Paint mist treatment method and spraying tank

A treatment method and spray box technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems that the purification treatment system cannot operate normally, affect the effect of waste gas treatment, blockage of water channels and gas channels, etc., and achieve good results. Paint mist removal effect, beneficial to cleaning, and prevents the effect of clogging the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for treating paint mist, comprising the steps of:

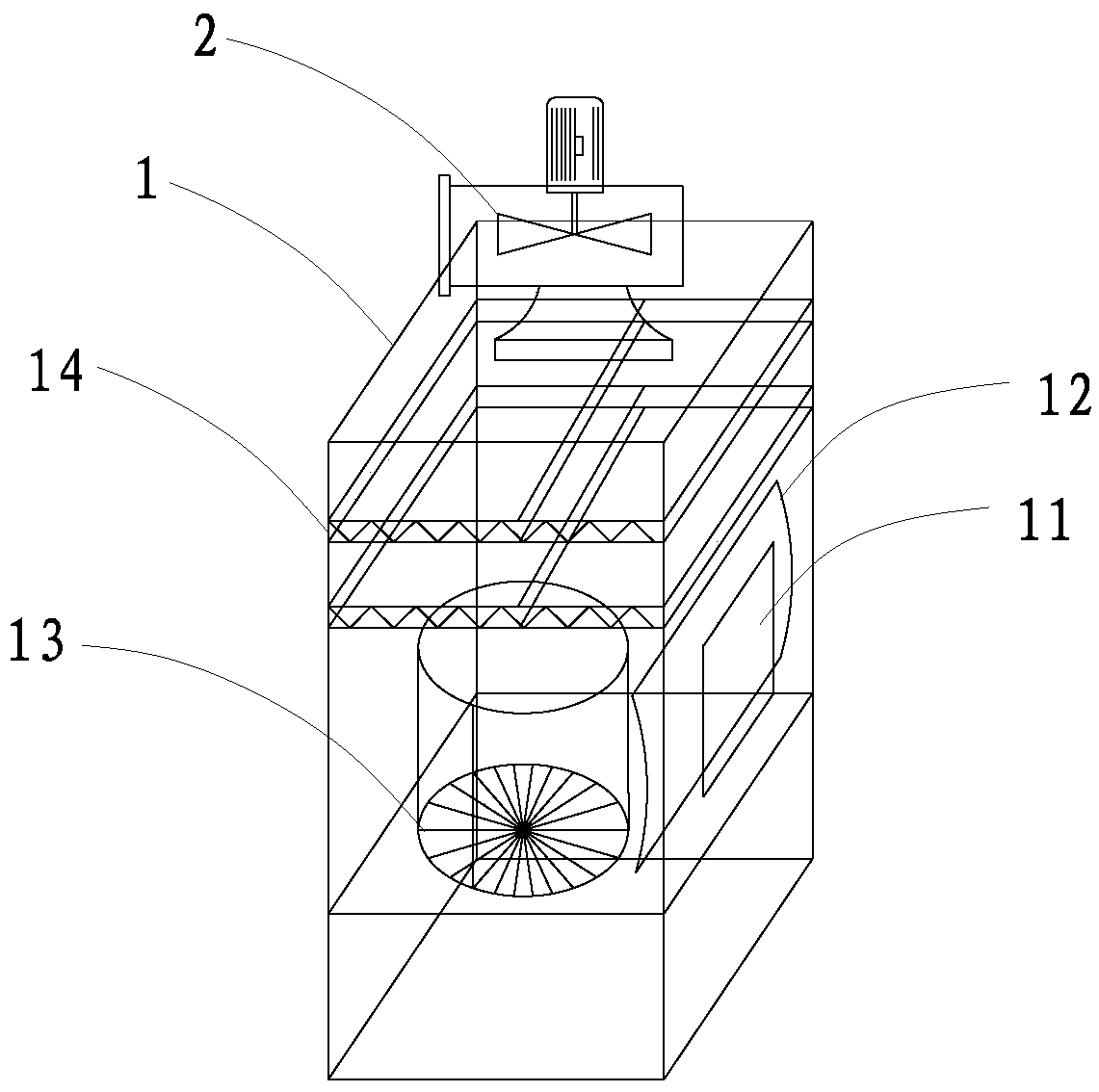

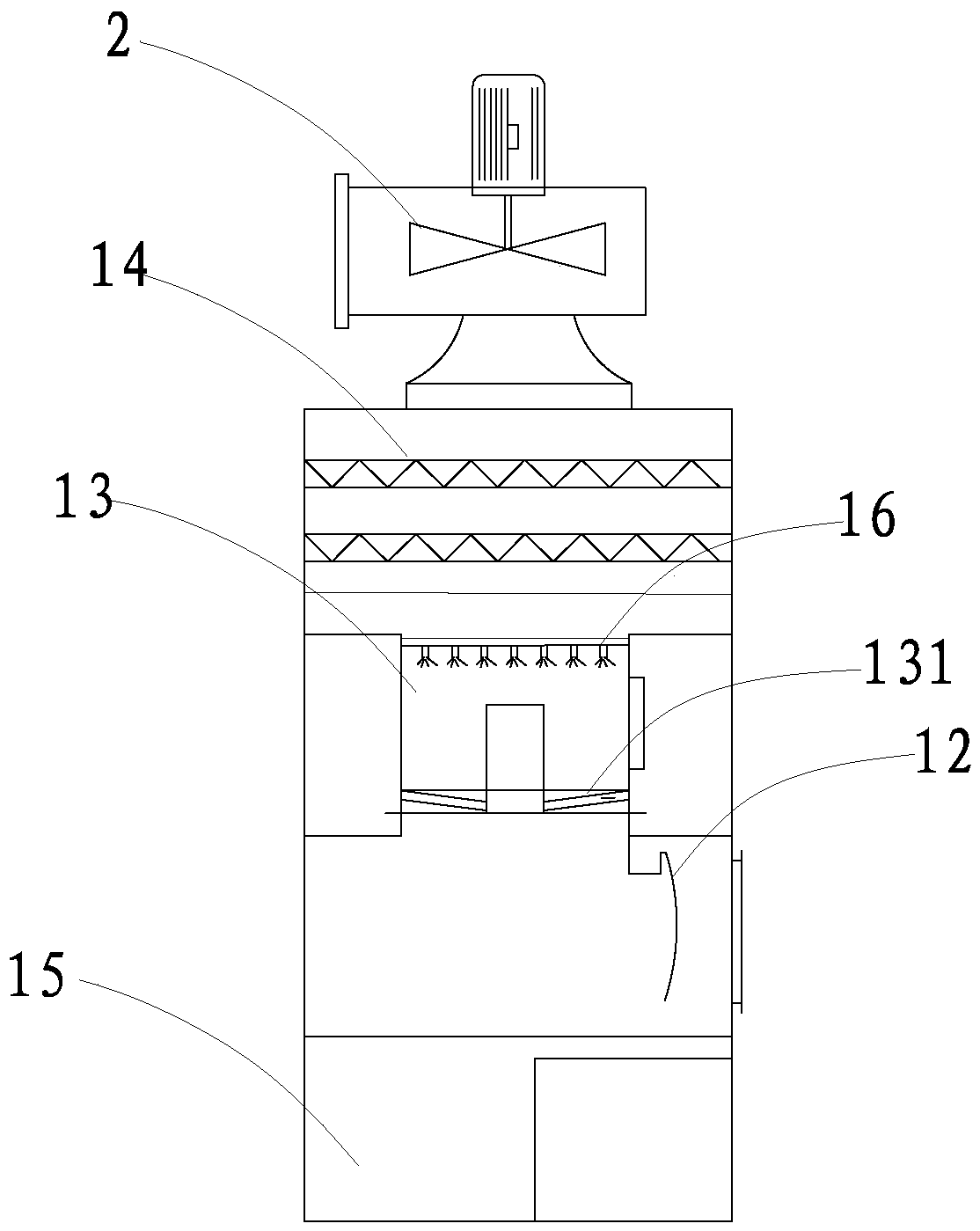

[0053] (1) The spraying exhaust gas generated in the spraying process enters the paint mist treatment chamber, and the water curtain formed by the circulating water on the water curtain baffle 12 washes and absorbs the spraying exhaust gas, and part of the paint mist of the spraying exhaust gas is brought into the spray box by the water curtain Circulating pool 15 at the bottom;

[0054] (2) After part of the paint mist is treated by the water curtain, the spraying exhaust gas enters the rotating washing drum for rotating washing. Under the action of the deflector swirl plate and the washing ball, the spraying exhaust gas is fully mixed with the circulating water in the rotating washing drum, and the rotating washing drum The spray device 16 on the top sprays and absorbs the spraying exhaust gas, and the paint mist is trapped and brought into the circulating pool 15;

[0055] (3) After the spraying exhaust ga...

Embodiment 2

[0075] The difference between this embodiment and embodiment 1 is:

[0076] In this embodiment, the paint mist decomposer includes the following components in mass percent:

[0077] Active foaming agent 10%

