Patents

Literature

35results about How to "Real-time monitoring content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-channel real-time bioaerosol monitoring method and device thereof

InactiveCN101858847AReduce false alarm rateShort detection cycleWithdrawing sample devicesFluorescence/phosphorescencePhysicsFluorescence

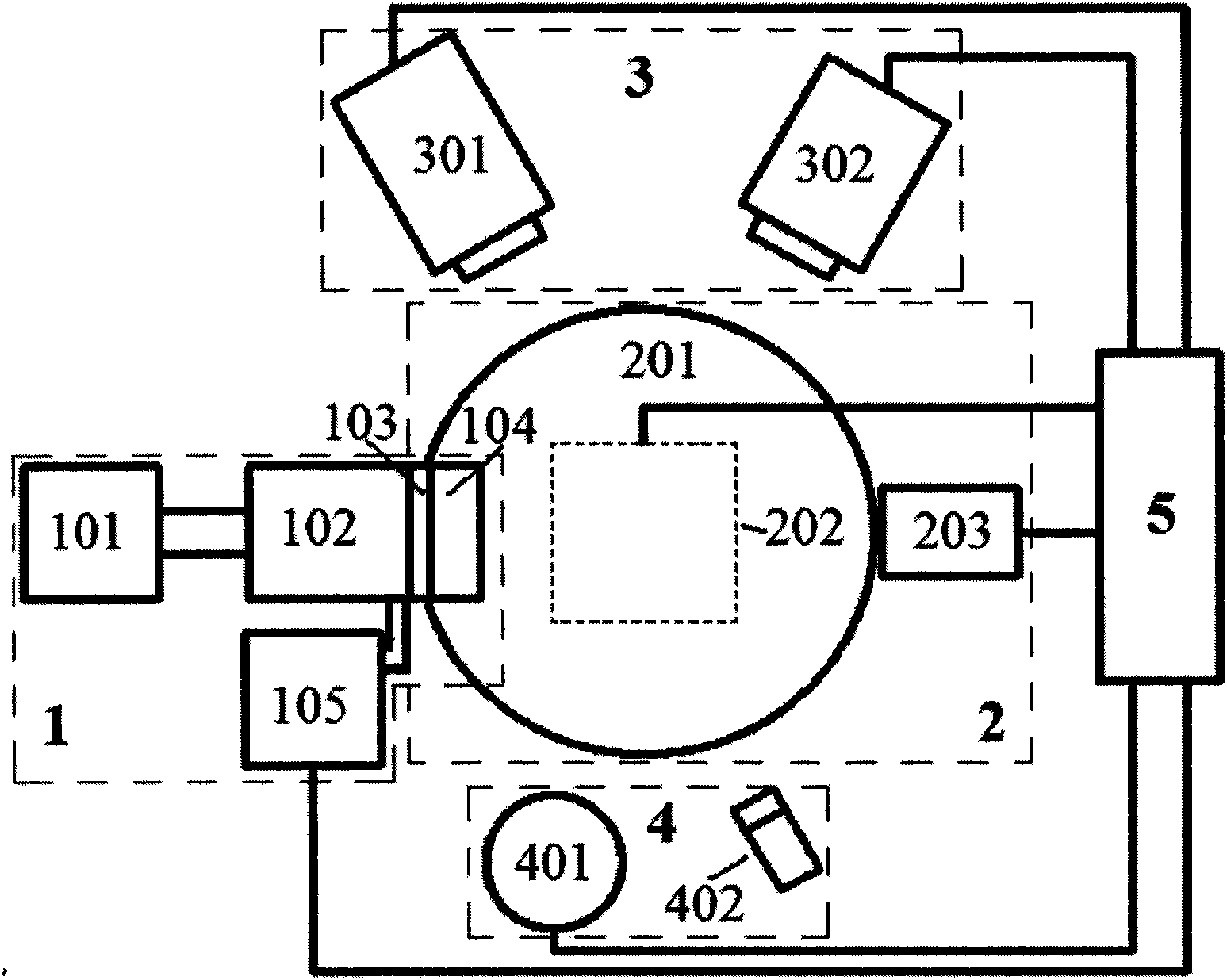

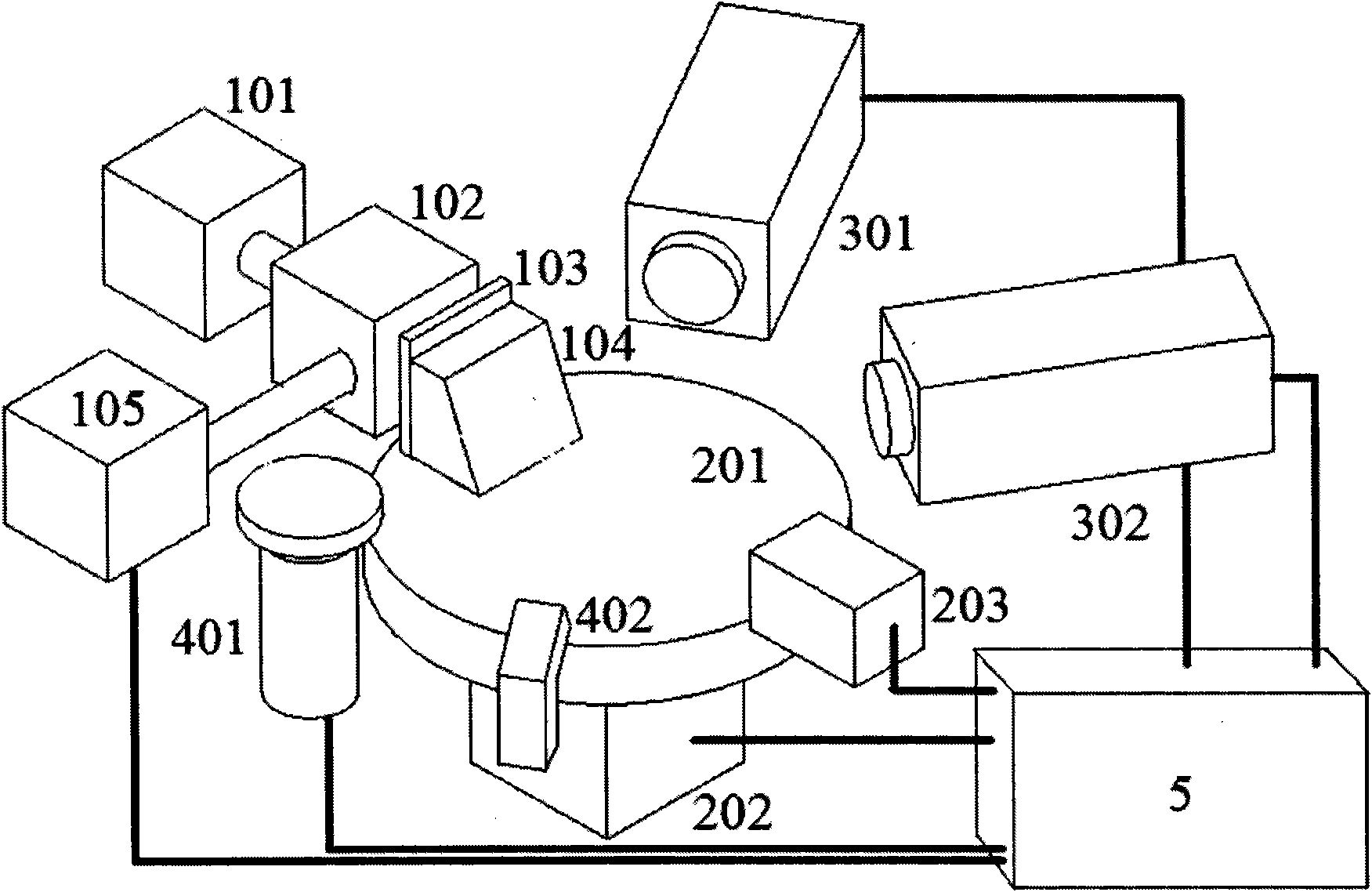

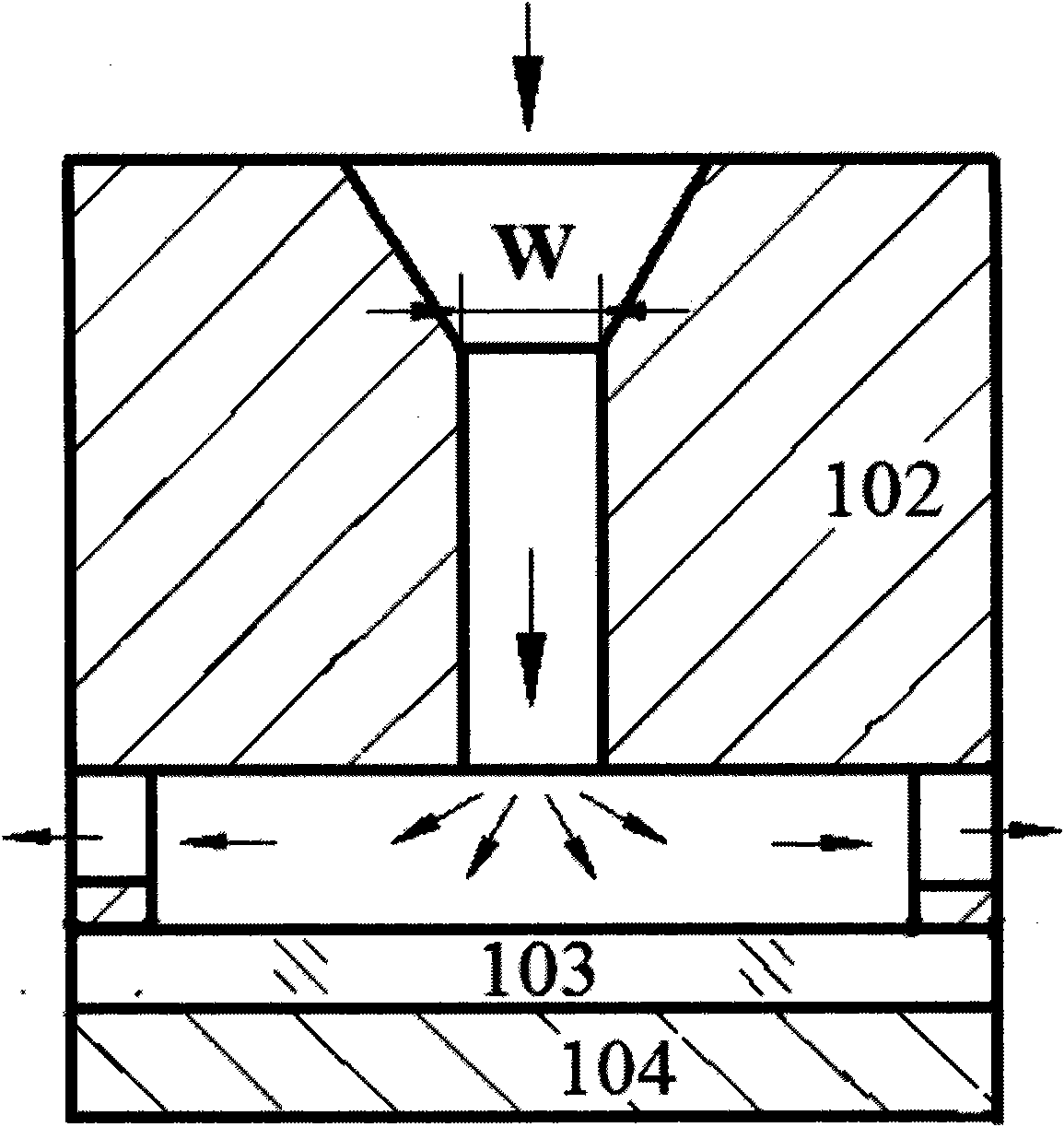

The invention provides a double-channel real-time bioaerosol monitoring method and a device thereof. The method is characterized by comprising the following steps: (1) concentrating atmospheric aerosol particles; (2) carrying out double-channel ultraviolet induced fluorescence detection; (3) data-processing; (4) cleaning the surface of an enrichment board of the particles and regenerating; and (5) repeatedly carrying out a new round of loop detection. The device comprises an aerosol-particles concentration unit, a double-channel ultraviolet induced fluorescence detection unit, a particle enrichment board regeneration mechanism, a rotary table and a control system. The invention can measure the density and the change of bio-particles such as bacteria, spores, viruses and the like in an ambient atmosphere in real time so as to achieve an early warning function on bioaerosol content in the atmosphere.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

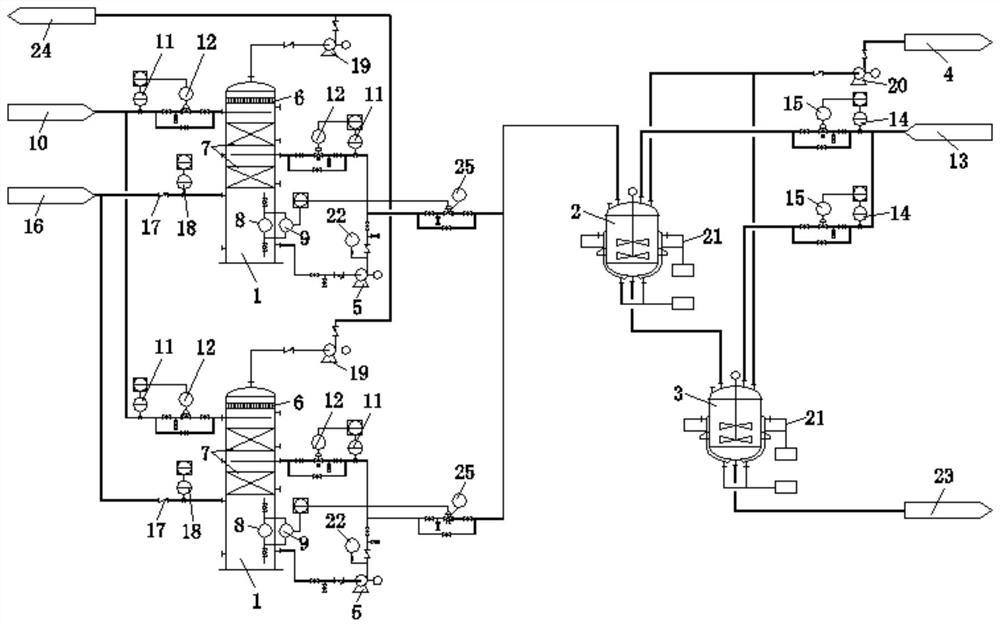

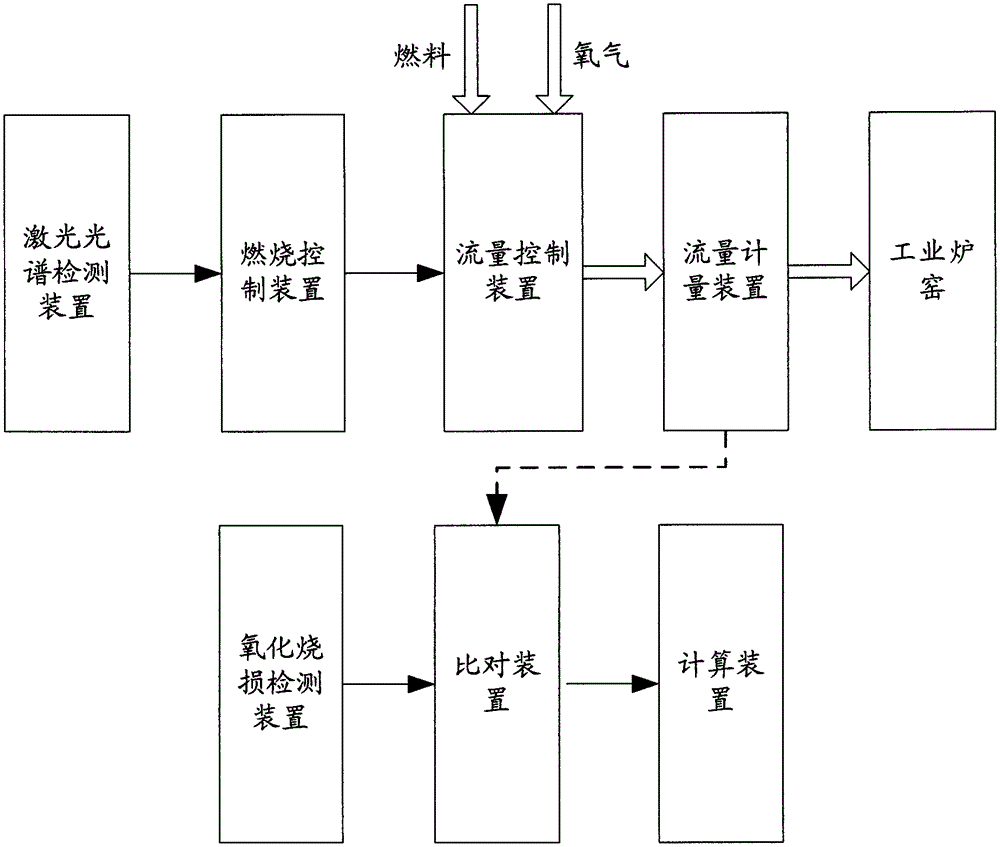

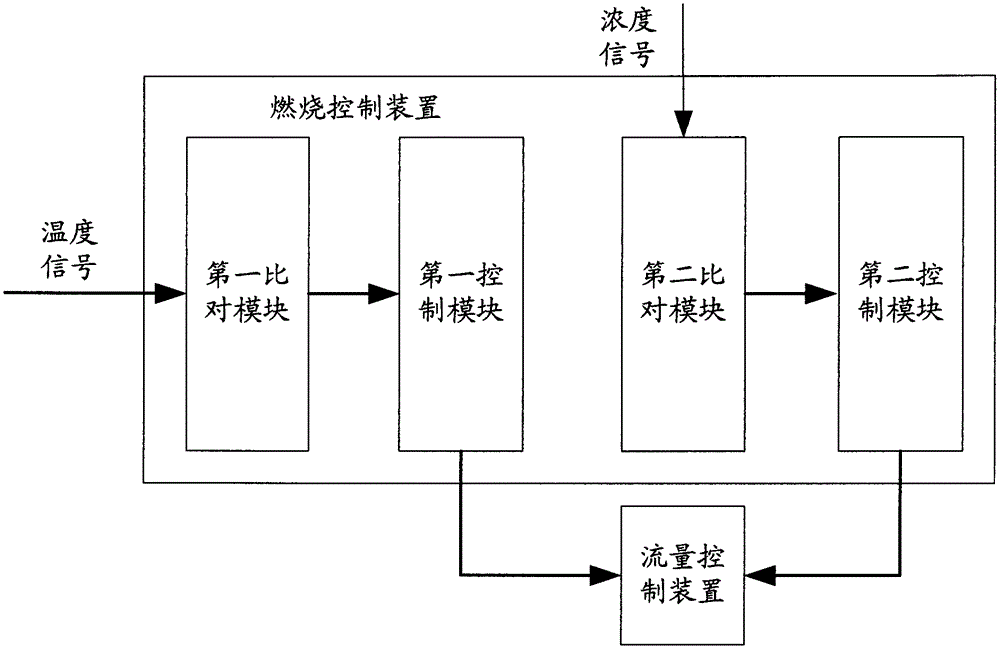

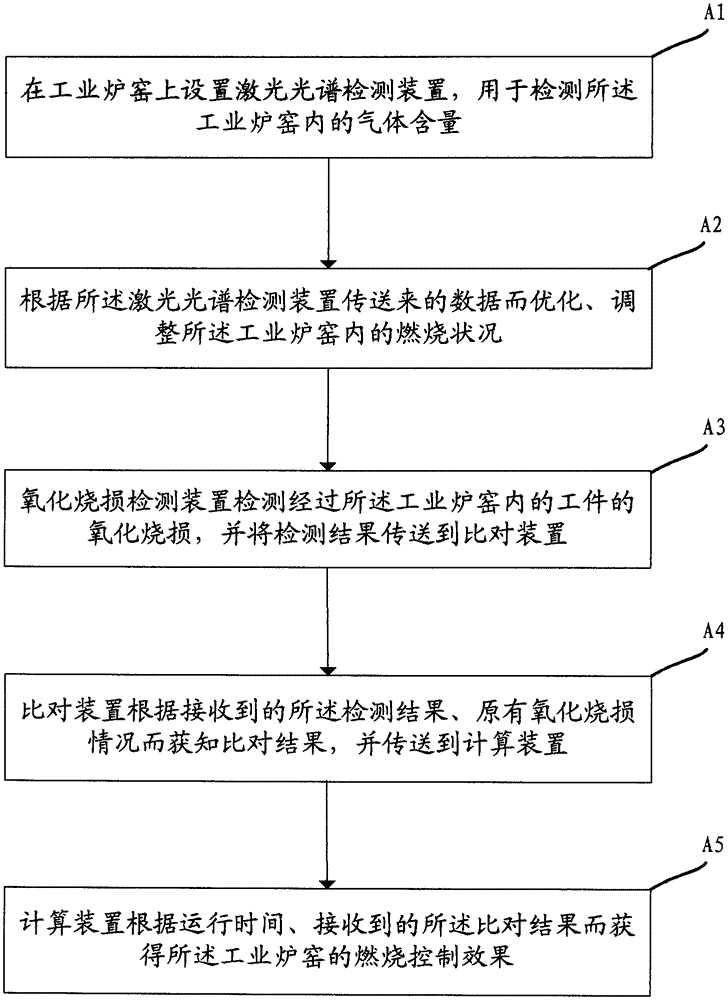

Combustion control system and method of industrial furnace

ActiveCN103672948AGood energy saving effectSave fuelFuel supply regulationProduct gasIndustrial furnace

