Patents

Literature

40results about How to "Monitor traffic in real time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

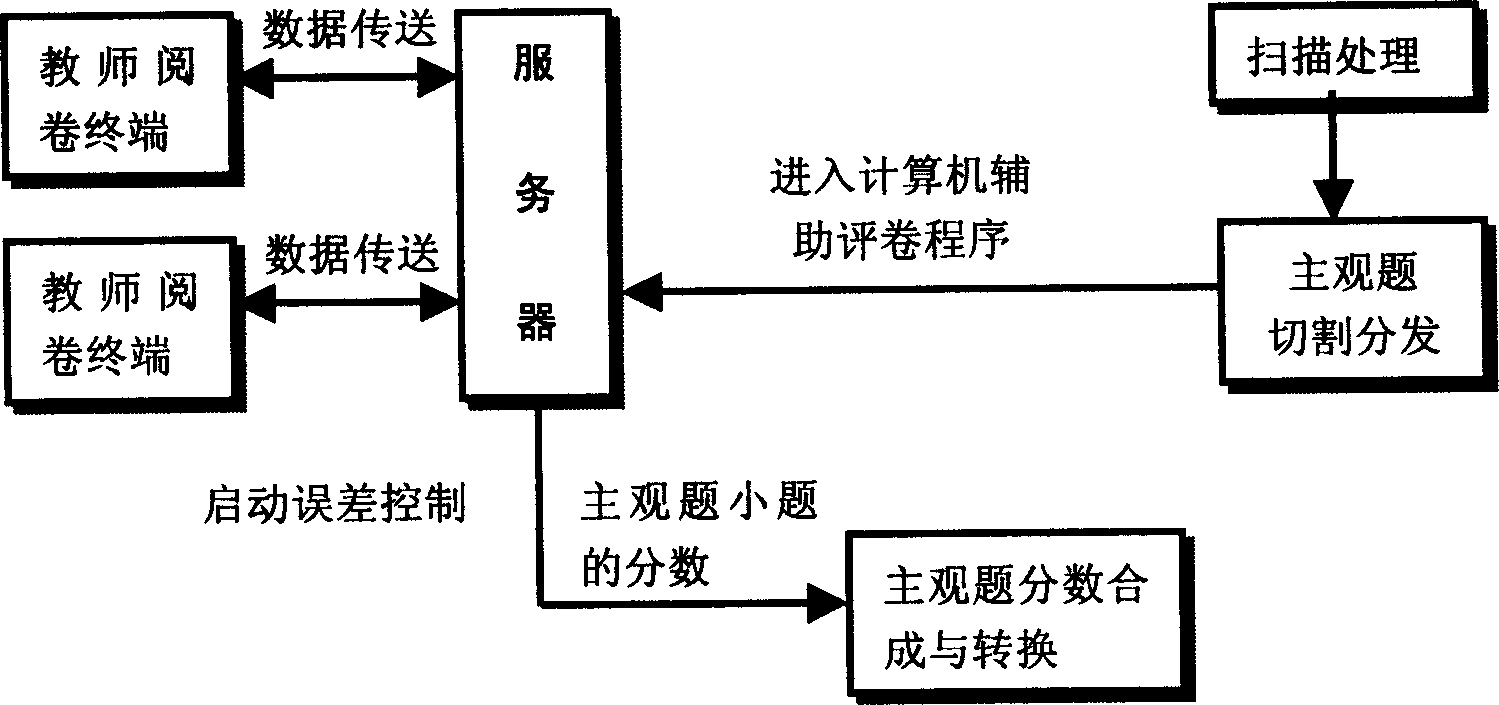

Network exanmination paper go-over method for subjective question

The invention discloses a method used to online review subject items. Its steps include answer card scanning and inputting, image curving and dispatching, computer aided grading and error control and grade composing and conversion. The invention adapts to entrance examination for college, self-teach examination, adult entrance examination for college, entrance examination for high school and other society examinations. Adopting the invention, reviewing error of subjection items is controlled to furthest realize equality and justice in process of reviewing and misjudge is avoided by adopting special treatment on question test papers to guarantee examinees' benefit.

