Patents

Literature

57results about How to "Intelligent production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

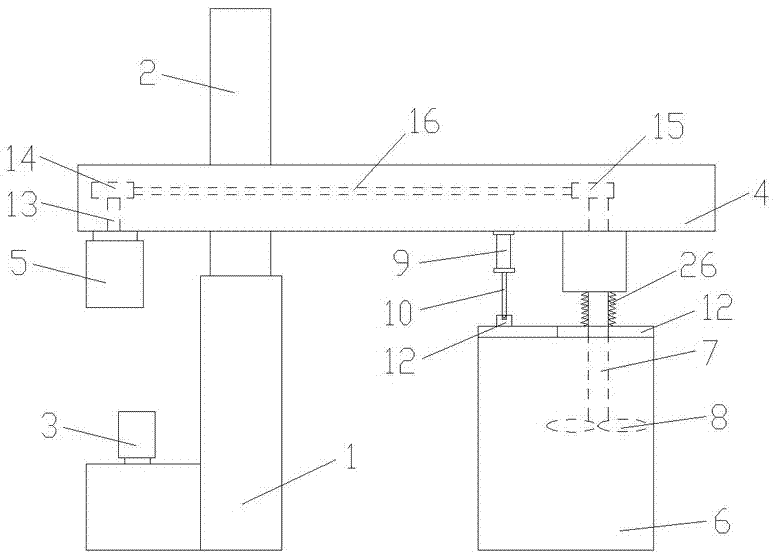

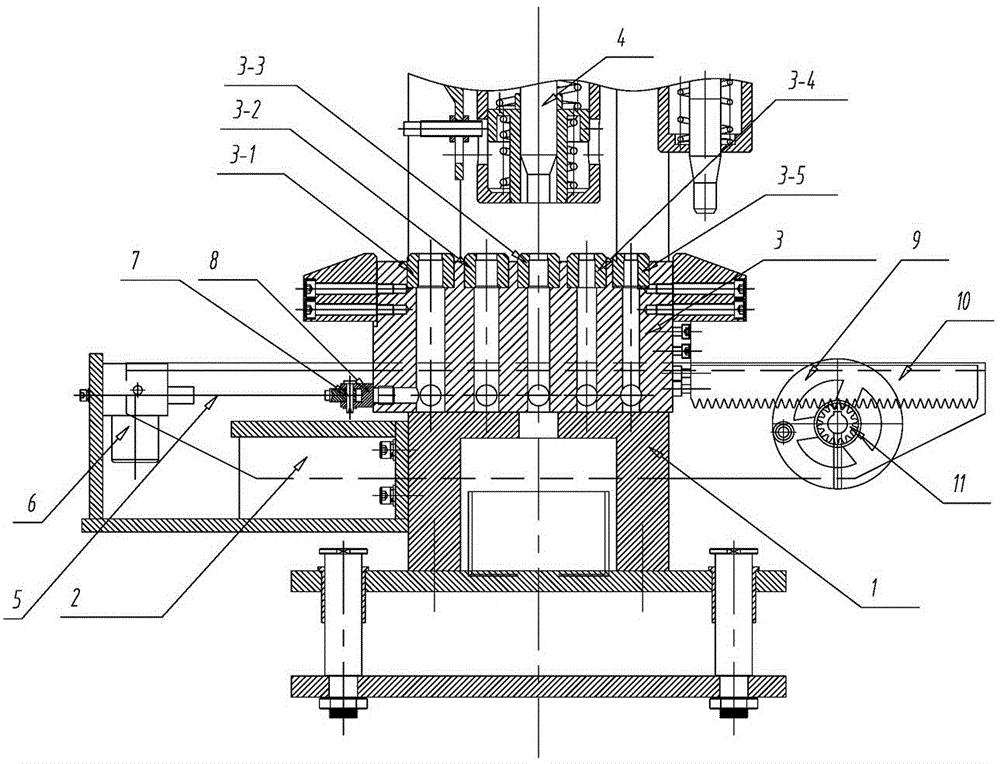

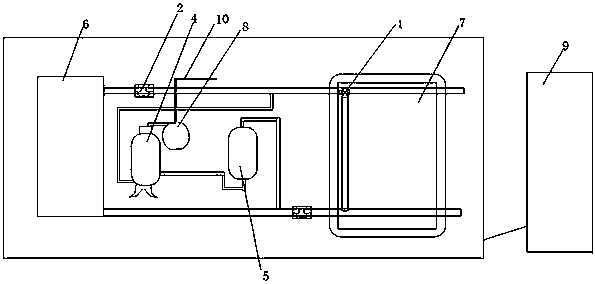

Intelligent flexible polishing method for non-spherical optical element and intelligent flexible polishing device adopted for intelligent flexible polishing method

PendingCN108161646AGood face shape adaptabilityHigh precisionOptical surface grinding machinesAutomatic grinding controlMaterial removalOptical processing

