Patents

Literature

231results about How to "Fast flocculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing high-purity vanadium pentoxide from roasting-method vanadium solution

The invention discloses a method of preparing high-purity vanadium pentoxide from roasting-method vanadium solution. The method comprises the following steps: adding a purifying agent into the roasting-method vanadium solution, wherein the purifying agent is polyaluminium chloride, magnesium chloride or calcium chloride, or the purifying agent is polyaluminium chloride and magnesium chloride, or polyaluminium chloride and calcium chloride; uniformly stirring the roasting-method vanadium solution containing the purifying agent, standing for settling, then filtering, and adding ammonium salt into the filtrate to precipitate vanadium; and finally, calcining meta-ammonium and deaminizing to prepare vanadium pentoxide with the purity being higher than 99.5%. Polyaluminium chloride serving as the purifying agent can be used for polymerizing jellies with several molecules into large particles with several tens of thousands of molecules, even hundreds of thousands of molecules. The large-particle molecular polymer is easy to settle in the vanadium solution and can be separated from the solution. The method provided by the invention has the advantages that the consumption of polyaluminium chloride is low, the flocculation process is simple, the flocculation capacity is strong, the flocculation speed is high, pollution is hardly caused and the cost is low.

Owner:贵州义信矿业有限公司

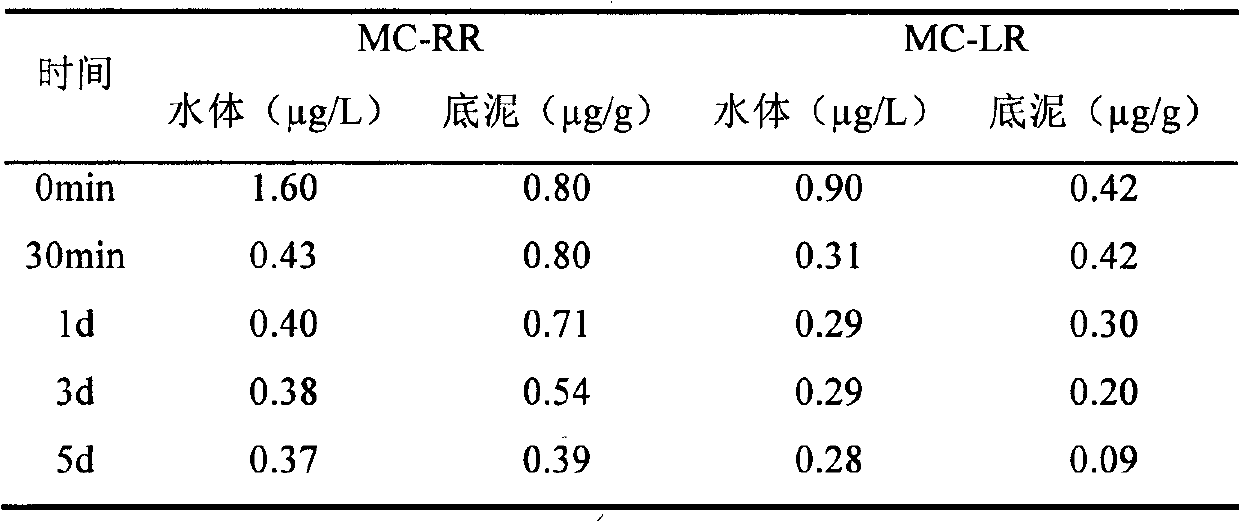

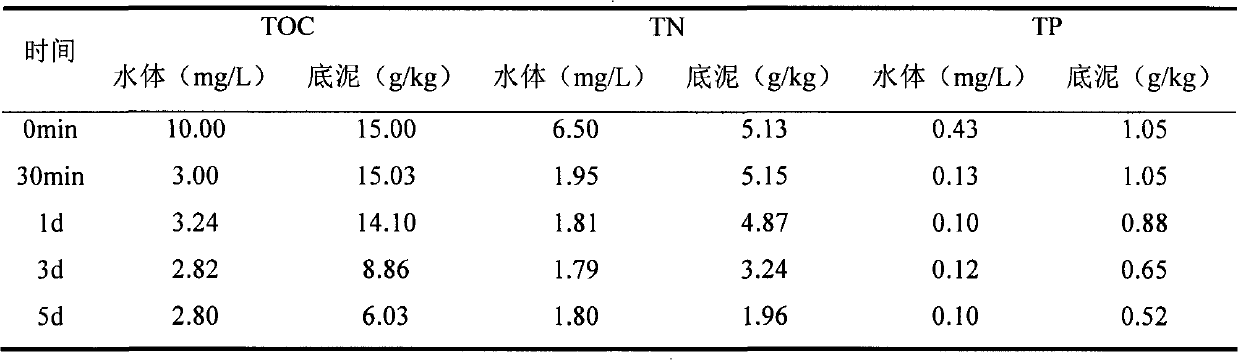

Material and method for repairing polluted water and bottom mud

InactiveCN102674562AHigh transparencyFast flocculationOn/in inorganic carrierBiological sludge treatmentFlocculationParticulates

The invention provides a material and a method for repairing polluted water and bottom mud. Specifically, nontoxic and innoxious solid particulates are adopted and are loaded with microbes according to a certain method before preparing a composite material; the composite material is used for in-situ flocculation or adsorption of pollutants in water, and transfers the pollutants to the bottom mud, so as to realize in-situ collection and concentration of the pollutants in water and fast degradation in the bottom mud; and after settling to the bottom mud, the composite material can also degrade pollutants in the bottom mud, so as to improve the water quality bottom matter environment. The invention can be applied to the comprehensive repairing of shallow water type lakes, slow flow river channels, small-sized reservoirs, wetlands and ponds which are eutrophicated or seriously polluted by organic substances.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