Owner:SHENZHEN SEA SKY LAND TECH

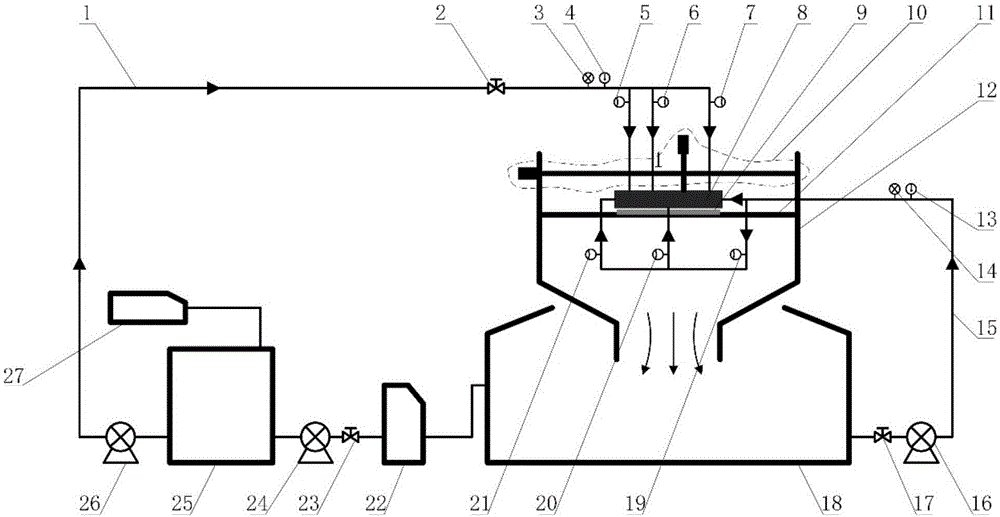

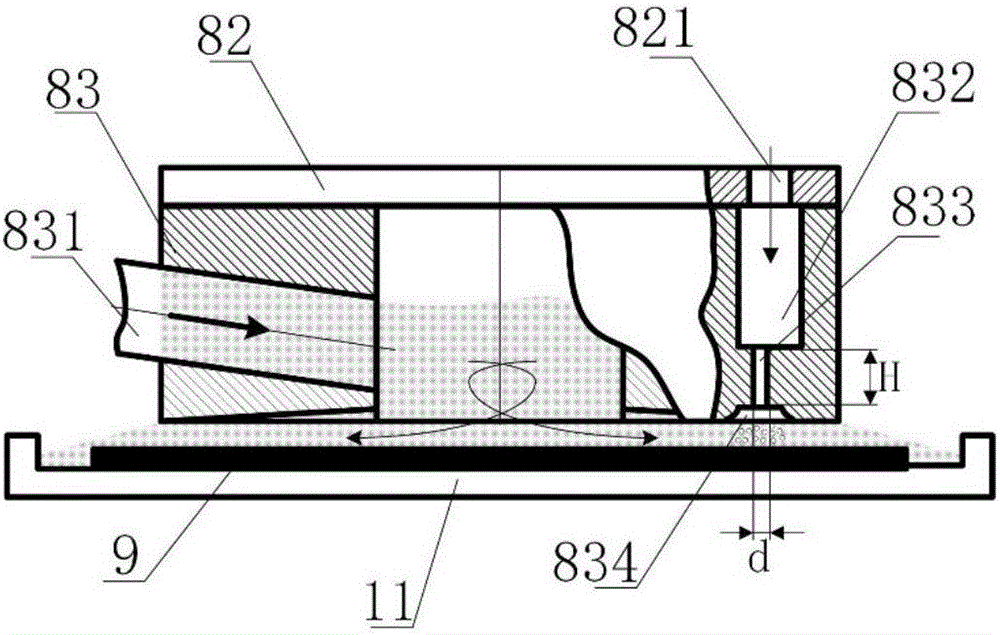

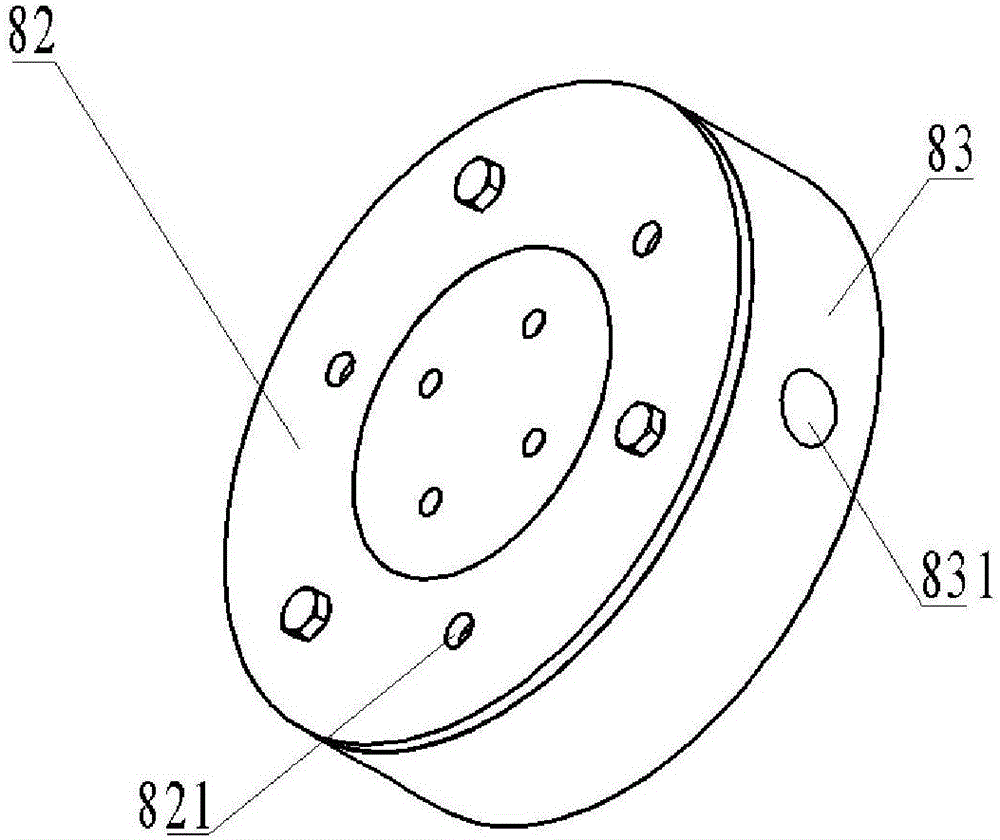

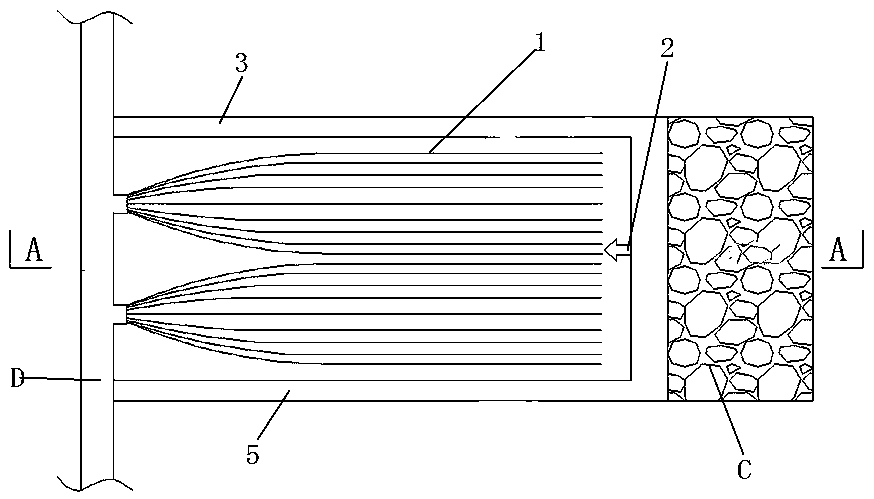

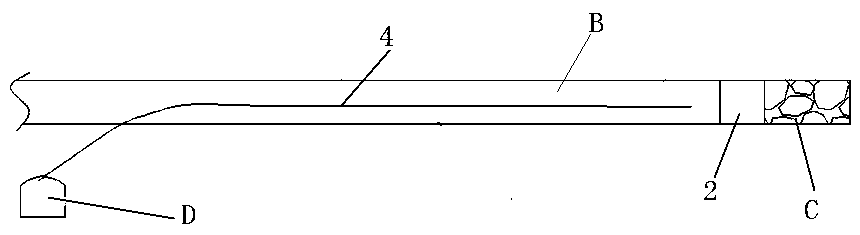

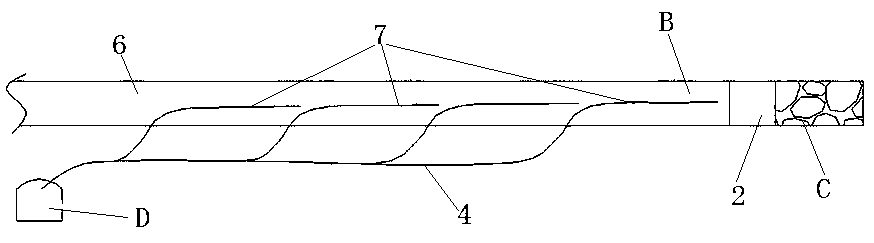

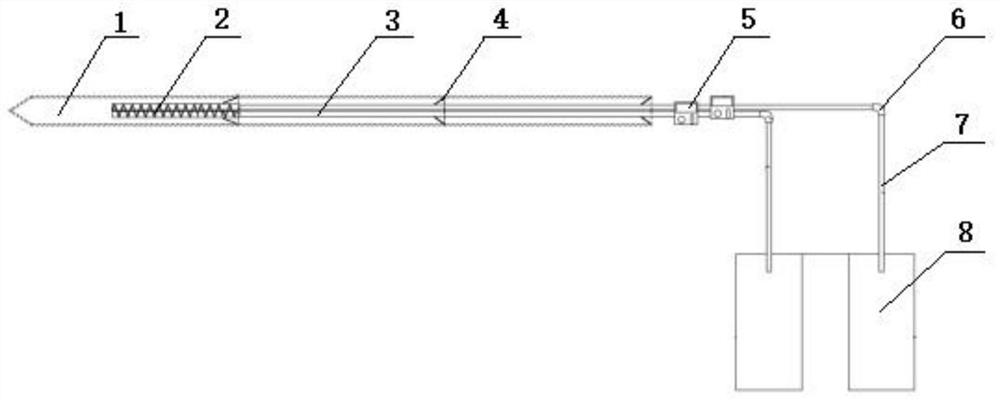

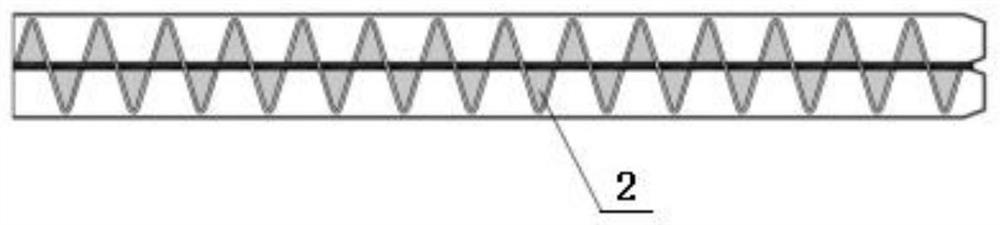

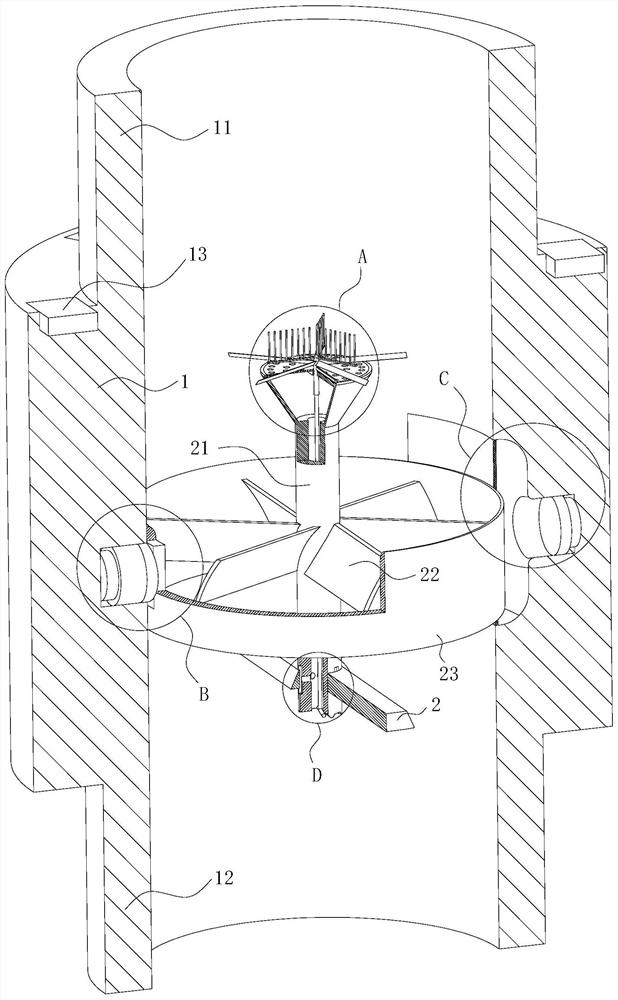

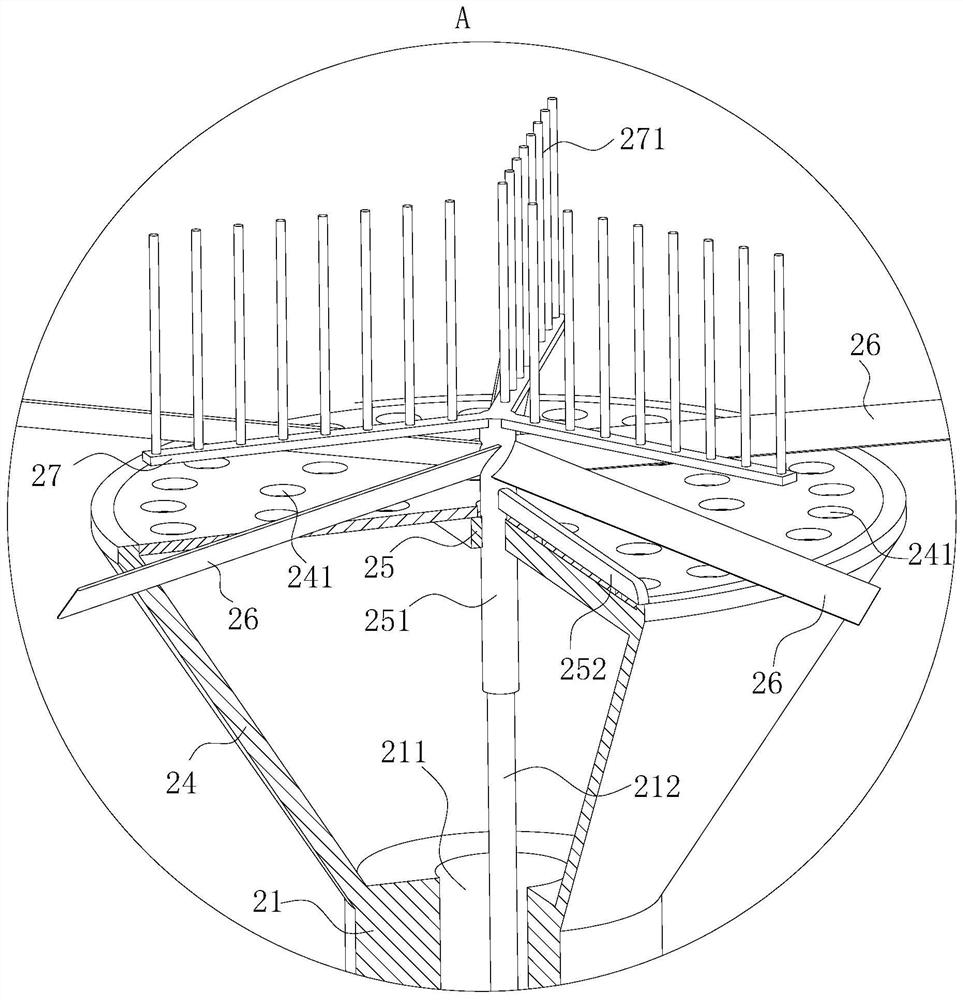

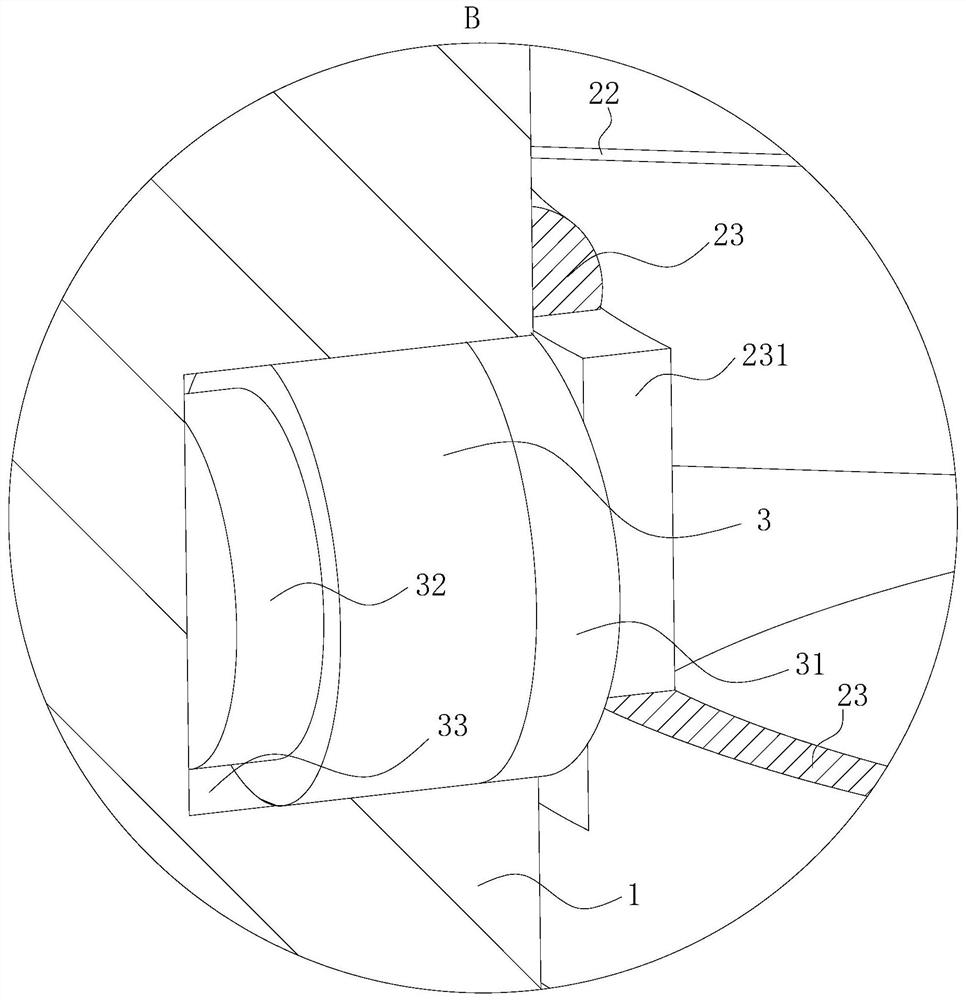

Efficient fluid finishing method and device based on structure cavitation effect

ActiveCN106392863ACollapse drive effect is obviousSimple structureEdge grinding machinesPolishing machinesBubble cavitationWear particle

The invention discloses an efficient fluid finishing method based on the structure cavitation effect. According to the efficient fluid finishing method, the Venturi tube cavitation effect is introduced to fluid finishing, strong bubble cavitation action is formed in the effective polishing area formed between a processing tool and a workpiece to be processed by arranging a Venturi tube structure on the processing tool, and the bubble cavitation action is utilized to drive a liquid-solid abrasive flow in the formed effective polishing area to move in a high-speed turbulent vortex mode to achieve processing on the surface of the workpiece to be processed through abrasive particles. According to the efficient fluid finishing method based on the structure cavitation effect, the Venturi tube structure is utilized to achieve growth and collapse of bubbles in the microspur gap between the processing tool and the workpiece to be processed so as to achieve unordered and high-speed turbulent flow of the abrasive particles; compared with processing equipment adopting ultrasonic waves, the structure is simpler and the cost is lower; and compared with normal bubble-free-collapse processing equipment, the controllability is better, and the bubble collapse driving effect is more obvious.

Owner:ZHEJIANG UNIV OF TECH

Continuous circulating type oil-gas adsorption recovery method

InactiveCN101259358AEasy to realize fully automatic controlEasy to realize remote monitoringDispersed particle separationHigh concentrationRecovery method

The invention discloses a sustained circulating type method for adsorbing and recycling oil gas , which consists of the following steps: (1) adsorbing and recycling the oil gas by means of an active carbon bed in an adsorption tower; (2) the desorption and regeneration of the adsorption tower saturated is carried out; (3) the oil gas desorbed with high concentration enters a recovery tower to be absorbed by the body of liquid meager gasoline; (4) the tail gas in the recovery tower reenters the adsorption tower to be cycled in a sustaining way, wherein, at least two adsorption tanks in the adsorption tower alternately carry out adsorption and desorption generation, thus leading the oil gas adsorption to be carried out in a sustained circulating way, at the same time, the remote monitoring can be realized by using an automatic control program. The sustained circulating type method for adsorbing and recycling oil gas of the invention is characterized by high efficiency, low energy consumption, convenient operation and safe and reliable running.

Owner:BAY ENVIRONMENTAL TECH BEIJING

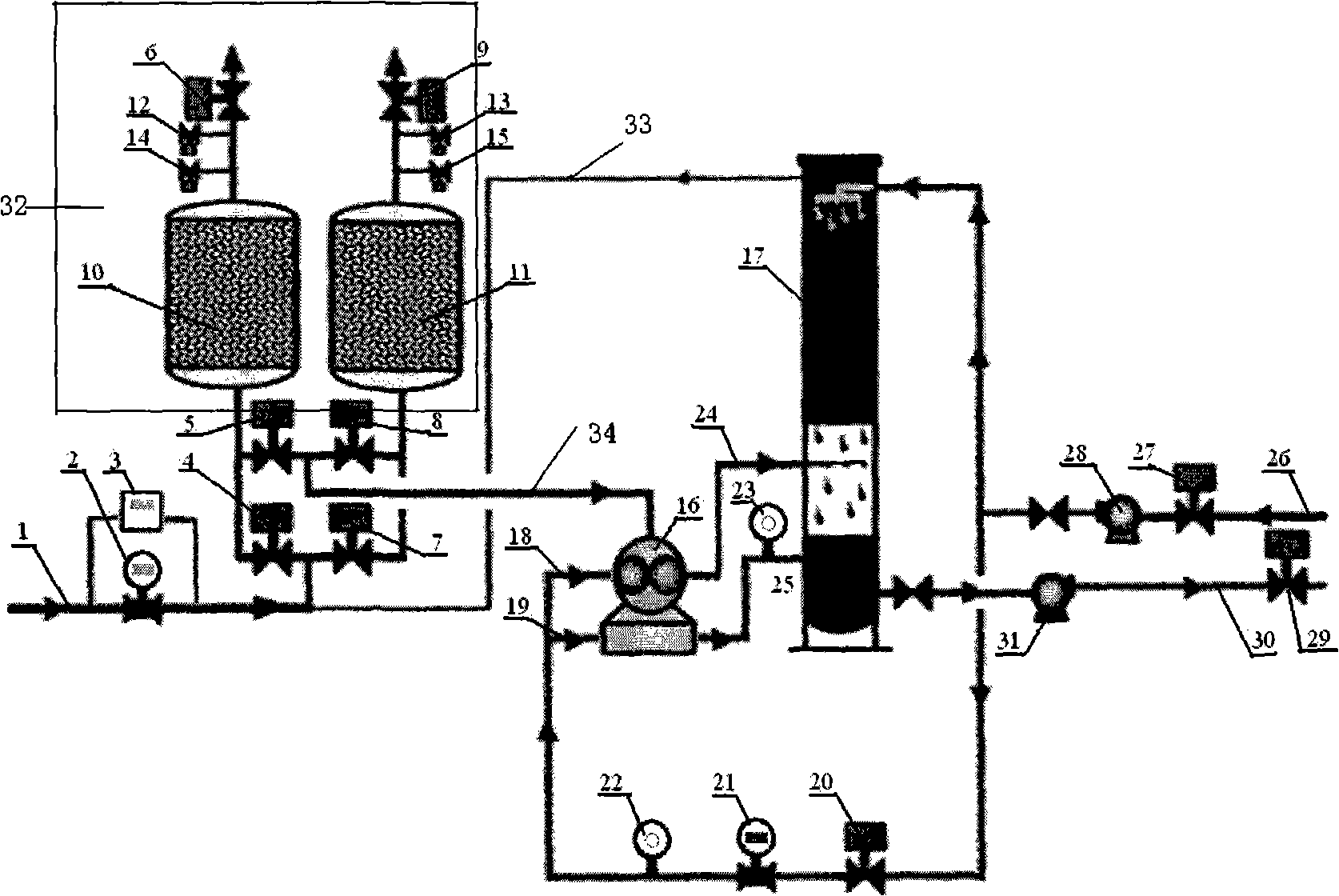

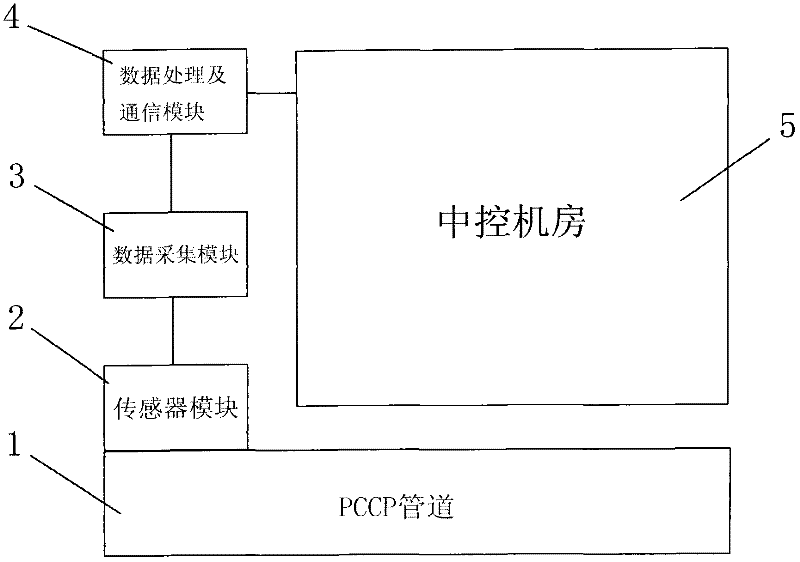

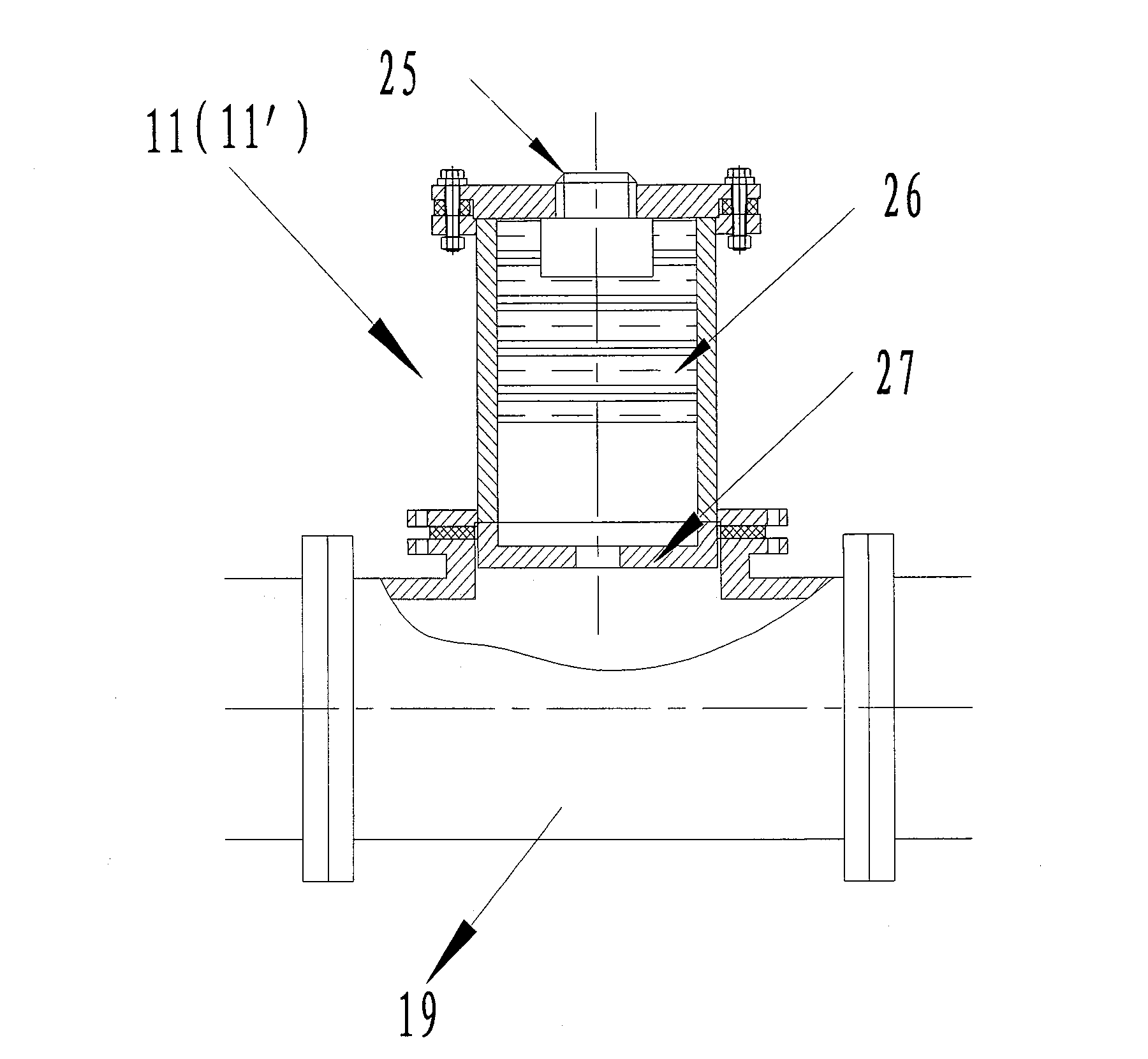

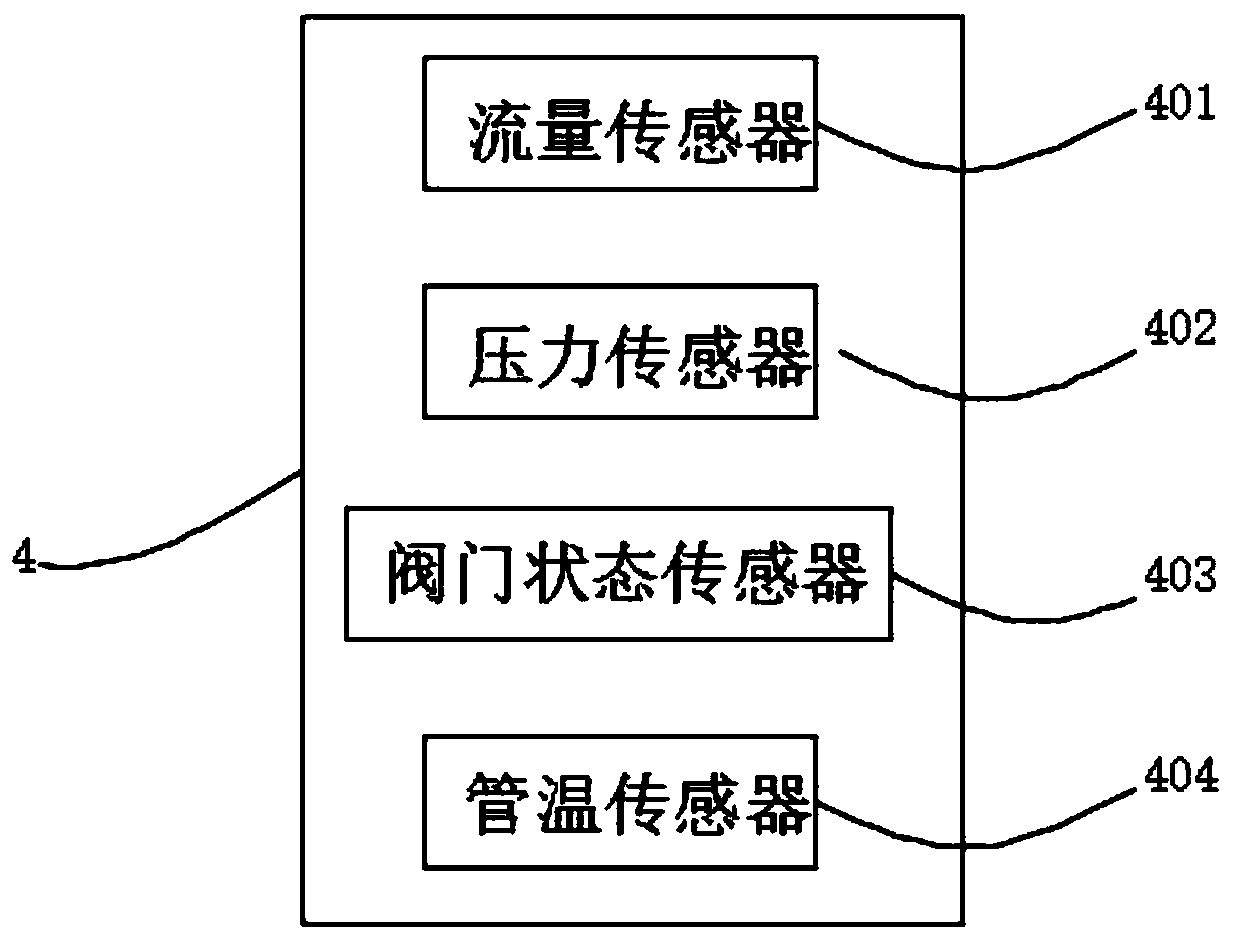

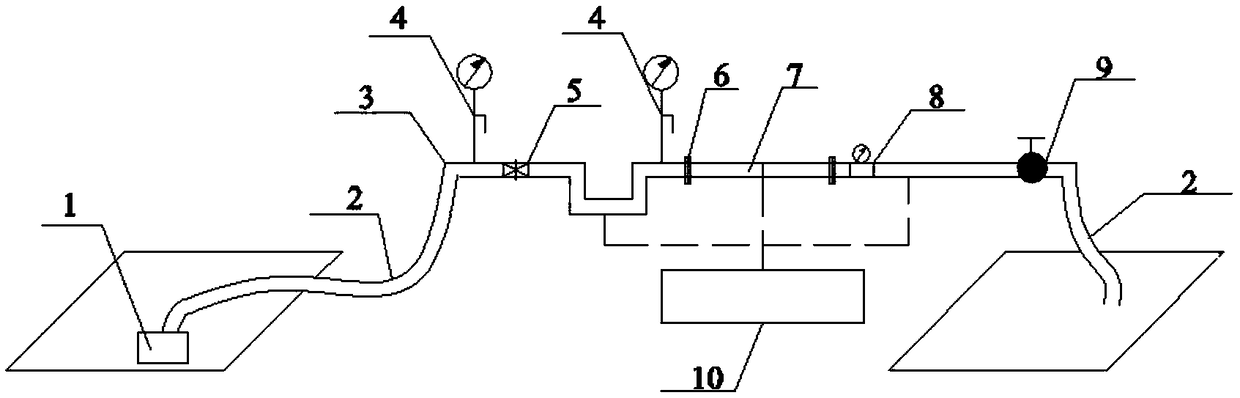

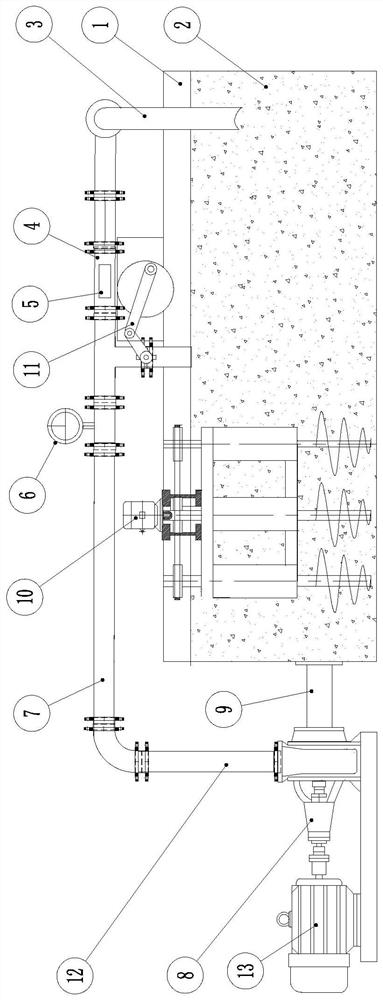

Online real-time monitoring system for an embedded delivery pipeline

InactiveCN102635786AImprove the level of informatizationReduce maintenance costsPipeline systemsTraffic volumeWater delivery

The invention discloses an online real-time monitoring system for an embedded delivery pipeline, which is characterized by comprising a PCCP (prestressed concrete cylinder pipeline), a sensor module, a data processing module, a communication module and a center control machine room. The sensor module is attached onto the PCCP, and is connected with the data processing module on earth surface or embedded shallowly through a cable, the data processing module is then connected with the communication module, and the communication module is connected with the center control machine room. Compared with the prior art, the online real-time monitoring system for the embedded delivery pipeline has the advantages that statues of pressure, flow rate, vibration, sedimentation and the like of the delivery pipeline can be monitored in real time, detail operation and safety states of the full delivery pipeline can be controlled in real time, history monitoring data can be accumulated, an emergency monitoring warning mechanism can be established, informatization level of engineering running can be increased, and safety of water delivery engineering can be guaranteed while operation maintenance cost can be lowered.

