Patents

Literature

111results about How to "Reduce the amount of sediment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating smelting wastewater containing heavy metals

InactiveCN102381789AEasy to handleSimple processWaste water treatment from metallurgical processMultistage water/sewage treatmentChemical treatmentElectrolysis

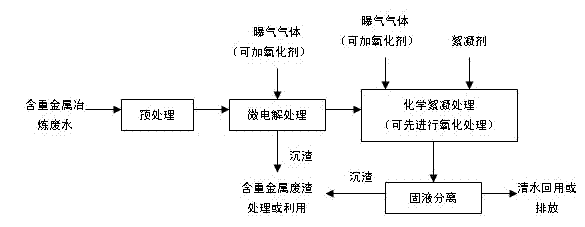

The invention discloses a method for treating smelting wastewater containing heavy metals. The method comprises the following steps: 1, the smelting wastewater containing heavy metals is pretreated to remove particulate impurities in the wastewater and adjust the wastewater to be acidic; 2, the wastewater is transferred to an iron-carbon micro-electrolytic reactor to be subjected to single-stage or multi-stage micro-electrolytic electrochemical treatment under acidic conditions to remove most heavy metal ions in the wastewater, the wastewater is adjusted to be weakly alkaline or alkaline, is subjected to single-stage or multi-stage chemical flocculation treatment to further remove other heavy metal ions, and pollutants of arsenic, fluorine, chlorine and the like in the wastewater; and 3, solid-liquid separation is carried out to obtain production water which can be recycled. The method comprises steps of wastewater pretreatment, iron-carbon micro-electrolysis, chemical flocculation and solid-liquid separation which are organically coupled in series. The method which organically combines the micro-electrolysis with the chemical flocculation and allows them to mutually cooperate with each other and co-perform effects has the advantages of simple treating process and technology, low treatment cost, high treatment efficiency, and standard-reached discharge and recovery of the treated wastewater.

Owner:KUNMING UNIV OF SCI & TECH

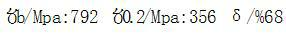

Seamless steel pipe for line pipe and a process for its manufacture

ActiveUS20080219878A1Stable supplyHigh strengthFurnace typesHeat treatment furnacesChemical compositionHigh intensity

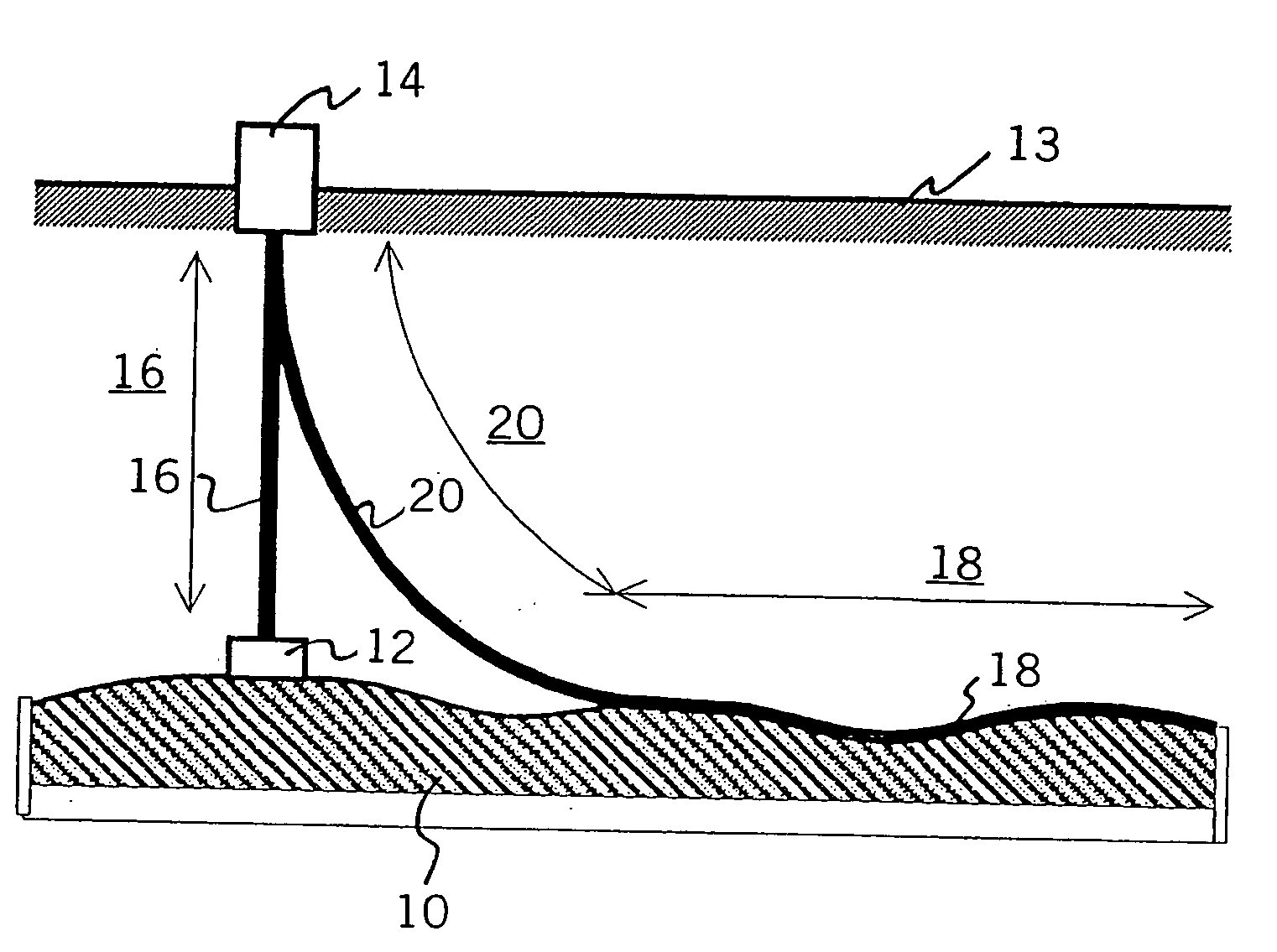

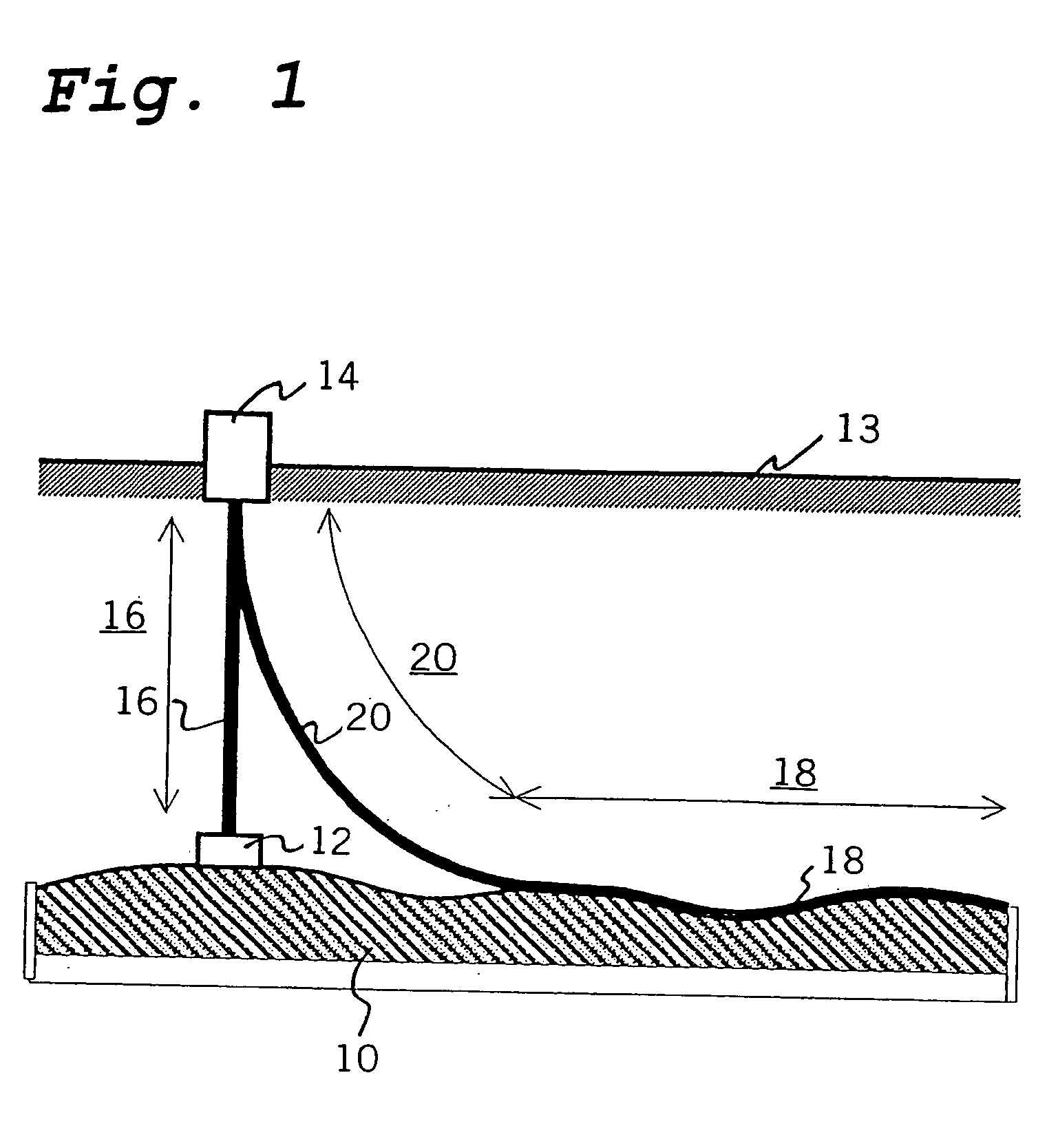

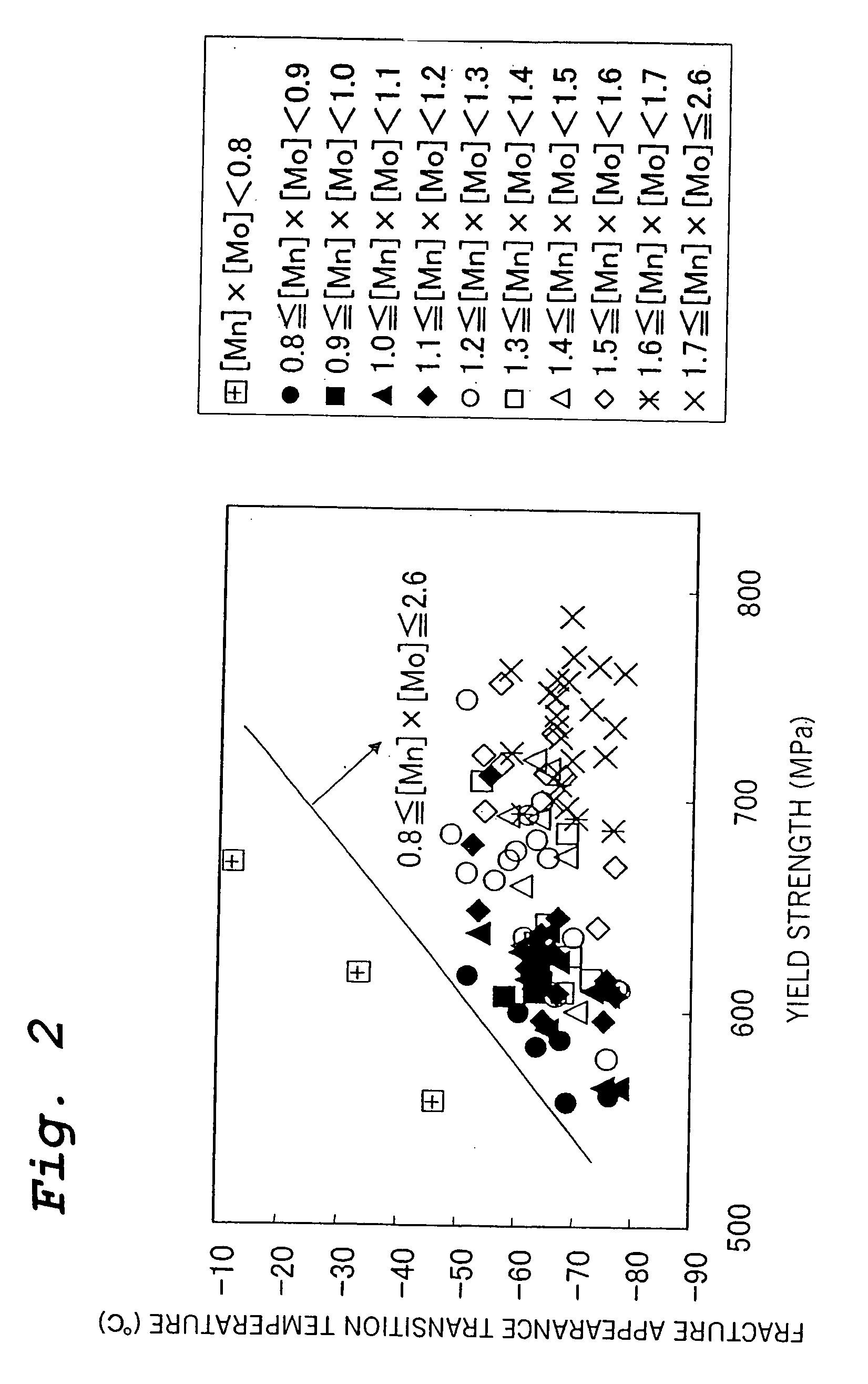

A thick-walled seamless steel pipe for line pipe which has a high strength and improved toughness and corrosion resistance in spite of the thick wall and which is suitable for use as a riser and flow line has a chemical composition comprising, in mass percent, C: 0.02-0.08%, Si: at most 0.5%, Mn: 1.5-3.0%, Al: 0.001-0.10%, Mo: greater than 0.4%-1.2%, N: 0.002-0.015%, at least one of Ca and REM in a total amount of 0.0002-0.007%, and a remainder of Fe and impurities, with the impurities having the content of P: at most 0.05%, S: at most 0.005%, and O: at most 0.005%, the chemical composition satisfying the inequality: 0.8≦[Mn]×[Mo]≦2.6, wherein [Mn] and [Mo] are the numbers equivalent to the contents of Mn and Mo, respectively, in mass percent.