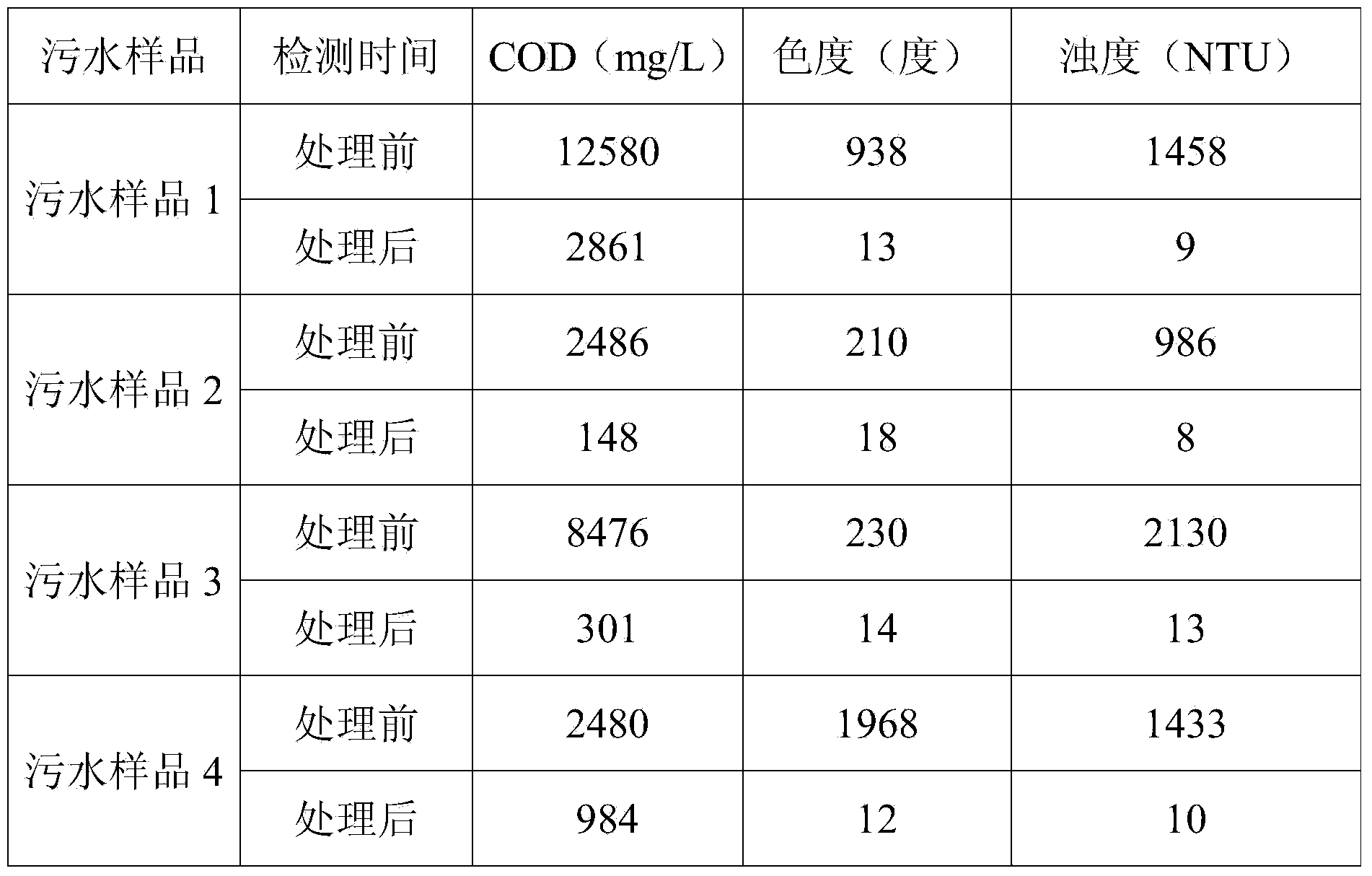

Flocculating agent for waste water treatment, and preparation method thereof

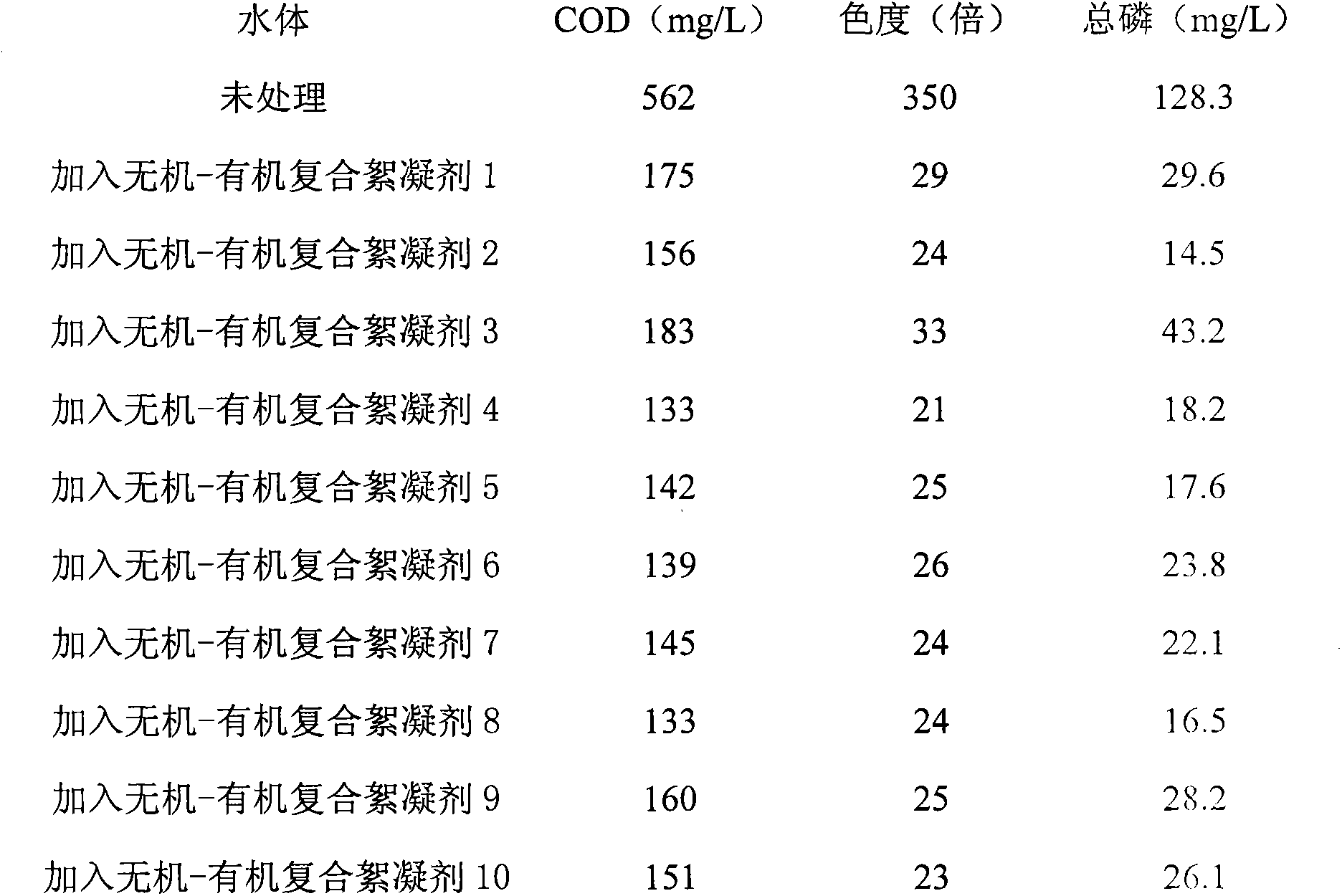

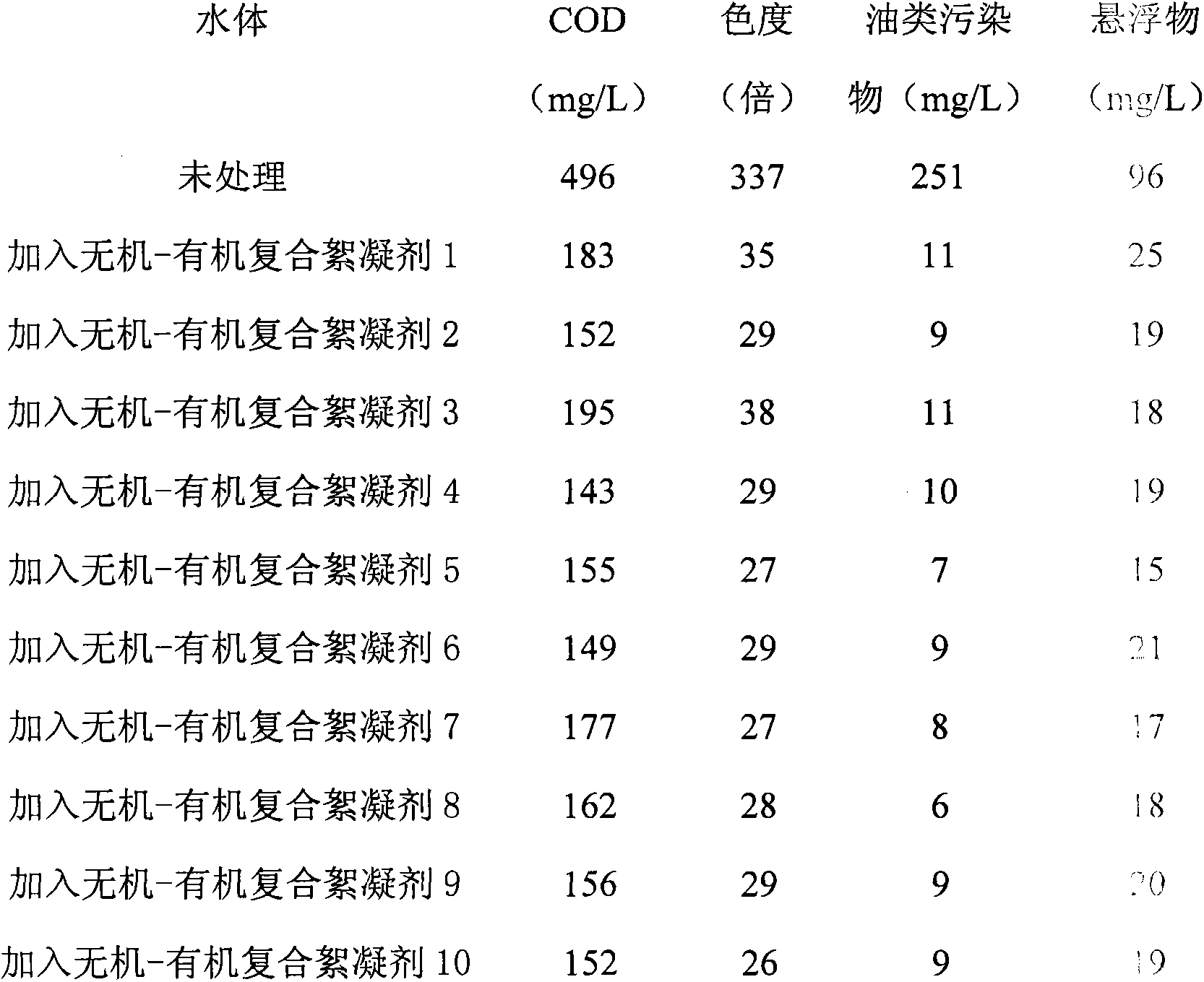

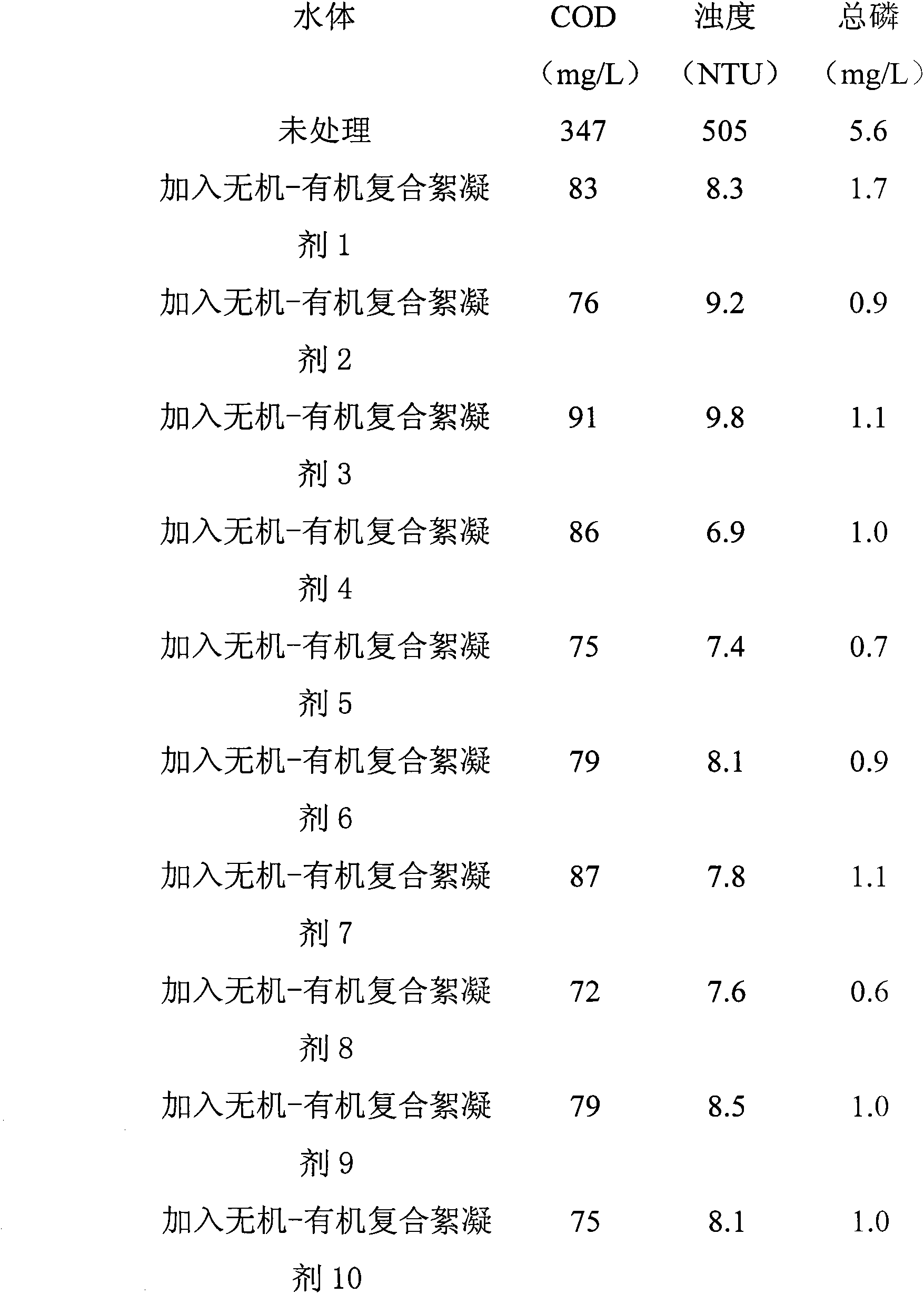

InactiveCN104071881AReduce CODReduce chromaWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminum IonTurbidity

The invention discloses a flocculating agent for waste water treatment. The flocculating agent comprises components of calcium sulfate, aluminum ion salt, sodium carbonate, polyacrylamide, sodium thiosulfate, chitosan, chitosan quaternary ammonium salt, diatomite, cement and a pH adjusting agent, can be used for treating waste water discharged from food processing plants, metal manufacturing plants, chemical plants and the like, can also be used for treating waste water discharged from farms and slaughter plants, can also be used for purification of water quality in river channels and lakes, and can effectively reduce COD, color and turbidity of waste water.

Owner:廉勇

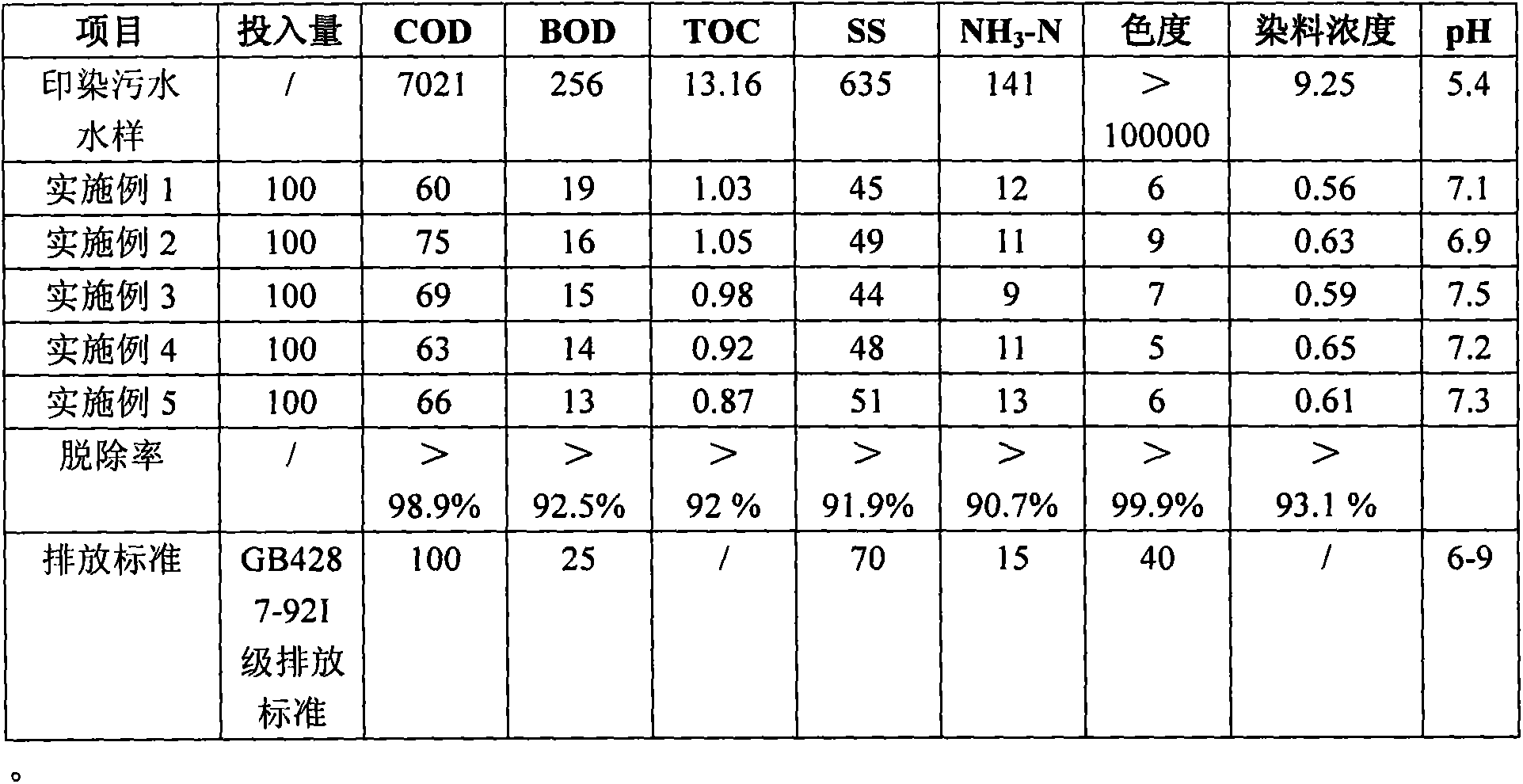

Dyeing wastewater treatment agent and preparation method thereof

InactiveCN103708593ASustainable processingHigh chromaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDyeing wastewaterPollution

The invention relates to the technical field of wastewater treatment, and particularly relates to a dyeing wastewater treatment agent and a preparation method thereof. The dyeing wastewater treatment agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 0.5-2 parts of polyacrylamide, 10-20 parts of iron nitrate, 1-5 parts of nickel nitrate, 40-60 parts of polyaluminum chloride, 10-20 parts of modified kieselguhr, 8-22 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 5-10 parts of chitosan-graphene composite material and 1-3 parts of graphene nano layer / MnO2 compound. The dyeing wastewater treatment agent provided by the invention has the advantages of convenient production method, low investment, quick effect taking and no secondary pollution.

Owner:HANDAN COLLEGE

Method for compressing marine microalgae

InactiveCN101095459AFast flocculationVigorousDead plant preservationAnimal feeding stuffFlocculationOrganic acid

The invention relates to a method for condensing ocean micro-algae, which comprises following steps: adding organic acid solution of chitosan into micro-algae culture solution to make the chitosan solution concentration in micro-algae culture solution be 0.3-8.0 mg / l, adjusting micro-algae culture solution pH to be 4.5-8.5 for micro-algae flocculation, collecting floccule with static hierarchical or gas-floating method. The invention is characterized by non-toxic chitosan, simple solution preparation, fast flocculation speed, good activity of flocculated micro-algae. The micro-algae can be dispersed into single cells in water after a certain time of storage, and can be used for breeding as algae seed. The chitosan can improve the animal immunity, and micro-algae can be used in foodstuff and medical treatment field.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

Dyeing wastewater treating agent and manufacturing method thereof

InactiveCN105152296AReduce COD valueGood processing effectWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationChemistryTreatment effect

The invention discloses a dyeing wastewater treating agent and a manufacturing method thereof. The dyeing wastewater treating agent is prepared from the following raw materials in parts by mass: 70-100 parts of diatomite, 40-70 parts of attapulgite, 90-120 parts of modified starch, 15-40 parts of acrylamide, 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 10-25 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 0.5-2 parts of polyacrylamide, 20-30 parts of cationic monomer, 0.17-0.21 part of initiator and 0.09-0.1 part of crosslinking agent. The treating agent can perform the flocculating settling purification and disinfection functions on the dyeing wastewater, has the characteristics of wide raw material sources, lower cost and favorable treatment effect, and is convenient for popularization and application.

Owner:杨洋

Composite reagent for deep removal of heavy metals in wastewater and preparation method thereof

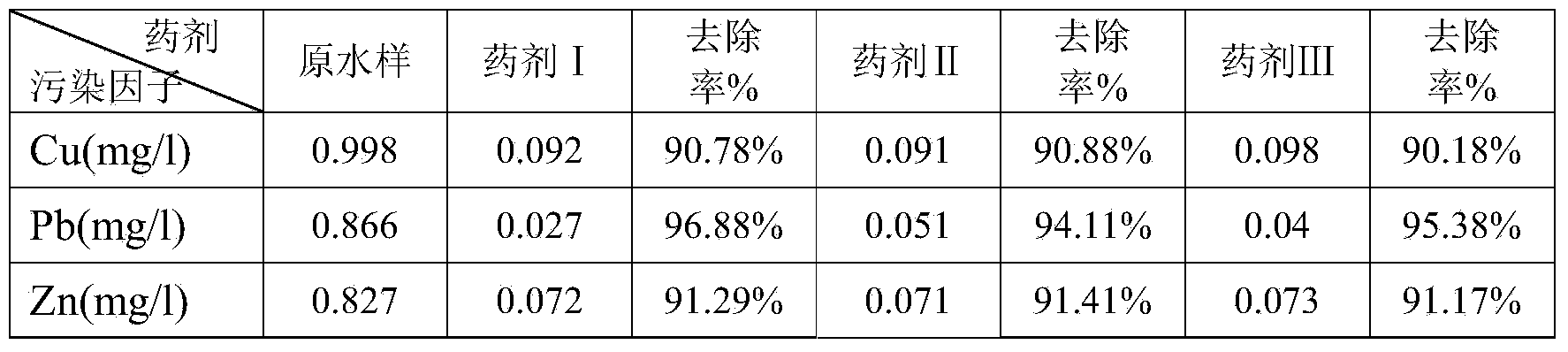

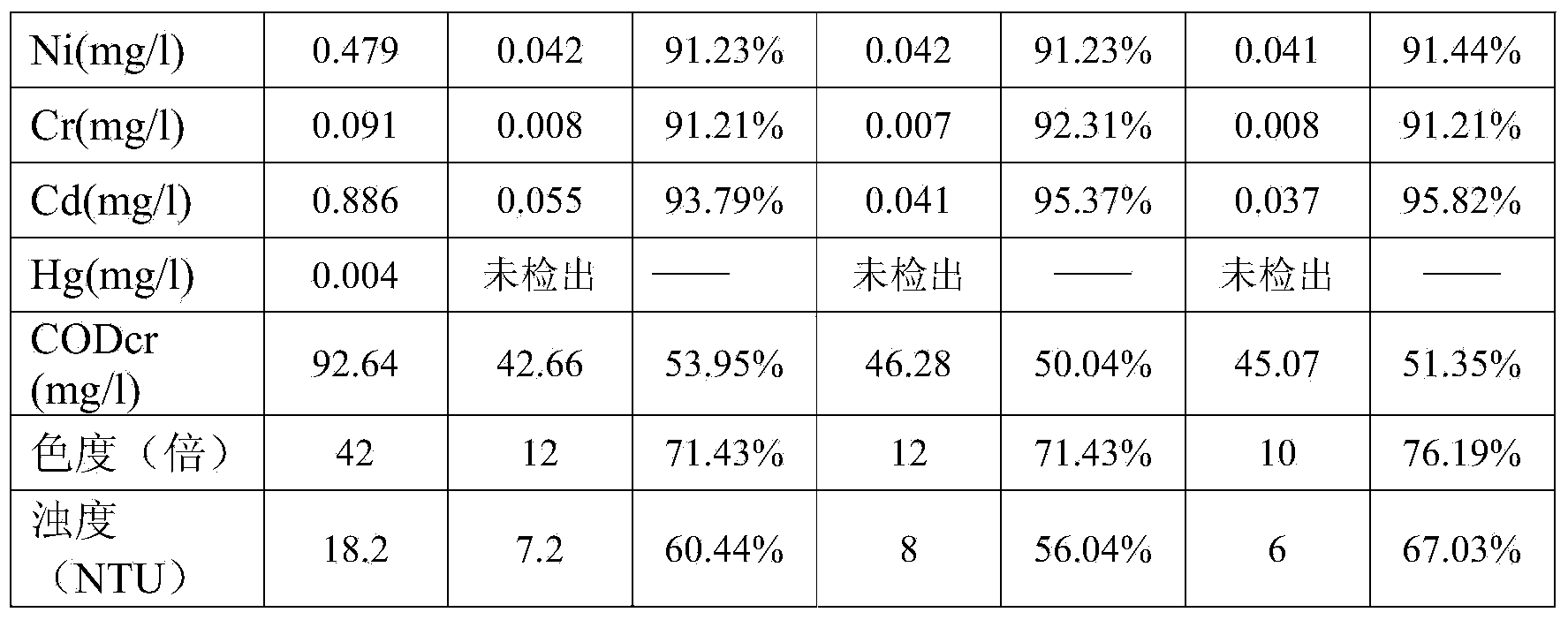

ActiveCN103482750AImprove adsorption capacityStrong chelationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFlocculationChemical oxygen demand

