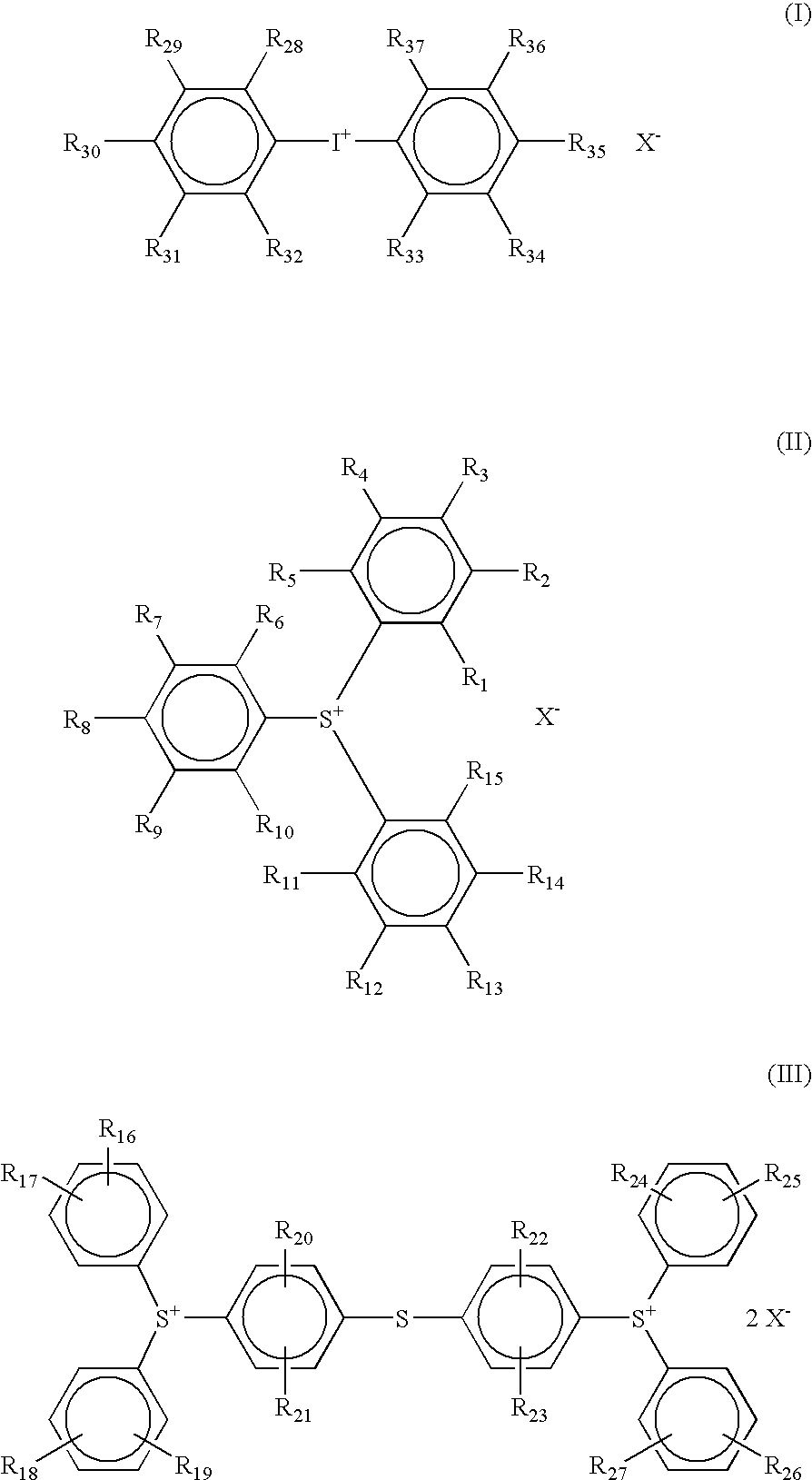

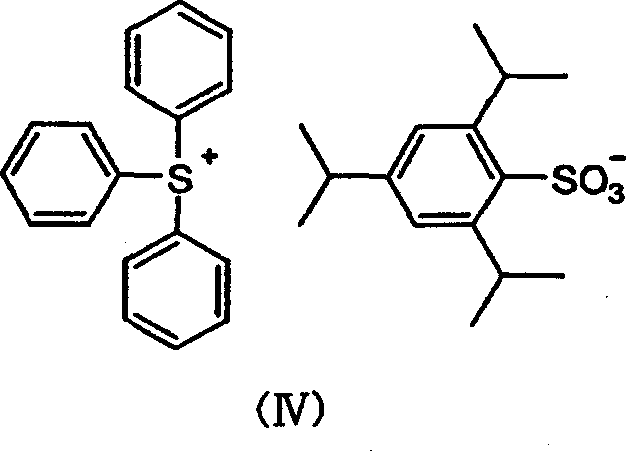

Radiation-Sensitive, Wet Developable Bottom Antireflective Coating Compositions and Their Applications in Semiconductor Manufacturing

InactiveUS20090098490A1Eliminates scummingReduce scumPhotosensitive materialsPhotomechanical apparatusPhotoacidPhotoacid generator

The present invention is directed to novel radiation-sensitive, wet developable bottom antireflective coating (DBARC) compositions and their use in semiconductor device manufacturing. The DBARC compositions contain a photoacid generator that produces a photoacid upon exposure to activating radiation. In a photolithographic imaging process, the relatively strong photoacid reduces or eliminates scumming. Further, the relatively large size of the photoacid limits its diffusion through the DBARC, thus minimizing or preventing undercut. The inventive method also limits diffusion of the photoacid by controlling the temperature of the post-exposure baking step. Use of the DBARC compositions with a photoresist in photolithography results in highly resolved features having essentially vertical profiles and no scumming and no undercut, which is critical as microelectronics and semiconductor components become increasingly miniaturized.

Owner:JSR MICRO

Positive photosensitive composition

InactiveUS20050130060A1High resolutionIncrease exposureOrganic compound preparationRadiation applicationsActinic RaysPhotochemistry

A positive photosensitive composition comprises a compound capable of generating a specified sulfonic acid upon irradiation with one of an actinic ray and radiation and (B) a resin capable of decomposing under the action of an acid to increase the solubility in an alkali developer.

Owner:FUJIFILM CORP

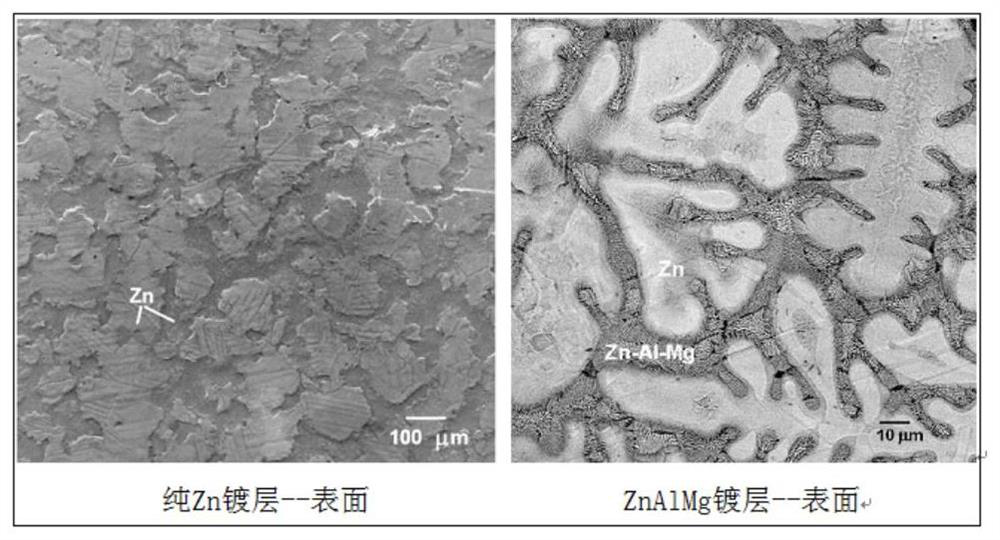

Corrosion-resistant hot galvanized steel plate and preparation method thereof

ActiveCN101948991AStrong adhesionImprove corrosion resistanceHot-dipping/immersion processesSheet steelSlag

The invention relates to a corrosion-resistant hot galvanized steel plate and a preparation method thereof. The hot galvanized steel plate is formed by processing a cold rolled steel plate and forming a zinc coating on the cold rolled steel plate by a hot galvanizing process, wherein the zinc coating contains the following components in percentage by weight: 0.35-0.45% of aluminum and 0.04-0.06% of ytterbium-enriched rare earth. The method comprises the following steps: 1. carrying out cold-rolling on a hot rolled blooming base plate to form a cold rolled steel plate; 2. cleaning the cold rolled steel plate with alkali and water; 3. annealing the cleaned cold rolled steel plate; 4. carrying out hot galvanizing on the annealed plate in a galvanizing pot; 5. subsequently straightening and flattening the hot galvanized plate; and 6. passivating and greasing the flattened hot galvanized plate. By using the zinc alloy coating containing aluminum and rare earth, the invention ensures that the galvanizing pot has little bottom slag, the scum is reduced by 20%, the coating has fine adhesive capacity, and the corrosion resistance of the coating is improved by two times.

Owner:ZHEJIANG HUADA NEW MATERIAL

Molten metal anti-oxidation reducing agent, preparation method and application thereof

InactiveCN101532130AReduce scumSpeed up the flowMetallic material coating processesO-Phosphoric AcidPhytic acid

The invention relates to a molten metal anti-oxidation reducing agent and a preparation method and application thereof. The molten metal anti-oxidation reducing agent comprises the following main compositions in portion by weight: 51.19 to 91.19 portions of nonylphenol polyoxyethylene ether, 3 to 15 portions of organic amine, 0.3 to 5 portions of phosphoric acid and 0.5 to 8 portions of phytic acid; the anti-oxidation reducing agent can further comprise essence in proper amount; and the molten metal anti-oxidation reducing agent is water-soluble oily liquid. The reducing agent has no flash point, does not splash when being added into molten metal and can automatically and rapidly diffuse; the molten metal anti-oxidation reducing agent is lighter than molten metal liquid and can overspread the whole flowing liquid level to isolate air and effectively prevent oxidation; contained active substances and organic or inorganic acid can disperse the inner gravitation of oxidized metal scruff, and actively scatter an inner structure of the oxidized metal scruff to reduce useful metal out; the reduction efficiency is 95 percent or so; cost performance is high; the residual scruff is little, soluble in water and convenient to clean; and the molten metal anti-oxidation reducing agent is convenient to maintain equipment.