Owner:NIPPON STEEL CORP

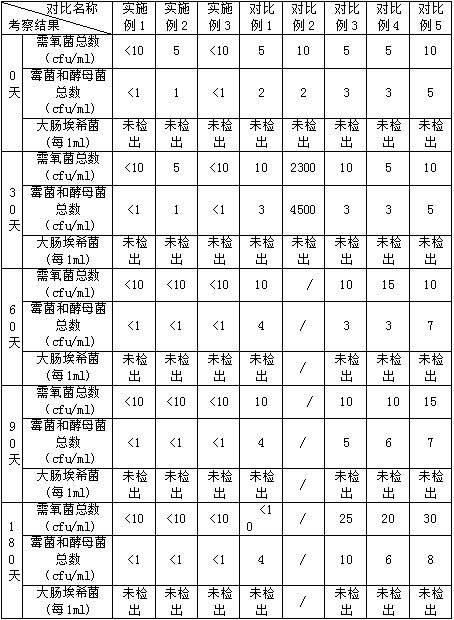

Compound microorganism agent for treating black and odorous water body

ActiveCN108441444AImprove the problem of smelly and blackHigh transparencyFungiBacteriaBacillus licheniformisCandida tropicalis

The invention provides a compound microorganism agent for treating a black and odorous water body. The compound microorganism agent comprises compound bacteria and a compound enzyme preparation, wherein the compound enzyme preparation comprises candida tropicalis, candida utilis, bacillus natto, bacillus subtilis, bacillus licheniformis, nitrobacter, achromobacter denitrificans, nitrosomonus, acinetobacter, lactobacillus, aspergillus niger, aspergillus oryzae and photosynthetic bacteria; the compound enzyme preparation comprises protease, amylase, lipase, sucrase, and cellulase.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

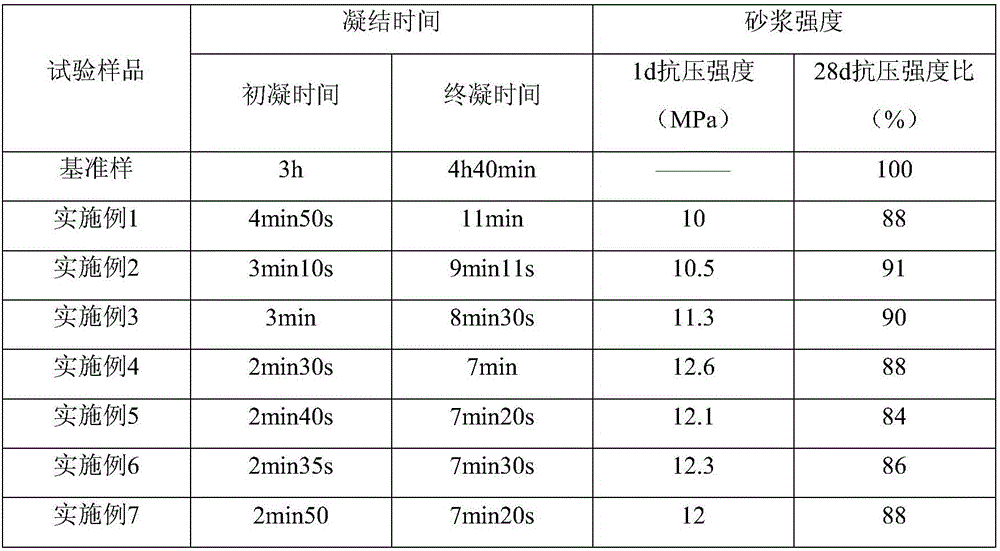

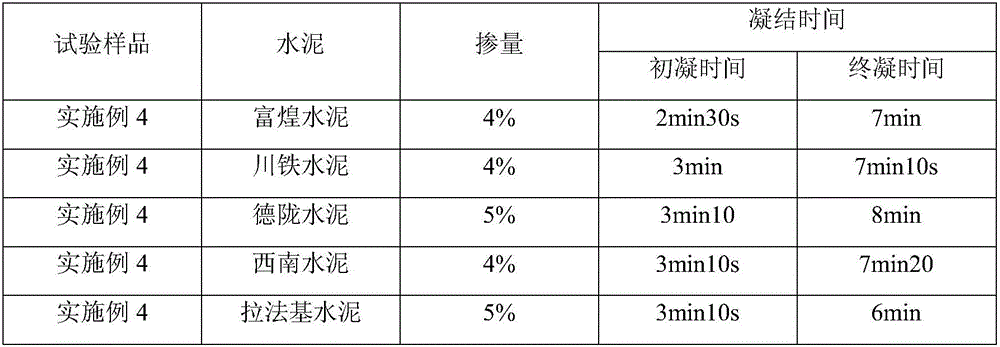

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

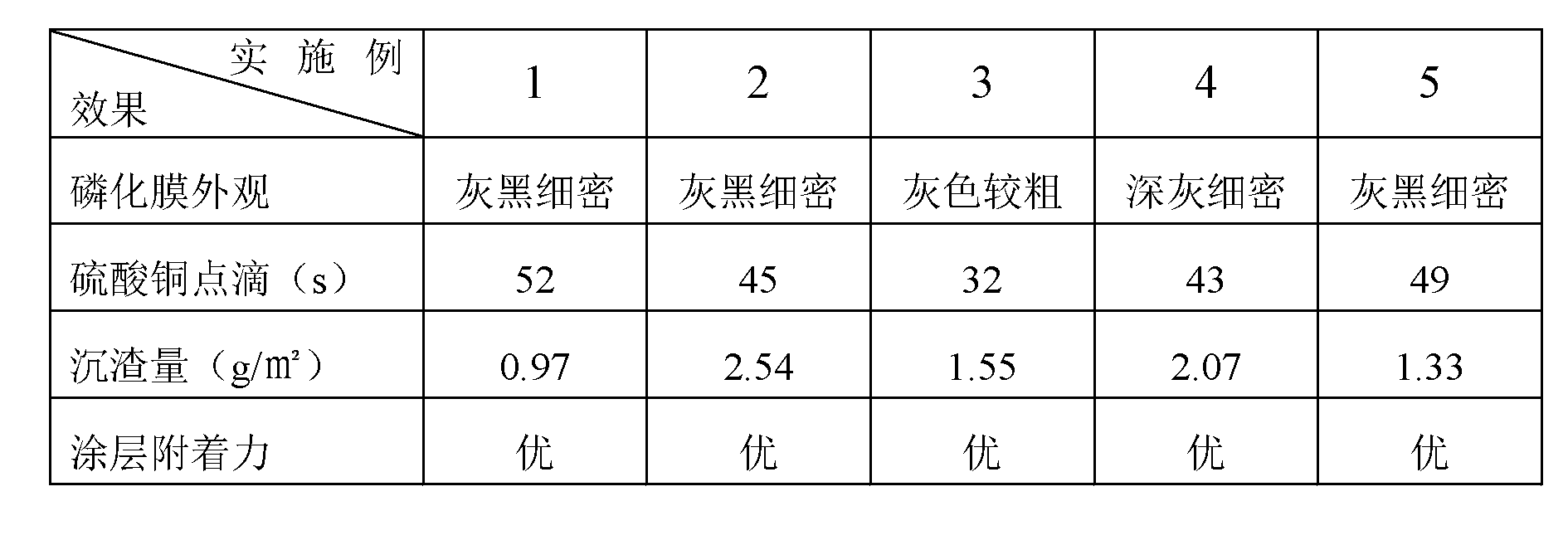

Acid cleaning and phosphorizing method of electromobile frame

InactiveCN103243338AReduce labor intensityModerate thicknessMetallic material coating processesSurface conditionsDisposal Technique

The invention relates to an acid cleaning and phosphorizing method of an electromobile frame, belonging to the technical field of metal surface treatment. The method comprises the following steps: (1) degreasing the metal frame; (2) cleaning with water; (3) immersing the metal frame in an acid cleaning solution to carry out acid cleaning; (4) flushing with water; (5) immersing in a surface conditioning tank to carry out surface conditioning; (6) immersing in a phosphorizing tank to carry out phosphorization and film formation; (7) cleaning in a clean water tank; and (8) drying in a phosphorizing line baking oven. The invention has the advantages of low technical difficulty, strong operability, simple technique, low deposit amount, high film formation speed, is simple and convenient for maintenance, greatly lowers the labor intensity of workers, and reduces the technical pollution; and the finally obtained grey phosphorized film has the advantages of uniform crystallization and moderate thickness, and greatly prolongs the service life of the electromobile metal frame.

Owner:山东威斯特车业有限公司

Novel hillside rainwater collection system and mountain torrent and debris flow control method

InactiveCN105220731AIncrease coverageReduce the amount of sedimentFatty/oily/floating substances removal devicesSewerage structuresEarly warning systemCollection system

The invention discloses a novel hillside rainwater collection system and a mountain torrent and debris flow control method and relates to the technical field of rainwater collection and utilization and geological disaster control technologies. The novel hillside rainwater collection system mainly comprises four major subsystems, namely a hillside rainwater converging subsystem, a water-stone separation subsystem, a power generation subsystem and an irrigation subsystem, wherein the hillside rainwater converging subsystem comprises a debris flow monitoring and early warning module, an ecological slope protection module and netted open channels; the water-stone separation subsystem comprises flexible drainage guide grooves, silt accumulation pools and a sub-hill tunnel; the power generation system comprises a power generation workshop, a barrier dam and a reservoir; the irrigation subsystem comprises open channels and a drip irrigation subsystem. The novel hillside rainwater collection system and the mountain torrent and debris flow control method have the advantages of being simple in design, convenient to construct, low in project cost and general in applicability.

Owner:甘建军

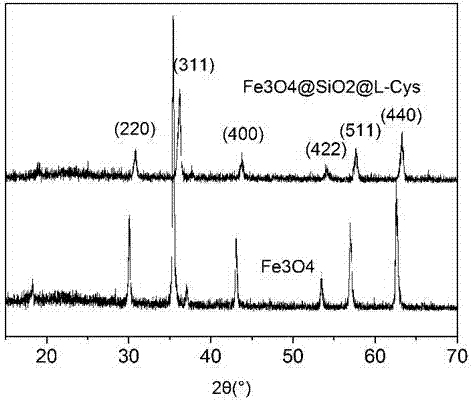

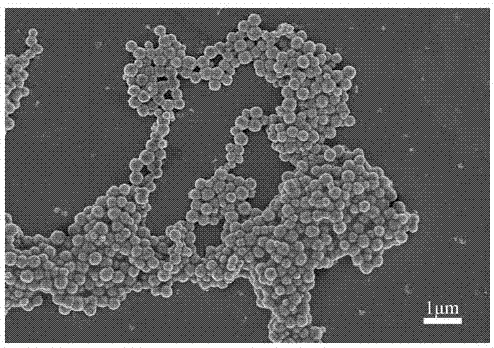

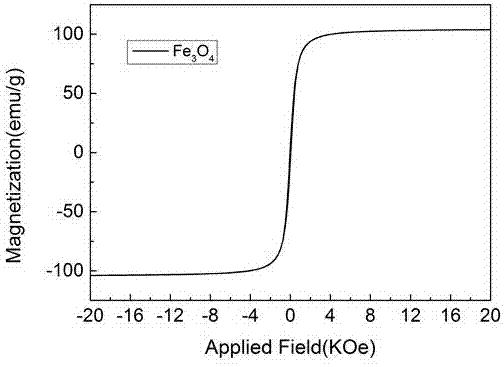

Group enhanced type magnetic nanometer water treatment agent and preparation method and application thereof

InactiveCN106955672AImprove the magnetic adsorption effectImprove adsorption capacityOther chemical processesWater contaminantsPolyethylene glycolMagnetite Nanoparticles

The invention discloses a group enhanced type magnetic nanometer water treatment agent and a preparation method and application thereof. The preparation method is characterized by comprising the following steps: accurately weighting hexahydrate ferric chloride and anhydrous sodium acetate as reaction raw materials; firstly, dissolving the raw materials into ethylene glycol; then, adding polyethylene glycol to disperse; adding solution into a high-pressure reaction reactor container to react; carrying out magnetic adsorption to obtain Fe3O4 magnetic nanoparticles; taking ethyl orthosilicate as a silicon source to enable silicon dioxide to cover the surface of the Fe3O4 magnetic nanoparticles; taking silane coupling agent as an amino source to graft an -NH2 group to the surface of the silane coupling agent to obtain Fe3O4@SiO2-NH2 magnetic nanoparticles; finally, under a constant temperature, stirring to modify the amino and sulfydryl group of cysteine on the surfaces of the Fe3O4@SiO2-NH2 magnetic nanoparticles to obtain group-enhanced magnetic nanometer water treatment agent Fe3O4-SiO2-NH2-L-Cys. The preparation method has the advantages of simpleness in preparation process operation and easiness in realizing reaction conditions. In addition, the group enhanced type magnetic nanoparticles prepared with the preparation method has the advantages of narrow particle size distribution, good stability, good adsorption function for various heavy metal ions and high adsorption efficiency.

Owner:CHONGQING UNIV

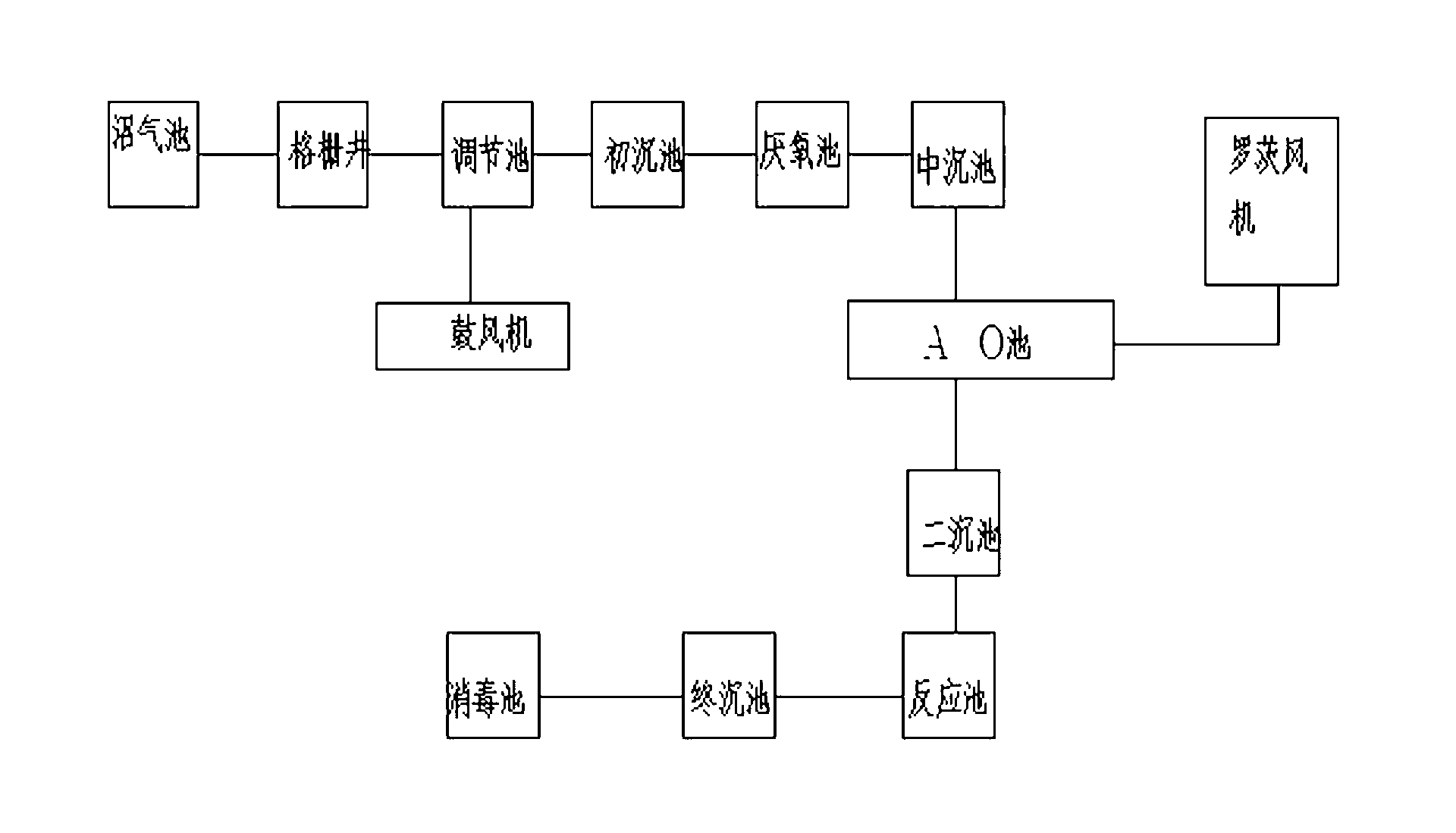

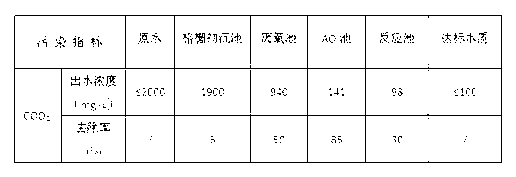

Large-scale pig farm wastewater treatment method

ActiveCN103241908AImprove biodegradabilityAvoid churnMultistage water/sewage treatmentPig farmsMedicine

The invention relates to a large-scale pig farm wastewater treatment method comprising anaerobic fermentation, filtering, regulating pool treatment, primary precipitation, anaerobic pool treatment, secondary precipitation, A / O pool treatment, precipitation of secondary sedimentation tank, flocculent precipitation treatment, final precipitation treatment and disinfecting tank treatment. The treatment method provided by the invention is simple in treatment procedures, low in treatment cost and strong in treatment ability, thereby being suitable for popularization and application of large-scale pig farm wastewater treatment.

Owner:巨星农牧有限公司

Ultralow-temperature welded alloy steel and production method thereof

Owner:JIANGSU TIANYE ALLOY MATERIAL

Low-temperature single-component zinc series phosphating solution and preparation method thereof

InactiveCN102703889AFast film formationImprove corrosion resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a low-temperature single-component zinc series phosphating solution and a preparation method thereof. The low-temperature single-component zinc series phosphating solution comprises the components of 5-9 g / L of zinc oxide, 12.5-30 g / L of phosphoric acid, 3-6.2 g / L of nitric acid, 0.3-1 g / L of nickel nitrate, 0.5-1.5 g / L of sodium m-nitrobenzenesulfonate, 1.5-2.5 g / L of sodium chlorate, 1-2.5 g / L of hydroxylamine sulphate, 1-2 g / L of citric acid, and the balance of water. According to the invention, sodium chlorate, hydroxylamine sulphate and sodium m-nitrobenzenesulfonate are used together as a compound accelerator, and the characteristics of the three accelerators are brought into full play, so that the prepared phosphating solution is stable, the sediment weight is light, and the performance of the phosphate film is good. The low-temperature single-component zinc series phosphating solution has the advantages of convenience in use, less difficulty in control technique, high speed of film formation, wide applications and simple preparation method.