The invention discloses a composite reagent for deep removal of heavy metals in wastewater and a preparation method thereof. The composite reagent is prepared from the following raw materials in parts by weight: a component A including 20-30 parts of modified attapulgite powder, 30-50 parts of a modified natural high molecular polymer and 0-3 parts of a surfactant; a component B namely an inorganic flocculating agent, wherein the weight ratio of the component A to the component B is (2.5-8.3):1. The composite reagent disclosed by the invention has very strong adsorption, chelating and flocculation performances on heavy metal ions in water, has a plurality of effects of auxiliary reduction of COD (chemical oxygen demand), decoloration, dephosphorization and the like at the same time, and is good in treatment effect, and the preparation method is simple and easy.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

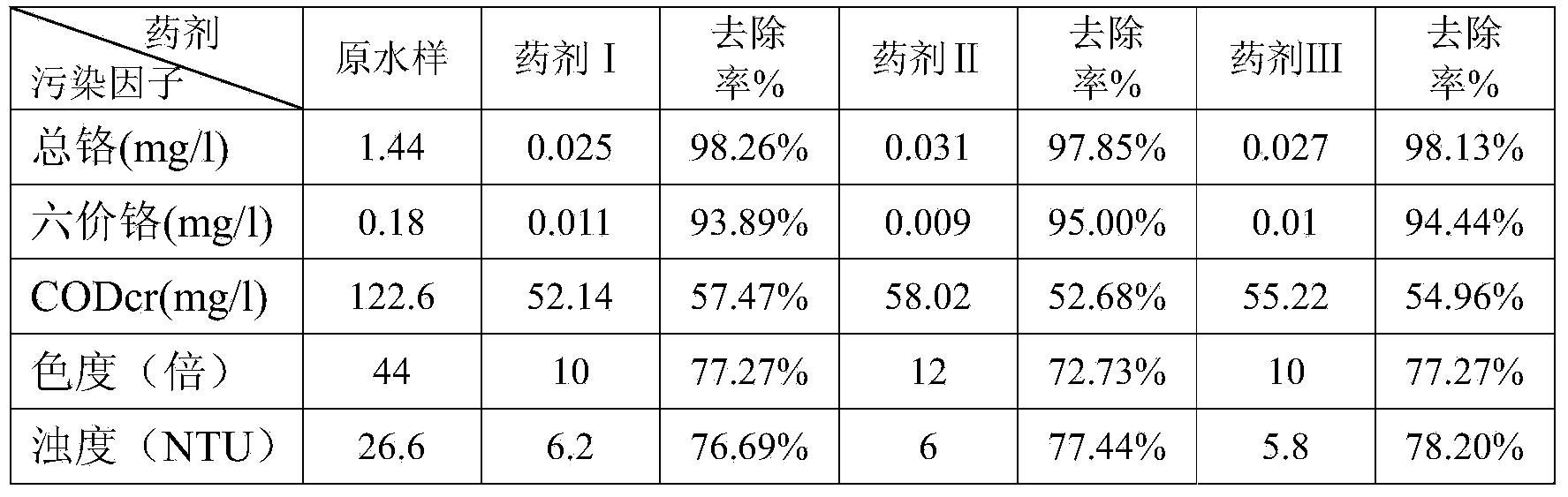

Cationic polyacrylamide-modified Fe3O4 magnetic flocculant and preparation method thereof

InactiveCN103073101AReduce dosageFast flocculationOrganic/organic-metallic materials magnetismWater/sewage treatment by flocculation/precipitationFlocculationSuperparamagnetism

The invention relates to a magnetic flocculant and a preparation method thereof, wherein the magnetic flocculant is cationic polyacrylamide-modified magnetic nanometer Fe3O4 particles. The magnetic flocculant provided by the invention retains the advantages of low dosage of organic high molecular flocculant, high flocculation speed, coexistence of salts, low pH value and temperature influence, low total amount of flocculating constituent and the like; and the superparamagnetism of the flocculant enables the flocculant to quicken the precipitation under the effect of an applied magnetic field and to realize quick and efficient separation of residual flocculant and flocculation. The magnetic flocculant provided by the invention has the advantages of simple preparation technique, low cost, easiness in amplification and no secondary pollution, and facilitates realizing efficient and economic flocculation operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Organic-inorganic ionic hetero high efficiency flocculant

InactiveCN1554592AIncrease profitReduce dosageWater/sewage treatment by flocculation/precipitationMicroparticleOrganic polymer

The efficient flocculant consists of hydroxide colloid 0.5-15 wt%, acrylamide 50-95 wt% and cationic monomer 0-45 wt%. The hydroxide colloid may be aluminum other, iron hydroxide, magnesium hydroxide or zinc other, and has colloid size of 10-200 nm. The cationic monomer includes DMDAAC or DMC. The organic-inorganic hetero efficient flocculant has in-situ polymerized acrylamide / cationic monomer copolymer linked to the surface of charged inorganic colloid particle, so that it has the synergistic effect of electrically neutralizing effect of inorganic flocculant and the bridging effect of organic polymer and greatly raised flocculating efficiency.

Owner:ZHEJIANG UNIV

Soil conditioner for passivation of heavy metals and preparation method of soil conditioner

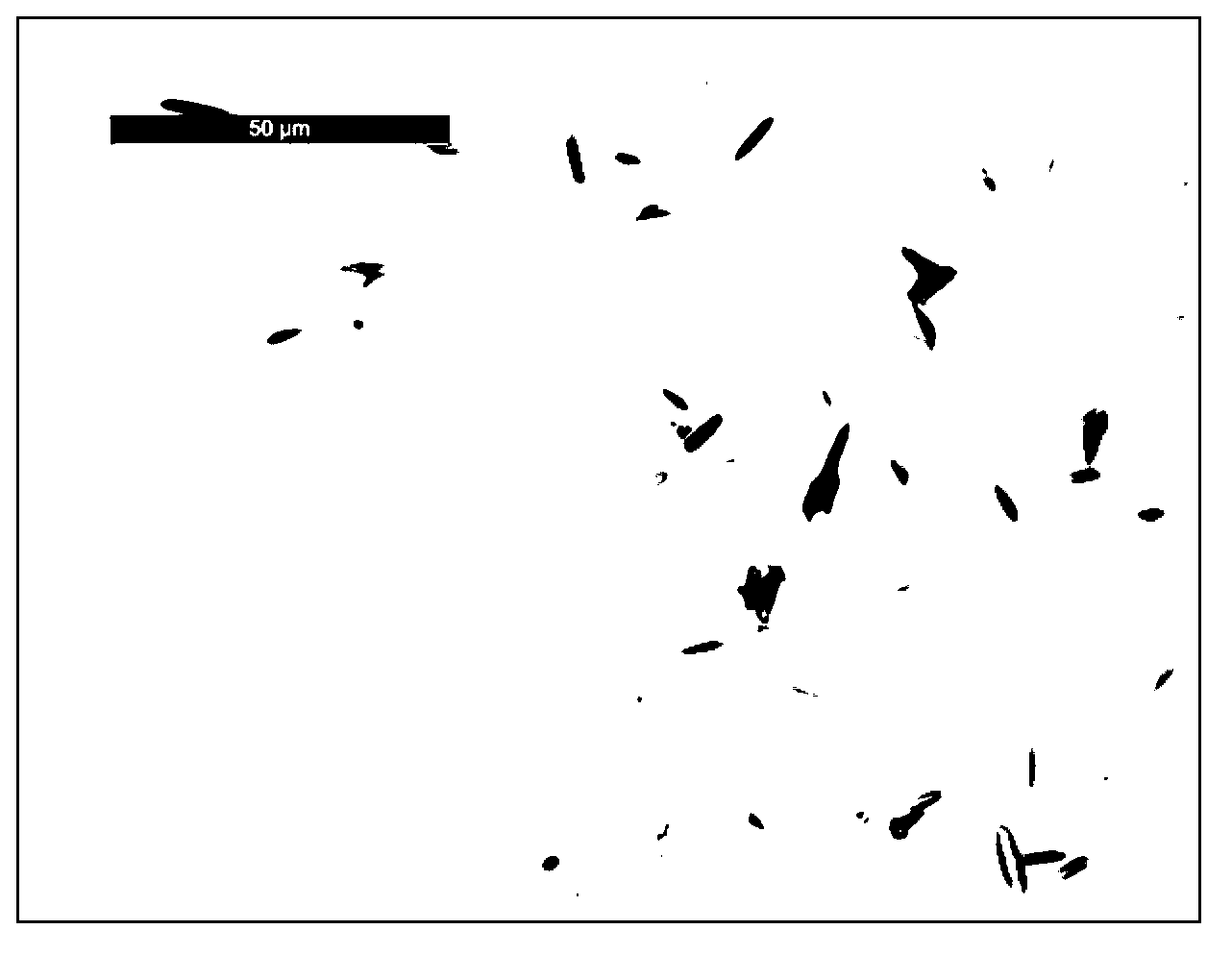

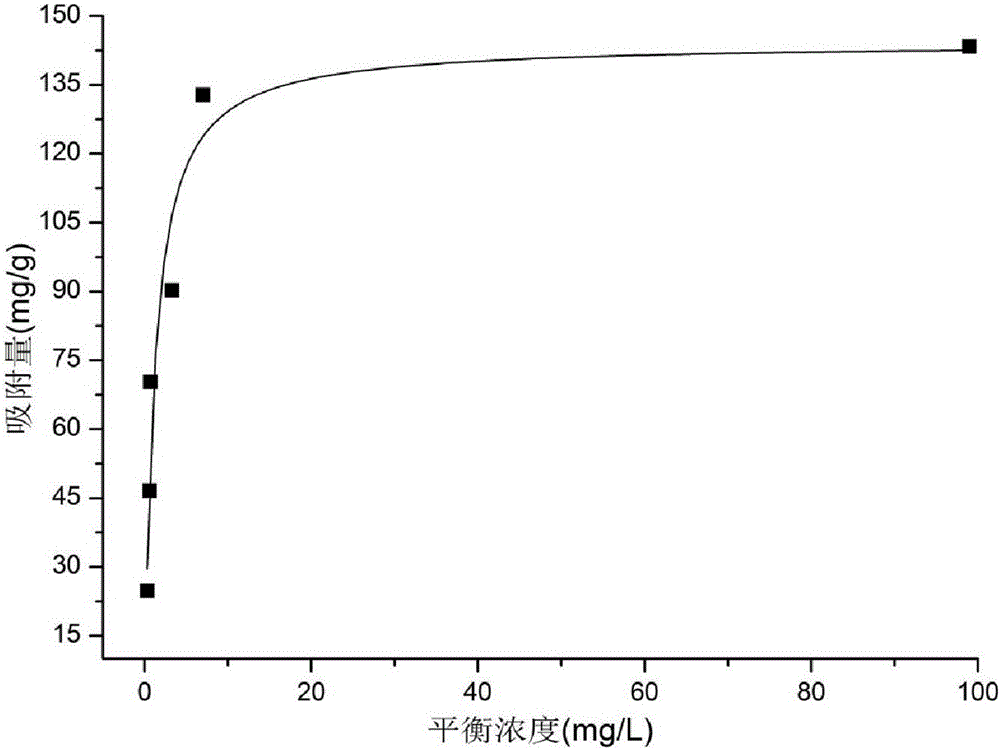

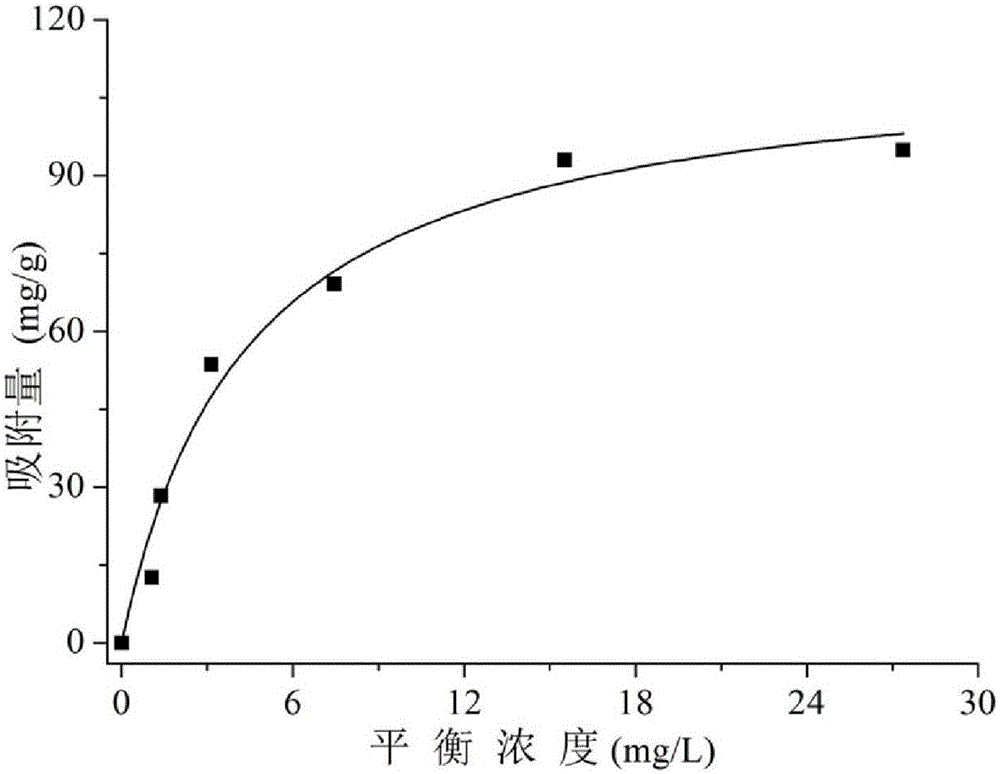

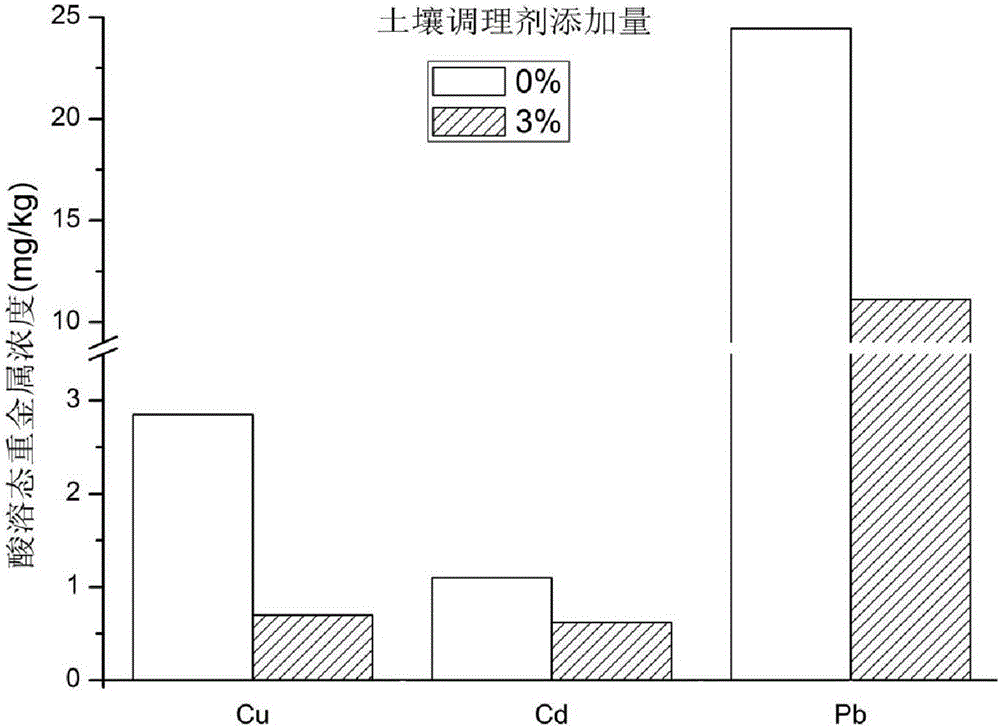

InactiveCN105733596AEasy to separateEliminate emissionsAgriculture tools and machinesContaminated soil reclamationFlocculationSoil conditioner

