Method for processing wastewater containing heavy metal ions

A technology for heavy metal ions and waste water, applied in chemical instruments and methods, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc., can solve the problems of environmental secondary pollution, incomplete separation, and low treatment efficiency, and achieve The effect of wide application range, shortened settling time, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

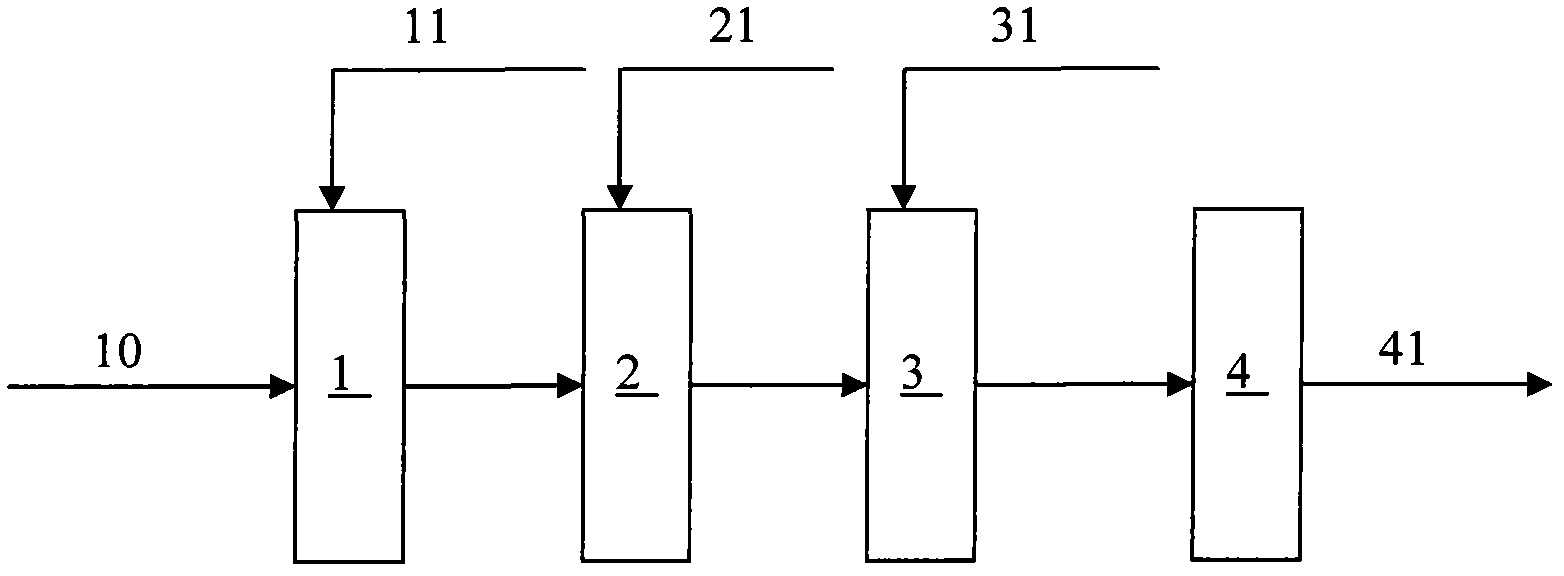

Image

Examples

Embodiment 1

[0048] At 18°C, will contain Pb 2+ , Hg 2+ , Zn 2+ 、Cu 2+ Wastewater such as heavy metal ions is discharged into the pH value adjustment tank with stirring device, and Ca(OH) is continuously added at the same time 2 Adjust the pH of the wastewater to 8 ± 0.5. Next, the wastewater is discharged into the vulcanization analysis reactor with a mechanical stirring device, and at the same time, the chemical formula is Na 2 S 3 The sodium polysulfide, its addition is calculated as S:Me=2:1 with the total molar ratio of heavy metal ions in sulfur and waste water. After reacting in the vulcanization desorption reactor with mechanical stirring device for 60 minutes, the waste water is discharged into the flocculation tank with stirring device, and anionic polyacrylamide is continuously added under stirring at the same time, and the addition amount is 15 mg per liter of waste water. After the wastewater stays in the flocculation tank for 3 minutes, it is discharged into the sedimen...

Embodiment 2

[0052] At 20°C, will contain Pb 2+ 、Cr 3+ 、As 3+ 、Cu 2+ , Zn 2+ Wastewater containing heavy metal ions is discharged into a pH value adjustment tank with a stirring device, and NaOH is continuously added to adjust the pH value of the waste water to 7±0.5. Then, the waste water is discharged into the vulcanization analysis reactor with mechanical stirring device, while continuously adding chemical formula is Na S Sodium polysulfide, its addition is calculated as S: Me=3: 1. After reacting for 90 minutes in the vulcanization analysis reactor with mechanical stirring device, the waste water is discharged into the flocculation tank with stirring device, and at the same time, non-ionic polyacrylamide is continuously added under stirring, and the addition amount is 20 mg per liter of waste water. After the wastewater stays in the flocculation tank for 4 minutes, it is discharged into the sedimentation tank, and after it stays in the sedimentation tank for 75 minutes, the supern...

Embodiment 3

[0056] At 28°C, will contain Pb 2+ , Hg 2+ , Zn 2+ 、Ni 2+ Wastewater containing heavy metal ions is discharged into a pH value adjustment tank with a stirring device, and NaOH is continuously added to adjust the pH value of the waste water to 9±0.5. Next, the wastewater is discharged into the vulcanization analysis reactor with a mechanical stirring device, and at the same time, the chemical formula is Na 2 S 2 The sodium polysulfide, its addition is calculated as S:Me=2.5:1 with the total molar ratio of heavy metal ions in sulfur and waste water. After reacting for 45 minutes in the vulcanization analysis reactor with mechanical stirring device, the waste water is discharged into the flocculation tank with stirring device, and at the same time, anionic polyacrylamide is continuously added under stirring, and the addition amount is 15 mg per liter of waste water. After the wastewater stays in the flocculation tank for 5 minutes, it is discharged into the sedimentation tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com