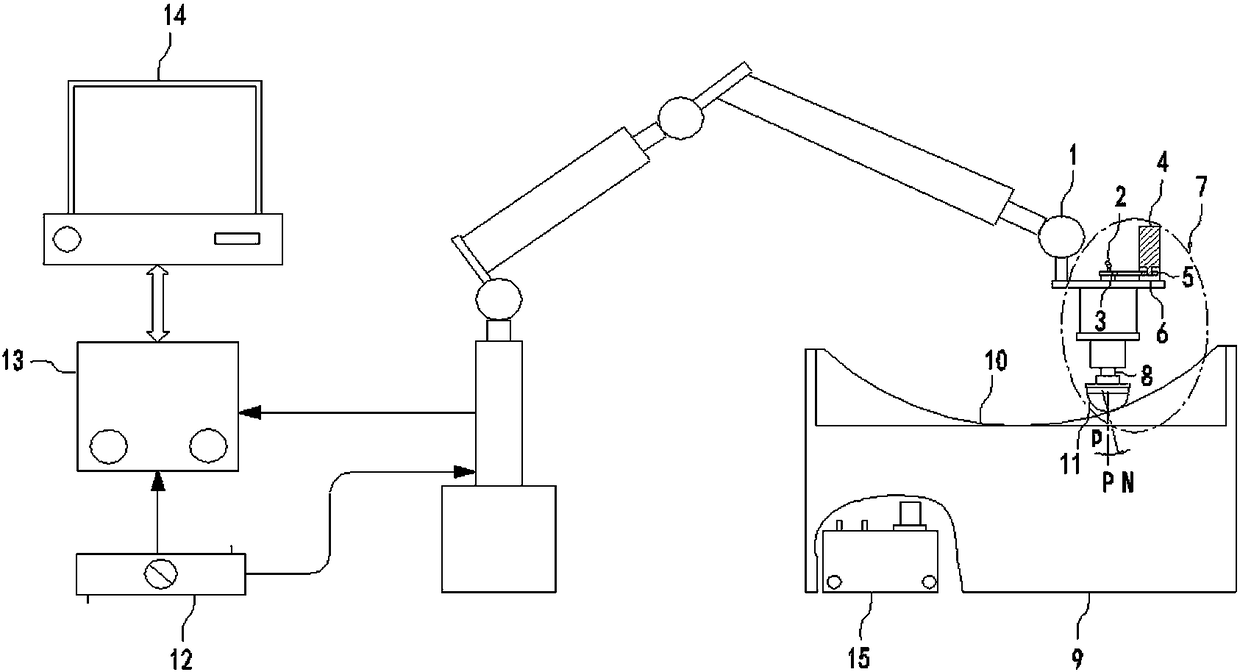

The invention belongs to the technical field of optical machining and particularly relates to an intelligent flexible polishing method for a non-spherical optical element and an intelligent flexible polishing device adopted for the intelligent flexible polishing method. The intelligent flexible polishing method includes the steps that (1) a robot scans a workpiece through a sensor to collect characteristic information of the workpiece; (2) a robot control system determines a polishing theoretical track; (3) a polishing mechanism drives a polishing airbag to move on the surface of the workpiecealong the polishing theoretical track, and the material removal quantities of various points on the surface of the optical element are accurately controlled; and (4) the robot control system carriesout iterative operation repeatedly so as to control the surface shape error of the workpiece. The intelligent flexible polishing device comprises the robot (1), a rotating joint (2), a workbench (10),an air pressure adjusting device (12), the robot control system (13), the polishing mechanism (7) and a computer (14). A machine area is stable, surface shape adaptability is good, the operating conditions of a polishing system can be monitored in real time, and ultraprecise polishing of large-size high-curvature non-spherical surfaces is achieved.

Owner:SHENYANG ACAD OF INSTR SCI

3D-printing-based education equipment manufacturing and realizing method, device and memory

InactiveCN107221026AFast preparationMade preciselyAdditive manufacturing apparatus3D modellingLevel data3d printer

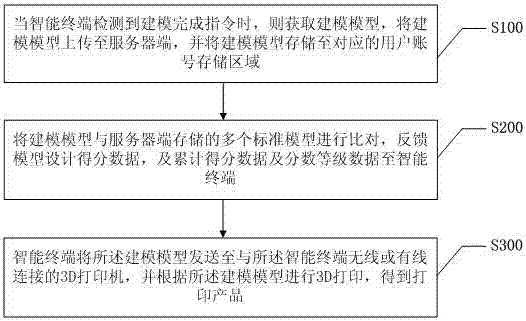

The invention discloses a 3D-printing-based education equipment manufacturing and realizing method, device and memory. The method includes the steps of obtaining modeling model when a smart terminal detects a modeling finish instruction, uploading the modeling model to a server side, storing the modeling model to the corresponding user account storage zone, comparing the modeling model with a plurality of standard models stored in the server side, feeding back the model design score data, accumulated score data and score level data to the smart terminal, and the smart terminal sending the modeling model to a 3D printer connected to the smart terminal in a wired or wireless way, and conducting 3D print according to the modeling model to obtain a printed product. Teaching concept model, teaching aids, toys and school supplies models and creative art pieces can be rapidly and accurately manufactured through 3D digital modeling. Corresponding products can be rapidly and accurately printed out, thereby shortening the manufacture cycle, and making the product manufacturing process more intelligent.

Owner:广州畅德科技有限公司

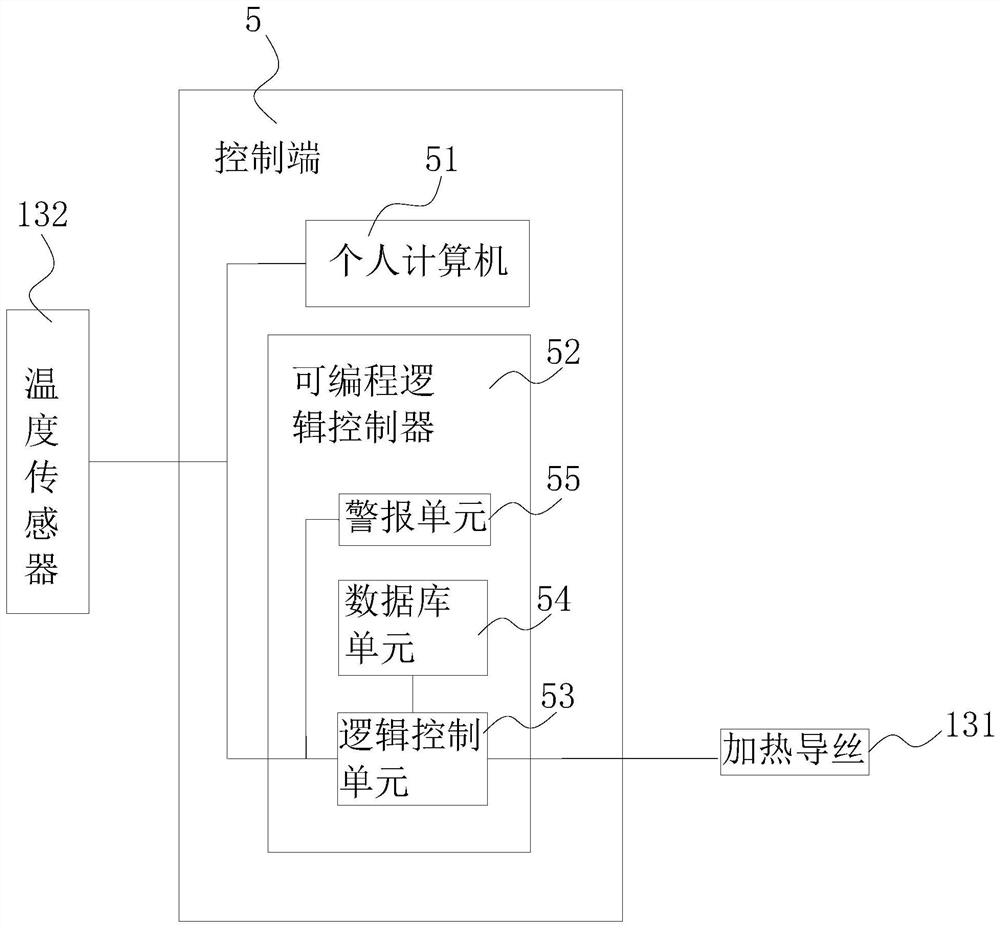

Combustion control system of foamed glass foaming furnace

InactiveCN101306913AEliminate wastePromote environmental protectionGlass furnace apparatusTotal factory controlTemperature controlCombustion