The invention relates to a soil conditioner for passivation of heavy metals and a preparation method of the soil conditioner. The preparation method comprises the following steps: mixing a material which is rich in humic acid and a strongly alkaline solution; extracting the humic acid after heating the mixture; and carrying out combined flocculation on the humic acid to obtain the soil conditioner for passivation of the heavy metals. According to the preparation method, lignite and weathered coal which are distributed widely, abundant in reserves, low in price and easy to obtain are used as raw materials and are extracted in an environmentally friendly process, and the soil conditioner for passivation of the heavy metals is obtained by initiative combined flocculation. The soil conditioner contains calcium humate, is rich in functional groups such as carboxyl and hydroxyl, can effectively adsorb the heavy metals so as to reduce biological effectiveness of the heavy metals, and can be used for conditioning and repairing heavy metal polluted farmlands including acid soil.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI +1

Dephosphorization flocculating agent and preparation method thereof

ActiveCN104261530AGood flocculation effectGood dephosphorization effectWater/sewage treatment by flocculation/precipitationAluminateWater quality

The invention discloses a dephosphorization flocculating agent and a preparation method thereof. The dephosphorization flocculating agent is formed by compounding an inorganic flocculating agent and an organic flocculating agent. The raw materials of the inorganic flocculating agent comprise sodium ferrate, borax, ferrous sulfate, silicate or aluminate; the raw materials of the organic flocculating agent comprise modified chitosan or modified polyacrylamide. The preparation process comprises the following steps: firstly adding a non-oxidizing acid into the silicate or aluminate to obtain a polysilicate colloid or an aluminum hydroxide colloid, then adding a borax solution and a sodium ferrate solution sequentially while stirring, further dropping a ferrous sulfate solution, mixing to form the inorganic flocculating agent, standing, then adding the modified polyacrylamide or modified chitosan into the inorganic flocculating agent, curing and adding the acid till the pH value is less than 7 to obtain the finished dephosphorization flocculating agent. The flocculating agent is suitable for a wide range of water quality, is little affected by co-existing salts, the pH value of sewage and temperature and is particularly effective for dye wastewater, oilfield sewage and the like.

Owner:内蒙古昕晟科贸有限责任公司

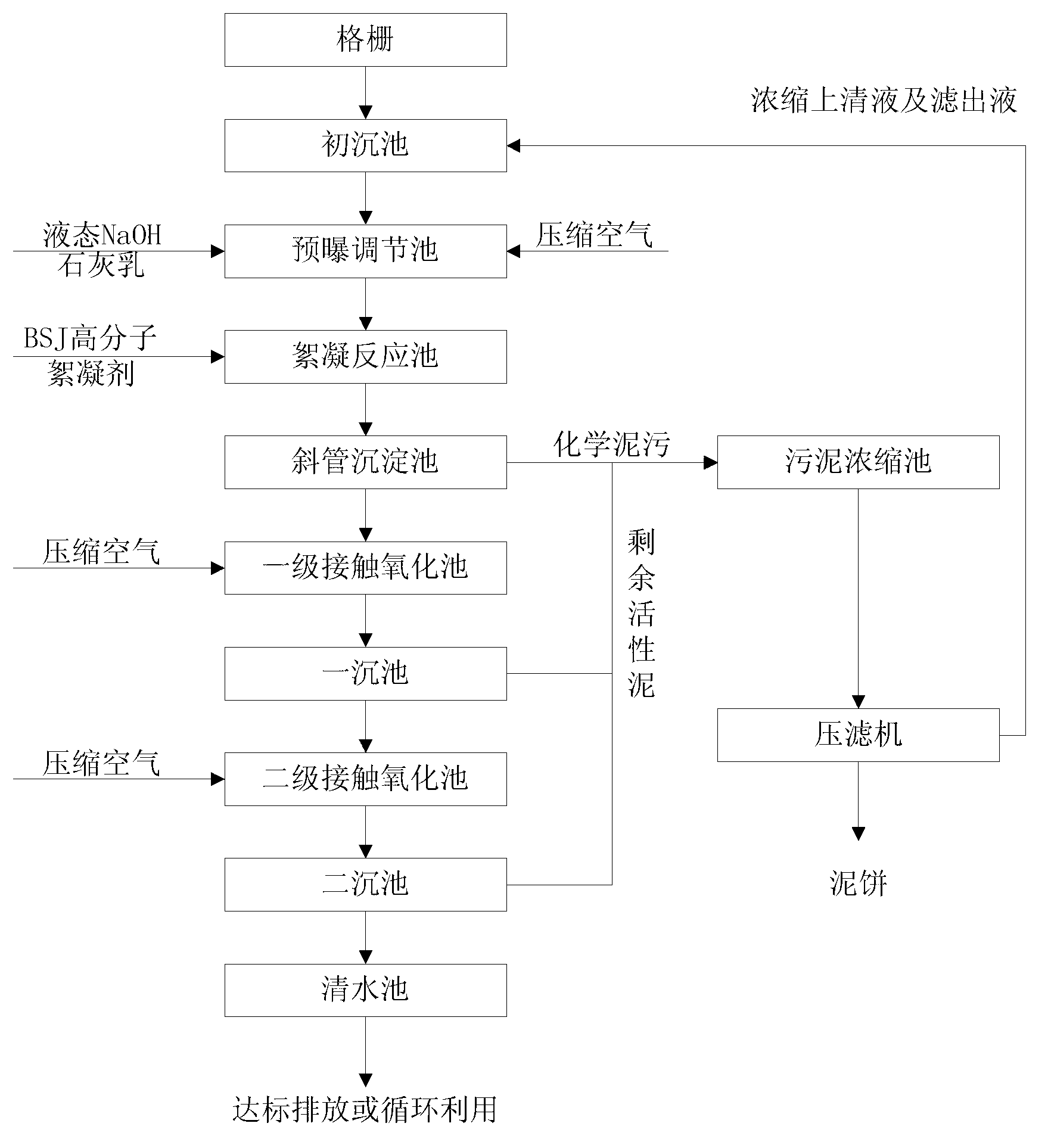

Waste water treatment process

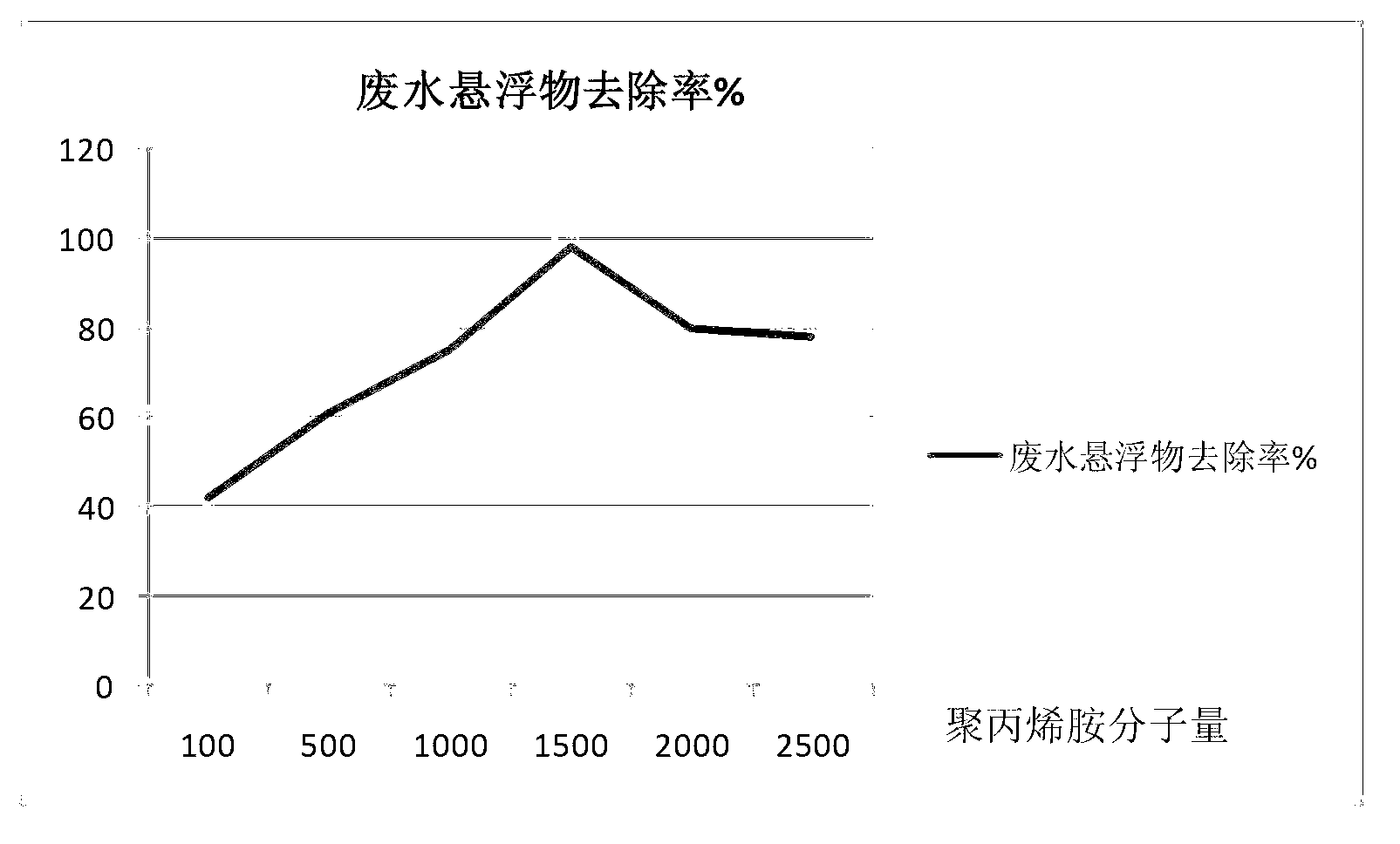

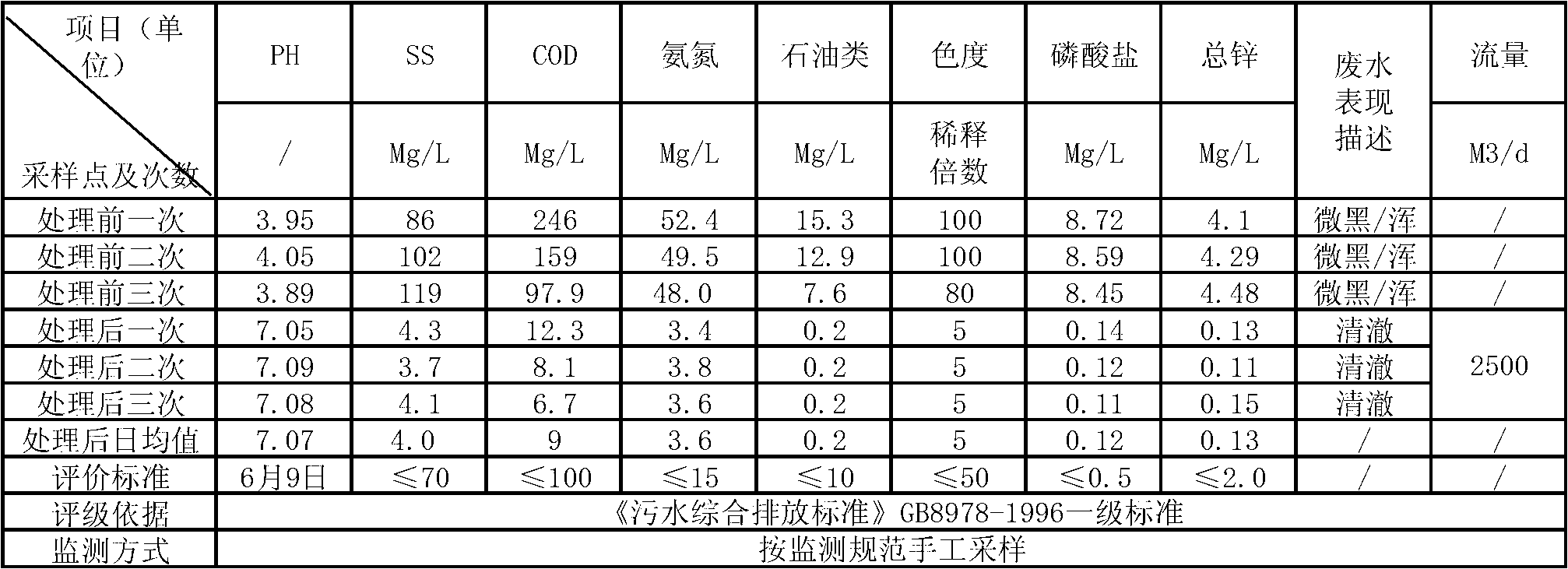

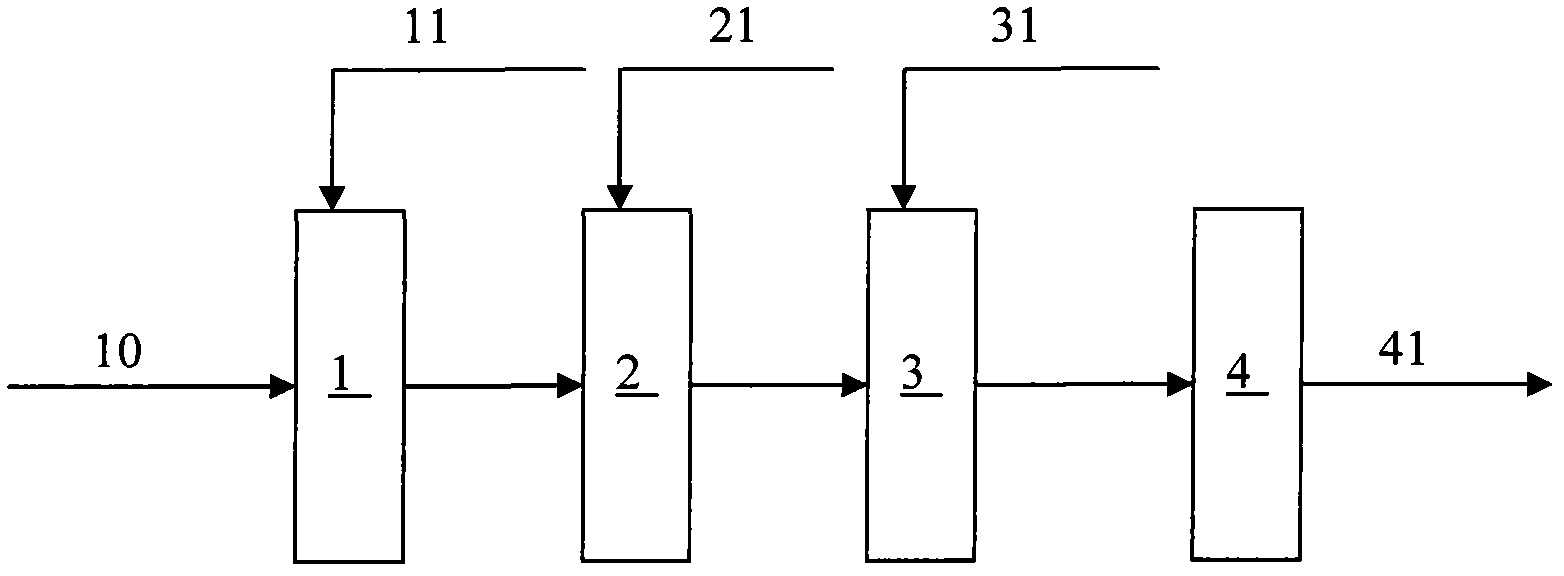

InactiveCN102795747AHigh removal rateFast flocculationMultistage water/sewage treatmentPolyacrylamideSewage