Owner:武汉永正科技发展有限公司

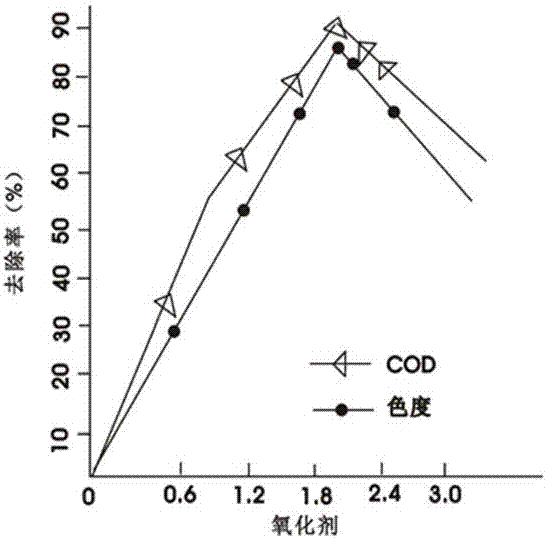

Method for treating highly-difficult-to-treat industrial wastewater through catalytic oxidation and micro-electrolysis

InactiveCN102951759AEfficient degradationReduce workloadMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrolysisCatalytic oxidation

The invention relates to a wastewater treatment method, in particular to a wastewater treatment method through catalytic oxidation and micro-electrolysis. The wastewater treatment method comprises the following steps of: 1, iron and carbon pretreatment; 2, micro-electrolysis reaction: regulating pH (potential of hydrogen) of wastewater to 2-3 by using acid, feeding pretreated iron chips and pretreated activated carbon according to weight ratio of the iron chips to the activated carbon being 1:1 and ratio of the total weight of the iron chips and the activated carbon to the weight of the wastewater being 1:3, conducting aeration by using compressed air, adding H2O2 according to ratio being 1 / 1000 when pH reaches 4-5, stopping reaction till pH reaches 6, draining the wastewater into an intermediate pond and adding polyacrylamide (PAM) for settlement; and 3, catalytic oxidation: after settlement, feeding the wastewater into a reaction pond with an agitator, regulating pH to 3-4 by using acid, adding powder activated carbon and 4A molecular sieves according to ratio being 0.2 / 1000, then adding oxidant H2O2 according to ratio being 2.1 / 1000, keeping reaction for 60min, and after the reaction is stopped, regulating pH to 6-7 by using NaOH solution and adding PAM for settlement. The method for treating highly-difficult-to-treat industrial wastewater through catalytic oxidation and micro-electrolysis has the advantages that the treatment effect of the highly-difficult-to-treat industrial wastewater can be improved and the application scope is wide.

Owner:YUNNAN CHUNCHENG IND GRP

Formula of phosphatizing liquid for metal surface anti-rusting and phosphatizing process

InactiveCN1769522ADense grainUniform grainMetallic material coating processesPhosphorCompound (substance)

This invention discloses an anti-rust phosphor solution formula of a metal and its technology method, the formula is composed of the following materials: XMn(H2PO4)2íñYfe(H2PO4).4H2O is 20-100g / lú¼Mn(NO3)2íñ6H2O is 20-100g / lú¼Zn(NO3)2íñ6H2O is 100-200g / lú¼Ni+2 is 0.5-10g / lú¼exterior active formula is 0.5-20g / l, water takes up 2 / 3 of the whole chemical, there also has some proper crap irons. The technology method as followsú‘Firsly, preparing solution by the formula; secondly, adjusting the acid proportion of the solution; thirdly, doing the pretreatment on the surface of the metal; fourthly, phosphating; fifthly, ost-treatment, oiling. The phosphor film crystal grain made in this invention is dense, symmetrical, the film is thin, the phosphor coating is symmetrical and dense, and the color is plentiful.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

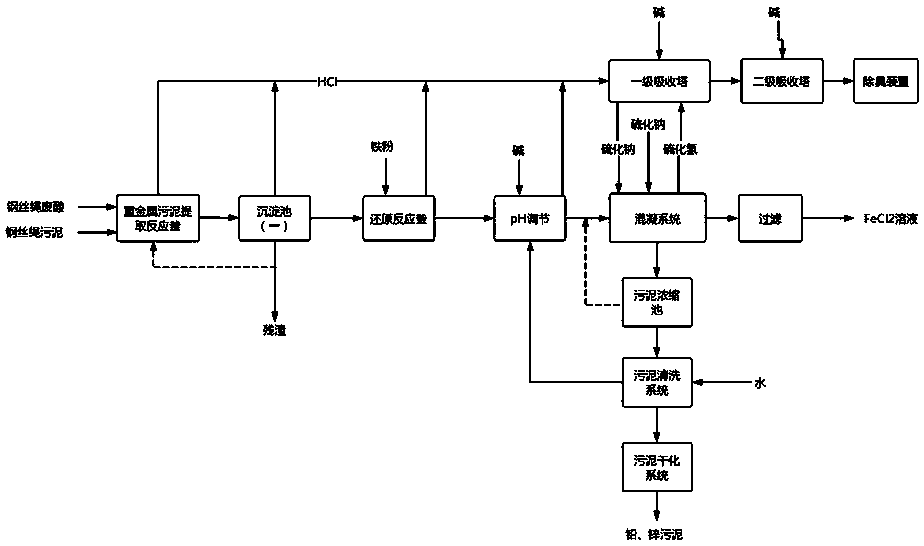

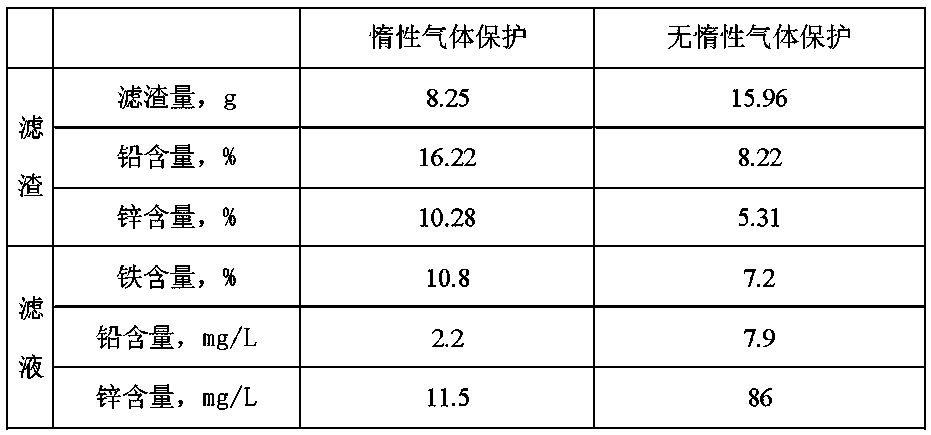

Waste acid recovery treatment method for sludge generated in steel wire rope plant

InactiveCN108383272AAchieve separationReduce usageSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeAcid washing

The invention discloses a waste acid recovery treatment method for sludge generated in a steel wire rope plant. Steel wire rope acid washing waste acid is used for leaching metal irons of iron, lead and zinc in the steel wire rope sludge; sludge residue is conveyed to a hazardous waste treatment center to be treated; iron powder is used for reducing ferric ions into ferrous ions; through sulfide precipitation, lead and zinc ions are precipitated; the generated lead and zinc precipitates are cleaned and dried; the material can be used as a lead and zinc melting raw material due to the lead andzinc abundance; the purified ferrous chloride solution can be sold as production raw materials of polymeric ferric chloride flocculant; hydrogen sulfide gas generated in the reaction process and unorganized emission hydrogen sulfide gas are treated by two-stages of filling material adsorption towers and an active carbon deodorization device, the discharge is performed after the contaminant discharge standard is met; the generated sulfide is reused in a coagulation precipitation system. The method provided by the invention solves the problems that the sludge and waste acid generated in the steel wire rope production process of high toxicity, great harm, high yield, difficult processing and secondary pollution generation and the like.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Hypothermal nontoxic phosphatization liquid containing accelerant of hydroxylamine sulfate, and preparation method

InactiveCN1563491AReduce pollutionGood for healthMetallic material coating processesNitriteHydroxylamine sulfate

A low temperature atomic phosphide liquor containing hydroxylamine sulfate accelerant is composed of HNO3: 10-15ml / L, H3PO412-18ml / L, ZnO 8-12G / l, CuSO4, 5H2O 0.6-1.0G / l, HAS 2.0-4.0g / L, Na2 MoO4 2H2o 0.03-0.05%g / L, NaC103 0.8-1.3G / l, C6H8O7. H2O 2.0-3.0g / L characterizing in taking hydroxylamine sulfate accelerant as the master accelerant matched with other additives.

Owner:大连理工大学技术转移中心有限公司

Treatment method for simultaneous removal of fluoride ions and chloride ions in industrial wastewater

InactiveCN107628687AReduce residual concentrationReduce dosageWater contaminantsBiological water/sewage treatmentThiobacillus ferrooxidansHigh concentration

The invention discloses a treatment method for simultaneous removal of fluoride ions and chloride ions in industrial wastewater. The method removes fluoride ions and chloride ions in industrial wastewater through a two-stage process consisting of pretreatment and advanced treatment, wherein Ca(OH)2 and NaAlO2 are used for precipitation in pretreatment, and a biological coagulant is used for coagulation and sedimentation in advanced treatment. According to the invention, the biological coagulant is prepared from directionally domesticated Thiobacillus ferrooxidans and has the advantages of no toxicity, high efficiency, no secondary pollution, national degradability and the like. The treatment method provided by the invention can simultaneously remove fluoride ions and chloride ions in high-concentration industrial wastewater, has low sediment amount, low residual concentration of fluoride ions and chloride ions and good application prospects, and is of great significance to the development of treatment of industrial water pollution in China.

Owner:广西华锡集团股份有限公司

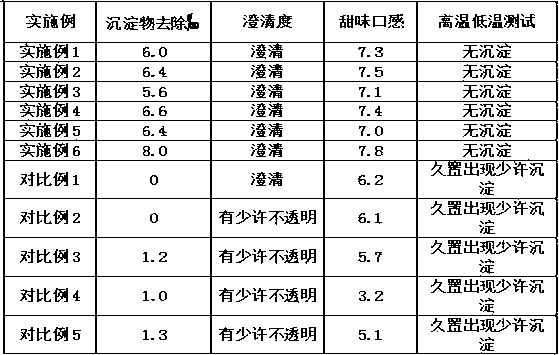

Technique for preparing low sugar Huadiao wine

The present invention relates to a wine production process, especially relates to the production process of huadiao liquor with little sugar, the production process is: after soaking rice in the rice, steams rice, puts into the cylinder and ferments, the pot raises the unfiltered wine, after presseing out the liquor, lowers degree, adds the yeast, and blends after second fermentation blends and flavors, then filters, fries the liquor, then melts in jars, after attracting the liquor then filters, after the canning sterilization then pastes the sign, the packing goes into storage for the end product. This invention fermentation is complete, greatly reduced sugar and soaks output soaking, and adapted drink to the diabetes patient and the obese crowd, simultaneously reduces precipitation quantity, and lengthened the goods time.

Owner:周卫芳

Preparation method of powerful loquat syrup

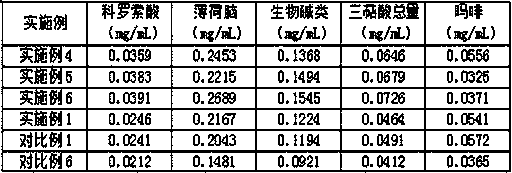

ActiveCN109125258AHigh in corosolic acidHigh active ingredientDispersion deliveryHydroxy compound active ingredientsMicroorganismMenthol

The invention provides a preparation method of powerful loquat syrup. The preparation method comprises the following steps of adding water to the remaining 6 kinds of components including loquat leaves in a formula except menthol, performing decoction for two times, wherein the decoction time each time is 2 hours, combining decoction solutions, performing filtration, performing concentration, thenperforming centrifuging, decocting centrifugate, and then performing enrichment after concentration, so that effective components of the powerful loquat syrup are wholly increased. According to the technology of the preparation method disclosed by the invention, sediments in traditional Chinese medicine extracts are removed, so that 0.05% or above of removal rate can be achieved, the clarity of products is effectively guaranteed, the quality problem that a conventional powerful loquat syrup product generates a few precipitates during storage easily is solved, besides, the risk that the product produces microorganisms is greatly reduced, and the mouth feel of the product is better.