Owner:深圳市合益自动化科技发展有限公司 +3

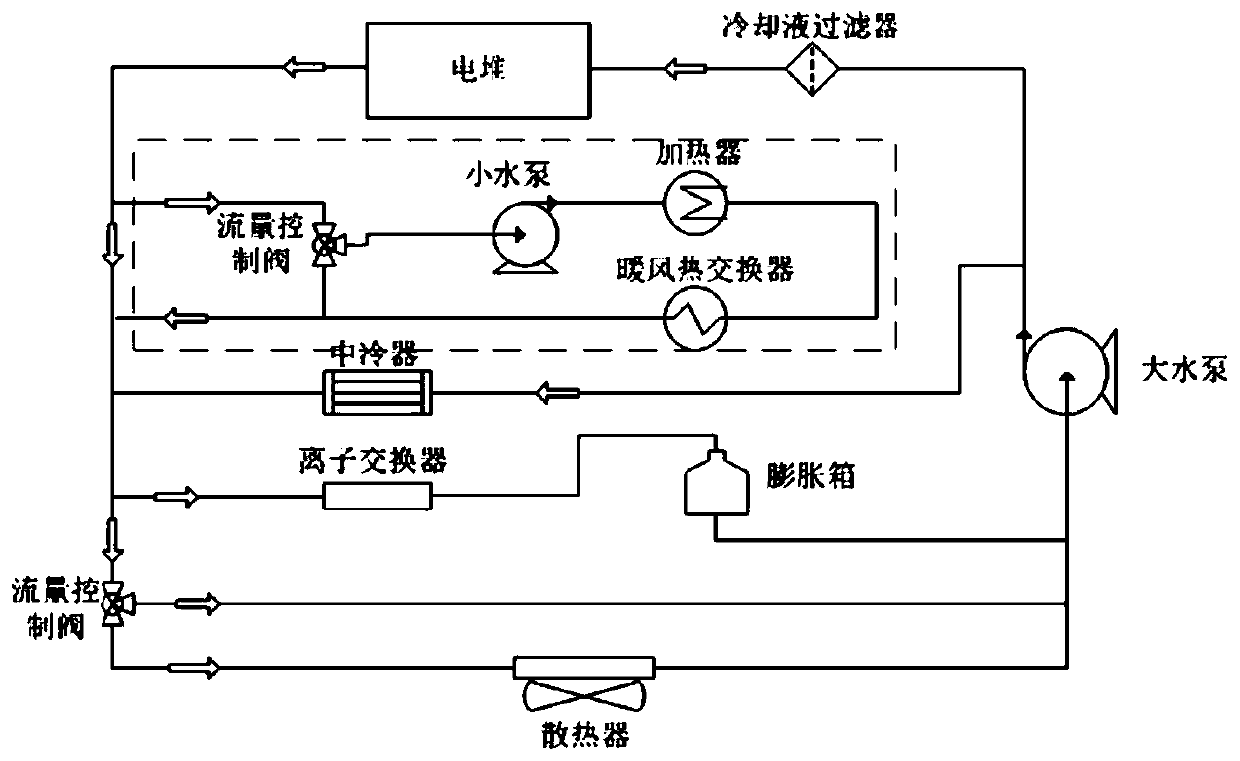

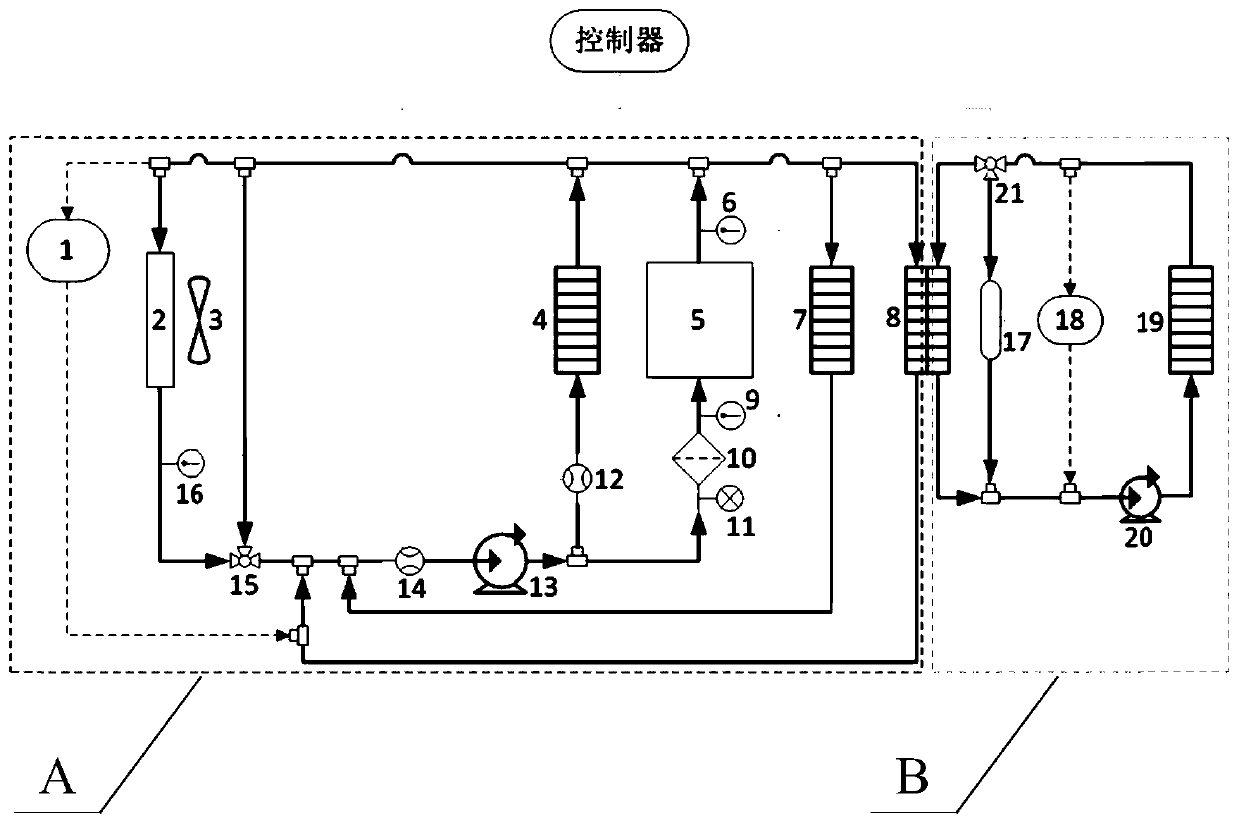

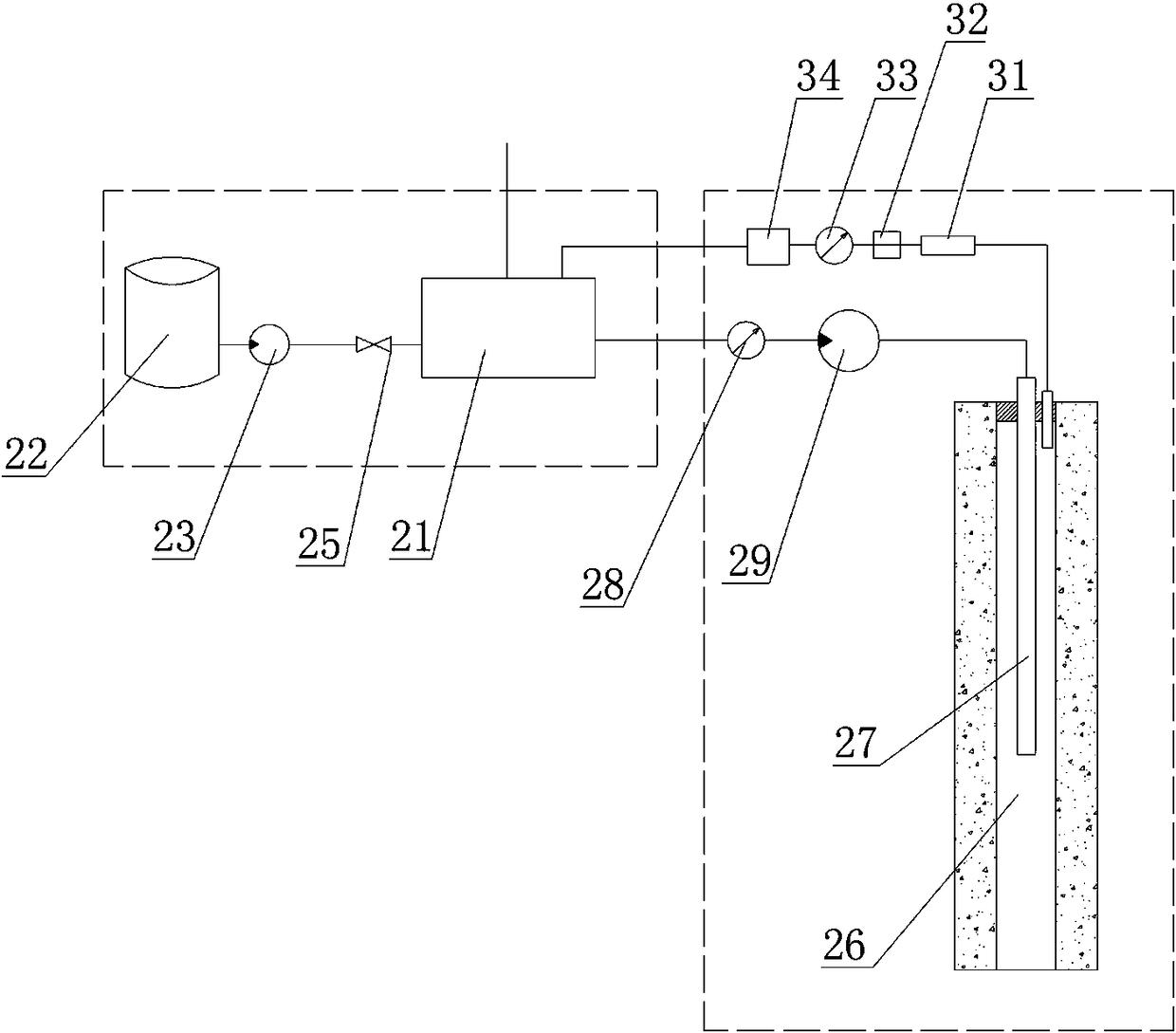

Thermal cycle management system for vehicle fuel cell

PendingCN111129541AExtended replacement cycleReduce raiseAir-treating devicesVehicle heating/cooling devicesFuel cellsCooling fluid

A thermal cycle management system for a vehicle fuel cell includes a stack cooling circuit, a cabin heating circuit, and a controller; the stack cooling circuit includes a first water pump, a deionization and filter assembly, a stack, and a cabin heat exchanger. The first water pump is arranged on a main loop of the stack cooling loop and used for providing circulating power for the galvanic pilecooling loop; the deionization and filter assembly is connected in series behind the first water pump and is used for removing ions and impurities in the cooling liquid; the stack is connected in series behind the deionization and filter assembly and is used for generating electric energy; the cabin heat exchanger is connected in series behind the stack and used for exchanging a part of heat generated by the stack to the cabin heating loop. According to the thermal cycle management system of the vehicle fuel cell, an integrated scheme of integrating the ion exchanger and the cooling liquid filter is adopted, the system performance is guaranteed, and the number of parts is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

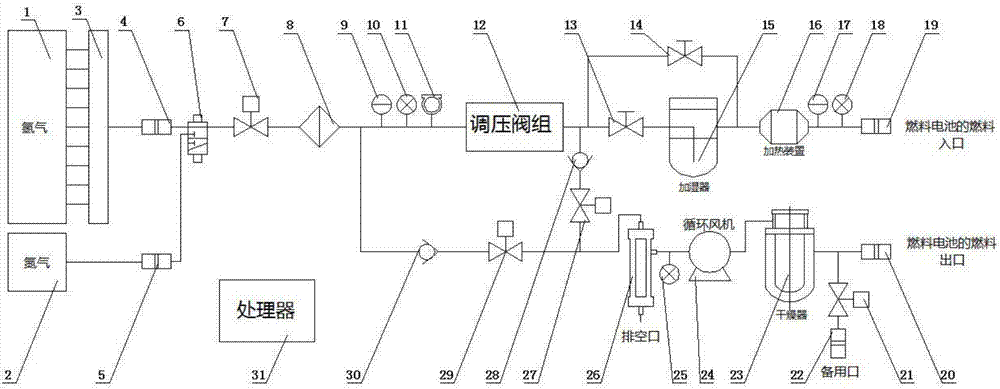

Fuel real-time monitoring and recycle device of fuel cell vehicle

PendingCN107017421AMonitor temperature in real timeMonitor pressure in real timeFuel cell controlVehicular energy storageProcess engineeringHydrogen supply