The invention discloses a waste water treatment process which comprises the following steps that 1) waste water enters a primary sedimentation tank through a grid to remove suspended matters; 2) the waste water overflows from the primary sedimentation tank into a regulating tank after the suspended matters are removed, and lime milk is added to adjust the pH value of the waste water to be neutral; 3) the waste water of which the pH value is adjusted to be neutral naturally flows into a neutral aeration tank and is mixed with compressed air in the aeration tank, and Fe<2+> in the waste water is converted to Fe<3+>; 4) the waste water in the aeration tank is injected to a flocculation reaction tank, polyacrylamide flocculant is added to the waste water, and then the waste water is pumped to an inclined tube sedimentation tank; and 5) supernate of the waste water in the inclined tube sedimentation tank overflows into a contact oxidation tank and is mixed with the compressed air filled into the contact oxidation tank, organic matters in the waste water are subjected to oxygenolysis, and the waste water in the contact oxidation tank is deposited through a sedimentation tank and then overflows into a clean water tank. After being treated by the waste water treatment process, the waste water can reach the standard of Integrated Waste Water Discharge Standard (GB 8978-1996); and in addition, the operating cost of a waste water treatment system is lower, and the waste water treatment volume is large .

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Method for processing wastewater containing heavy metal ions

ActiveCN102923874AEasy to operateReduce settling timeWater contaminantsMultistage water/sewage treatmentIonHeavy metals

The invention relates to a method for processing wastewater containing heavy metal ions, and belongs to the chemical field. The method comprises the following steps: 1, discharging the wastewater to a pH adjustment tank at normal temperature in order to adjust the pH value of the wastewater to a predetermined value; 2, discharging the wastewater obtained after step 1 to a curing precipitation reactor, adding a polysulfide precipitating agent to covert the heavy metal ions in the wastewater into insoluble substances of the heavy metal ions, and precipitating the insoluble substances of the heavy metal ions while precipitating elementary sulfur; 3, discharging the wastewater obtained after step 2 to a flocculating tank, adding a flocculating agent to flocculate the insoluble substances of the heavy metal ions and the elementary sulfur; and 4, discharging the wastewater obtained after step 3 to a precipitating tank, precipitating, and discharging the obtained supernatant. The method has the advantages of high removal rates of a plurality of the heavy metal ions, no secondary pollution, low cost, and easy realization.

Owner:CHINA PETROLEUM & CHEM CORP +1

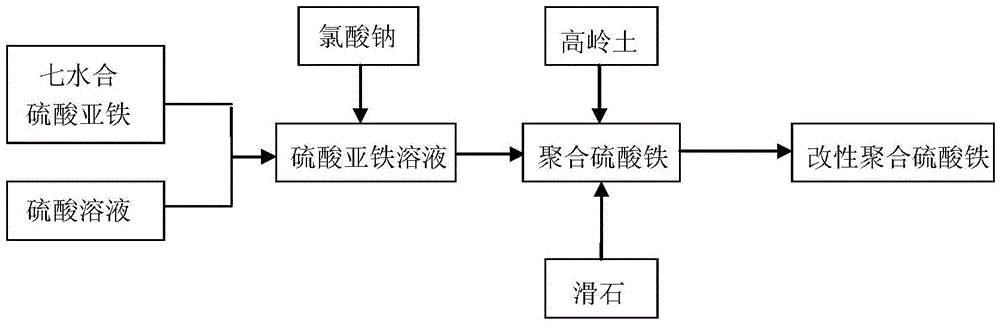

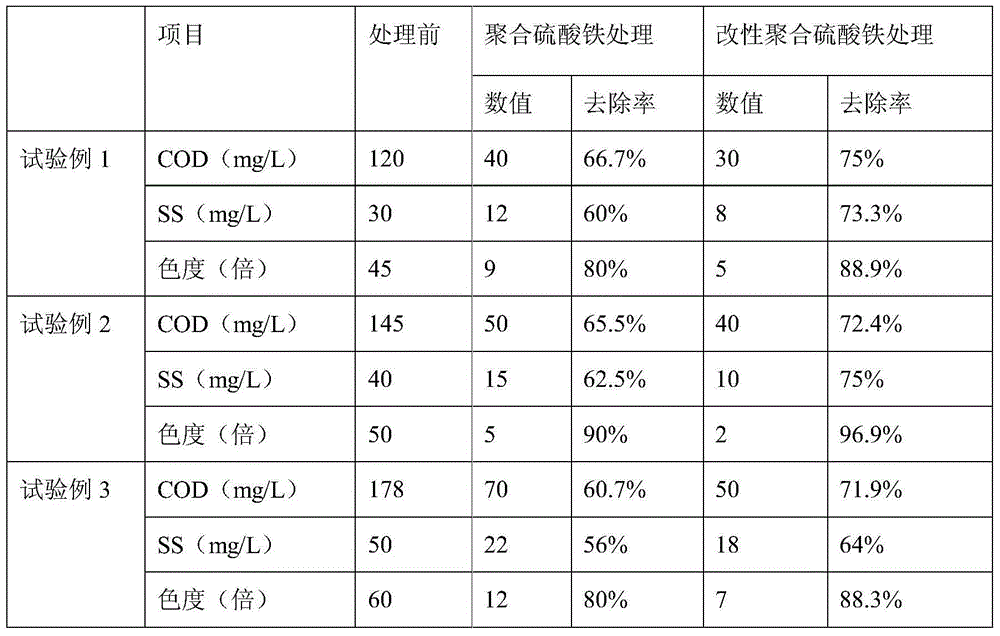

Preparation method and application of modified polyferric sulfate for treating industrial wastewater

ActiveCN104478050ASimple processLow priceIron sulfatesWaste water treatment from plant processingChemical oxygen demandIndustrial waste water

The invention provides a preparation method of modified polyferric sulfate. Kaolin and talcum are utilized to perform modification treatment on the polyferric sulfate. When the modified polyferric sulfate is used in a waste paper papermaking advanced wastewater treatment technique, the pollutant removal ratio is high, and the chroma removal effect is good: the removal ratio of the modified polyferric sulfate for COD (chemical oxygen demand) in wastewater is up to 71.9-75%, the SS (suspended sediment) removal ratio is up to 64-75%, and the chroma removal ratio is up to 88.3-96.9%. Under the same conditions, compared with the polyferric sulfate, the COD removal ratio is enhanced by 8.3-11.2%, the SS removal ratio is enhanced by 9-12.5%, and the chroma removal ratio is enhanced by 6.9-8.3%. The modified polyferric sulfate has high flocculation speed and has the same decolorization effect; and the consumption of the modified polyferric sulfate is greatly lower than that of the polyferric sulfate, so the generated chemical sludge quantity is low, thereby saving the cost and simplifying the technique.

Owner:ZHENGZHOU UNIV

Preparation method for biological flocculant

InactiveCN101121920AEasy to handleNo pollution in the processFungiWater/sewage treatment by flocculation/precipitationFlocculationAspergillus

The invention discloses a method to prepare bio-flocculant. The invention is characterized in that aspergillus fermentating cultivation is adopted. The aspergillus is agitated and fermented (28-30 DEG C, pH6-7, under ventilating condition) for 48-60 hours; the fermentation broth is filtered and condensed, and then proper amount of ethanol is added into the condensed broth and centrifugal separation is conducted after stewing; the deposition is washed with ethanol and dried in vacuum to achieve a crude product of fawn flocculant. The prevention method has the advantages of simple condition of production and low cost. The bio-flocculant prepared by the method is applicable to disposing sewage containing granular contaminants or filth, and the dosage generally drops in 0.1 to 0.3 per mill. It is proved by flocculation treatment that, compared with the prior art, the invention has sound flocculation effect, low flocculant speed and small dosage; besides, the invention is environment-friendly and harmless to human body.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

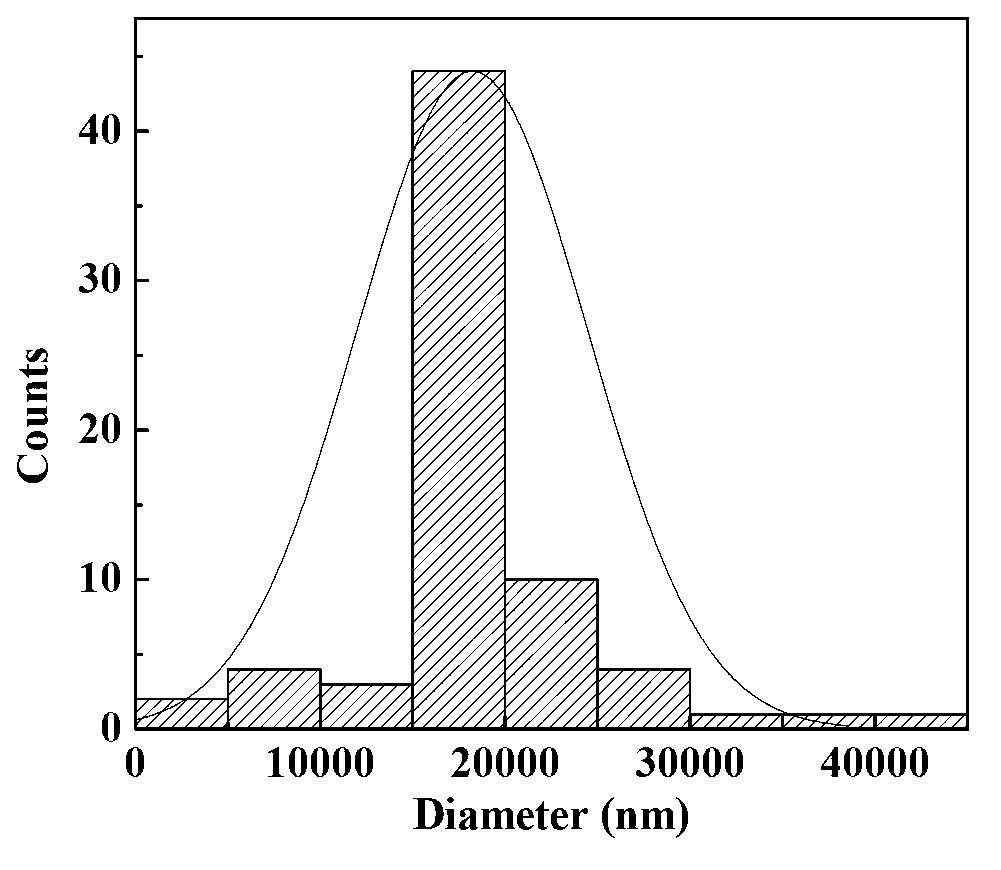

Heavy metal wastewater treatment medicament and treatment method of heavy metal wastewater

ActiveCN105293603ASmall molecular weightFast flocculationWater contaminantsWater/sewage treatment by flocculation/precipitationIonChemistry

The invention relates to a heavy metal wastewater treatment medicament. The heavy metal wastewater treatment medicament comprises the following raw materials by weight: 1 part of cationic polyacrylamide, 3 to 8 parts of anionic polyacrylamide, 10 to 30 parts of an inorganic flocculating agent, 1 to 3 parts of a heavy metal chelating agent, and 58 to 85 parts of an absorbent. The invention further provides a heavy metal wastewater treatment method which comprises the following steps: taking 1 L of chemical wastewater; adding a NaOH solution into the wastewater till the pH of the obtained solution is 8.0 to 9.0; adding the heavy metal wastewater treatment medicament into the obtained solution, wherein the addition volume of the heavy metal wastewater treatment medicament is 0.04 to 0.08 percent of the weight of the chemical wastewater; stirring fast for 10 seconds; stirring slowly for 20 minutes; stopping stirring; allowing the obtained liquid to stand still for 10 minutes for layering. The heavy metal wastewater treatment medicament and the heavy metal wastewater treatment method have the benefits that 1, the preparation is simple; 2, the molecular weight of cationic polyacrylamide is low, and positive charge groups of cationic polyacrylamide can adsorb negative charges of bentonite, so that a filtration aiding system of a tight structure is formed; 3, anionic polyacrylamide is high in molecular weight, so as to subside fast and generate thick floc.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

Flocculant for sewage treatment

ActiveCN102701365AGreenLow costWater/sewage treatment by flocculation/precipitationPotassium persulfatePeroxydisulfate

The invention relates to a flocculant for sewage treatment. The flocculant is prepared by compounding the raw materials of polyacrylamide, starch, sodium hypochlorite, sodium carboxymethylcellulose, sodium silicate, potassium peroxydisulfate, sodium sulfite and water. The prepared flocculant has the advantages of green and environmental protection, low cost, small addition amount, quick flocculation speed, little sludge, convenience and safety in use and the like.

Owner:湖南科尔顿水务集团有限公司

Industrial sewage treatment agent

InactiveCN105948213AImprove securityFast flocculationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionPhosphateThiourea

The invention discloses an industrial sewage treatment agent, which comprises the following raw materials by weight: 20-40 parts of chrysotile, 10-30 parts of diatomite, 10-30 parts of modified activated carbon, 10-20 parts of polymeric aluminum phosphate, 5-15 parts of polymeric phosphate-ferric chloried, 1-5 parts of aluminum potassium sulfate, 5-10 parts of bentonite, 1.5-2.5 parts of polyacrylamide, 1.4-2.5 parts of sodium hexametaphosphate, 1-3 parts of modified attapulgite, 10-30 parts of isopropanol, 5-15 parts of sodium nitrite, 2-10 parts of thiourea, and 2-4 parts of acrolein. The industrial sewage treatment agent provided by the invention can be used for industrial sewage treatment, and has the advantages of fast flocculation and purification speed, thorough sewage treatment, excellent stability and high safety.

