Circulating system and process for PAM-containing tailing wastewater treatment

A wastewater treatment and circulation system technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve problems such as increased chemical and salt content, high operating costs, and increased sludge volume , to achieve a high degree of automation, save electricity consumption and chemical costs, and reduce the amount of sludge sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

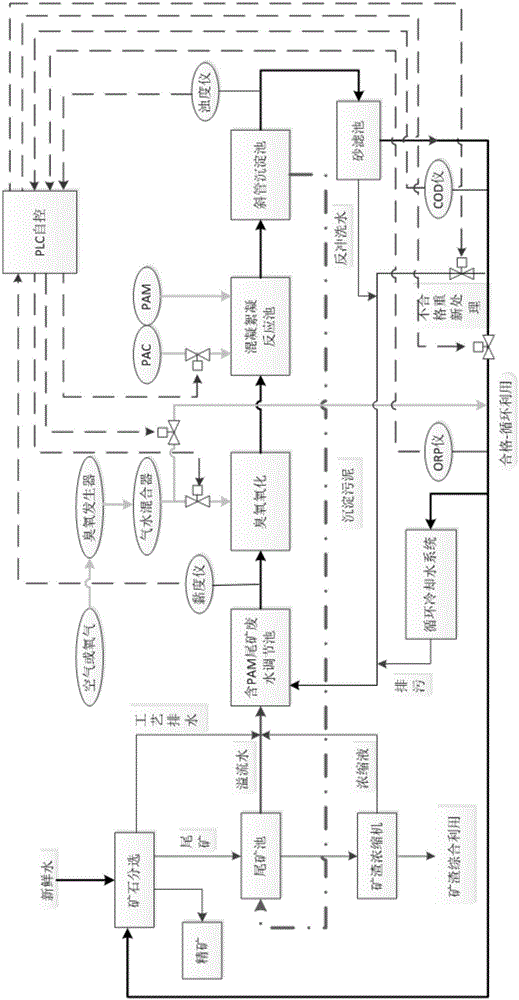

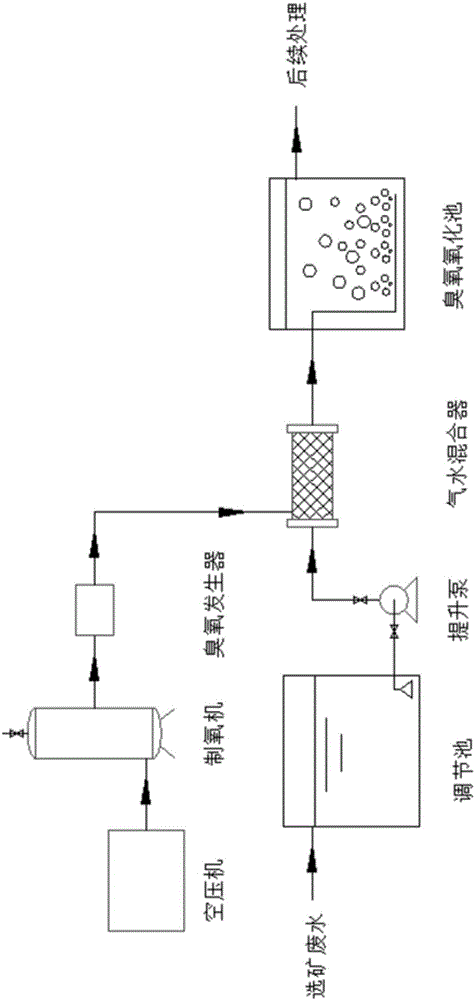

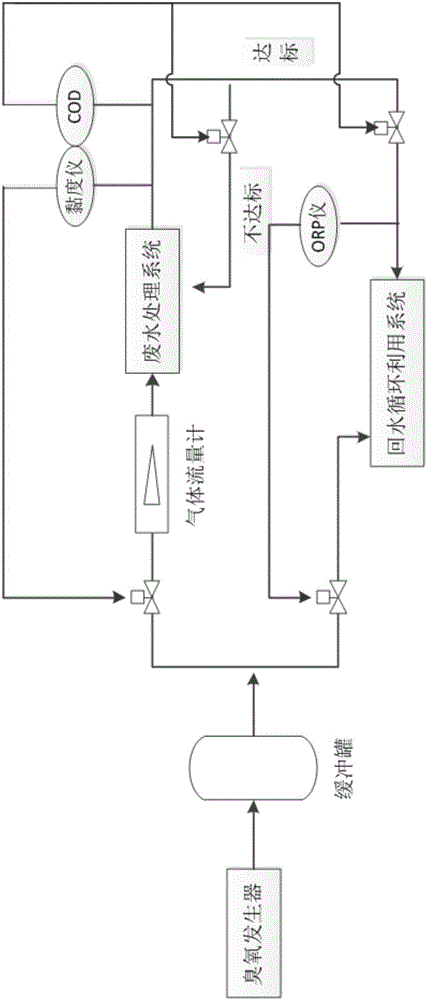

[0027] see Figure 1-3 , the present invention is based on the fact that the COD treatment load of the wastewater is not high and the biodegradability is poor. Therefore, the physical and chemical treatment is selected in the subsequent process of ozone treatment, that is, the combined process of ozone pre-oxidation + coagulation sedimentation + sand filtration, to ensure that the effluent is stable and meets the water quality requirements of circulating water , to achieve wastewater reuse. The whole process adopts feedback mechanisms such as viscosity, turbidity, and ozone concentration in water to realize automatic control of chemical dosage, which is conducive to a virtuous cycle of water reuse.

[0028] The process flow of ozone + coagulation sedimentation + sand filtration process combination treatment for the reuse of PAM tailings wastewater is as follows:

[0029] The tailings wastewater containing PAM mainly comes from ore separation process drainage, tailings pond ov...

Embodiment 2

[0047] The original tailings reuse water of an aluminum mine factory contains polyacrylamide, which is reused after simple coagulation and sedimentation treatment, which often blocks the equipment pipeline system, increases the frequency of equipment cleaning and the work intensity of workers, and affects the production efficiency of the enterprise. To this end, we took water samples from the plant for small-scale experiments, and after several process combinations and comparisons, we finally selected the combined process of ozone pre-oxidation + coagulation sedimentation + sand filtration. Under the weakly alkaline pH value of tailings effluent, add ozone 1-4mg / L, react for 30 minutes, measure the viscosity in the water with a viscometer, control the viscosity within 1mPa·s, and add 120mg of PAC to the effluent into the coagulation reaction tank / l, depending on the size of the alum, adjust the dosage of PAC in real time or add a small amount of PAM to aid coagulation. After p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com