Owner:华润三九(南昌)药业有限公司

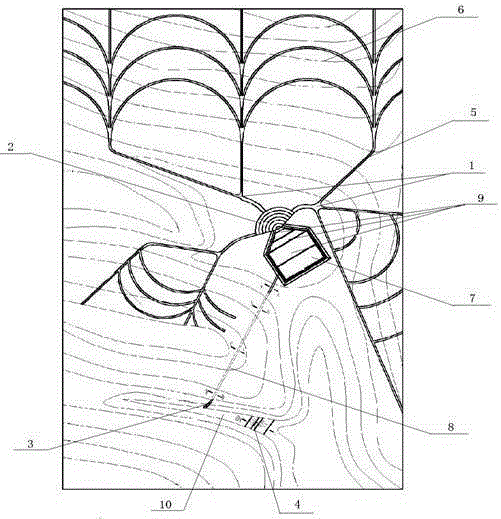

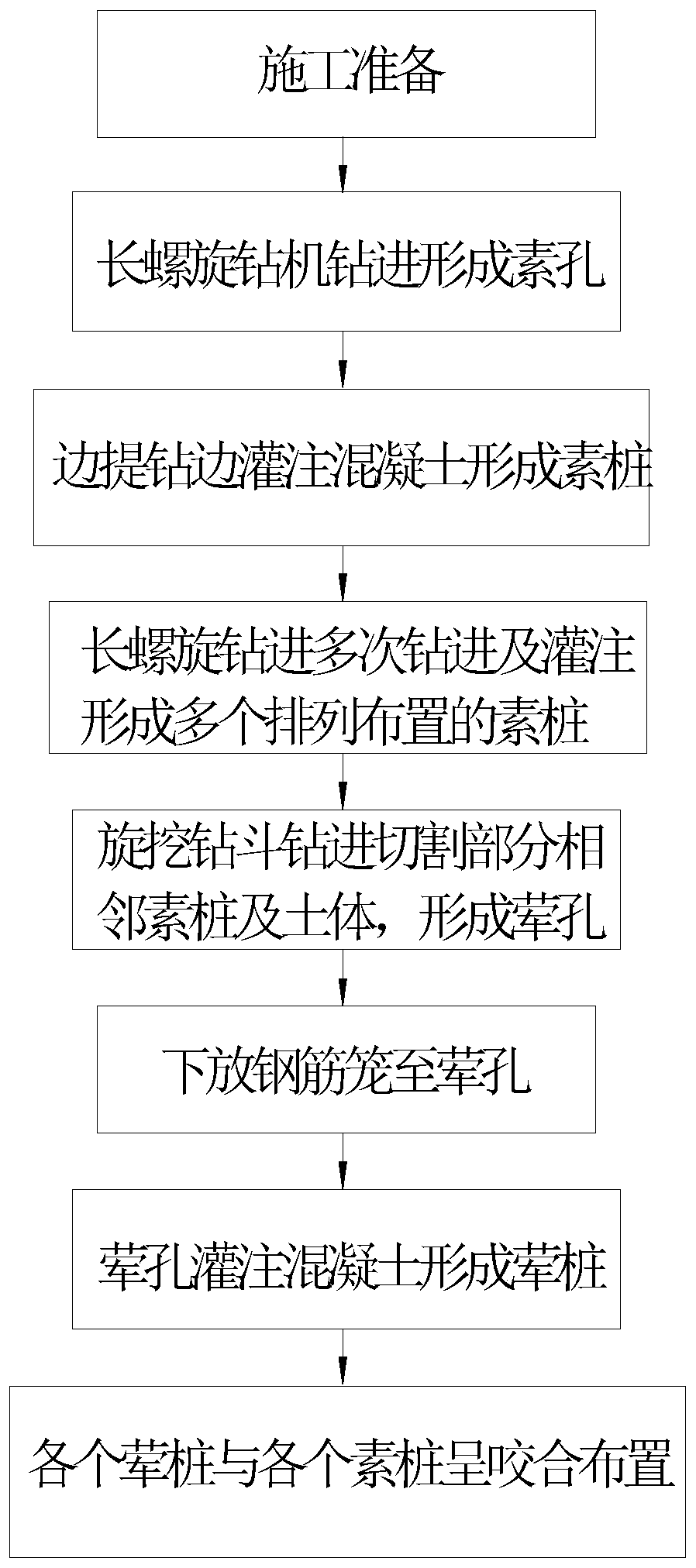

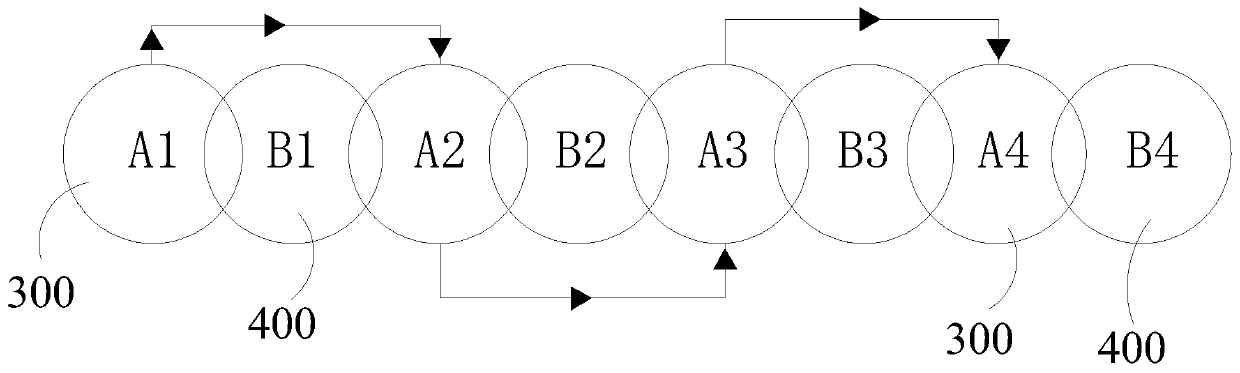

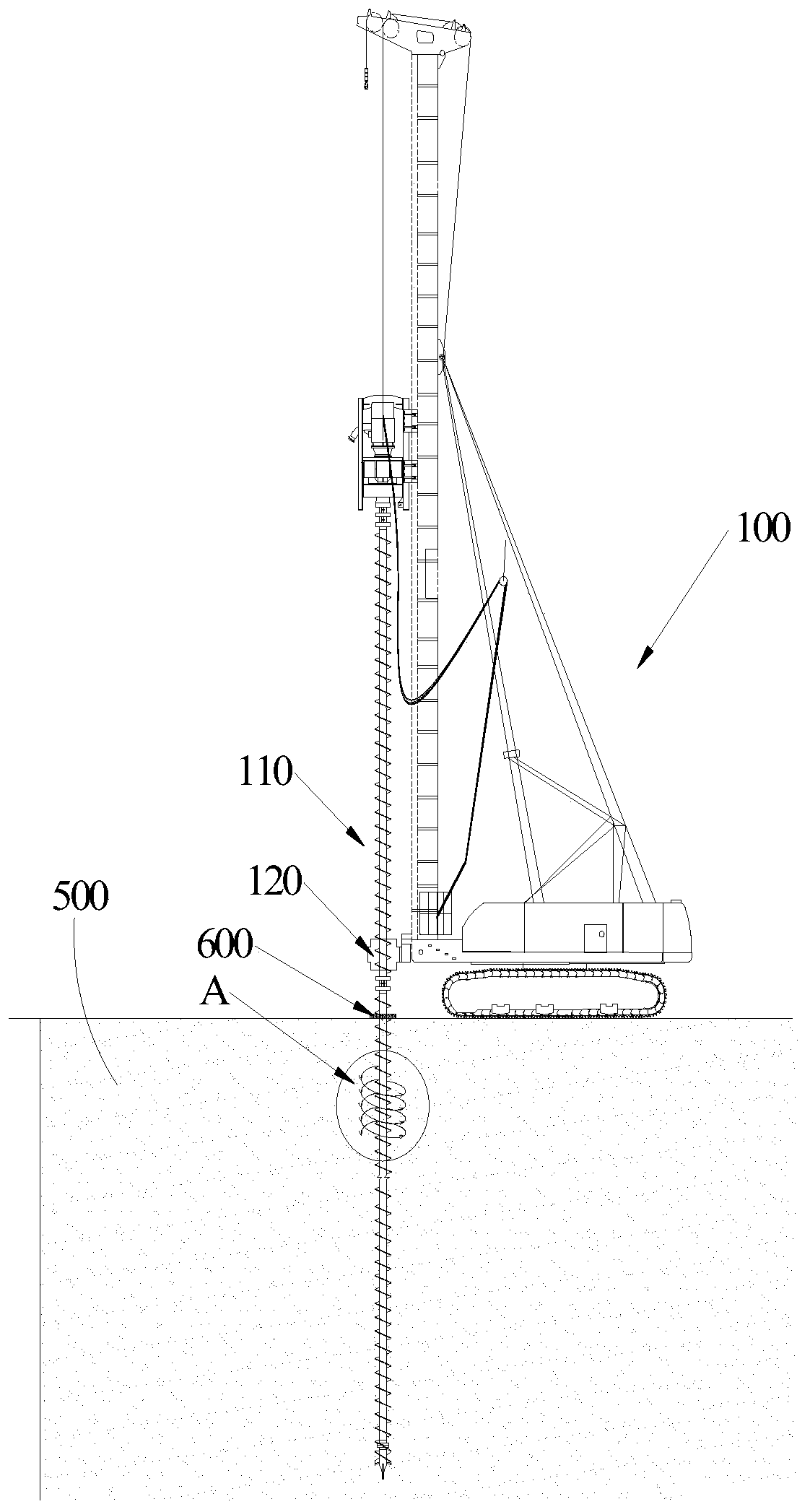

Reinforced and plain concrete pile matched occlusive pile construction method

ActiveCN110016920AImprove pile qualityEasy to collect and processEarth drilling toolsDrilling rodsRebarReinforced concrete

The invention relates to the technical field of occlusive pile construction, and discloses a reinforced and plain concrete pile matched occlusive pile construction method. A long spiral drilling machine and a rotary drilling bucket are included. The construction method comprises the following steps: (1) drilling through the long spiral drilling machine, to form a plain concrete hole; (2) lifting the drill while pouring concrete, to form a plain concrete pile; (3) repeating the step (1) and the step (2) to form a plurality of plain concrete piles which are arranged at intervals; (4) drilling through a rotary excavating drilling bucket, and performing hard cutting on adjacent plain concrete piles and soil bodies, to form a reinforced concrete hole; (5) putting a reinforcement cage down to the reinforced concrete hole; (6) pouring concrete into the reinforced concrete hole, to form a reinforced concrete piles; and (7) repeating the steps (4)-(7), and arranging the reinforced concrete piles and the plain concrete piles in a one-to-one corresponding occlusion manner. The sediment amount at the bottom of the plain concrete hole is reduced, collapse of the wall of the plain concrete holeand falling of orifice soil are avoided, the pile body quality is improved, repeated drill bit replacement is not needed, and the construction efficiency is improved; and under the cooperation of thereinforced concrete piles and the plain concrete piles, the waterproof effect of the support structure formed by construction is enhanced.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

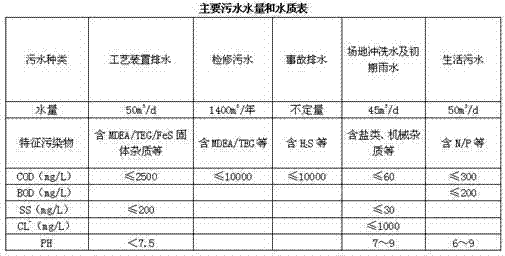

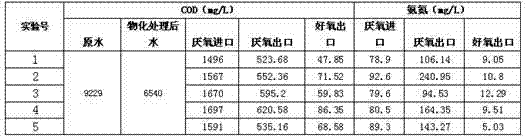

Efficient and deep treatment process for high-concentration waste water in natural gas industry

ActiveCN102923910AReduce the amount of sedimentGood precipitation effectMultistage water/sewage treatmentPre treatmentSewage

The invention discloses an efficient and deep treatment process for high-concentration waste water in a natural gas industry. High-concentration industrial wastewater is subjected to physicochemical pretreatment to improve the biodegradability of the wastewater, and toxic and harmful substances in the wastewater are eliminated simultaneously, medium and low-concentration gas-field wastewater and domestic wastewater are mixed, and biochemical treatment is performed, accordingly, the biochemical treatment efficiency is improved, poison and impact resistances of a system are enhanced, and the denitrification function is strengthened. The technological process is simple, the operation is stable, the removal rate is high, investments and operation costs are saved, the process can be fully applied to treat industrial wastewater of various gas fields, and discharged water can achieve environment friendly emission standards required by the country.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

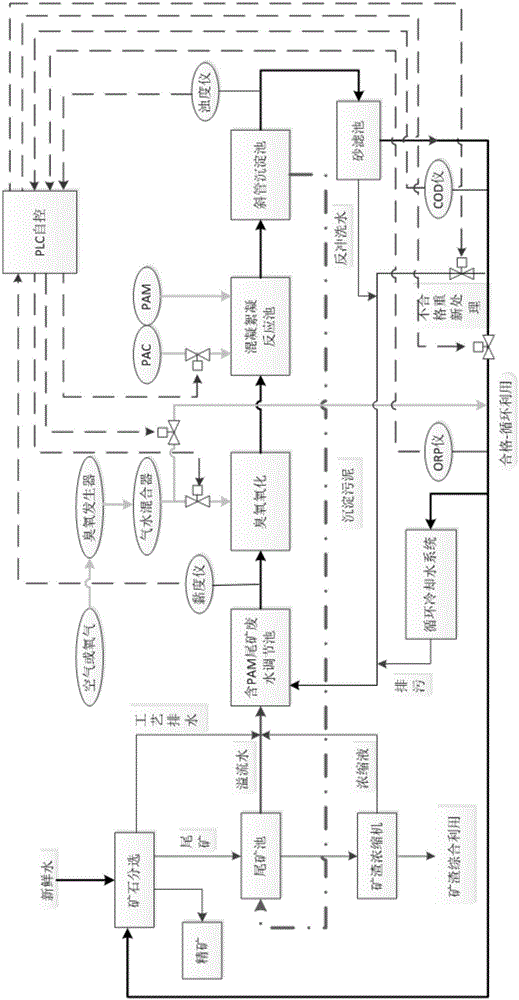

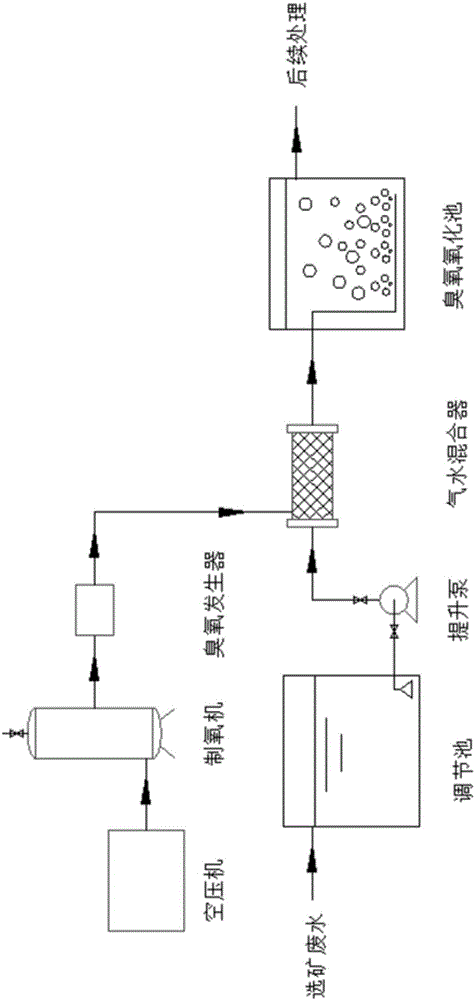

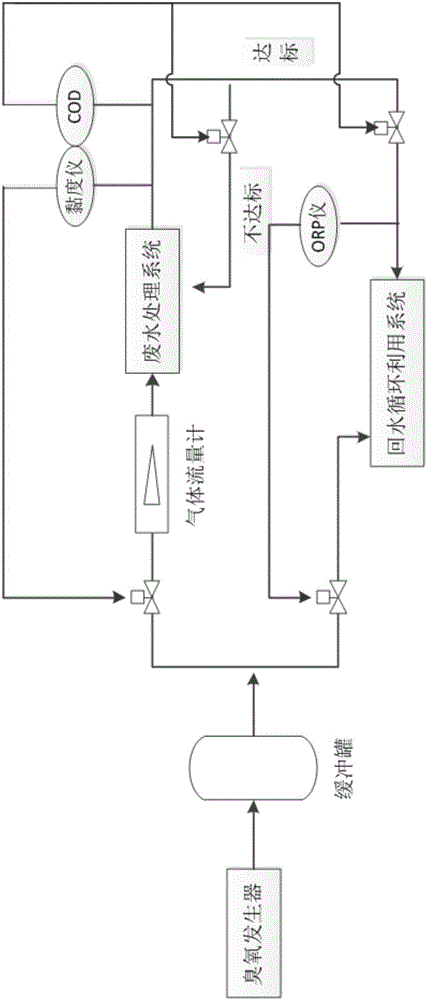

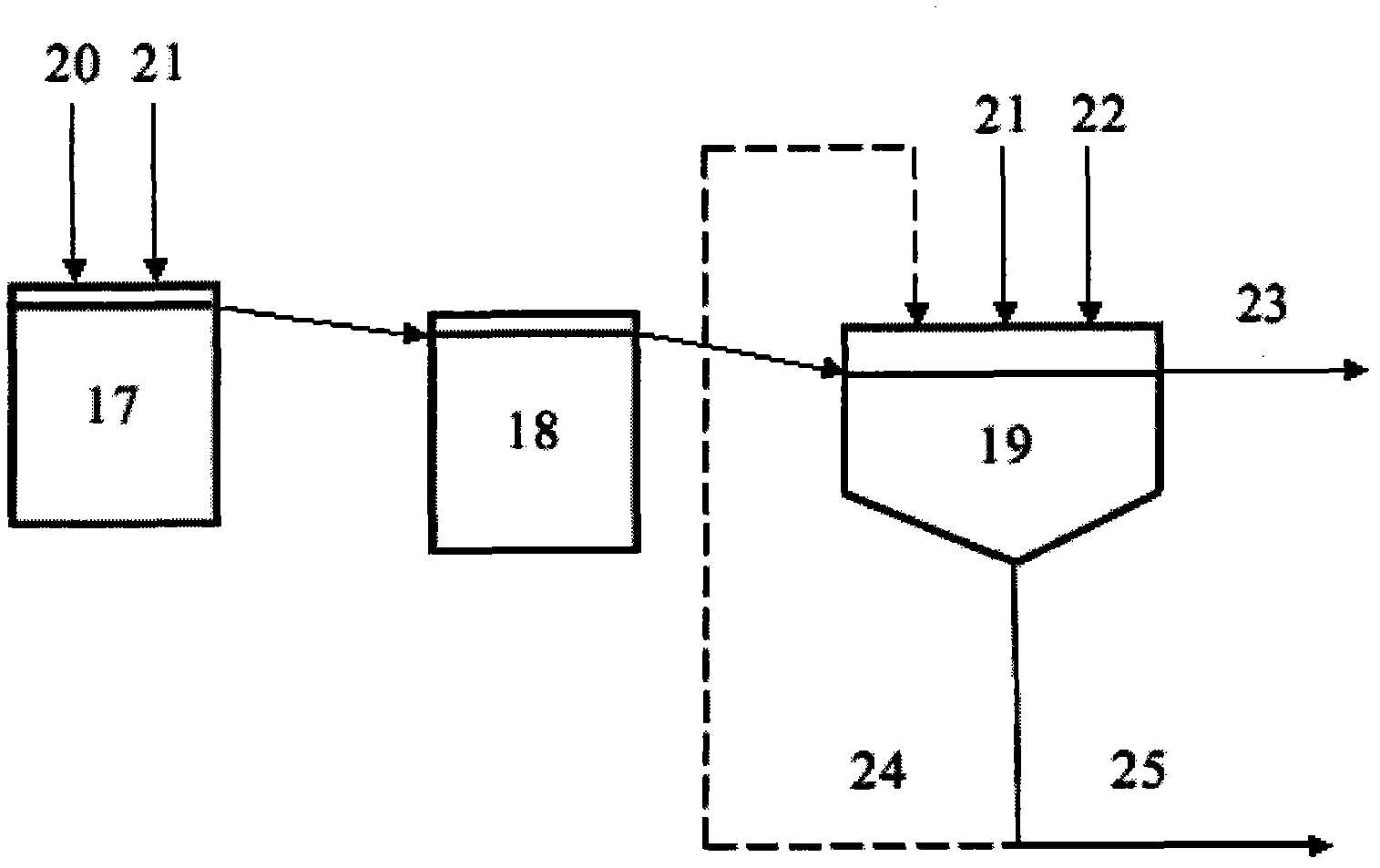

Circulating system and process for PAM-containing tailing wastewater treatment

PendingCN106746008AReduce viscosityReduce turbidityWaste water treatment from quariesTreatment involving filtrationElectricityFlocculation

The invention relates to a circulating system for PAM-containing tailing wastewater treatment. The circulating system comprises a tailing wastewater regulating tank, an ozone oxidation device, a coagulation-flocculation reaction tank and a physical filtering device which are sequentially connected and communicated, and further comprises a control unit and a viscosimeter, wherein a pipe for purified water obtained after filtration of the physical filtering device is connected with an ore sorting water inlet; ozone and wastewater are mixed at the ozone oxidation device; the coagulation-flocculation reaction tank is connected with an externally-connected PAC and PAM adding channel for flocculating PAM; the viscosimeter monitors the wastewater viscosity at the front end of the ozone oxidation device in real time; the control unit is electrically connected with an ozone supply flow control valve on the ozone oxidation device and the viscosimeter respectively. According to the characteristic that ore wastewater has relatively large turbidity, a viscometer is skillfully used for monitoring the viscosity of the wastewater before ozone oxidation real time, the viscosity is fed back to the control unit, and hereby the control unit controls the ozone supply flow in real time, so that an optimal effect is achieved.