Positive photosensitive composition

InactiveUS7435526B2High resolutionIncrease exposurePhotosensitive materialsOrganic compound preparationActinic RaysPhotochemistry

A positive photosensitive composition comprises a compound capable of generating a specified sulfonic acid upon irradiation with one of an actinic ray and radiation and (B) a resin capable of decomposing under the action of an acid to increase the solubility in an alkali developer.

Owner:FUJIFILM CORP

High-strength sulfur-oxygen nucleating agent

The invention provides a high-strength sulfur-oxygen nucleating agent. The high-strength sulfur-oxygen nucleating agent comprises the following elements in percentages by mass: 70-76% of Si, 0.2-1.0%of Ca, 0.3-0.5% of Ba, 1.5-2.0% of La, 0.5-1.5% of Al, 0.3-0.9% of S, 0.3-0.9% of O, 0.5-1.5% of Sb and the balance of iron. The sulfur-oxygen nucleating agent is prepared from the following raw materials in parts by weight: 2-4 parts of steel scrap, 130-140 parts of silicon iron, 1-1.4 parts of silicon barium, 1-1.8 parts of calcium silicon, 2-4 parts of pure lanthanum, 1.5-2.5 parts of stibonium, 1-2 parts of FeS and 1-1.4 parts of FeO. By the prepared high-strength sulfur-oxygen nucleating agent, the number of graphite nodules in nodular cast iron can be increased obviously, the strength and toughness of the nodular cast iron can be improved, the chilling tendency of the nodular cast iron is relieved obviously, the nodularity, the number of graphite nodules and the number of ferrites ofthe nodular cast iron are increased, shrinkage in a casting process is eliminated, and complicated castings with excellent quality can be formed.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Molten metal oxidation resistance reducing agent

InactiveCN101215712AReduce scumSpeed up the flowWelding/cutting media/materialsSoldering mediaPhosphoric acidPhytic acid

The invention relates to metal melting antioxidative reducing agent, wherein the main component and the content of weight by parts comprises nonyl phenol polyoxyethylene thioether 51.19-91.19 parts, cyclohexylamine hydrobromate 5-20 parts, diphenyl guanidine hydrobromate 3-15 parts, phosphoric acid 0.3-5 parts, and phytic acid 0.5-8 parts, and further contains right amount of perfume compounds. The invention is oil liquid, since the invention is added with surface-active substance, when two liquids contact, relative / infrequent two-way molecular linkage can be generated, the surface tension of high-melting metal can be reduced, and simultaneously antioxidative reducing liquid is promoted to automatically diffuse rapidly. The invention is lighter than metal melting liquid, which can bespread whole flowing liquid and isolate air, and effectively prevent oxidation, while active substance and organic or inorganic acid which are contained in the invention can disperse inner gravity of oxygenized metal dross, take the initiative to break the inner structure of oxygenized metal dross, deacidize available metal, and deacidizing efficiency is about 95%, and the invention has high performance price ratio, less residual dross, cleanness and convenience, which is convenient for equipment maintenance.