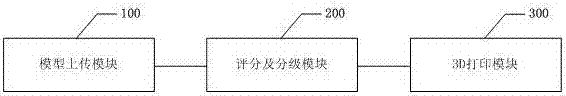

The invention relates to a foam glass foaming furnace combustion control system, which comprises a temperature control system, a host computer and a field control box, wherein, a foaming furnace is divided into a plurality of furnace regions; the inside of each furnace region is divided into more than one temperature region; each temperature region is respectively provided with temperature control points; various temperature control points are connected with HC900 miniature distributed controllers; an industrial control computer is taken as the host computer, is communicated with the HC900 miniature distributed controllers by combination with industrial control software, and can realize the functions of dynamic display of the state of a furnace body, dynamic display of the state of a pipeline, parameter setting, recording of history data, manual control and failure logging; the field control box is used for realizing control of manual start of each burner, realizing the functions of flame display, flame malfunction alarm and fuel shutoff, and realizing the two-way communication between the field control box and the HC900 miniature distributed controllers. The foam glass foaming furnace combustion control system realizes large-scale and intelligentized production of foam glass, low energy consumption, high quality and friendly environment.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

Intelligent ecological resource utilization production method of light-weight calcium carbonate

InactiveCN107902686AEnergy saving productionProduction environmental protectionCalcium/strontium/barium carbonatesFood processingFlue gasCarbonization

The invention discloses an intelligent ecological resource utilization production method of light-weight calcium carbonate. By a carbonization production method, limestone and other raw materials arecalcined to produce lime and carbon dioxide, then water is added for slaking the lime to produce lime milk, and then the carbon dioxide is inflated for carbonizing the lime milk to produce a calcium carbonate precipitate, and finally the calcium carbonate precipitate is dehydrated, dried and pulverized to obtain the light-weight calcium carbonate; the intelligent ecological resource utilization production method is characterized in that in the calcining production process, materials are automatically fed into a calcining furnace in an elevator way, and the materials are discharged from the lower part of the calcining furnace in a swinging way; in the dehydrating and drying process, a rice husk combusting furnace is used for producing hot air for drying, comprehensive utilization of afterheat of the hot air is achieved in a multi-layer circulating way, and flue gas produced by combustion of rice husk is settled for pollution-free discharge so as to achieve intelligent ecological resource utilization production of the light-weight calcium carbonate.