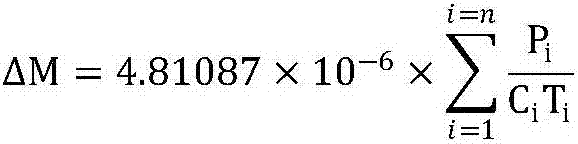

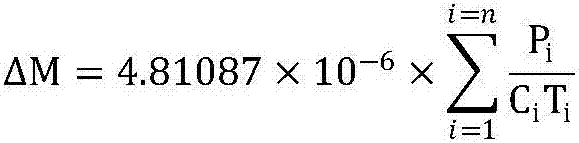

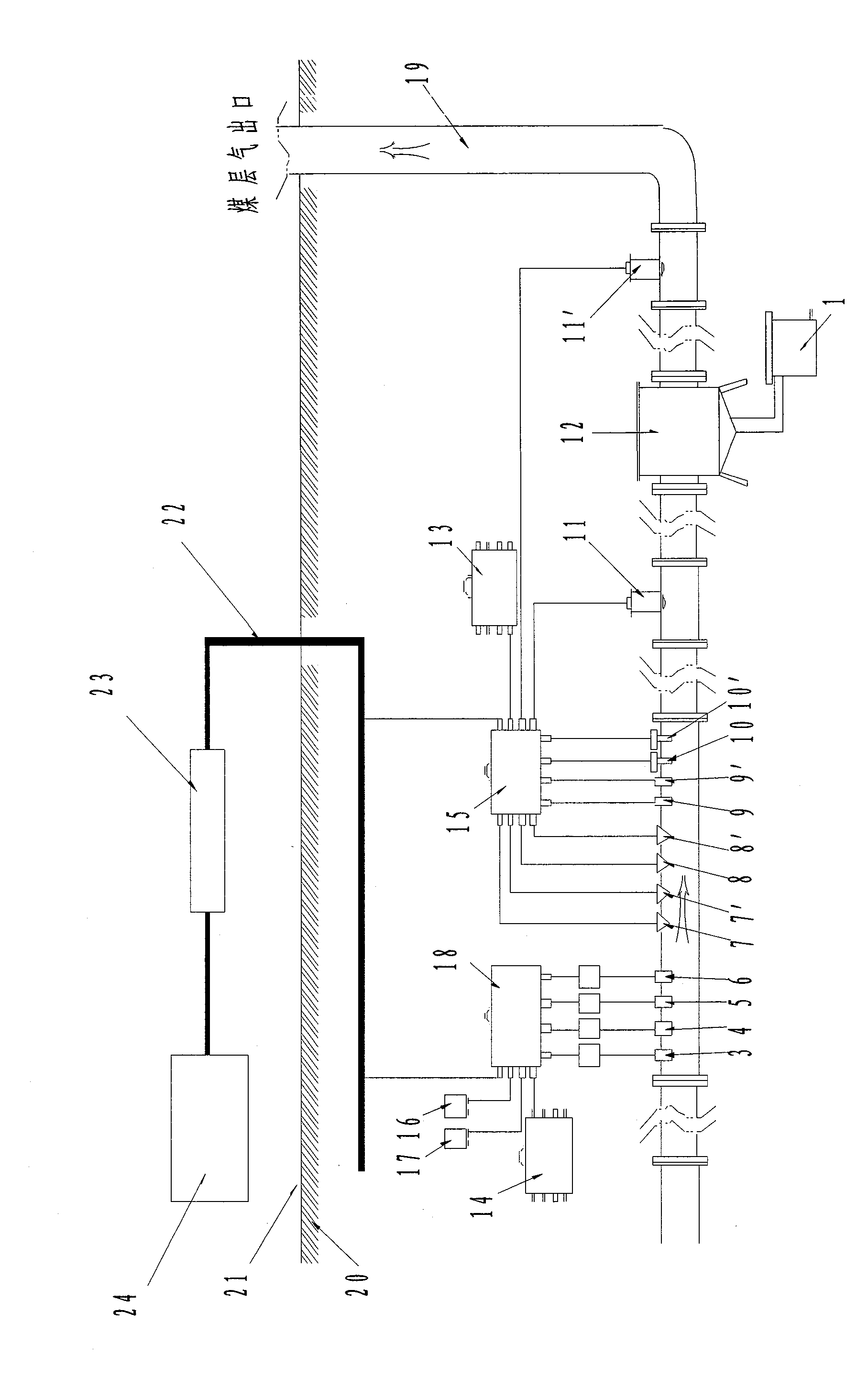

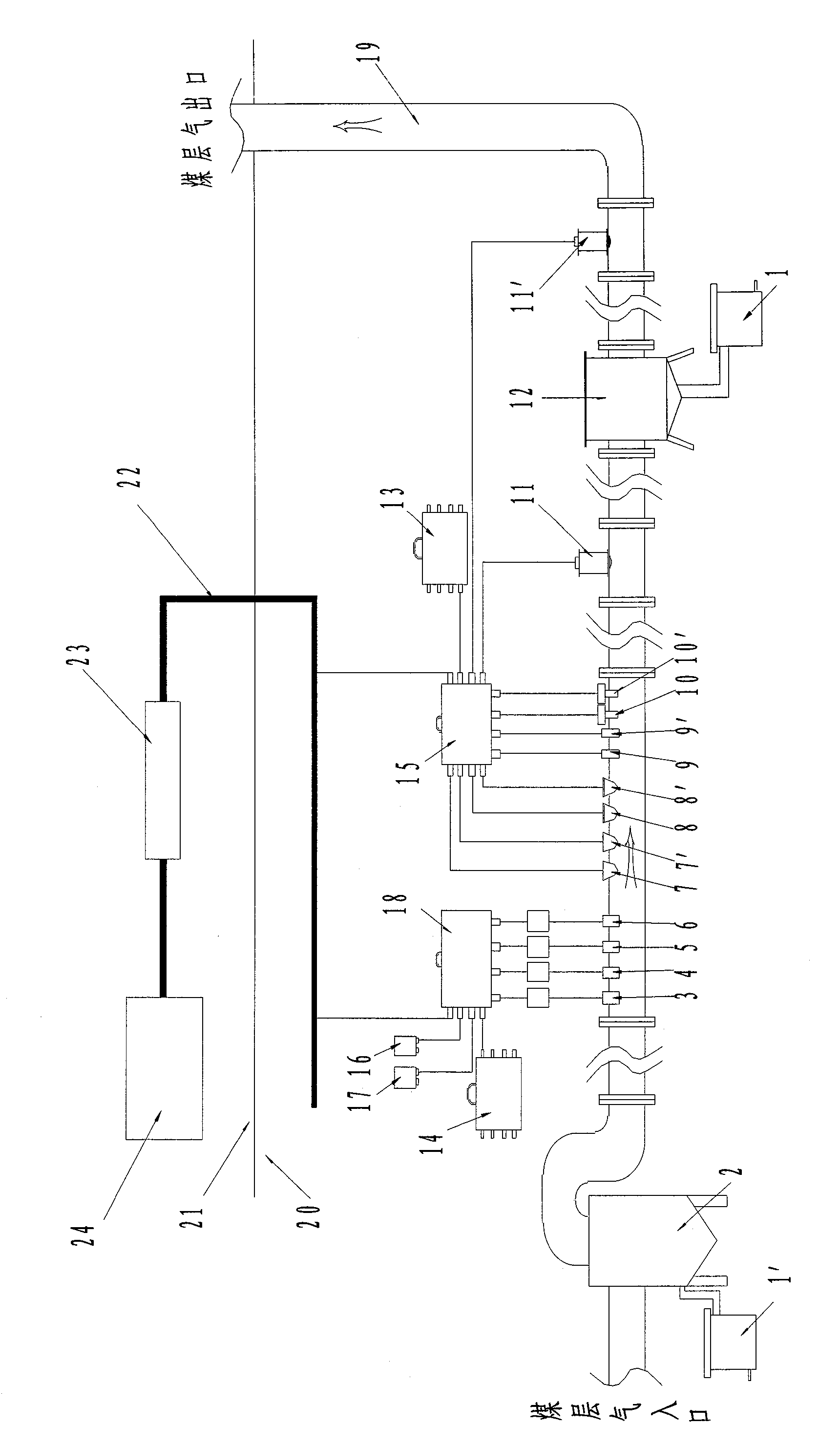

The invention provides a fuel real-time monitoring and recycle device of a fuel cell vehicle. The fuel real-time monitoring and recycle device comprises a main hydrogen supply pipeline and a hydrogen recycle pipeline, wherein the main hydrogen supply pipeline is used for adjusting pressure, temperature and humidity of hydrogen at an air outlet of the device by devices such as a temperature sensor, a heating device, a pressure regulation valve group and a pressure sensor, monitoring state quantity of the hydrogen in real time and calculating mass of the consumed hydrogen by an algorithm, and the hydrogen recycle pipeline is used for separating moisture and air from the hydrogen discharged out of the air outlet of the device, pressurizing the remaining hydrogen and then combining the remaining hydrogen to the main hydrogen supply pipeline. The main hydrogen supply in the device provided by the invention can be used for monitoring the temperature, the pressure and the flowing quantity of the hydrogen in real time and calculating the consumed hydrogen quantity by the algorithm, the pressure and the flowing quantity of the hydrogen at an inlet can be adjusted by the pressure regulation valve group, the temperature of the hydrogen at the inlet can be adjusted by the heating device, so that the optimal working condition of a fuel cell is reached.

Owner:BEIJING JIAOTONG UNIV

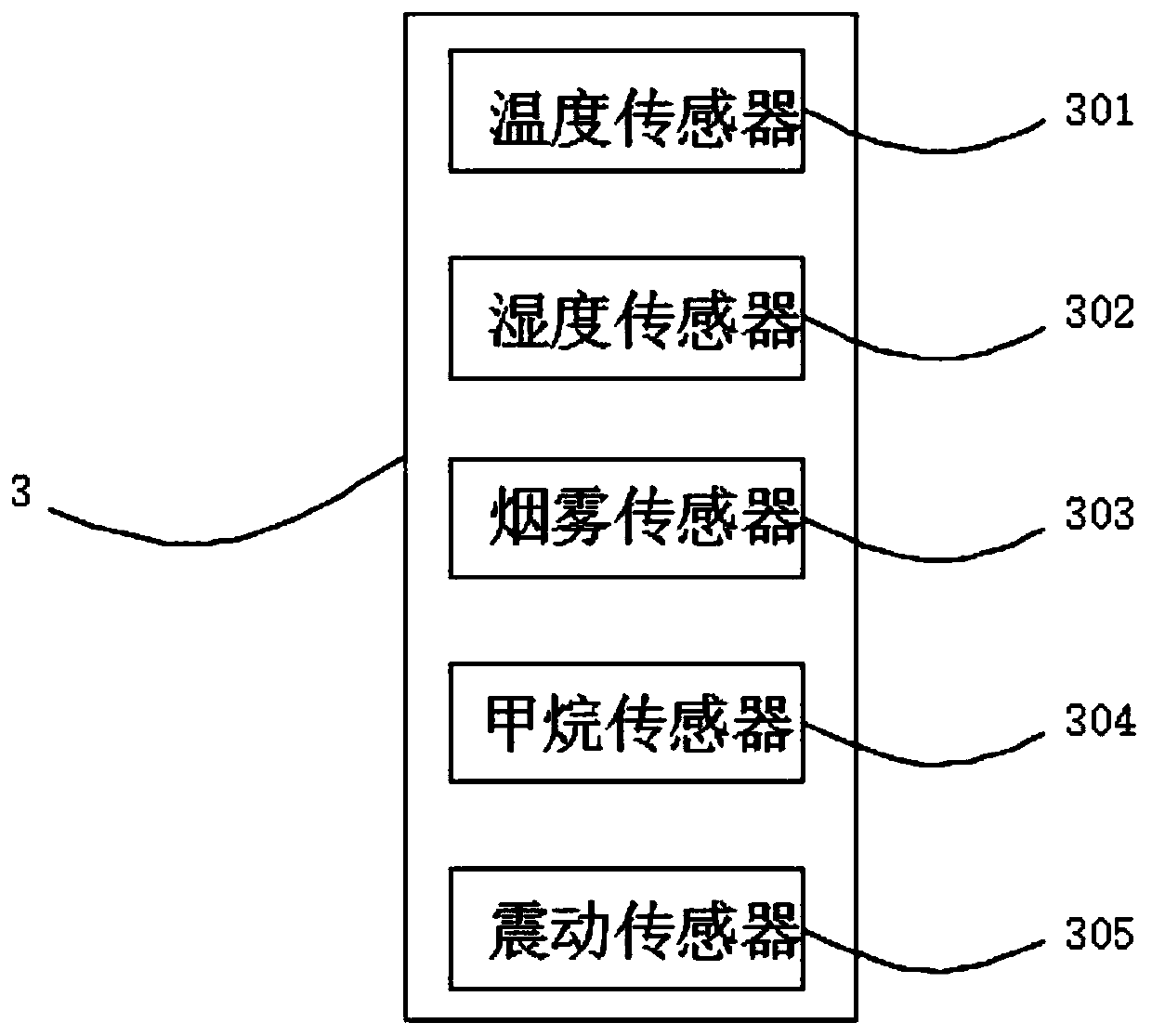

Safe delivery system for coal bed gas

ActiveCN104110582AReduce false alarm rateReduce non-report ratePipeline systemsSafe deliveryCommunication interface

The invention relates to a safe delivery system applied to downhole coal bed gas (gas) in coal mining. A monitoring device, an automatic powder spraying and explosion suppression device and a fire retarding device are sequentially arranged on a delivery pipeline along the coal bed gas delivery direction, the automatic powder spraying and explosion suppression device is connected with a controller, and output ends of the monitoring device and the controller are connected with a monitoring system on the ground through information data buses and communication interfaces respectively. By the safe delivery system, information like methane, carbon oxide, temperature and flow in the delivery pipeline is monitored at any time; once the circumstance of limit exceeding is found, an alarm is given timely, and the circumstance is transmitted to a control center on the ground and even a national safety monitoring center. Once a fire disaster occurs, the disaster is controlled within a certain range under action of the fire retarding device and the automatic powder spraying and explosion suppression device.

Owner:SHANDONG ANYI MINING EQUIP CO LTD

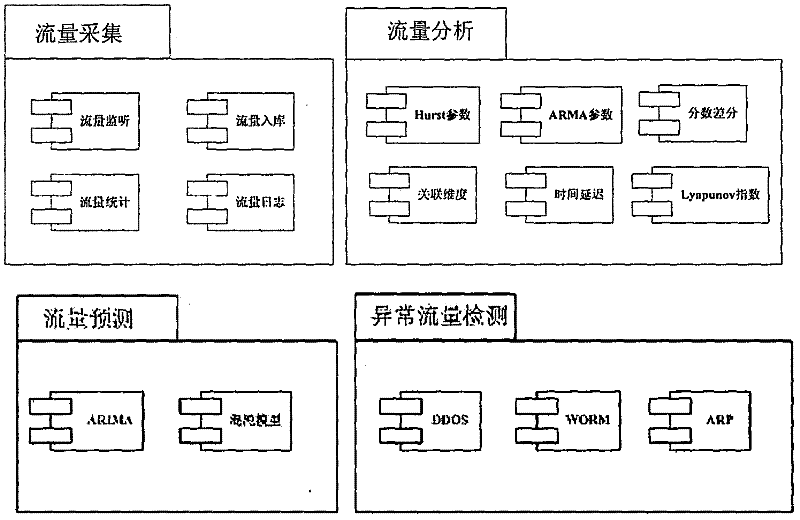

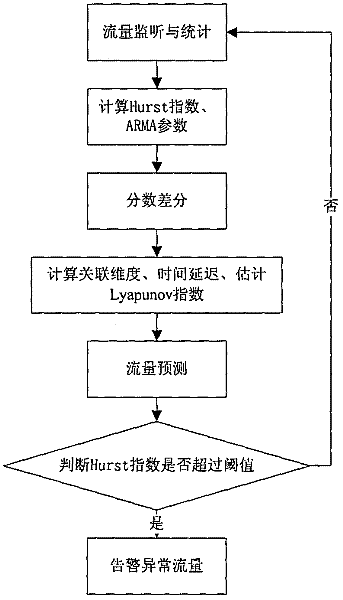

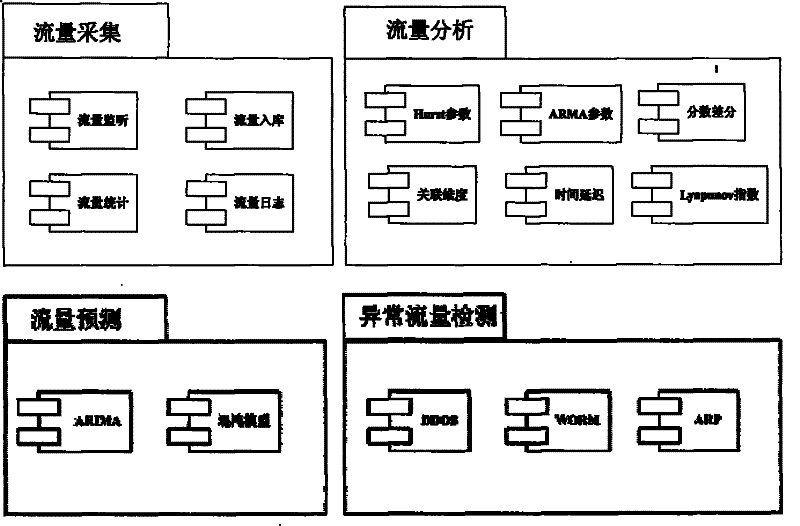

Flow analysis method based on ARMA (Autoregressive Moving Average) model and chaotic time sequence model

InactiveCN102404164ARealize detectionActual prediction application value is goodData switching networksMoving averageTraffic flow analysis

The invention discloses a flow analysis method based on an ARMA (Autoregressive Moving Average) model and a chaotic time sequence model. By adopting the flow analysis method, the flow gathering, the feature extraction, the flow analysis, the flow forecasting and the abnormal flow detection can be realized. The flow analysis method comprises the following steps of firstly, monitoring and counting flow by calculating Hurst indexes, ARMA parameters, fractional difference, relevant dimension and time delay and estimating Lyapunov indexes; carrying out certain step-length forecasting on a sample point according to the parameters and the forecasting formula which are provided by the flow analysis; and early warning the abnormal flow in a network according to the variation of the Hurst indexes.

Owner:JIANGSU XINWANG TEC TECH

Outburst coal seam 'five-fixation' gas treatment method based on directional drilling machine

PendingCN110645040AReduce biasReduce outstanding riskSurveyFluid removalThermodynamicsMonitoring system

The invention provides an outburst coal seam 'five-fixation' gas treatment method based on a directional drilling machine. The outburst coal seam 'five-fixation' gas treatment method based on the directional drilling machine comprises the following steps of (1) evaluating the feasibility of each extraction geological unit adopting the'five-fixation' gas treatment method; (2) directionally drillingeach extraction geological unit; (3) carrying out positioning disturbance in permeability improvement holes, and improving the permeability of a coal bed; (4) sealing the permeability improvement holes and extraction holes; and (5) sampling fixed points in a sealing way for determining gas parameters, quickly extracting gases conveniently, monitoring the gas concentration and the flow on an extraction pipeline in real time through a gas extraction online monitoring system, and furthermore, carrying out real-time statistic and display on the gas extraction amount and the gas amount to be extracted on a displayer through a cloud chart form through system calculation, so that the extraction time of drilling can be accurately controlled, the gas extraction amount and the participated gas content of each drill hole or hole group are displayed with a cloud chart in different colors, and an extraction effect is intuitively reflected.

Owner:郑州慧矿智能科技有限公司

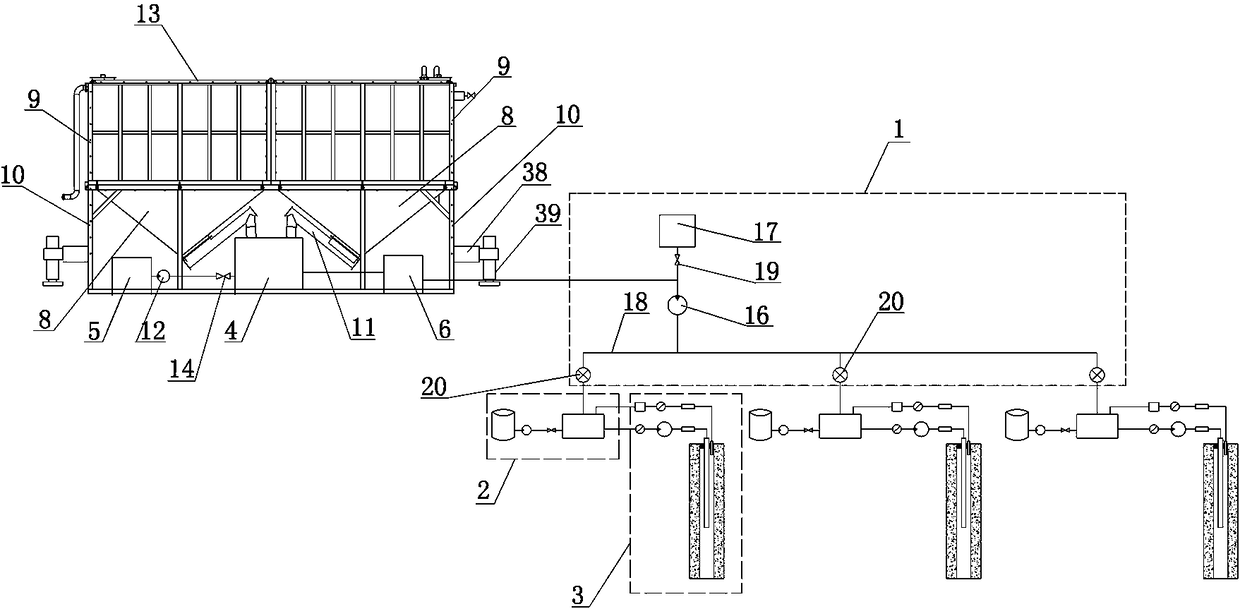

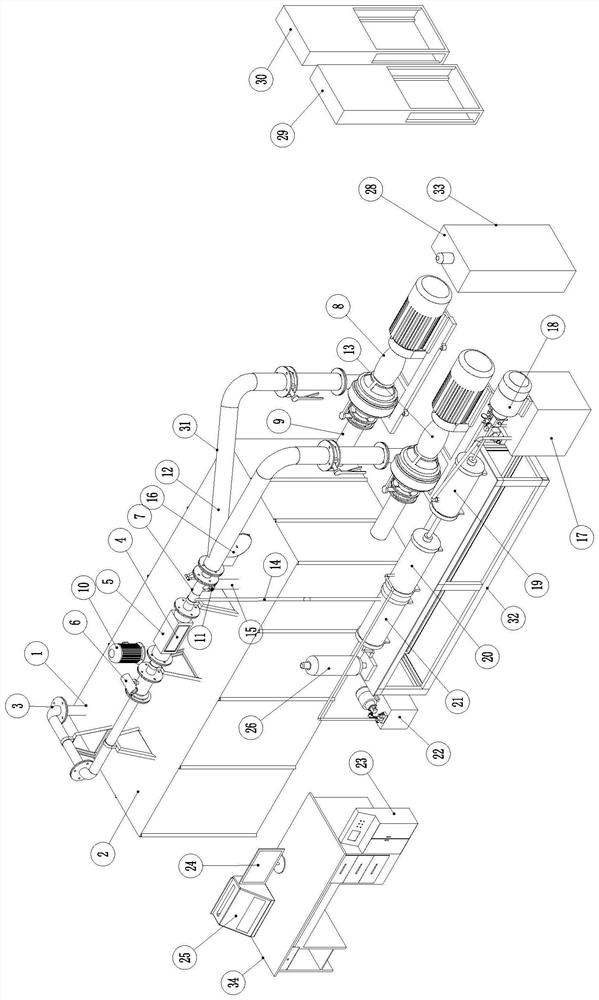

Automatic grouting production system

InactiveCN108705678ARealize continuous preparationEasy to controlMixing operation control apparatusFoundation engineeringControl systemMonitoring system

The invention discloses an automatic grouting production system. The automatic grouting production system comprises a control system, a grout making station, a grout conveying system, grout proportionstations and grouting monitoring systems. The automatic grouting production system has the advantages that the automation degree is high, the labor cost is saved, the operation is simple, the unmanned production or the flexible manpower line is realized, the proportion precision is improved, and the labor intensity is reduced.