Owner:SHENZHEN KUNQI XINHUA

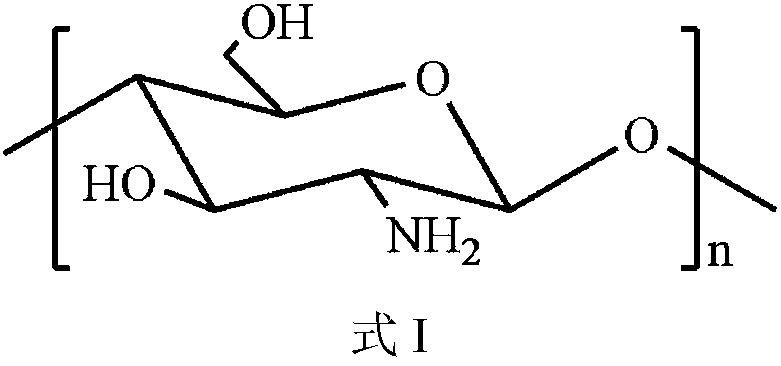

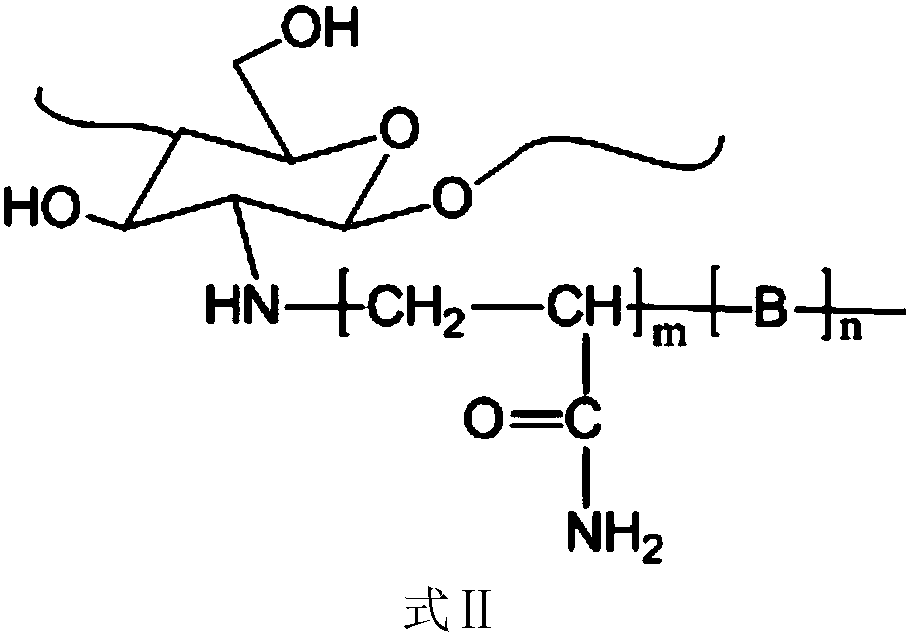

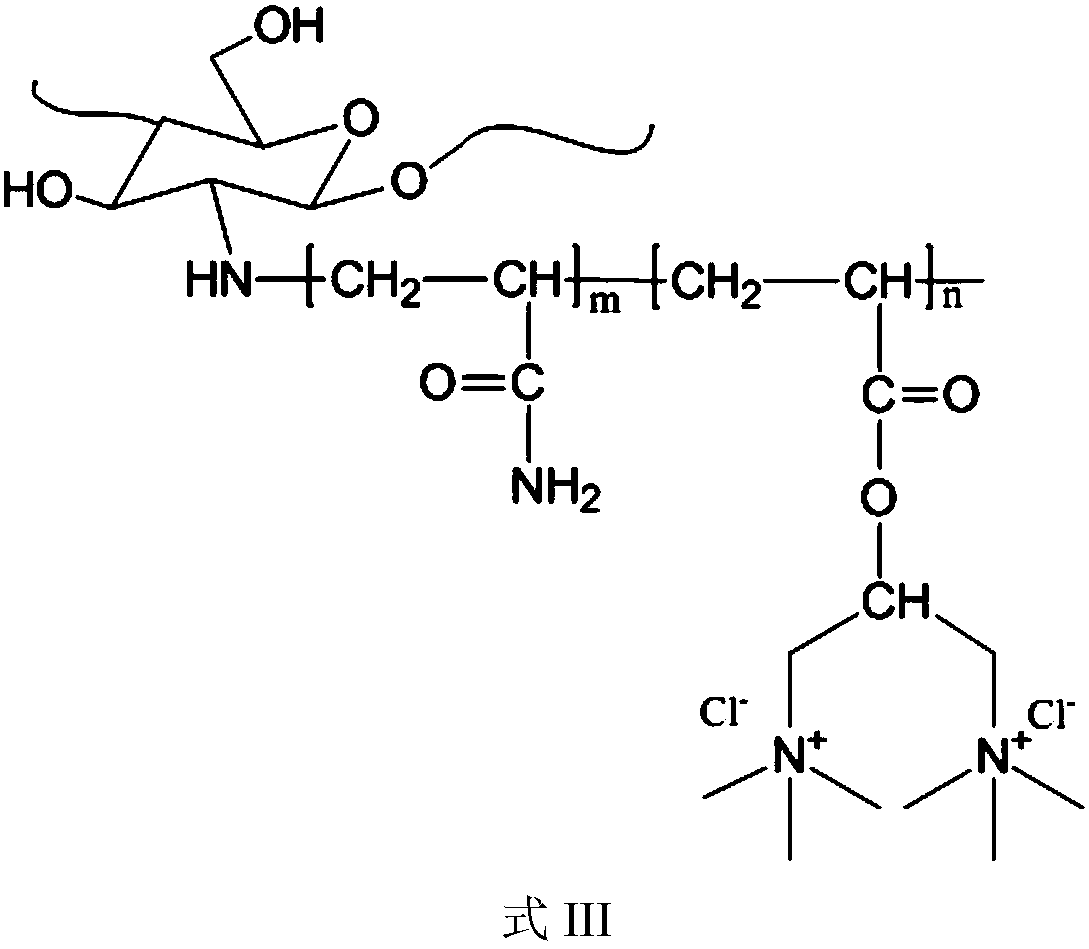

Chitosan flocculating agent, method for preparing same and application

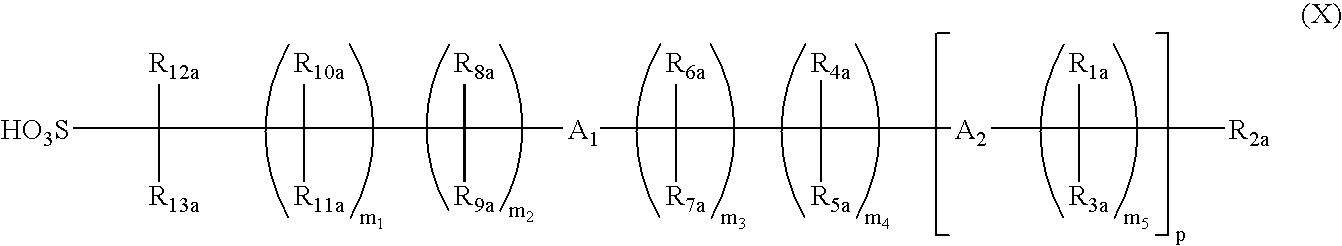

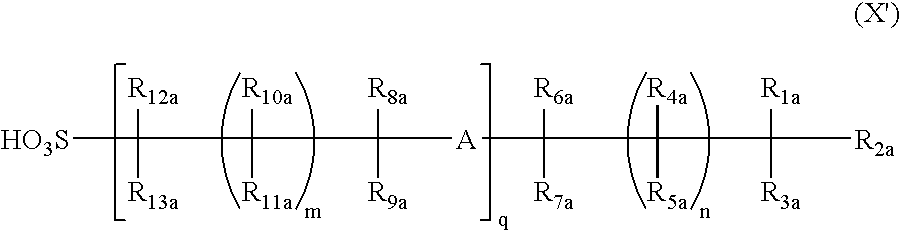

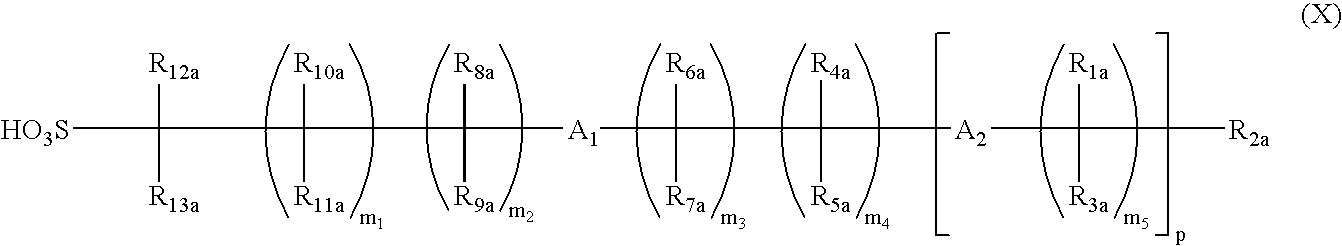

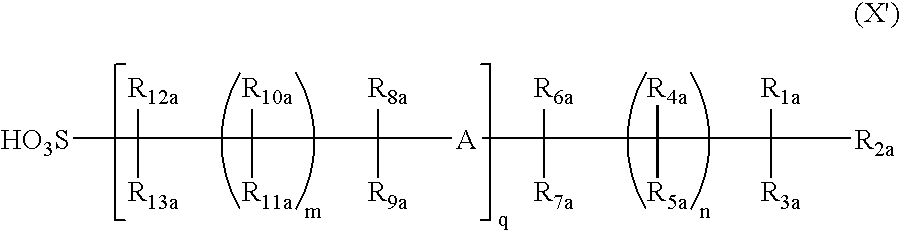

InactiveCN108264610AReduce dosageFast flocculationWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationFunctional monomerDouble bond

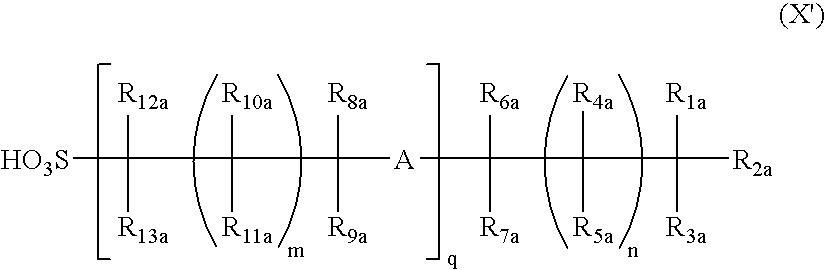

The invention provides a chitosan flocculating agent. A structural formula of the chitosan flocculating agent is shown as a formula II. A B in the formula II represents a functional monomer with biquaternary ammonium salt cations and unsaturated double bonds, and an m and an n in the formula II represent number-average degrees of polymerization. The invention further provides a method for preparing the chitosan flocculating agent. The method includes steps of 1), dissolving chitosan in ionic liquid and adding initiators into the ionic liquid under the protection of inert gas to obtain mixtures; 2), sequentially adding propylene acyloxy propane-1, 3-bis-trimethyl ammonium chloride and acrylamide into the mixtures obtained at the step 1), heating the propylene acyloxy propane-1, 3-bis-trimethyl ammonium chloride, the acrylamide and the mixtures and carrying out reaction to obtain products; 3), washing and filtering the products obtained at the step 2) and then drying the products to obtain the chitosan flocculating agent. The invention further provides application of the chitosan flocculating agent to the field of oilfield produced water purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Easily degraded molten metal oxidation resisting reducing agent

The invention discloses an easily degraded molten metal oxidation resisting reducing agent. The reducing agent comprises the following components of: Tween-80, malic acid, citric acid and water. The reducing agent has the advantages of easy degradation, high water solubility, high environmental protection performance and no halogen. The reducing agent also has the advantages of convenient use, easy operation, capability of playing the role in resisting oxidation and actively reducing at the same time, assistant improvement on binding ability of the molten metal, low cost, high cost performance, obvious effect, sustained effect, simple and convenient cleaning and optimized process.

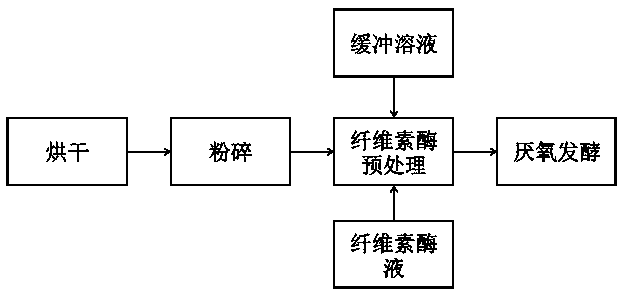

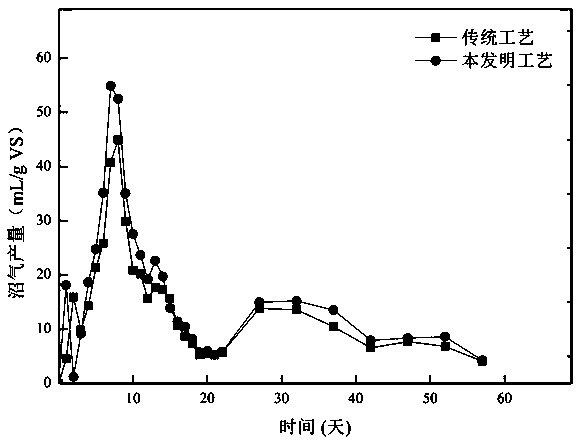

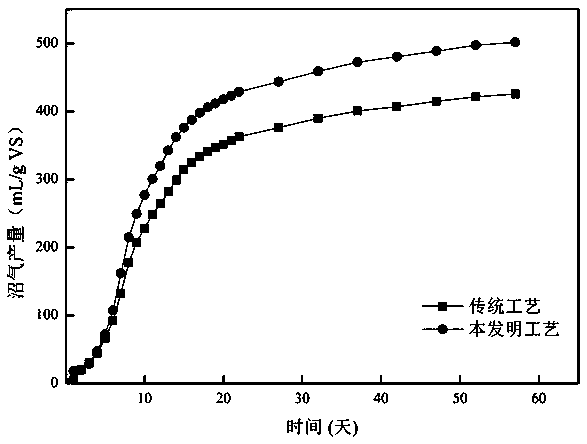

Lignocellulose anaerobic methane-producing pretreatment and fermentation technology

InactiveCN105506030AEffective hydrolysisIncrease concentrationWaste based fuelFermentationEngineeringMicrobiology

The invention relates to a lignocellulose anaerobic methane-producing pretreatment and fermentation technology. Pretreatment is conducted on lignocellulose through cellulase, and hydrolysis of the lignocellulose in the anaerobic fermentation process is facilitated. The technology comprises the steps that the moisture content of the raw materials is adjusted to below 10%; physical crushing is conducted on the lignocellulose through a crushing machine; the cellulase is added into the crushed lignocellulose; a buffer solution is added into lignocellulose and cellulase mixed liquor, and the solid content is controlled to blow 10%; a reaction is conducted for 72 h at 50 DEG C, and full stirring is conducted; an anaerobic fermentation inoculum is directly added into the lignocellulose and cellulase mixed liquor to be fermented, and the additive amount of dry matter of the inoculum is 50%-300% of that of the dry matter of the lignocellulose. According to the lignocellulose anaerobic methane-producing pretreatment and fermentation technology, the content of the cellulase inside a reactor can be increased, the content of the cellulase in the anaerobic fermentation process is increased, the efficiency of anaerobic fermentation is promoted, and the daily gas yield, the accumulated gas yield and the unit raw material gas yield are increased.

