Method for determining taurine content in solution and method for purifying taurine

A technology of taurine and solution, applied in the field of purifying taurine, can solve problems such as weak anti-interference ability, unsuitable for industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

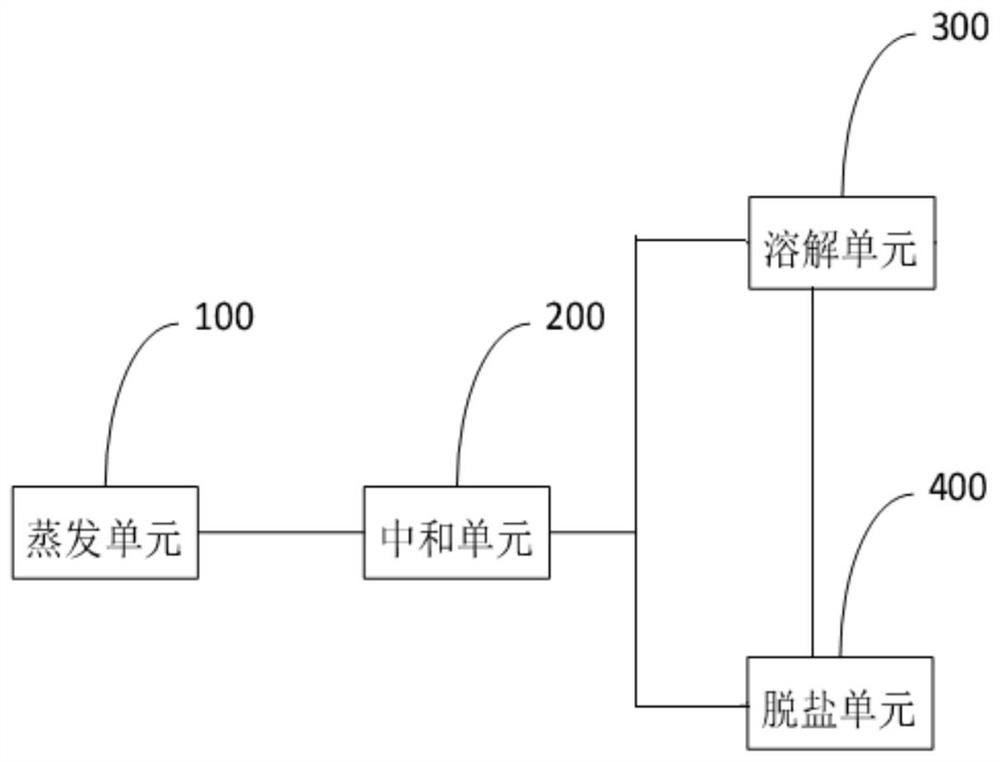

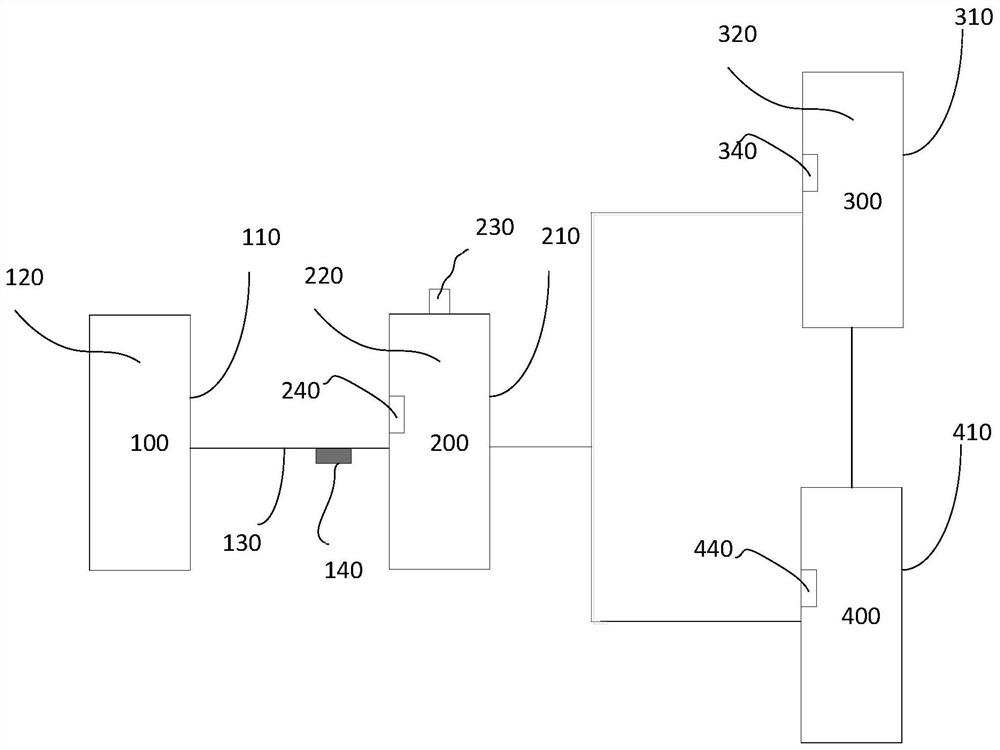

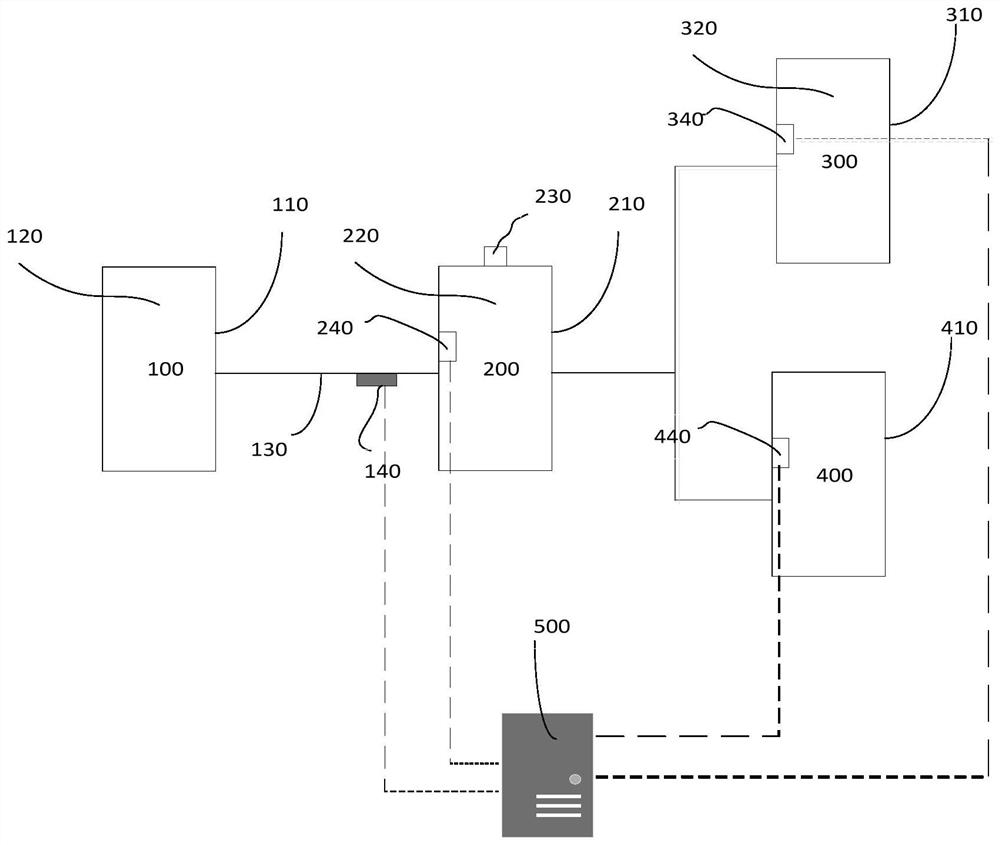

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1 utilizes taurine to prepare a preliminary standard curve, comprising the following steps:

[0066] Take the balance to accurately weigh 40g taurine, 60g ultrapure water, put the weighed sodium taurine and ultrapure water into a 250ml beaker and stir evenly, and configure a pure taurine solution with a mass concentration of 40w%. , divided into 20 parts on average, each with a mass of 5g, and marked as 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17 , 18, 19, 20, and pure cows with numbers 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19 47.5g, 45g, 42.5g, 40g, 37.5g, 35g, 32.5g, 30g, 27.5g, 25g, 22.5g, 20g, 17.5g, 15g, 12.5g, 10g, 7.5g of deionized water in the sulfonic acid solution , 5g, 2.5g Dilute the taurine solution 10.5 times, 10 times, 9.5 times, 9 times, 8.5 times, 8 times, 7.5 times, 7 times, 6.5 times, 6 times, 5.5 times, 5 times, 4.5 times, 4 times, 3.5 times, 3 times, 2.5 times, 2 times, 1.5 times, the contents of t...

Embodiment 2

[0068] In embodiment 2, the preliminary standard curve obtained in embodiment 1 was corrected in combination with the solution components of the evaporation unit, including:

