Waste water treatment process

A waste water treatment, waste water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as low water treatment capacity, long flocculation time, unstable effluent quality, etc. , to achieve the effects of improved wastewater treatment capacity, faster flocculation speed, and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

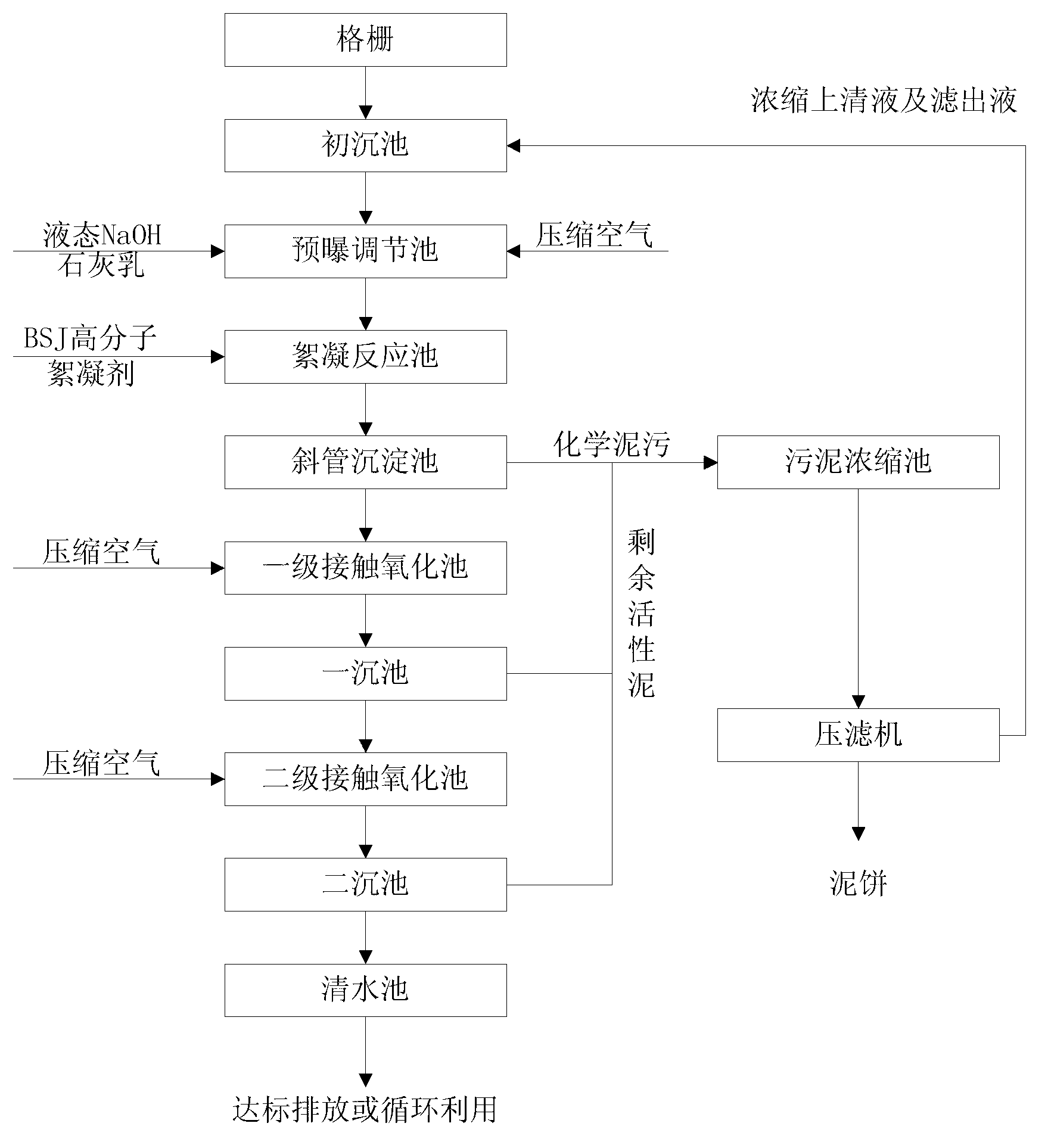

[0028] Such as figure 1 Shown is a flow chart of an embodiment of the wastewater treatment process of the present invention. The wastewater treatment process of this embodiment includes the following steps:

[0029] 1) Waste water enters the primary sedimentation tank through the grid to remove suspended solids;

[0030] 2) The waste water after removing the suspended solids overflows from the primary sedimentation tank to the adjustment tank, and adding lime milk to adjust the pH value of the waste water to neutral. Since cheap lime milk is used as a neutralizer instead of NaOH, the cost is greatly reduced;

[0031] 3) After the pH value is adjusted to neutral, the wastewater flows to the neutralization aeration tank, and the aeration tank is stirred with compressed air, and the Fe in the wastewater 2+ Convert to Fe 3+ , The neutralization and aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com