Owner:TONGJI UNIV

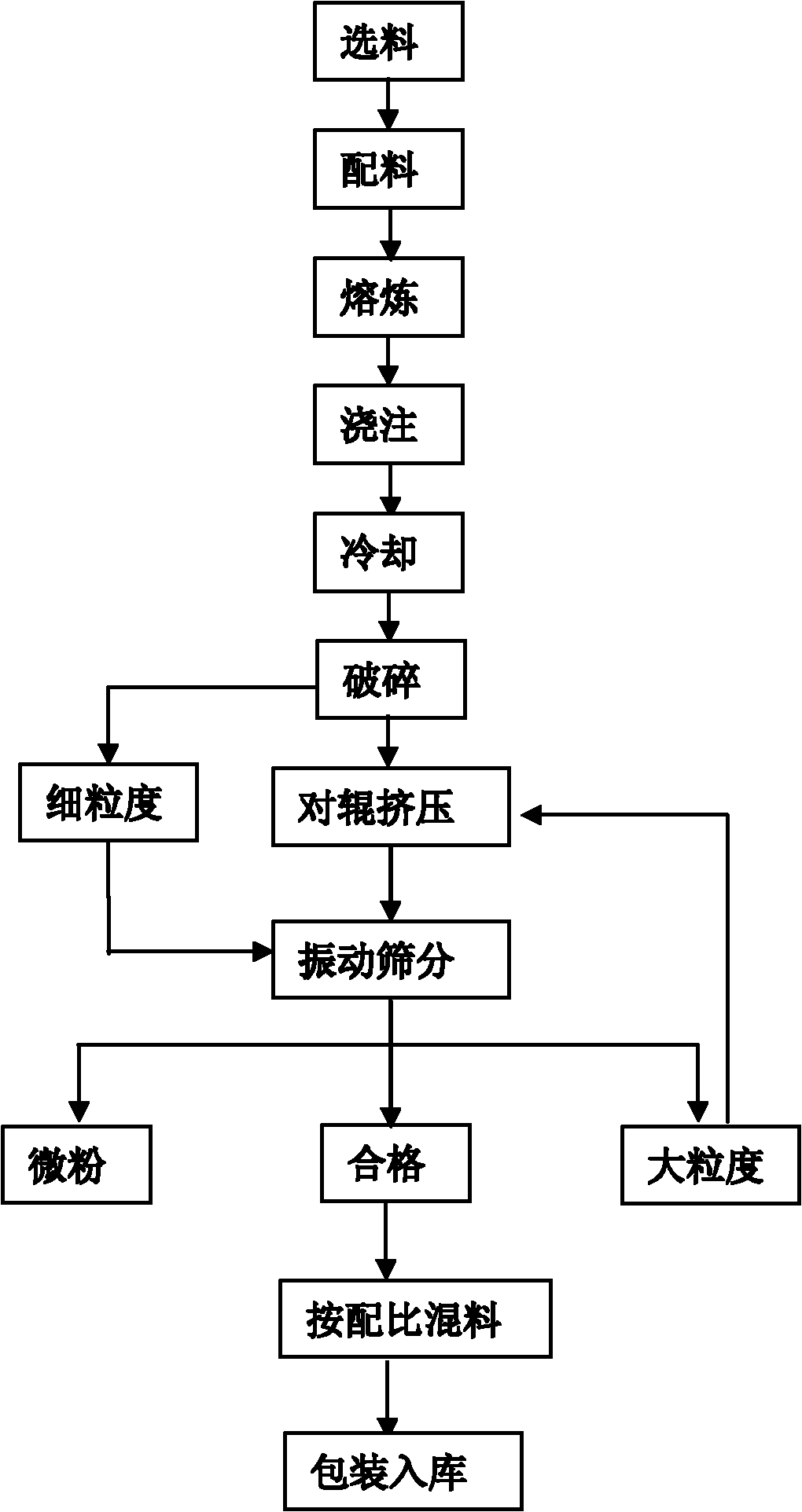

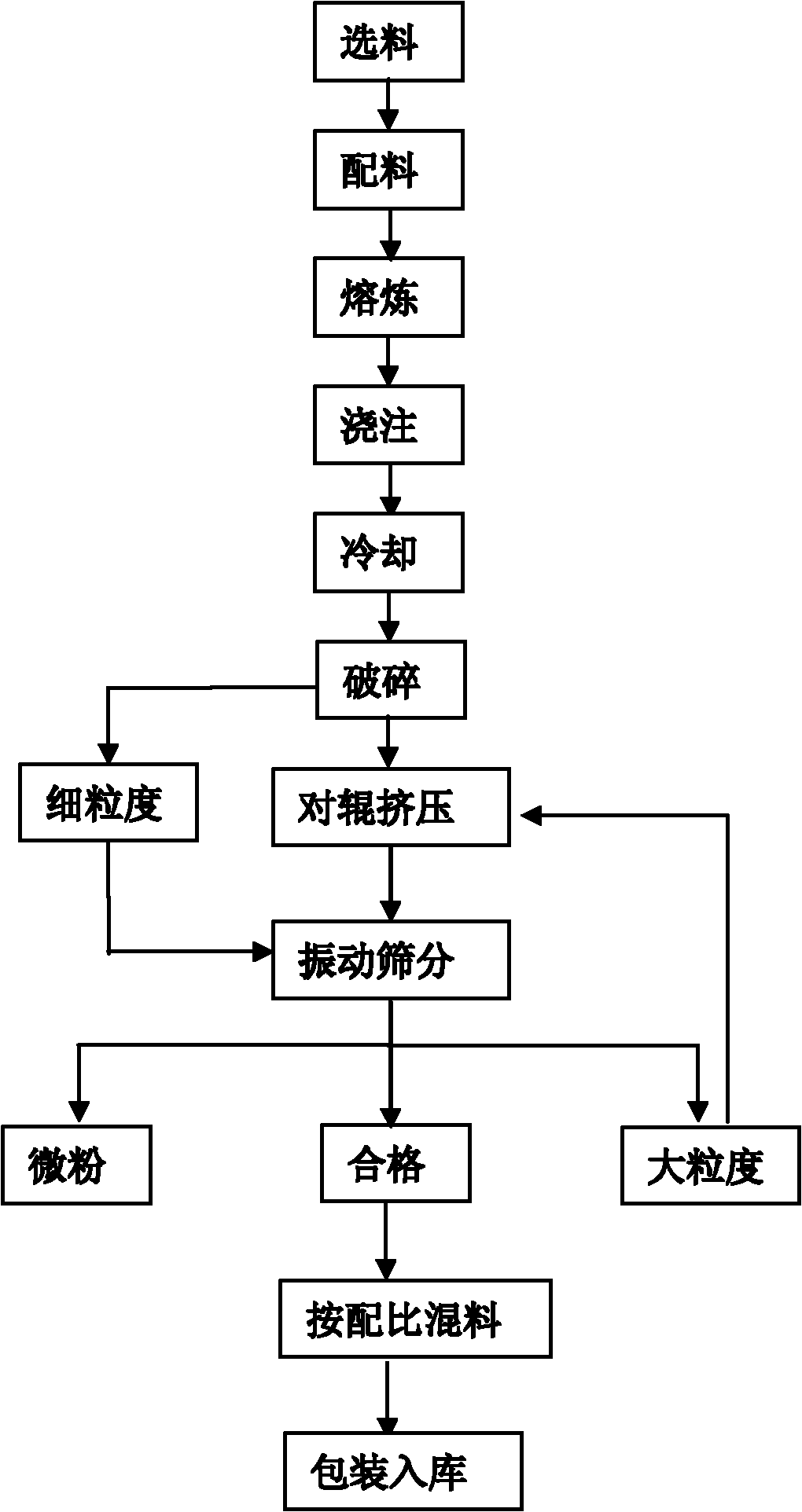

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

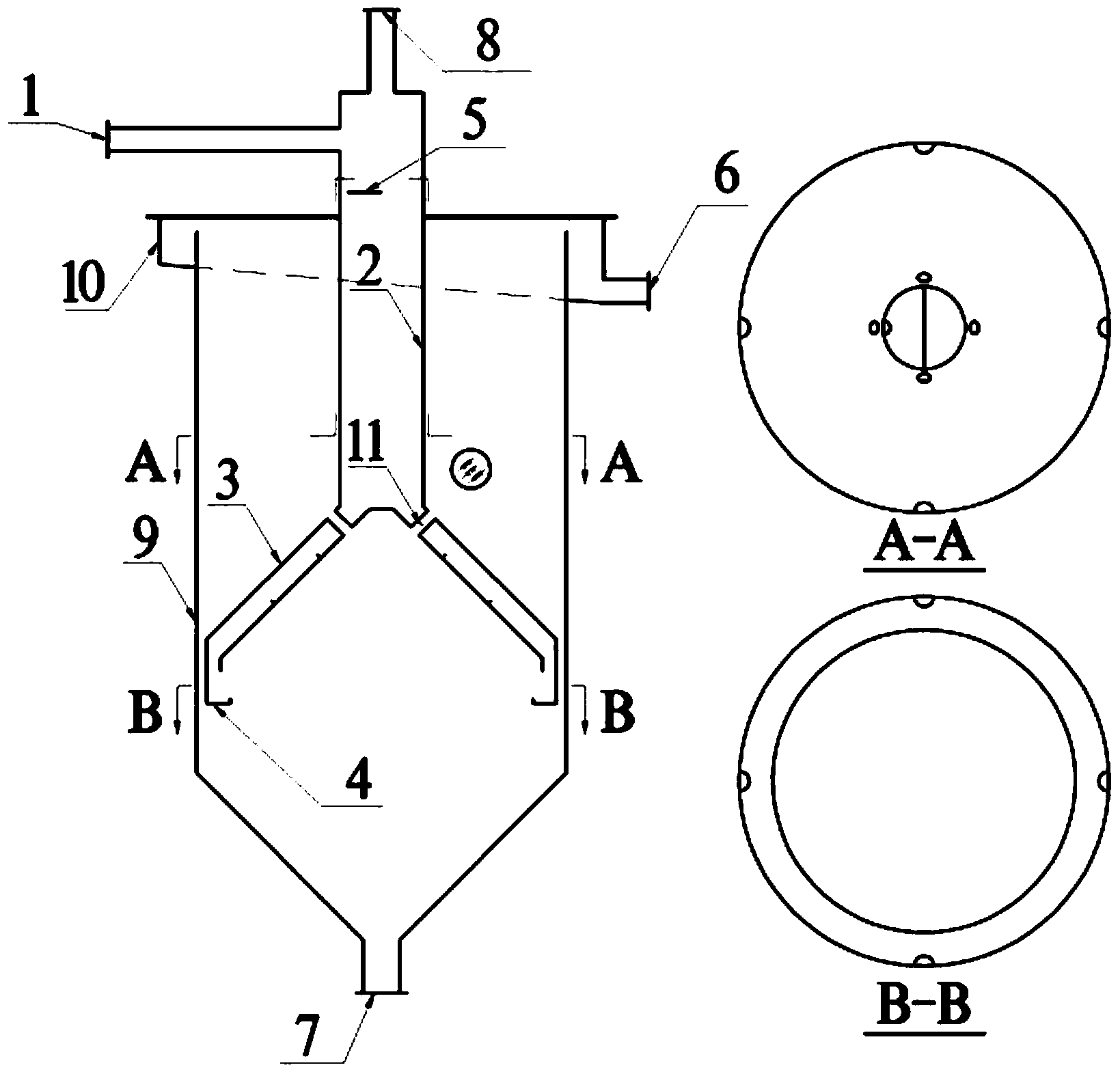

Quick precipitator for clarifying during sugar making

ActiveCN103961910AReduce flow rateSmall fluctuationPurification by physical meansSedimentation settling tanksFlocculationSludge

The invention provides a quick precipitator for clarifying during sugar making. The quick precipitator is characterized by comprising a cylinder body and a sugarcane juice flow guiding device, wherein a cavity is formed in the cylinder body and the cylinder body is composed of a cylinder and a taper hopper; an overflow trough is formed in the cavity at the upper end of the cylinder body, and is connected with a clear juice outlet; the lower end of the cylinder body is connected with a mud juice outlet pipe; the sugarcane juice flow guiding device takes the shape of an inverted funnel, and comprises a slowdown distributor, a gas disperse pipe, a gas disperse outlet pipe and a sugarcane juice inlet pipe; the slowdown distributor is fixedly connected with the gas disperse pipe; an opening is designed at the connecting part of the upper end of the slowdown distributor and the gas disperse pipe; the lower part of the slowdown distributor is fixedly connected with the inner wall of the cylinder body; the upper end of the gas disperse pipe is connected with the sugarcane juice inlet pipe and the gas disperse outlet pipe respectively; the sugarcane juice flow guiding device is positioned in the cavity of the cylinder body. The quick precipitator has an obvious clarifying effect, is good in flocculation effect, quick in settling, clear in discharged juice, few in floating sludge, high in efficiency and low in cost, and has a wide market prospect in the application of clarifying and solid-liquid separation of sugar juice in the sugar making field.