Owner:XIYI AUTOMATION SYST ENG CHENGDU +1

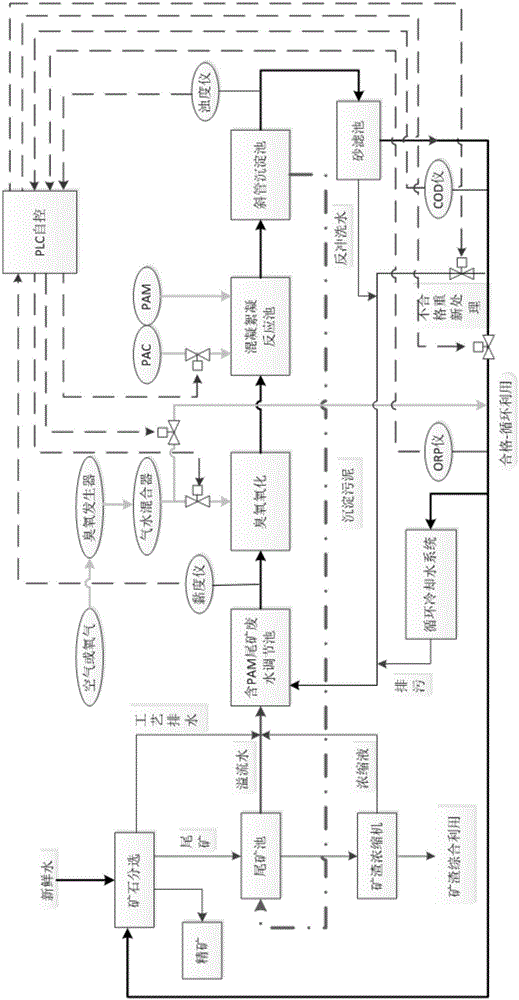

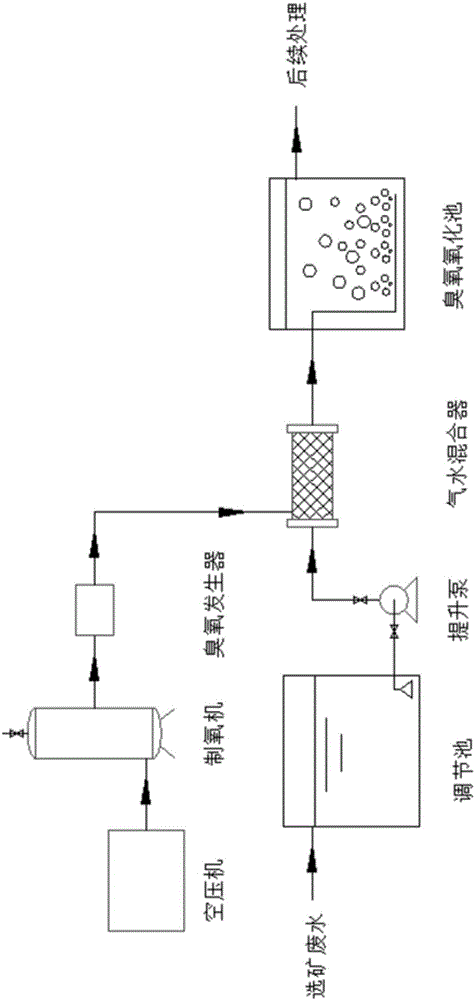

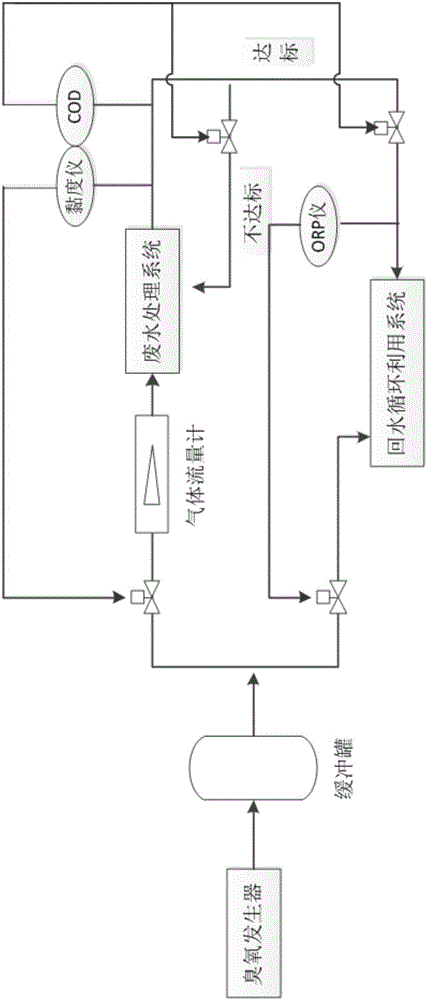

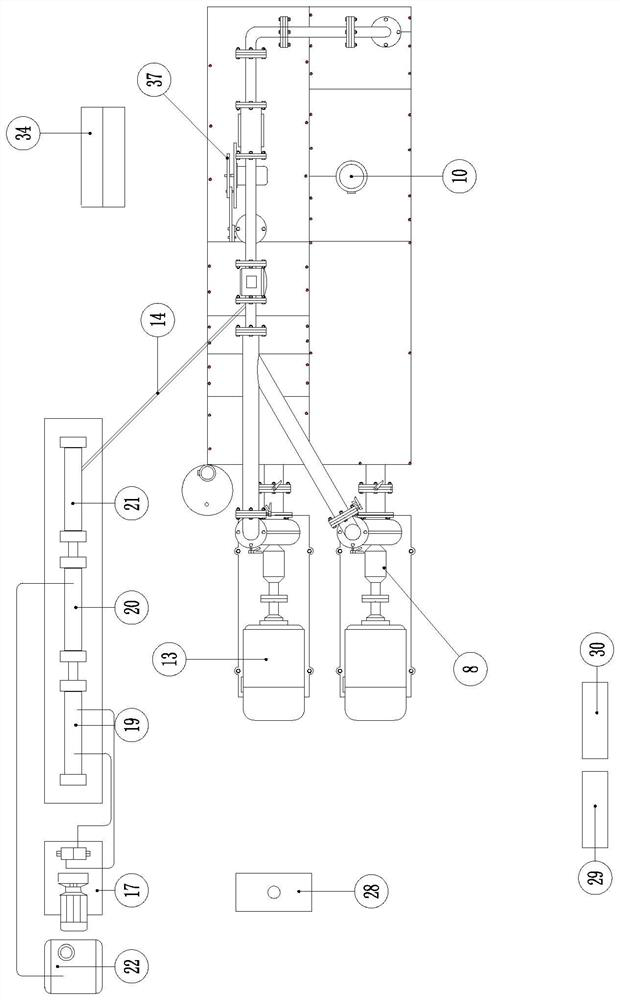

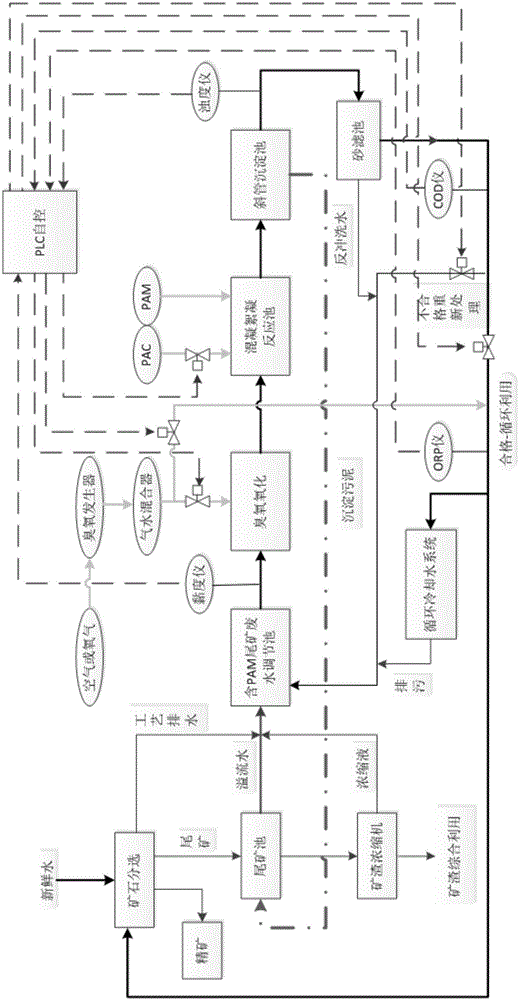

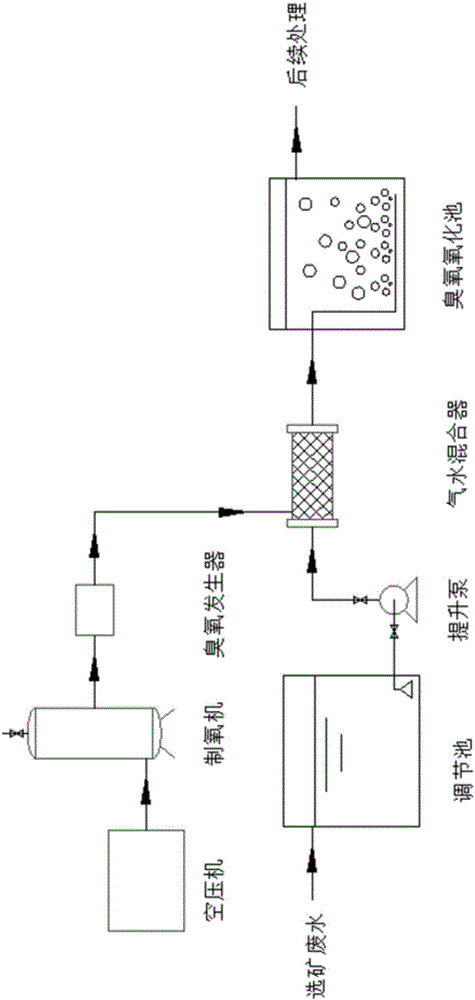

Circulating system and process for PAM-containing tailing wastewater treatment

PendingCN106746008AReduce viscosityReduce turbidityWaste water treatment from quariesTreatment involving filtrationElectricityFlocculation

The invention relates to a circulating system for PAM-containing tailing wastewater treatment. The circulating system comprises a tailing wastewater regulating tank, an ozone oxidation device, a coagulation-flocculation reaction tank and a physical filtering device which are sequentially connected and communicated, and further comprises a control unit and a viscosimeter, wherein a pipe for purified water obtained after filtration of the physical filtering device is connected with an ore sorting water inlet; ozone and wastewater are mixed at the ozone oxidation device; the coagulation-flocculation reaction tank is connected with an externally-connected PAC and PAM adding channel for flocculating PAM; the viscosimeter monitors the wastewater viscosity at the front end of the ozone oxidation device in real time; the control unit is electrically connected with an ozone supply flow control valve on the ozone oxidation device and the viscosimeter respectively. According to the characteristic that ore wastewater has relatively large turbidity, a viscometer is skillfully used for monitoring the viscosity of the wastewater before ozone oxidation real time, the viscosity is fed back to the control unit, and hereby the control unit controls the ozone supply flow in real time, so that an optimal effect is achieved.

Owner:上海铱钶环保科技有限公司

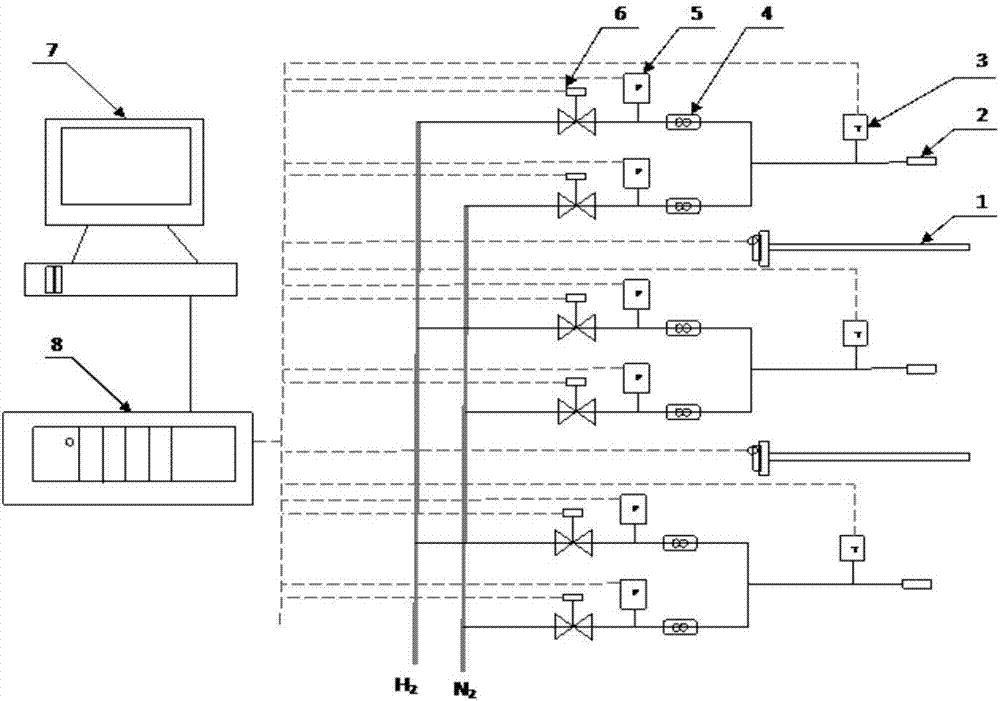

Tin bath atmosphere control system and float glass tin bath

The invention provides a tin bath atmosphere control system and a float glass tin bath. The tin bath atmosphere control system comprises an oxygen content probe, a protection gas supplying pipeline and a controller, wherein the oxygen content probe is used for detecting oxygen content and is arranged in the tin bath; the protection gas supplying pipeline is used for supplying protection gas into the tin bath; the controller is used for controlling the content of hydrogen gas in the protection gas in the tin bath through controlling the protection gas supplying pipeline in real time according detection information of the oxygen content probe. According to the control system provided by the invention, a nitrogen-hydrogen ratio is adjusted by the controller in real time according to the measured concentration of oxygen in tin liquid and / or a space of the tin bath, a reducing atmosphere of the tin bath is strengthened directly aiming at oxidization and reduction properties on tin and oxygen interfaces and reaction of the hydrogen and the oxygen is promoted to be efficiently and rapidly carried out; the content of the oxygen in the space of the tin bath and the tin liquid can be effectively reduced and oxidization of the tin liquid is reduced so that the aim of improving tin impregnation of glass is realized.

Owner:河北视窗玻璃有限公司

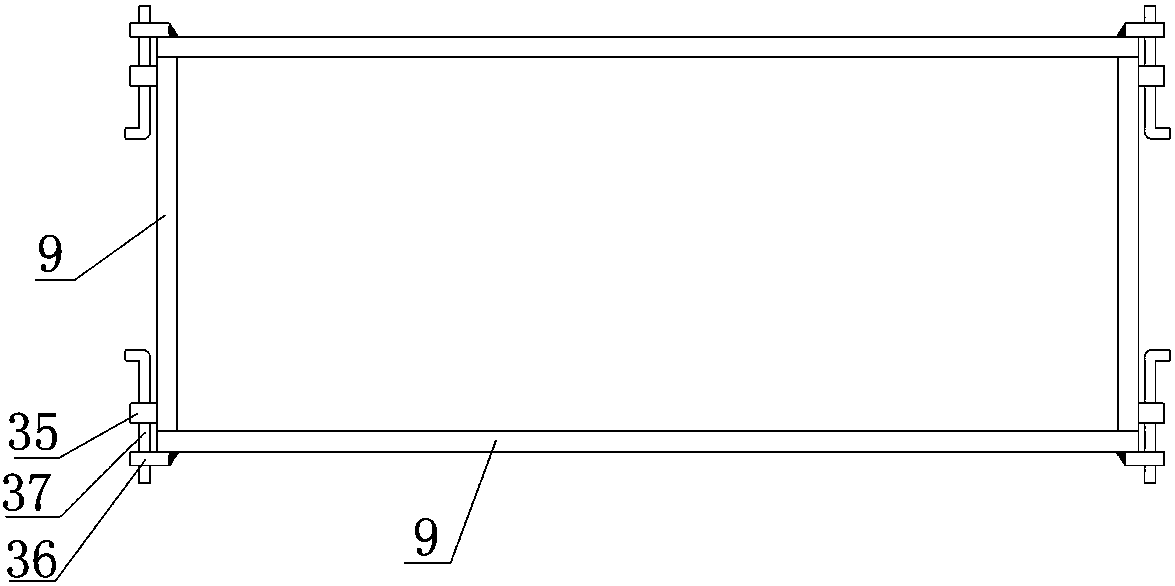

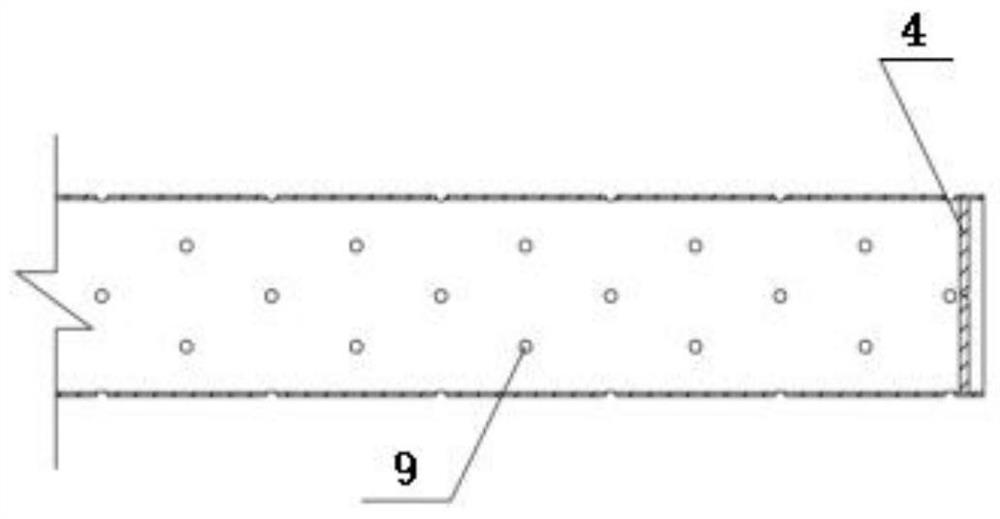

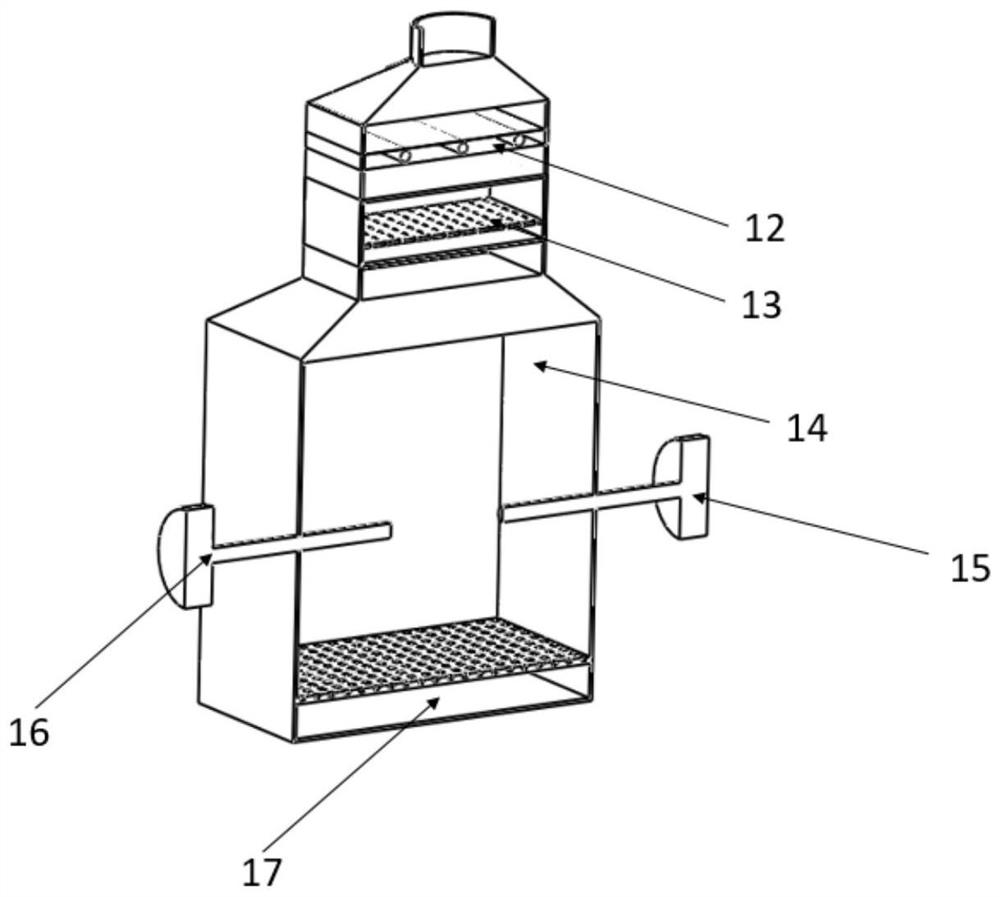

Segmented grouting device with instant grout mixing function and grouting method

PendingCN113236305AHigh Mobility DurationHigh Mobility Duration Long Mobility DurationUnderground chambersTunnel liningPipeSteel tube

The invention discloses a segmented grouting device with an instant grout mixing function and a grouting method. The segmented grouting device with the instant grout mixing function comprises a steel sleeve, wherein one end of the steel sleeve is open, the other end of the steel sleeve is plugged, a plurality of grouting holes are formed in the circumferential outer wall of the steel sleeve, a grout spiral mixing pipe is axially inserted into the plugged end of the steel sleeve in a sliding mode, and a plurality of grouting steel pipes communicating with the grout spiral mixing pipe are axially inserted into the open end of the steel sleeve in a sealing mode; the grout inlet ends of the grouting steel pipes axially extend out of the steel sleeve and sequentially communicate with a pressure flow meter, a turning connector, a grouting hose and a grouting pump correspondingly. According to the segmented grouting device with the instant grout mixing function and the grouting method, the grouting pressure and the grout proportion can be controlled in real time, surrounding rock grouting reinforcement after tunnel excavation can be carried out, advanced curtain grouting reinforcement before tunnel excavation can be carried out, and the segmented grouting device with the instant grout mixing function have the advantages of being late in double-grout mixing, high in fluidity, long in duration time, capable of conducting segmented grouting, low in cost, easy to assemble and the like.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