Owner:林元文

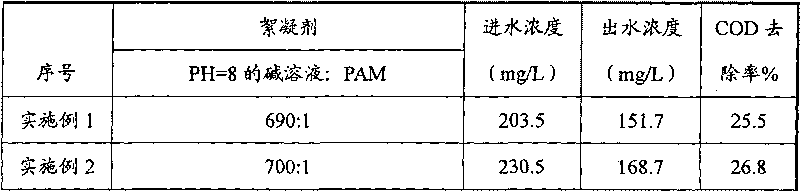

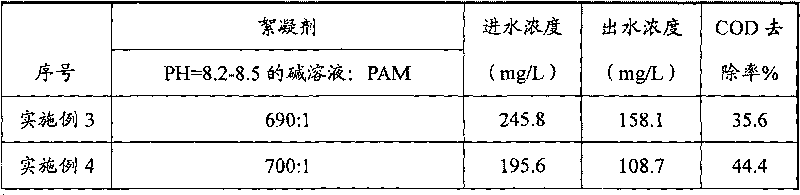

Sewage treatment flocculating agent and using method thereof

ActiveCN101704570ALow costConvenient sourceWater/sewage treatment by flocculation/precipitationWater qualityTherapeutic effect

The invention discloses a sewage treatment flocculating agent and a using method thereof. The flocculating agent comprises the following components in part by weight: 690 to 700 parts of alkali solution of which pH range is 8 to 9, 25 to 40 parts of aluminium polychloride, 10 to 15 parts of sodium silicate and 1 part of polyacrylamide. In the sewage treatment flocculating agent and the using method thereof provided by the invention, because the alkali solution of a novel formulation is adopted, the agent cost is reduced, the treatment effect is improved, the preparation process is simple, the raw material source is convenient, the wastewater treatment efficiency is high, the effect of purifying the water is good, the flocculating speed is high, the produced sludge is little, and the flocculating agent and the using method are particularly suitable for treating the mixed discharged sewage in the industries of printing and dyeing, food and the like and have great popularization and application values in the aspects of purification and treatment of printing and dyeing wastewater and other industrial wastewater.

Owner:SHENZHEN HONGKONG INSTITUTION OF IND EDUCATION & RES ENVIRONMENTAL ENG TECH CO LTD

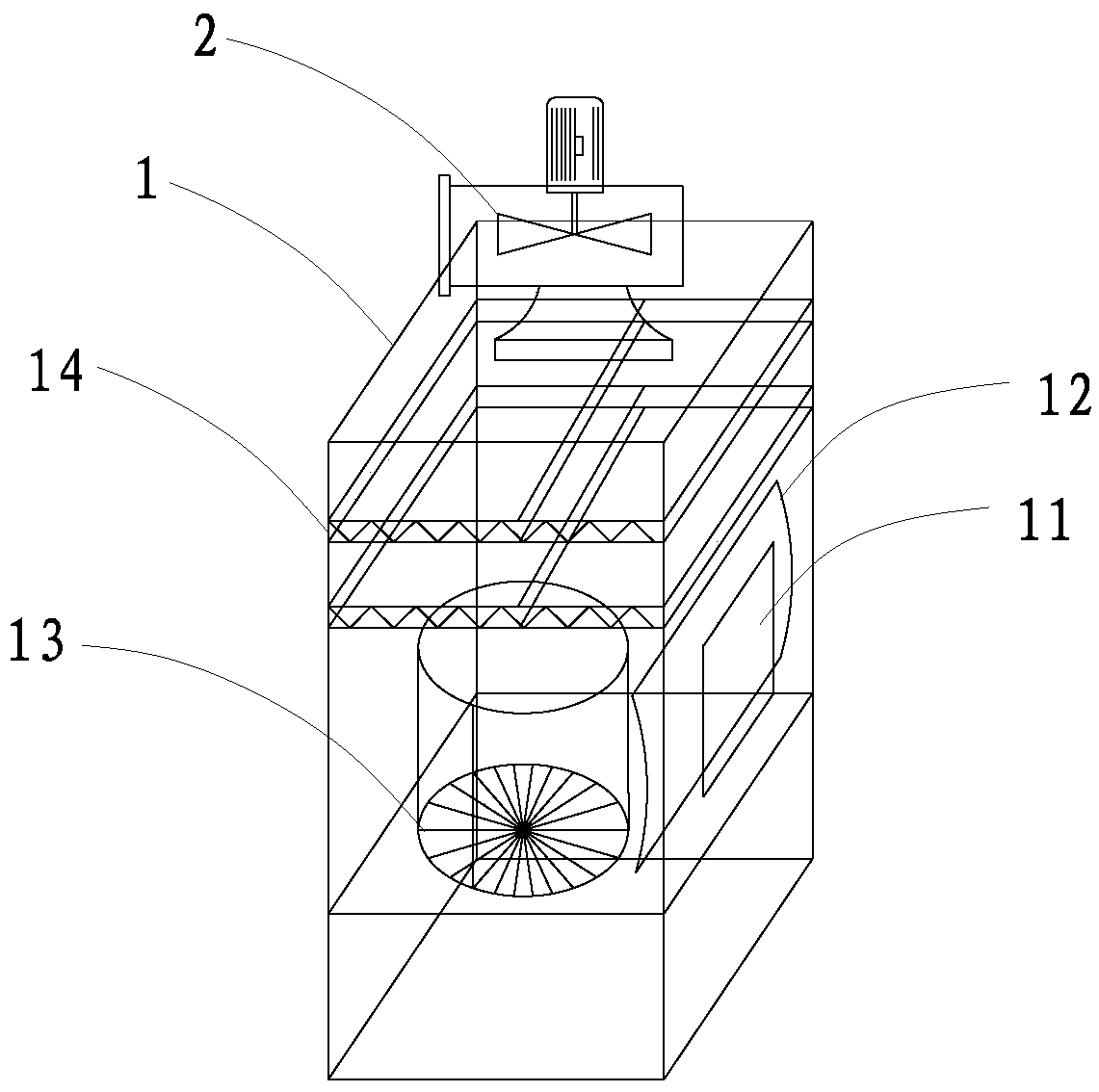

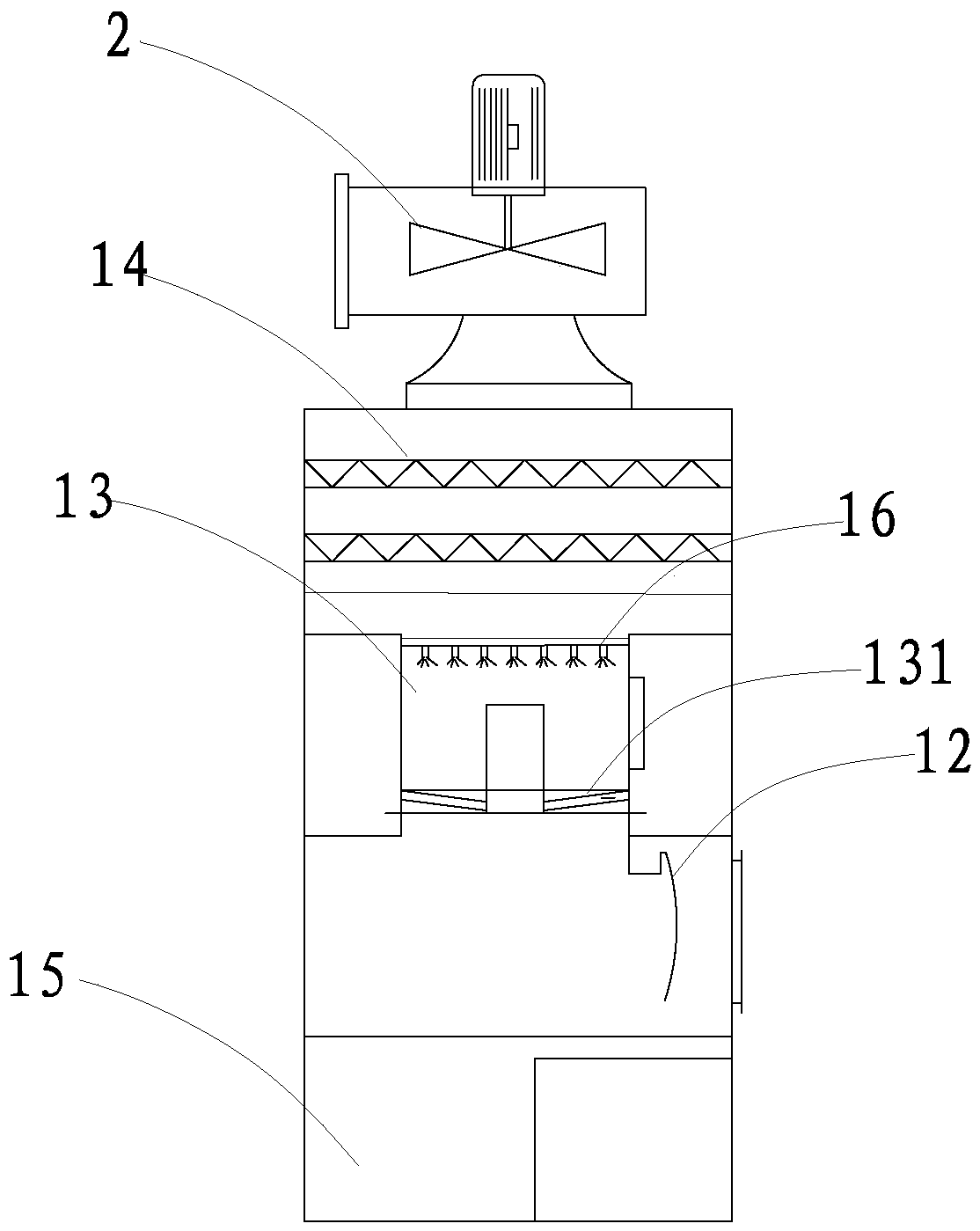

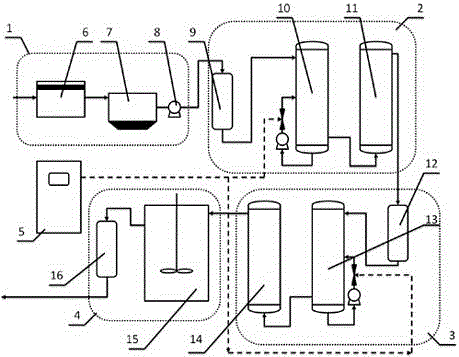

Paint mist treatment method and spraying tank

ActiveCN105498400AAvoid decompositionPromote degradationCombination devicesGas treatmentWater curtainDecomposer

The invention relates to the technical field of spraying waste gas treatment, in particular relates to a paint mist treatment method and a spraying tank. The paint mist treatment method comprises the following steps: (1) carrying out spraying adsorption on spraying waste gas by a water curtain formed by circulating water on a water screen baffle plate; (2) enabling the spraying waste gas to enter a rotary washing drum, carrying out rotary washing on the spraying waste gas, and carrying out spraying absorption on the spraying waste gas by a spraying device arranged at the top part of the rotary washing drum; (3) exhausting the spraying waste gas after treating the spraying waste gas through a demisting layer, wherein a paint mist decomposer and a paint mist catcher are added in the circulating water which is used for treating the spraying waste gas. According to the paint mist treatment method disclosed by the invention, the technologies of water screen spraying, rotary washing and spraying adsorption are combined, and a good paint mist removing effect is obtained; the paint mist decomposer and the paint mist catcher are matched with each other to be added in the circulating water, so that paint mist can be effectively prevented from sticking on the inner wall of the spraying tank; the paint mist in the circulating water is enabled to be flocculated and floats up, so that cleaning of floating paint mist scum is facilitated, the service cycle of the circulating water is prolonged, and the damage to equipment is reduced.

Owner:吴永光 +1

Method for treating refuse leachate membrane-concentrated liquid by using ozone advanced oxidation

InactiveCN105800871AFast separationEasy to separateTreatment involving filtrationTreatment with anaerobic digestion processesCatalytic oxidationOxidative treatment

The invention relates to a method for treating refuse leachate membrane-concentrated liquid by using ozone advanced oxidation. Refuse leachate membrane-concentrated liquid is fully mixed with metal salt like inorganic macromolecular flocculant and polyacrylamide, then the mixture is delivered to a gas floatation clarifier for performing mud-water separation, the PH value of clear liquid obtained after the separation is regulated, and then the clear liquid is drained into a settling pond for performing settlement treatment; supernatant of the settling pond is delivered to an ozone catalytic oxidation reaction device; wastewater obtained after ozone catalytic oxidation is delivered to an advanced oxidation device for performing advanced oxidation; the wastewater obtained after the advanced oxidation is delivered to denitrification equipment for performing denitrification treatment; the wastewater obtained after denitrification treatment can reach a discharge standard. The method for treating refuse leachate membrane-concentrated liquid by using ozone advanced oxidation has the characteristics of simple process line, high treatment cost performance and no secondary pollution.

Owner:史义

Flocculant for sewage treatment

InactiveCN1594127APromote growthLarge adsorption capacityWater/sewage treatment by flocculation/precipitationMontmorilloniteSewage

The invention provides a flocculant for sewage treatment comprising, one or two of seawater, underground bittern water, bittern water after salt preparation from seawater, one or two of poly ferric sulfate, polyaluminium chloride, and the mixture of poly ferric sulfate and polyaluminium chloride, one or two of silica, montmorillonite, kaolin, and talcum powder, wherein the weight percentage for each component is 98-99.5 : 0.03-1 : 0.03-1.