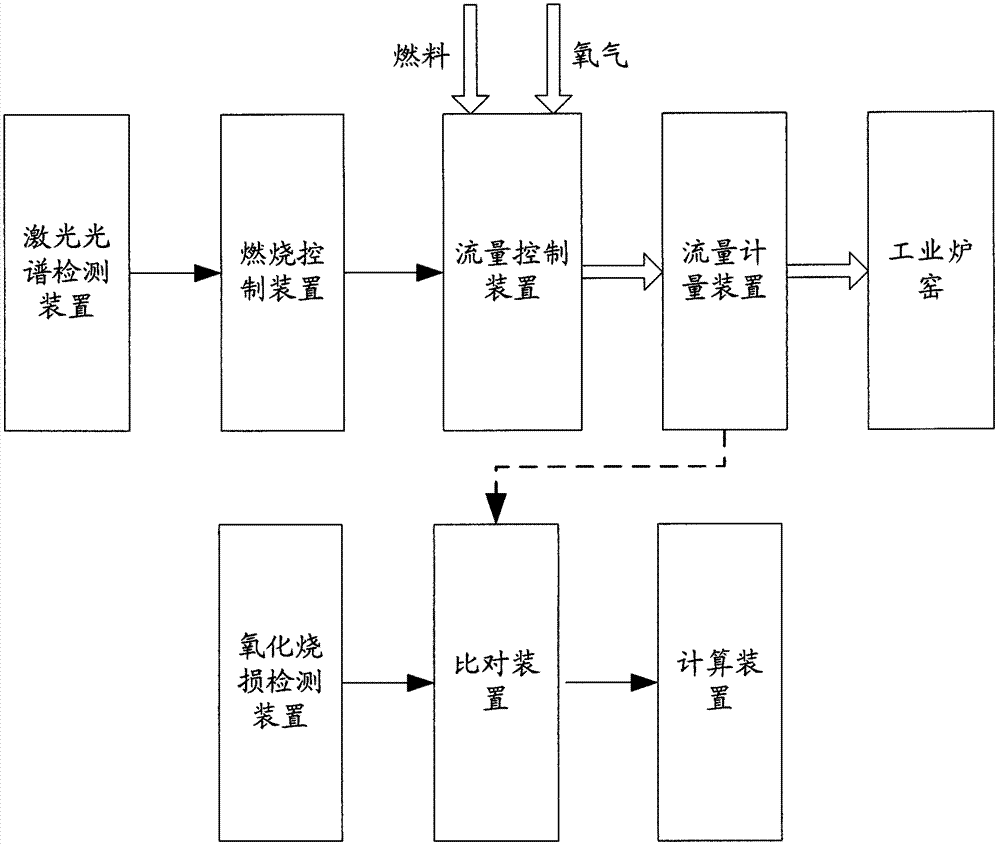

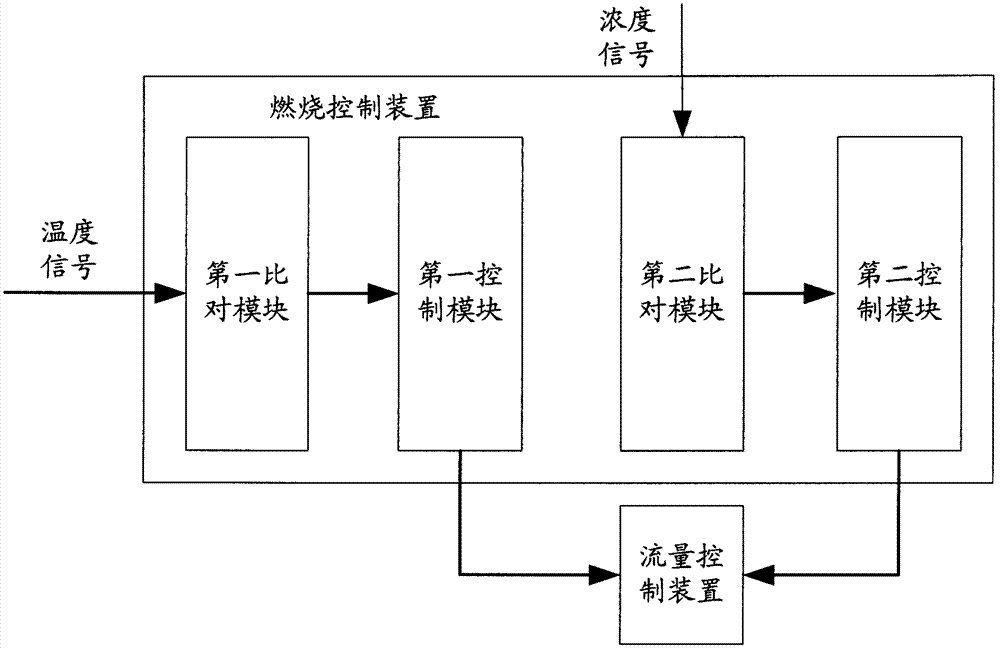

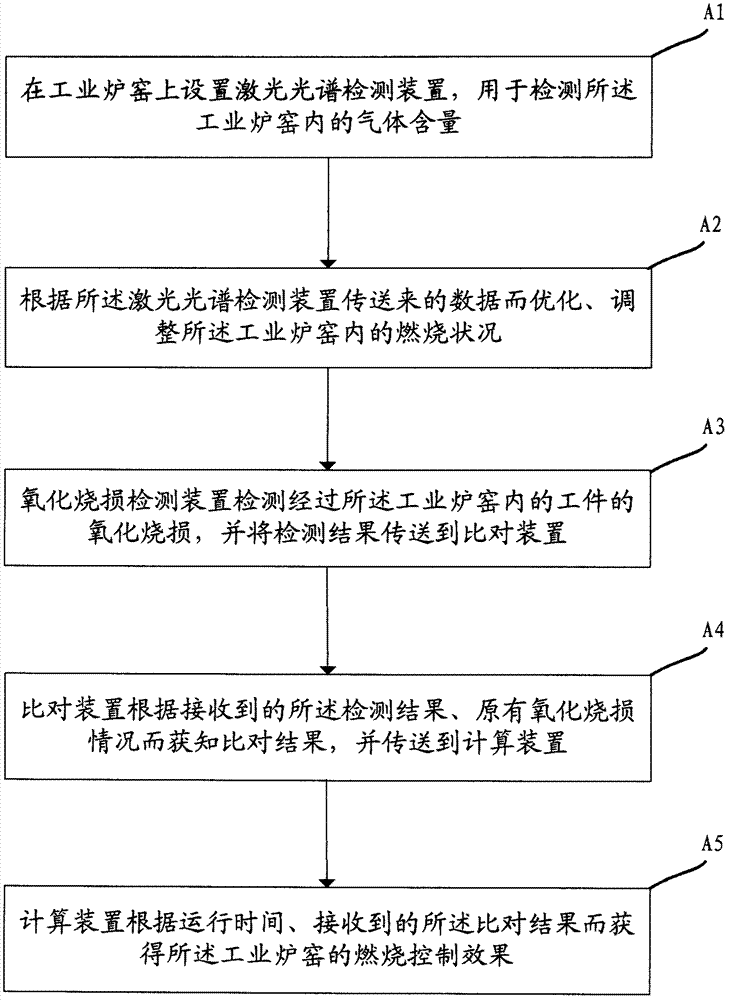

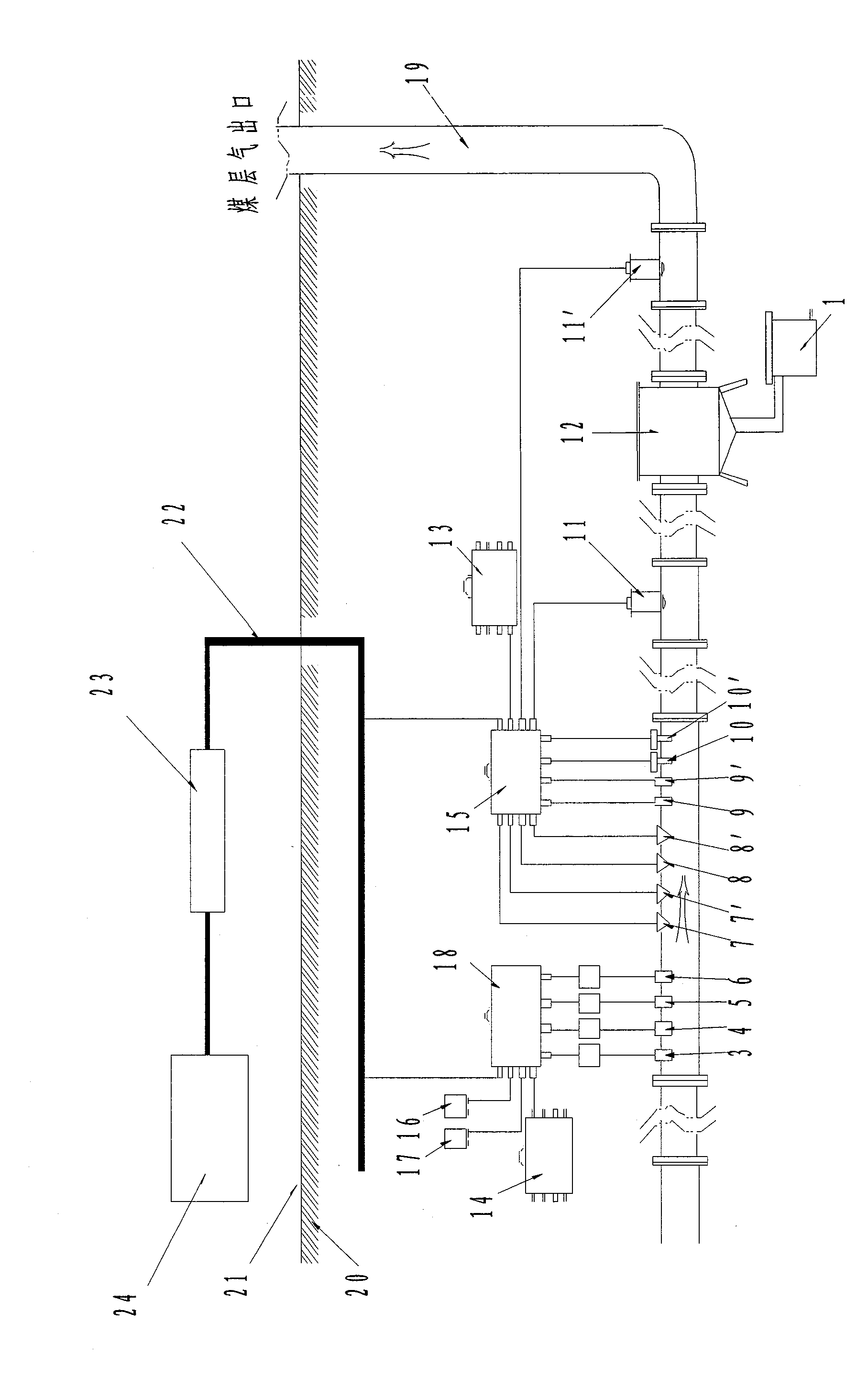

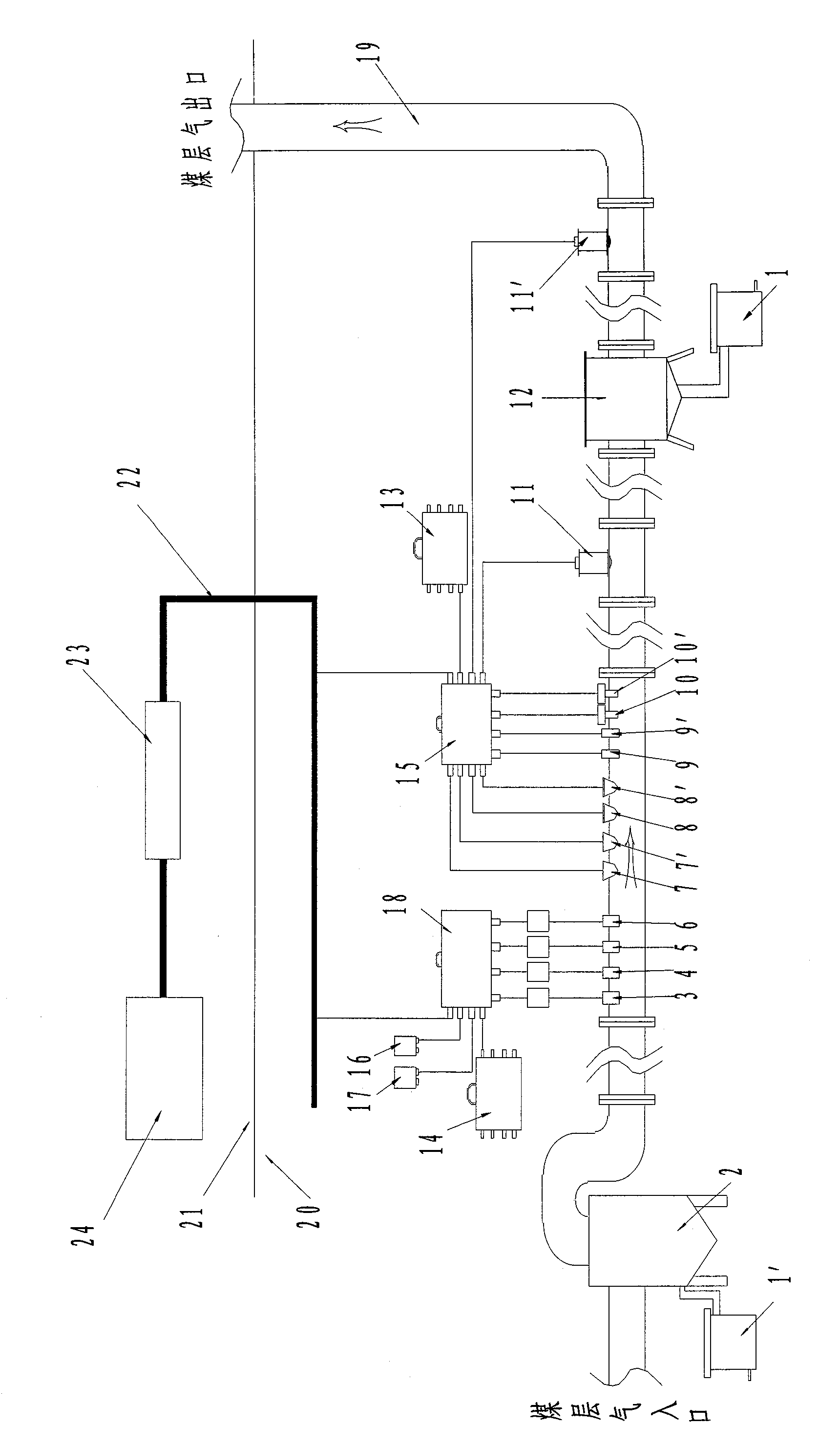

The invention provides a combustion control system and method of an industrial furnace. The combustion control system of the industrial furnace comprises a laser spectrum detection device, a combustion control device, an oxidation burning loss detection device, a comparison device and a computing device, wherein the laser spectrum detection device is used for detecting the content of gas in the industrial furnace, the laser spectrum detection device comprises a laser, a detector and an analysis module, the combustion control device is used for optimizing and adjusting the combustion conditions in the industrial furnace according to data transmitted by the laser spectrum detection device, the oxidation burning loss detection device is used for detecting oxidation burning loss of workpieces which pass through the industrial furnace, and transmitting the detection result to the comparison device, the comparison device is used for obtaining the comparison result according to the received detection result and the original oxidation burning loss conditions, and transmitting the comparison result to the computing device, and the computing device is used for obtaining the combustion control result of the industrial furnace according to the received comparison result. The combustion control system and method of the industrial furnace have the advantages that detection accuracy is high, the detection speed is high, the cost is low, and energy is saved.

Owner:FOCUSED PHOTONICS

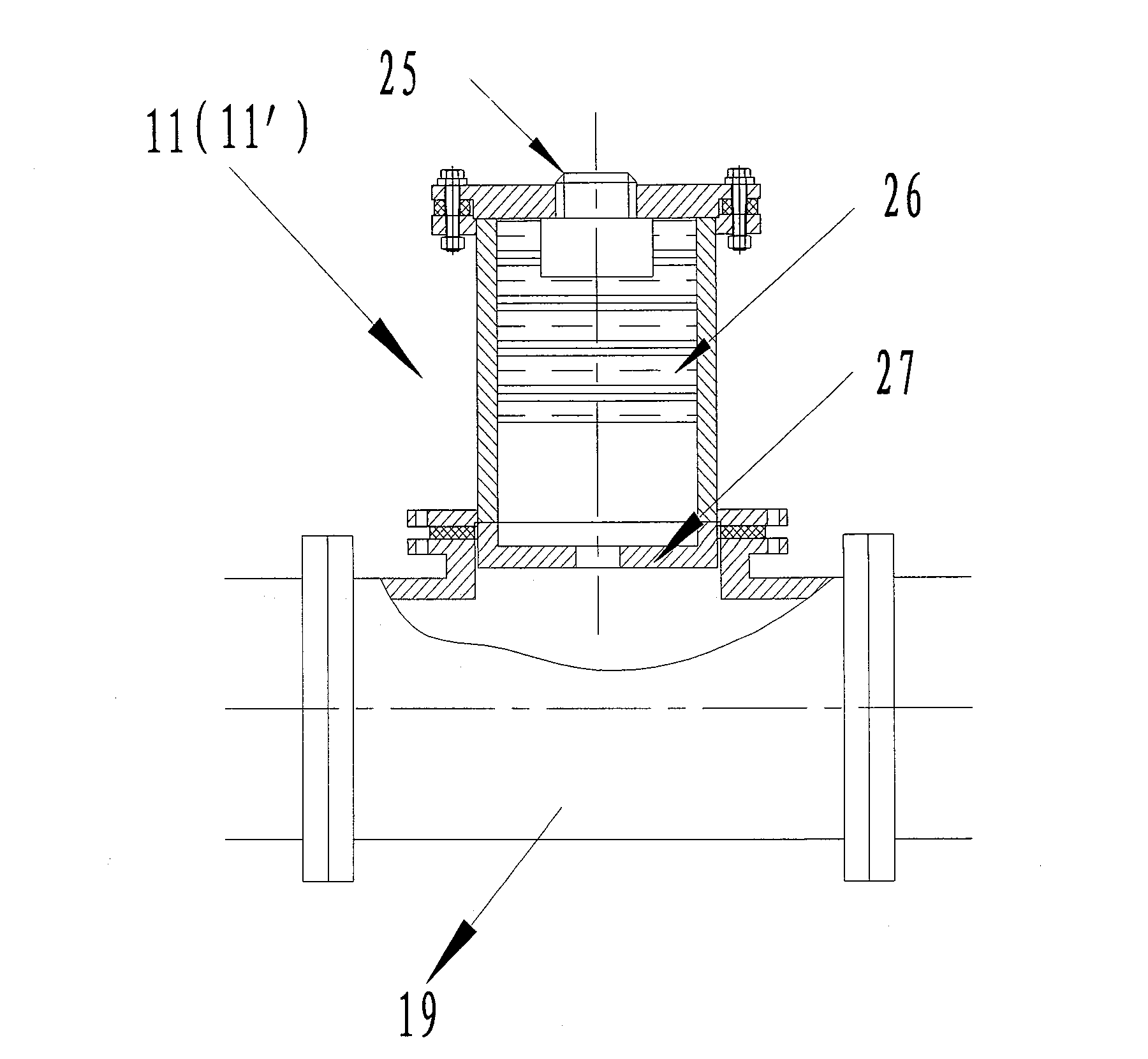

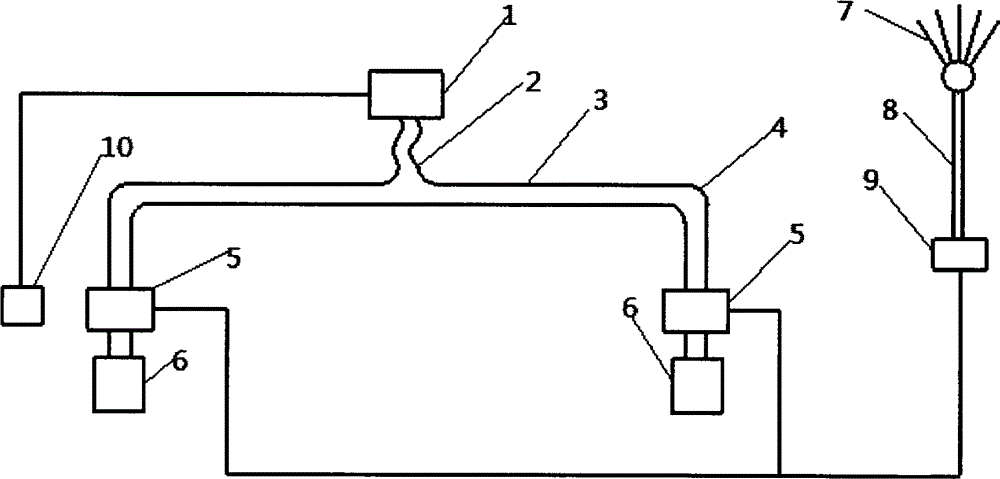

Safe delivery system for coal bed gas

ActiveCN104110582AReduce false alarm rateReduce non-report ratePipeline systemsSafe deliveryCommunication interface

The invention relates to a safe delivery system applied to downhole coal bed gas (gas) in coal mining. A monitoring device, an automatic powder spraying and explosion suppression device and a fire retarding device are sequentially arranged on a delivery pipeline along the coal bed gas delivery direction, the automatic powder spraying and explosion suppression device is connected with a controller, and output ends of the monitoring device and the controller are connected with a monitoring system on the ground through information data buses and communication interfaces respectively. By the safe delivery system, information like methane, carbon oxide, temperature and flow in the delivery pipeline is monitored at any time; once the circumstance of limit exceeding is found, an alarm is given timely, and the circumstance is transmitted to a control center on the ground and even a national safety monitoring center. Once a fire disaster occurs, the disaster is controlled within a certain range under action of the fire retarding device and the automatic powder spraying and explosion suppression device.

Owner:SHANDONG ANYI MINING EQUIP CO LTD

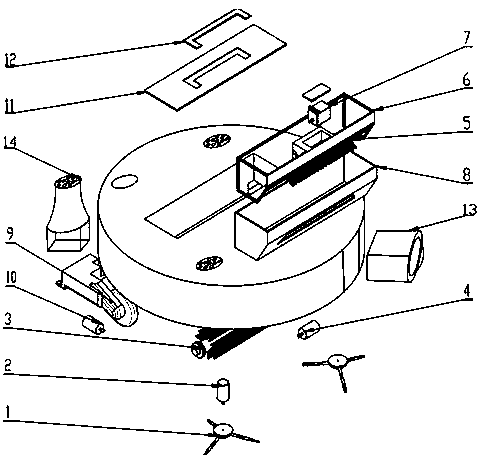

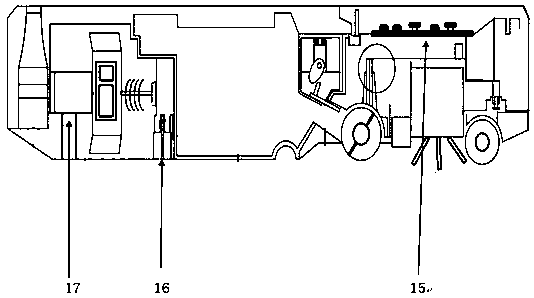

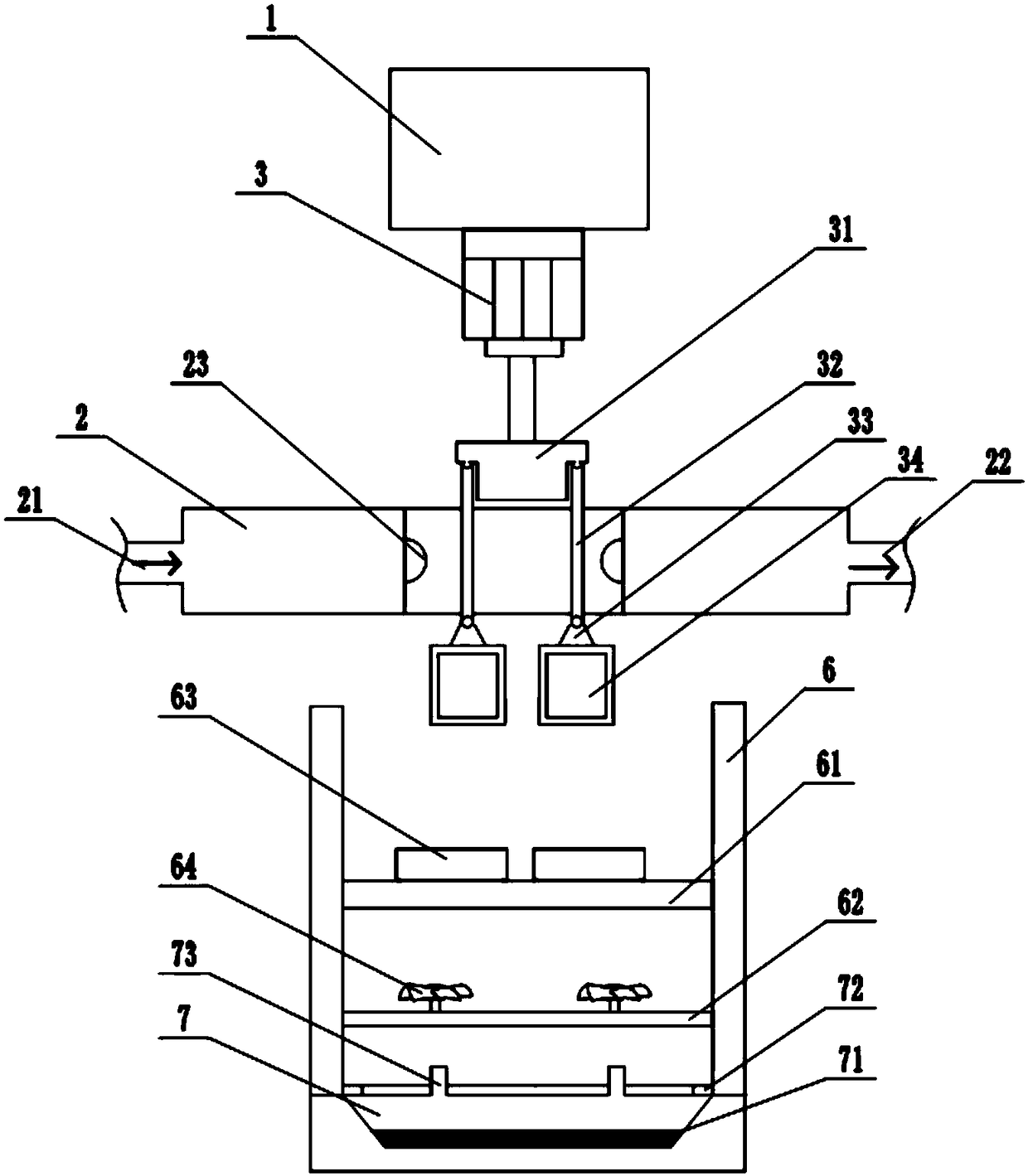

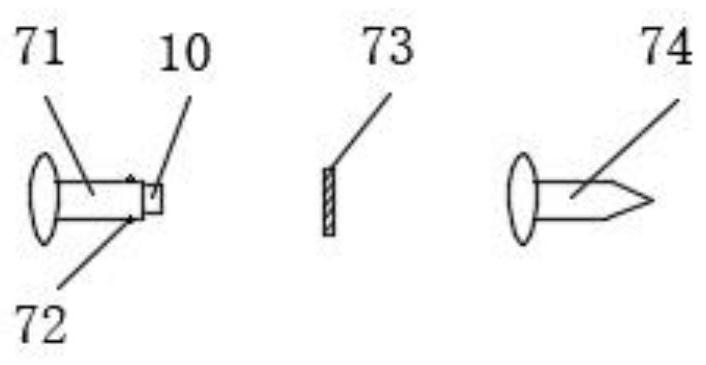

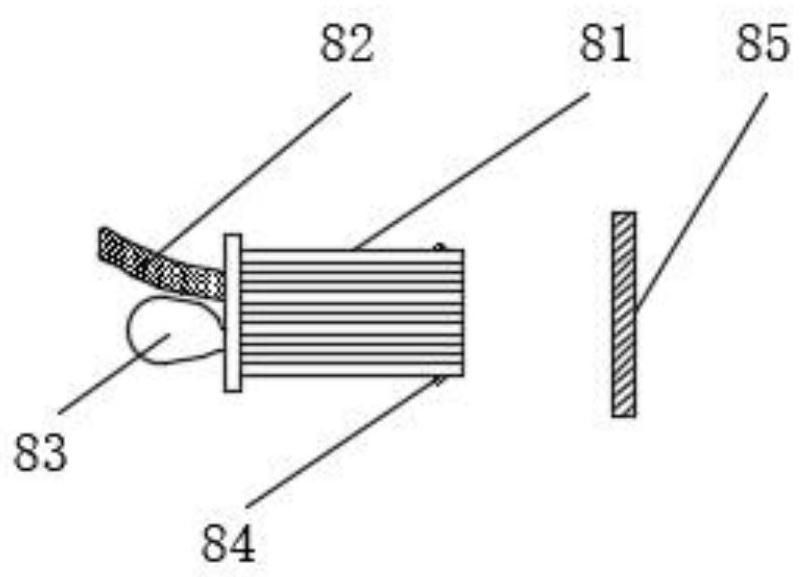

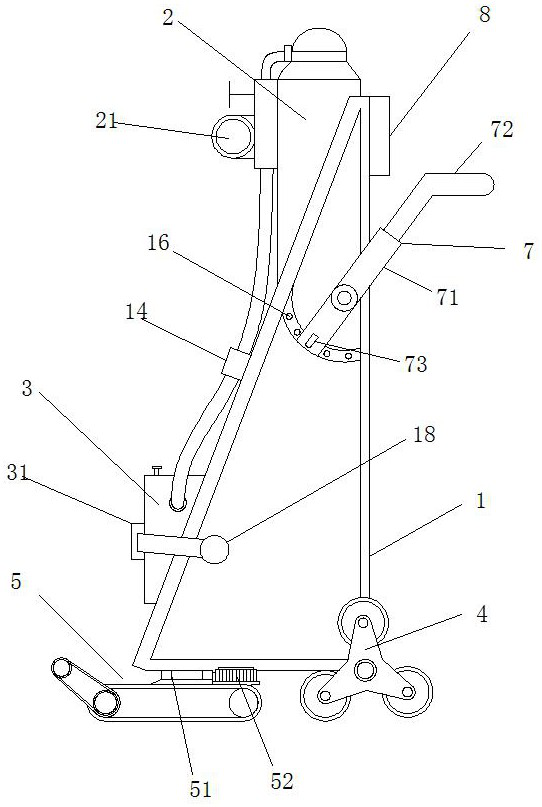

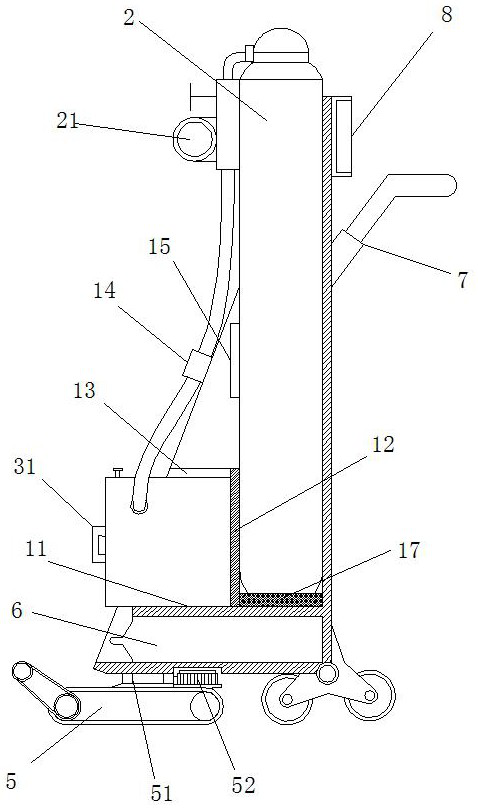

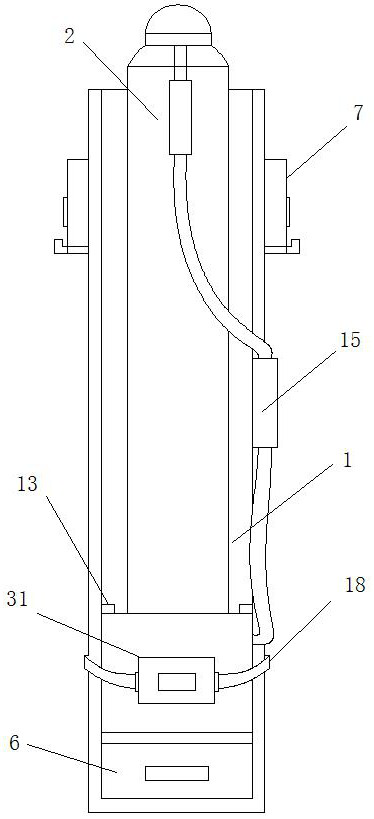

A multi-functional automatic cleaning device for preventing hair winding and the control principle of the system

PendingCN109222749AReal-time monitoring contentRealize monitoringSuction cleanersEngineeringLiving environment

The invention discloses a multi-functional automatic cleaning device for preventing hair winding and the control principle of the system, and solves the problems that the household floor hair is difficult to be cleaned or the hair is easy to be entangled with various floor sweeping devices and rotating bearings, the addition of auxiliary functions of the device makes the multifunctional characteristics obvious, in order to cater to the extreme pursuit of the living environment of the modern people and meet their living needs, the invention fully exerts all the value characteristics of the device, utilizes the flexibility of the device, adds an air humidifying device, replaces the original air humidifier which is open at a fixed time and place, and realizes the air humidification of one humidifier in multiple spaces; depending on its good flexibility and concealment, the device is equipped with patrol camera device to realize the monitoring and security of the family environment. In addition, considering the existing household decoration materials, furniture will volatilize a large number of harmful volatile gases, the installation of TVOC indoor air volatile harmful substances detector, real-time monitoring of the content of harmful volatiles in the air, and upload data prompt users to ventilate in time.