Owner:湖南恒旺碳酸钙有限公司

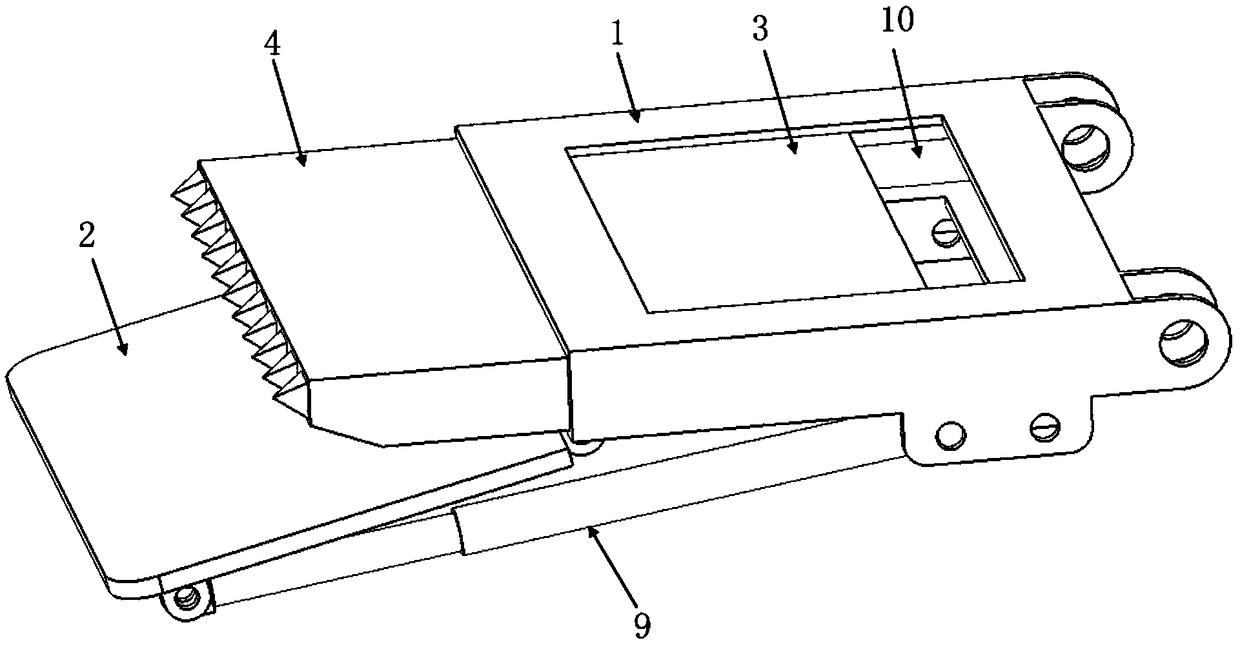

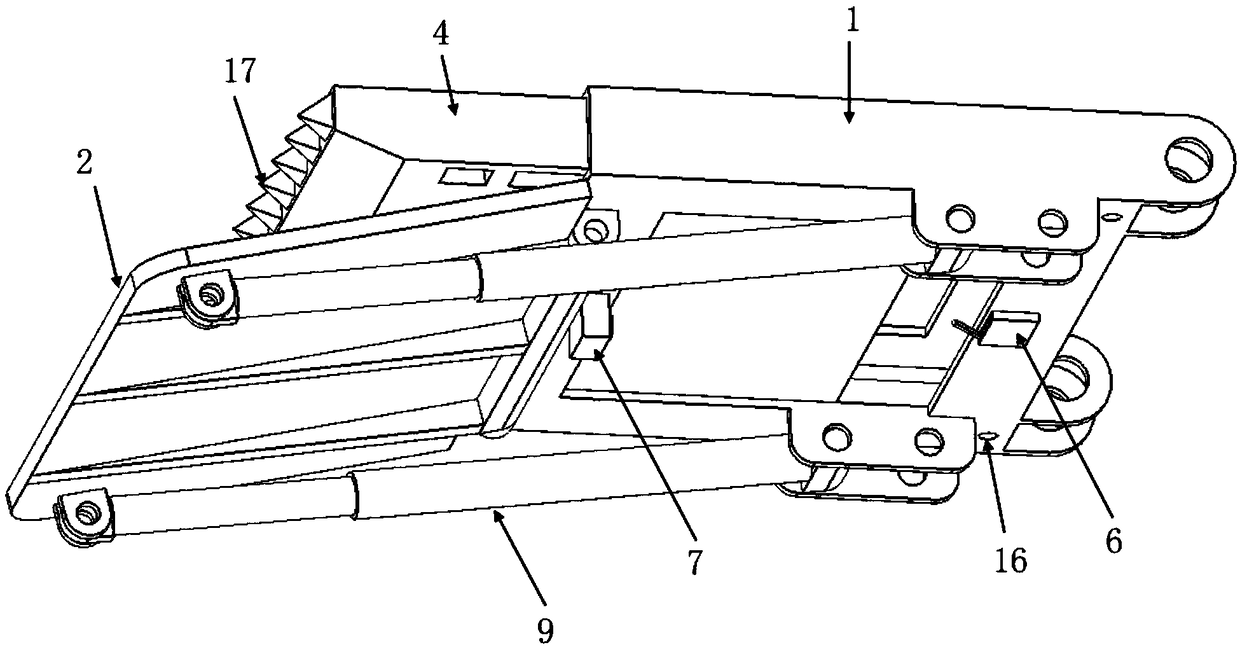

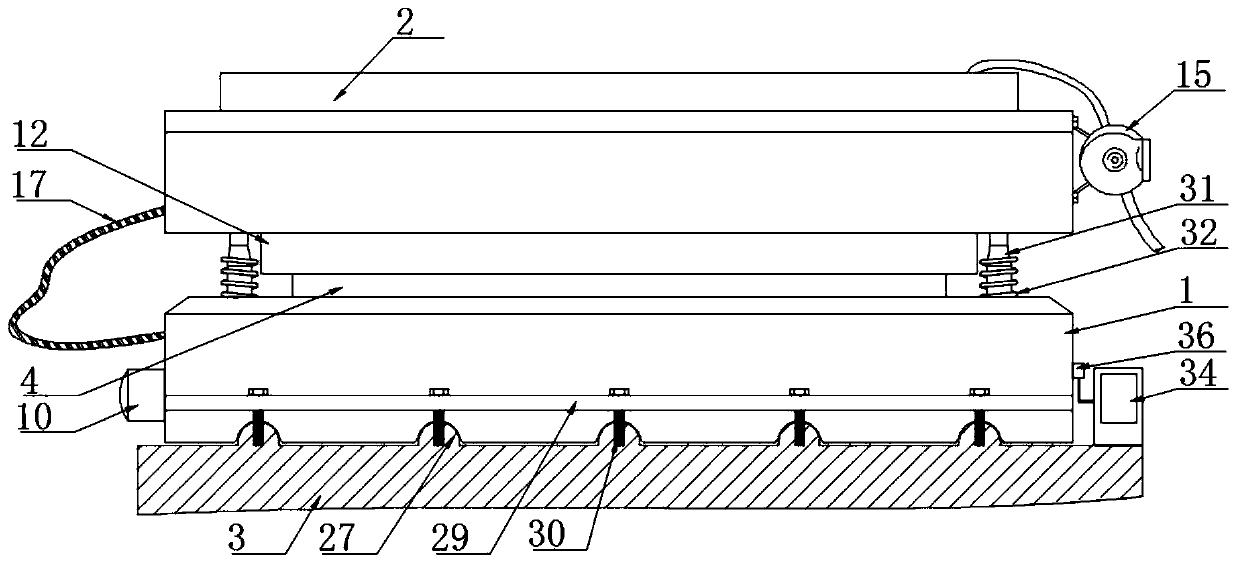

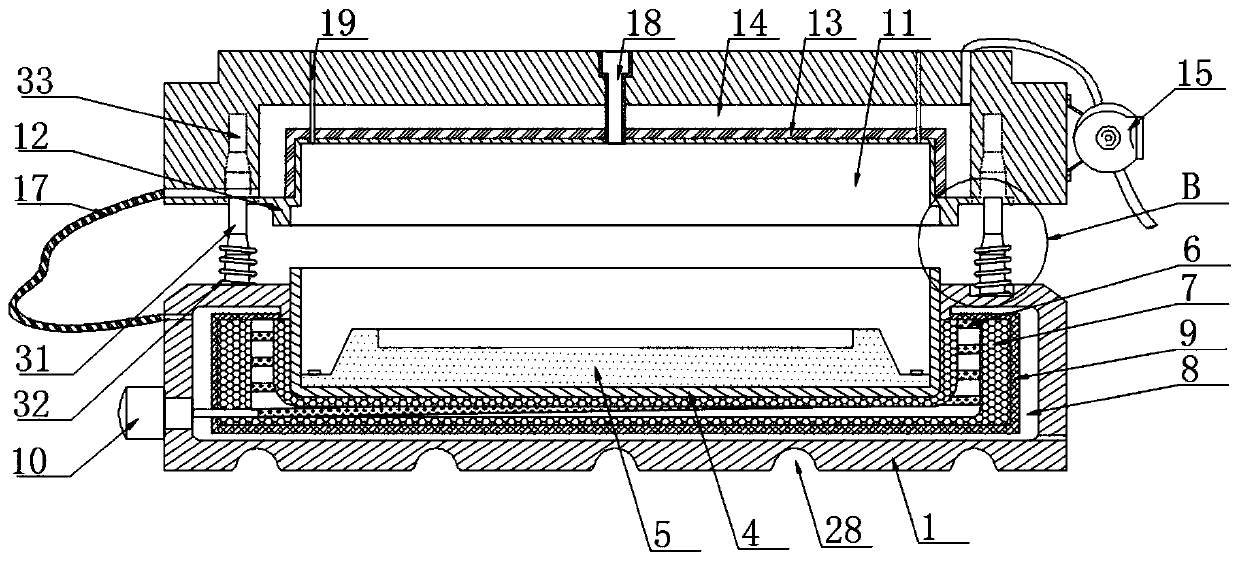

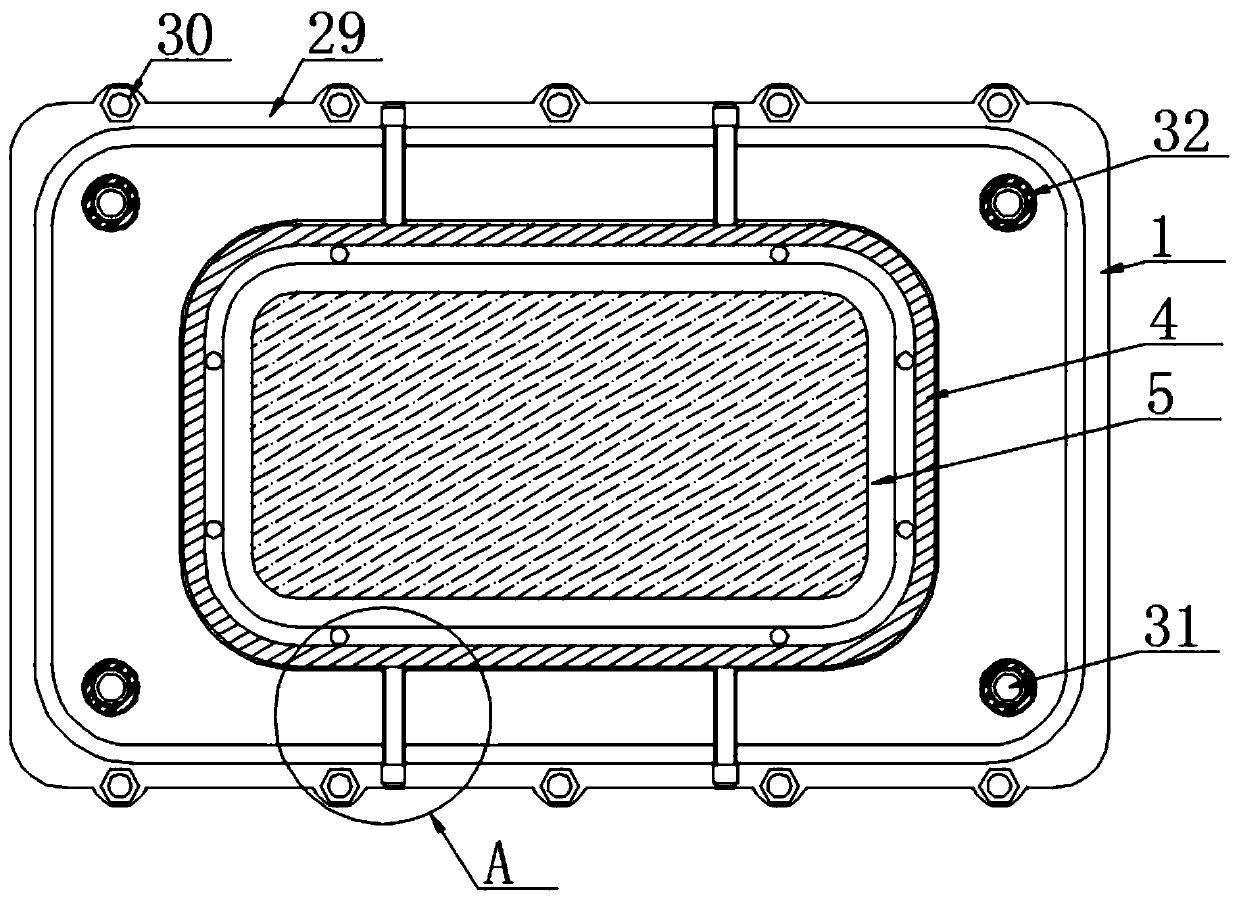

Intelligent coal caving mechanism of full-mechanized caving mining

PendingCN109026109AEfficient releaseSmooth releaseMining devicesMine roof supportsCoal briquetteMonitoring system

The invention discloses an intelligent coal caving mechanism of full-mechanized caving mining, and belongs to the technical field of full-mechanized top coal caving mining equipment. The intelligent coal caving mechanism of full-mechanized caving mining comprises a tail beam outer box, tail beam baffle, a monitoring system and a controller, wherein the monitoring system comprises a coal and ganguerecognizing instrument, a gas monitoring instrument and an ultrasonic crushing instrument; the upper and lower faces of the tail beam outer box are provided with coal caving ports respectively, a tail beam insertion plate can be telescopically inserted into the tail beam outer box through driving of a driving mechanism and used for opening or closing the coal caving ports; the lower surface of the tail beam outer box is provided with the coal and gangue recognizing instrument and the ultrasonic crushing instrument, and the gas monitoring instrument is arranged on the lower surface of the front end of the tail beam insertion plate. The intelligent coal caving mechanism of full-mechanized caving mining has the advantages that effective discharging of top coals can be achieved under the situation that a hydraulic support tail beam does not rotates, visible gangues are automatically closed, coal briquettes with larger blockness and not passing through a coal caving window is broken safelyby adopting an ultrasonic disruption technology to ensure smooth discharging of the top coals, the gas monitoring instrument monitors the gas concentration in a gob in real time, equipment can be controlled to be turned off when gas is excessive, thereby achieving safe, efficient and intelligent production.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