Owner:上海铱钶环保科技有限公司

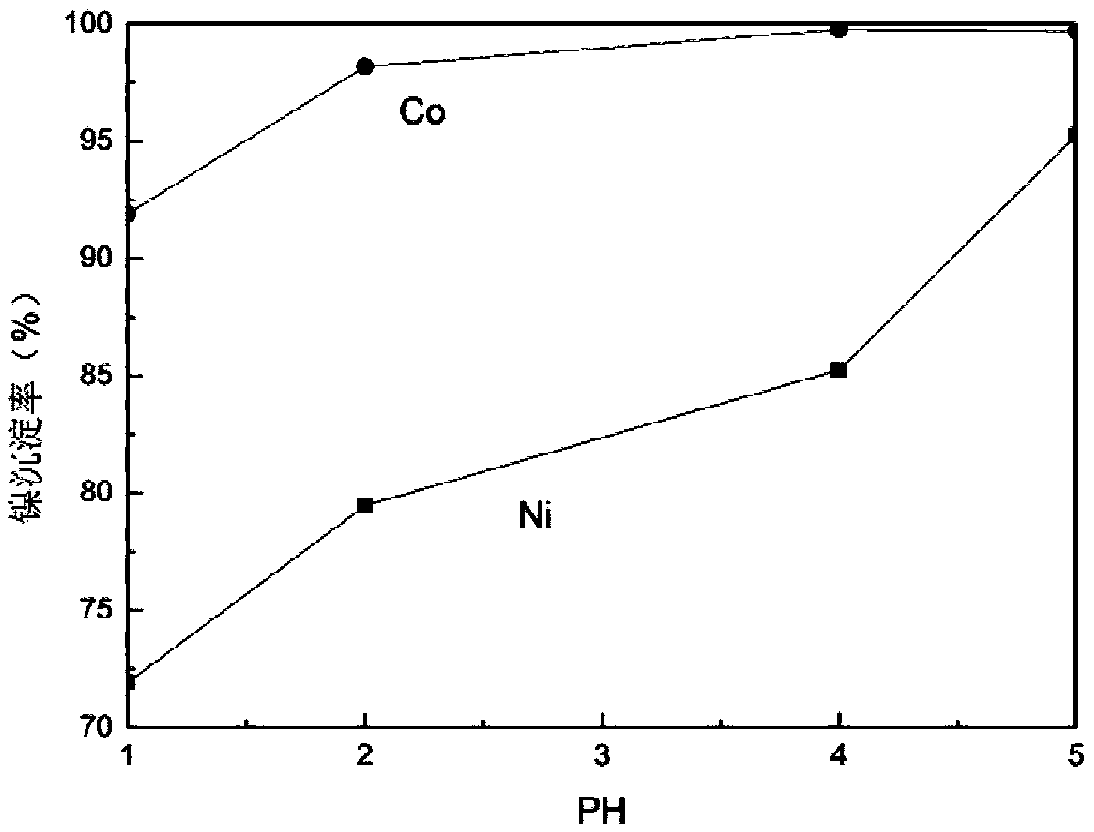

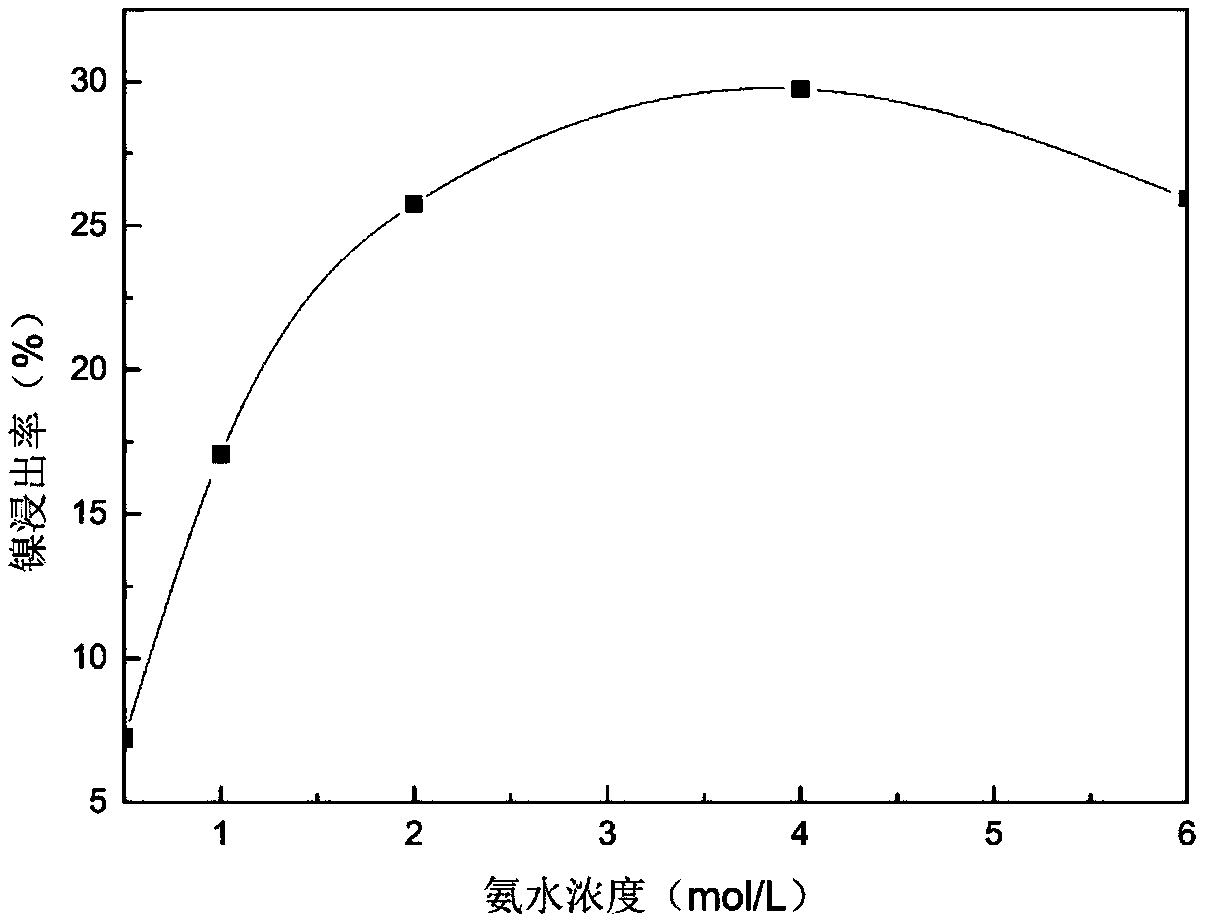

Method for extracting valuable metals from mixed manganese-rich waste leachate of lithium ion battery

ActiveCN109136571AImplement extractionAchieve separationWaste accumulators reclaimingProcess efficiency improvementSludgeManganese

The invention discloses a method for efficiently separating valuable metals from mixed manganese-rich waste leachate of a lithium ion battery. The method comprises the following steps: firstly, nickel-cobalt components are selectively precipitated and separated from a manganese-rich solution with a precipitation method; then, by aid of difference of complexing bonding of ammonia with cobalt and nickel and of a precipitant with cobalt and nickel, an ammonia and ammonium salt mixed solution is adopted for selectively dissolving nickel component in nickel-cobalt precipitated sludge, and efficientseparation of nickel and cobalt is realized; finally, manganese component in the solution with nickel and cobalt precipitated is extracted selectively with a solvent extraction method, and efficientseparation of manganese and lithium is realized. According to the provided process of selective nickel-cobalt precipitation-raffinate manganese and lithium extraction and separation-precipitated sludge selective nickel dissolution and nickel-cobalt separation, operation is simple, flow is short, cost is low, and efficient separation and recovery of valuable component elements in the manganese-richleachate of the waste lithium ion battery can be realized.

Owner:广西埃索凯循环科技有限公司

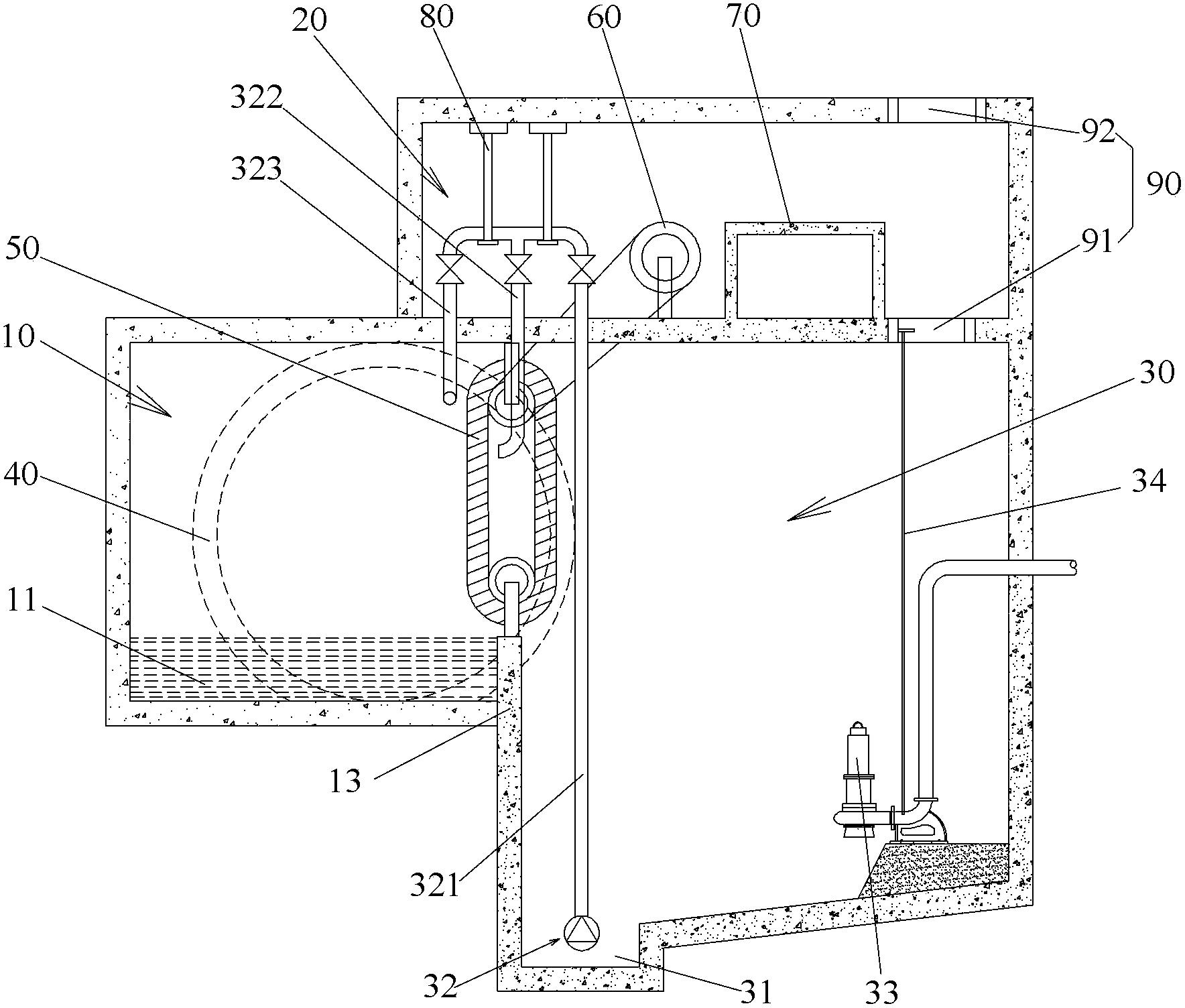

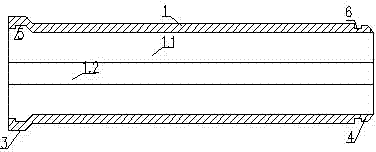

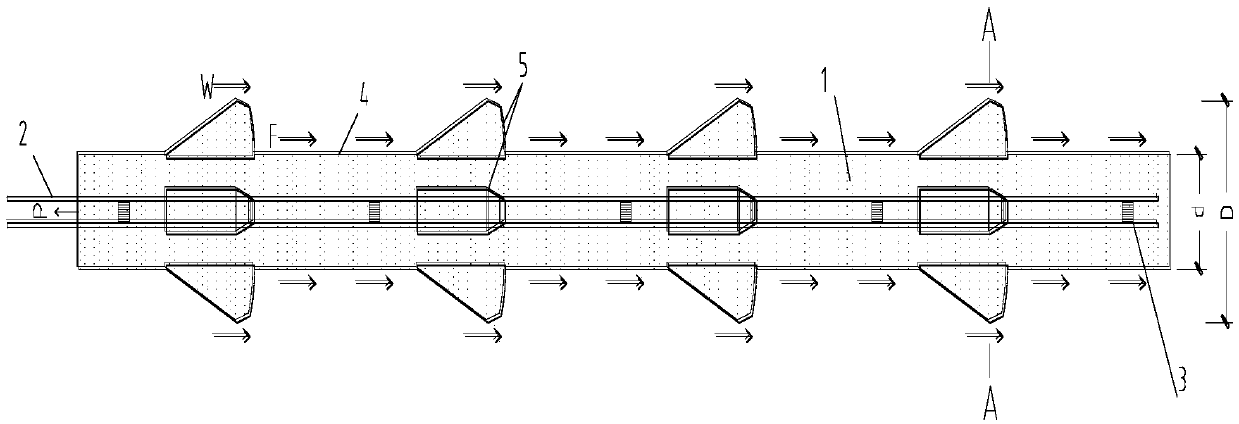

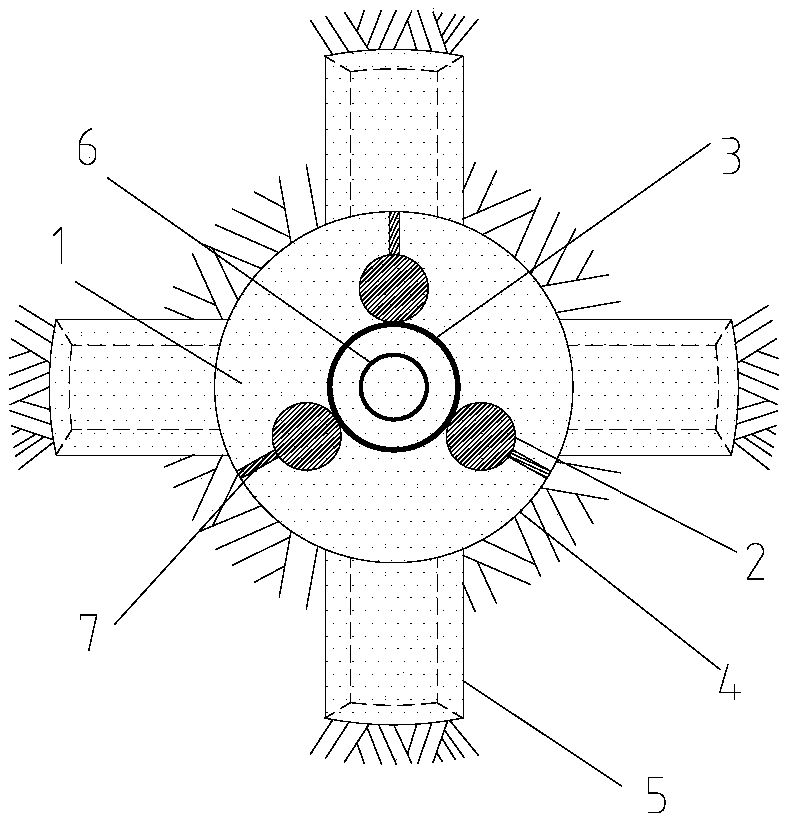

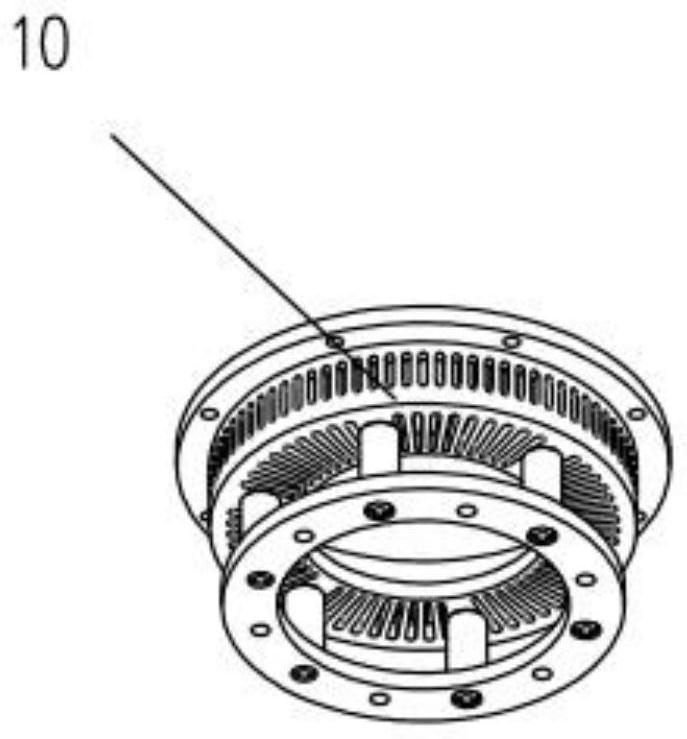

Water-taking mechanism of sewage source heat pump system and sewage source heat pump system with same

