Chitosan flocculating agent, method for preparing same and application

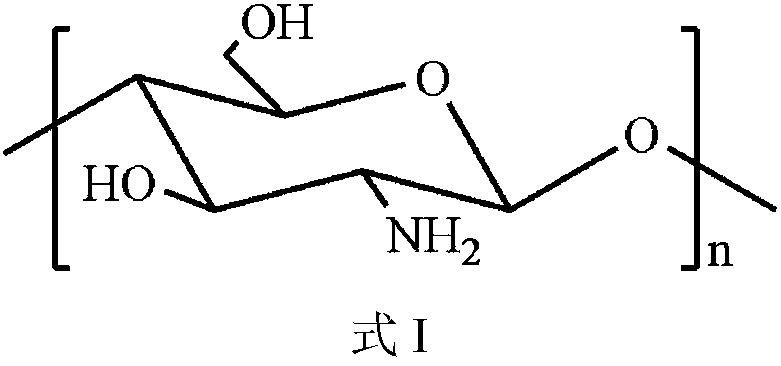

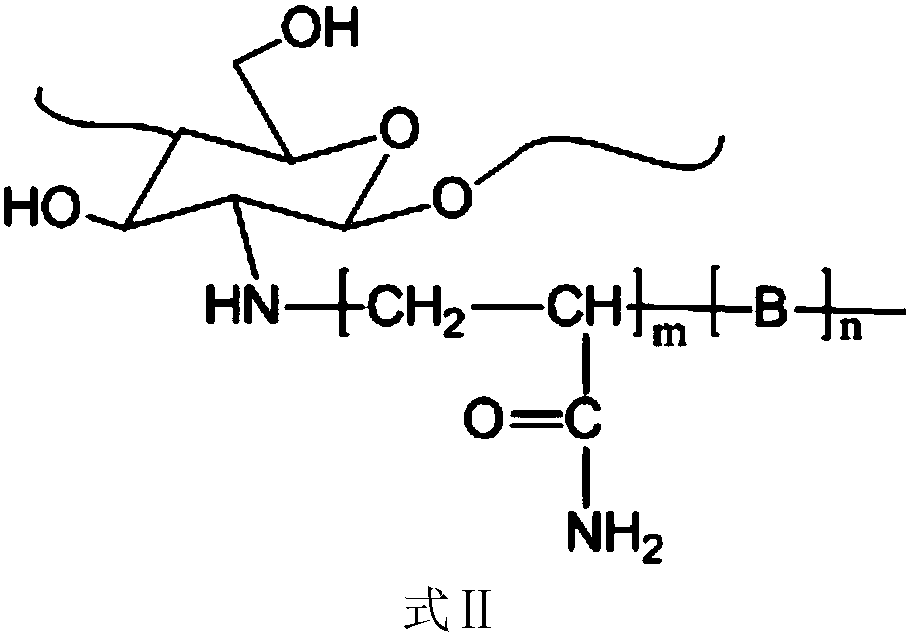

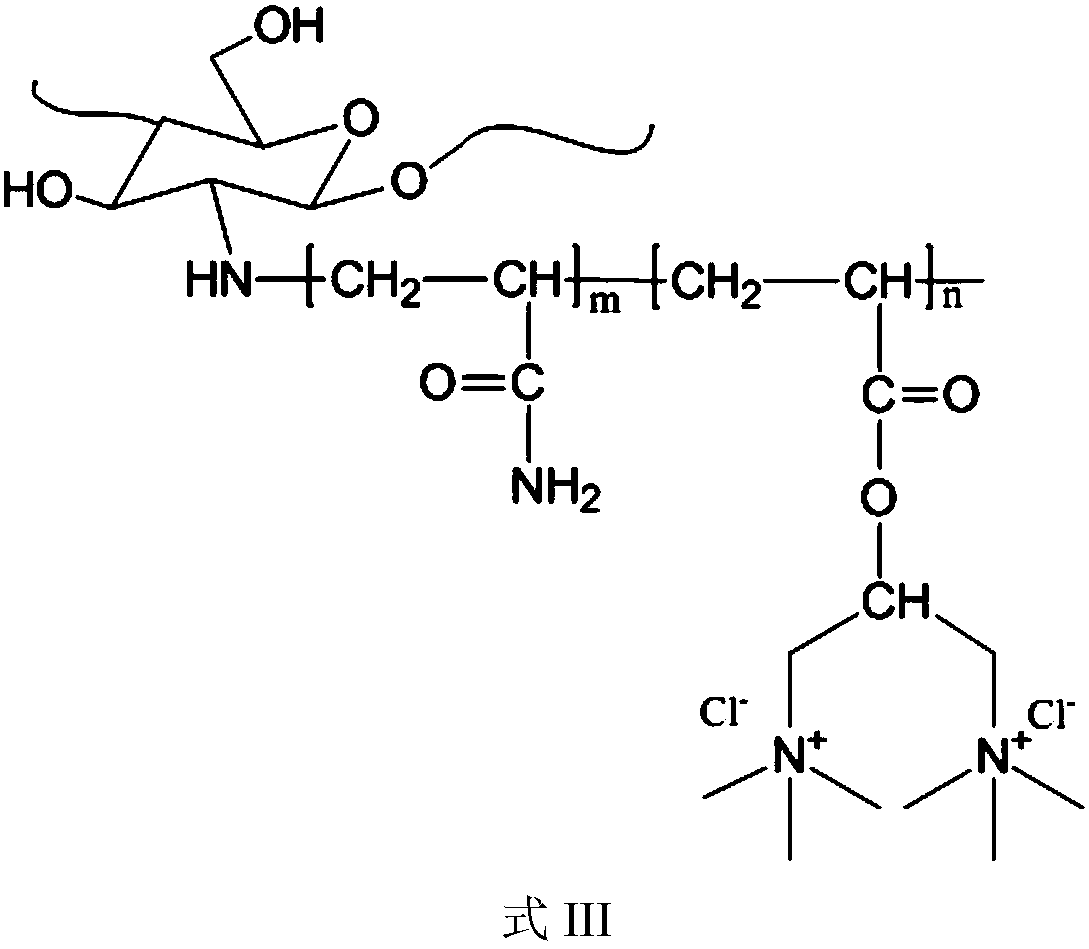

A technology of chitosan and flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problem of complex water quality that cannot adapt to the oil concentration of oilfield produced water, difficult to apply oilfield produced water treatment, flocculant flocculation effect Limited problems, to achieve the effect of shortening the settling time, improving water solubility and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] At room temperature, 3 g of chitosan with a viscosity-average molecular weight of 850,000 and a degree of deacetylation of 85% was dissolved in 100 ml of a 0.5% glycine hydrochloride ionic liquid aqueous solution, and stirred until the chitosan was completely dissolved. Under the protection of nitrogen, the initiator potassium persulfate (the addition amount is 2% of the chitosan unit moles) was added. Add PBC solution and AM solution successively (the mass ratio of monomer to chitosan is 10:1, and the mass ratio of PBC and AM in monomer is 1:1). After the dropwise addition, react at 60°C for 6h. Then use acetone as a precipitant to precipitate and separate the product and dry it to obtain a chitosan flocculant. It is proved by testing that AM and PBC are grafted on chitosan.

[0041] The solubility of the chitosan flocculant measured at 25°C was greater than 5%, and the grafting rate was 91%. Use it to treat the produced water of an oilfield containing 100mg / L of sus...

Embodiment 2