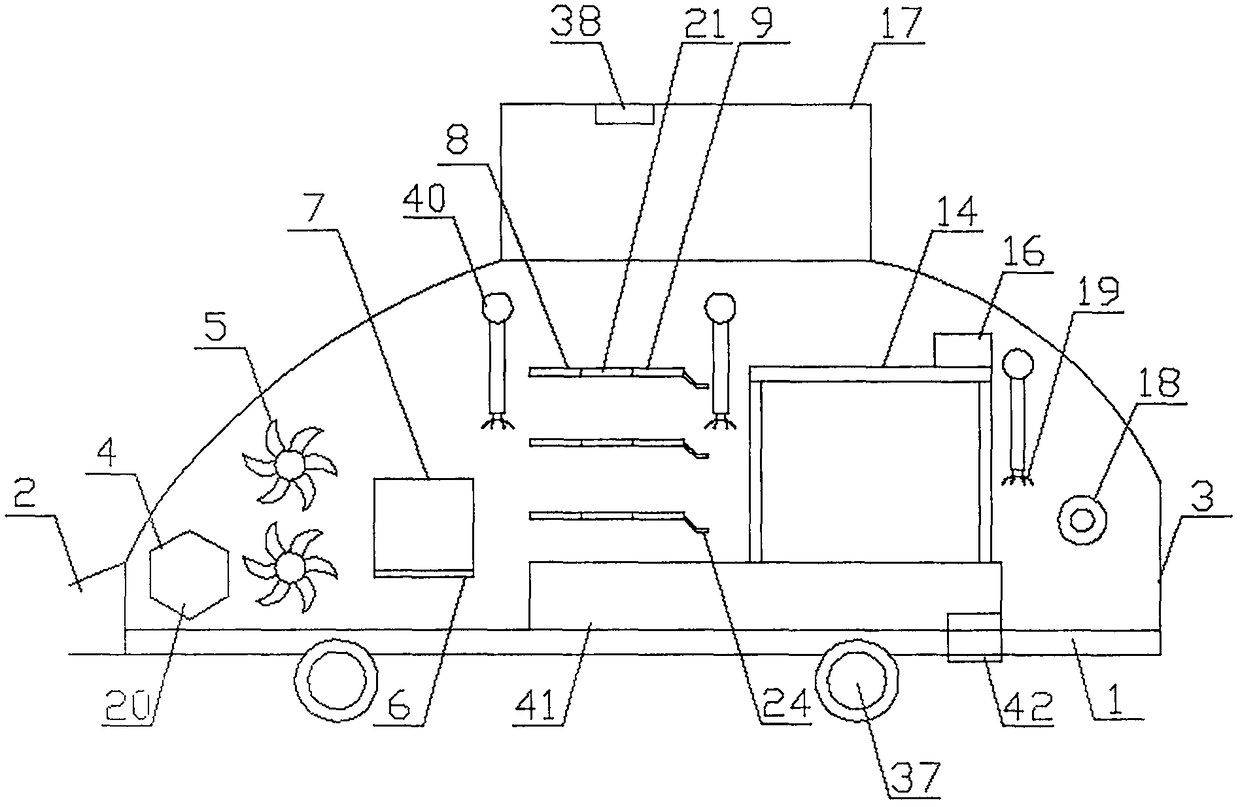

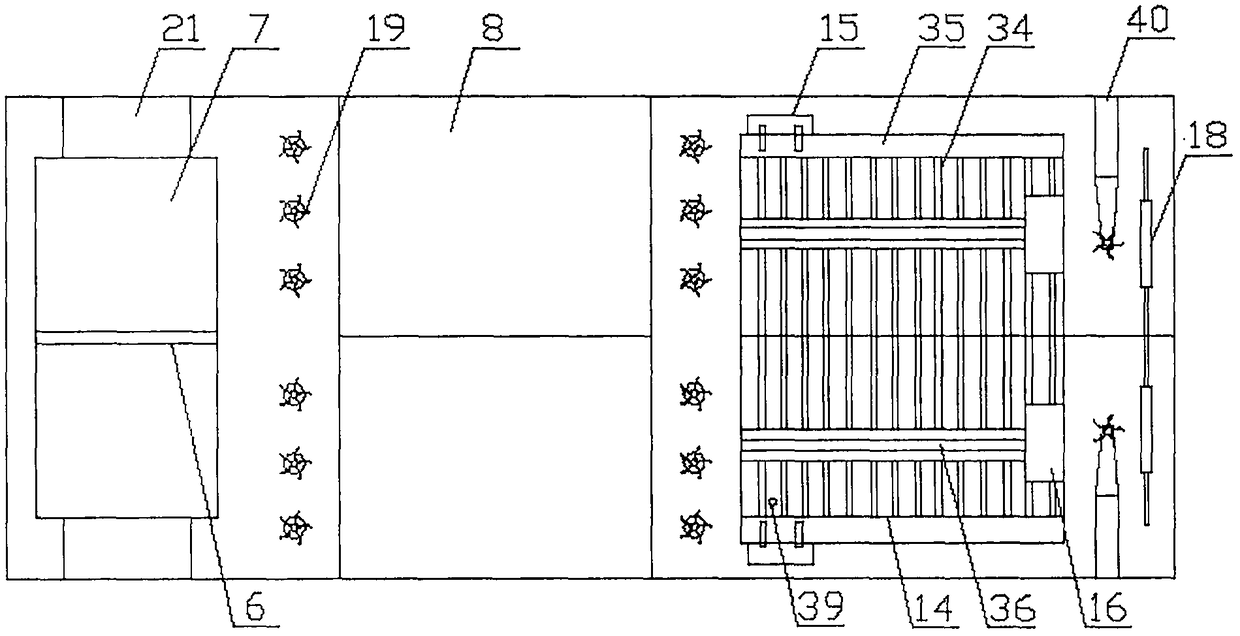

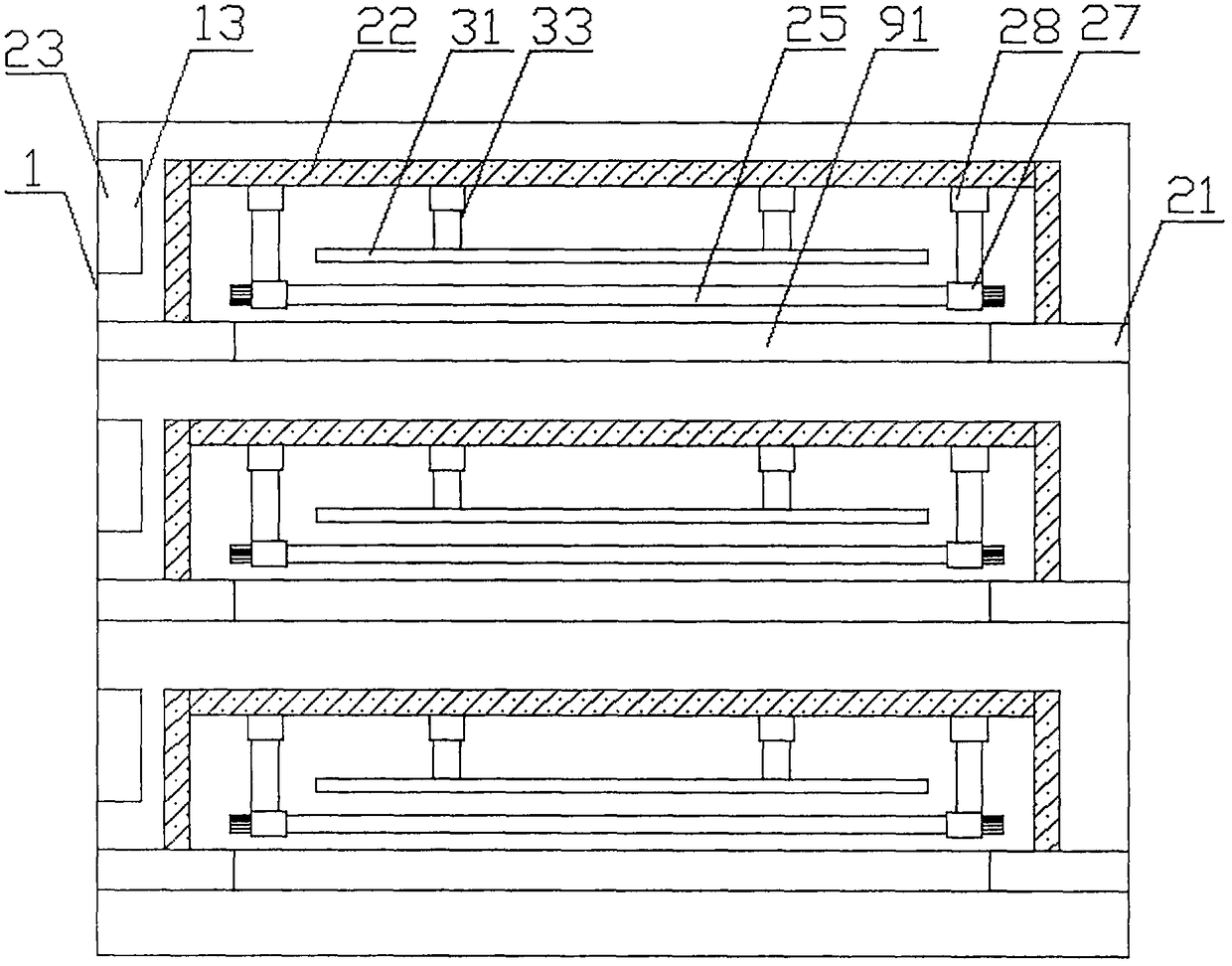

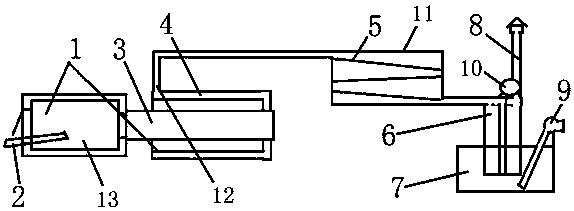

Waste-heat multilayer circulation light calcium carbonate energy-saving baking method and device

InactiveCN107915246ADrying operation production operation mode changesEnergy saving productionCalcium/strontium/barium carbonatesDrying gas arrangementsChaffEcological resources

The invention discloses a waste-heat multilayer circulation light calcium carbonate energy-saving baking method. According to the method, carbonized, filtered and dewatered light calcium carbonate wetcakes are dried by a drying oven. The method is characterized in that the light calcium carbonate wet cakes are dried by a vertically stacked multilayer circulation light calcium carbonate baking oven, hot air is prepared by a chaff burning furnace, so that circularly drying is achieved, the hot air is prepared by the chaff burning furnace in the dewatering and drying engineering to perform drying, the waste heat of the hot air is comprehensively utilized by the aid of a multilayer circulation mode, smoke generated by chaff burning is precipitated, so that pollution-free discharge of the smoke is achieved, and light calcium carbonate is produced by intelligently utilizing ecological resources.

Owner:湖南恒旺碳酸钙有限公司

Electromechanical integrated die capable of adjusting temperature

InactiveCN110253837AQuality improvementImprove processing efficiencyInsulation layerMechanical engineering

The invention discloses an electromechanical integrated die capable of adjusting temperature, and particularly relates to the technical field of casting processing. The electromechanical integrated die comprises a lower die body and an upper die body, the upper die body is arranged over the lower die body, a working base table is arranged at the bottom of the lower die body, and a heating tank is arranged at the top of the lower die body. The lower die body is buckled with the upper die body, a lower die shell and the upper die body are fixed by a connecting sleeve, an electric heater is electrified to enable a heat conduction wire to heat a heat accumulator, when a workpiece is subjected to injection molding, plastic is continuously melted, old skin on