ActiveCN103541407AReduce the amount of sedimentTraffic averageHeat pumpsService pipe systemsSludgeWater source

The invention provides a water-taking mechanism of a sewage source heat pump system and the sewage source heat pump system with the water-taking mechanism. The water-taking mechanism of the sewage source heat pump system comprises a sewage taking pool and a buffering pool, wherein the sewage taking pool is communicated with a sewage main canal, part of sewage in the sewage main canal is discharged into the sewage taking pool, the buffering pool is communicated with the sewage taking pool, and a sewage passage is arranged between the buffering pool and the sewage taking pool. The sewage source heat pump system comprises the water-taking mechanism of the sewage source heat pump system. According to the water-taking mechanism of the sewage source heat pump system and the sewage source heat pump system with the water-taking mechanism, the water-taking mechanism of the sewage source heat pump system comprises the sewage taking pool and the buffering pool, the precipitation amount of dirt in the buffering pool can be reduced, uniform flow of the system is guaranteed, and stable operation of the system is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

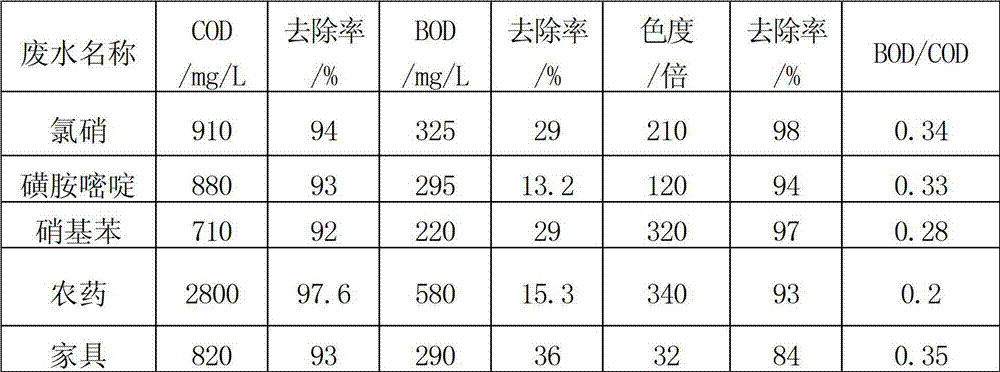

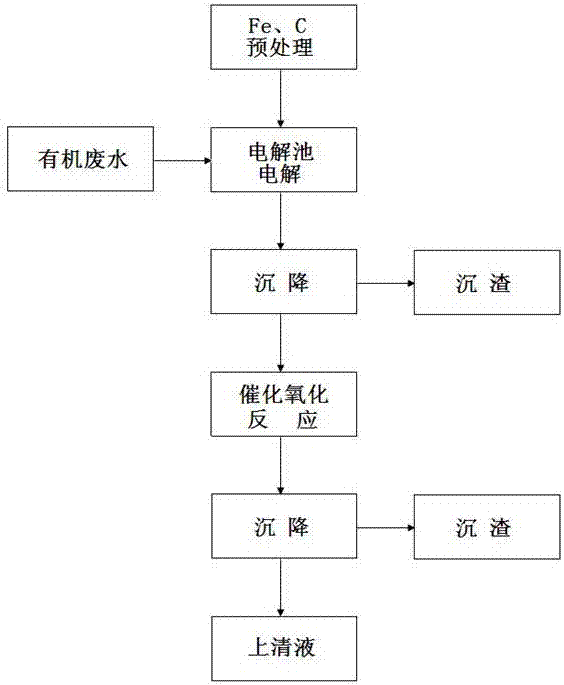

Treatment method of organic industrial wastewater

InactiveCN106957091AAchieve emission standardsReduce workloadWater treatment parameter controlWater contaminantsChemical oxygen demandElectrolysis

The invention discloses a treatment method of organic industrial wastewater. The treatment method comprises the steps of pre-treating, electrolyzing and carrying out catalytic oxidation, and specifically comprises the following steps: pre-treating casting iron dreg and active carbon for later use; adding the pre-treated casting iron dreg and active carbon into an electrolysis tower containing the wastewater; introducing compressed air and carrying out an aeration reaction for 30min-50min; adding H2O2 and continuing to react for 20min-30min; stopping reacting and putting the wastewater into an intermediate tank; adding a precipitation agent and precipitating for 8h-24h; carrying out catalytic oxidation: pumping the wastewater treated by step B into a reaction tank with a stirring function; adjusting the pH (Potential of Hydrogen) value to be 1 to 4 with acid; adding a catalyst which accounts for 0.07%-0.09% of the volume of the wastewater, the active carbon which accounts for 0-0.08% of the volume of the wastewater, a molecular sieve catalyst which accounts for 0.01%-0.03% of the volume of the wastewater and an oxidant which accounts for 0.20%-0.22% of the volume of the wastewater to react for 50min to 70min; adjusting the pH value to be 6 to 7 with an alkaline solution; adding the precipitation agent for precipitating. The treatment method of the organic industrial wastewater, disclosed by the invention, has the advantages that the degradation rate of extra-high-difficulty wastewater COD (Chemical Oxygen Demand) and chrominance is high, the sediment amount is reduced, the working amount of sludge dehydration and the treatment cost are reduced and the treatment effect is improved.

Owner:苏文灿

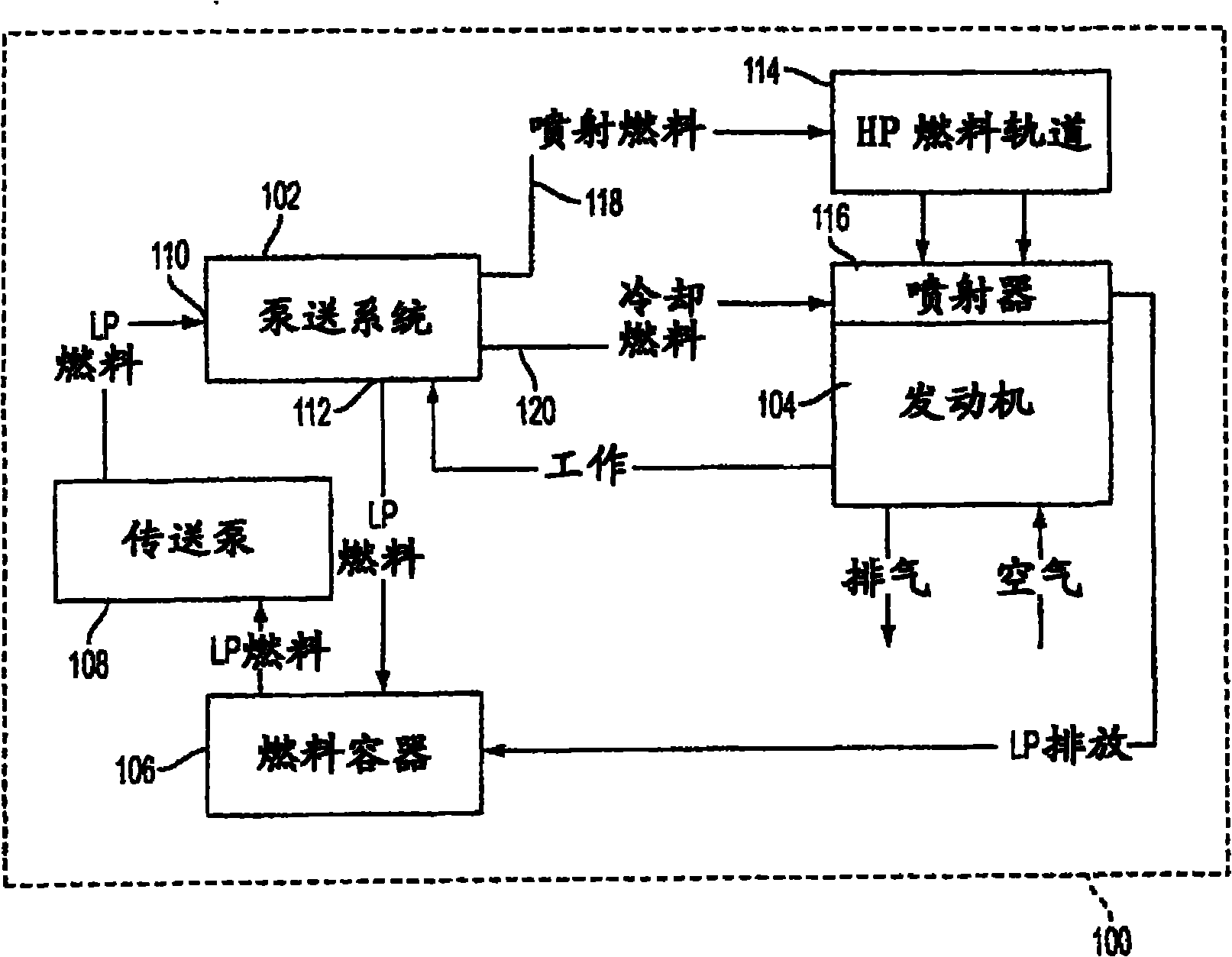

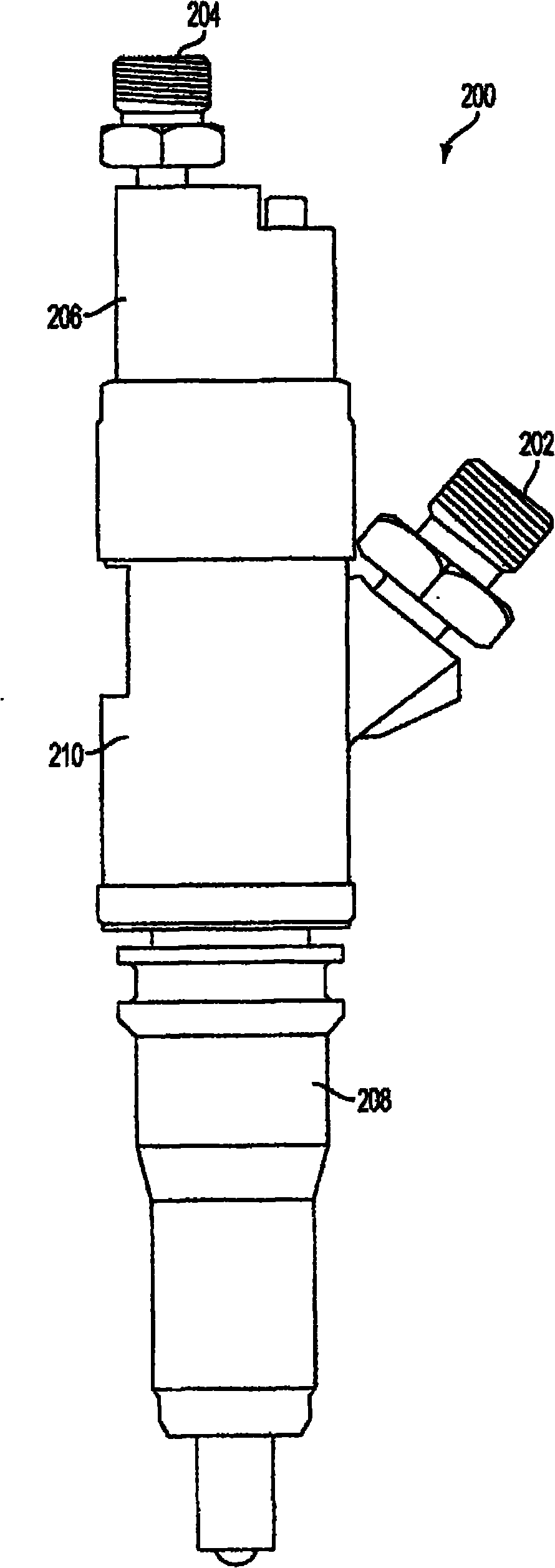

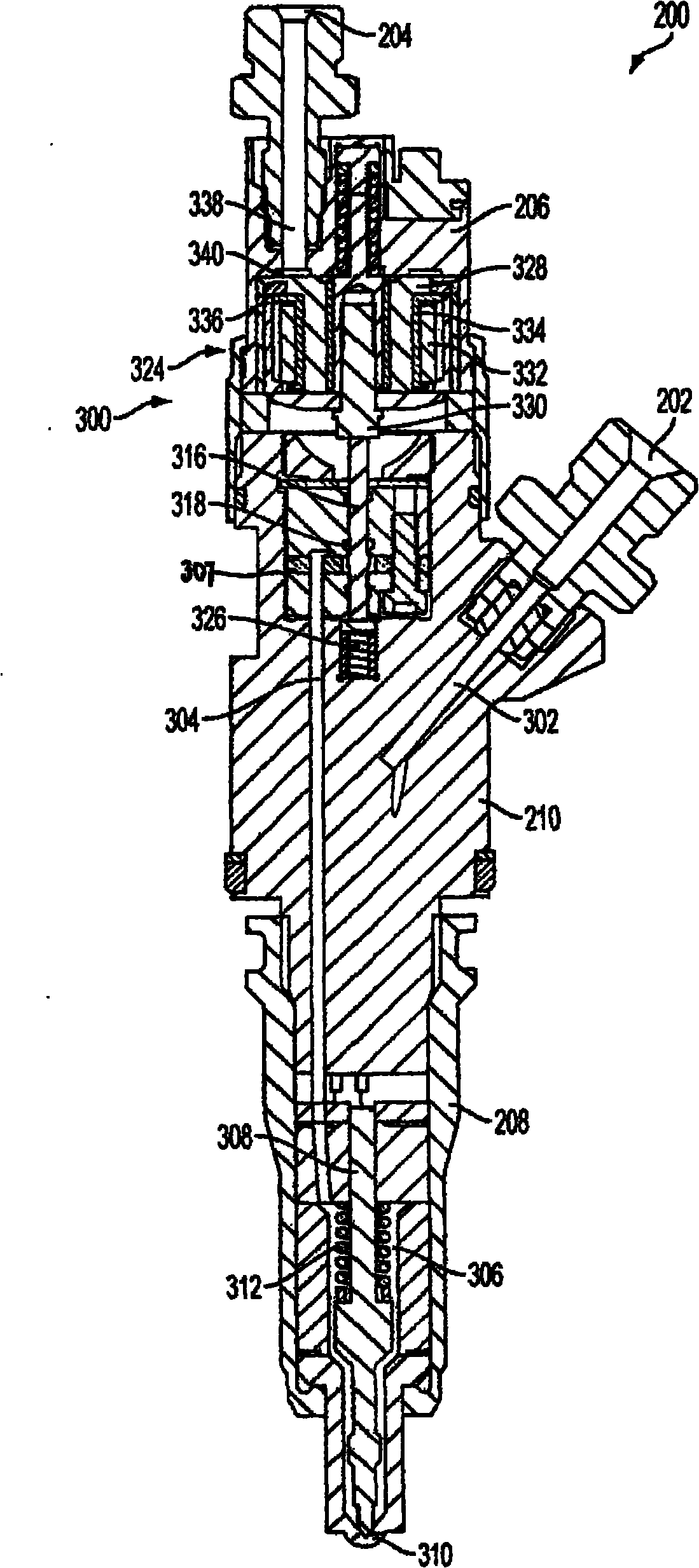

System and method for internal cooling of a fuel injector

ActiveCN101886596AReduce internal temperatureReduce sedimentFuel injection apparatusMachines/enginesActuatorControl theory

A fuel injector includes an injector body forming an actuator portion. An actuator bore is formed in the actuator portion and is at least partially defined by an inner surface and by an end surface. An actuator disposed in the actuator bore and has an outer surface such that a flow channel can be defined between the inner surface of the actuator bore and the outer surface of the actuator. A cooling flow passage is formed in the injector body, in fluid communication with the actuator bore, and is adapted to supply cooling fluid to the actuator bore. A drain passage is formed in the injector body, in fluid communication with the actuator bore. An internal cooling fluid flow path extends from the cooling flow passage, through the flow channel, and from the flow channel through the drain passage.

