Extrusion reaming anchor rod and construction method

A technology of reaming anchor rods and construction methods, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve problems such as difficult to control the expansion shape of the anchorage section, reduce the strength of rock and soil mass, and disturb the rock and soil mass. Achieve the effect of grasping the geological conditions intuitively, reducing the bolt density and increasing the bolt spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0035] In conjunction with the accompanying drawings.

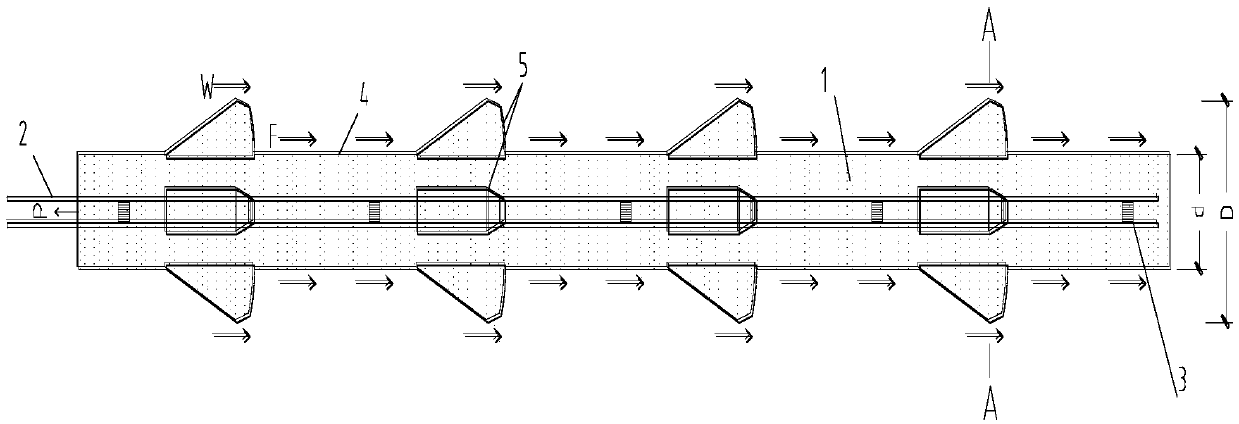

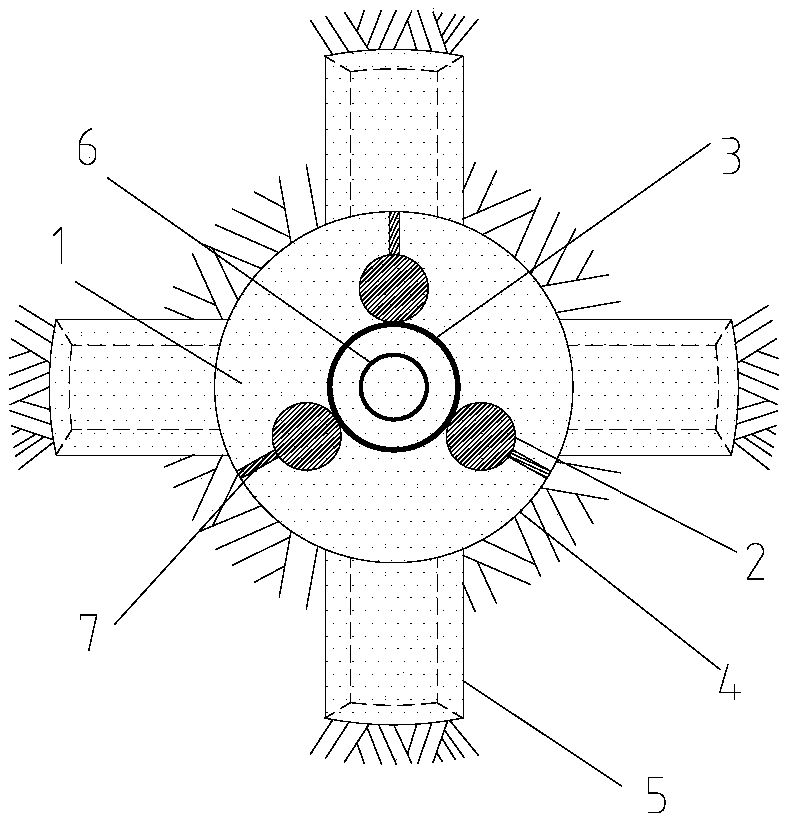

[0036] Such as figure 1 As shown, the present invention is made up of anchor rod 1, anchor rod main rib 2, spacer bracket 3, main anchor rod body 4, anchor rod expanding diameter body 5, and centering bracket 7. d is the diameter of the main bolt body, D is the maximum diameter of the bolt expanding body, W is the end bearing force of the expanding body, and F is the side friction of the bolt.

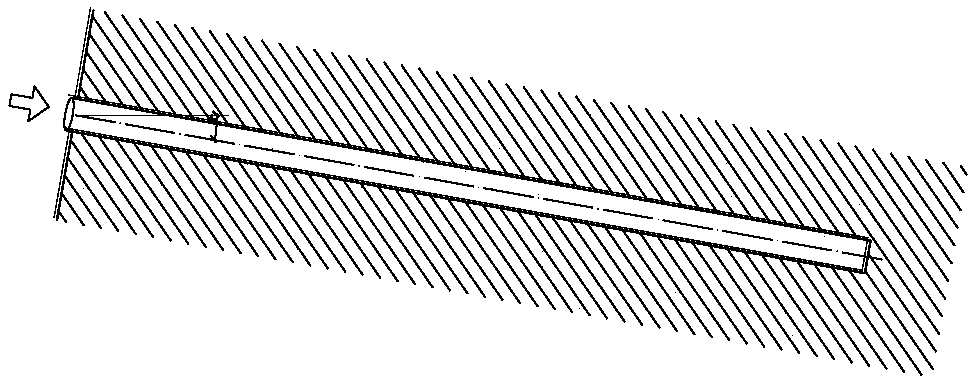

[0037] Extruded reaming anchor rod, after the anchor rod 1 is dug into a hole by mechanical drilling, the main reinforcement 2 of the anchor rod is added, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com