Intelligent coal caving mechanism of full-mechanized caving mining

An intelligent, fully mechanized caving technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as blockage of coal windows and difficulty in coal caving, and achieve the effect of strong adaptability and intelligent production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

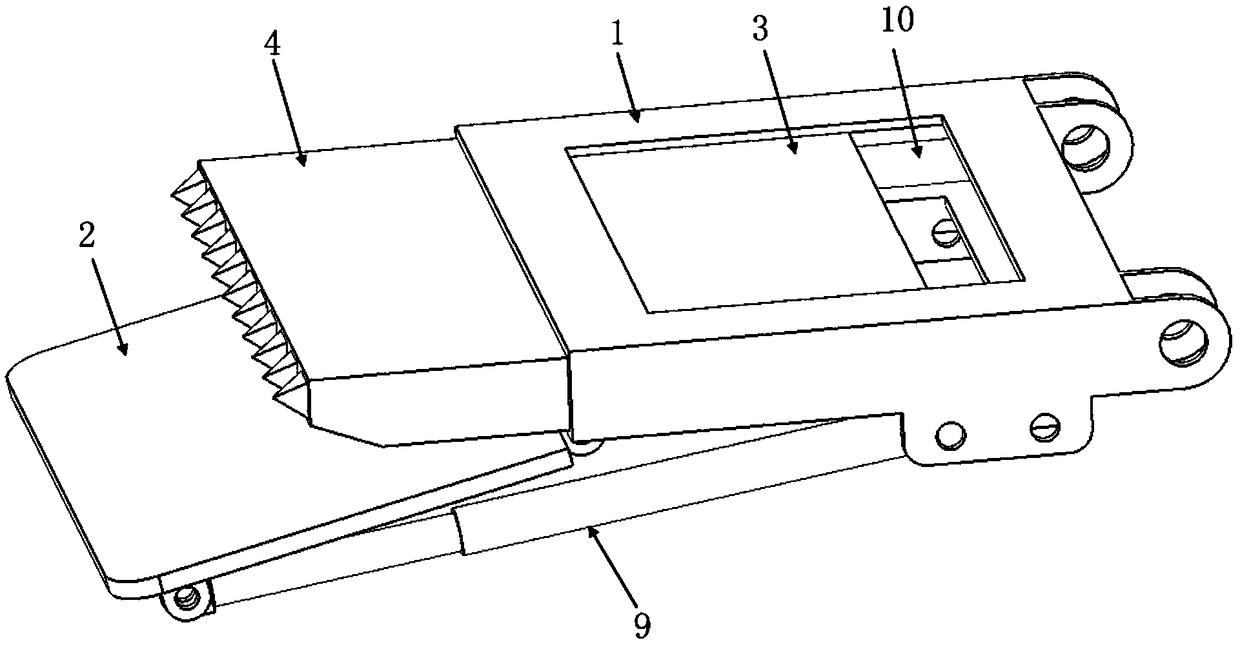

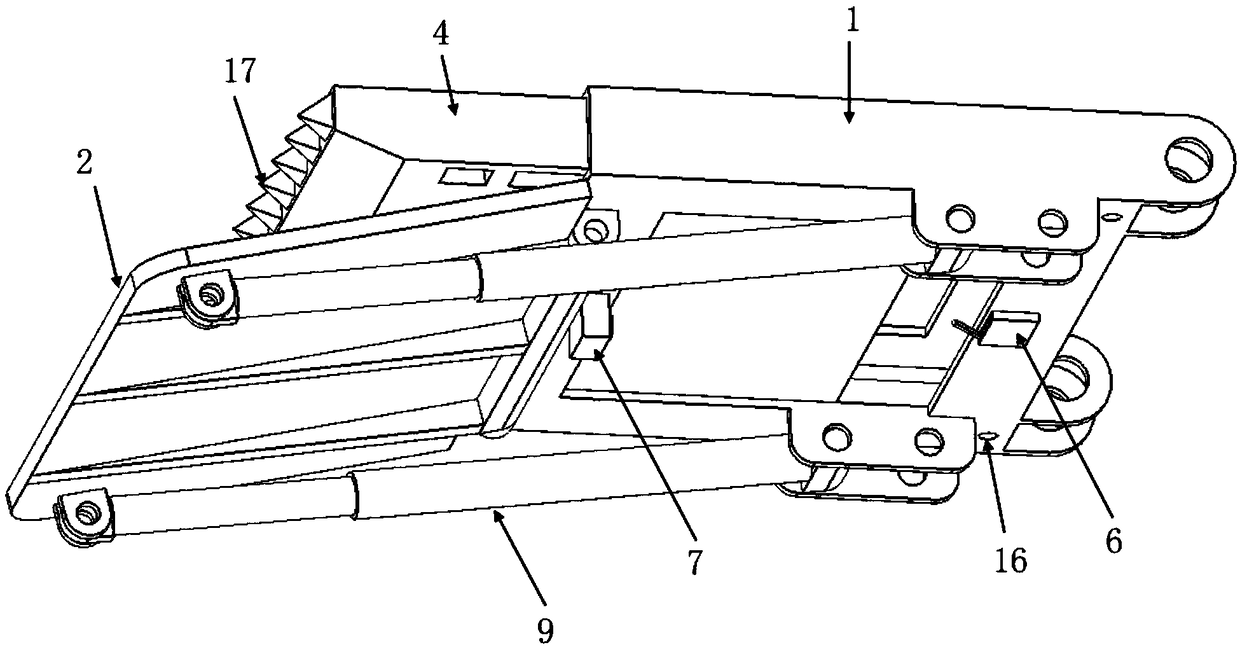

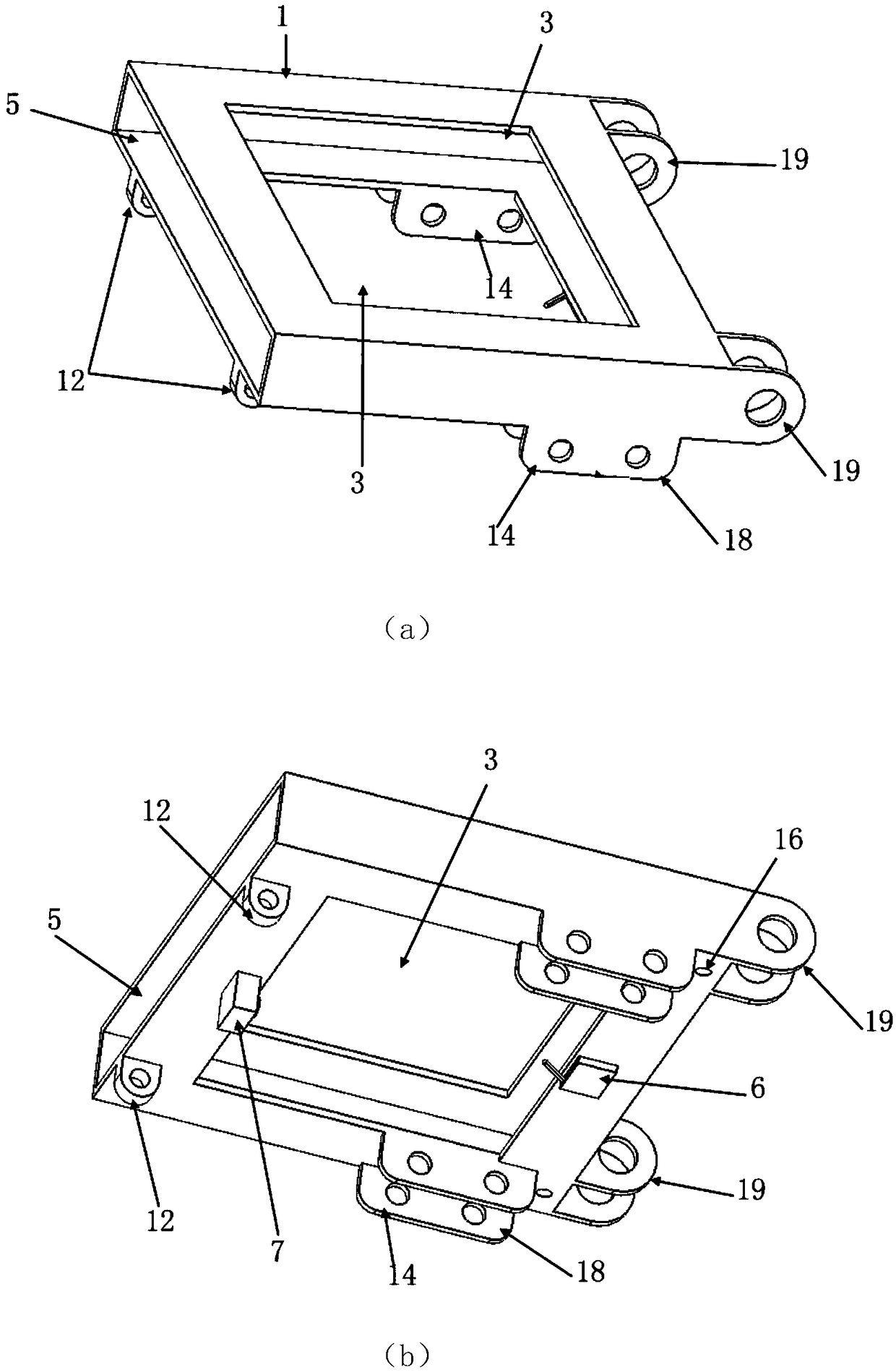

[0032] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a kind of intelligent coal discharge mechanism for fully mechanized caving mining, including tail boom outer box 1, tail beam baffle plate 2, monitoring system and controller; The coal outlet 3, the tail beam outer box 1 is inserted with a tail beam inserting plate 4 for opening or closing the coal opening, and the tail beam inserting plate 4 is telescopically inserted into the Inside the tail boom outer box;

[0033] The front end of the tail beam outer box 1 is provided with an insertion hole 5 for the insertion of the tail beam inserting plate 4, the rear end of the tail beam outer box 1 is pivotally connected with the shielding beam of the hydraulic support, and the tail beam baffle plate 2. is rotatably connected to the lower surface of the front end of the tail boom outer box 1 through the driving of the driving mechanism;

[0034] The monitoring system includes an ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com