Coated controlled-release fertilizer using crop straws as degradable film and production method of fertilizer

A technology of crop stalks and controlled-release fertilizers, applied in fertilizer mixtures, agriculture, fertilization devices, etc., can solve problems such as difficulty in maintaining sustainable development of controlled-release fertilizers, achieve excellent nutrient release, meet growth needs, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

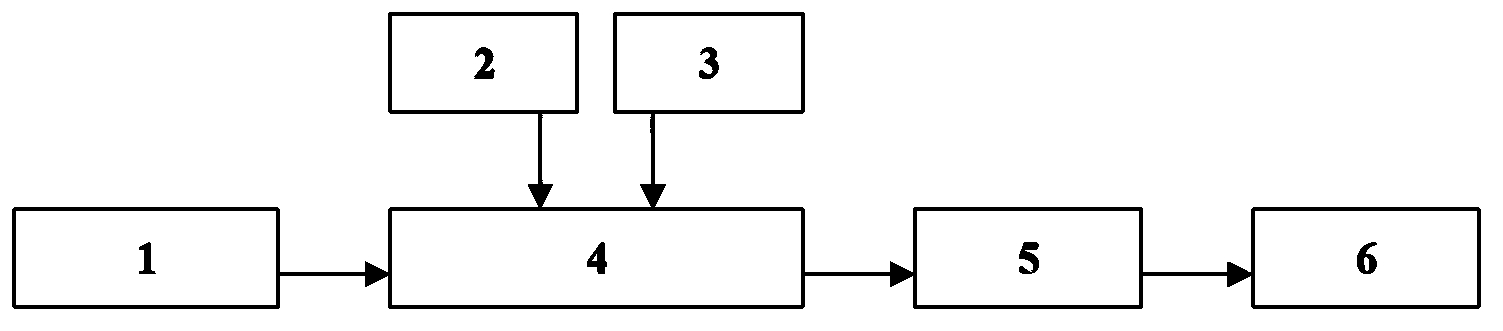

Method used

Image

Examples

Embodiment 1

[0022] Add 100g of diethylene glycol, 50g of wheat straw and 3g of concentrated sulfuric acid into a three-necked flask equipped with a mechanical stirrer and a condenser, and stir to make them evenly mixed. React at 140-150 DEG C for 1.5 hours, then cool in an ice-water bath to terminate the reaction, and obtain the wheat straw coating liquid. Put 500g of large granule urea with a diameter of 2-4mm into the drum, heat it to 50-70°C, then add 5.61g of wheat straw coating liquid and 3.31g of curing agent polymethylene polyphenyl polyphenylene preheated to 100°C At the same time, the isocyanate is quickly sprayed onto the surface of urea granules, and after 5-6 minutes, it can directly react and form a film on the surface of the fertilizer. This process is repeated 3 times. Finally, the fertilizer is cooled to room temperature by a cooler, and then it can be packaged and stored. The obtained controlled-release fertilizer film material accounts for about 5% of the total weight o...

Embodiment 2

[0024] Add 100g of diethylene glycol, 40g of corn stalks and 3g of concentrated sulfuric acid into a three-necked flask equipped with a mechanical stirrer and a condenser, and stir to make them evenly mixed. React at 140-150 DEG C for 1.3 hours, then cool with an ice-water bath to terminate the reaction, and obtain the corn stalk coating liquid. Put 500g of large granule urea with a diameter of 2-4mm into the drum and heat it to 50-70°C; then put 5.11g of corn stalk coating solution preheated to 100°C and 3.67g of curing agent polymethylene polyphenyl The polyisocyanate is quickly sprayed onto the surface of the urea at the same time, and after 5-6 minutes, it can directly react and form a film on the surface of the fertilizer. This process is repeated 3 times. Finally, the fertilizer is cooled to room temperature by a cooler, and then it can be packaged and stored. The obtained controlled-release fertilizer film material accounts for about 5% of the total weight of all contr...

Embodiment 3

[0026] Add 80g of ethylene carbonate, 20g of ethylene glycol, 40g of wheat straw and 3g of concentrated sulfuric acid into a three-necked flask equipped with a mechanical stirrer and a condenser, and stir to make them evenly mixed. React at 140-150 DEG C for 1 hour, then cool with an ice-water bath to terminate the reaction, and obtain the wheat straw coating liquid. Put 500g of large granule urea with a diameter of 2-4mm into the drum and heat it to 50-70°C; then add 5.01g of wheat straw coating solution and 3.82g of curing agent polymethylene polyphenyl polyphenylene preheated to 100°C At the same time, the isocyanate is quickly sprayed onto the surface of the urea, and after 5-6 minutes, it can directly react and form a film on the surface of the fertilizer. This process is repeated 3 times. Finally, the fertilizer is cooled to room temperature by a cooler, and then it can be packaged and stored. The obtained controlled-release fertilizer film material accounts for about 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com