Chemical reinforcing type positive photoresist composition

A positive photoresist, enhanced technology, applied in optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc., can solve the problem of scum generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

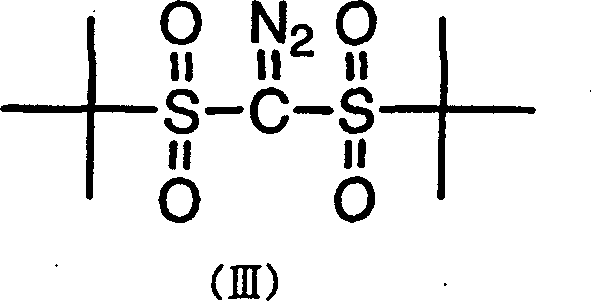

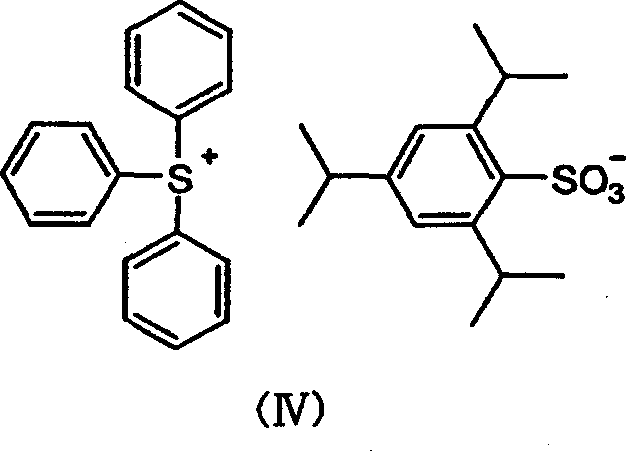

[0008] The resin component of the photoresist composition of the present invention basically has two kinds of polymerized units, namely, a polymerized unit derived from hydroxystyrene and a polymerized unit derived from 2-ethyl-2-adamantyl (meth)acrylate . Although the resin component itself is insoluble or hardly soluble in alkali, it is chemically changed by the action of acid to become alkali-soluble. These polymerized units are formed by opening the double bonds in the styrene moiety and the double bonds in the (meth)acrylic acid moiety, specifically represented by the following formulas (I) and (II):

[0009] where R 1 Represents a hydrogen atom or a methyl group, R 2 Indicates ethyl.

[0010] In the hydroxystyrene unit of formula (I), the positional relationship between the hydroxyl group and the vinyl group is not particularly limited, but p-hydroxystyrene is generally used.

[0011] A resin having polymerized units derived from hydroxystyrene and polymerized unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com