Owner:HENAN POLYTECHNIC UNIV

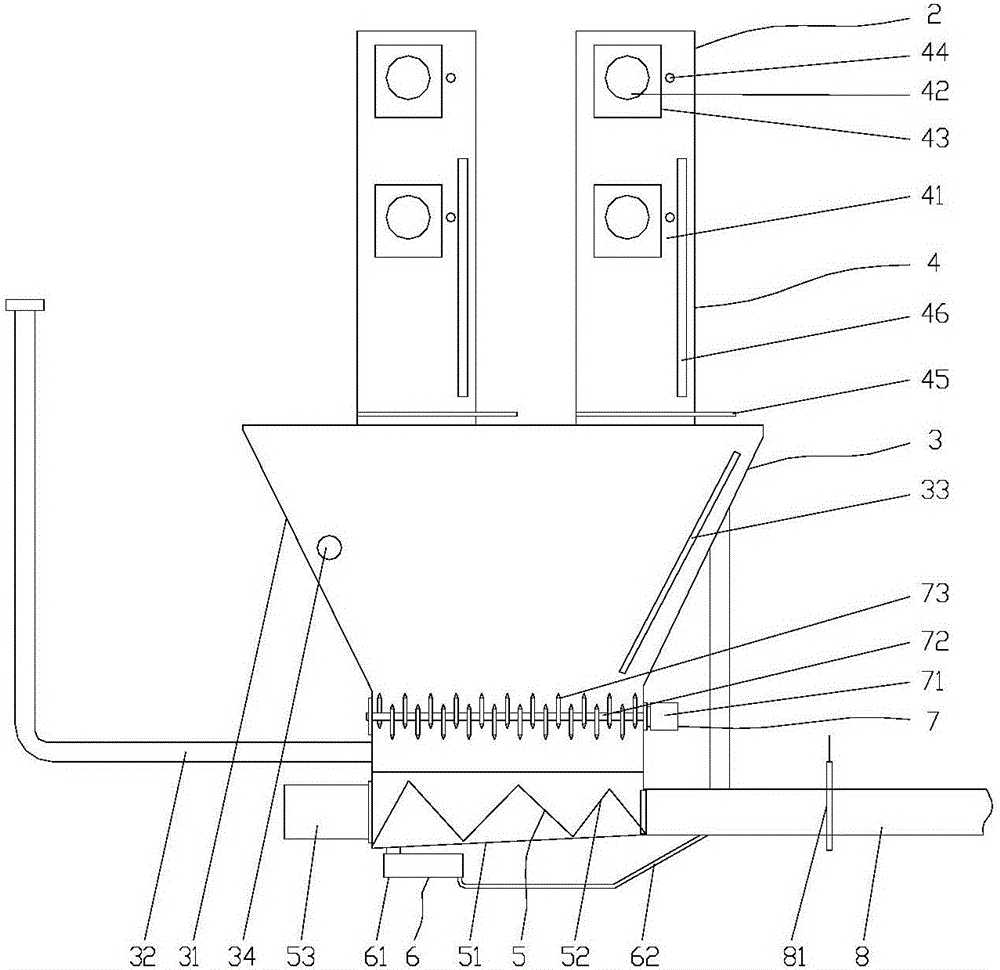

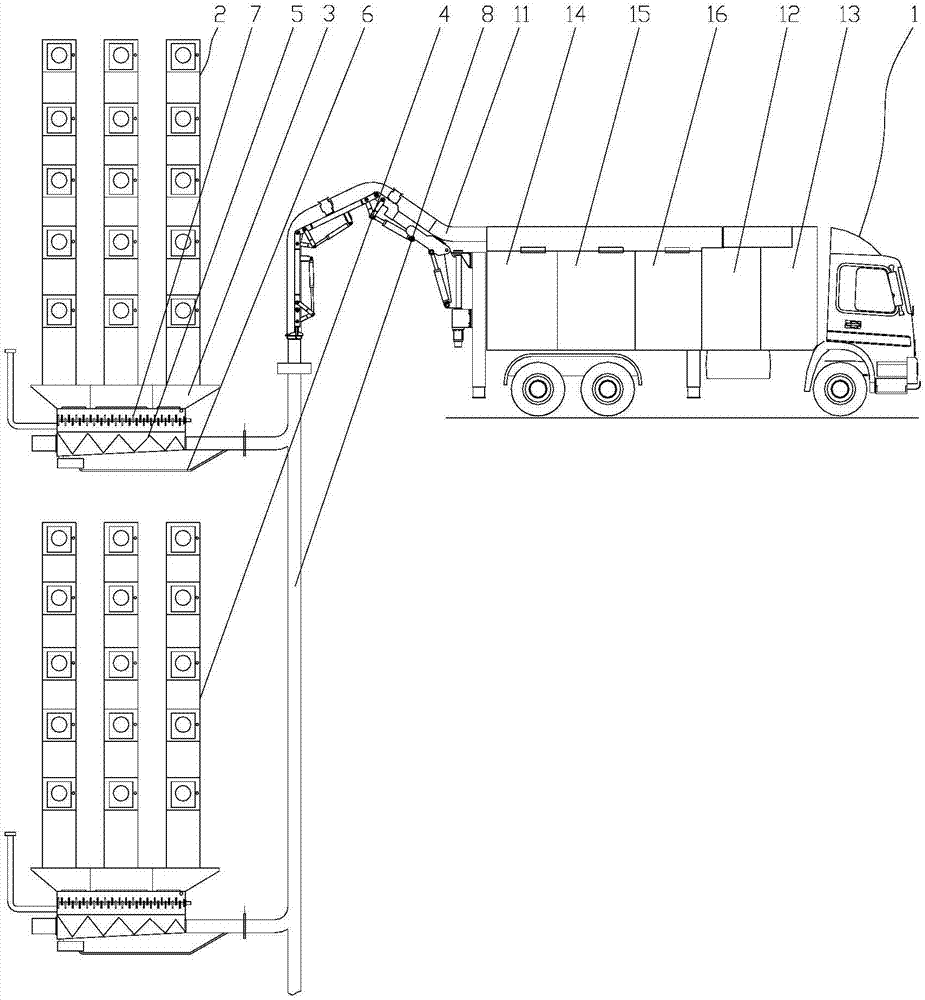

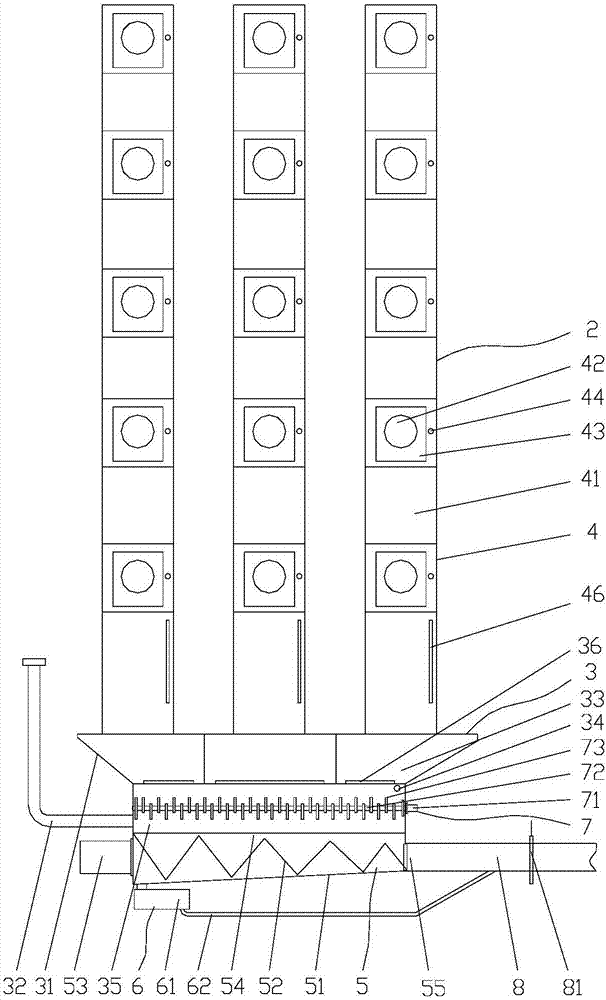

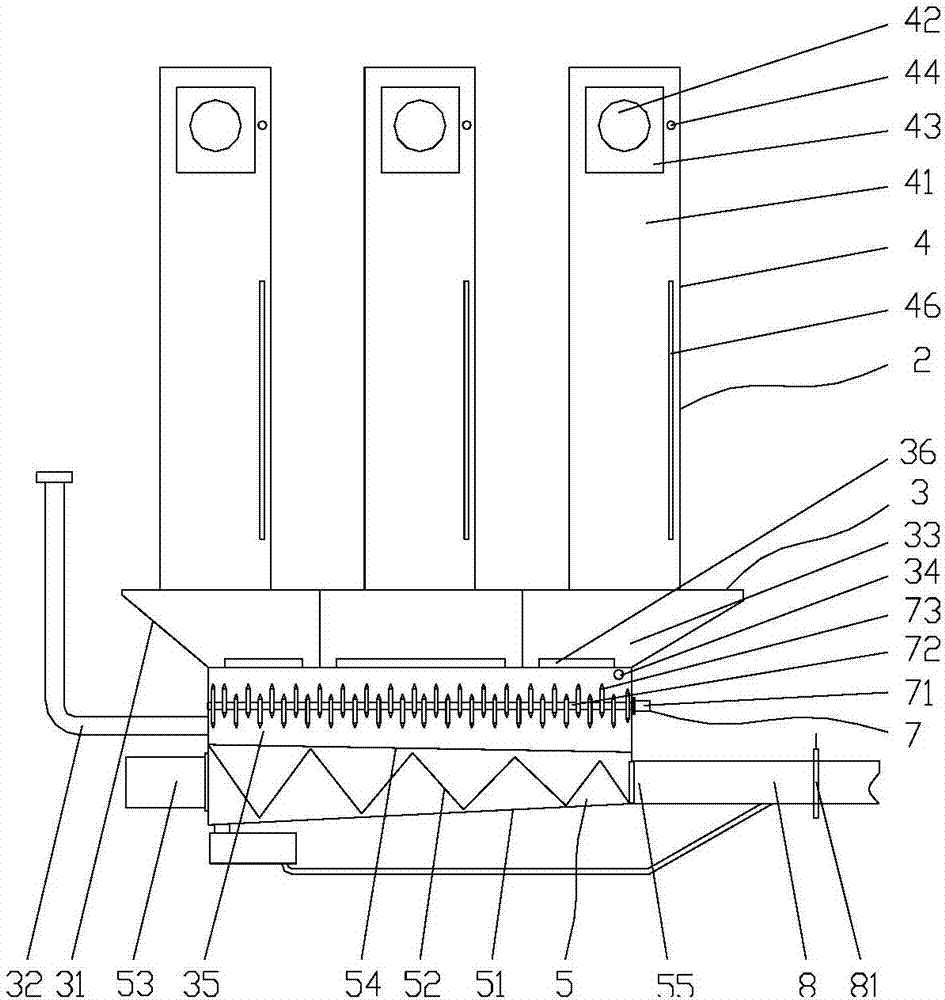

Closed automated garbage collection system

InactiveCN106429127AMake sure the suction speedReduce frictional resistanceRefuse receptaclesRefuse transferringRefuse collectionCollection system

The invention relates to a closed automated refuse collection system, comprising a control center, a suction transit equipment and one or more garbage collection devices. The control center is respectively connected with the suction transit equipment and the garbage collection devices through communication. The garbage collection devices comprise a garbage storage mechanism utilized to store garbage. A garbage disposal mechanism utilized to put and transport garbage into the garbage storage mechanism is arranged on the upper part of the garbage storage mechanism. A screw driving mechanism utilized to stir, drive and transport the garbage in the garbage storage mechanism is arranged at the lower part of the garbage storage mechanism. A pollution discharge mechanism utilized to collect and discharge waste residual liquid is arranged at the lower part of the screw driving mechanism. A plurality of bag breaking mechanisms utilized to crush bulky waste and garbage bags is arranged between the screw driving mechanism and the garbage disposal mechanism. A discharge port of the screw driving mechanism is connected with the suction transit equipment through suction tubes. The suction transit equipment pumps and transfers the garbage stored in the screw driving mechanism into the suction transit equipment through negative pressure formed in the suction tubes.

Owner:福建海山机械股份有限公司

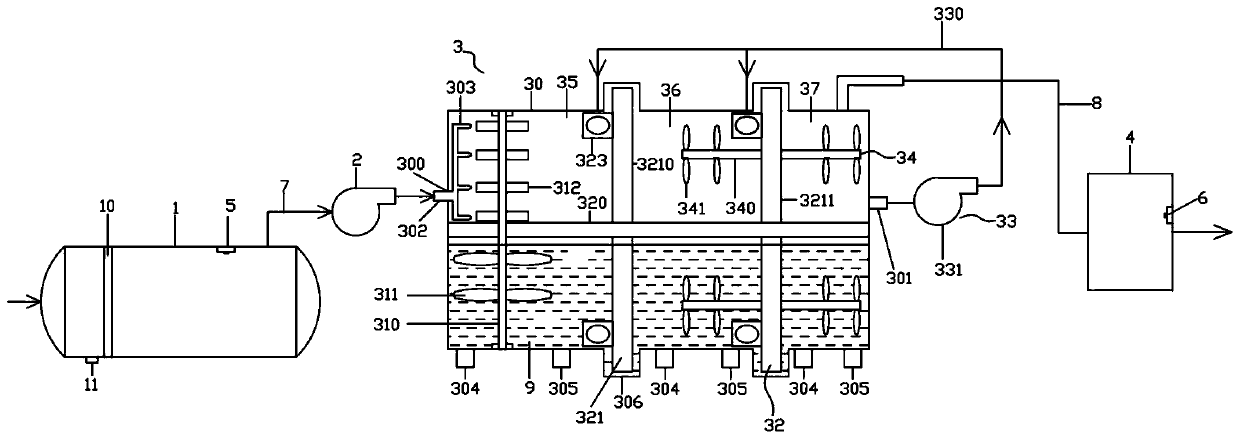

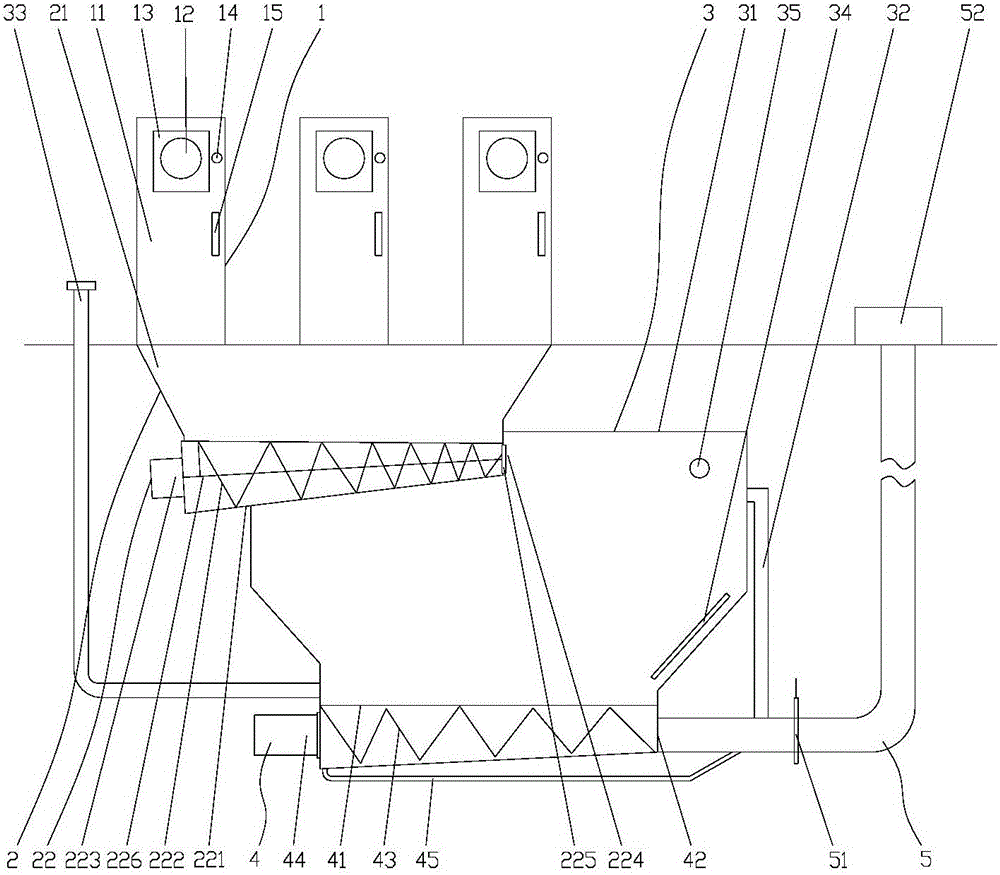

Industrial waste gas treatment device with monitoring function

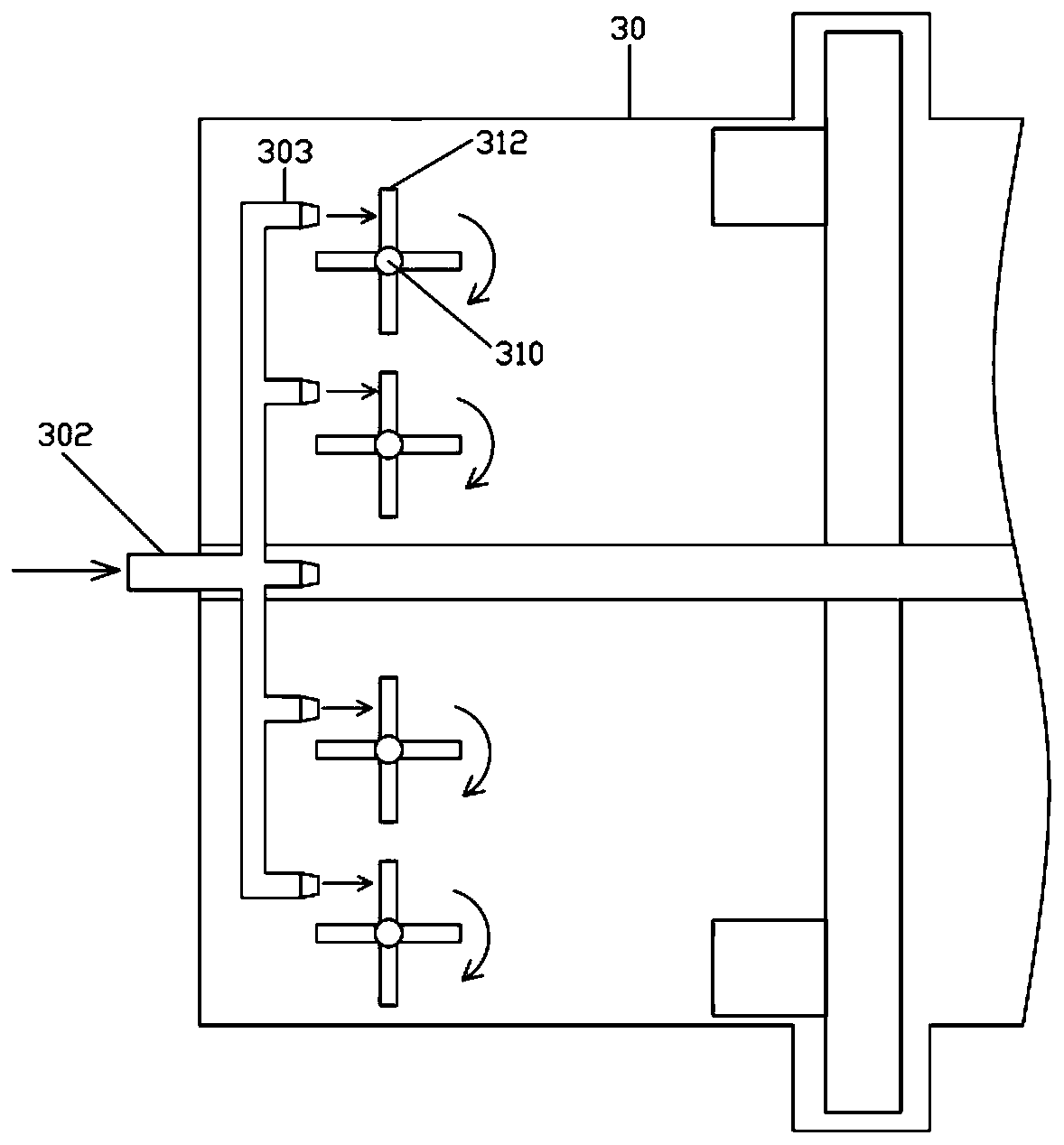

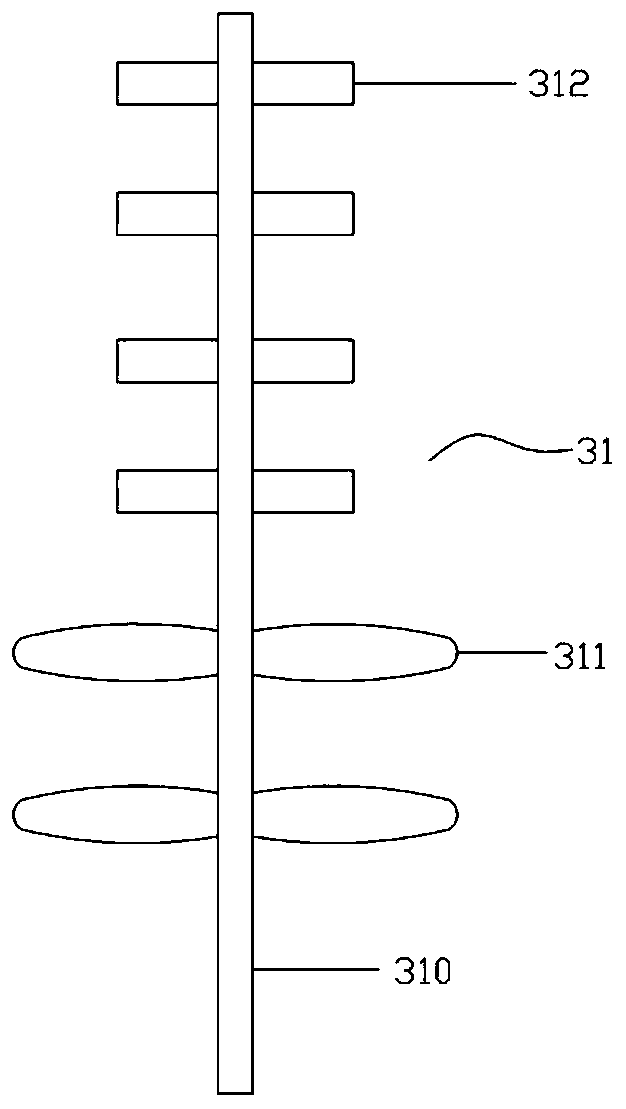

PendingCN110523249AProcess waste gas treatment effect is goodEasy to handleCombination devicesGas treatmentTherapeutic effectProduct gas

The invention discloses an industrial waste gas treatment device with a monitoring function. The industrial waste gas treatment device with the monitoring function comprises a buffering tank, a gas inlet fan, a waste gas treatment tank, a filtering device, a first gas monitoring device and a second gas monitoring device, wherein the buffering tank, the gas inlet fan, the waste gas treatment tank and the filtering device are arranged sequentially along the gas flow direction; the first gas monitoring device is arranged in the buffering tank; the second gas monitoring device is arranged at the gas outlet end of the filtering device; and the waste gas treatment tank comprises a cylindrical treatment tank body, a main stirring device, a gas treatment disk assembly and a gas circulating assembly. According to the industrial waste gas treatment device with the monitoring function, the waste gas is filtered in advance through a filtering net in the buffering tank, and the waste gas is treatedsequentially by the waste gas treatment tank and the filtering device, so that good process waste gas treatment effect can be achieved, and the device is simple in structure.