Owner:广西糖业集团防城精制糖有限公司

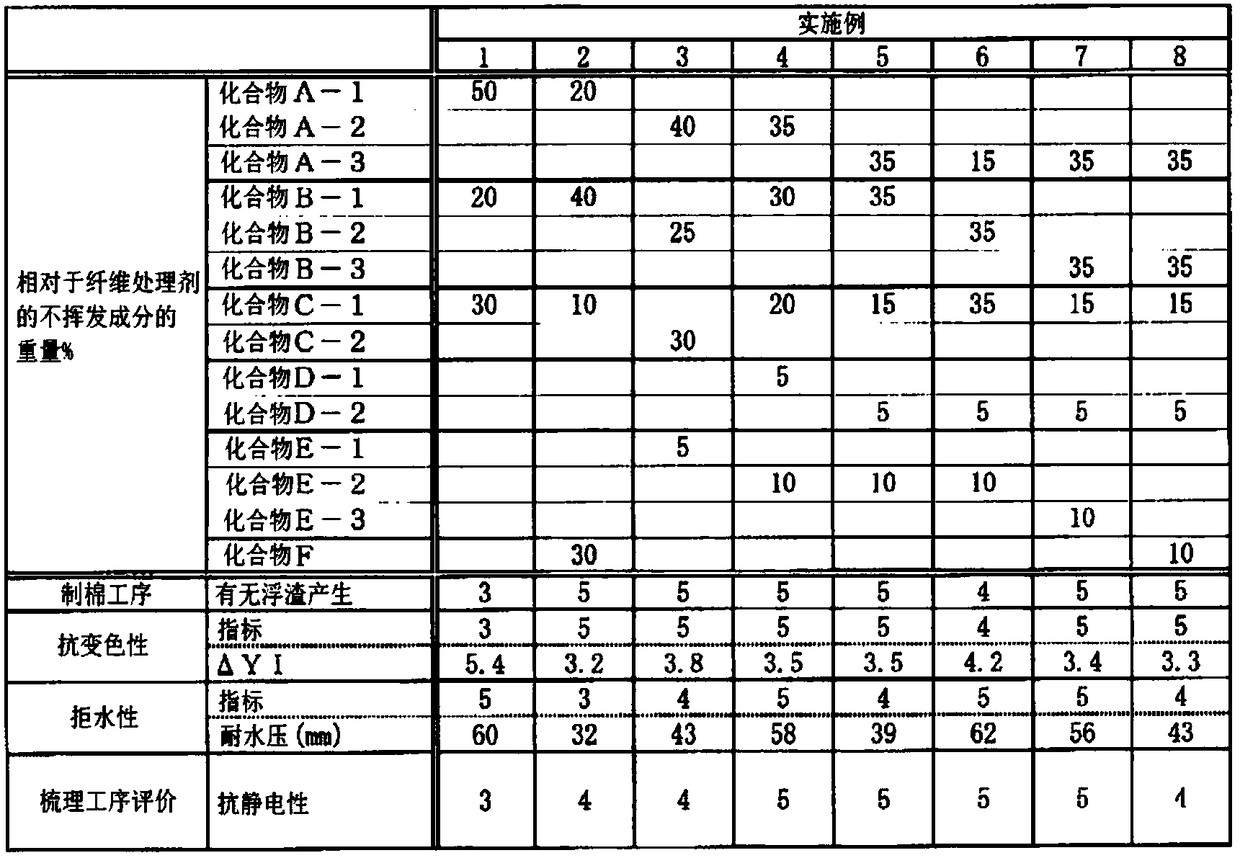

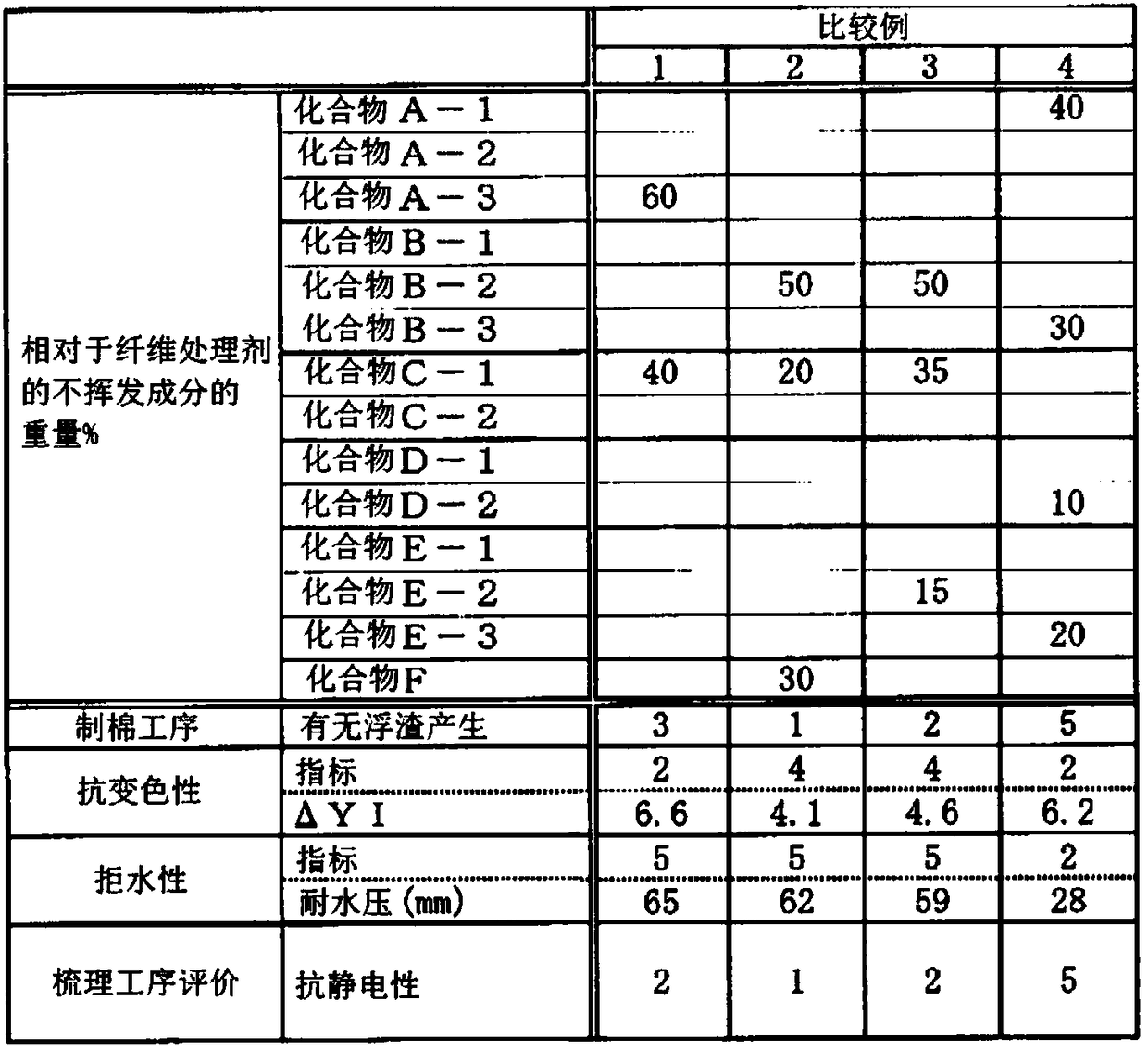

Fiber treating agent for staple fibers, and use for said agent

The present invention provides a fiber treating agent for staple fibers which excels in the ability to prevent discoloration of fibers and in which there is little occurrence of scum during milling. The present invention provides a fiber and a non-woven fabric to which the treating agent is bonded. A fiber treating agent for staple fibers, the fiber treating agent essentially containing a component (A), a component (B), and a component (C), wherein the proportion by weight of the component (A) in the nonvolatile component of the treating agent is 10-60%, the proportion by weight of the component (B) is 20-60%, and the proportion by weight of the component (C) is 5-40%. Component (A): an alkyl phosphate salt having a C14-22 hydrocarbon group and / or an alkyl phosphate salt containing a polyoxyalkylene group that has a C14-22 hydrocarbon group; component (B): an ester compound of alcohol having a C6-22 hydrocarbon group and a fatty acid having a C6-22 hydrocarbon group; component (C): a silicone compound.