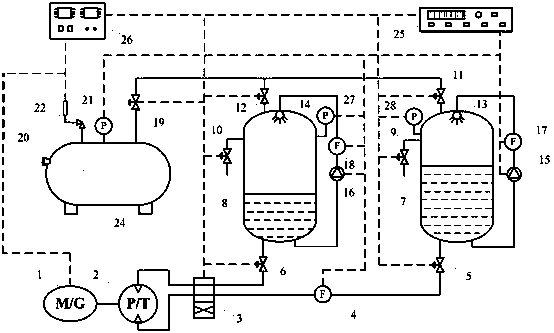

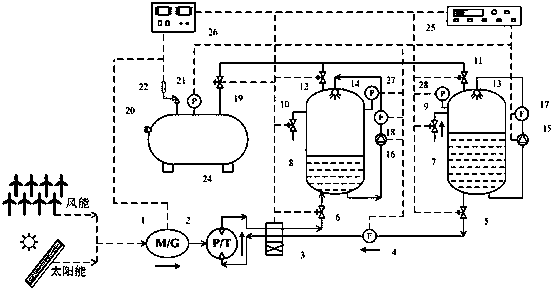

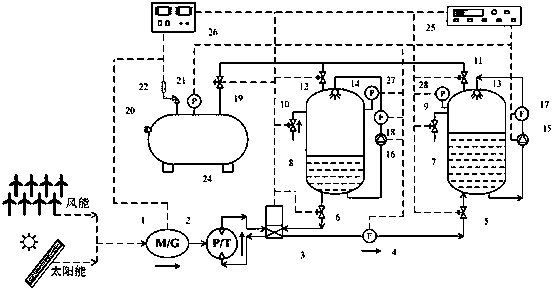

Hydraulic pump and sprayer based open type isothermal compressed air energy storage system and method

ActiveCN110985356ARealize continuous energy releaseReduce the heat of compressionPositive displacement pump componentsPressure pumpsSprayerHydraulic pump

The invention discloses a hydraulic pump and sprayer based open type isothermal compressed air energy storage system and method. The system comprises an electric machine / power generator which is connected with a hydraulic pump / turbine, wherein the hydraulic pump / turbine communicates with a reversing valve; the reversing valve separately communicates with a first working cavity and a second workingcavity through a first valve group; the first working cavity and the second working cavity separately communicate with a high-pressure gas storage tank through a second valve group; pressure monitoring devices are arranged on the first working cavity, the second working cavity and the high-pressure gas storage tank; and a spraying mechanism and a third valve group are arranged on the first working cavity and the second working cavity. The hydraulic pump and sprayer based open type isothermal compressed air energy storage system adopts the hydraulic pump and the sprayer to realize isothermal compression / expansion, so that compression work is reduced, expansion work is improved, and energy storage efficiency and energy utilization efficiency of the system are improved; and the reversing valve is adopted, so that two working cavities alternatively work, and therefore, a compression / expansion time ratio of the system is increased, continuous energy storage / release is realized, and systemcapacity and manufacturing cost are reduced.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

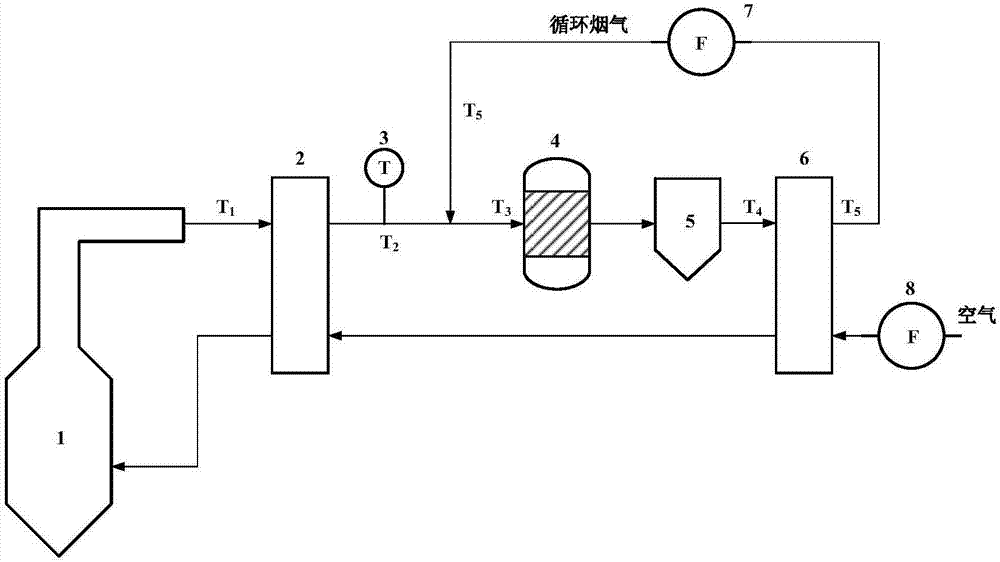

System and method for graded rotary type air preheaters for reducing ammonium bisulfate deposition

ActiveCN107965787AAvoid cloggingAvoid corrosionCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention discloses a system and method for graded rotary type air preheaters for reducing ammonium bisulfate deposition. The system is based on the graded rotary type air preheaters and mainly comprises the first stage rotary type air preheater, a flue gas on-line monitoring system, a reaction chamber, a dust remover, the second stage rotary type air preheater, a circulating air fan and an air feeder. According to the system and method for the graded rotary type air preheaters for reducing the ammonium bisulfate deposition, by means of the manner that the rotary type air preheaters are arranged in a graded manner, under the premise that the original heat transfer efficiency of the rotary type air preheaters is guaranteed, the ammonium bisulfate deposition and corrosion inside the airpreheaters and the cold end corrosion problem caused by sulfuric acid are significantly reduced; a one-stage air preheater frequently used in a boiler system is changed into two stages in the flowingdirection of flue gas, and the reaction chamber and the dust remover are arranged between the two stages; and by means of real-time feedback adjustment performed on the circulating air fan by the fluegas on-line monitoring system, the temperature of the flue gas at an inlet of the reaction chamber is made to be always maintained in a required range, and the safe and efficient operation of the system is guaranteed.

Owner:XI AN JIAOTONG UNIV

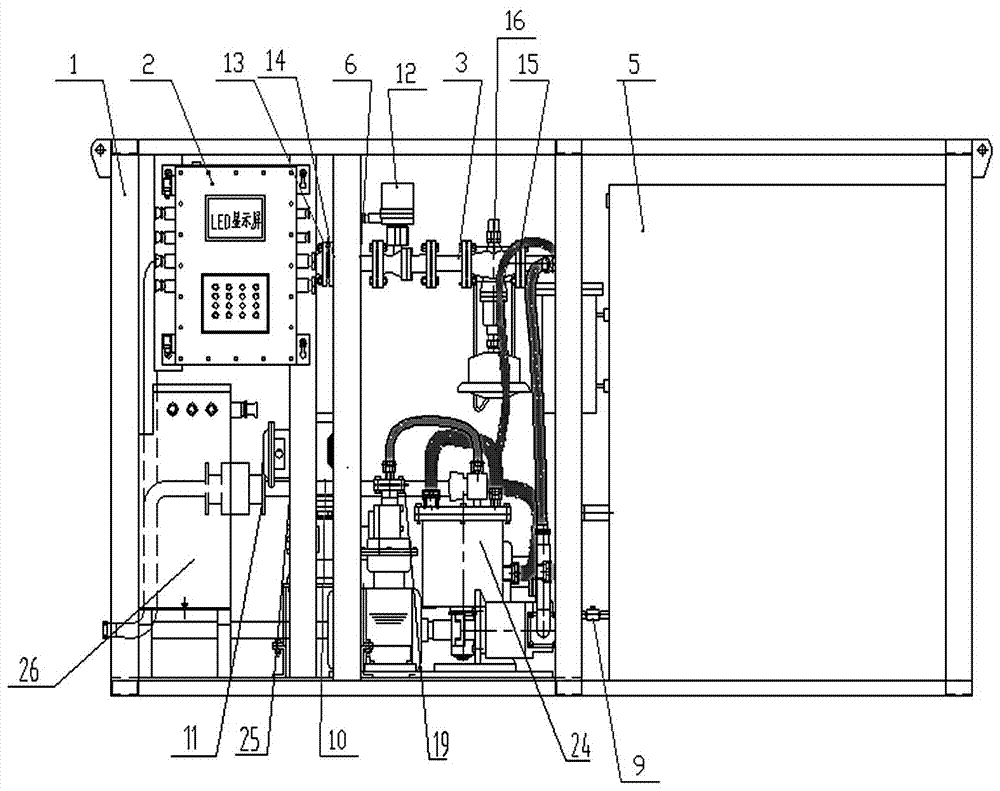

Intelligent emulsion matching device for coal mine

InactiveCN107463188AMonitor pressure in real timeMonitor traffic in real timeControlling ratio of multiple fluid flowsLiquid level sensorPetroleum engineering

The invention is an intelligent proportioning device for emulsion used in coal mines. The emulsified oil tank is provided with a liquid level sensor. The front end of the oil tank is provided with an oil filter cartridge and a water filter cartridge. The inlet of the water filter cartridge is connected to a water inlet pipeline. The water inlet pipeline includes Pipes, pressure reducing valves, pressure gauges, pressure sensors, manual ball valves, electric ball valves, flow regulating valves, the inlet of the oil filter cartridge is connected to the oil inlet pipeline, which includes gear pumps, explosion-proof motors, flow sensors, oil inlet The outlet of the pipeline and the oil filter cartridge are connected to the emulsified oil tank through the pipeline. The proportioning pump is driven by a frequency conversion motor. The oil inlet of the proportioning pump is connected to the emulsified oil tank through a rubber hose. The outlet of the water filter cartridge is connected to the mixed liquid filter through a pipeline, the outlet of the proportioning pump is connected to the mixed liquid filter, the liquid outlet is connected to the liquid outlet below the mixed liquid filter, and the concentration sensor and flow sensor are arranged on the liquid outlet pipe , Manual ball valve, intelligent control box is set on the frame.

Owner:TAIZHOU XINGDONG COAL MINING MACHINERY

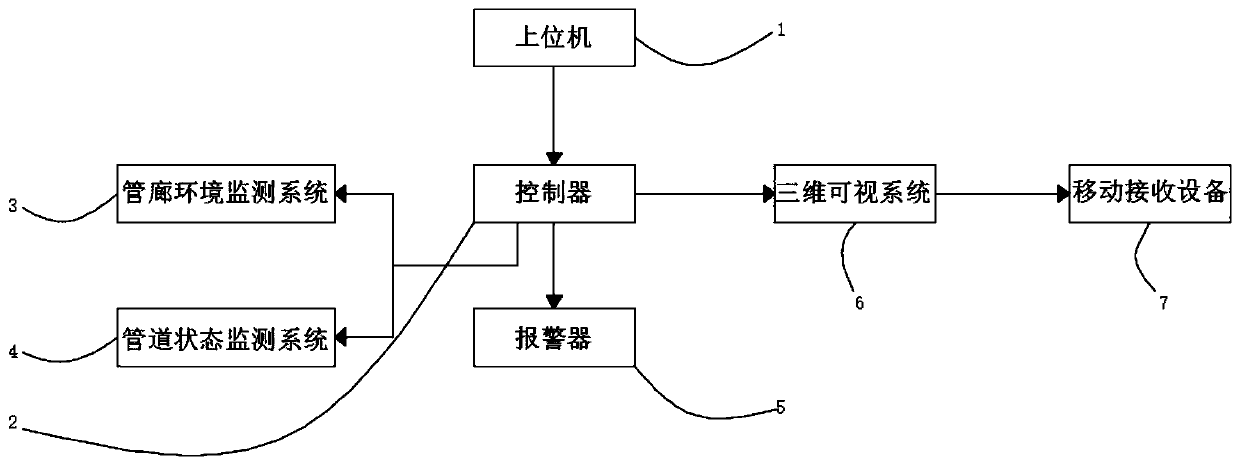

Intelligent auxiliary control system based on Internet of Things and three-dimensional visualization technology

InactiveCN110809133AMonitor temperatureMonitor temperature in real timeTelevision system detailsArtificial islandsAlarm messageControl system

The invention belongs to the technical field of underground pipe gallery control systems, in particular to an intelligent auxiliary control system based on the Internet of Things and the three-dimensional visualization technology. The system comprises an upper computer, a controller, a pipe gallery environment monitoring system, a pipeline state monitoring system, an alarm, a three-dimensional visualization system and mobile receiving equipment, and the output end of the upper computer is electrically connected with the input end of the controller. According to the invention, the pipe galleryenvironment monitoring system and the pipeline state monitoring system are arranged; the operation conditions of the pipe gallery and the pipeline can be monitored more comprehensively; therefore, various parameter information of the pipe gallery and the pipeline can be understood; when the operation condition is abnormal, management personnel can timely receive alarm information, take measures, check problems and hidden dangers, and can complete inspection work on line by arranging a three-dimensional visual system and mobile receiving equipment, so that monitoring dead angles are greatly reduced, regular manual inspection is not needed, and the labor intensity of workers is reduced.

Owner:JIANGSU I FRONT SCI & TECH CO LTD

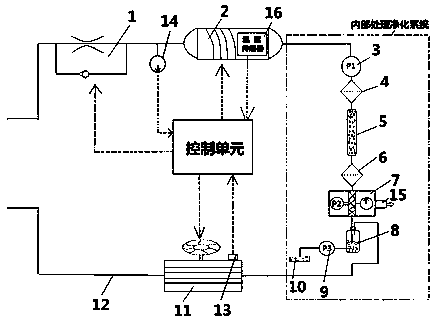

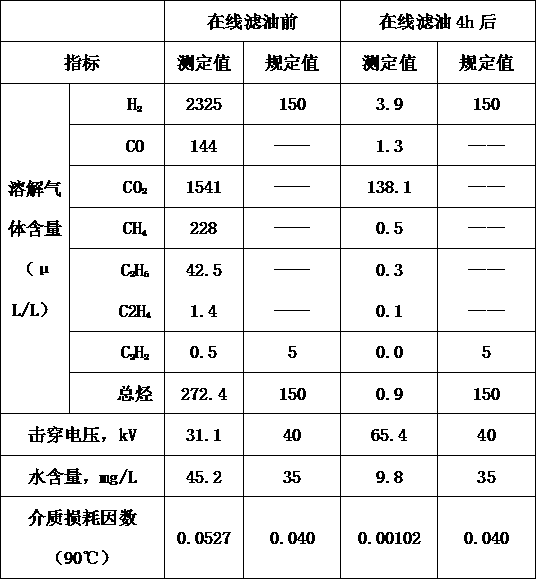

Efficient online oil filtering method for transformer insulating oil

InactiveCN111085034AReal-time monitoring of working conditionsReal-time monitoring of oil temperatureFiltration circuitsWater storageAutomatic control

The invention discloses an efficient online oil filtering method for transformer insulating oil. The method comprises the following steps: filtering a transformer in a loaded and / or unloaded environment. The method adopts an external circulation system and an internal treatment and purification system, wherein the external circulating system comprises a pipeline, a valve, a heater and a heat exchanger; the internal treatment purification system comprises an oil discharge pump, a primary filter, an adsorption column, a fine filter, a vacuum pump, a vacuum cylinder, a vacuum meter, a water pump,a water storage device and an exhaust nozzle; the internal treatment purification system further comprises an automatic control system which is composed of a control unit, an inlet temperature sensor, an outlet temperature sensor and a flow sensor, wherein the control unit receives signals of the inlet temperature sensor, the outlet temperature sensor and the flow sensor and controls the valve, the heater and the radiator according to the signals hereinbefore. By means of the online oil filtering method, the oil filtering efficiency can be fully improved, and the oil filtering effect is guaranteed.

Owner:江苏万标检测有限公司

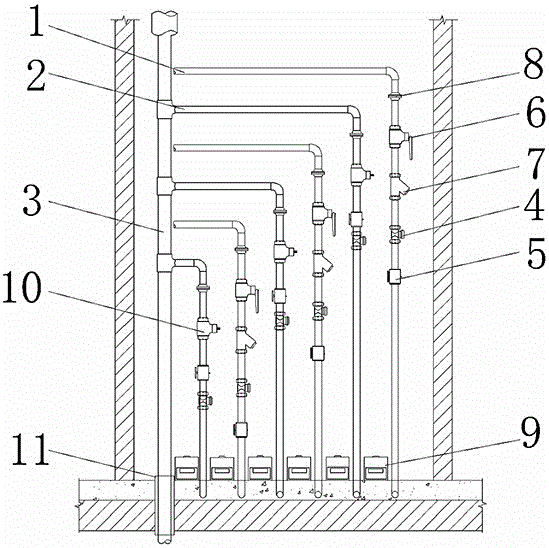

Water supply pipeline security operation monitoring system and method

InactiveCN109029578AMonitor pressure in real timeMonitor traffic in real timeMeasurement devicesData acquisitionMonitoring system

The invention relates to the field of comprehensive pipe gallery security operation and maintenance, and discloses a water supply pipeline security operation monitoring system. The water supply pipeline security operation monitoring system comprises a water pressure and flow monitoring device and a stress monitoring device, which are arranged on a water supply pipeline; and both the water pressureand flow monitoring device and the stress monitoring device are connected with a data acquisition device. The water pressure and flow monitoring device and the stress monitoring device are installedon the water supply pipeline; the pressure, the flow and the stress of the water supply pipeline are monitored in real time; the data acquisition device summarizes, analyzes and stores monitoring data; data support is provided for water supply pipeline security operation and engineering designers; the operation condition of the water supply pipeline is monitored in real time; potential safety hazards of the water supply pipeline are conveniently eliminated; economic loss is reduced; the municipal infrastructure service capability is improved; and thus, establishing of a smart city is easily realized.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

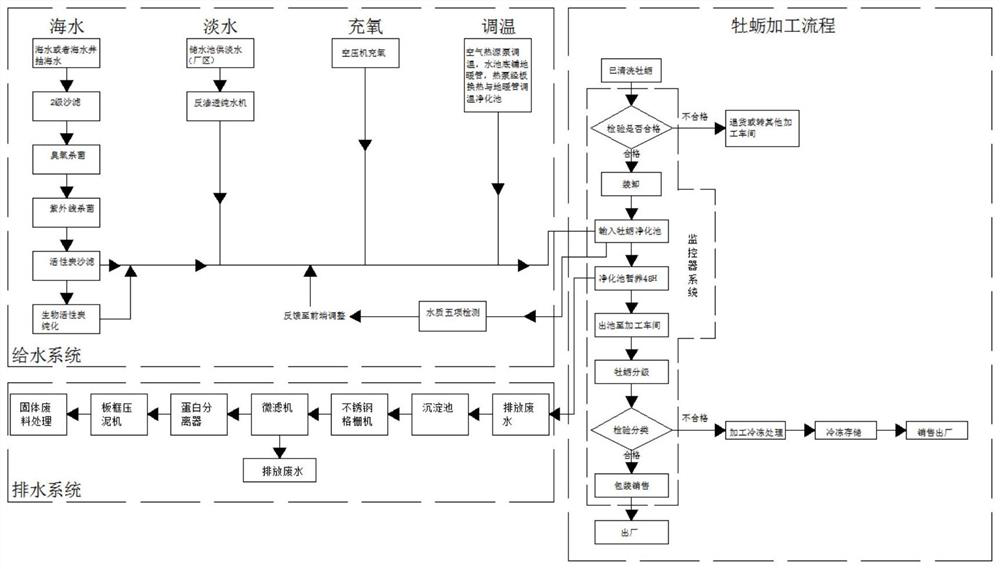

Raw oyster purification process capable of realizing real-time monitoring and multi-element purification

InactiveCN114304015AImprove utilizationImprove the bactericidal effectClimate change adaptationPisciculture and aquariaUncooked FoodsOyster

The invention discloses an uncooked oyster purification process capable of realizing real-time monitoring and multi-element purification, which comprises the following steps: S1, collecting and purchasing raw materials, detecting whether the surfaces of the collected and purchased oysters are neat and whether shells of the collected and purchased oysters are broken, opened and compounded with double bodies of the oysters, performing the next step on the qualified oysters, and returning the unqualified oysters or transferring the unqualified oysters to other processing workshops; s2, the qualified oysters are conveyed into an oyster purification pond, and a water supply system is connected into the oyster purification pond; and S3, purification is conducted, specifically, the oysters are subjected to purification management in the purification pond for 48 hours for multi-element purification of fungi, heavy metal, sludge, parasites and the like, and a drainage system is arranged in the purification pond. According to the invention, the problem that no professional purification equipment and technology capable of reaching the international standard exist in the uncooked oyster eating industry can be solved, the technology can be used for carrying out dead-corner-free sterilization on seawater, the PH value, salinity, temperature and flow of the purified seawater can be monitored in real time, and oysters can be well cleaned and classified, so that the oysters can reach the uncooked oyster eating quality required by European Union.

