Magnesium oxidation protection method for hot-dip galvanized aluminum magnesium alloy coating product

An aluminum-magnesium alloy and oxidation protection technology, applied in the field of metallurgy, can solve the problems of poor coating quality, dark and rough coating surface, etc., achieve reasonable design and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

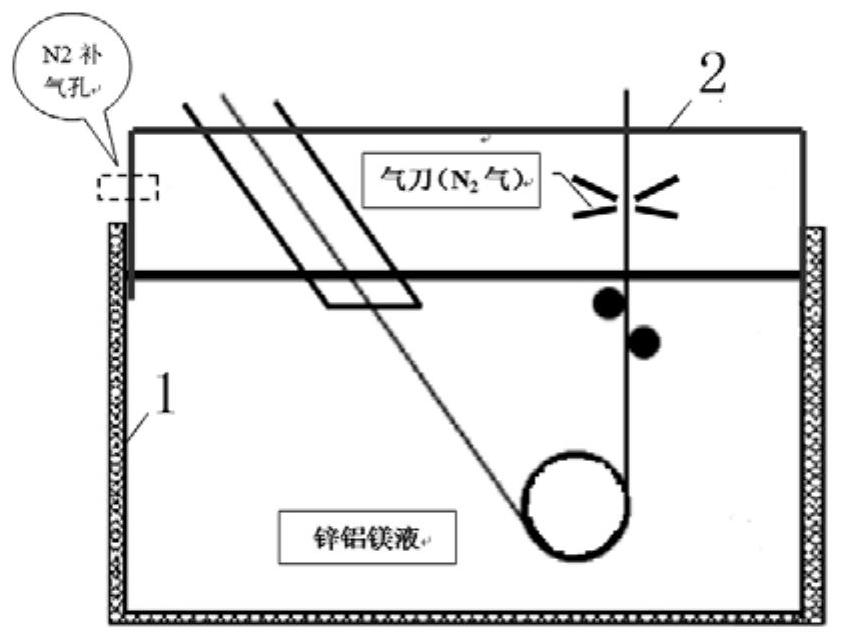

[0024] Such as figure 1 As shown, the magnesium oxidation protection method of the hot-dip galvanized aluminum-magnesium alloy coating product comprises the following steps:

[0025] A protective cover 2 is added above the zinc-aluminum-magnesium pot 1. The size and shape of the protective cover can be customized according to the spatial position of the zinc-aluminum-magnesium pot area of different galvanizing production lines;

[0026] Make full use of the nitrogen brought by the air knife during the production process, and collect the nitrogen in the protective cover to protect the liquid surface of the zinc pot and the surface of the strip;

[0027] A nitrogen replenishment hole is added to the protective cover 2. According to the pressure detection value in the protective cover, the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com