Auto-precipitation pretreatment method of high-salt wastewater

A precipitation treatment, high salt content technology, applied in the direction of flocculation/sedimentation water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc. , cumbersome operation and other problems, to achieve the effect of easy operation and maintenance, reduce infrastructure costs, and reduce the amount of sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

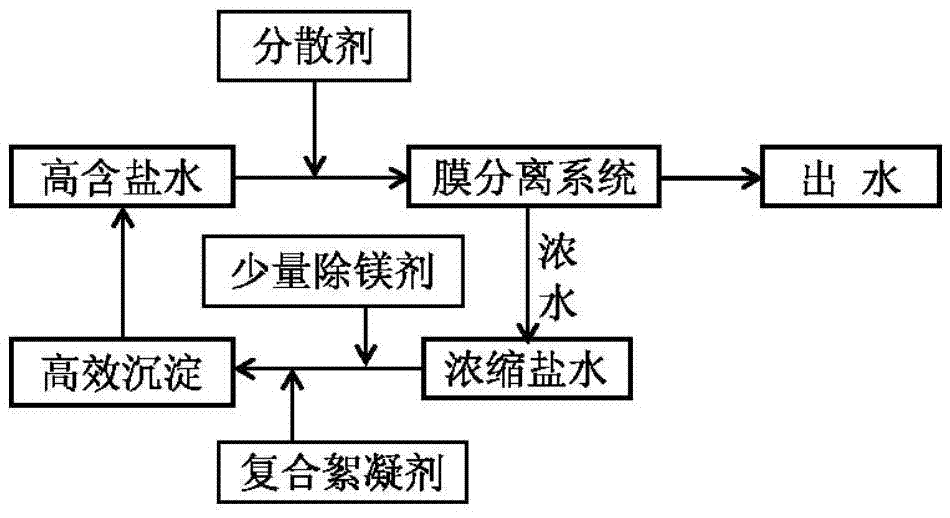

[0020] Attached below figure 1 Embodiments of the present invention will be described.

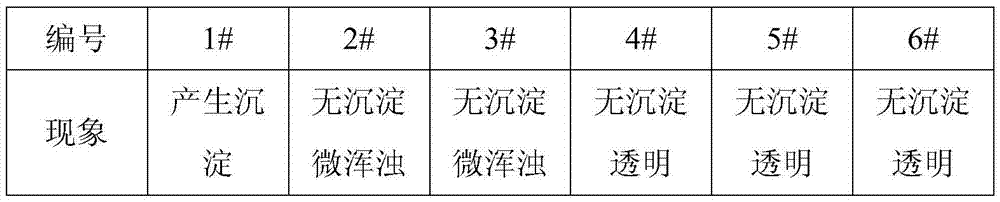

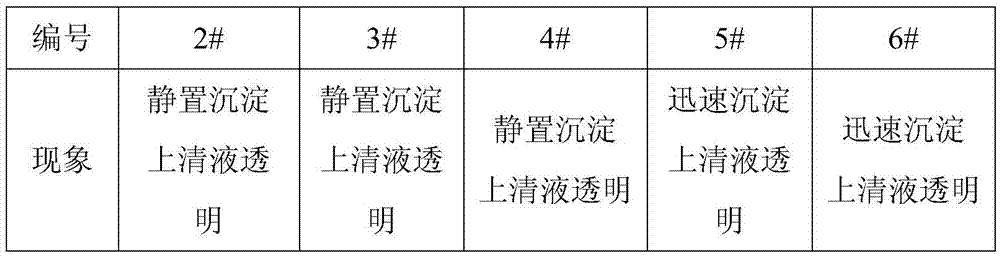

[0021] The high-salt wastewater enters the water distribution adjustment tank, and the environmentally friendly phosphorus-free agent (such as conventional polyepoxysuccinic acid and sulfonate copolymer or PA3, etc.) , fully mixed; then use a lift pump and a high-pressure pump to introduce the concentrated water from the distribution tank into the membrane separation system. The membrane separation system is a near-nanofiltration membrane system not larger than 0.25 microns. 2+ , Mg 2+ , SO 4 2- The separation rate of divalent ions and monovalent ions is 99%, which greatly reduces the salt content of the effluent. The concentrated water of the membrane separation system is recycled and enters the high-efficiency sedimentation tank. A small amount of magnesium removal agent and iron salt compound flocculant are added to the sedimentation tank. , the precipitate can be recycled as a desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com