High performance lubricating oil based on graphene and magnetic rare earth nanocomposite additives

A nano-composite and graphene technology, applied in the field of lubricating oil, can solve the problems of nano-additives that are difficult to achieve high-performance lubricating oil expectations, performance limitations, and inability to overcome extreme pressure, so as to improve heat export, oxidation resistance, and increase temperature Interval and lifespan, the effect of good intelligent repair characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

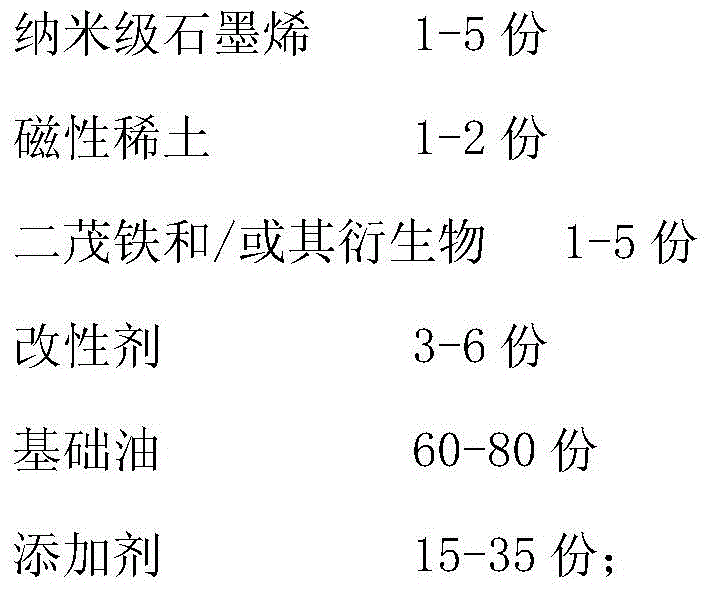

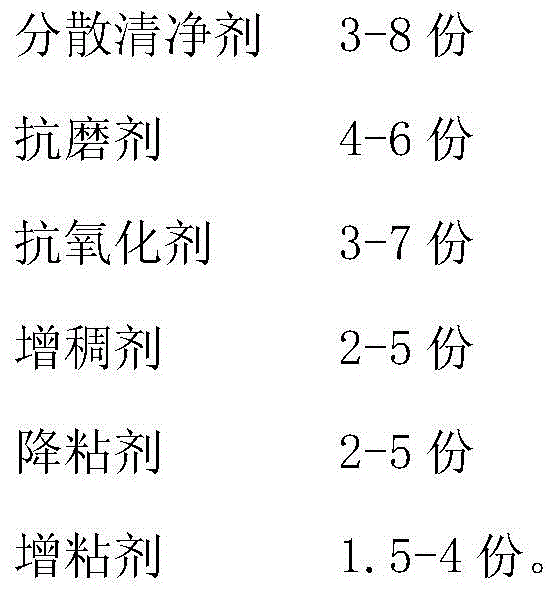

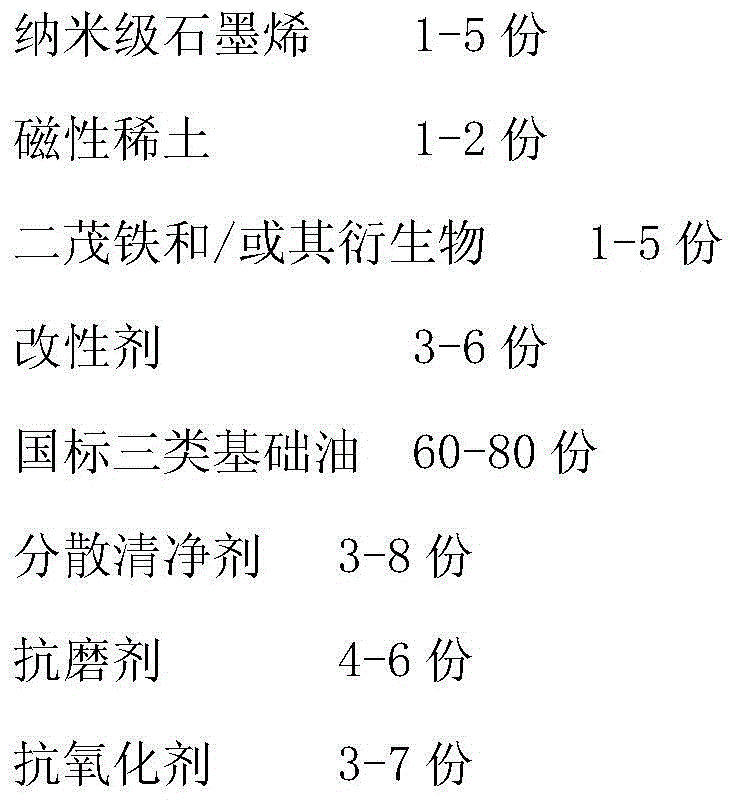

[0045] (1) Conventional preparation method: After heating the components such as the above-mentioned nanoscale graphene, magnetic rare earth, ferrocene and / or its derivatives, modifier, base oil and other additives to 50-80 degrees Celsius, It is made after pneumatic stirring.

[0046] (2) A better preparation method: the above-mentioned nano-scale graphene, magnetic rare earth, ferrocene and / or its derivatives, base oil and other components are stirred uniformly in the range of 50-80 degrees Celsius in advance, and then mixed with modifier It is prepared by adding other additives and other components into the base oil and stirring evenly at 50-80 degrees Celsius.

Embodiment 1

[0048]

[0049]

Embodiment 2

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com