[0043]At room temperature, 3 g of chitosan with a viscosity-average molecular weight of 750,000 and a degree of deacetylation of 85% was dissolved in 100 ml of a 2% glycine hydrochloride ionic liquid aqueous solution, and stirred until the chitosan was completely dissolved. Under the protection of nitrogen, the initiator potassium persulfate (the addition amount is 2% of the chitosan unit moles) was added. Add PBC solution and AM solution successively (the mass ratio of monomer and chitosan is 10:1, and the mass ratio of PBC and AM in monomer is 1:10). After the dropwise addition, react at 60° C. for 4 h. Then use acetone as a precipitating agent to precipitate and separate the product and dry it to obtain chitosan flocculant.

[0044] The solubility of the chitosan flocculant measured at 25°C was greater than 5%, and the grafting rate was 87%. Use it to treat the produced water of an oilfield containing 20mg / L of suspended solids, add the flocculant 2-10mg / L, the water samp...

Embodiment 3

[0046] At room temperature, 3 g of chitosan with a viscosity-average molecular weight of 850,000 and a degree of deacetylation of 85% was dissolved in 100 ml of a 0.5% glycine hydrochloride ionic liquid aqueous solution, and stirred until the chitosan was completely dissolved. Under the protection of nitrogen, the initiator potassium persulfate (the addition amount is 2% of the chitosan unit moles) was added. Add PBC solution and AM solution successively (the mass ratio of monomer to chitosan is 1:1, and the mass ratio of PBC and AM in the monomer is 1:1). After the dropwise addition, react at 60° C. for 5 h. Then use acetone as a precipitating agent to precipitate and separate the product and dry it to obtain chitosan flocculant.

[0047] The solubility of the chitosan flocculant measured at 25°C was greater than 5%, and the grafting rate was 96%. Use it to treat the produced water of an oilfield containing 1000mg / L of suspended solids, add the flocculant 5-20mg / L, the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com