Owner:OCEAN UNIV OF CHINA

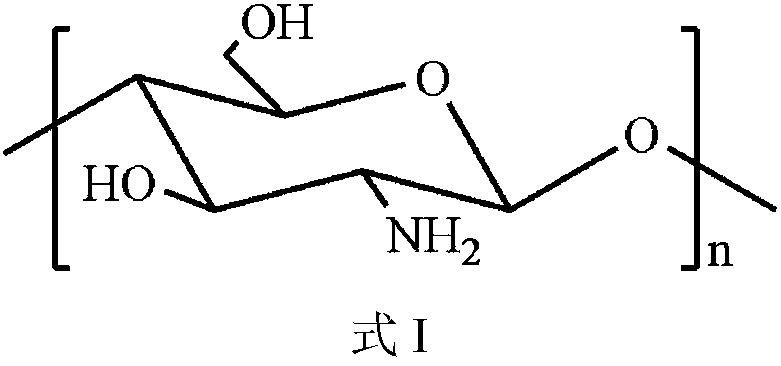

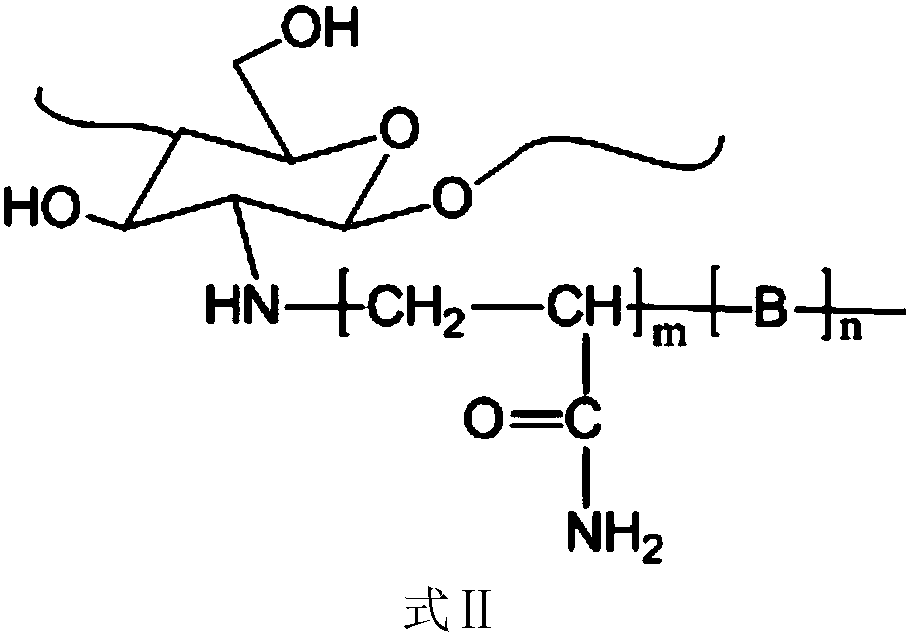

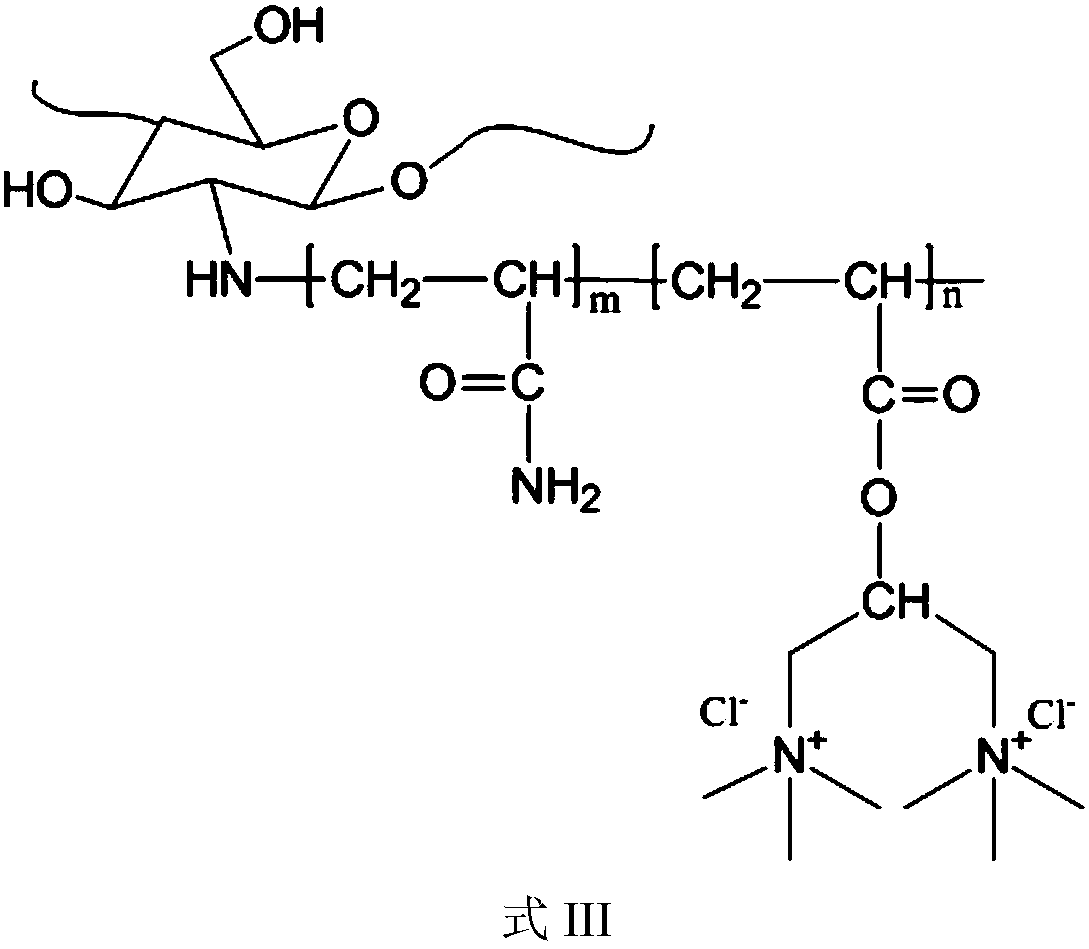

Chitosan flocculating agent, method for preparing same and application

InactiveCN108264610AReduce dosageFast flocculationWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationFunctional monomerDouble bond

The invention provides a chitosan flocculating agent. A structural formula of the chitosan flocculating agent is shown as a formula II. A B in the formula II represents a functional monomer with biquaternary ammonium salt cations and unsaturated double bonds, and an m and an n in the formula II represent number-average degrees of polymerization. The invention further provides a method for preparing the chitosan flocculating agent. The method includes steps of 1), dissolving chitosan in ionic liquid and adding initiators into the ionic liquid under the protection of inert gas to obtain mixtures; 2), sequentially adding propylene acyloxy propane-1, 3-bis-trimethyl ammonium chloride and acrylamide into the mixtures obtained at the step 1), heating the propylene acyloxy propane-1, 3-bis-trimethyl ammonium chloride, the acrylamide and the mixtures and carrying out reaction to obtain products; 3), washing and filtering the products obtained at the step 2) and then drying the products to obtain the chitosan flocculating agent. The invention further provides application of the chitosan flocculating agent to the field of oilfield produced water purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparing method of acidophilus milk lump

The invention discloses a preparation method for yogurt lump. The method comprises the steps of fermenting, acidization, curdling, whey discharging, water washing, storing, forming, sealing, after-ripening and packaging by adopting special lactic acid bacteria to inoculate milk or goat milk which is standardized and pasteurized. The invention can not only lead the traditional yogurt lump product to be safer and more sanitary with stable quality, subtle taste and modest hardness. And since the step of the after-ripening is controlled appropriately, the prepared yogurt lump is of fuller flavor with little cream precipitated, high yielding rate and can meet popular taste and be used for producing yogurt lump with different water content, tastes and textural quality, which has more market competitiveness and can greatly enrich the processing technology and flavor of traditional yogurt lump.

Owner:SOUTH CHINA AGRI UNIV +1

Flocculating agent for sewage and preparation method thereof

InactiveCN105967292AIncrease in sizeHigh densityWater/sewage treatment by flocculation/precipitationSodium bicarbonateTotal nitrogen

The invention discloses a flocculating agent for sewage and a preparation method thereof. The flocculating agent for the sewage is prepared from the following raw materials in parts by weight: dimethyl diallyl ammonium chloride, sodium silicate, acrylamide, dibenzoyl beroxide, tert-butyl alcohol, ferric chloride, aluminum sulfate octadecahydrate, polyaluminum chloride, ferrous sulfate, polyphosphorus ferric chloride, chitosan, sodium alginate, polyvinyl pyridine salt, a porous adsorbent, sodium bicarbonate, lignin, triethylenetriamide, formaldehyde sodium bisulfite, propionic aldehyde and alums. The capacity and density of the flocculating agent are increased and the flocculating effect is improved; suspension substances in the sewage can be effectively and rapidly flocculated and are gathered into clustered substances which are not easy to disperse and convenient to separate; meanwhile, the corrosion of the flocculating agent to pipeline equipment is lower than that of other similar flocculating agents; the chemical oxygen demand COD, the biochemical oxygen demand BOD and the suspension substances SS of the treated sewage are obviously reduced, and the total nitrogen, ammonia nitrogen and chroma are also reduced.

Owner:张能力

Combined flocculating agent with controllable flocculation and using method thereof

InactiveCN101700920AWide variety of sourcesLow costWater/sewage treatment by flocculation/precipitationAluminium chlorideNon toxicity

The invention relates to a modified natural polymer combined flocculating agent and a using method thereof. The flocculating agent is the combination of modified natural polymer and complexing agent, wherein the modified natural polymer is prepared by carrying out phosphorylation modification, sulfonation modification or etherification modification on one or combination of two in shells of shelled animals such as shrimps, crabs and insects, cotton, straw, bagasse and starch; the complexing agent is combination of at least two in magnesium chloride, calcium chloride, sodium hydroxide, potassium hydroxide, aluminium chloride, aluminum sulfate, aluminium potassium sulfate, calcium oxide, sodium tetraborate, ferric chloride, ferrous sulfate, ferrous chloride, ferric sulfate, boric acid, hydrochloric acid and sulfuric acid. After the modified natural polymer is added, the complexing agent can be added into the natural polymer at any time within 12h according to the need of flocculation, and the flocculation reaction can be immediately finished. The invention has the advantages of controllable flocculation, rapid flocculation speed, large and firm flocculating body, low water content, safety, non-toxicity and wide temperature adaptation range.

Owner:武汉循环经济研究院 +2

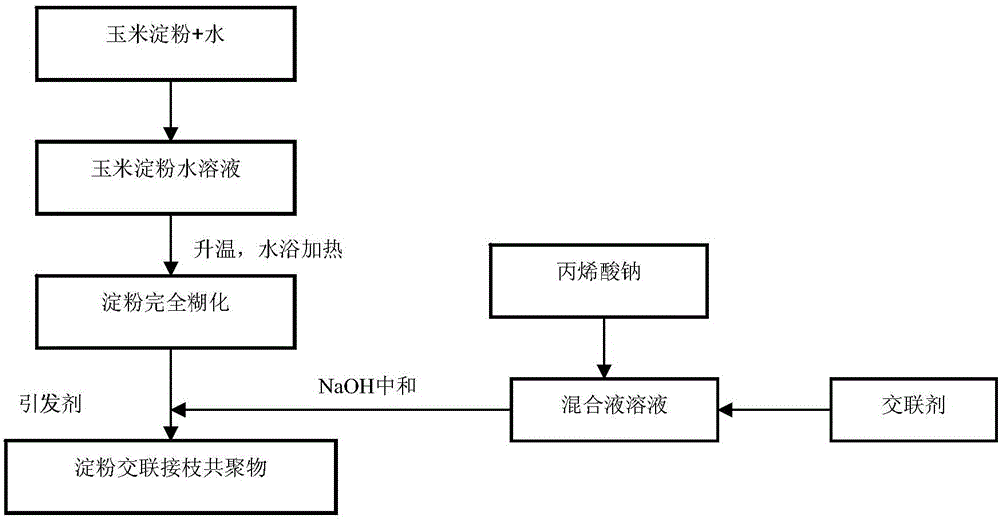

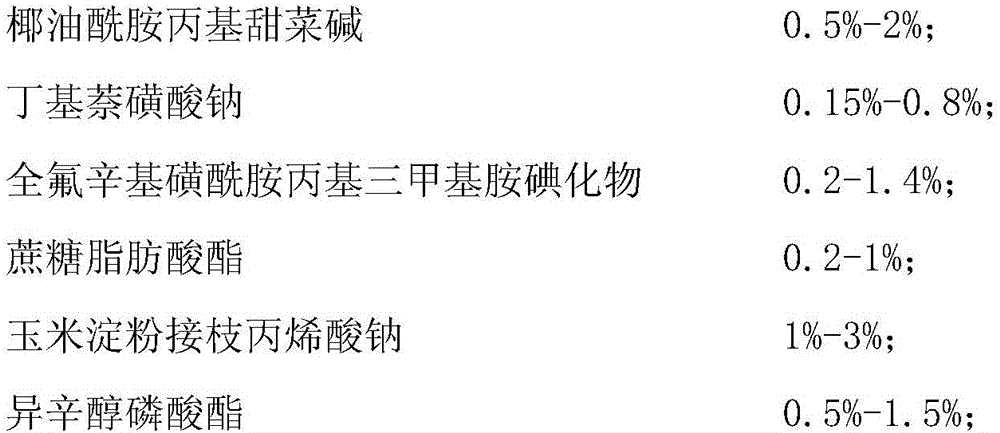

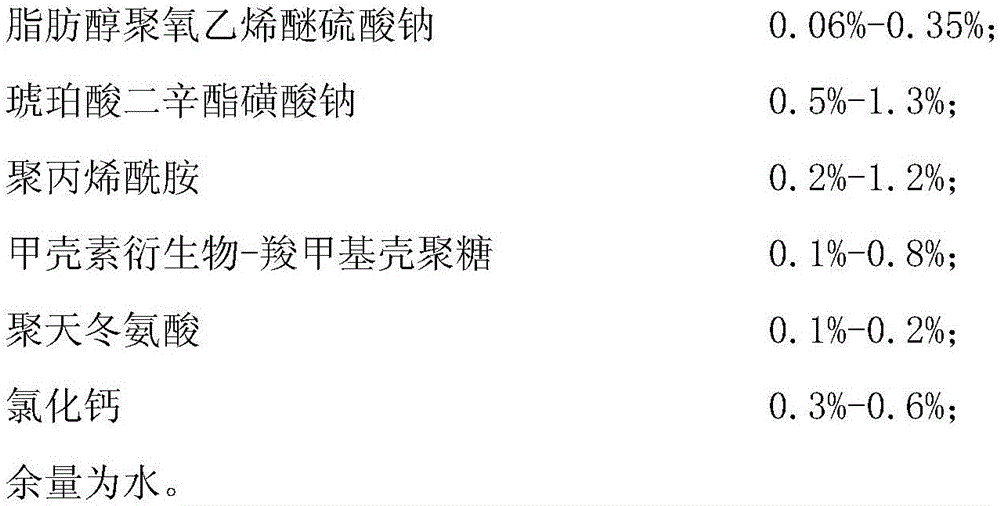

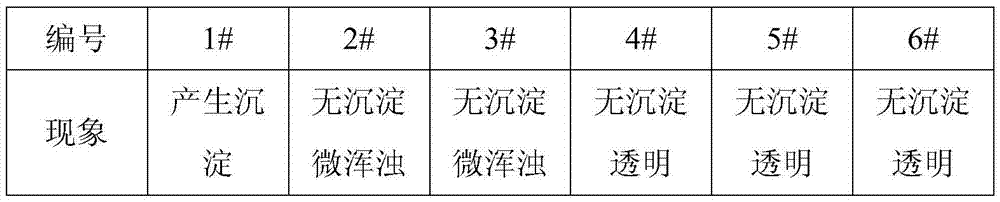

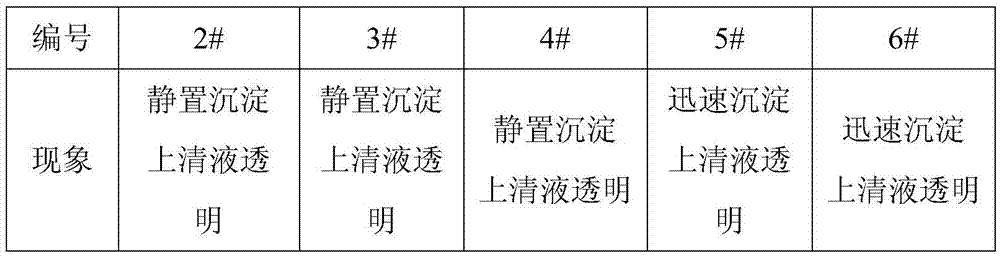

Permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control

ActiveCN105778867AReduce surface tensionIncrease surface tensionOther chemical processesDust removalSucrosePhosphate

The invention discloses a permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control. The permeability-increasing and coagulation-accelerating wetting agent comprises 0.5%-2% of cocamidopropyl betaine, 0.15%-0.8% of butylnaphthalenesulfonic acid sodium salt, 0.2%-1% of trimethyl-1-propanaminium iodide, 0.2%-1% of sucrose fatty acid ester, 1%-3% of corn starch grafting sodium acrylate, 0.5%-1.5% of isooctanol phosphate, 0.06%-0.35% of sodium alcohol ether sulphate, 0.5%-1.3% of sodium diethylhexyl sulfosuccinate, 0.2%-1.2% of polyacrylamide, 0.1%-0.8% of chitin derivative-carboxymethyl chitosan, 0.1%-0.2% of polyaspartic acid, 0.3%-0.6% of calcium chloride and the balance water. The ermeability-increasing and coagulation-accelerating wetting agent for wet-type dust control has the advantages that wetting ability of water for coal is enhanced and water molecules can wrap coal dust particles quickly, so that coagulation and falling of the coal dust particles are facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

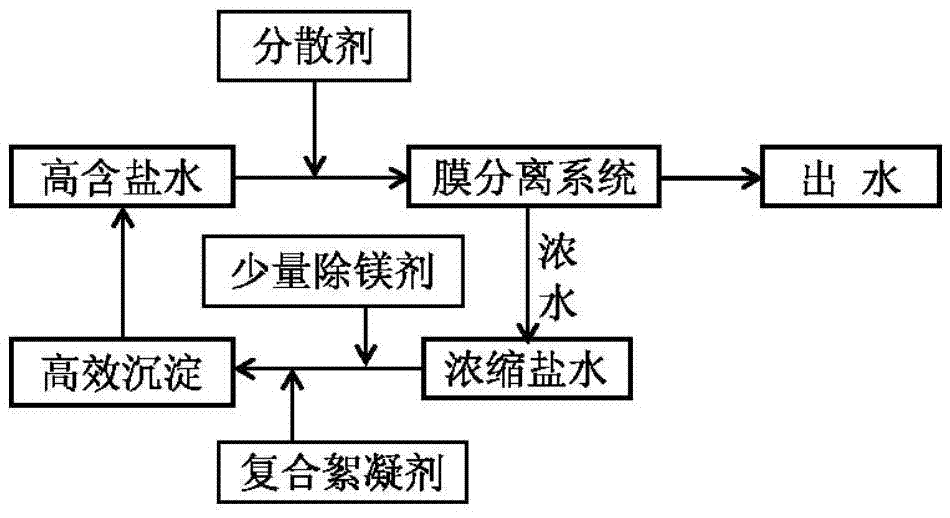

Auto-precipitation pretreatment method of high-salt wastewater

ActiveCN105439346ANot easy to scaleImprove qualityWater contaminantsWater/sewage treatment bu osmosis/dialysisChemistryPre treatment

An auto-precipitation pretreatment method of high-salt wastewater comprises steps as follows: 1) a proper amount of dispersant is added to the high-salt wastewater, and then the wastewater enters a primary membrane separation system for treatment via a high-pressure pump; 2) concentrated water of the membrane separation system is collected, and a small amount of magnesium removing agent and a compound flocculant are added, so that the concentrated water is destabilized to produce precipitates; 3) the concentrated water of the membrane separation system is subjected to solid-liquid separation with an efficient precipitation technology, high-salt water returned by a supernatant and incoming water reenters the membrane separation system for treatment to form circulation, precipitates are products mainly comprising CaSO4 and Mg(OH)2 and are recycled to be used as desulfurizers; 4) the salt of water produced by the membrane separation system contains monovalent ions, the salt content is decreased, the water is classified, evaporated and treated after being subjected to membrane concentration and recycled to be used as fresh water, and salts mainly containing monovalent NaCl and KCl are recycled.

