Preparation method and application of modified polyferric sulfate for treating industrial wastewater

A technology of polymerizing ferric sulfate and hydrated ferrous sulfate, which is applied in the fields of ferric sulfate, water/sewage treatment, chemical instruments and methods, etc., and can solve problems such as difficult disposal of excess sludge, slow settling speed of flocs, and large chemical sludge , to achieve the effect of good chroma removal effect, low cost and guaranteed source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

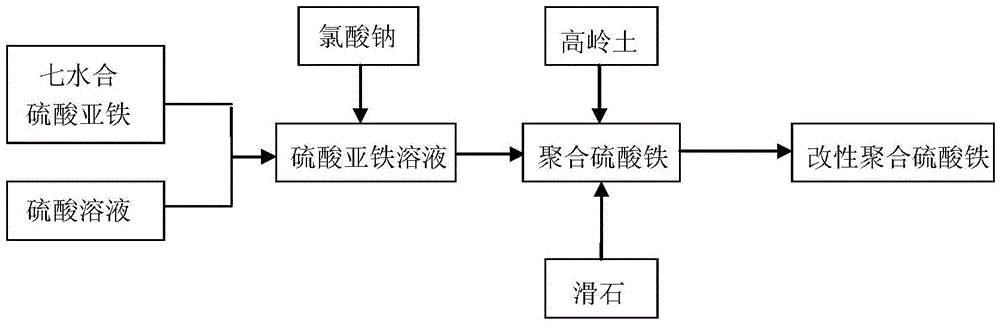

Method used

Image

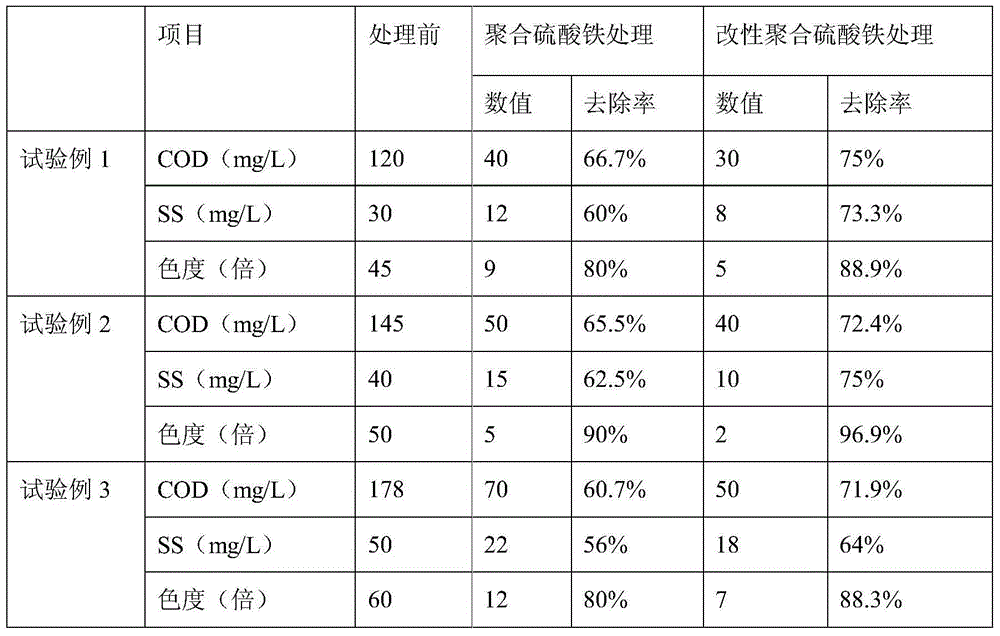

Examples

Embodiment 1

[0063] 1. Prepare ferrous sulfate solution

[0064] Add 10.9 mL of concentrated sulfuric acid into 480 mL of distilled water, and stir while adding to obtain a sulfuric acid solution with a mass fraction of 4%; weigh 263.2 heptahydrate ferrous sulfate crystals and add them to the above sulfuric acid solution, stir and dissolve at 200 r / min for 12 min, Make ferrous sulfate heptahydrate and the weight ratio of sulfuric acid solution be 1:2, promptly add 1g ferrous sulfate heptahydrate in every 2g sulfuric acid solution, make ferrous sulfate solution;

[0065] Sulfuric acid has two functions in the synthesis process of polyferric sulfate: one is to participate in the polymerization reaction as a raw material for the reaction, and the other is to determine the acidity of the reaction system, and its dosage directly affects the performance of polyferric sulfate. An appropriate increase in the amount of sulfuric acid is beneficial to improve the synthesis reaction, but the amount of...

Embodiment 2

[0075] 1. Prepare ferrous sulfate solution

[0076] Add 13.5mL of concentrated sulfuric acid into 525.25mL of distilled water, and stir while adding to obtain a sulfuric acid solution with a mass fraction of 4.5%; weigh 263.2 heptahydrate ferrous sulfate crystals and add them to the above sulfuric acid solution, stir and dissolve at 220r / min for 13min , so that the weight ratio of ferrous sulfate heptahydrate and sulfuric acid solution is 1:2.2, promptly add 1g ferrous sulfate heptahydrate in every 2.2g sulfuric acid solution, make ferrous sulfate solution;

[0077] 2. Preparation of polyferric sulfate solution

[0078] Take by weighing sodium chlorate 11.9g, make the weight of sodium chlorate and the ratio of ferrous sulfate heptahydrate weight in step 1) be 1:21, under the stirring speed of 220r / min, 5.95g sodium chloride is added to sulfuric acid In the ferrous solution, stir for 13min, then add 1.49g sodium chlorate, then add 1.49g sodium chlorate every 4min, after all th...

Embodiment 3

[0083] 1. Prepare ferrous sulfate solution

[0084] Add 8.6mL of concentrated sulfuric acid into 434.25mL of distilled water, and stir while adding to obtain a sulfuric acid solution with a mass fraction of 3.5%; weigh 263.2 heptahydrate ferrous sulfate crystals and add them to the above sulfuric acid solution, stir and dissolve at 150r / min for 12min , so that the weight ratio of ferrous sulfate heptahydrate and sulfuric acid solution is 1:1.8, promptly add 1g ferrous sulfate heptahydrate in every 1.8g sulfuric acid solution, make ferrous sulfate solution;

[0085] 2. Preparation of polyferric sulfate solution

[0086] Take by weighing sodium chlorate 11.36g, make the weight of sodium chlorate and the ratio of ferrous sulfate heptahydrate weight in step 1) be 1:22, under the stirring speed of 150r / min, 5.68g sodium chloride is added to sulfuric acid In the ferrous solution, stir for 12min, then add 1.42g sodium chlorate, then add 1.42g sodium chlorate every 4min, after sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com