Owner:苏州仕净科技股份有限公司

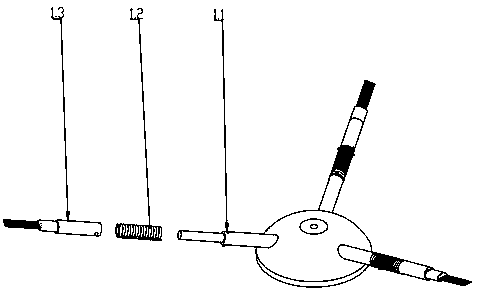

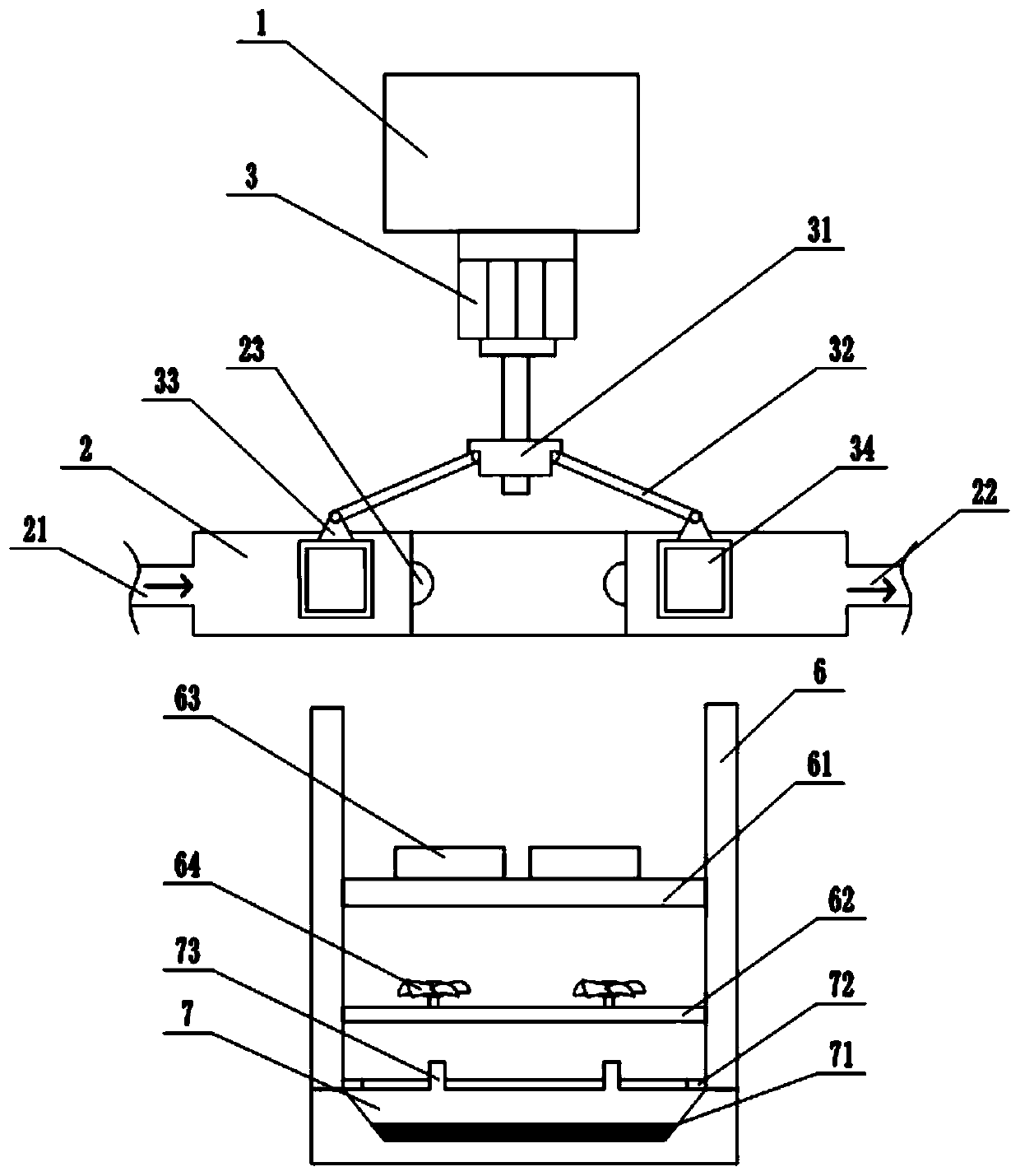

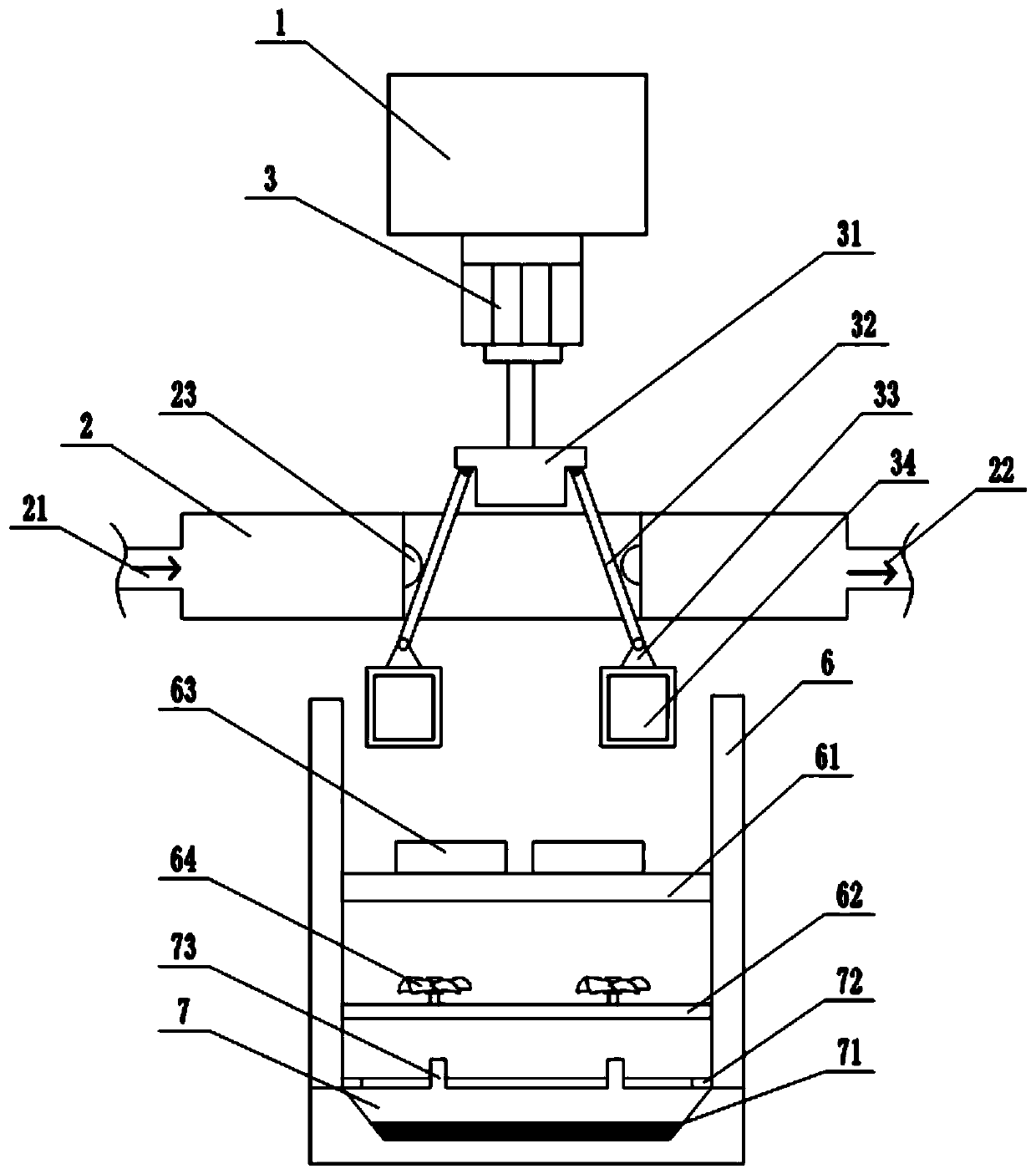

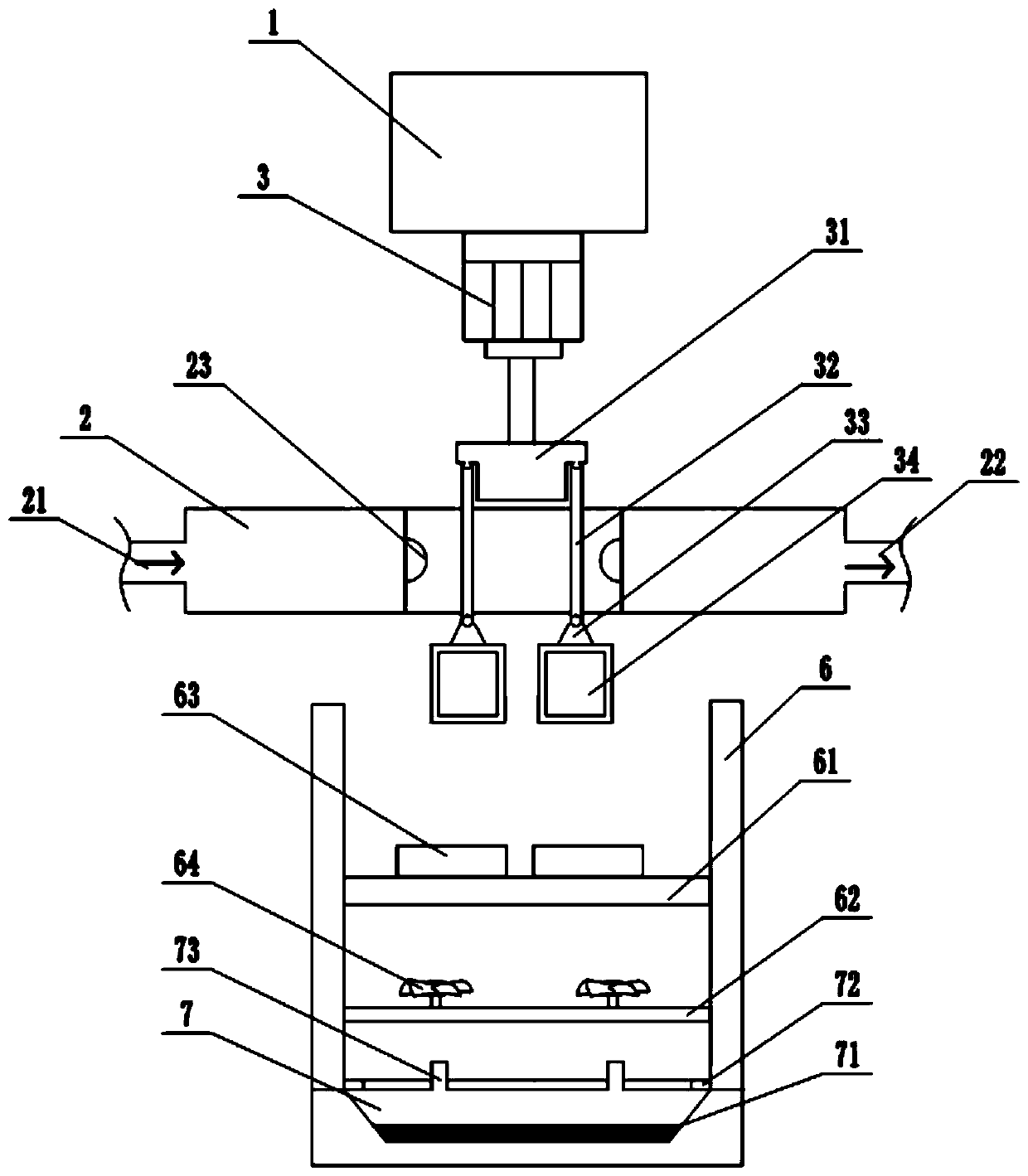

Laver processing device

InactiveCN109221362AIndirect judgment of cleaning degreeAvoid stickingFood shapingFood treatmentSpray nozzleEngineering

The invention relates to the technical field of food processing equipment, and discloses a laver processing device. The laver processing device comprises a machine frame, wherein a lifting mechanism,a cleaning mechanism and a drying mechanism are arranged in the machine frame from top to bottom, the lifting mechanism is connected with a first motor, a rotating table is fixedly installed on the output shaft of the first motor, a connection rod is hinged to the rotating table, and a material storage box is connected with the connection rod; and the drying mechanism comprises an open cylinder body, a first separation plate and a second separation plate are arranged in the cylinder body, a plurality of fans are arranged on the upper surface of the second separation plate, a heating box is arranged below the second separation plate, a heating plate is arranged in the heating box, a plurality of air outlet nozzles are further arranged on the heating box, and the air outlet nozzles are located right below the fans. When the laver processing device is used, laver is placed into the material storage box, cleaning and dehydrating of the laver are achieved through cooperation of the liftingmechanism, the first motor, the rotating table and the connection rod, and the laver is finally dried under the action of the drying mechanism.

Owner:象山锦绣升平食品有限公司

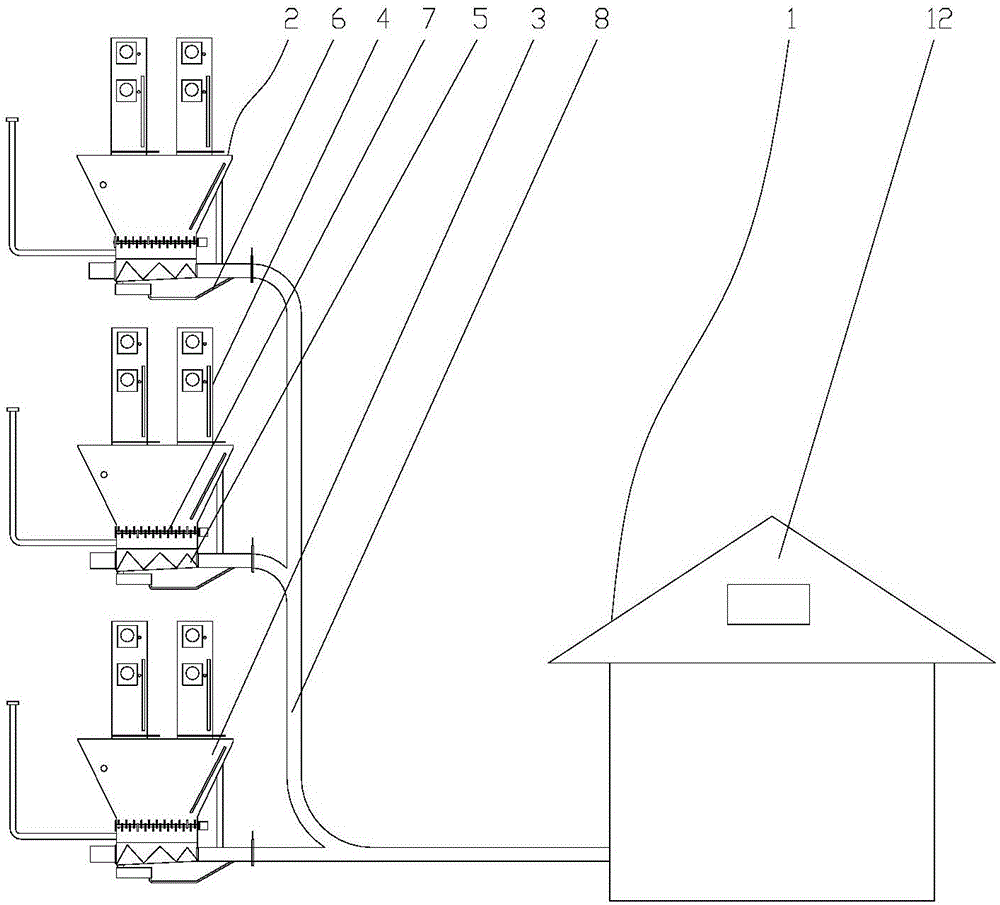

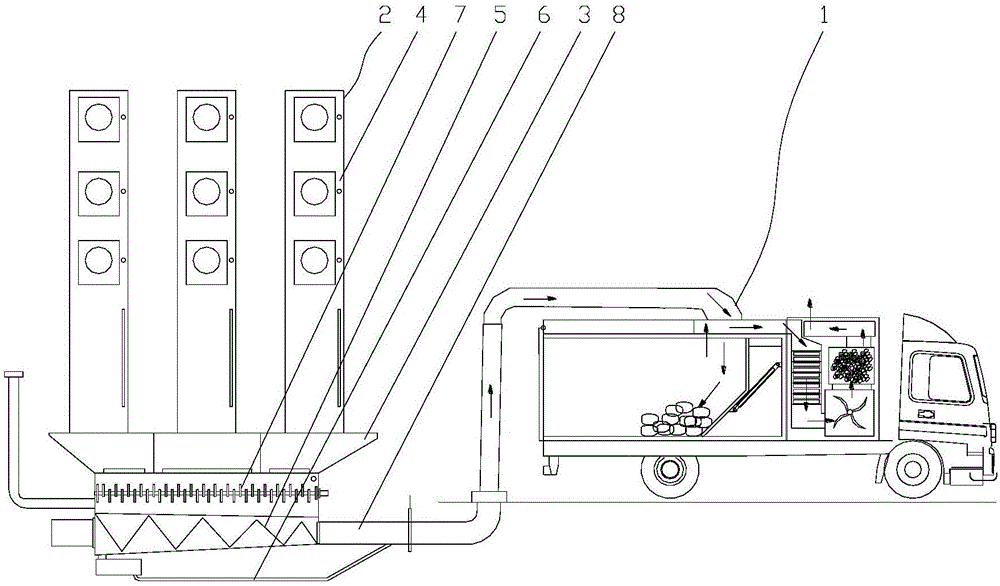

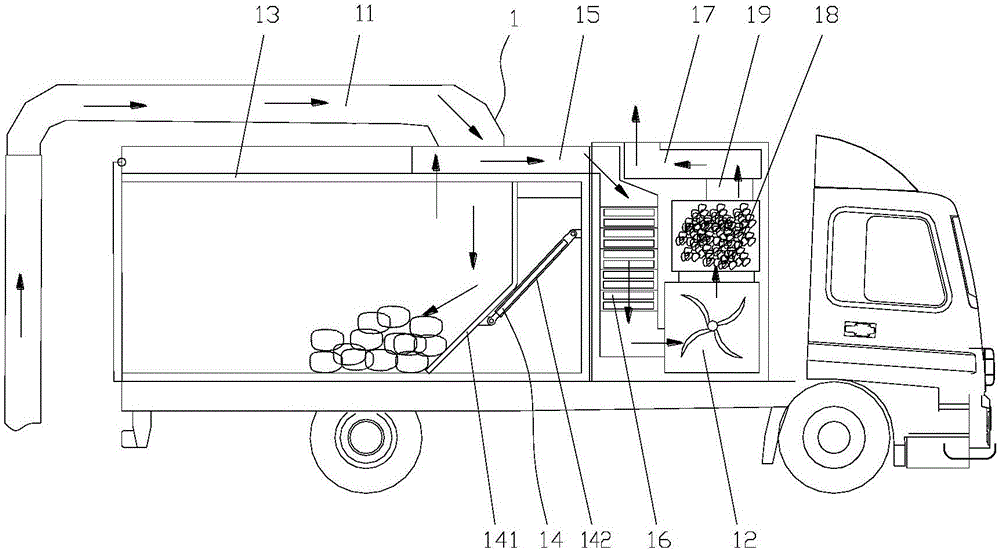

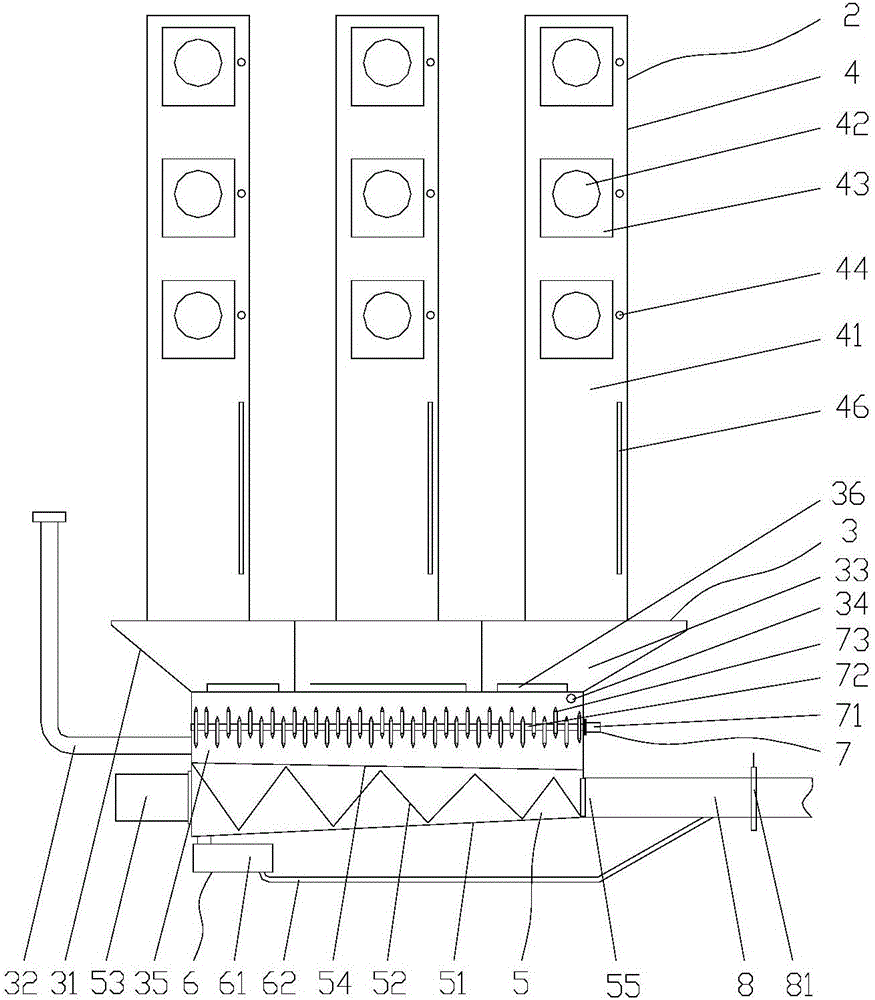

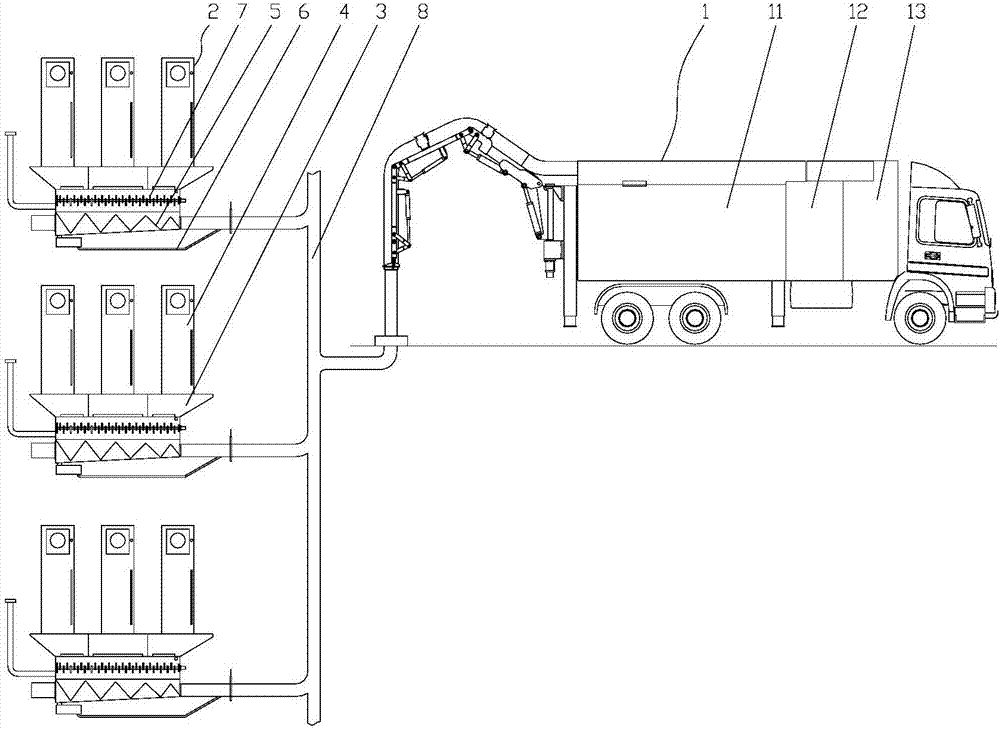

Environment-friendly classification and different-cabin type automatic garbage collection system

InactiveCN106395188AEasy to sort and storeMake sure the suction speedWaste collection and transferRefuse receptaclesCollection systemWaste collection

The invention relates to an environment-friendly classification and different-cabin type automatic garbage collection system. The environment-friendly classification and different-cabin type automatic garbage collection system comprises a control center, a suction type garbage collection vehicle and a garbage collection device, wherein the control center is in communication connection with the suction type garbage collection vehicle and the garbage collection device respectively; the garbage collection device comprises a garbage storage mechanism and three garbage dumping mechanisms; the three garbage dumping mechanisms are used for dumping and conveying recyclable garbage, unrecyclable garbage and other garbage to be judged respectively; three storage cabins are arranged at the upper part of the garbage storage mechanism; a transition cabin is arranged at the lower part of the garbage storage mechanism; the transition cabin is internally provided with a bag breaking mechanism; a spiral propelling mechanism is arranged at the bottom of the garbage storage mechanism; the suction type garbage collection vehicle is communicated with the spiral propelling mechanism through a suction pipeline; the suction type garbage collection vehicle is used for sucking and transferring garbage in the spiral propelling mechanism into the suction type garbage collection vehicle through forming needed negative pressure in the suction pipeline; and the suction type garbage collection vehicle is used for compressing garbage in the vehicle and exhausting and purifying garbage.

