Group enhanced type magnetic nanometer water treatment agent and preparation method and application thereof

A water treatment agent, magnetic nano technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve low adsorption efficiency, irregular shape, wide particle size distribution, etc. problem, to achieve a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

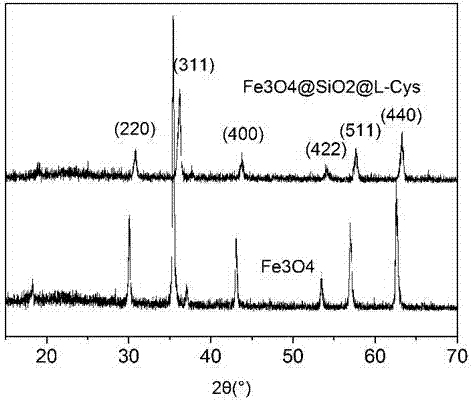

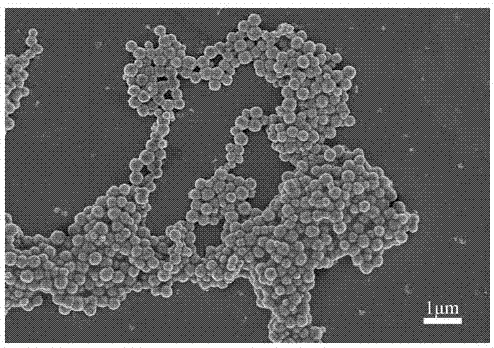

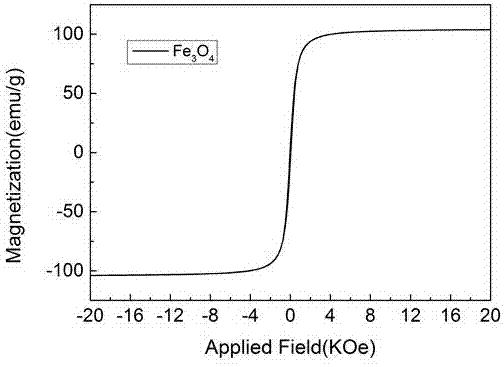

[0035] (1) Accurately weigh 3 g of ferric chloride hexahydrate and 7.5 g of anhydrous sodium acetate powder, and add 75 ml of ethylene glycol solution, stir vigorously at normal temperature until completely dissolved; then add 0.5 g of polyethylene glycol (Mw = 10000) stirred for 2 hours until the system was uniformly dispersed;

[0036] (2) Pour the solution obtained by stirring in step (1) into a titanium-zirconium alloy high-pressure reactor container and react for 8 hours to obtain a reaction product, and the reaction temperature is 200° C.;

[0037] (3) Magnetically absorb the reaction product obtained in step (2), wash the reaction product 5 times with ethanol and deionized water, and place it in a freeze dryer to dry for 10 hours at a drying temperature of 60°C and a vacuum degree of Less than 1000Pa; get Fe 3 o 4 magnetic nanoparticles;

[0038] (4) Magnetic Fe obtained in step (3) 3 o 4 Add 500ml of ethanol aqueous solution with a volume concentration of 75% to t...

Embodiment 2

[0042] (1) Accurately weigh 3 g of ferric chloride hexahydrate and 9 g of anhydrous sodium acetate powder, add 75 ml of ethylene glycol solution, stir vigorously at normal temperature until completely dissolved; then add 0.5 g of polyethylene glycol (Mw=10000 ) stirred for 2 hours until the system was uniformly dispersed;

[0043] (2) Pour the solution obtained by stirring in step (1) into a titanium-zirconium alloy high-pressure reactor container and react for 7 hours to obtain a reaction product, and the reaction temperature is 200° C.;

[0044] (3) Magnetically absorb the reaction product obtained in step (2), wash the reaction product 5 times with ethanol and deionized water, and then place it in a freeze dryer to dry for 10 hours at a drying temperature of 70°C and a vacuum degree of Less than 1000Pa; get magnetic Fe 3 o 4 nanoparticles;

[0045] (4) Fe obtained in step (3) 3 o 4 Add 500ml of ethanol aqueous solution with a volume concentration of 70% to the magnetic...

Embodiment 3

[0049] (1) Accurately weigh 3 g of ferric chloride hexahydrate and 6 g of anhydrous sodium acetate powder, add 75 ml of ethylene glycol solution, stir vigorously at normal temperature until completely dissolved; then add 0.5 g of polyethylene glycol (Mw=10000 ) stirred for 2 hours until the system was uniformly dispersed;

[0050] (2) Pour the solution obtained by stirring in step (1) into a titanium-zirconium alloy high-pressure reactor container and react for 9 hours to obtain a reaction product, and the reaction temperature is 200° C.;

[0051] (3) Magnetically absorb the reaction product obtained in step (2), wash the reaction product 5 times with ethanol and deionized water, and then place it in a freeze dryer to dry for 10 hours at a drying temperature of 80°C and a vacuum degree of Less than 1000Pa; get magnetic Fe 3 o 4 nanoparticles;

[0052] (4) Fe obtained in step (3) 3 o 4 Add 500ml of ethanol aqueous solution with a volume concentration of 80% to the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com