Owner:MATSUMOTO YUSHI SEIYAKU

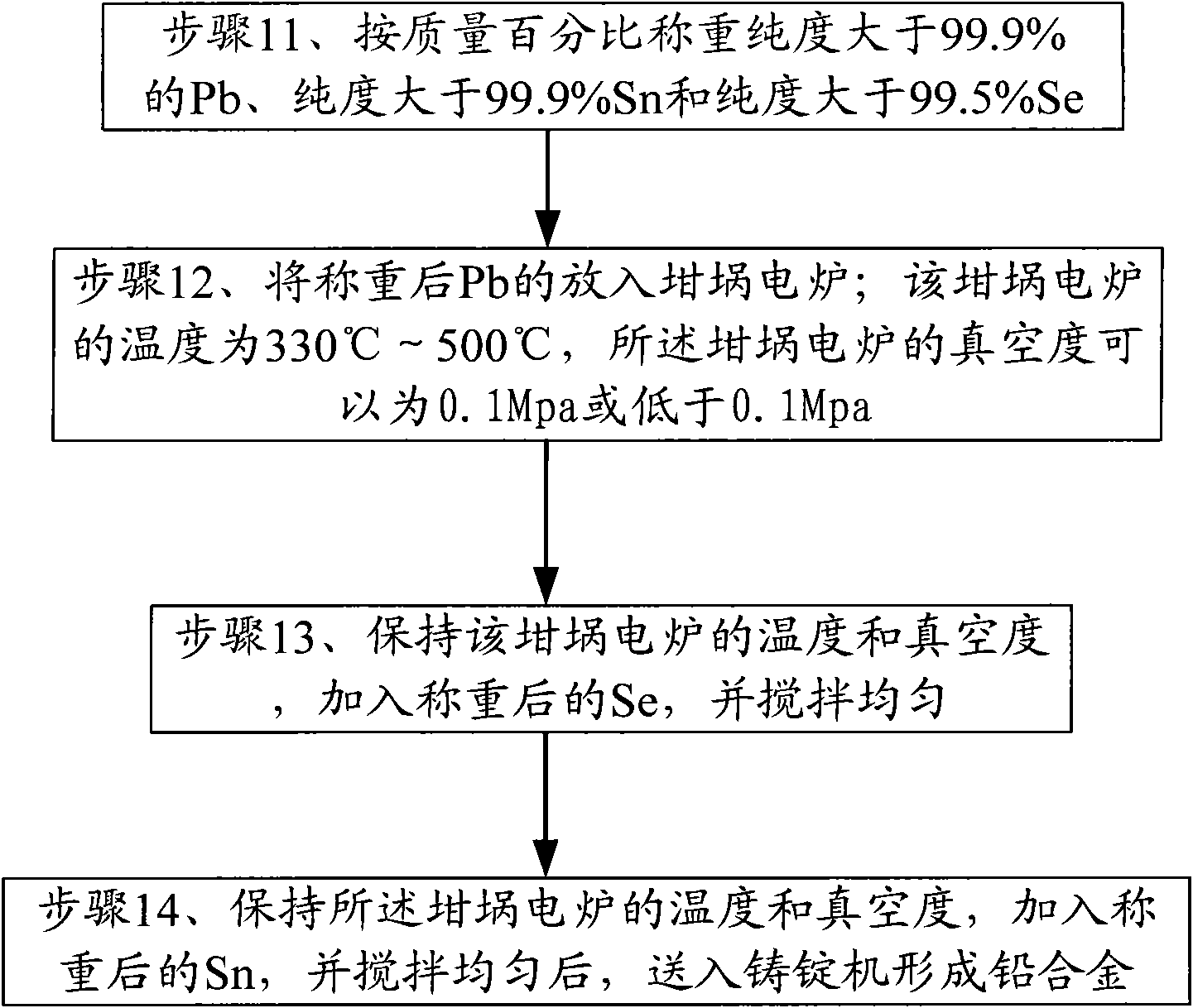

Aluminum alloy and applications and production method of aluminum alloy

The embodiment of the invention provides an aluminum alloy and application and a production method of the aluminum alloy and relates to the chemical field. The aluminum alloy includes: 0.1-2.0 percent of Sn; 0.001-1.0 percent of Se; and the balance of Pb. The purity of Sn is 99.9 percent or above, the purity of Se is 99.5 percent or above, and the purity of Pb is 99.9 percent or above. The specific embodiment also provides applications of the aluminum alloy and a production method thereof. The technical proposal provided by the invention has the advantages of good liquidity, corrosion resistance and prolonged service life of batteries.

Owner:ZHUZHOU SMELTER GRP +1

Deslagging agent for lead alloy smelting and preparation method thereof

The invention discloses a deslagging agent for lead alloy smelting. The deslagging agent comprises sodium nitrate and wood charcoal powder; the deslagging agent at least also comprises potassium permanganate and / or pyritic ash; the deslagging agent for lead alloys is formed by mixing the potassium permanganate and / or the pyritic ash with the sodium nitrate, wood charcoal powder and other deslagging agent components; through the potassium permanganate component, oxygen can be decomposed at a temperature of a melting point of lead and oxidation reaction on the oxygen and the wood charcoal is carried out, and a large amount of heat is produced to ensure that a temperature of a melting agent is quickly raised to reach a decomposition temperature of the sodium nitrate, and the sodium nitrate isfurther decomposed and the oxygen is released, and then oxidation reaction on the oxygen and the wood charcoal is carried out, so that a large amount of heat is produced, a slag temperature is further raised, and separation of slag and lead liquid is promoted; by adding the pyritic ash, copper harmful elements can be further removed in a smelting process.