Owner:福建海山机械股份有限公司

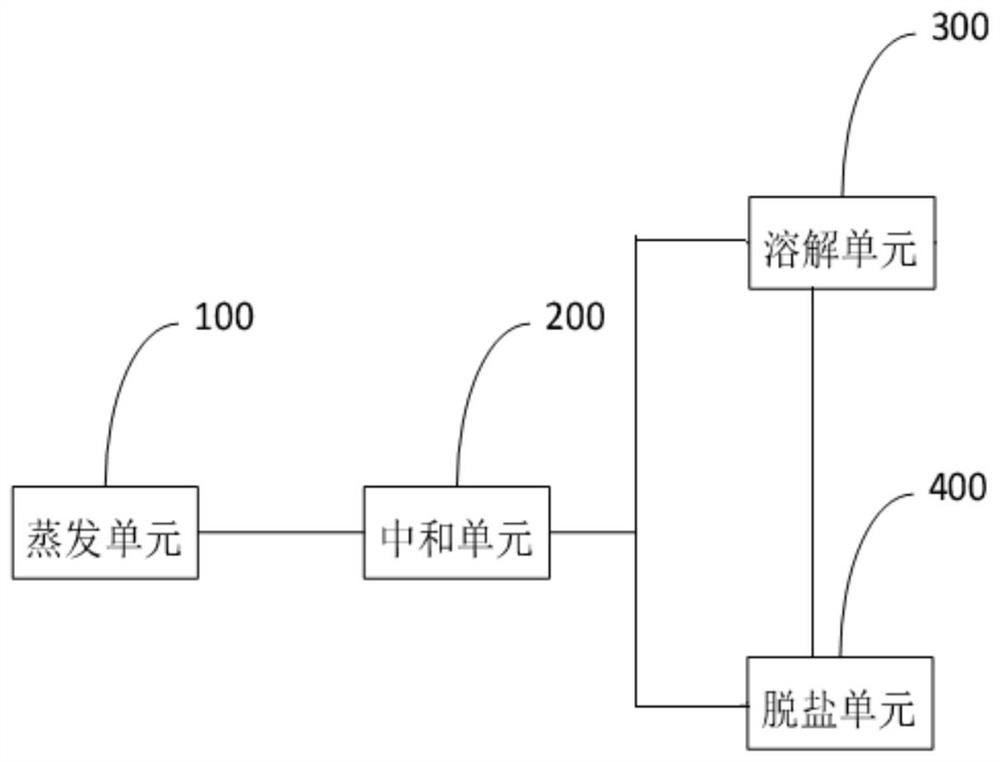

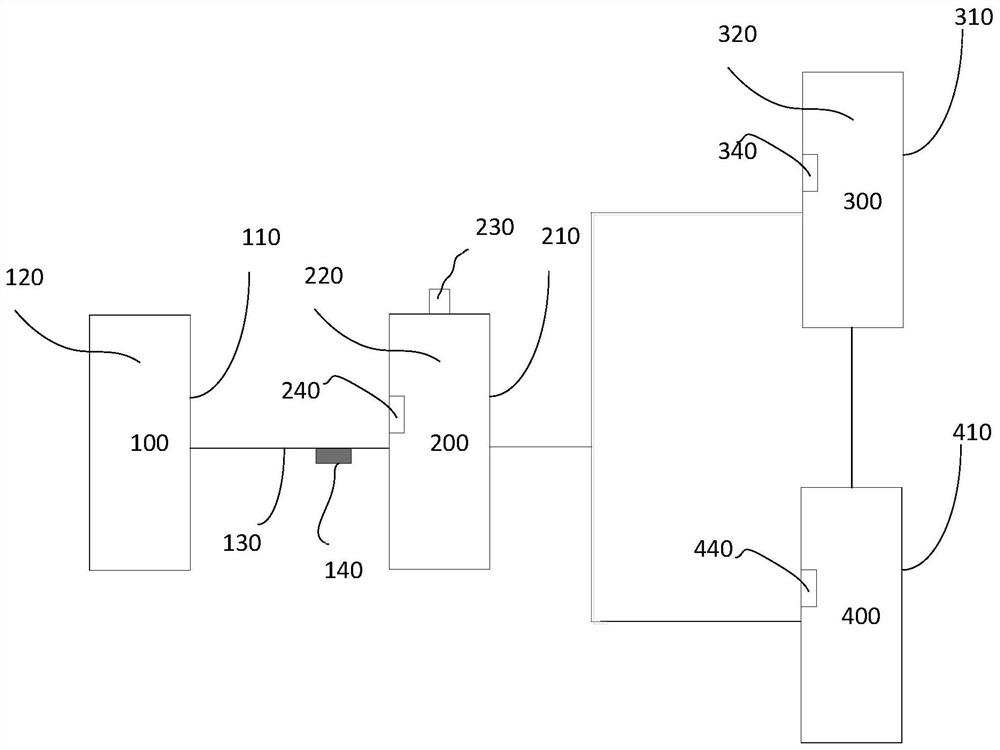

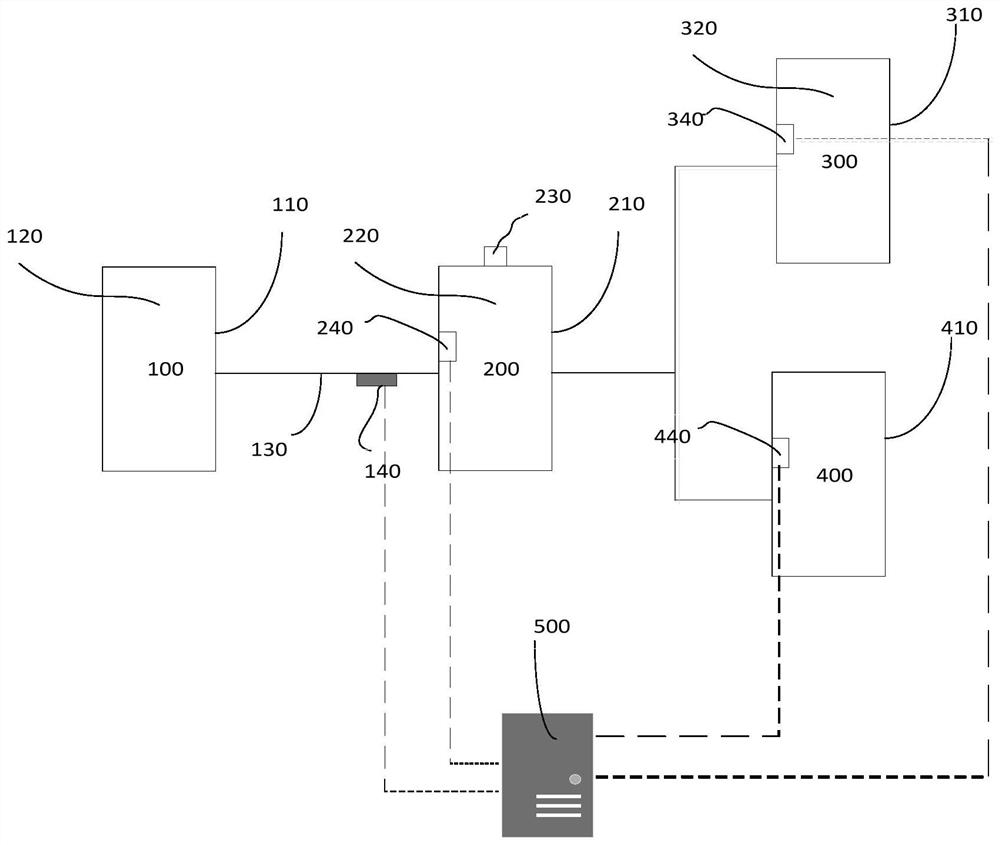

Method for determining taurine content in solution and method for purifying taurine

ActiveCN113049540AConcentration real-time monitoringSave manpower and material costsPreparing sample for investigationPhase-affecting property measurementsSodium IsethionatePhysical chemistry

The invention provides a method for determining a content of taurine in a solution and a method for purifying the taurine. The method comprises the steps of determining the refractive index of a to-be-detected solution, wherein the to-be-detected solution contains taurine or salt thereof and impurities, and the impurities comprise at least one of ethylene glycol, sodium isethionate, sodium sulfate and polyethylene glycol; establishing a standard curve of the taurine concentration in the taurine solution based on the refractive index; and performing optical detection on the to-be-detected solution, and determining the content of the taurine or the salt thereof in the to-be-detected solution according to the position of the obtained optical detection value in the standard curve. Through the method, the content of taurine in various taurine solutions with complex components can be effectively detected.

Owner:HUBEI GRAND LIFE SCI & TECH CO LTD

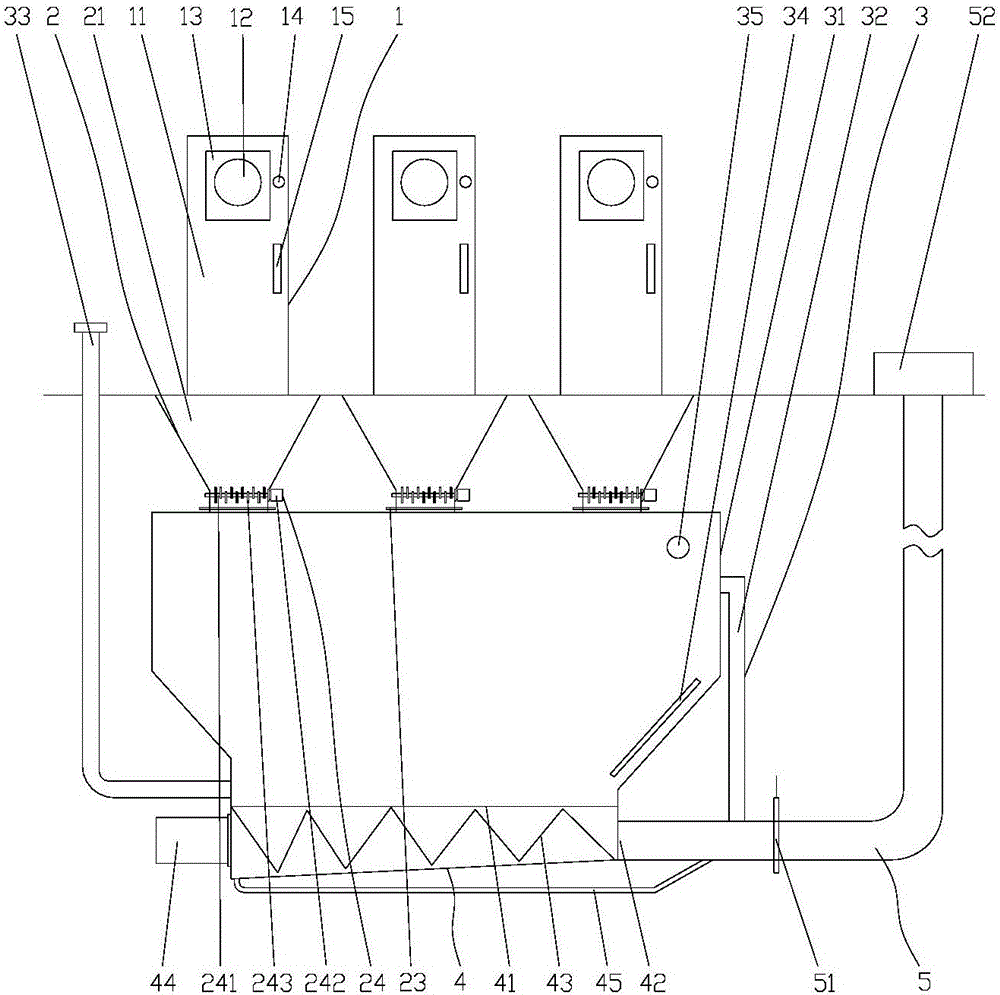

Acidic-exhaust gas treatment device with exhaust gas monitoring function

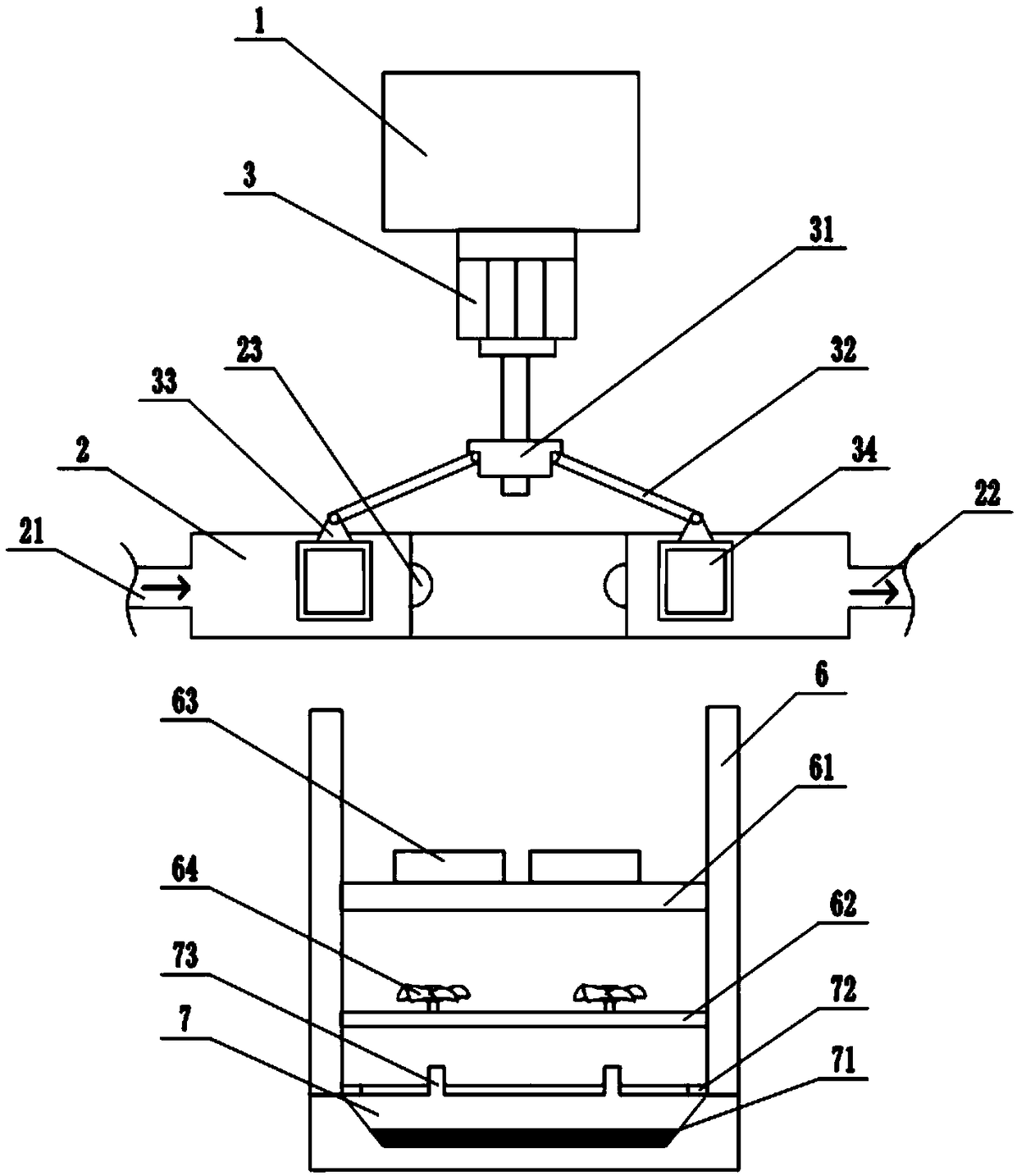

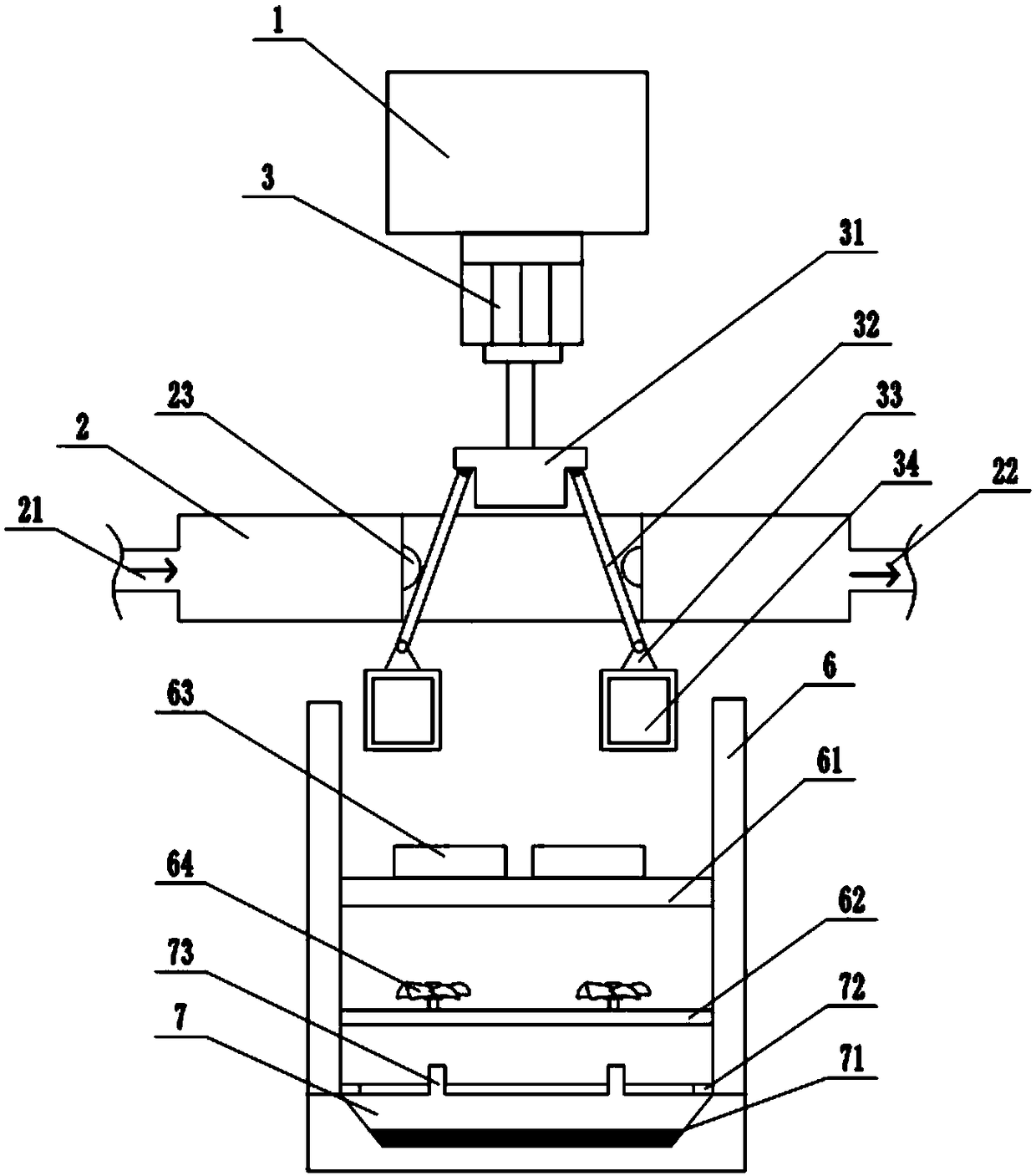

PendingCN110538564AEasy to handleEfficient SupplementCombination devicesGas treatmentEngineeringTherapeutic effect

The invention discloses an acidic-exhaust gas treatment device with an exhaust gas monitoring function. The acidic-exhaust gas treatment device includes a dust removal device, a liquid absorption device and a filter device which are sequentially arranged in the air flow direction, wherein the liquid absorption device includes a box body for holding an absorption liquid, a plurality of absorbing plates which are arranged at intervals in the box body in the air flow direction, stirring devices which are arranged in the box body, a gas circulating device and an absorbing liquid circulating device. According to the acidic-exhaust gas treatment device with the exhaust gas monitoring function, a good acidic exhaust gas treatment effect can be achieved through combination of the liquid absorptiondevice and the filter device, and an existing exhaust gas treatment technique can be supplemented and improved effectively; and the acid gas content of tail gas which is obtained through treatment ofthe acidic-exhaust gas treatment device can be monitored in real time through a gas monitoring device, so that the treatment effect of the acidic-exhaust gas treatment device is monitored.

Owner:苏州仕净科技股份有限公司

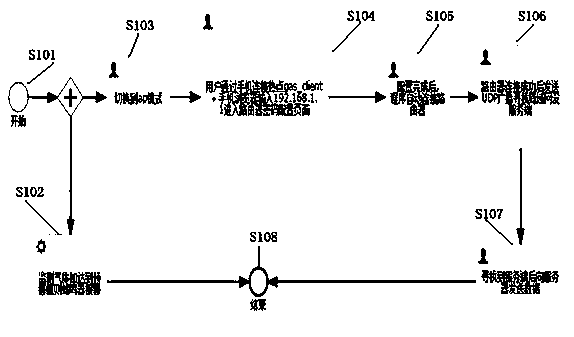

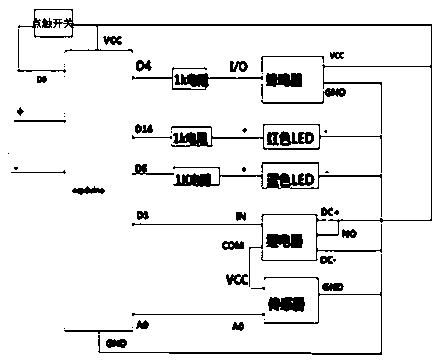

Intelligent combustible gas detector and detection method thereof

InactiveCN105513260AReal-time monitoring informationReal-time monitoring contentFire alarm smoke/gas actuationReal-time dataCombustible gas

The invention discloses an intelligent combustible gas detector and a detection method thereof. The intelligent combustible gas detector comprises a shell, and a smoke sensor, a buzzing alarm system and an ESP8266 WIFI module are arranged in the shell. The intelligent combustible gas detector has the following advantages that the functions of indoor gas detection, buzzing alarming, real-time data viewing, automatic connection between WIFI and a router, automatic alarming of a mobile phone and the like are achieved, effective warning can be performed in the initial stage of combustible gas leakage, and the hazard range is decreased to be minimum in time.

Owner:SHANDONG LANCHUANG NETWORK TECH

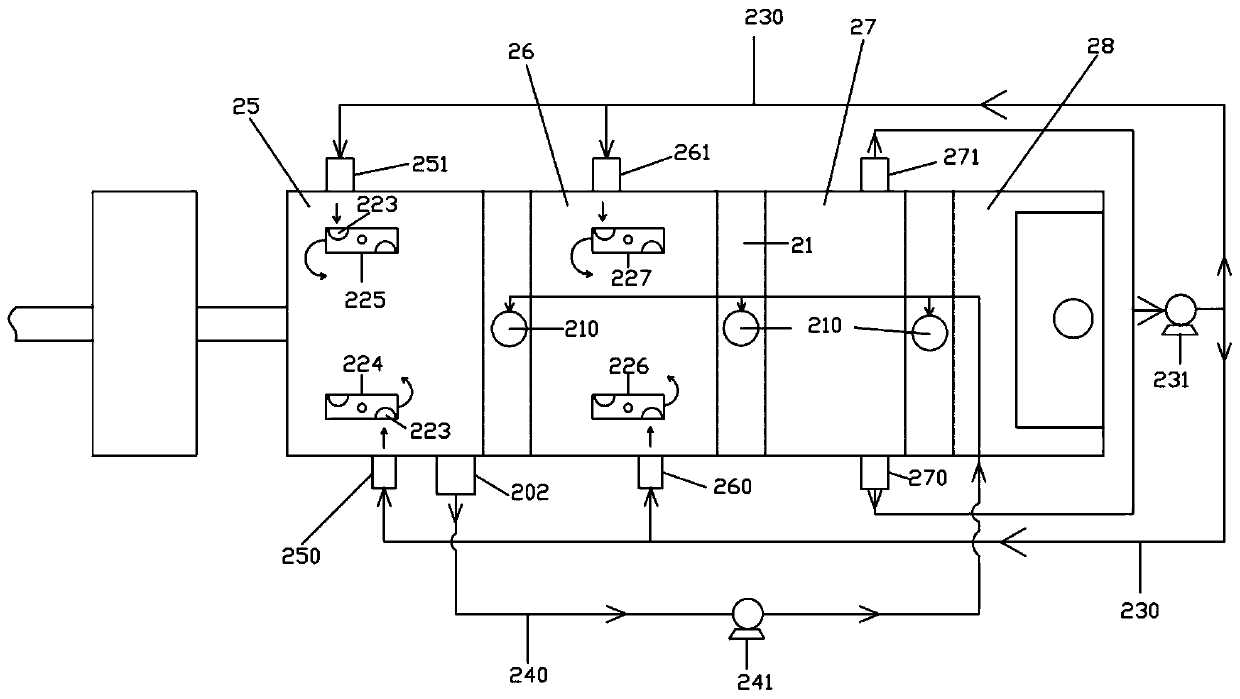

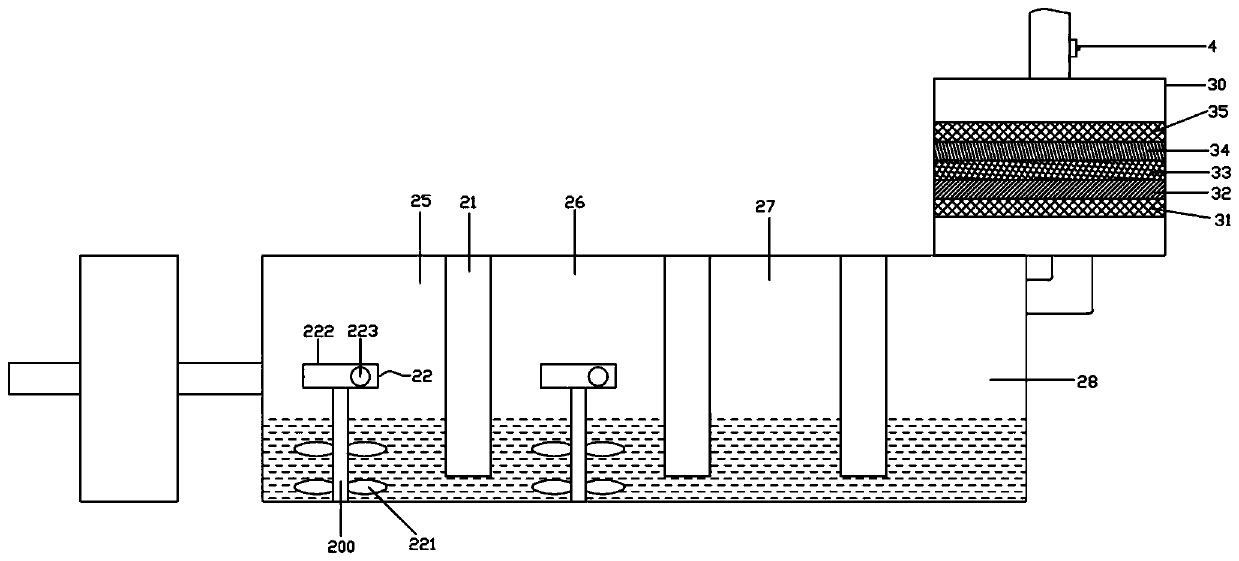

Barn circulating fumigation system

InactiveCN104082407ASolving Fumigation ProblemsExtended service lifeSeed preservation using chemicalsAir volumeHydrogen phosphide

The invention discloses a barn circulating fumigation system which comprises one or more groups of circulating fumigation systems, wherein each system comprises a fan, and one end of the fan is connected with a flexible pipe; the other end of the flexible pipe is connected with two or more pipelines, and the other end of each pipeline is connected with an automatic regulator; each automatic regulator is connected with a medicine chest through a pipeline and connected with a gas detection chest through an electric wire, and the gas detection chest is connected with a plurality of gas pipes through a main gas pipe. The circulating fumigation system can effectively solve the fumigation problem of high grain pile bulk storage, the fan is effectively protected when being overloaded, and the service life of the fan is prolonged. Medicine is put out of a barn, so that the contact between operators and toxic agents is reduced, and the healthy and safety of the operators is protected. The content of hydrogen phosphide in the barn can be monitored in time, the information is fed back to the automatic regulator, and the air volume is regulated so that the content of hydrogen phosphide achieves the optimal value. The medicament is saved, and the effect is enhanced.

Owner:ANHUI KEJIE LIANGBAO STORAGE EQUIP

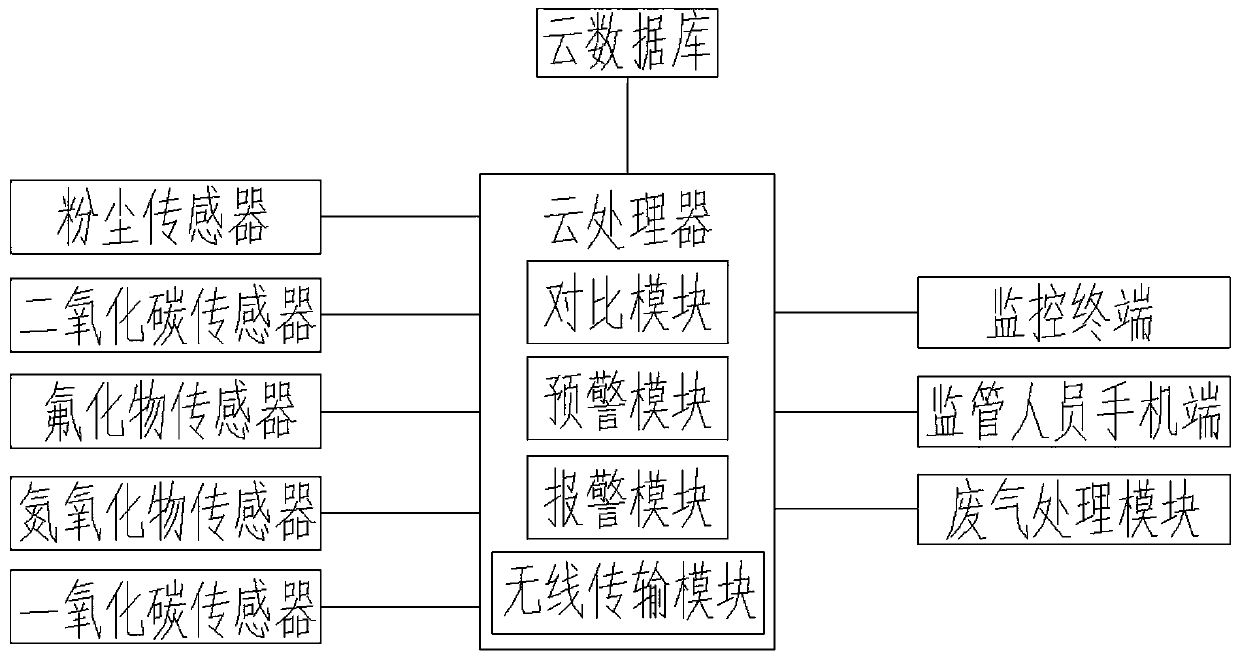

Industrial area atmospheric environment health risk assessment system

InactiveCN110175750AReal-time monitoring contentIncrease processing powerDigital data information retrievalVisible signalling systemsIndustrial areaData information

The invention discloses an industrial area atmospheric environment health risk assessment system. The system comprises a plurality of waste gas sampling modules and a cloud processor. The waste gas sampling modules are respectively installed at waste gas exhaust ports of factories. The waste gas sampling modules are responsible for collecting information of various data in waste gas and transmitting the information to the cloud processor, and the cloud processor analyzes and processes the data information to obtain corresponding treatment schemes. The cloud processor comprises a comparison module, an early warning module and an alarm module. The cloud processor is further connected with a cloud database, the air quality parameters of the area in the same period of years are stored in the cloud database, the cloud processor compares the received waste gas parameter information with the air quality information in the same period of years in the cloud database, and if the real-time wastegas pollution index approaches an early warning value, an early warning module is triggered; and if the real-time exhaust gas pollution index exceeds the early warning value, the alarm module is triggered.