[0069] According to the impurity content composition of the evaporation post to simulate the site solution component content, accurately weigh 24g ethylene glycol, 30 ethanolamine, 60g isethionic acid, 10g sodium sulfate, 105g taurine, 71g ultrapure water with a balance, and weigh the Sodium taurine and ultrapure water are made in a 500ml beaker and stirred evenly, and the configuration percentage is 8% ethylene glycol, 10% ethanolamine, 20% sodium isethionate, 10% sodium sulfate, 35% aqueous solution of taurine, the solution is divided into 15 parts on average, each part has a mass of 20g, marked as 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 . Add 155g, 96.7g, 67.5g, 50.0g, 38.3g, 30g, 23.8g, 18.9g, 15g, 11.8g, 9.2g, 6.9g, 5.4g, 3.4g, 1.9g of ultrapure water, so that the bovine Sulfonic acid content wa...

Embodiment 3

[0071] Embodiment 3 provides a kind of on-the-spot taurine content online detection simulation experiment, comprises the steps:

[0072] As shown in Table 1 below, use a balance to weigh and measure taurine, ethylene glycol, sodium isethionate, sodium sulfate, and ethanolamine, add them to deionized water and dissolve them, stir evenly, and prepare taurine with a known mass concentration The solution was measured by two different methods of titration and refractometer detection, an online simulation experiment was established, the accuracy of the instrument measurement was checked, and the concentration curve was simulated. The results are shown in Table 1 and Figure 5 Shown:

[0073] Table 1 Online taurine content simulation experiment record table and measurement results

[0074]

[0075] From Table 1 and Figure 5 It is not difficult to see that accurate results can be obtained by using the refraction method to detect the taurine solution containing impurities. Moreo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com