Owner:ZHUZHOU CHUANGLIN ALLOY

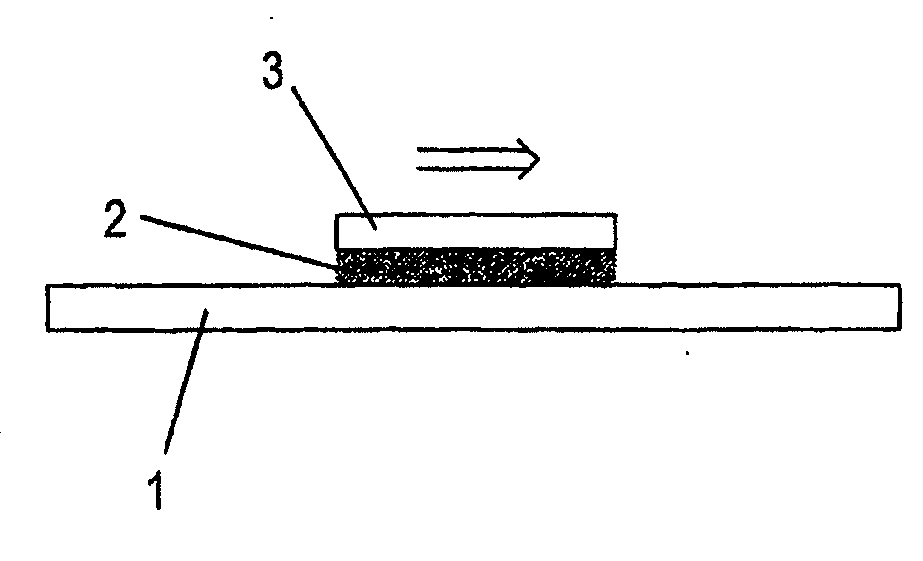

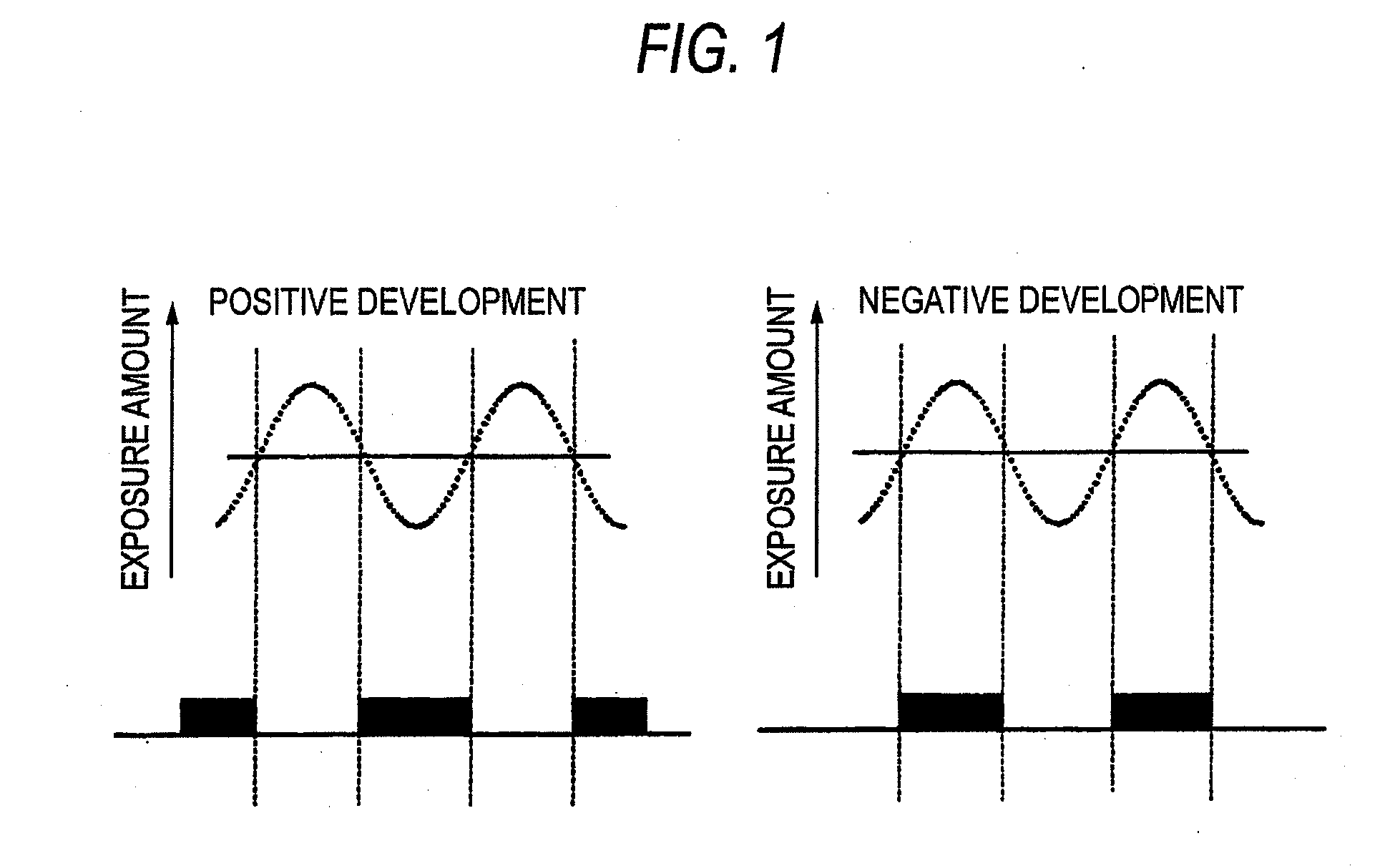

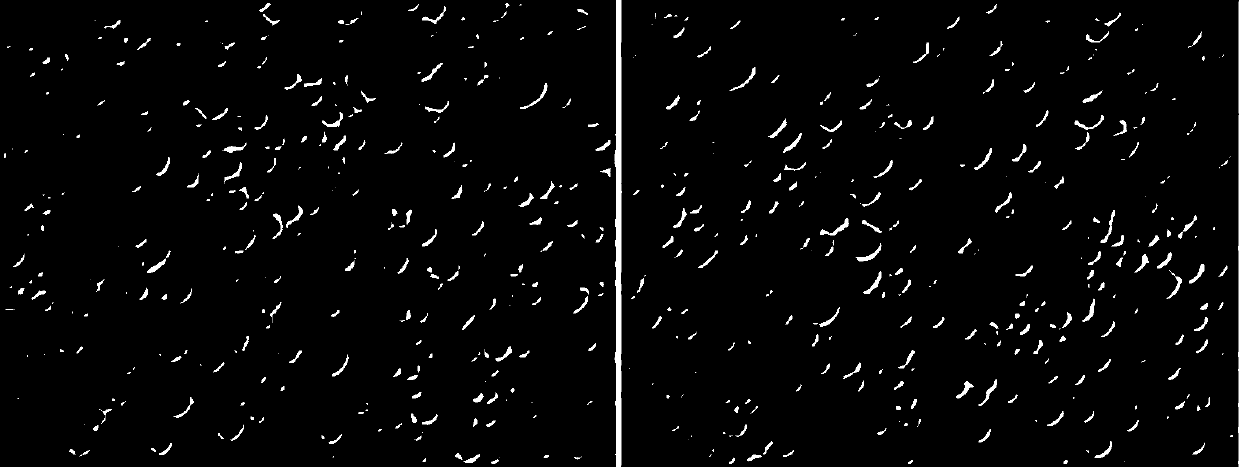

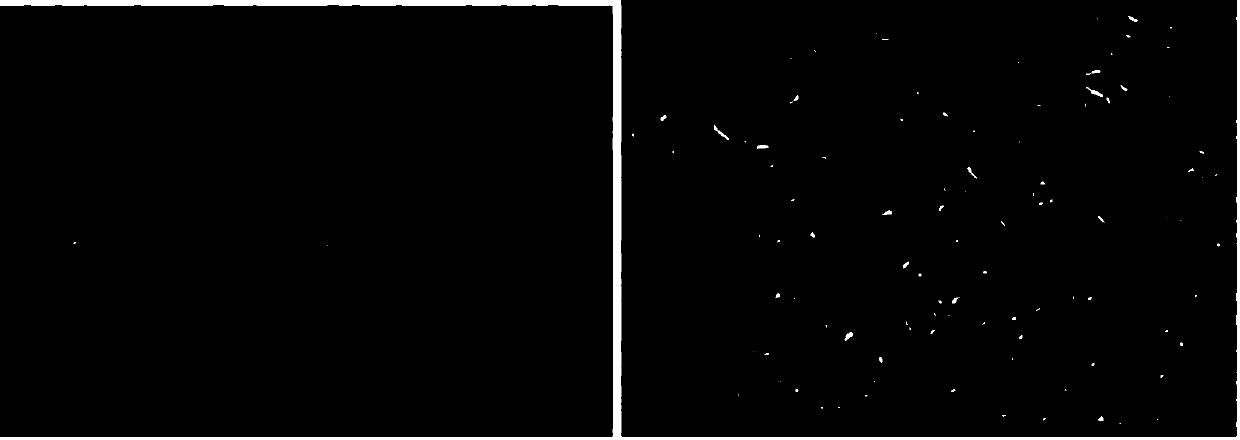

Method of forming patterns

ActiveUS20110076625A1Reduce scumReduce roughnessRadiation applicationsSemiconductor/solid-state device manufacturingActinic RaysRay

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

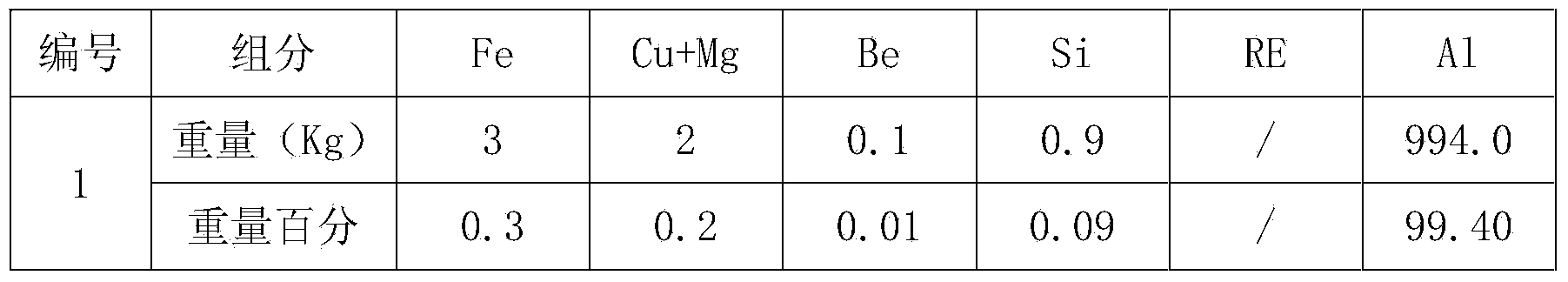

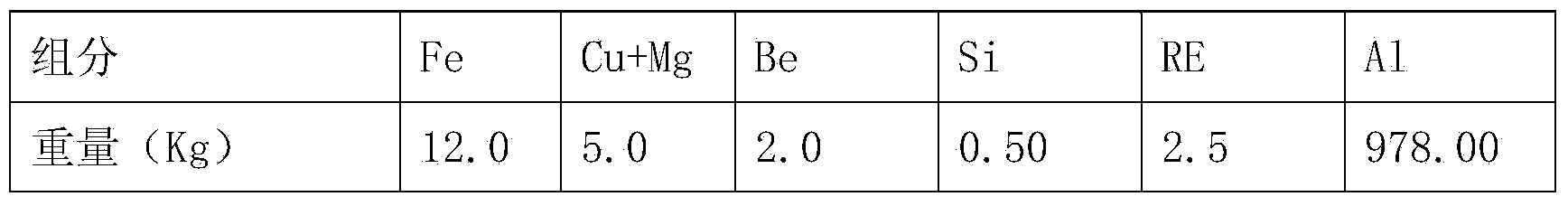

Al-Fe-Cu-Mg-Be alumium alloy for automobile wire and wiring harness therefore

PendingCN103725930AHigh mechanical strengthImprove tensile propertiesNon-insulated conductorsMetal/alloy conductorsSurface finishUltimate tensile strength

The invention discloses an Al-Fe-Cu-Mg-Be alumium alloy for an automobile wire and a preparation method thereof, and an automobile wiring harness prepared by the preparation method. The Al-Fe-Cu-Mg-Be alumium alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu+Mg, 0.001-0.2wt% of Be, and the balance of Al and inevitable impurities. According to the invention, Fe element is added so that the mechanical strength and the tensile property of the alloy can be improved; Fe is also capable of obviously improving the high-temperature creep resistance and the fatigue resistance of the alloy; the addition of Cu+Mg is capable of improving the strength and the high-temperature creep property and the fatigue resistance of the alloy; Be is capable of improving the smelting quality of the alloy and the compactness of the surface oxide film, so that good-quality castings good in surface smoothness, high in strength and improved in ductility can be obtained; Be is also capable of improving the fluidity of the alloy so that the fluidity of the melt is improved, and can further improve the tensile strength and the limit of yielding of the alloy.

Owner:ANHUI JOY SENSE CABLE

Water-based fluorine-containing polymer dispersed emulsion and preparation method thereof

The invention relates to a water-based fluorine-containing polymer dispersed emulsion and a preparation method thereof. The method comprises the following steps: 1) adding deionized water, an initiator and an emulsifier into a high-pressure kettle, and introducing a fluorine-containing monomer mixture to carry out polymerization reaction, wherein a pH regulator is continuously added in the polymerization process to control the pH value of the polymerization system at 7-8; and 2) after the polymerization reaction finishes, adding a surfactant into the fluorine-containing polymer dispersed emulsion, and concentrating in a water bath, wherein the pH regulator is continuously added in the concentration process to keep the pH value of the concentration system at 7-8. The method effectively reduces the iron ion content in the emulsion, thereby reducing the scum of the fluorine-containing polymer dispersed emulsion, and effectively improving the appearance of the fluorine-containing dispersed emulsion. The added pH regulator can be effectively removed in the construction process, and thus, can not pollute the product.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Method of forming patterns

ActiveUS8632942B2Reduce scumReduce roughnessPhotosensitive materialsPhotoprinting processesActinic RaysFluence

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

Negative pattern forming method and resist pattern

ActiveUS20130266777A1Reduce scumExcellent performanceDecorative surface effectsDuplicating/marking methodsSolventActinic Rays

A negative pattern forming method, includes: (i) forming a film having a film thickness of 200 nm or more from a chemical amplification resist composition containing (A) a resin capable of increasing a polarity of the resin (A) by an action of an acid to decrease a solubility of the resin (A) for a developer containing one or more organic solvents, (B) a compound capable of generating an acid upon irradiation with an actinic ray or radiation, and (C) a solvent; (ii) exposing the film, so as to form an exposed film; and (iii) developing the exposed film with a developer containing one or more organic solvents.

Owner:FUJIFILM CORP

Reductant composition and preparation method thereof, and welding method

InactiveCN103212921AReduce scumSpeed up the flowWelding/cutting media/materialsSoldering mediaTherapeutic effectReducing agent

The invention provides a reductant composition which comprises a nonionic surfactant, an antioxidant and ammonium metaphosphate. Meanwhile, the invention further discloses a preparation method of the reductant composition and a welding method. The reductant composition provided by the invention used in wave-soldering is excellent in scum treatment effect, and convenient and safe to use.