Owner:天津环科环安科技有限公司

Garbage conveying device

PendingCN106628766AMake sure the suction speedReduce frictional resistanceRefuse transferringStorage devicesCollection systemWaste management

The invention relates to a garbage conveying device. The device is applied to the garbage automatic collection system and carries out garbage transportation operation under the control of a control center. The device comprises a plurality of garbage throwing mechanisms for throwing in and delivering garbage. A garbage temporary storage and crushing mechanism for temporary storing and crushing the garbage is communicated with the lower parts of the garbage throwing mechanisms, and a garbage storage mechanism for storing the crushed garbage is communicated with the lower part of the garbage temporary storage and crushing mechanism. The bottom of the garbage storage mechanism is communicated with a spiral feeding mechanism for spiral stirring and delivering broken garbage, and the discharge port of the spiral feeding mechanism is connected with a garbage discharge passage. The garbage discharge passage is provided with a discharge valve, the end of the garbage discharge passage away from the spiral feeding mechanism is provided with a suction port, and the suction port is used to connect a suction transfer device with a negative pressure power source device to form the negative pressure required to suck the garbage into the garbage discharge passage.

Owner:福建海山机械股份有限公司

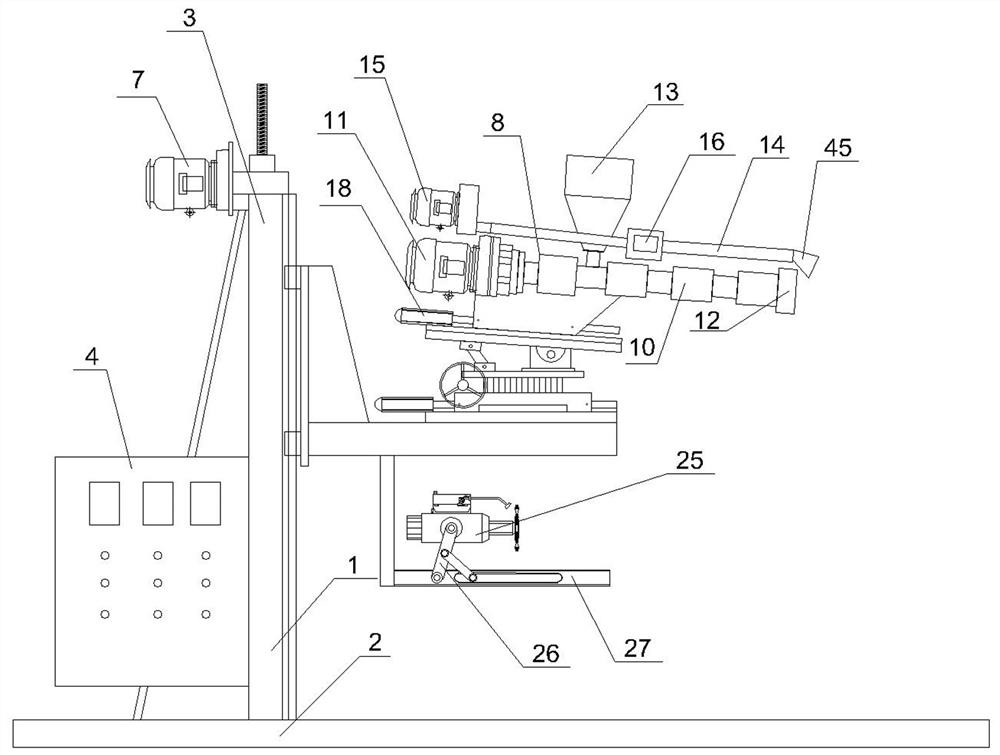

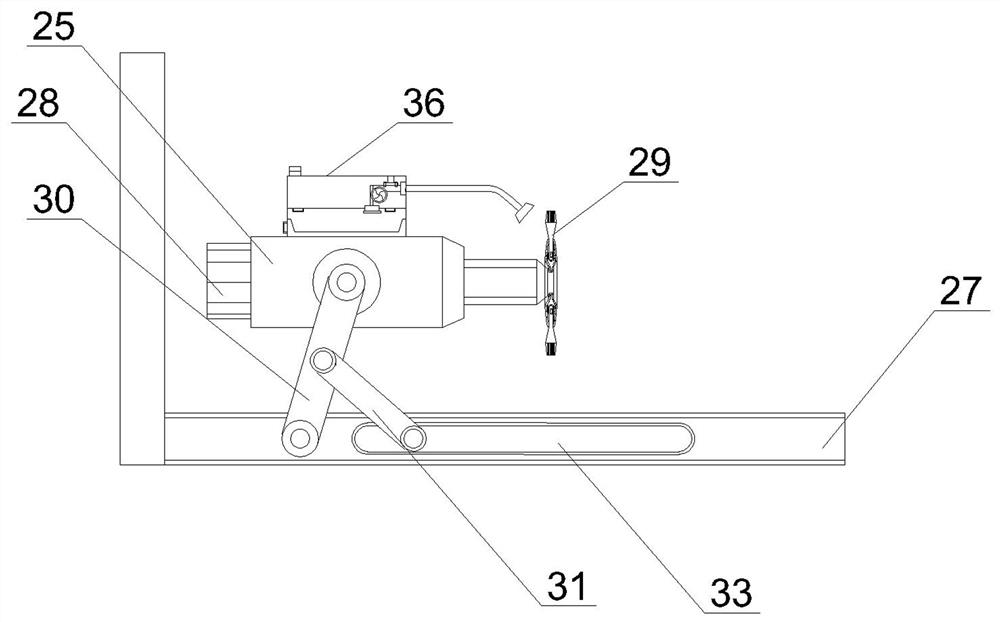

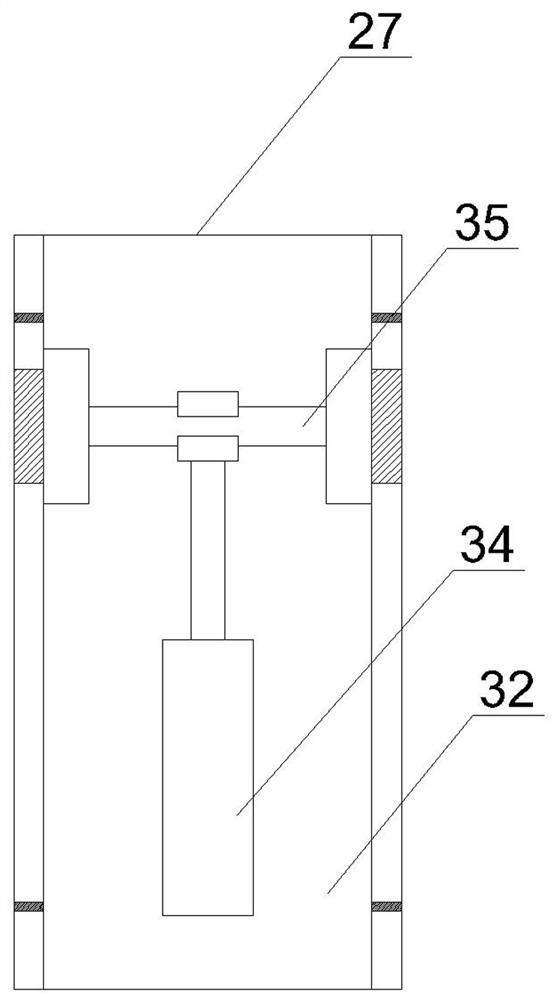

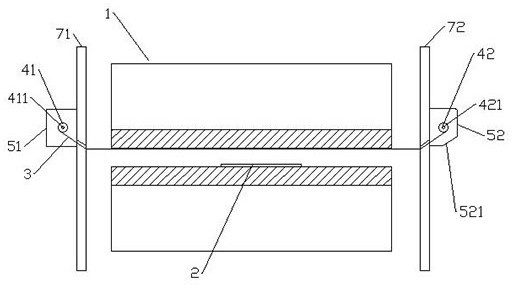

Tank bottom head automatic welding device and control method thereof

InactiveCN112570934AImprove work efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Electric machinery

The invention discloses a tank bottom head automatic welding device and a control method thereof. The device comprises a main support playing a supporting role, the main support comprises a base, a sliding rod perpendicular to the base is arranged on the base, a control cabinet is arranged at the left side of the sliding rod, a welding bracket is connected to the sliding rod in a sliding mode, a welding device is arranged on the welding bracket, a welding slag cleaner is arranged below the welding bracket, a plastic tank is arranged at the right side of the welding device, an up-down adjustingdriving motor is arranged at the top of the sliding rod, and a control end of the welding device, a control end of the welding slag cleaner and a control end of the up-down adjusting driving motor are separately and electrically connected with the control cabinet. According to the device and the method, the problems that in the prior art, when the traditional welding device for welding a barrel and a bottom head is used, the pressure applied by a welding gun is insufficient, the welding speed is not uniform, and the welding slag treatment process is time-consuming after welding are solved. According to the device and the method, advantages of short operation time, low operation cost, high operation efficiency, high overall gains for customers and the like are achieved.

Owner:HANGZHOU ZHONGHUAN CHEM EQUIP +1

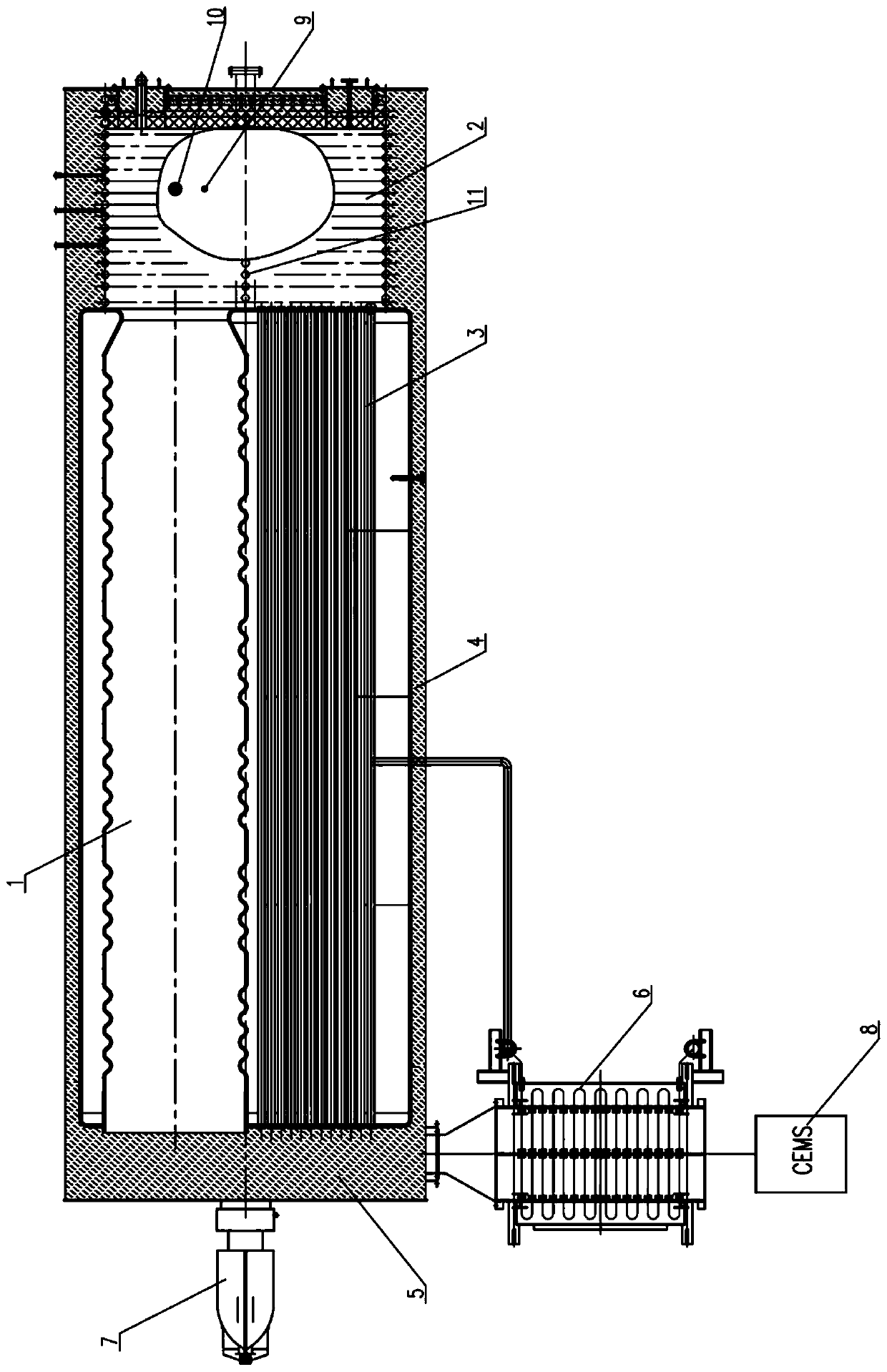

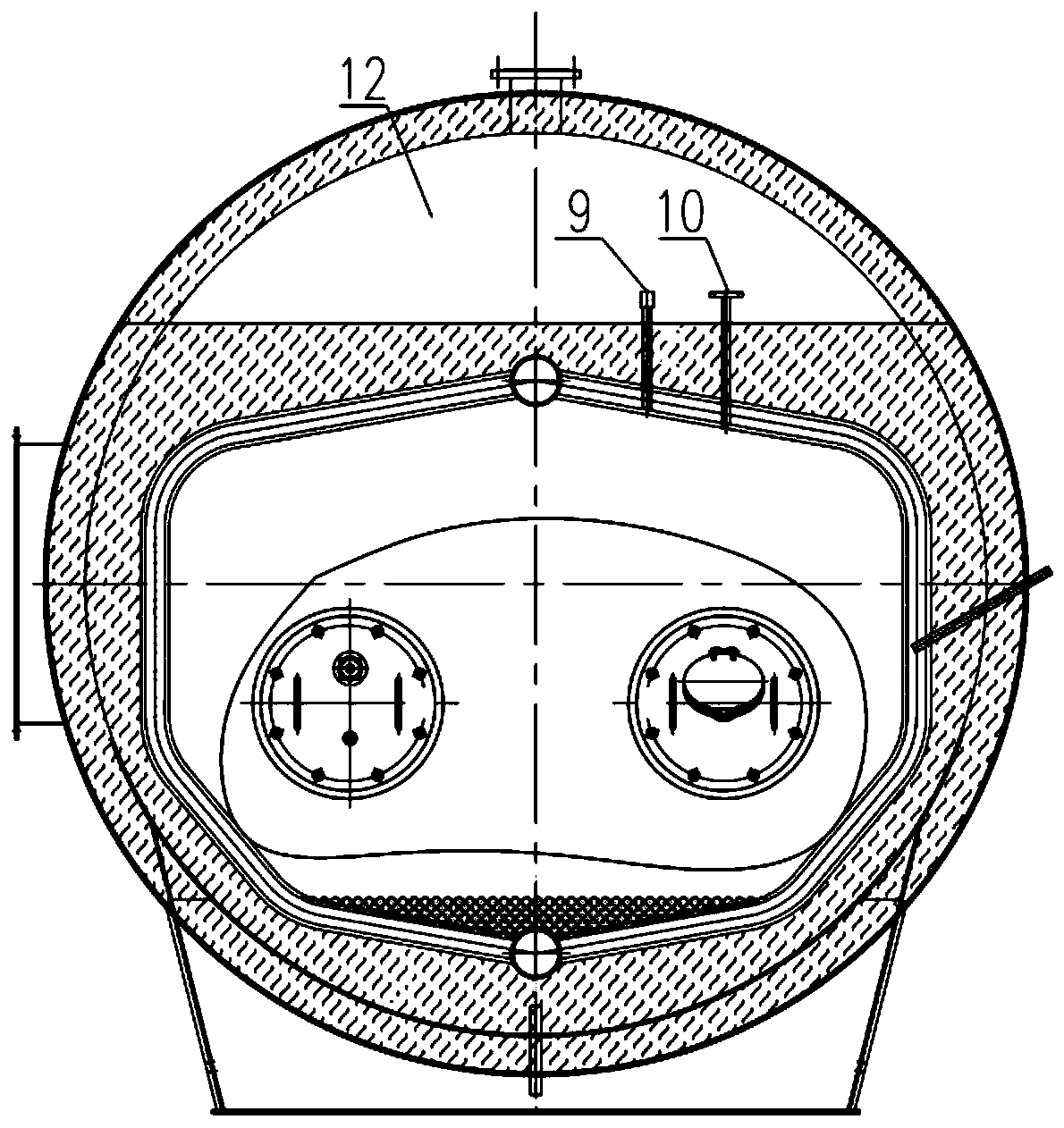

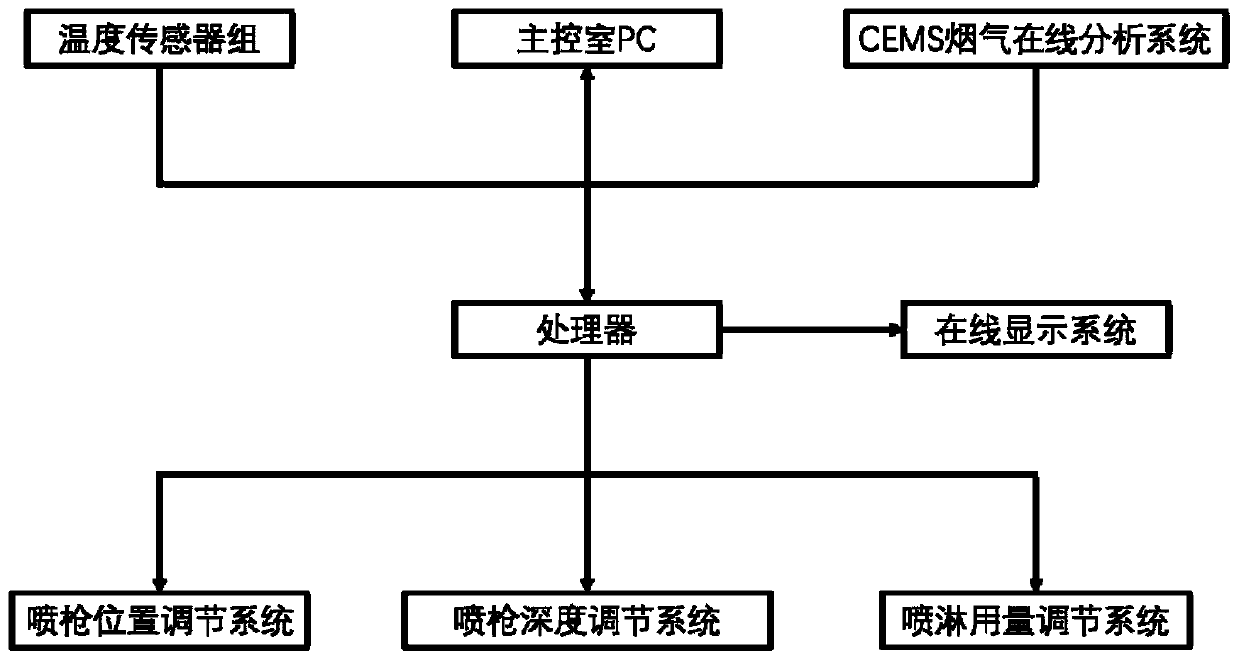

Low-nitrogen shell boiler

PendingCN110748905AGuaranteed to workImprove denitrification efficiencyEmission preventionChimneysThermodynamicsCombustor

The invention discloses a low-nitrogen shell boiler which is mainly composed of a furnace pipe, a smoke transfer chamber, a smoke pipe, a boiler shell, a front smoke box, an economizer, a combustor, aCEMS smoke online monitoring system, a denitration temperature measuring point and a denitration reducing agent jetting device. The furnace pipe and the smoke pipe are transversely arranged in the boiler shell. The smoke transfer chamber is arranged at the rear portion of the boiler shell. A film type wall structure is adopted for the smoke transfer chamber to form a diversion film type wall andcommunicates with the furnace pipe so that after fuel is completely combusted in the furnace pipe, generated smoke enters the smoke transfer chamber. The low-nitrogen shell boiler has the beneficial effects that the smoke transfer chamber with the large volume is arranged at the rear portion of the boiler, and the film type wall structure is adopted for the smoke transfer chamber; a temperature sensor and the denitration reducing agent jetting device are arranged in the boiler smoke transfer chamber; due to detection of the temperature of smoke, it can be ensured that a denitration reducing agent can work in the best temperature interval, and the denitration efficiency is improved; and the diversion film type wall is arranged in the boiler smoke transfer chamber, the process is prolonged,sufficient and effective contact and mixing of the denitration reducing agent and the smoke can be ensured, and the denitration efficiency is improved.

Owner:杭州华源前线能源设备有限公司

Portable intestinal juice circulation feedback system and method

The invention discloses a portable intestinal juice circulation feedback system and method. The system comprises a device body, a peristaltic pump, a micro inflator pump and a controller are respectively arranged on the inner side of the device body, hoses are arranged at the two ends of the peristaltic pump, a pumping-out end pressure sensor is arranged on the surface, close to the pumping-out end, of the hose, a component analyzer is arranged at the side end of the pump-out end pressure sensor, an input end fixator is arranged at the tail end of the hose and comprises a mushroom-shaped fixator, a first reverse buckle, a first disc-shaped fixator and an abdominal wall guiding puncher, and a negative pressure suction end fixator is arranged at the other end of the hose. The portable intestinal juice circulation feedback system is convenient for a patient to carry, the problems of intestinal juice loss and nutrient substance loss of the patient can be solved, and the life quality of thepatient can be improved.

Owner:武汉瑞麟医疗科技有限公司

Electrified automatic gas supplementing device for SF6 equipment

PendingCN112325153AFlexible assemblyShorten the timeContainer filling methodsPressure vesselsGas cylinderProcess engineering

The invention discloses an electrified automatic gas supplementing device for SF6 equipment, belongs to the technical field of electrician equipment maintenance, and is used for moving a gas cylinderto supplement gas. The electrified automatic gas supplementing device comprises a frame body, a gas supplementing device, a crawler belt mechanism, a power supply with a handle and a control panel. Byarranging an interlayer A for inserting the power supply, an interlayer B for placing the bottom of the gas cylinder, a bandage for flexibly fixing the middle part of the gas cylinder and an interlayer C for placing the gas supplementing device on the frame body, a worker can flexibly assemble the power supply, the gas cylinder and the gas supplementing device, so that the time consumed by early-stage preparation of emergency operation is reduced; and the crawler belt mechanism and ladder climbing wheels are additionally arranged at the bottom of the frame body, manual pushing is replaced, the stair climbing function is achieved, and the technical problems that the worker moves an SF6 gas cylinder far away, moving is difficult, and the working intensity is high are solved.

Owner:广西桂林金秉航科技有限公司

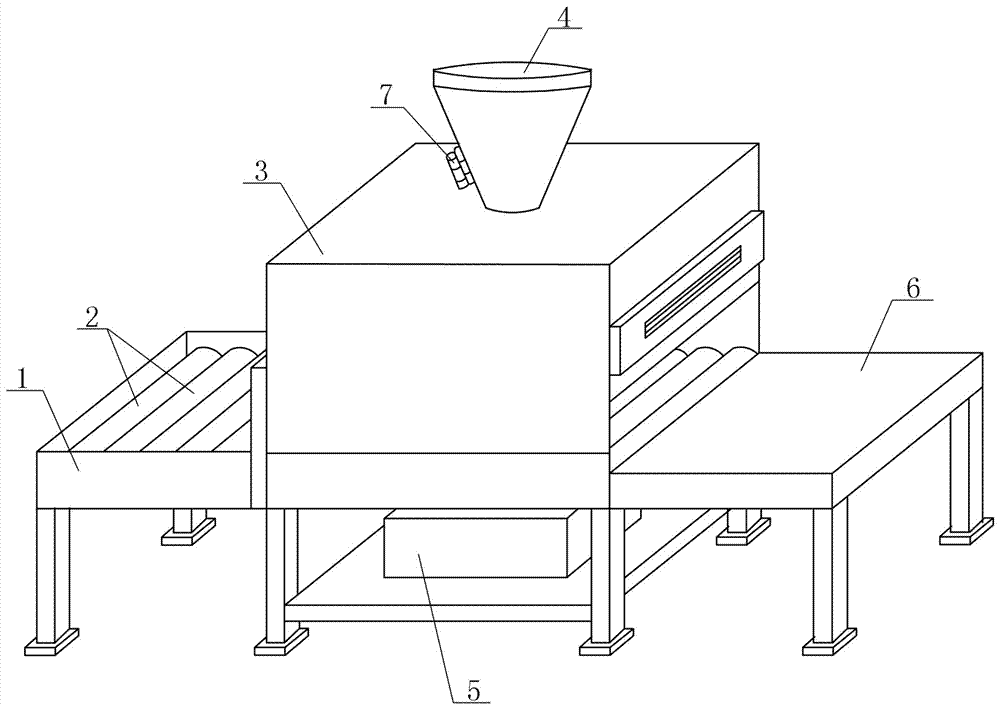

Sand blasting machine capable of preventing feeding inlet from blocking

InactiveCN107309812AMonitoring amountReal-time monitoring contentAbrasive machine appurtenancesAbrasive blasting machinesSand blastingWaste collection

A kind of anti-blocking sand blasting machine for material inlet, it includes a material discharge part, a sand blast part connected with the material discharge part, and a discharge part connected with the sand blast part, the material discharge part includes a material discharge platform, and There are material conveying rollers in the material table, the sandblasting part includes a sandblasting chamber, the top of the sandblasting chamber is provided with a feeding hopper, the bottom of the sandblasting chamber is provided with a waste collection box, the discharging part includes a discharge table, and the outer wall of the feeding hopper is set There is a micro-vibration motor, the micro-vibration motor is connected to the output port of the first main control chip, the input port of the first main control chip is connected to the monitoring module, the monitoring module is set inside the upper opening of the feeding hopper, and the first main control chip The output port is connected to the first communication module, the first communication module is connected to the second communication module, the second communication module is connected to the input port of the second main control chip, and the output port of the second main control chip is respectively connected to the alarm device and the display device connect. The invention can well monitor the loading condition of materials in the feed hopper, and effectively prevent blockage.

