Low-nitrogen shell boiler

A boiler shell and boiler technology, which is applied in the field of boilers, can solve the problems of reducing nitrogen oxide emissions, unable to significantly reduce nitrogen oxide emissions, etc., and achieves the effect of prolonging the process, improving the denitration efficiency, and improving the denitration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the drawings:

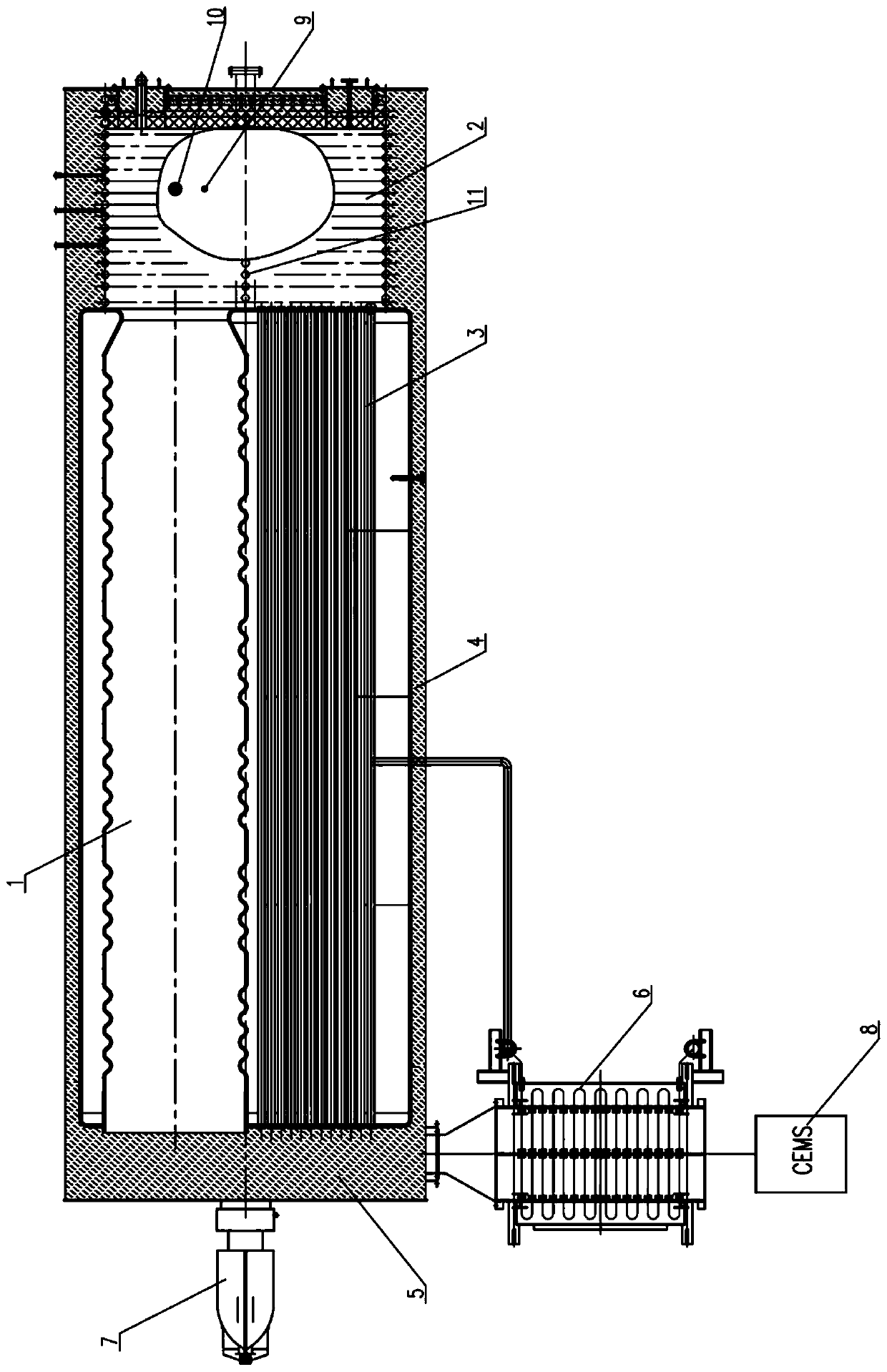

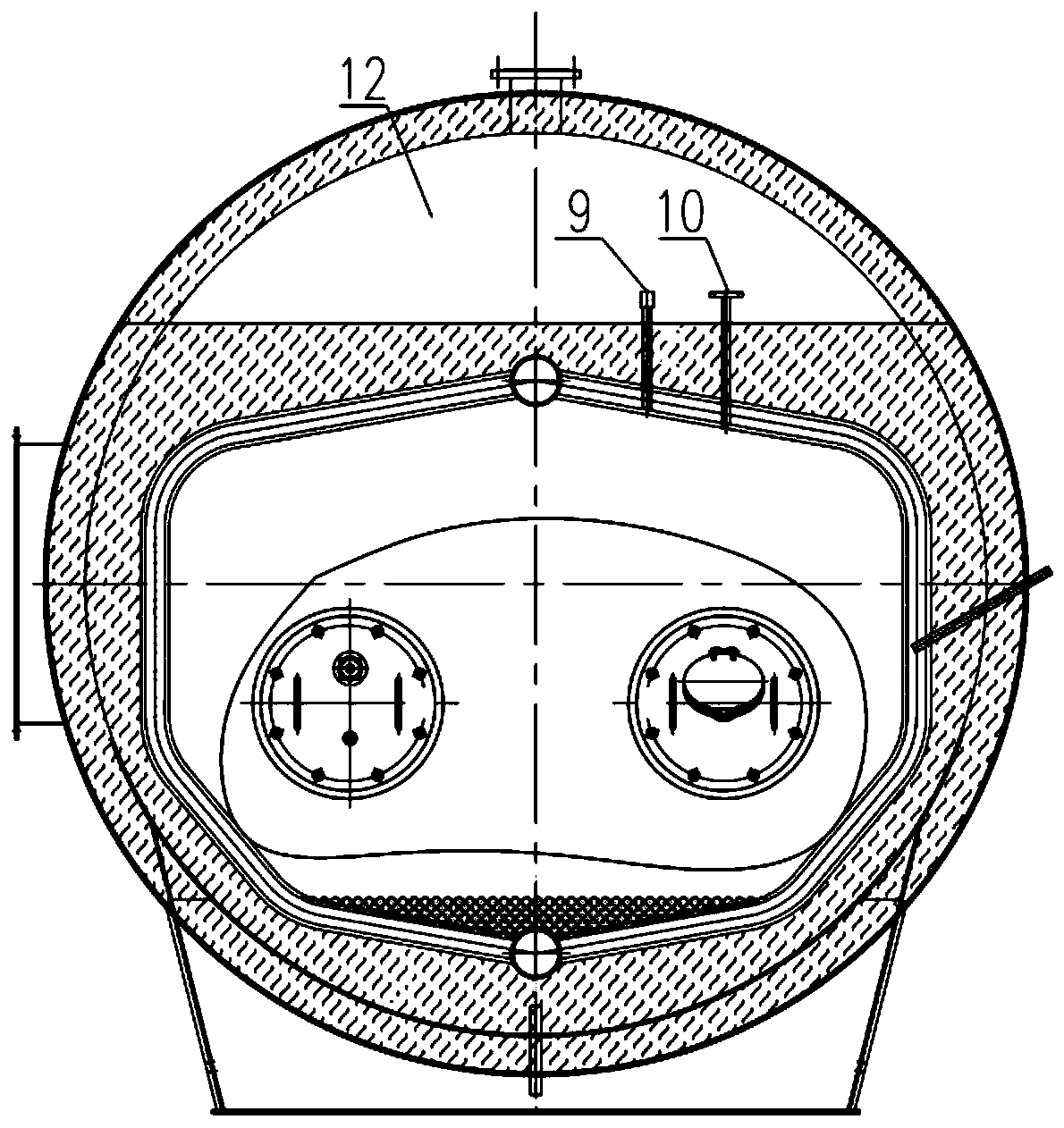