Owner:CATERPILLAR INC

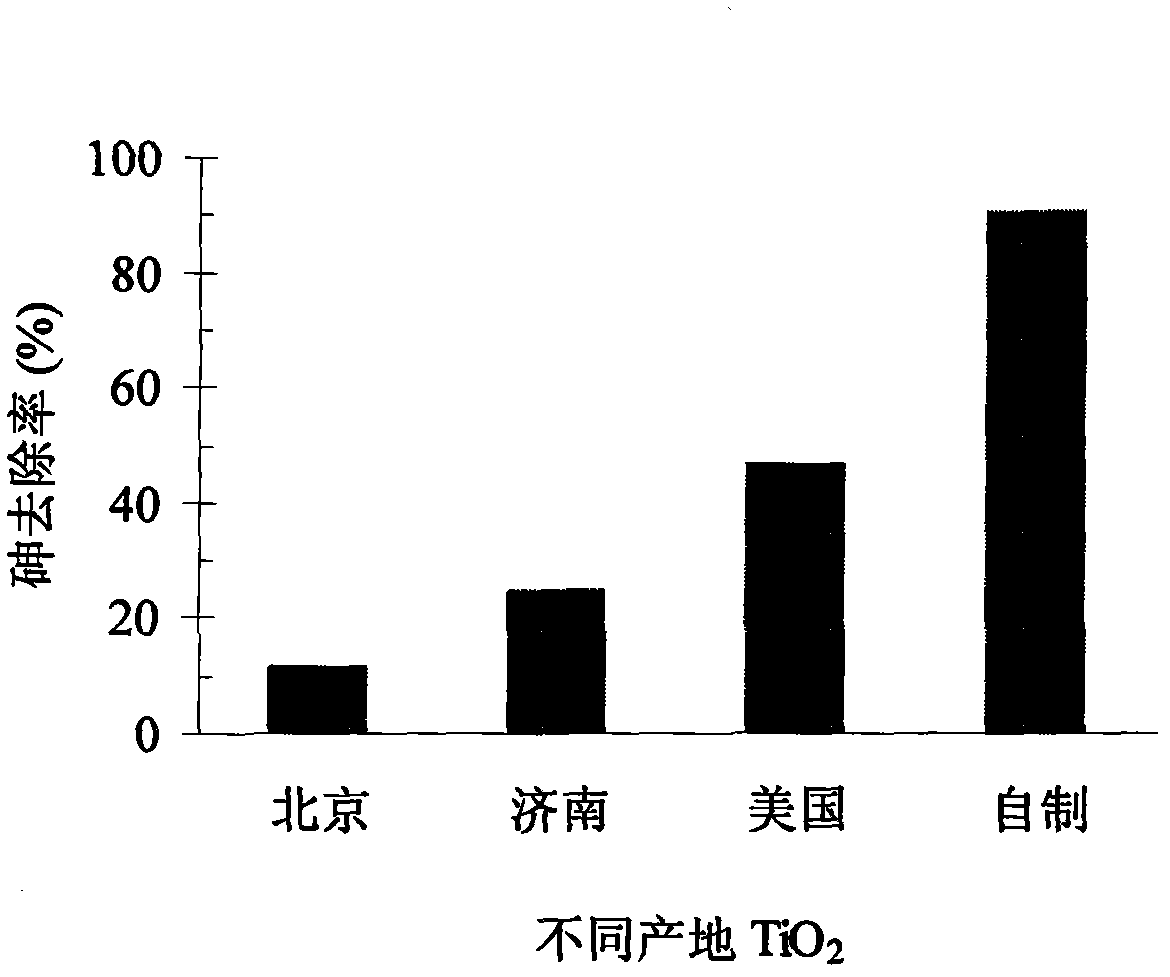

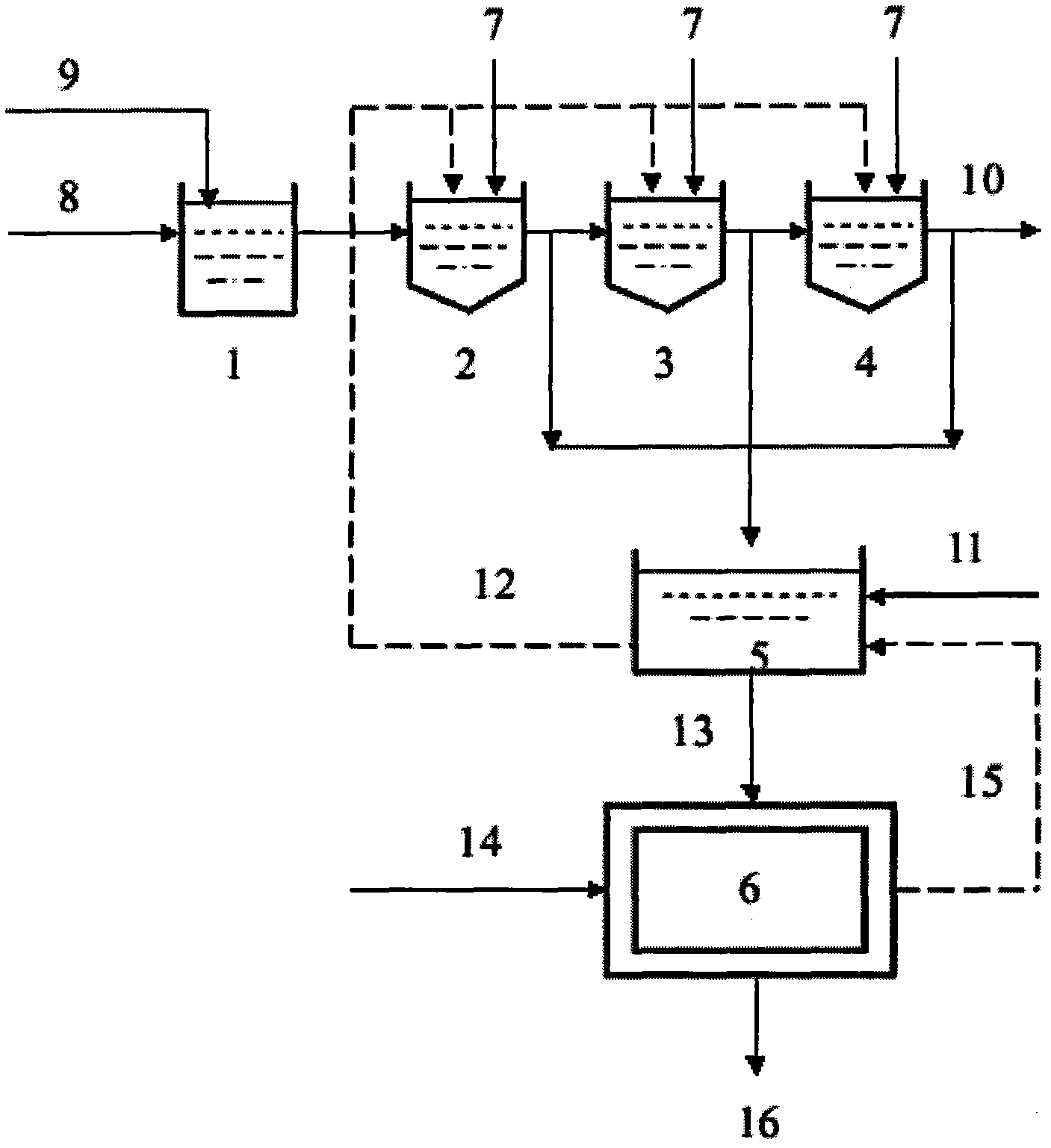

Method for treating acidic wastewater with high arsenic content by using nano TiO2 and recycling arsenic

InactiveCN102381777AEfficient removalReduce the amount of sedimentArsenites/arsenatesWater contaminantsIonHeavy metals

The invention provides a method for treating acidic wastewater with high arsenic content by using nano TiO2 and recycling arsenic, comprising the following steps of: adjusting the pH value of the wastewater to 5 by using lime milk, and separating the wastewater into a solid and liquid; continuously absorbing a solution with high arsenic content three times by using a nano TiO2 adsorbent, and adjusting the pH value to 7. The adsorbent can be recycled through the elution and regeneration of sodium hydroxide. Meanwhile, arsenic in backwash liquor is recycled through adding calcium oxide. According to the method, trivalent arsenic and heavy metal ions in the wastewater can be effectively removed, the adsorbent can be recycled, almost no waste residues are generated, and meanwhile, the arsenic can be recycled so that the pollution to the environment is reduced and economic benefits are obtained.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +4

Polyphenol-containing Kefir fermented whey beverage and manufacturing method thereof

InactiveCN107156325AFull of nutritionLow fermentation temperatureWhey manufactureFood additiveFruit juice

A polyphenol-containing Kefir fermented whey beverage belongs to the technical field of food processing. The polyphenol-containing Kefir fermented whey beverage is prepared from the following steps of 1) mixing and dissolving demineralized whey powder in water, and then filtering the mixture; 2) adding merchant concentrated juice into solution obtained in the step 1), adjusting the brix of the mixed liquid to 14 degrees Bx, performing homogenizing, keeping the homogenized liquid at 85 DEG C for 15 min for sterilization, then rapidly cooling down to 28-40 DEG C; 3) inoculating activated Kefir M into the mixed liquid obtained in the step 2) at a weight ratio of 2-8% of the mixed liquid, stirring to mixing the liquid and then fermenting the liquid at a constant temperature of 28-40 DEG C for 5-17 hours, and performing aseptic filling to obtain finished products. The polyphenol-containing Kefir fermented whey beverage is high in content of polyphenol and contains live probiotics without other food additives, and meanwhile, is fresh in taste and rich in nutrition.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