Owner:宜昌晶品玻璃制品有限公司

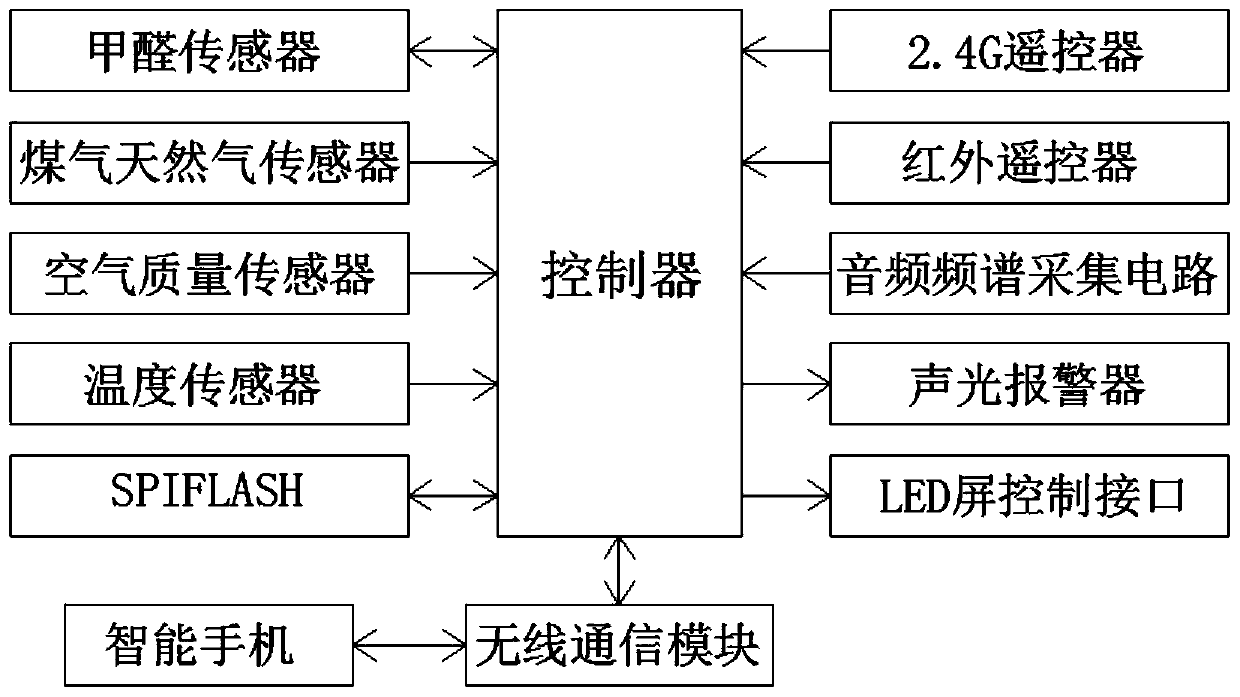

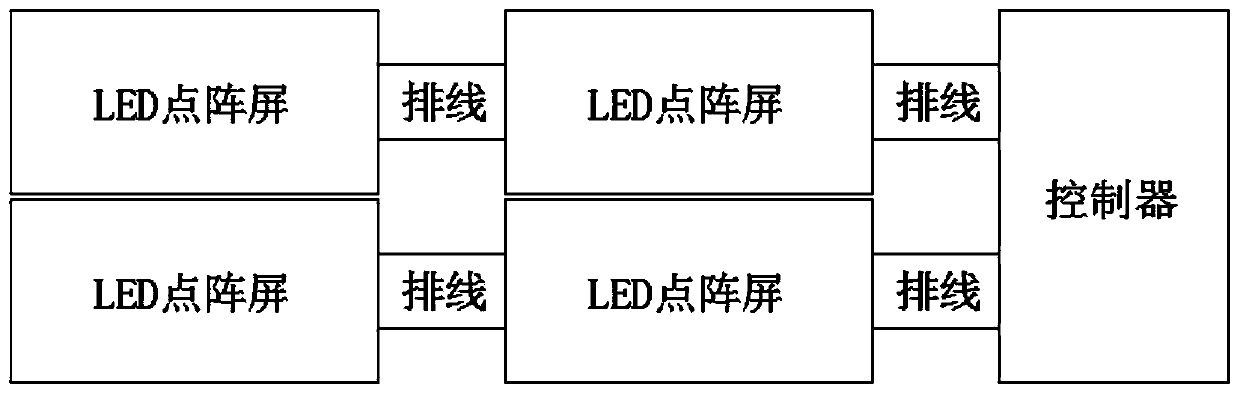

Multifunctional LED dot matrix display screen

PendingCN110120192ASolve the technical problem of single display functionReal-time monitoring contentMeasurement devicesStatic indicating devicesFast Fourier transformLED display

The invention discloses a multifunctional LED dot matrix display screen, relates to the technical field of LED dot matrix display screens, and solves the technical problem that an LED display screen in the prior art can only present a single static picture. The multifunctional LED dot matrix display screen comprises a control plate, a mounting frame, a LED dot matrix screen and a MCU, wherein theMCU is mounted on the control plate; the control plate is fixed in the mounting frame; the LED dot matrix screen is mounted on the mounting frame through bolts; and the control plate is integrated with an audio spectrum data acquiring circuit which is connected with the MCU through an AD (analog-digital) conversion interface. According to the multifunctional LED dot matrix display screen, the LEDdot matrix screen is used as a carrier, when music is played, the audio spectrum data acquiring circuit on the control panel acquires an audio signals, the MCU performs fast Fourier transform (FFT) processing on the audio signals, calculates the spectrum of audio and sends the spectrum to the LED dot matrix screen for display, so that the picture of the spectrum jumps along with the rhythm of themusic, and a user can experience the impact caused by the music audibly and visually.

Owner:沈德稳

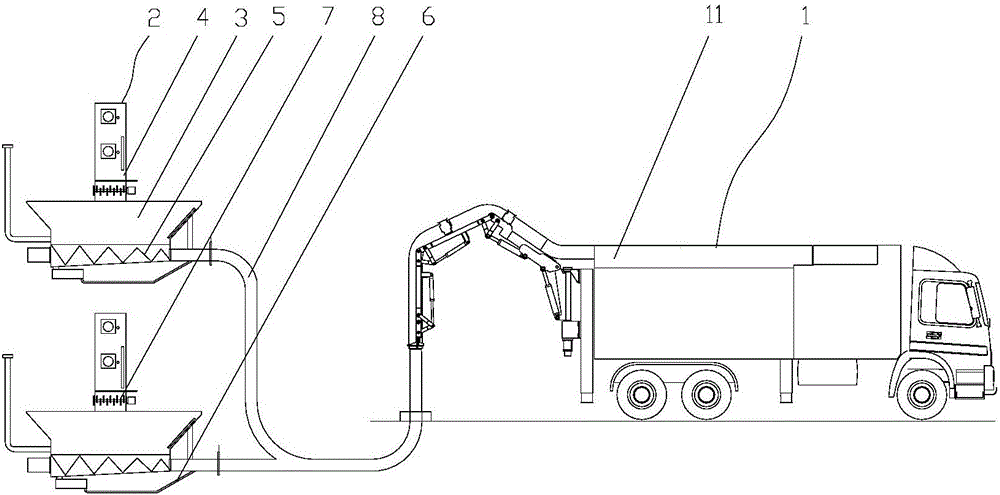

Classification and bin separation type garbage automatic collection system

InactiveCN107499796AEasy to sort and storeMake sure the suction speedWaste collection and transferRefuse receptaclesRefuse collectionCollection system

The invention relates to a classification and bin separation type garbage automatic collection system which comprises a control center, an air power suction car and two or more garbage collection devices. The control center is connected with the air power suction car and the garbage collection devices. Each garbage collection device comprises a garbage storage mechanism, three garbage throwing mechanisms and a suction pipe net. The three garbage throwing mechanisms of each garbage collection device are used for throwing and conveying recoverable garbage, unrecoverable garbage and other garbage to be judged correspondingly. Three storage bins correspondingly communicating with the corresponding three garbage throwing mechanisms are arranged on the upper portion of each garbage storage mechanism. A transition bin communicating with the corresponding three storage bins is arranged on the lower portion of each garbage storage mechanism. The air power suction car is provided with a suction arm, a recoverable bin, an unrecoverable bin, a bin for other garbage, vacuumizing equipment and deodorization equipment. The suction arm communicates with a spiral pushing mechanism of each garbage collection device through the corresponding suction pipe net.

Owner:福建海山机械股份有限公司

Low-concentration waste gas degassing conversion and high-concentration waste gas incineration recovery system and process

PendingCN112642273AAchieve recyclingAchieve enrichmentGas treatmentHydrogen sulfidesSpray towerExhaust gas

The invention discloses a low-concentration waste gas degassing conversion and high-concentration waste gas incineration recovery system and process. The system comprises a first-section reaction kettle, a second-section reaction kettle and at least one spray tower, an alkali liquor inlet and a waste gas inlet are formed in the top and the lower portion of each spray tower respectively, and a tail gas exhaust port is further formed in the top of each spray tower; the bottom of each spray tower is communicated with the top of the first-section reaction kettle through a pipeline, a circulating pump is arranged at the part, close to the spray tower, of the pipeline between each spray tower and the first-section reaction kettle, and the pipeline between each circulating pump and the first-section reaction kettle is communicated with the upper part of the corresponding spray tower through a return pipe; the bottom of the first-section reaction kettle is communicated with the top of the second-section reaction kettle through a pipeline, and the top of the first-section reaction kettle and the top of the second-section reaction kettle are respectively communicated with an incinerator through pipelines; and the top of the first-section reaction kettle and the top of the second-section reaction kettle are respectively provided with an acid liquor inlet and a waste gas outlet. Effective concentration of the low-concentration hydrogen sulfide gas is realized, so that recycling of the hydrogen sulfide gas is realized, and energy conservation and environmental protection are realized.

Owner:阿拉尔市中泰纺织科技有限公司 +1

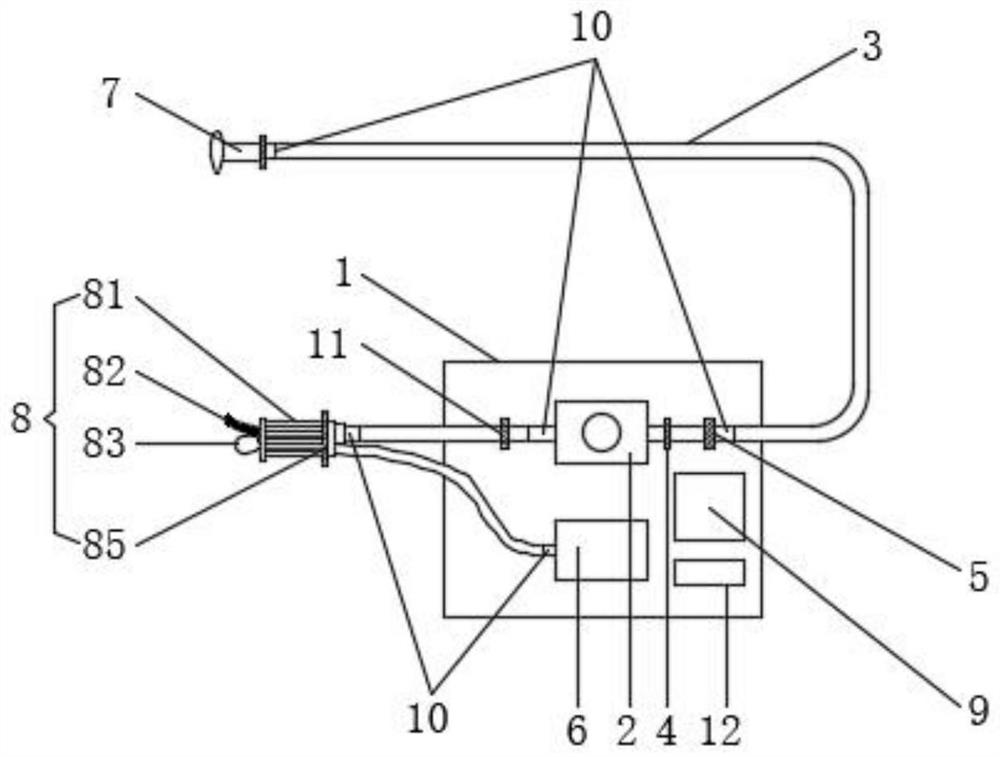

Combustion control system and control method for industrial furnace

ActiveCN103672948BReduce oxidation lossImprove energy savingFuel supply regulationControl systemProduct gas

The invention provides a combustion control system and method of an industrial furnace. The combustion control system of the industrial furnace comprises a laser spectrum detection device, a combustion control device, an oxidation burning loss detection device, a comparison device and a computing device, wherein the laser spectrum detection device is used for detecting the content of gas in the industrial furnace, the laser spectrum detection device comprises a laser, a detector and an analysis module, the combustion control device is used for optimizing and adjusting the combustion conditions in the industrial furnace according to data transmitted by the laser spectrum detection device, the oxidation burning loss detection device is used for detecting oxidation burning loss of workpieces which pass through the industrial furnace, and transmitting the detection result to the comparison device, the comparison device is used for obtaining the comparison result according to the received detection result and the original oxidation burning loss conditions, and transmitting the comparison result to the computing device, and the computing device is used for obtaining the combustion control result of the industrial furnace according to the received comparison result. The combustion control system and method of the industrial furnace have the advantages that detection accuracy is high, the detection speed is high, the cost is low, and energy is saved.

Owner:FOCUSED PHOTONICS

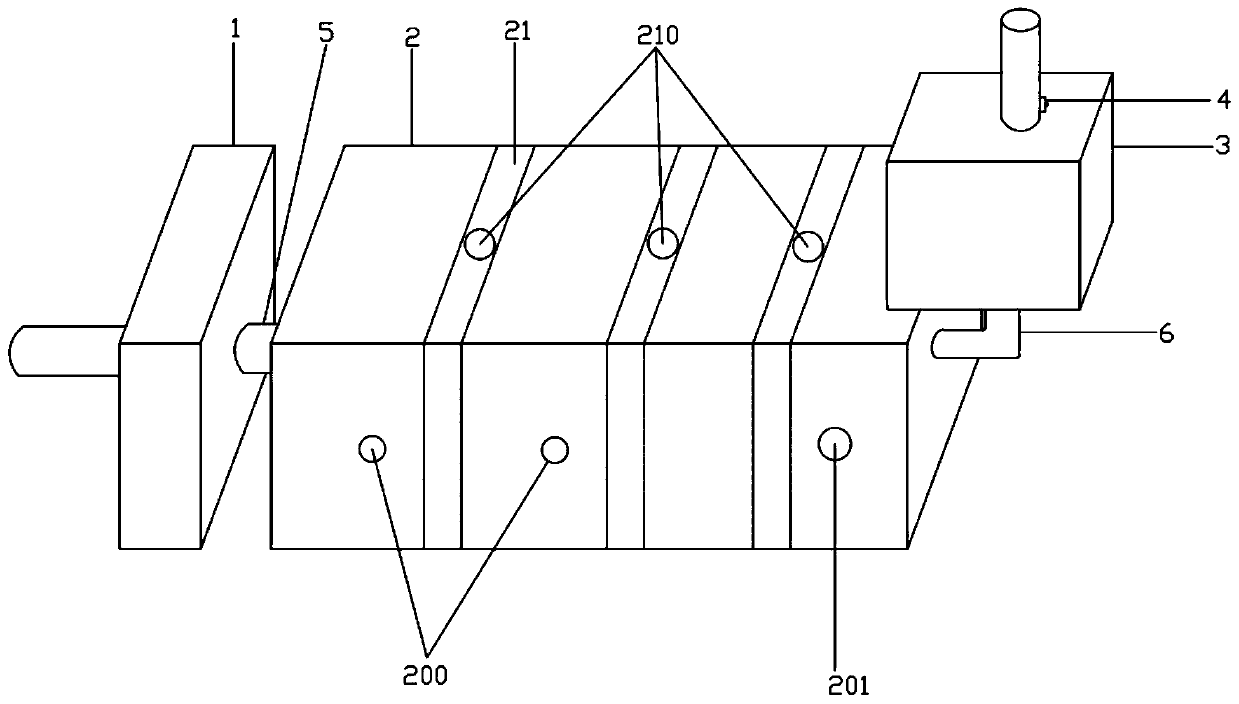

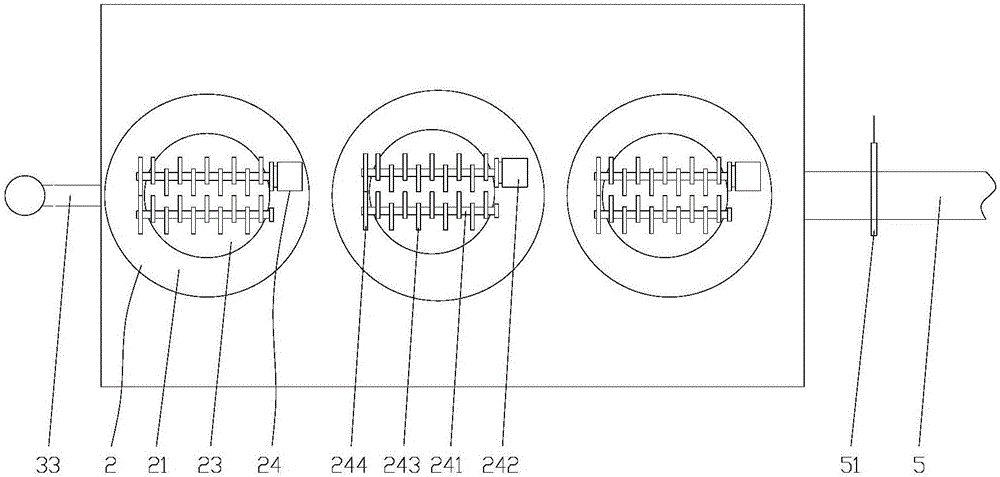

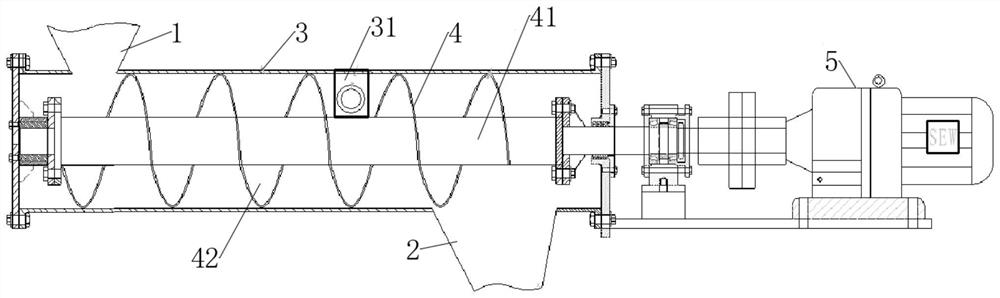

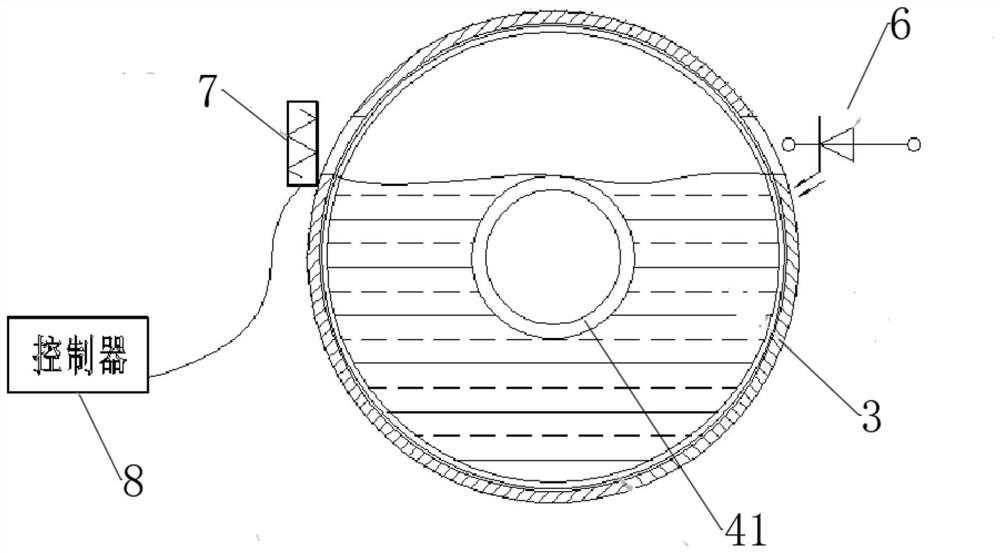

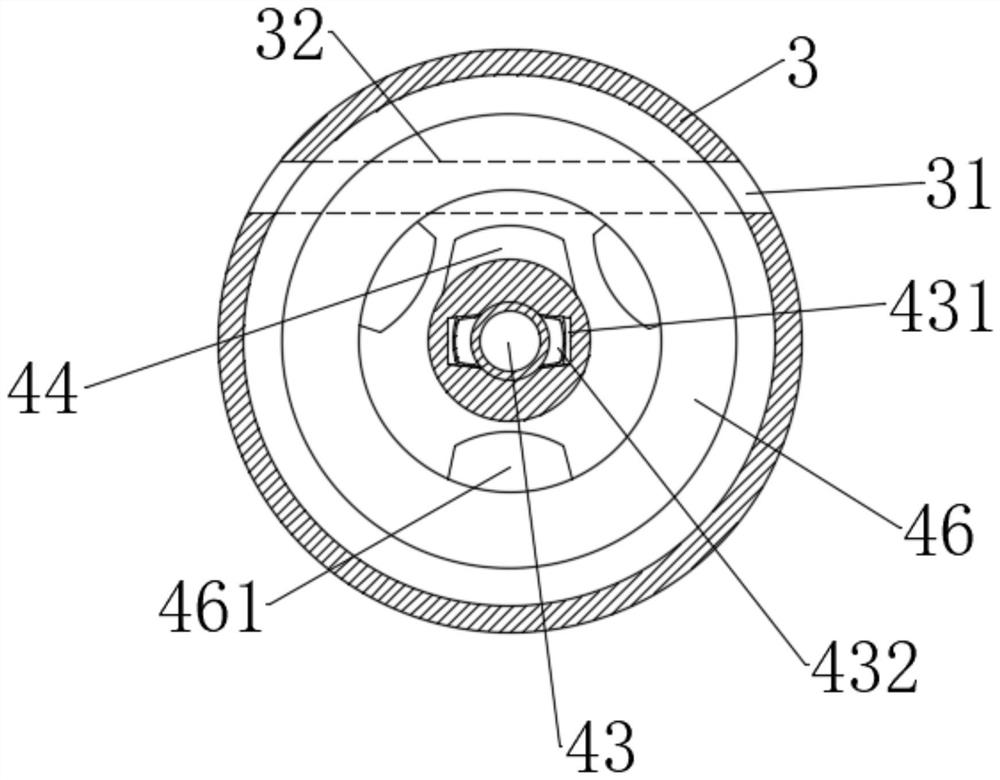

Powder conveyer device for circular pipe conveying reamer

ActiveCN113928827AReal-time monitoring contentReal-time control of delivery volumeCleaningControl devices for conveyorsStructural engineeringPipe

The invention discloses a powder conveyer device of a circular pipe conveying reamer. The powder conveyer device comprises a circular pipe conveying reamer shell, reamer blades arranged in the circular pipe conveying reamer shell, a circular pipe feeding port and a circular pipe outlet which are formed in the side walls of the two ends of the circular pipe conveying reamer shell separately. According to the powder conveyer device, the content of gypsum powder can be monitored in real time through a monitoring mechanism, and therefore the conveying amount of the gypsum powder is controlled in real time; during specific implementation, the reamer blades are driven by a transmission speed reducer to rotate in the circular pipe conveying reamer shell so that the gypsum powder is moved from the circular pipe feeding port to the circular pipe outlet according to the set content; in the process, the content of the gypsum powder in the circular pipe conveying reamer shell can be monitored through the monitoring mechanism in real time; and if the monitoring mechanism monitors that the content of the gypsum powder is lower than the set content of the gypsum powder in real time, a PLC can perform warning action to prompt persons on post to timely check whether a major fault occurs to the circular pipe conveying reamer or not.

Owner:湖北北新建材有限公司

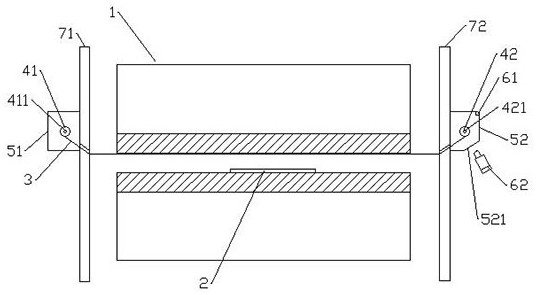

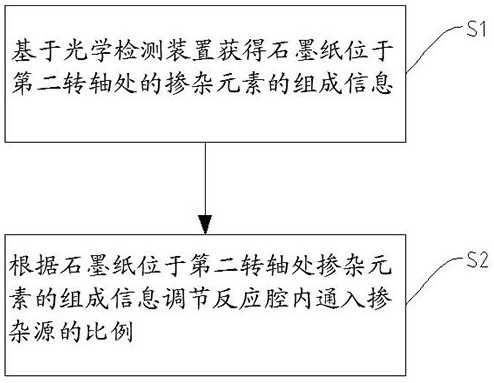

Reaction cavity inner surface protection device and epitaxial reaction monitoring device and method

ActiveCN114507900AReal-time monitoring contentImprove growth yieldPolycrystalline material growthFinal product manufactureGraphiteMechanical engineering

The invention relates to the field of semiconductor manufacturing, in particular to a reaction cavity inner surface protection device and an epitaxial reaction monitoring device and method.The reaction cavity inner surface protection device is used for protecting the inner surface of a reaction cavity of epitaxial equipment, and the reaction cavity inner surface protection device comprises graphite paper, a first rotating shaft and a second rotating shaft; the first rotating shaft and the second rotating shaft are mounted at the air inlet end and the air outlet end of the reaction cavity respectively, the first rotating shaft and the second rotating shaft are sleeved with the two ends of the graphite paper respectively, and the graphite paper is provided with a horizontal section at the inner top of the reaction cavity; the graphite paper can be horizontally conveyed on the inner top of the reaction cavity in the single direction under the rotation action of the first rotating shaft and the second rotating shaft, the protection device is arranged on the inner surface of the reaction cavity, the graphite paper continuously works to take away crystals on the graphite paper, the crystals are prevented from falling on a substrate, and the inner surface of the reaction cavity does not need to be frequently cleaned.

