Safe delivery system for coal bed gas

A transportation system and coalbed methane technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of no coal mine coalbed methane safe transportation system, few equipment, single and outdated methods, etc., and achieve light weight , low cost and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

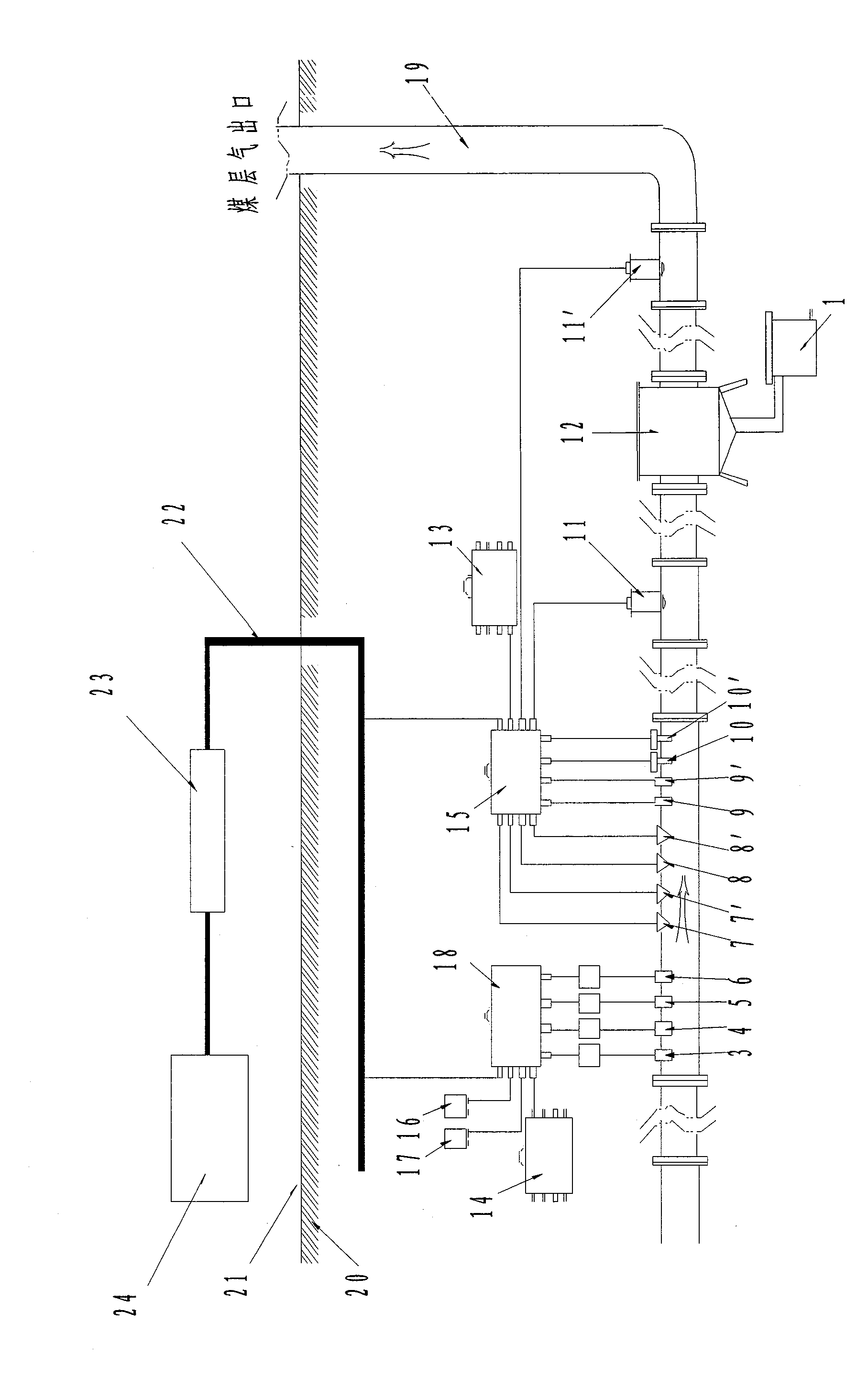

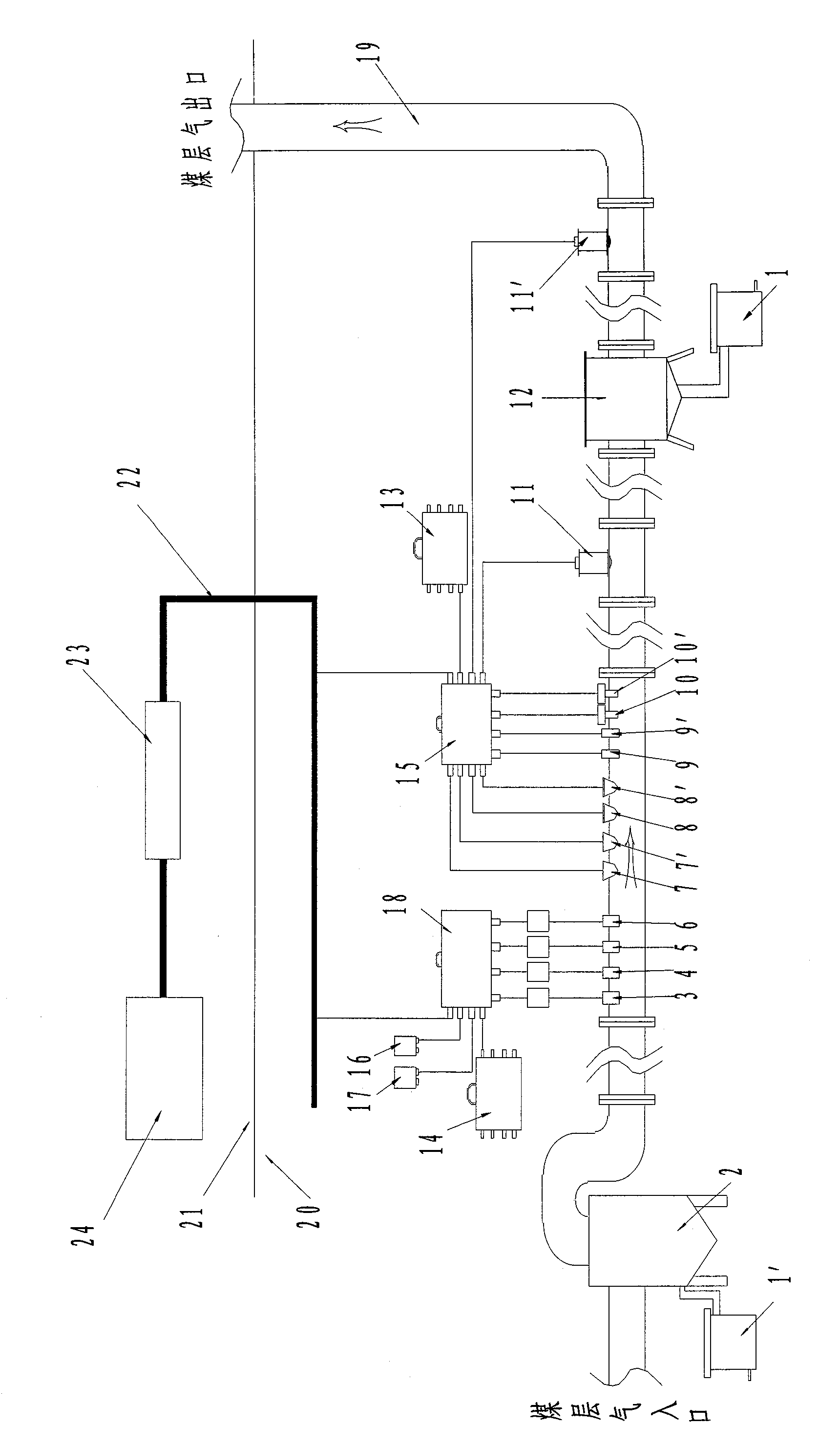

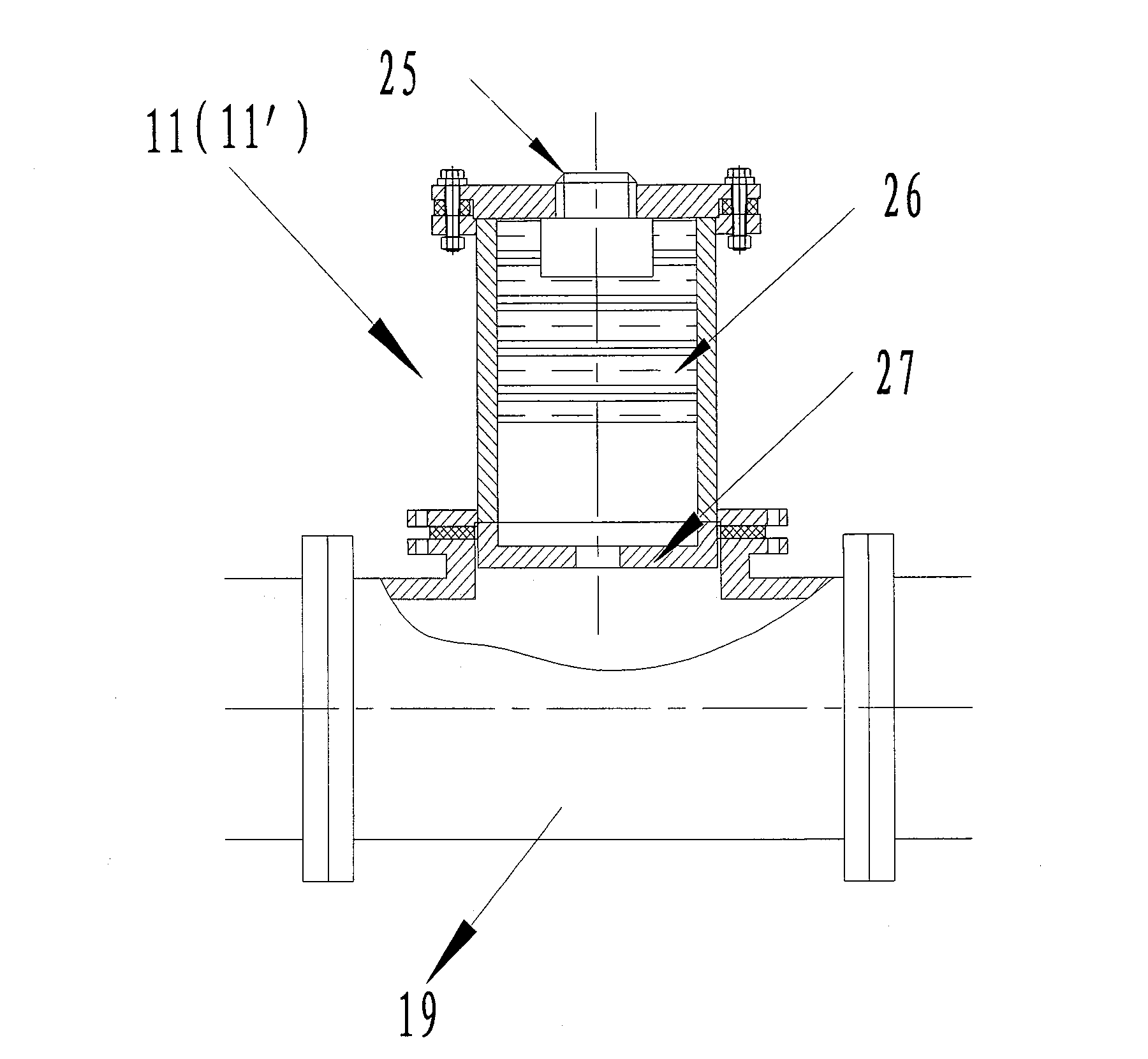

[0081] see figure 1 , figure 2 , a system for safe transportation of coalbed methane gas in coal mines provided by the present invention, a monitoring device 18, an automatic powder spraying explosion suppression device 11 and a fire arresting device 12 are sequentially arranged on the conveying pipeline 19 along the direction of coalbed methane transportation, and the automatic powder spraying suppression device 12 The explosion device 11 is connected with a controller 15, and the output terminals of the monitoring device 18 and the controller 15 are respectively connected to the monitoring system 24 of the ground 21 through the information data bus 22 and the communication interface 23.

[0082] The input end of described monitoring device 18 is respectively connected with the pipeline methane sensor 3 that is installed in delivery pipeline 19, pipeline carbon monoxide sensor 4, pipeline temperature sensor 5, flow sensor 6, and respectively with monitoring device power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com