Owner:SHENZHEN KUNQI XINHUA

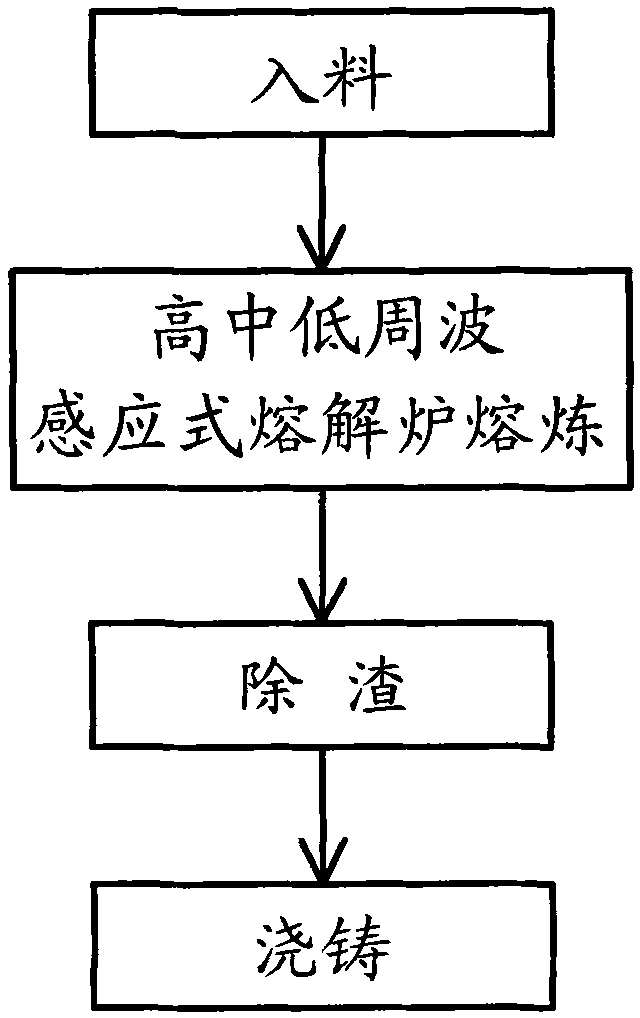

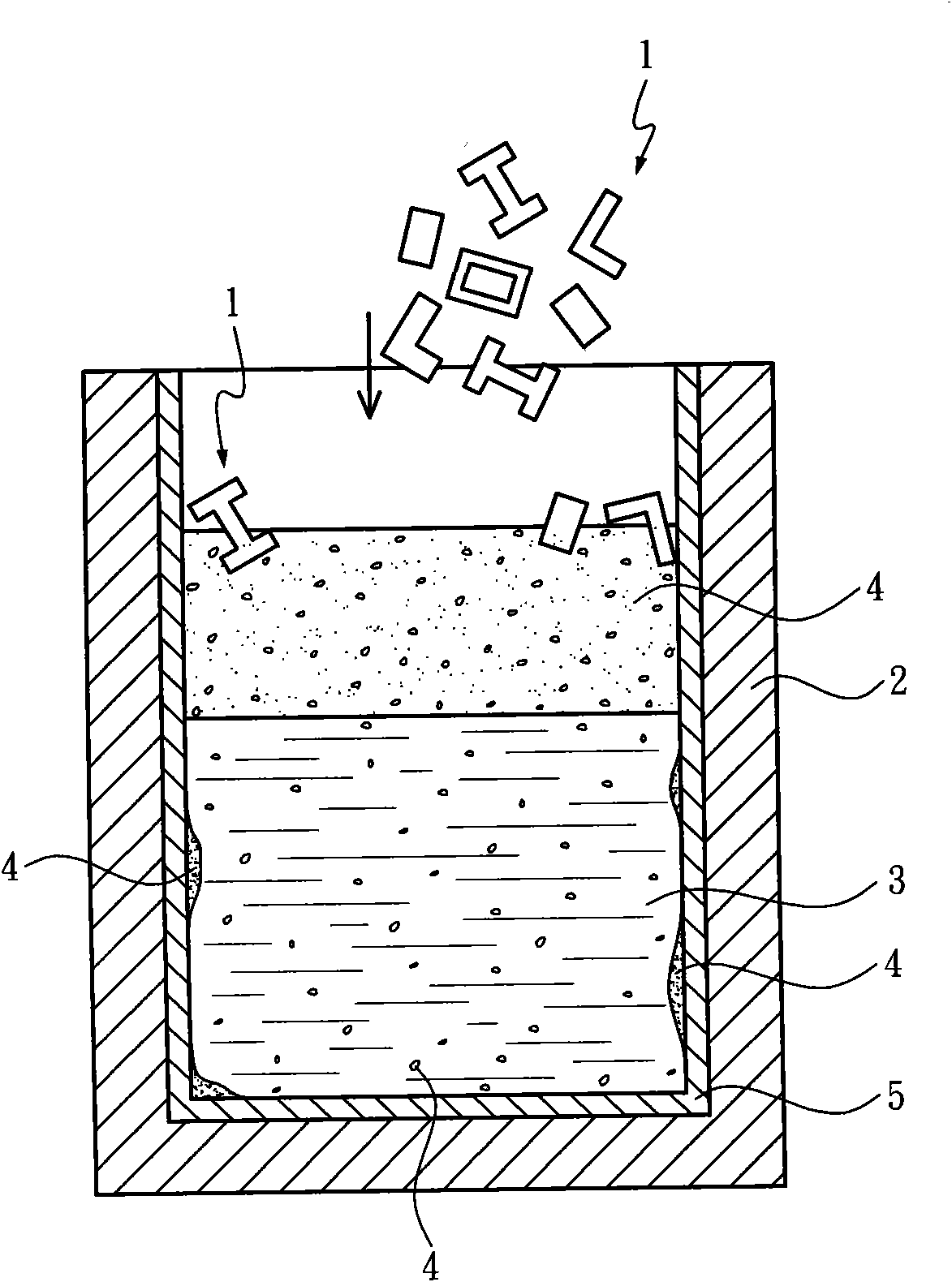

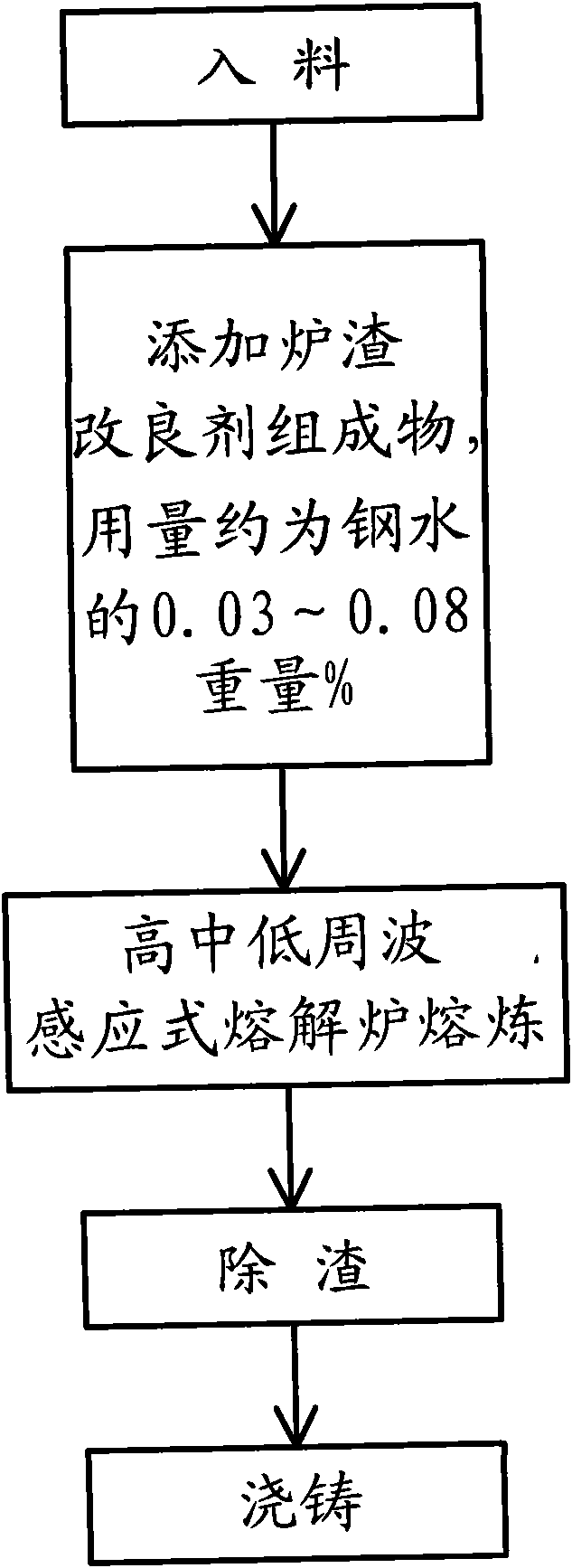

Cinder modifier composition for casting and use method thereof

InactiveCN102443684AReduce scumPrevent distance fromProcess efficiency improvementManganese oxideSlag

The invention provides a cinder modifier composition for casting and use method thereof. The composition substantially consists of calcium oxide CaO, sodium oxide Na2O, aluminum oxide Al2O3, silica SiO2 and ferric oxide Fe2O3; the invention further provides the use method of the modifier composition in the casting process, thereby reacting the composition with the oxides in the cinder ingredientssuch as ferric oxide, magnesium oxide and manganese oxide, rising the alkalinity degree of the cinder to weaken the bonding force of the ingredients in the cinder to soften the cinder, so that the occurrence of bridging is avoided, the durability of the liner of the induction melting furnace and the purification rate of the molten steel are improved.

Owner:NEW CHIEN TE HANG

Chemical reinforcing type positive photoresist composition

InactiveCN1366212AIncreased sensitivityHigh resolutionRadiation applicationsPhotosensitive materials for photomechanical apparatusImage resolutionPolypropylene glycol

The present invention provides a chemically enhanced positive photoresist composition with excellent sensitivity and resolution, and demonstrated to be scum-free, comprising polymerized units derived from hydroxystyrene and derived from (methyl styrene) ) The resin of the polymerized unit of 2-ethyl-2-adamantyl acrylate, the resin itself is insoluble or hardly soluble in alkali, but becomes alkali soluble after dissociating the above acid-labile group by the action of acid ; a radiation-sensitive acid generator; and polypropylene glycol.

Owner:SUMITOMO CHEM CO LTD

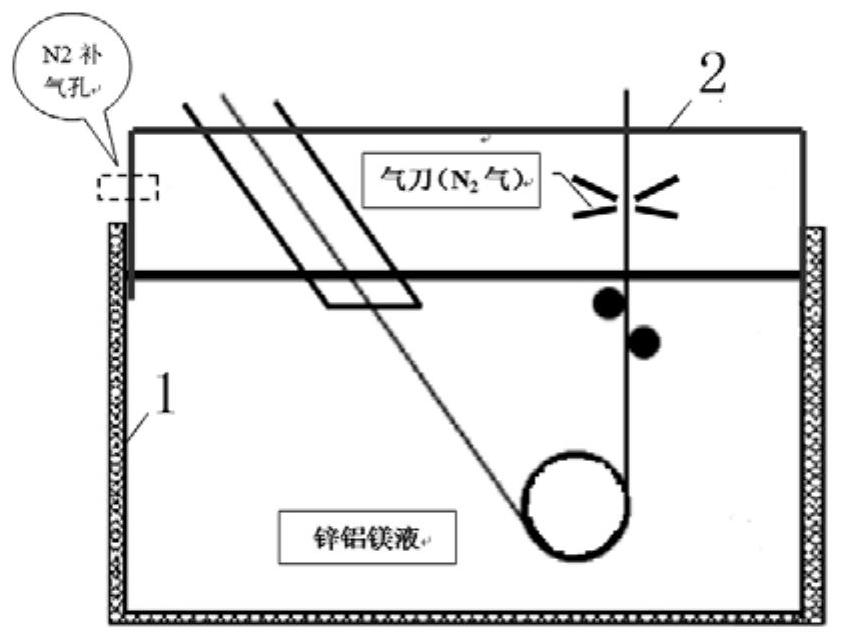

Magnesium oxidation protection method for hot-dip galvanized aluminum magnesium alloy coating product

PendingCN113529000AReasonable designReduce the effects of oxidationHot-dipping/immersion processesProduction lineStrip steel

The invention discloses a magnesium oxidation protection method for a hot-dip galvanized aluminum magnesium alloy coating product. The magnesium oxidation protection method comprises the following steps that (1), a protection cover is additionally arranged above a zinc-aluminum-magnesium pot, and the size and the shape of a protection cover body can be customized according to the spatial positions of zinc-aluminum-magnesium pot areas of different galvanizing production lines; (2), nitrogen brought by an air knife in the production process is fully utilized and collected in the protection cover, and the liquid level of a zinc pot and the surface of strip steel are protected; and (3), a nitrogen supplementing hole is additionally formed in the protection cover, the nitrogen supplementing amount of the supplementing hole is controlled according to the pressure detection value in the protection cover, and gas in the cover is kept in a positive pressure state. N2 brought by the air knife and supplemented N2 are collected in the box body to keep positive pressure. N2 in the protection cover reduces the influence of O2 oxidation in air on the liquid level of the zinc pot and the surface of the strip steel, so that the purpose of reducing scums on the surface of the plating liquid level and avoiding the quality problems of surface defects such as surface black spots caused by Mg oxidation on the surface of the strip steel is achieved, and the product quality is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com