the surface of the workpiece is reduced, the surface of the workpiece is uniform, redundant gas is exhausted from an exhaust hole, the injection molding density is guaranteed, the quality of the workpiece is improved, a second water chamber and a heat insulation layer effectively insulate heat, potential safety hazards are avoided, after injection molding is completed, the upper die body is lifted up, the lower die shell carrying the injection molded workpiece is separated from the lower die body to be away from a heat source, meanwhile, a miniature water pump works to draw cold water to enter the first water chamber and heat exchange fins for heat exchange, the workpiece is cooled, and the machining efficiency of the workpiece is improved.

Owner:SHANDONG LABOR VOCATIONAL & TECHN COLLEGE

Novel paint stirring device

InactiveCN107233816AThoroughly and evenly mix and stirCause harmRotary stirring mixersTransportation and packagingBiochemical engineering

The invention discloses a novel paint stirring device. The novel paint stirring device comprises a lifting base, wherein a lifting rod is extended in the direction of height on the lifting base, a lifting motor is arranged on one side of the lifting base, a stirring arm is arranged in a sliding manner on the lifting rod and driven by the lifting motor, a stirring motor is arranged at one end of the stirring arm, a stirring bucket is arranged below the other end of the stirring arm, a rotating shaft is arranged at the other end of the stirring arm, one end of the rotating shaft is driven by the stirring motor and connected with a stirring paddle, the stirring paddle extends into the stirring bucket through the rotating shaft, the stirring arm is arranged on the lifting rod in an up-and-down lifting manner through the lifting motor, and the stirring arm can be lifted and regulated up and down for paint buckets with different heights. The novel paint stirring device has wide applicability, and the stirring paddle extending into the stirring bucket can sufficiently and uniformly mix and stir paint, thereby reducing human resources, efficiently and quickly conducting production, having high working efficiency, avoiding manual operation, avoiding hazard to the human body, and being automatized and intelligent in production.