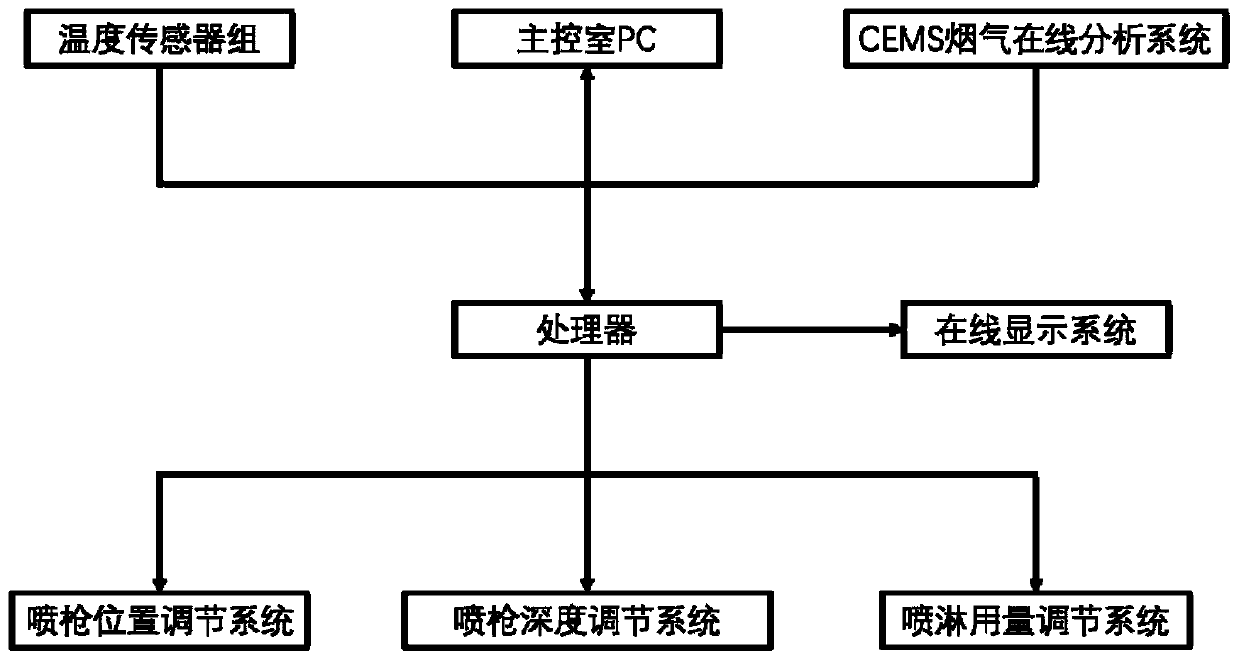

[0023] Such as Figure 1-2 As shown, a low-nitrogen shell-type boiler mainly includes the furnace liner 1, the smoke transfer chamber 2, the smoke pipe 3, the boiler shell 4, the front smoke box 5, the economizer 6, the burner 7, and CEMS flue gas online monitoring System 8. Denitration temperature measuring point 9 and denitration reducing agent injection device 10. The boiler shell 4 is provided with a furnace 1 and a smoke pipe 3 horizontally. The rear part of the boiler shell 4 is provided with a smoke transfer chamber 2, and the smoke transfer chamber 2 adopts a membrane The type wall structure forms a diversion membrane wall 11 and communicates with the furnace liner 1 so that the smoke generated after the fuel is completely burned in the furnace liner 1 enters the smoke transfer chamber 2; the smoke transfer chamber 2 is provided with a temperature sensor A denitration tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com