Sand blasting machine capable of preventing feeding inlet from blocking

An anti-blocking and sandblasting machine technology, applied in the field of sandblasting machines, can solve problems such as affecting glass processing, equipment damage, and clogging of feeding hoppers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

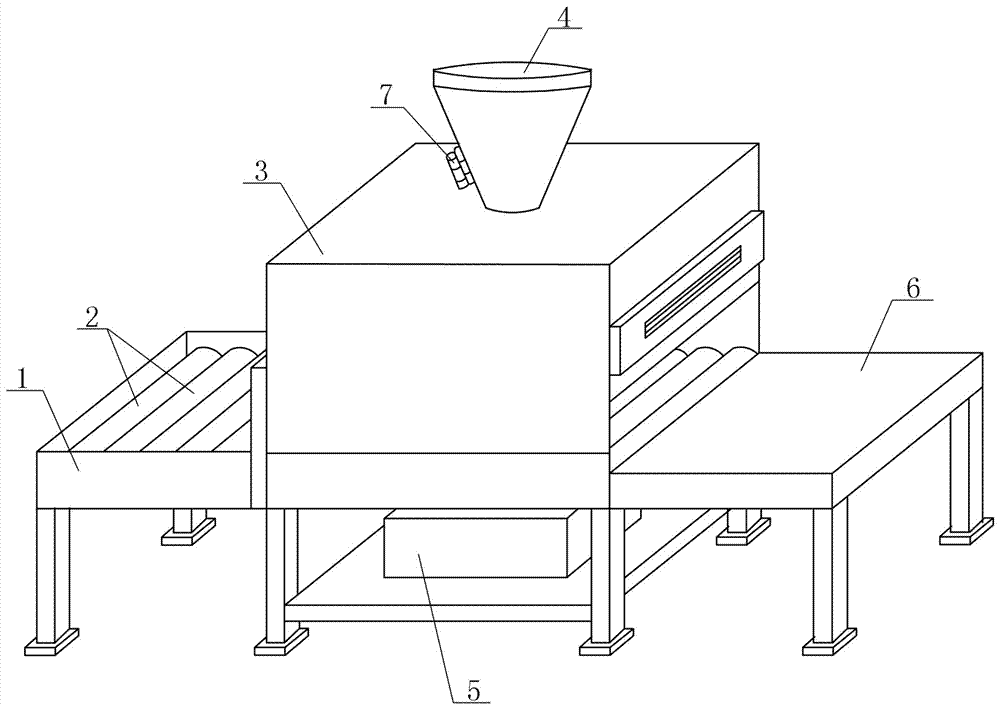

[0018] like figure 1 The shown sandblasting machine with an anti-blocking feeding port includes a discharging part, a sandblasting part connected with the discharging part, and a discharging part connected with the sandblasting part, and the discharging part includes a discharging table 1, A material conveying roller 2 is arranged in the discharging table 1, the sandblasting part includes a sandblasting chamber 3, a feeding hopper 4 is arranged on the top of the sandblasting chamber 3, a waste collection box 5 is arranged under the sandblasting chamber 3, and the discharging part includes an outlet. The feeding table 6 is provided with a micro vibration motor 7 on the outer wall of the feeding hopper 4;

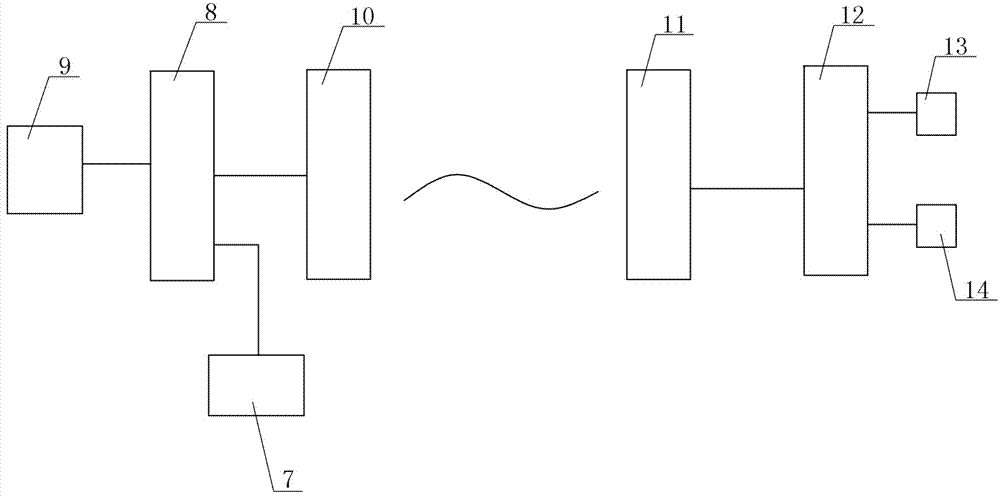

[0019] like figure 2 As shown, the micro vibration motor 7 is connected with the output port of the first main control chip 8, and the input port of the first main control chip 8 is connected with the monitoring module 9. The output port of the main control chip 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com