Owner:山东波士生蚝海洋生物科技有限公司

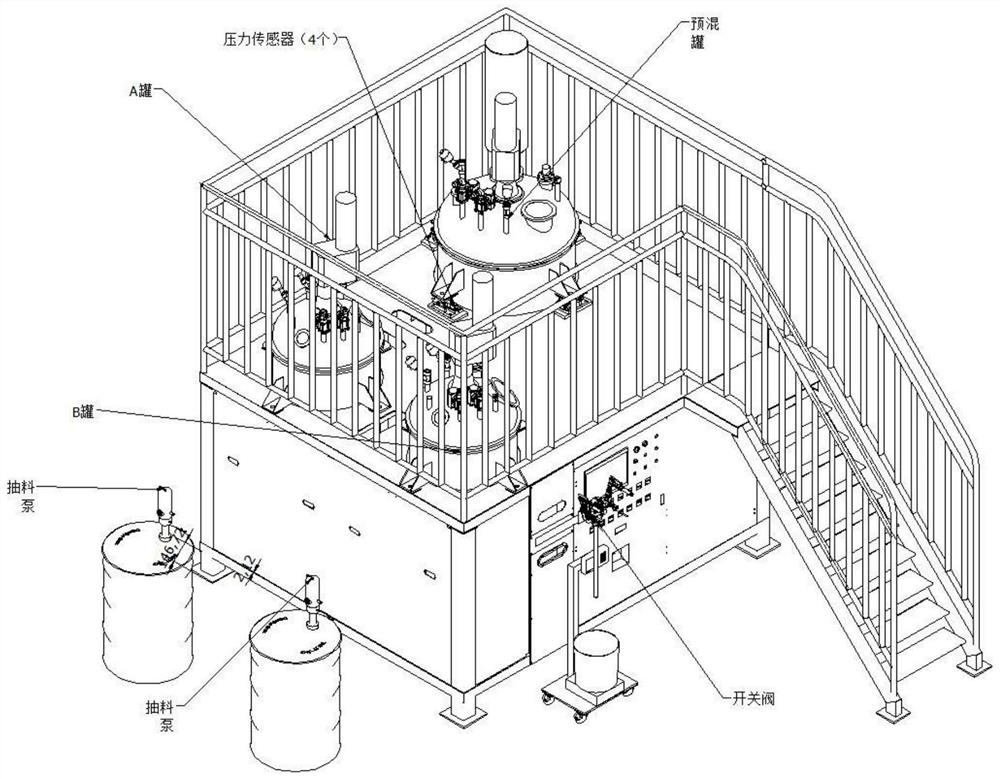

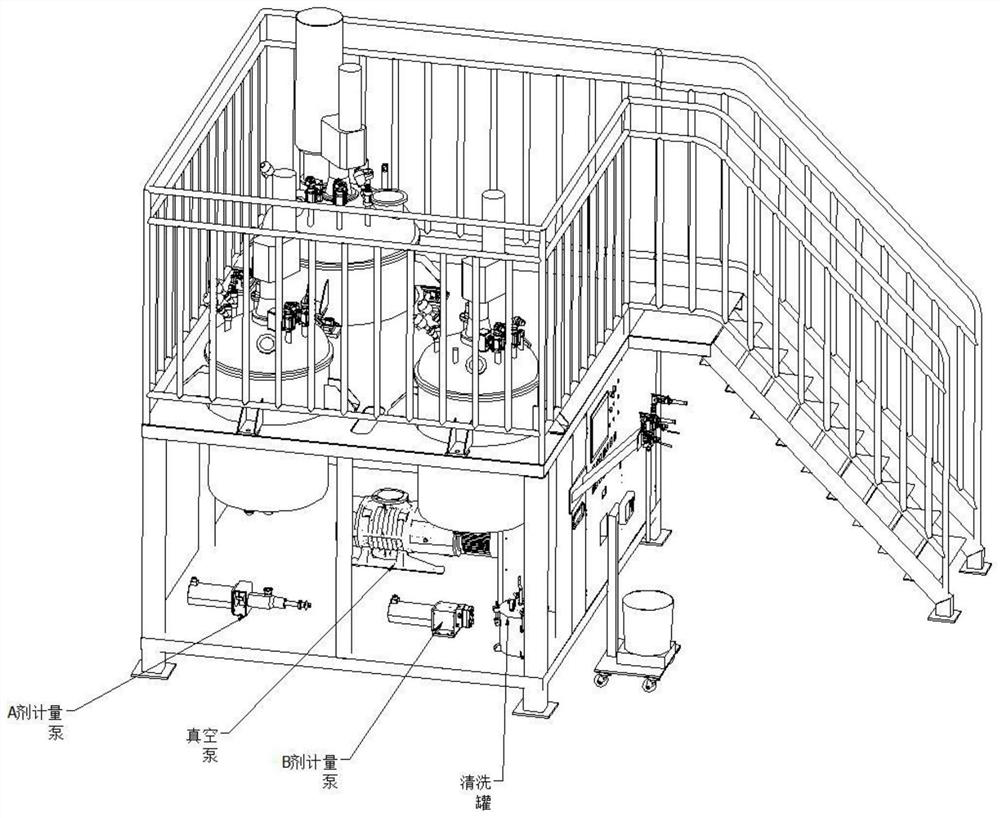

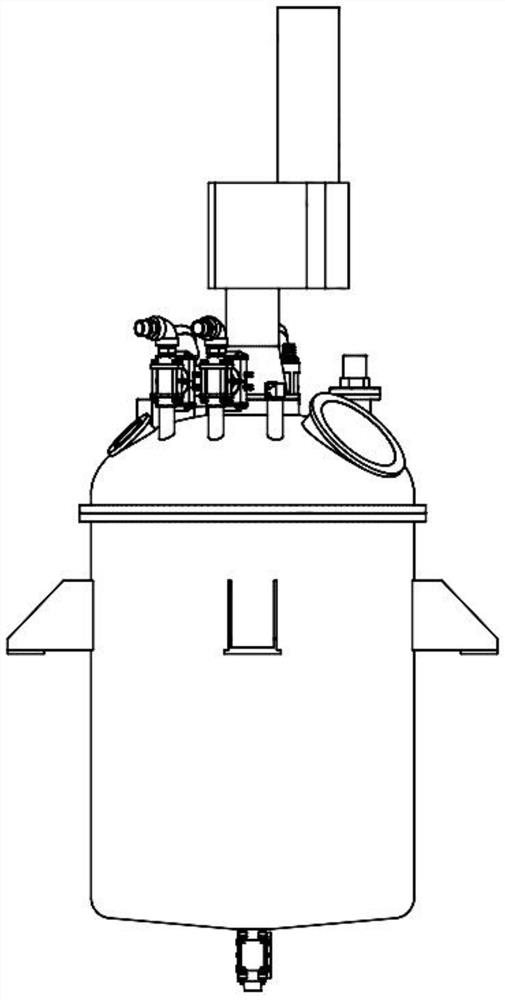

RTM automatic glue mixer

InactiveCN111672395APrevent Proportional MistakesAvoid misuseTransportation and packagingMixer accessoriesEngineeringProcess engineering

The invention provides an RTM automatic glue mixer, and particularly relates to the field of glue mixing devices. The RTM automatic glue mixer comprises a tank A, a tank B, a premixing tank, an agentA raw material tank and an agent B raw material tank. The agent A raw material tank is connected with the premixing tank through a pneumatic material pump on the agent A raw material tank, and the premixing tank is communicated with the tank A through a feeding valve; the agent B raw material tank is communicated with the tank B through a pneumatic material pump on the agent B raw material tank; discharge valves are arranged at the lower ends of the tank A and the tank B, the discharge valve of the tank A and the discharge valve of the tank B are connected to a mixing pipe in parallel throughpipelines, and a mixed glue discharge port is formed in the end part of the mixing pipe; and the tank A, the tank B and the premixing tank are each provided with a heating device, a filling port and astirring device. The RTM automatic glue mixer is high in filling efficiency, convenient to clean and easy to operate and control.

Owner:苏州红杉自动化科技有限公司

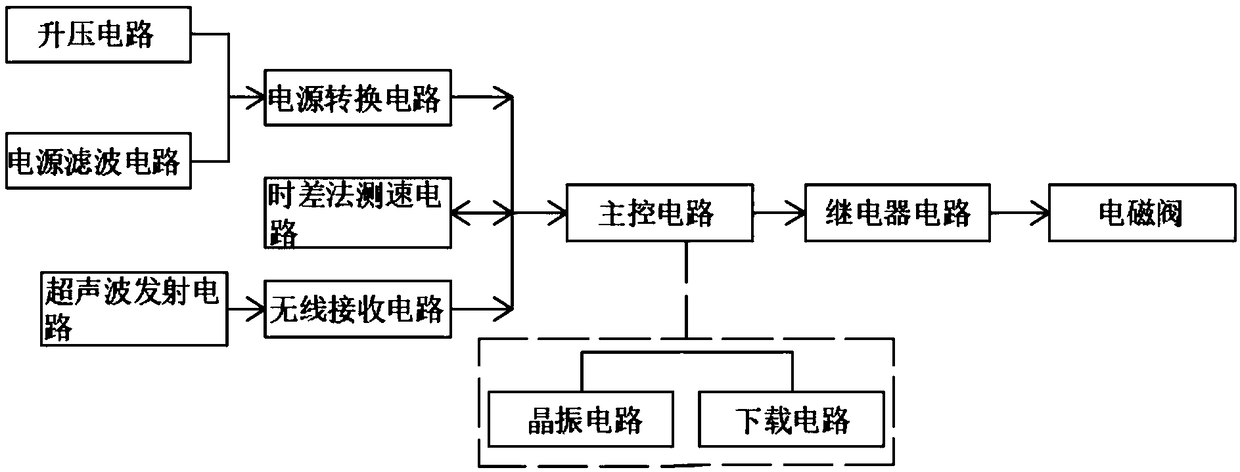

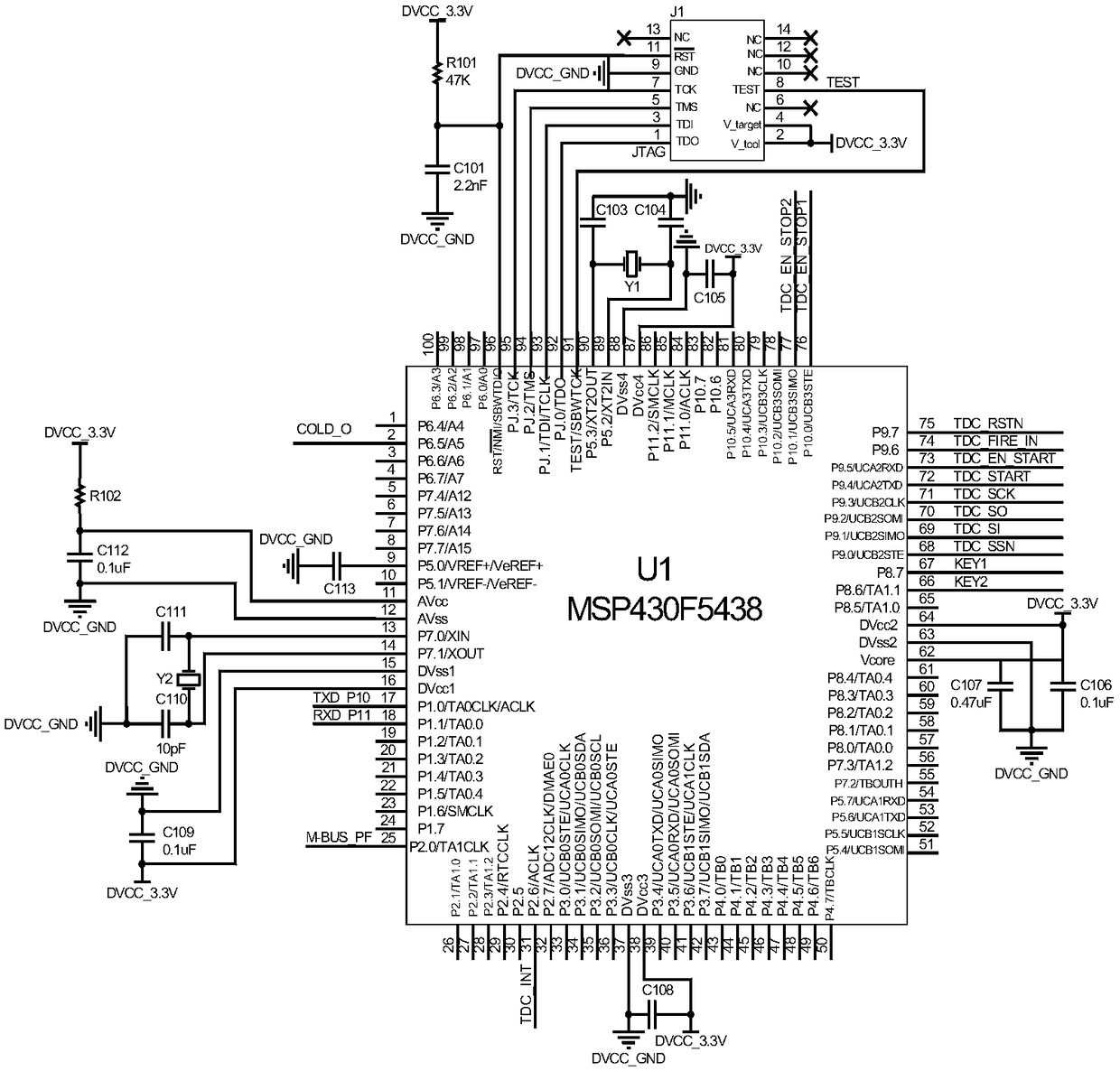

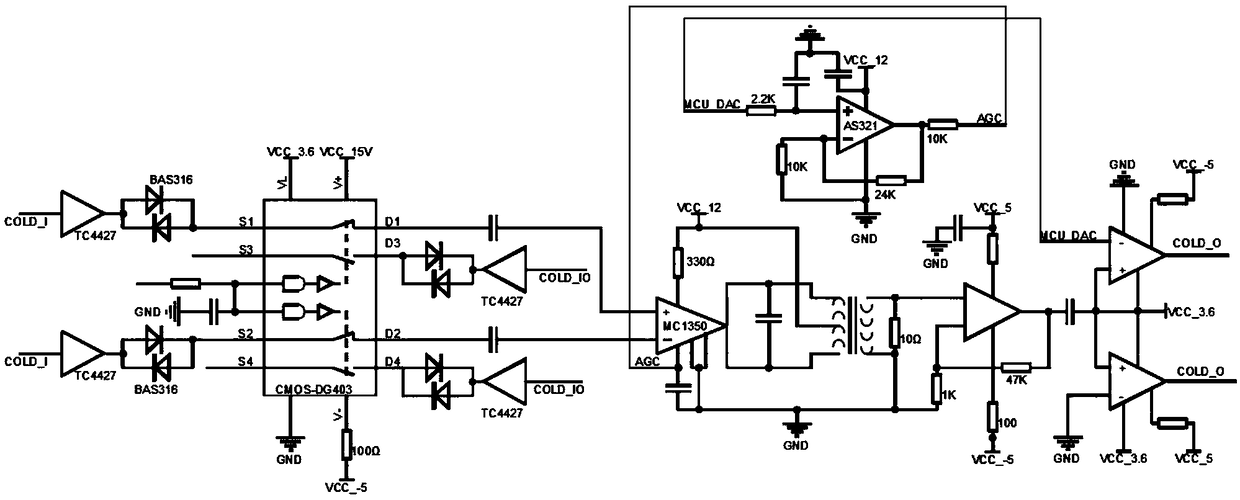

Multifunctional water leakage monitor and monitoring method thereof

InactiveCN109296948AFree from destructionEasy to installPipeline systemsWater leakageElectrical battery

The invention discloses a multifunctional water leakage monitor and a monitoring method thereof. The monitor comprises a master control circuit, the master control circuit is used for carrying out data processing on an input signal, the input end of the master control circuit is connected with a wireless receiving circuit, a time-difference method speed measuring circuit and a power source conversion circuit, the input end of the wireless receiving circuit is connected with an ultrasonic emission circuit, the input end of the ultrasonic emission circuit is connected to a pipeline to be measured, the power conversion circuit is connected with a power source filtering circuit, the output end of the master control circuit is connected with a relay circuit, and the relay circuit is connected with an electromagnetic valve. A battery is adopted for supplying power, and is in the lower-consumption work mode, the work time can be one year, the time for battery replacing can be saved, work efficiency is improved, the pipeline flow can be monitored in real time on a client side, active defense organizing and withdrawing are not manually operated, when it is monitored that leakage happens, avalve of a main pipeline is actively switched off, a leakage source is isolated, and the economic losses caused by human causes can be reduced.

Owner:天津优钛科技发展有限公司

Agricultural irrigation device based on network technology

InactiveCN112075326AEffective interceptionAvoid cloggingWatering devicesSpray nozzlesWater useAgricultural science

The invention belongs to the technical field of agricultural irrigation, and particularly relates to an agricultural irrigation device based on a network technology, which comprises a water pump, a main water supply pipe, a branch water supply pipe, a monitoring device and a spray nozzle which are connected in sequence. The monitoring device comprises a main body. The two ends of the main body areprovided with an upper joint and a lower joint. A controller and an Internet of Things unit are mounted in the main body. A first fixed rod is mounted in the monitoring device. A first rotating shaftis mounted on the first fixed rod. A first impeller is mounted on the first rotating shaft. A circular ring is mounted in the main body. A magnetic block is mounted on the circular ring. A first cavity is formed in the main body. A first sensor and a first extrusion block are mounted in the first cavity. A third cavity is formed in the main body, and a second sensor and a second extrusion block are mounted in the third cavity. A flexible plate is mounted at an opening of the third cavity. The agricultural irrigation device based on the network technology is simple in structure and can detectthe amount of water used for irrigation and the leakage condition of a pipeline.

Owner:ANHUI HUATENG AGRI TECH CO LTD

Precise controllable heat supply radiator

ActiveCN105864873AAvoid wastingReal-time control of water temperatureLighting and heating apparatusSpace heating and ventilation detailsIntegratorWater filter

The invention discloses a precise controllable heat supply radiator and mainly relates to the technical field of an industrial heat radiator. The precise controllable heat supply radiator comprises heat supply power supply pipes, heat supply water returning pipes and water charging and discharging pipes, wherein three sections of heat supply water feed pipes and three sections of heat supply water returning pipes are respectively arranged; the three sections of heat supply water feed pipes and the three sections of heat supply water returning pipes are both mutually connected by the water charging and discharging pipes; the body of each heat supply water feed pipe is sequentially provided with a locking and sealing regulator and a water filter; the body of each heat supply water returning pipe is provided with a locking and sealing valve; the body of each heat supply water feed pipe and the body of each heat supply water returning pipe are both provided with a flange, a flow sensor and a temperature sensor; the flow sensors and the temperature sensors are both connected with an integrator and an external controller; the bottom of each water charging and discharging pipe is provided with a sleeve. The radiator disclosed by the invention is capable of precisely controlling flow and water temperature; a worker can monitor transmission and loss conditions of heat in real time, so that unnecessary waste of energy is commendably prevented, and the overall running cost is lowered; besides, the radiator is durable in use and quite remarkable in heat radiation effect.