[0079] Citric acid 5%

[0080] water balance.

[0081] Further, the active foaming agent is an alkyl glycoside.

[0082] Further, the paint mist collector includes anionic polyacrylamide with a mass percentage of 10%. The molecular weight of the anionic polyacrylamide is 3 million.

[0083] Further, the paint mist collector also includes the following components in mass percentage:

[0084] Carboxymethylthiourea Chitosan 20%

[0085] Nano Zinc Oxide 10%

[0086] Monocetyl Maleate Sodium Salt 3%

[0087] Wherein, the particle size of the nano zinc oxide is 10nm.

[0088] Further, the defogging layer 14 is filled with Raschig rings.

[0089] Further, there are three swirl water washing drums 13, and using multiple swirl water washing ...

Embodiment 3

[0092] The difference between this embodiment and embodiment 1 is:

[0093] In this embodiment, the paint mist decomposer includes the following components in mass percent:

[0094] Active foaming agent 30%

[0096] Citric acid 8%

[0097] water balance.

[0098] Further, the active foaming agent is tea saponin and fatty alcohol polyoxyethylene ether, and the combination of these two surface active substances can mutually enhance the surface activity performance of the two, improve the foaming ability of the mixed liquid and the stability of the foam , the combination of the two can also improve the biodegradability of surfactants, reduce biological toxicity, and avoid pollution to the environment.

[0099] Further, the paint mist collector includes anionic polyacrylamide with a mass percentage of 30%. The molecular weight of the anionic polyacrylamide is 8 million.

[0100] Further, the paint mist collector also includes the following compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com