Owner:JIHUA LAB

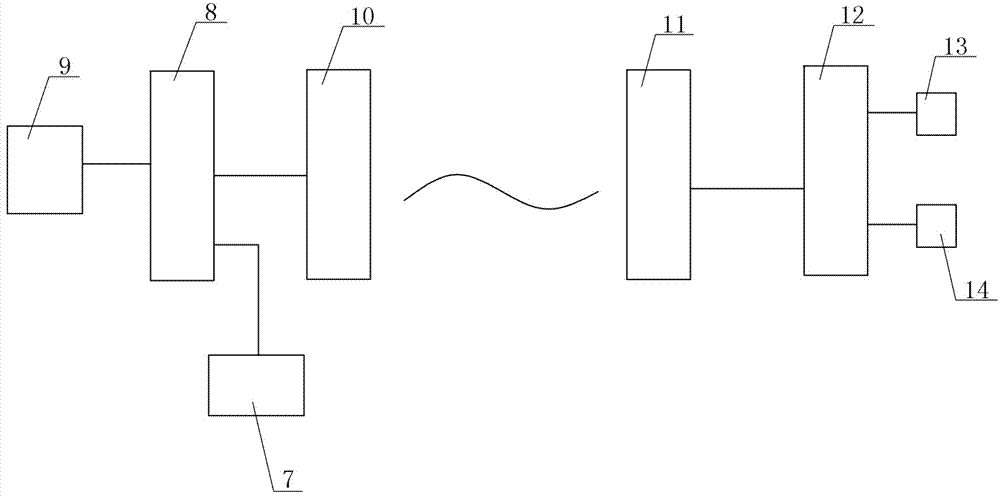

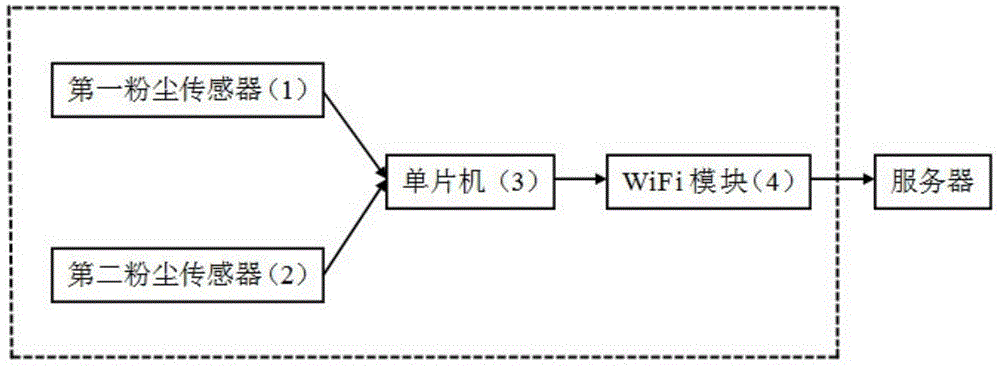

High-accuracy dust monitoring apparatus

InactiveCN105547938AReal-time monitoring contentGet value in real timeTransmission systemsParticle suspension analysisMicrocontrollerDust particles

The present invention discloses a high-accuracy dust monitoring apparatus, which comprises: a first dust sensor (1) and a second dust sensor (2), wherein the first dust sensor (1) and the second dust sensor (2) are respectively used for obtaining dust particles with a particle size of more than 1 [mu]m and a particle size of more than 2.5 [mu]m; a microcontroller (3) respectively connected to the first dust sensor (1) and the second dust sensor (2); and a WiFi module (4) connected to the microcontroller (3) and used for receiving data processed by the microcontroller (3) and transmitting to a server through a network.

Owner:XIAN MECENT PURIFICATION TECH

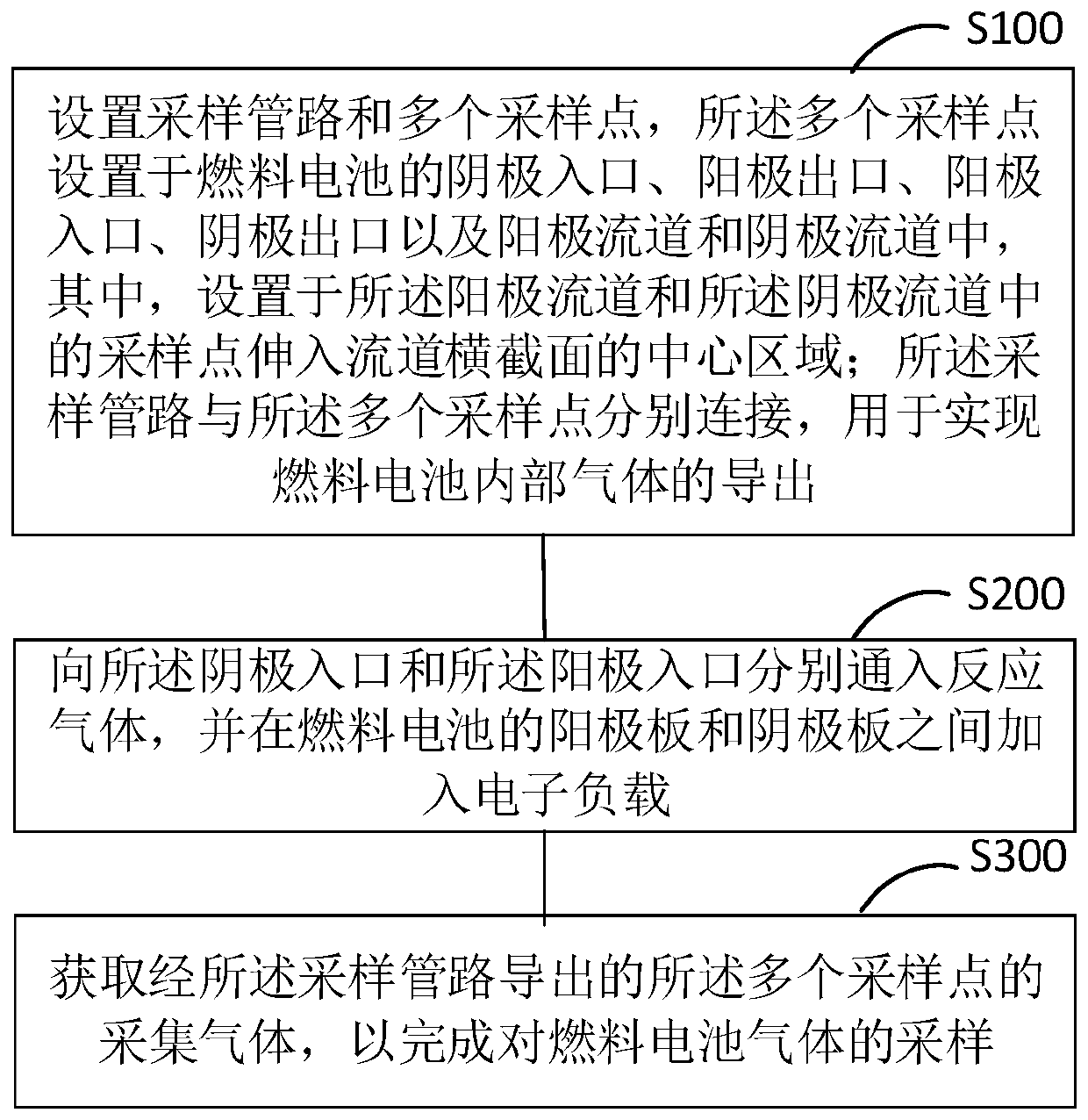

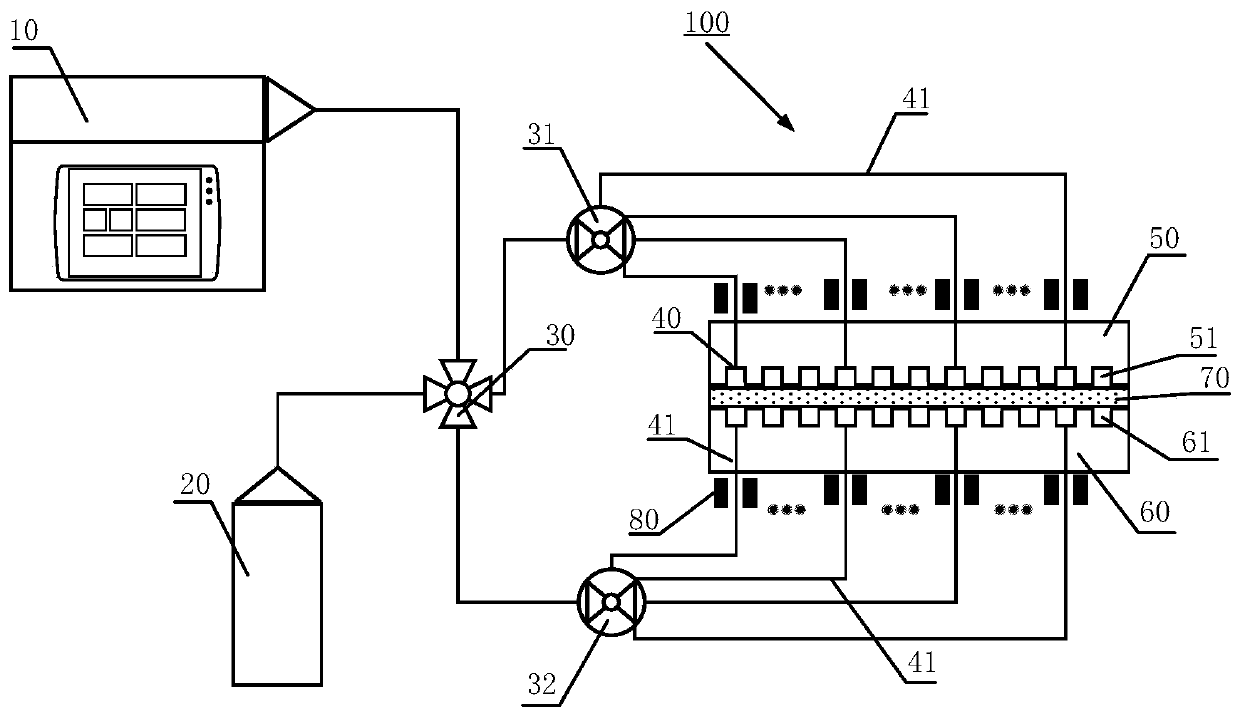

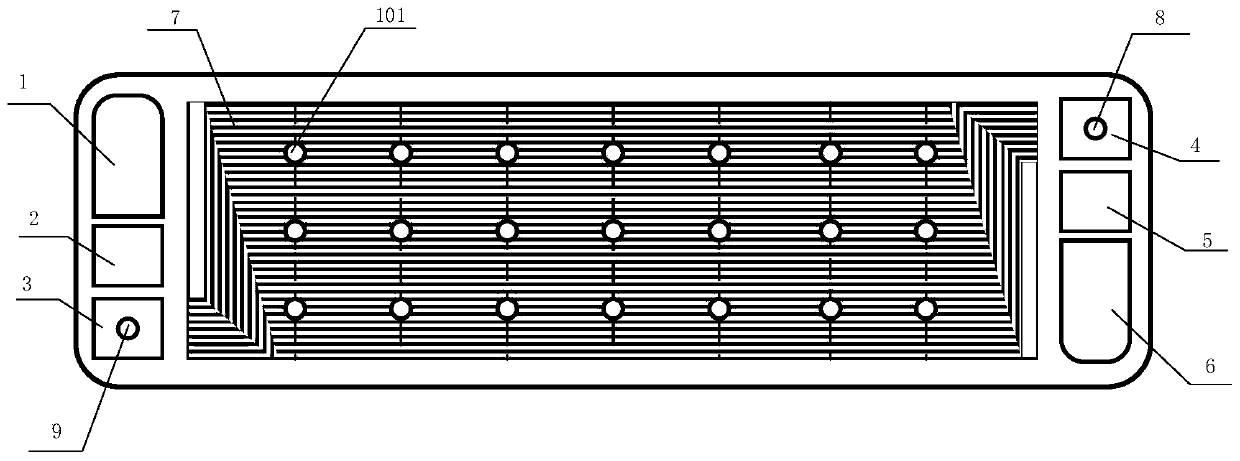

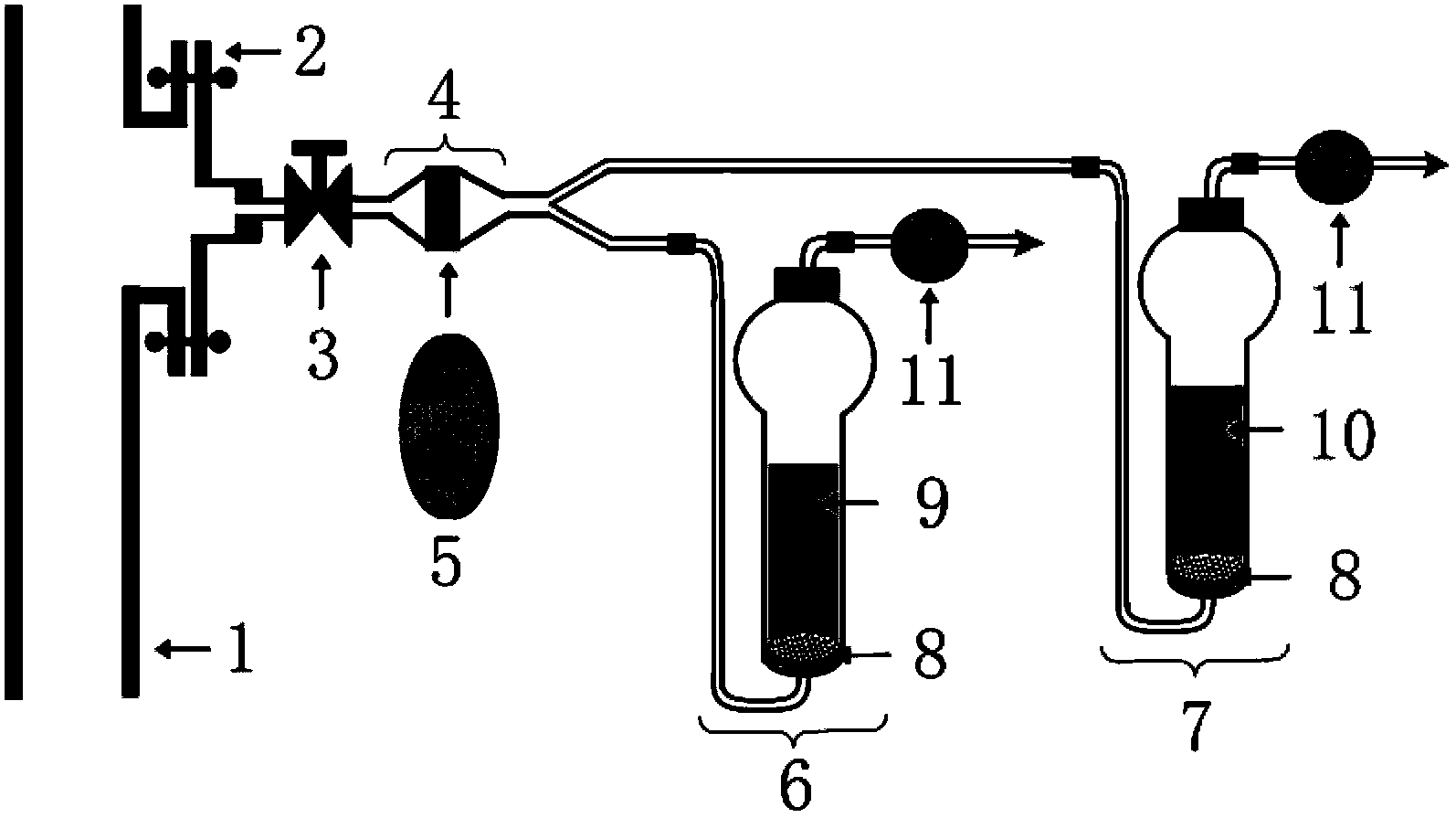

Fuel cell gas sampling system and sampling method

ActiveCN109802159BSafe and reliable working conditionsGuarantee job securitySamplingFuel cellsThermodynamicsFuel cells

The present invention belongs to the field of fuel cell technologies and relates to a fuel cell gas sampling system and a sampling method. In the fuel cell gas sampling method, a plurality of samplingpoints are set to acquire sampling gases at different positions in a fuel cell respectively, and therefore, the sampling of the gases at a plurality of points inside the fuel cell can be realized, and gas content at the different positions inside the fuel cell can be monitored in real time; and the plurality of sampling points extend into the central regions of the cross sections of an anode flowchannel and a cathode flow channel so as to accurately obtain gases flowing through the flow channels. The plurality of sampling points are arranged in the flow channels of the anode plate and cathode plate of the fuel cell, so as to obtain the sampling gases at each point; and the analysis of the gas content and concentration can help the fuel cell to obtain safer and more reliable working conditions, and is beneficial for ensuring the working safety and service life of the fuel cell and ensuring the utilization rate of the fuel cell.

Owner:TSINGHUA UNIV

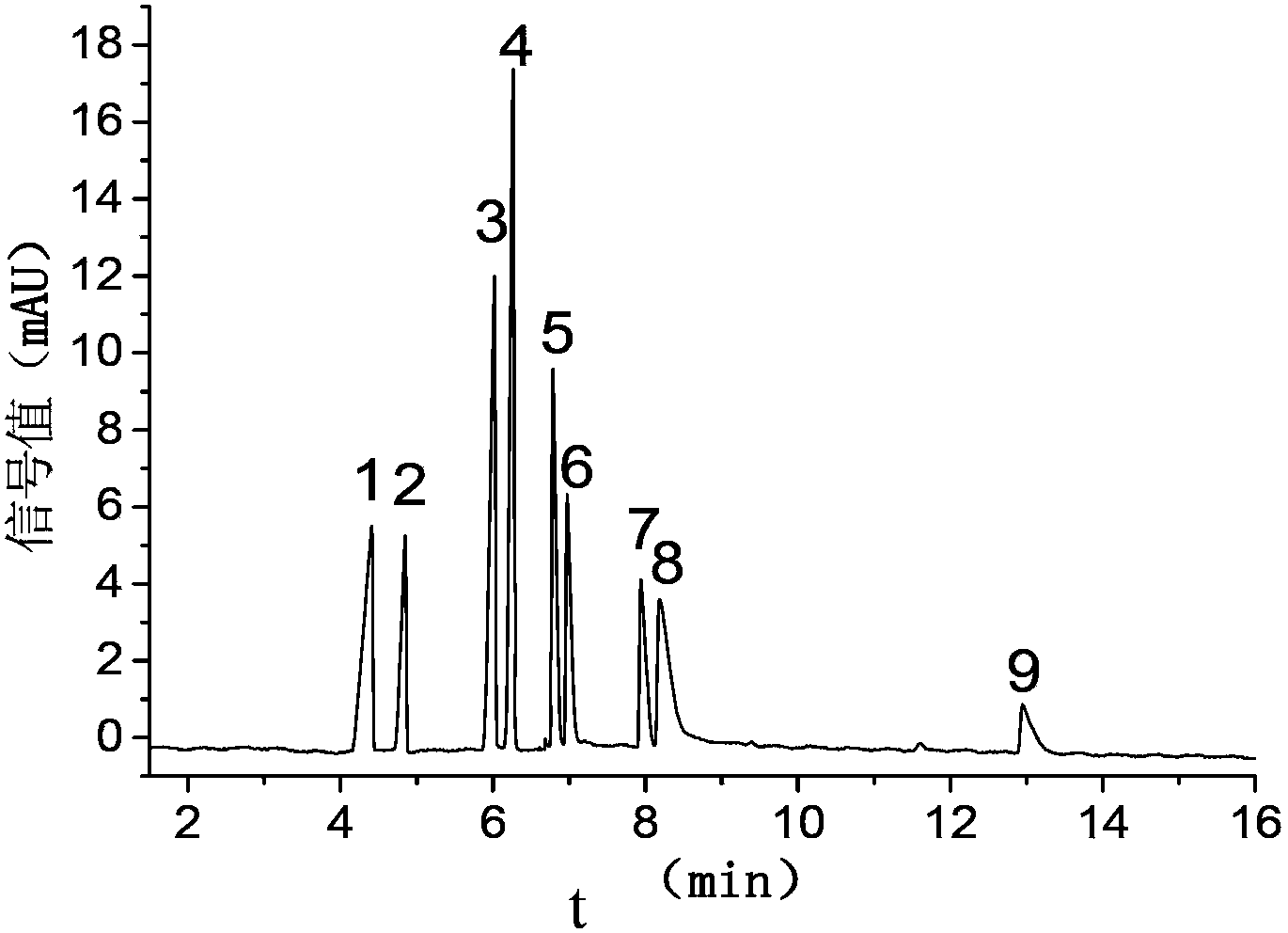

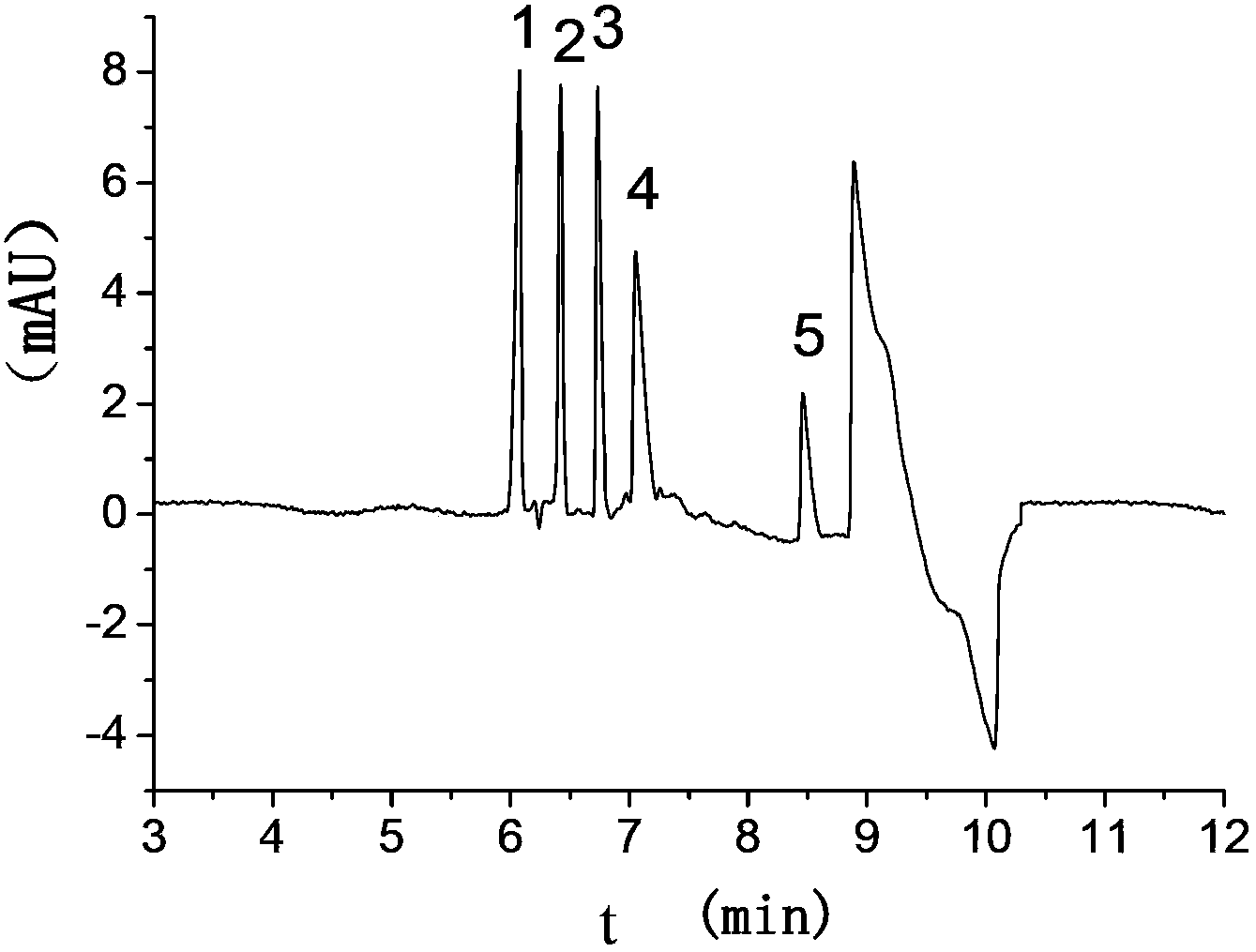

Method for determination of inorganic element in fuel gas

ActiveCN102706949BQuick checkEasy to collectComponent separationMaterial analysis by electric/magnetic meansCapillary electrophoresisFuel gas

The invention provides a method for determination of inorganic element in fuel gas, comprising the following steps: sample collection: the fuel gas is divided into two parts so as to flow through cation absorption liquid and anion absorption liquid respectively after the fuel gas flows through a filter membrance; sample handling: the filter membrance is equally divided into two parts, one part of the filter membrance is dispelled by acid liquor, then the cation absorption liquid is added, and through metered volume and filtering, filtrate for cation analysis is obtained, and the other part of the filter membrance is extracted with water, then the anion absorption liquid is added into the extract liquor, and through metered volume and filtering, filtrate for anion analysis is obtained; sample analysis: above filtrates are respectively subsjected to capillary electrophoresis test, and then data is treated. According to the method and the device provided by the invention, the defects of low efficiency, long consuming time, higher analytical cost and difficult in popularizing in traditional method are overcame. The aim to quick test multiple inorganic elements is realized, the operation cost is lower, the operation is simple, and the method is convenient to popularize.

Owner:TSINGHUA UNIV

A kind of laver cake production equipment

ActiveCN109259274BJudging the degree of cleaningAvoid stickingFood treatmentElectric machineryProcess engineering

The invention relates to the technical field of agricultural product processing equipment, and discloses a laver cake production device comprising a machine frame. A lifting mechanism, a cleaning mechanism and a drying mechanism are disposed in the machine frame from top to bottom. The lifting mechanism is connected with a first motor, a turntable is fixedly mounted on an output shaft of the firstmotor, a connecting rod is hinged to the turntable, and a storage box is connected to the connecting rod. The drying mechanism includes an open barrel body, a first partition plate and a second partition plate are disposed in the barrel body, the upper surface of the second partition plate is provided with a plurality of fans, a heating box is disposed below the second partition plate, an electric heating plate is arranged in the heating box, the heating box is further provided with a plurality of air outlet nozzles, and each air outlet nozzle is located under the fan. During use, laver is placed in the storage box, the laver is cleaned and dehydrated through mutual cooperation of the lifting mechanism, the first motor, the turntable and the connecting rod, and the laver is dried finallyunder the action of the drying mechanism.

Owner:象山锦绣升平食品有限公司

Automatic garbage collection system

InactiveCN107352199AEasy to classify and storeReduce frictional resistanceRefuse receptaclesCollection systemVacuum pumping

The invention relates to an automatic garbage collection system. The automatic garbage collection system comprises a control center, an aerodynamic suction vehicle and more than two garbage collection devices. The control center is in communication connection with the aerodynamic suction vehicle and the garbage collection devices; each garbage collection device comprises a garbage storage mechanism and three garbage putting mechanisms; the three garbage putting mechanisms are respectively used for putting and conveying recyclable garbage, unrecyclable garbage and other garbage to be determined; the upper part of the garbage storage mechanism is provided with three storage bins which are correspondingly communicated with the three garbage putting mechanisms respectively; the lower part of the garbage storage mechanism is provided with transition bins which are communicated with the three storage bins respectively; the interior of each transition bin is provided with a bag breaking mechanism, and the bottom of the garbage storage mechanism is provided with a spiral pushing mechanism; the aerodynamic suction vehicle is provided with a collection bin, a vacuum-pumping device and a deodorizing device; the collection bin is communicated with the spiral pushing mechanism of each garbage collection device through a suction pipe network; and the aerodynamic suction vehicle sucks and transfers garbage by forming negative pressure in the suction pipe network.

Owner:福建海山机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com