Owner:TAICANG SANYI HEATING & CHILLING PROJECT CO LTD

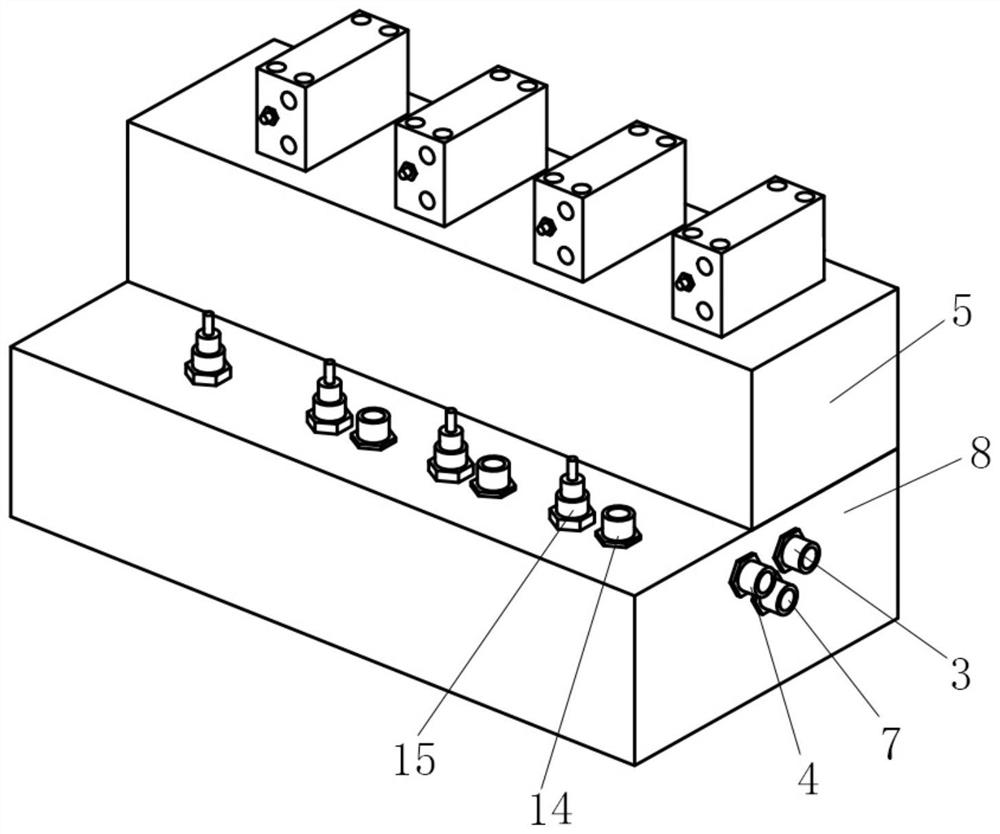

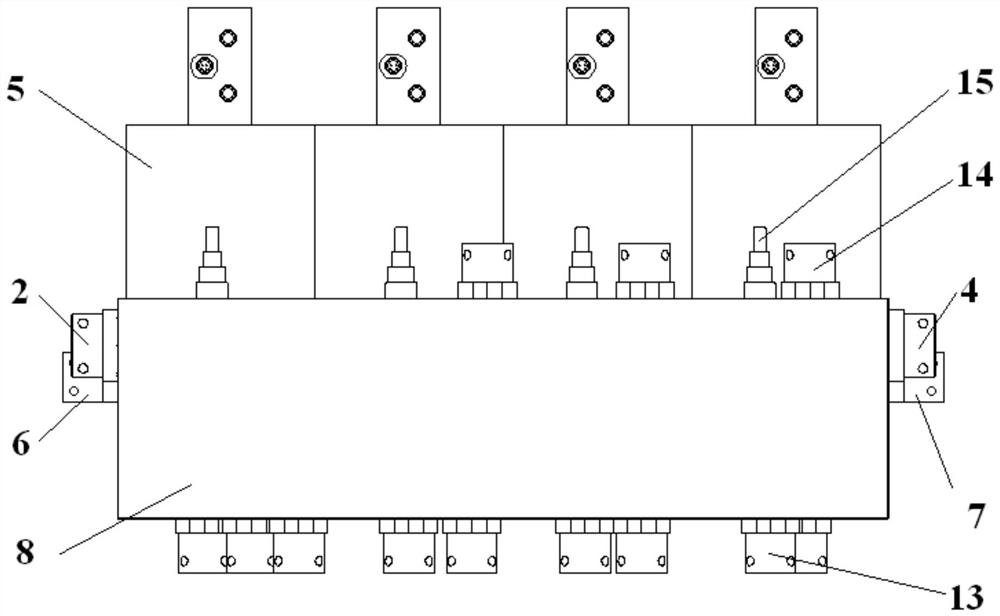

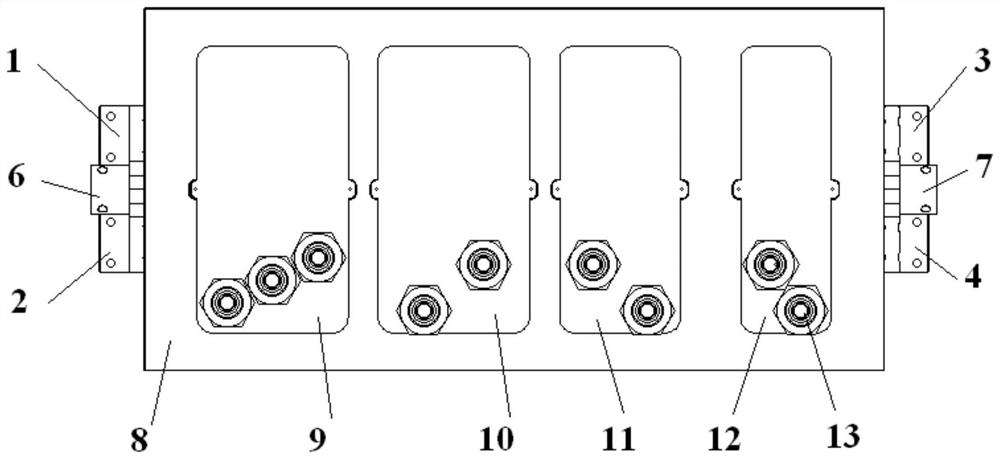

Multipurpose integrated hydraulic function valve group

ActiveCN113007166AAvoid the phenomenon of multiple and miscellaneous and chaotic on-site layoutReduce difficultyFluid-pressure actuator testingServomotor componentsWorking environmentPilot valve

The invention relates to the technical field of hydraulic systems of coal mine fully mechanized coal mining face transportation equipment, in particular to a multipurpose integrated hydraulic function valve group. The multipurpose integrated hydraulic function valve group comprises a main valve liquid distribution block, an embedded chain tightening motor function valve block, an embedded telescopic tail function valve block, an embedded lubricating device function valve block and an embedded cooling water system function valve block, the embedded chain tightening motor function valve block, the embedded telescopic tail function valve block, the embedded lubricating device function valve block and the embedded cooling water system function valve block are sequentially embedded into the main valve liquid distribution block from left to right in an embedded mode, a high-pressure liquid inlet, a high-pressure liquid return opening and a high-pressure liquid drainage opening are formed in the left side of the main valve liquid distribution block, a cooling water liquid inlet, a cooling water liquid return opening and a cooling water drainage opening are formed in the right side of the main valve liquid distribution block, four sets of electromagnetic pilot valves with the end faces connected are arranged on the upper surface of the main valve liquid distribution block so as to drive the corresponding function valve blocks to execute actions, and a corresponding connecting pipeline is arranged in the main valve liquid distribution block. The valve group is ingenious in design and reasonable in structure, and can effectively solve the problem that the number of hydraulic pipelines is large and the hydraulic pipelines are miscellaneous in the working environment of an underground coal mine.

Owner:山西煤矿机械制造股份有限公司

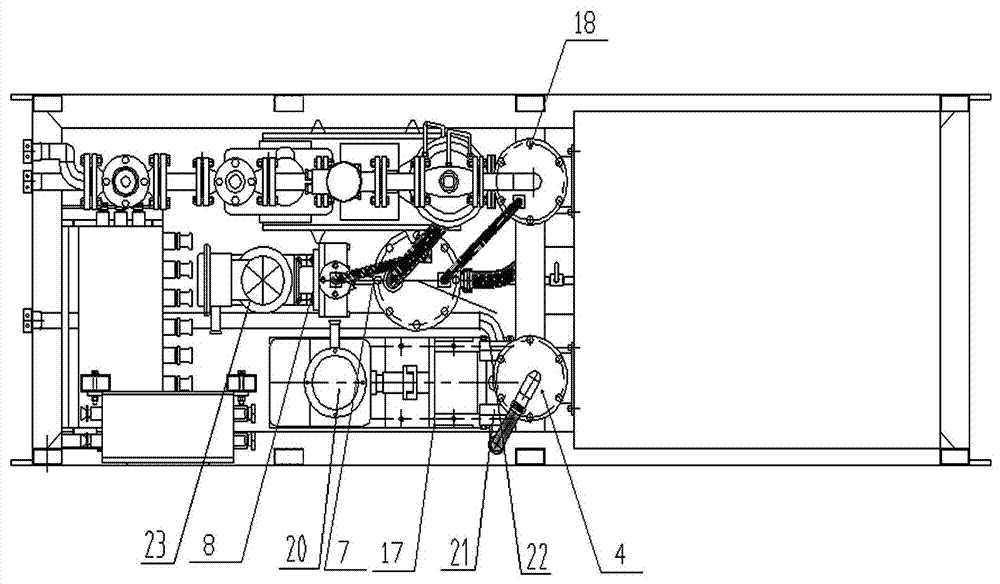

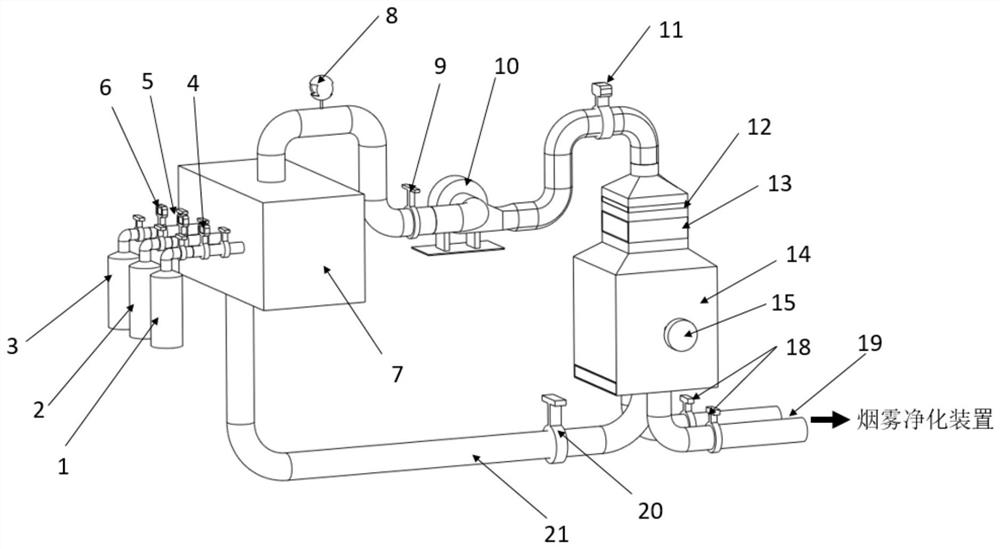

Animal chronic obstructive disease test device and method capable of recycling smoke

PendingCN113069240AProvide accuratelyAvoid the problem of inaccurate regulationBiological testingVeterinary instrumentsDiseaseAnimal science

Owner:XIAN PEIHUA UNIV

Erosion-resistant pressure experimental device for inner blowout prevention tool

InactiveCN113624630AReal-time monitoring of switching timesReal-time monitoring recordInvestigating abrasion/wear resistancePressure experimentPetroleum oil

The invention discloses an erosion-resistant pressure experimental device for an inner blowout prevention tool, and belongs to the field of petroleum and natural gas drilling devices. And erosion tests under various set working conditions can be carried out. The simulation pipe flow erosion test system loop is used for carrying out static simulation erosion test on a test valve core, the simulation pressure jet erosion test system loop is connected to the simulation pipe flow erosion test system loop and is used for carrying out pressure jet test on the test valve core, and the electric appliance assembly control cabinet is used for supplying power to the whole set of test equipment and providing kinetic energy. And the automatic experimental data monitoring, sampling and recording system is used for monitoring the flow, the flow velocity, the temperature, the pressure and the opening and closing times of the valve cover I in a test pipeline in real time, storing experimental data and printing an experimental table. According to the invention, the erosion test of the internal blowout prevention tool in the dynamic switching process can be realized. Two sets of erosion test systems are arranged, test parameters are easy to control, and the simulation test working condition environment can be adjusted.

Owner:MUDANJIANG XINBEIFANG PETROLEUM DRILLING TOOL +1

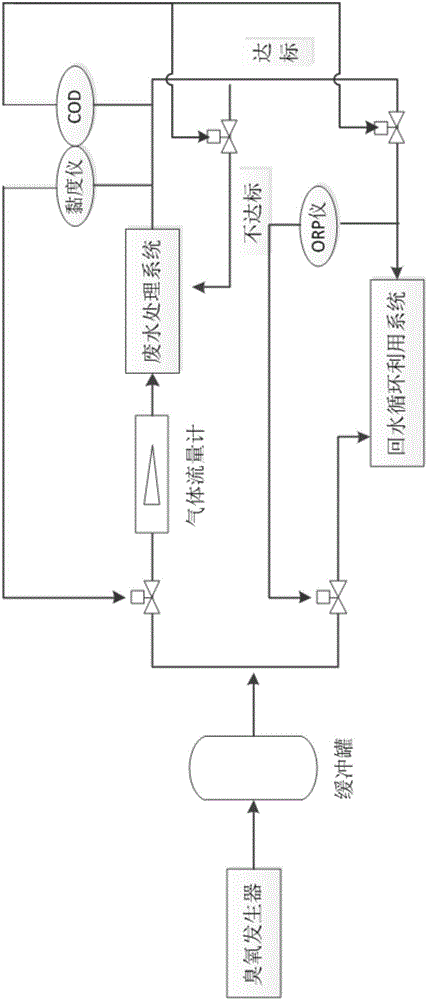

Ozone shunting system in PAM-containing wastewater treatment system

PendingCN106517600ATake advantage ofReduce wasteWater contaminantsMultistage water/sewage treatmentStreamflowOxidation reduction

The invention relates to an ozone shunting system in a PAM-containing wastewater treatment system. The ozone shunting system comprises a control unit, an ozone source, an ozone oxidation device and a surplus ozone flow adjusting device. A main ozone source channel is communicated with the ozone oxidation device, and a surplus ozone channel is communicated with a reusing water pipe after wastewater is completely purified; an ORP instrument electrically connected with the control unit and used for monitoring oxidation-reduction potential in real time in reusing water is arranged at the position, located behind the connecting part of the surplus ozone channel, on the reusing water pipe, and the control unit adjusts the opening degree of the surplus ozone flow adjusting device in real time according to the real-time monitoring data of the ORP instrument, According to the ozone shunting system, a water body after treatment is sterilized through surplus ozone; meanwhile, the oxidation-reduction potential in water after ozone is sterilized is subjected to real-time online monitoring so that whether the ozone is excessive or not can be judged, the flow of the ozone for sterilization is further automatically adjusted, oxidation and corrosion of a pipe are avoided, the surplus ozone is also fully used, and waste is avoided.

Owner:上海铱钶环保科技有限公司

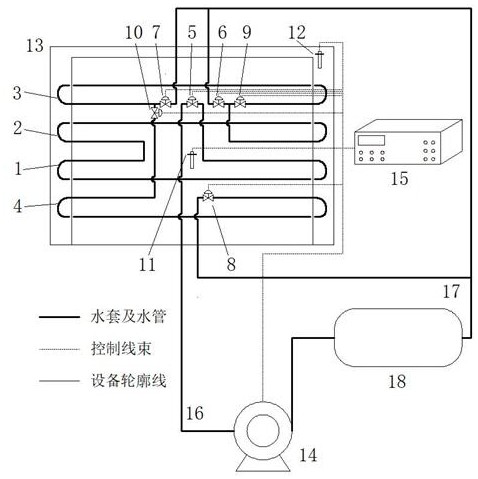

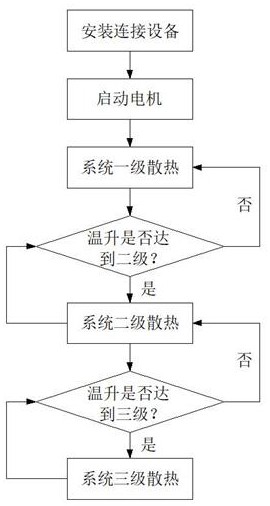

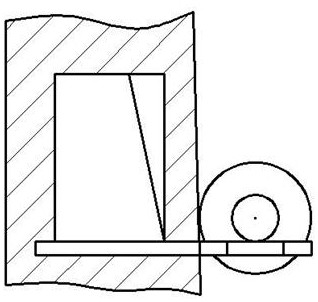

An adaptive motor heat dissipation system and an adaptive motor heat dissipation method

ActiveCN112421887BImprove efficiencySolve the problem of excessive pressure lossStructural associationCooling/ventillation arrangementThermodynamicsCoolant flow

The invention discloses an adaptive motor cooling system and an adaptive motor cooling method, comprising a motor temperature monitoring subsystem, a water jacket structure adjusting subsystem, a coolant flow adjusting subsystem and a controller. The present invention is applicable to various types of water-cooled motors at present, so as to control the temperature rise of each part of the motor, and independently adjust the number of layers of water channels and the flow of cooling liquid according to the working conditions and internal temperature of the motor, so as to avoid damage caused by excessive temperature of the motor. While causing component damage, the pressure loss of the heat dissipation water jacket is minimized, and the efficiency of the motor is improved.

Owner:浙江知管通网络科技有限公司

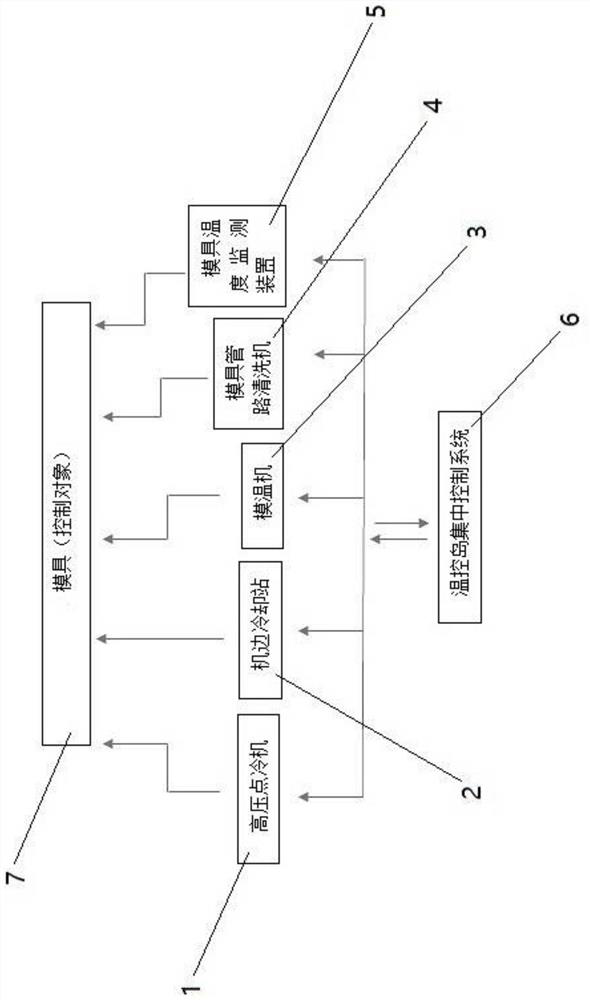

Temperature control island for realizing intelligent control based on die-casting production die

The invention discloses a temperature control island for realizing intelligent control based on a die-casting production die. The temperature control island comprises a high-pressure point cooling machine, a machine side cooling station, a die temperature controller, a die pipeline cleaning machine, a die temperature monitoring device, a temperature control island centralized control system and adie, and the high-pressure point cooling machine, the machine side cooling station, the die temperature controller, the die temperature monitoring device and the temperature control island centralizedcontrol system are all connected with the die through a plurality of pipelines and lines. The temperature control island has the beneficial effects balance of the die temperature can be controlled, product defects caused by high or low die temperature of local parts of castings are avoided, meanwhile, automatic control over the die temperature is achieved, manual operation is greatly reduced, andkey parameters such as flow, pressure and temperature in the die temperature control process can be monitored in real time; and data is collected and transmitted to an upper computer for product quality analysis, so that certain loss of an enterprise is avoided, and the labor intensity of workers is greatly reduced.

Owner:SUZHOU AODE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com