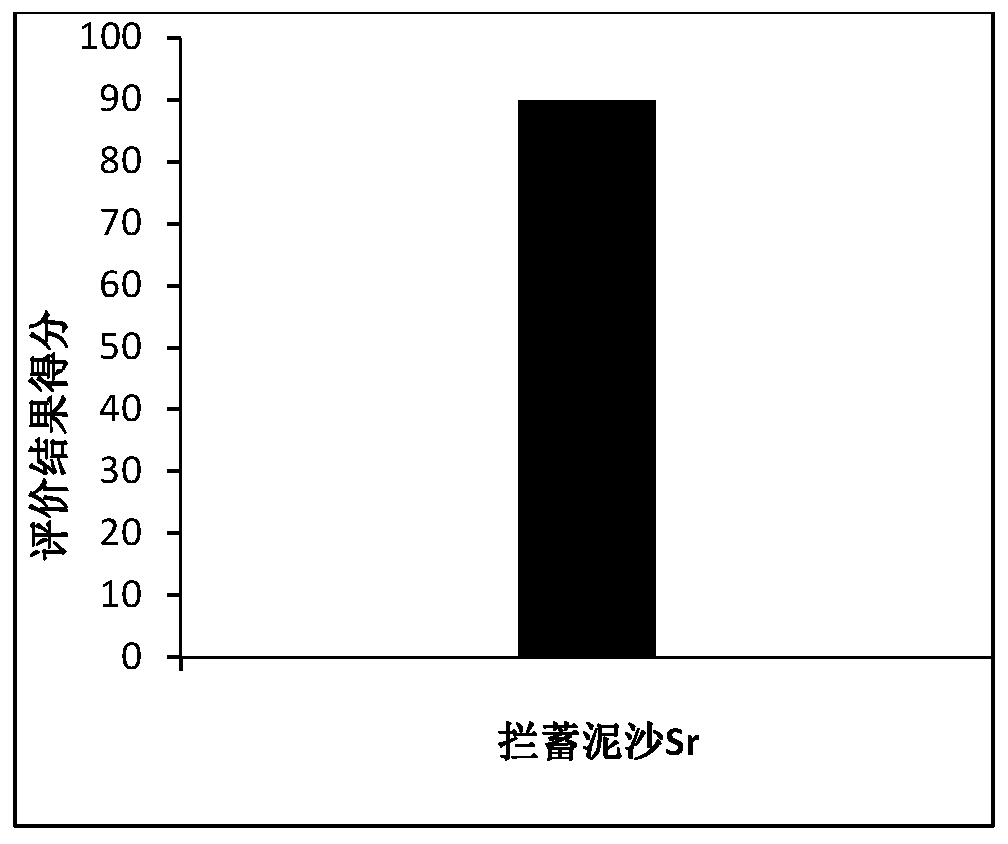

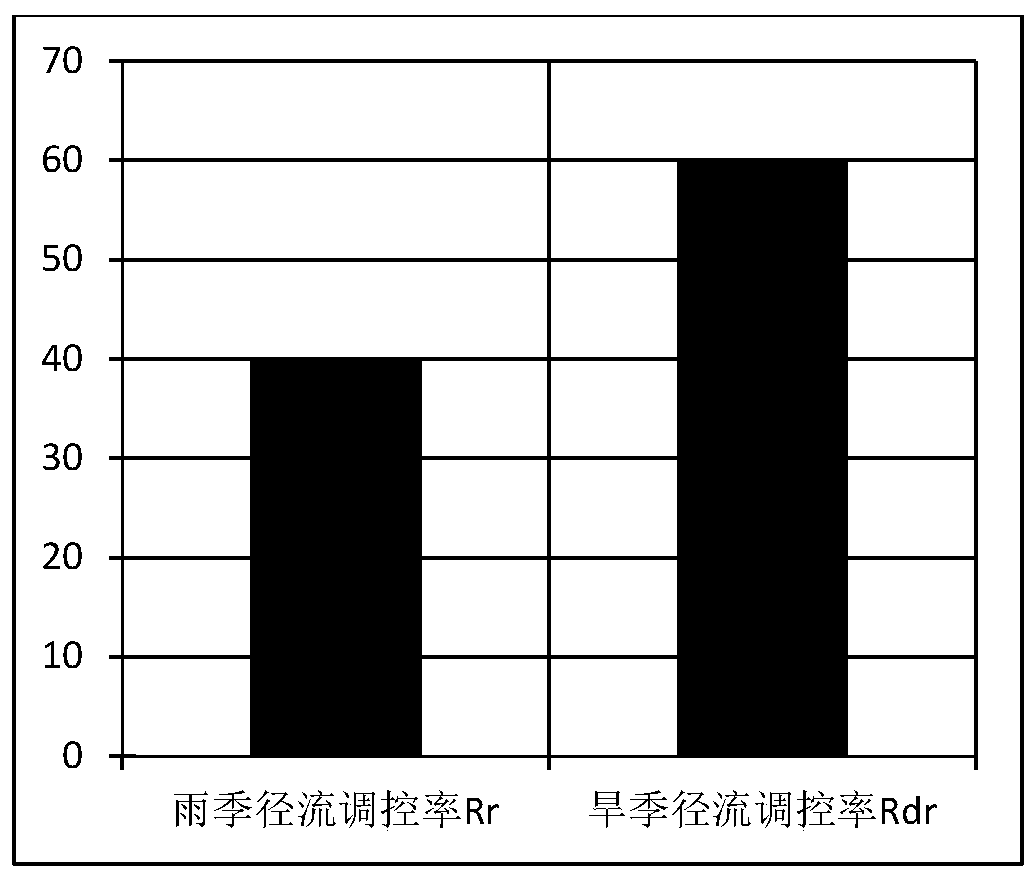

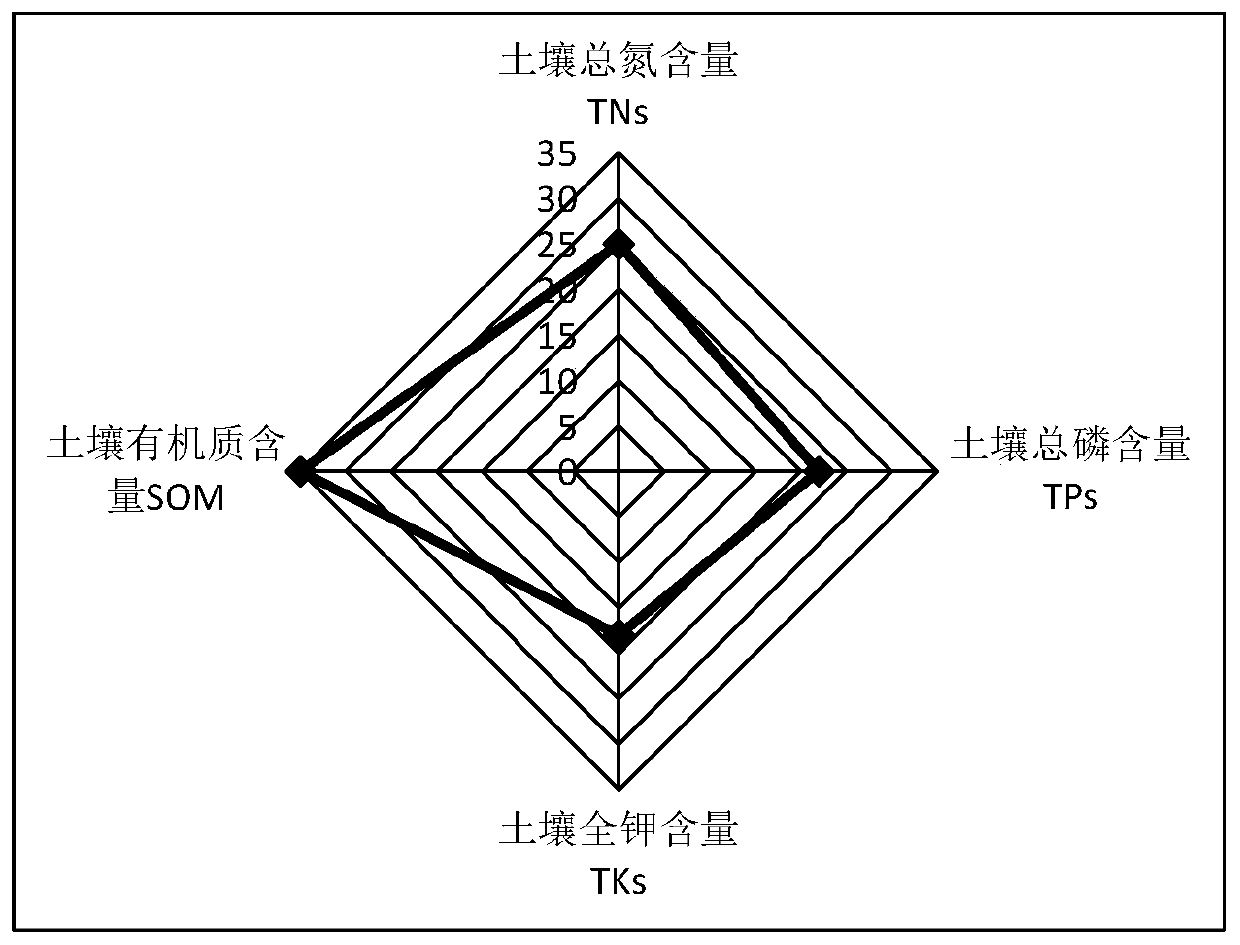

Water and soil conservation measure ecological service function evaluation method

PendingCN111260250AHighlight local characteristicsReduce churnResourcesEnvironmental resource managementEcological indicator

The invention provides a water and soil conservation ecological service function evaluation method. The method comprises the steps of: obtaining basic ecological indexes related to the water and soilconservation measure ecological service function of a drainage basin, and assigning a weight to each basic ecological index; and scoring the value of each basic ecological index, wherein the basic ecological indexes comprise indexes related to sediment loss, indexes related to runoff regulation and control in rainy seasons and indexes related to runoff regulation and control in dry seasons, and optionally comprise indexes related to forest product provision. The method is particularly suitable for evaluating the water and soil conservation measure ecological service function of the southern red soil hilly area small watershed, and therefore the current situation of the water and soil conservation measure ecological service function of the small watershed can be evaluated according to actual basic ecological indexes.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

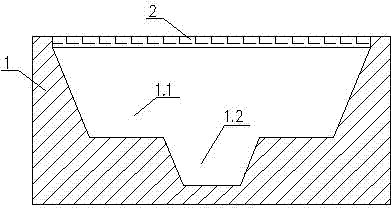

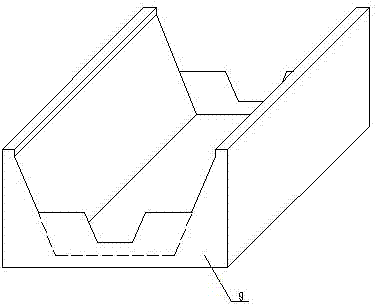

Rainwater drainage ditch

InactiveCN102767232AReduce sediment depositionReduce maintenance costsFatty/oily/floating substances removal devicesSewerage structuresPollutantDrainage flow

The invention discloses improvement on a rainwater drainage ditch. The rainwater drainage ditch is characterized in that a ditch-type rainwater channel consists of two homodromous reversed trapezoid trenches of different sizes, the two homodromous reversed trapezoid trenches are communicated with each other, the large homodromous reversed trapezoid trench is arranged on the upper part, and the small homodromous reversed trapezoid trench is arranged on the lower part. A water excess section is a reversed trapezoid of which the cross section is linearly increased according to the change of the height, and a section combined with two reversed trapezoids of which the upper parts are large and the lower parts are small is adopted, so that a large amount of rainwater and a small amount of rainwater can be drained separately; due to water drainage through the reversed trapezoid of which the lower part is small, the water drainage section is relatively small when the rainwater amount is small; therefore, the water drainage flow speed can be increased; by the enough water drainage flow speed, accumulation of pollutants in the rainwater ditch can be reduced; when the rainwater amount is small, the probability and amount of sludge deposition are reduced, and the self-cleaning capacity of the rainwater ditch is improved; moreover, due to the lower small section, the water consumption for flushing the sludge is reduced; meanwhile, the upper large section and the section are linearly increased along with the increase of a water level, so that the requirement on quick water drainage in a heavy rainstorm within short time can be met; and the shortcomings of the rainwater drainage ditch in the prior art are completely overcome.

Owner:WUXI MUNICIPAL DESIGN INST

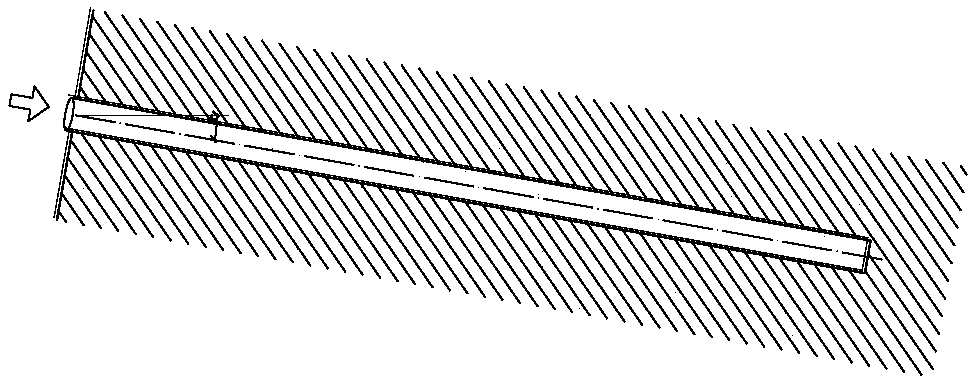

Extrusion reaming anchor rod and construction method

The invention discloses an extrusion anchor rod with larger pulling resistance and a construction method of the extrusion anchor rod. The anchor rod is formed in the way that after mechanical hole forming is conducted, an anchor rod main reinforcing bar is added, and grouting and cementing are conducted. After grouting, an anchor rod anchoring body is formed and comprises a main anchor rod body ofa standard anchoring section and multiple anchor rod diameter expansion bodies of an embedded extrusion and expanding section; the diameter expansion bodies are formed by compacting side-wall rock and earth mass by an extrusion reamer; the anchor rod diameter expansion bodies are arranged at intervals in the longitudinal direction of the main anchor rod body, and each anchor rod diameter expansion body comprises multiple protrusions which are symmetrically arranged; the maximal diameter formed by the anchor rod diameter expansion bodies is not less than twice the diameter of the main anchor rod body. The construction method comprises the steps of advance hole forming, sequential extrusion and reaming, anchor bar installing, grouting, and stretching and drawing for locking. Extrusion and reaming are conducted by a drilling tool according to designed spacing, and the diameter of the anchoring body is increased in section, so that the purposes of compacting the side wall of the anchoringbody, and improving the strength of the rock and earth mass are achieved; meanwhile, an embedded reaming body section is formed, the single stress mode of the anchor rod body is improved, thus the anti-pulling capability of the anchor rod is effectively improved, the labor is saved, and the engineering cost is reduced.

Owner:成都四海岩土工程有限公司

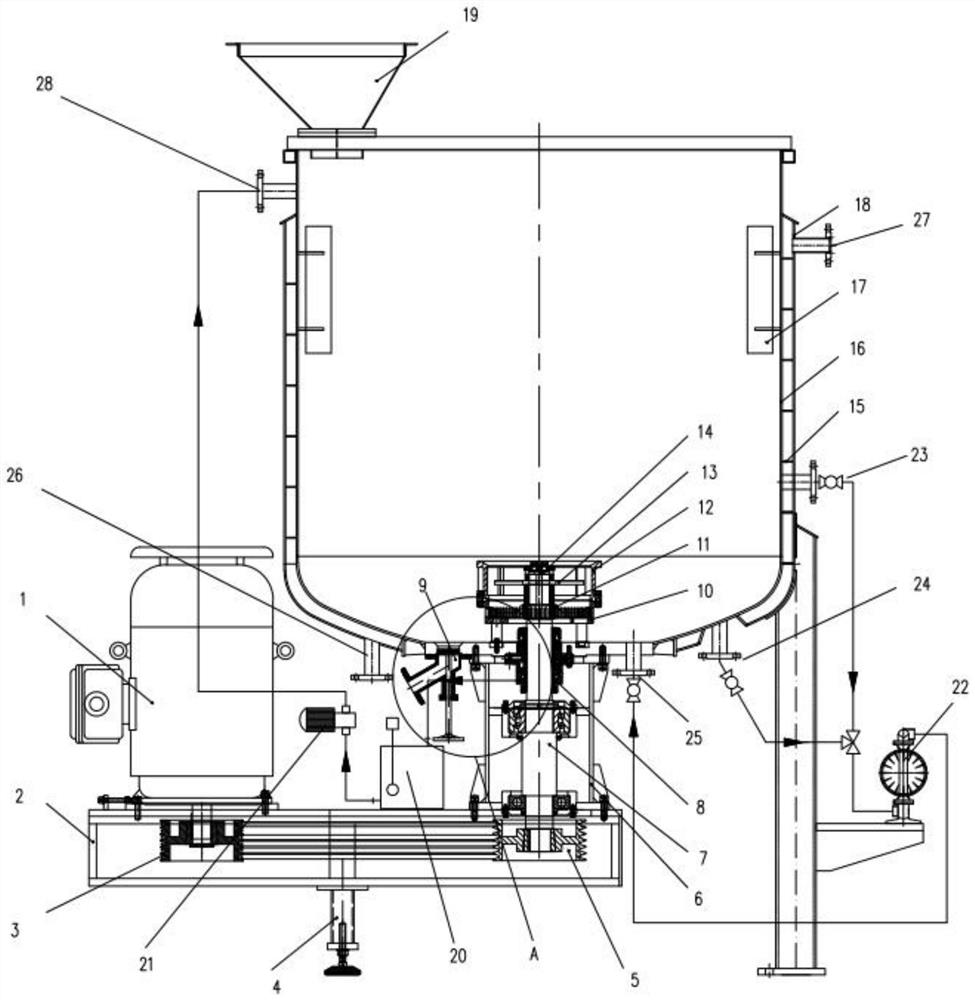

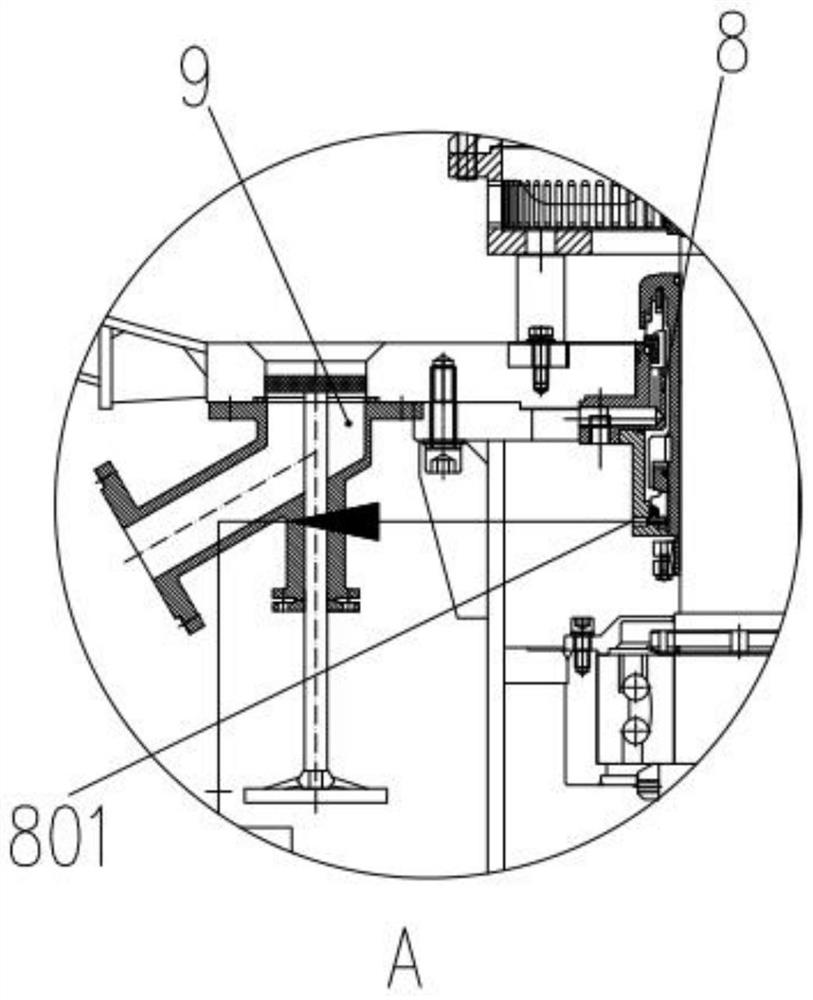

Wet crushing equipment capable of efficiently preventing precipitation

ActiveCN112657636AGood drainageAvoid short circuitFlow mixersRotary stirring mixersElectric machineDrive shaft

The invention discloses wet crushing equipment capable of effectively preventing precipitation. The equipment comprises a machine base and a main kettle body, the main kettle body is arranged above the machine base through a kettle body mounting supporting column on one side of the machine base, a shearing system is arranged in the main kettle body, and the machine base is of a cuboid cavity structure. A motor is fixedly arranged on one side of the table board of the machine base through a motor installation base, an output shaft of the motor penetrates through the top face of the machine base and is arranged in a cavity of the machine base, a driving belt wheel is fixedly arranged on the output shaft of the motor, and the motor drives the driving belt wheel to start to operate after being started, and the driving belt wheel transmits power to a driven belt wheel in a belt transmission mode. The driven belt wheel drives a transmission shaft to rotate, the transmission shaft drives a rotor, a first fly-cutter and a second fly-cutter to rotate at a high speed, a high-vacuum area is formed in the area near the stator and the rotor, therefore, surrounding materials are sucked in, the materials are sheared by the shearing system, uniform suspension liquid is formed, and the operability of different materials is greatly improved.

Owner:安徽儒特实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com