Owner:CEEP CO LTD

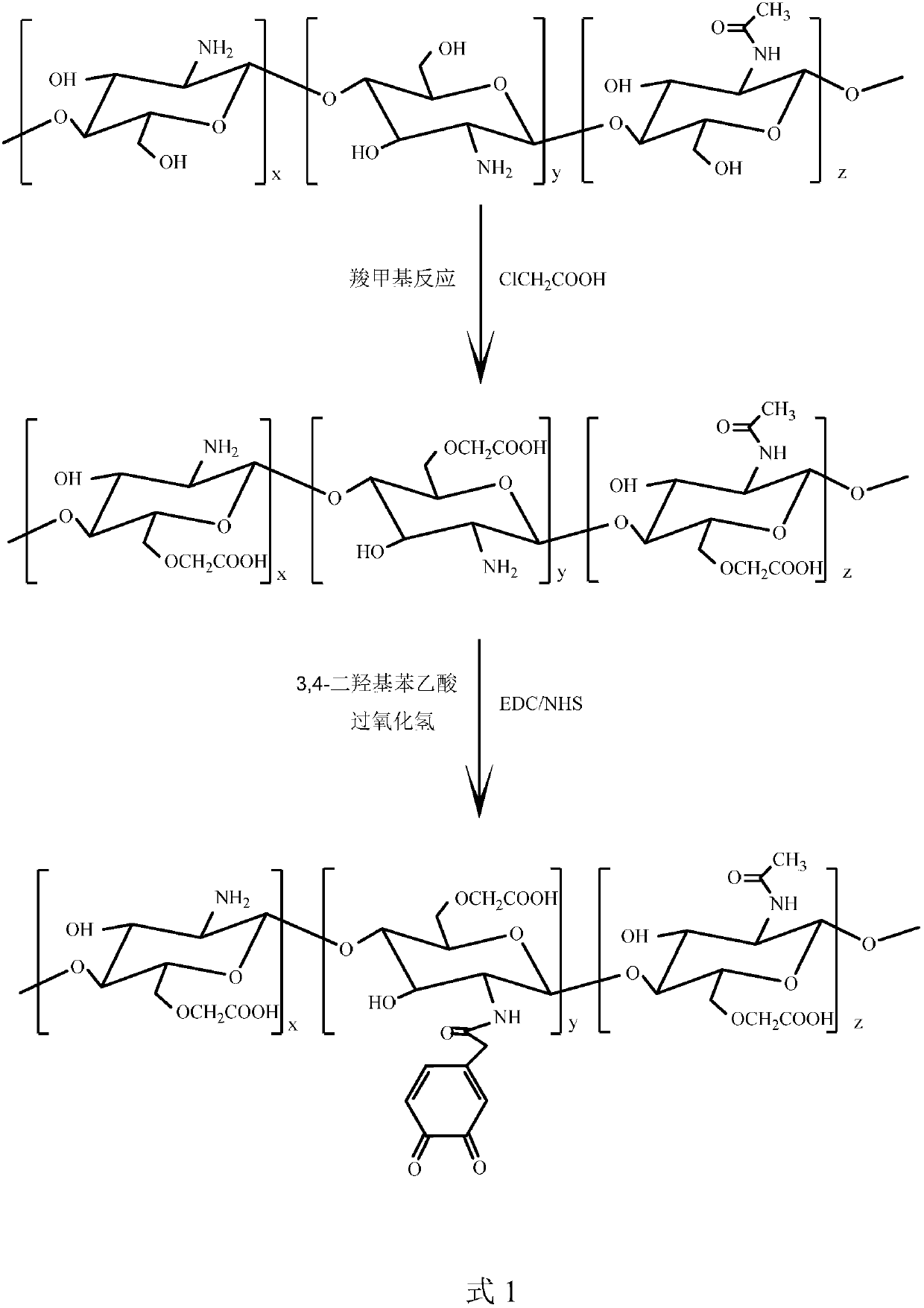

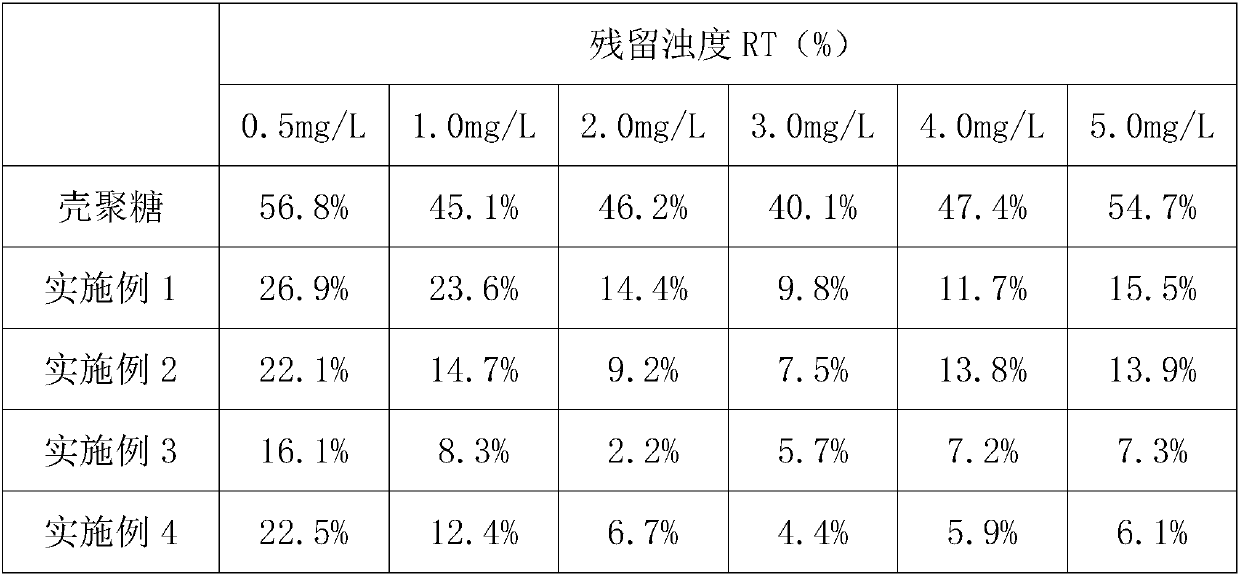

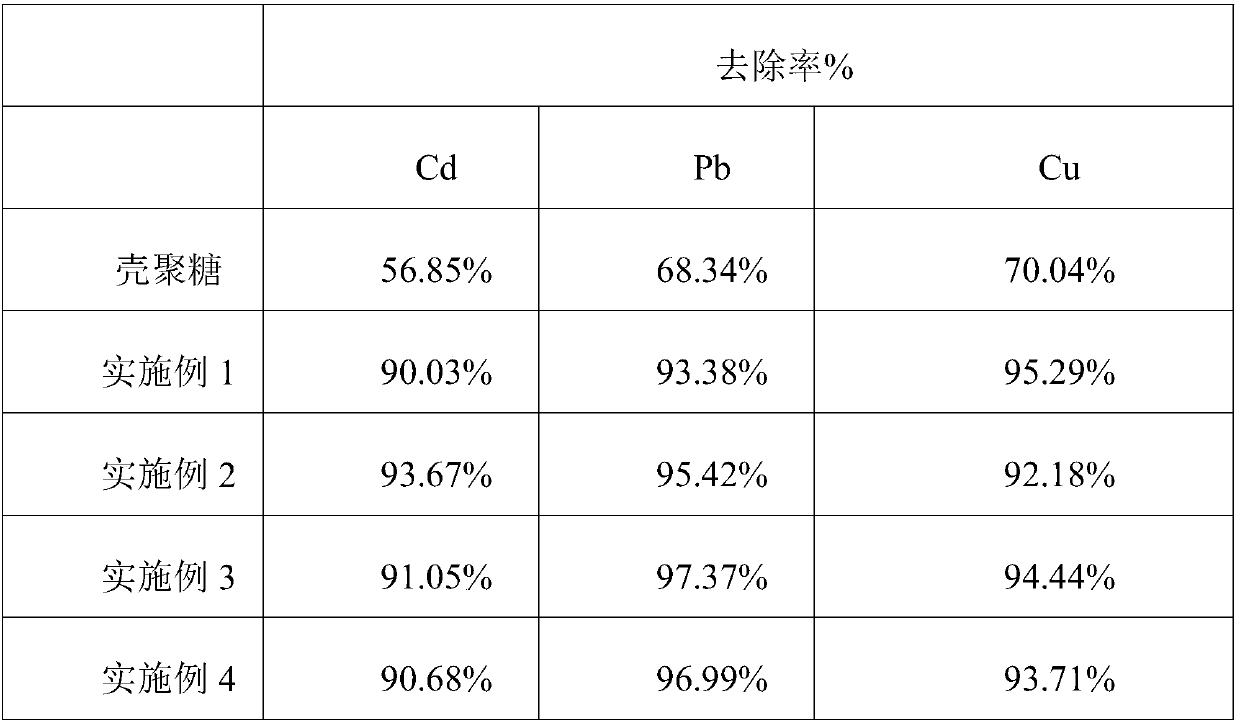

Modified water-soluble chitosan flocculating agent and preparation method thereof

ActiveCN107814434AImprove adsorption efficiencyFast flocculationWater/sewage treatment by flocculation/precipitationChemistrySolubility

The invention discloses a modified water-soluble chitosan flocculating agent and a preparation method thereof. The preparation method comprises the following steps: a carboxymethyl reaction step: dispersing chitosan into a mixed solution of isopropanol and sodium hydroxide, stirring for alkalization so as to obtain a reaction mixture, dissolving monochloro acetic acid into isopropanol to obtain asolution, dropwise adding the solution into the reaction mixture, reacting for 3-5 hours, adding an ethanol water solution to terminate the reaction, washing, and drying, so as to obtain carboxymethylchitosan; and a cross-linking reaction step: dissolving carboxymethyl chitosan into hydrochloric acid, adjusting the pH value to 5, dissolving 3,4-dihydroxyphenylacetic acid into a certain amount ofwater to obtain a solution, adding the solution into a carboxymethyl chitosan solution, dissolving a mixture of EDC and NHS into mixed liquid of water and ethanol to obtain a solution, adding the solution into a reaction solution, adding hydrogen peroxide into the reaction solution, stirring to maintain the pH value of the reaction solution at 4.5-5.0, and reacting at the room temperature for 9-11hours, so as to obtain the modified water-soluble chitosan flocculating agent. The flocculating agent disclosed by the invention has good water solubility and flocculating property.

Owner:GUANGZHOU ZHENQING ENVIRONMENTAL PROTECTION TECH

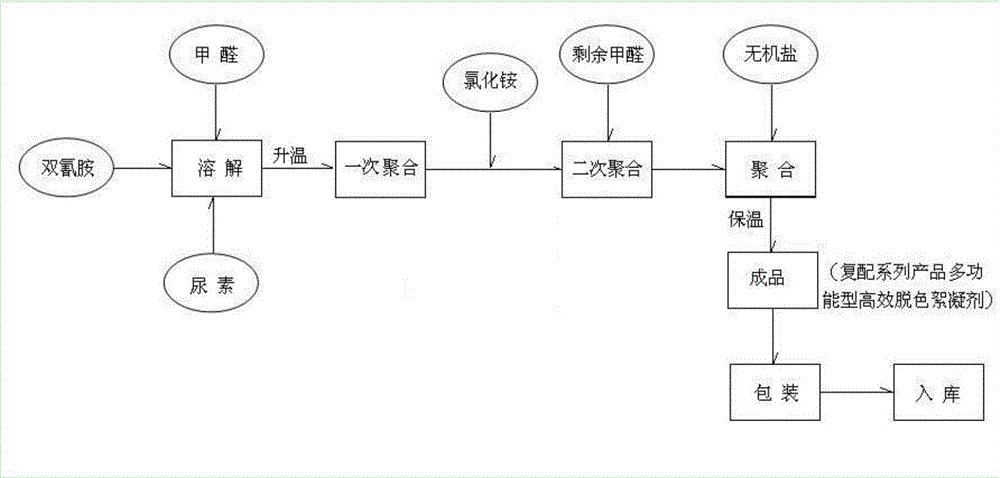

Multifunctional efficient decolorizing flocculant and preparation method thereof

ActiveCN104803458AFast flocculationSimple preparation processWater treatment parameter controlWater/sewage treatment by flocculation/precipitationIron saltsTherapeutic effect

The invention discloses a multifunctional efficient decolorizing flocculant and a preparation method thereof. The decolorizing flocculant includes 15-25% of formaldehyde, 12-20% of dicyandiamide, 22-28% of ammonium chloride, 13-18% of urea and 20-30% of inorganic salt; and the inorganic salt is one or more selected from aluminum salt, iron salt and silicon salt. The preparation is as below: adding formaldehyde accounting for 3 / 5-2 / 3 of the total formaldehyde in a reactor, then adding urea and dicyandiamide in turn for dissolving, heating to 40+ / -2 DEG C-50 + / -2 DEG C, and conducting a polymerization reaction; adding ammonium chloride and the remaining formaldehyde, controlling the temperature at 80+ / -2 DEG C-90+ / -2 DEG C, conducting a second polymerization, and insulating for 2-4 h; and adding inorganic salt and stirring uniformly to obtain the flocculant. The decolorization flocculant has the advantages of solid content of more than 55%, wide application, decolorization rate of more than 95%, high flocculation speed and COD removal rate reaching more than 65%, improves the process requiring repeated addition of different organic and inorganic flocculants in water treatment, and solves the problem of influence of different order of operations on wastewater treatment effects.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com