Owner:鹤山市君子兰涂料有限公司

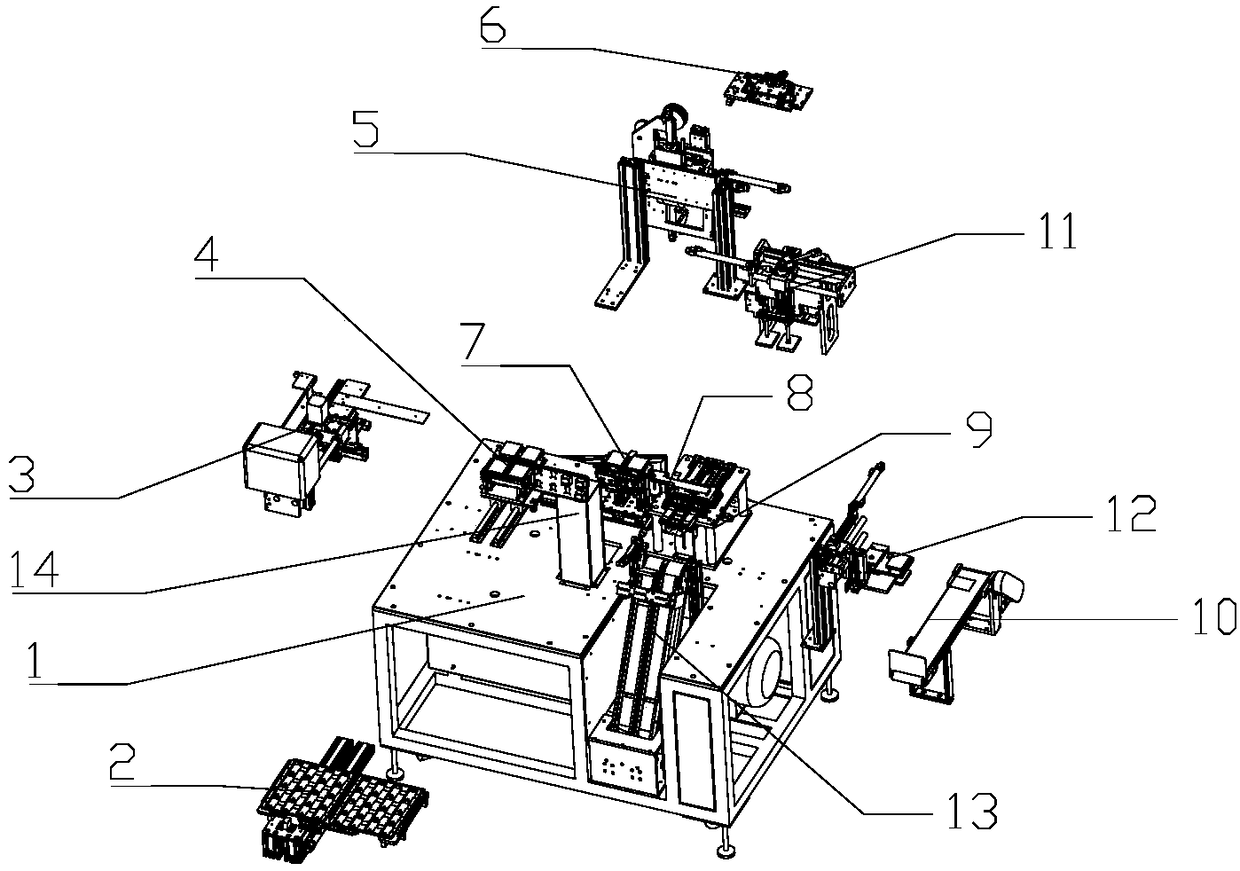

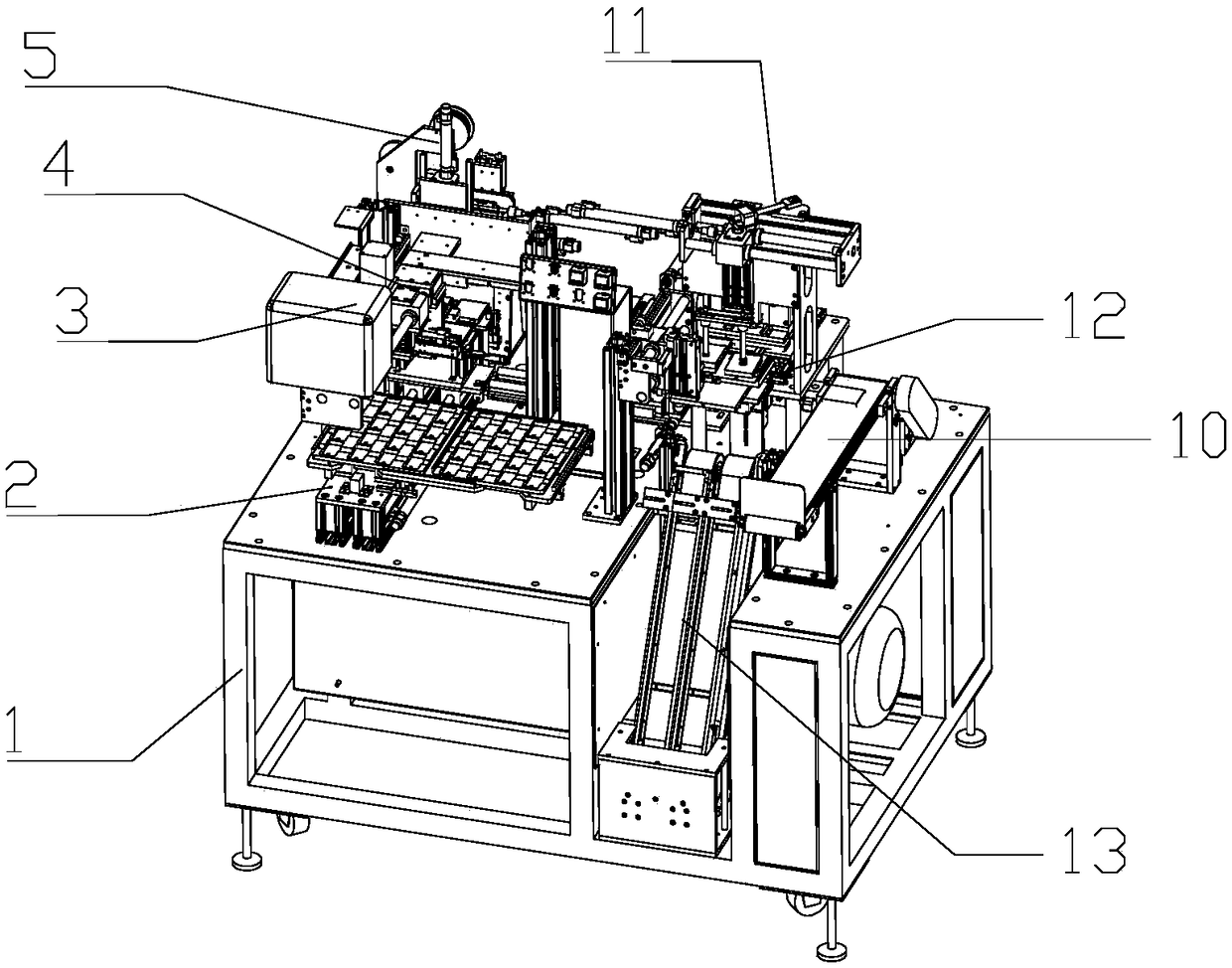

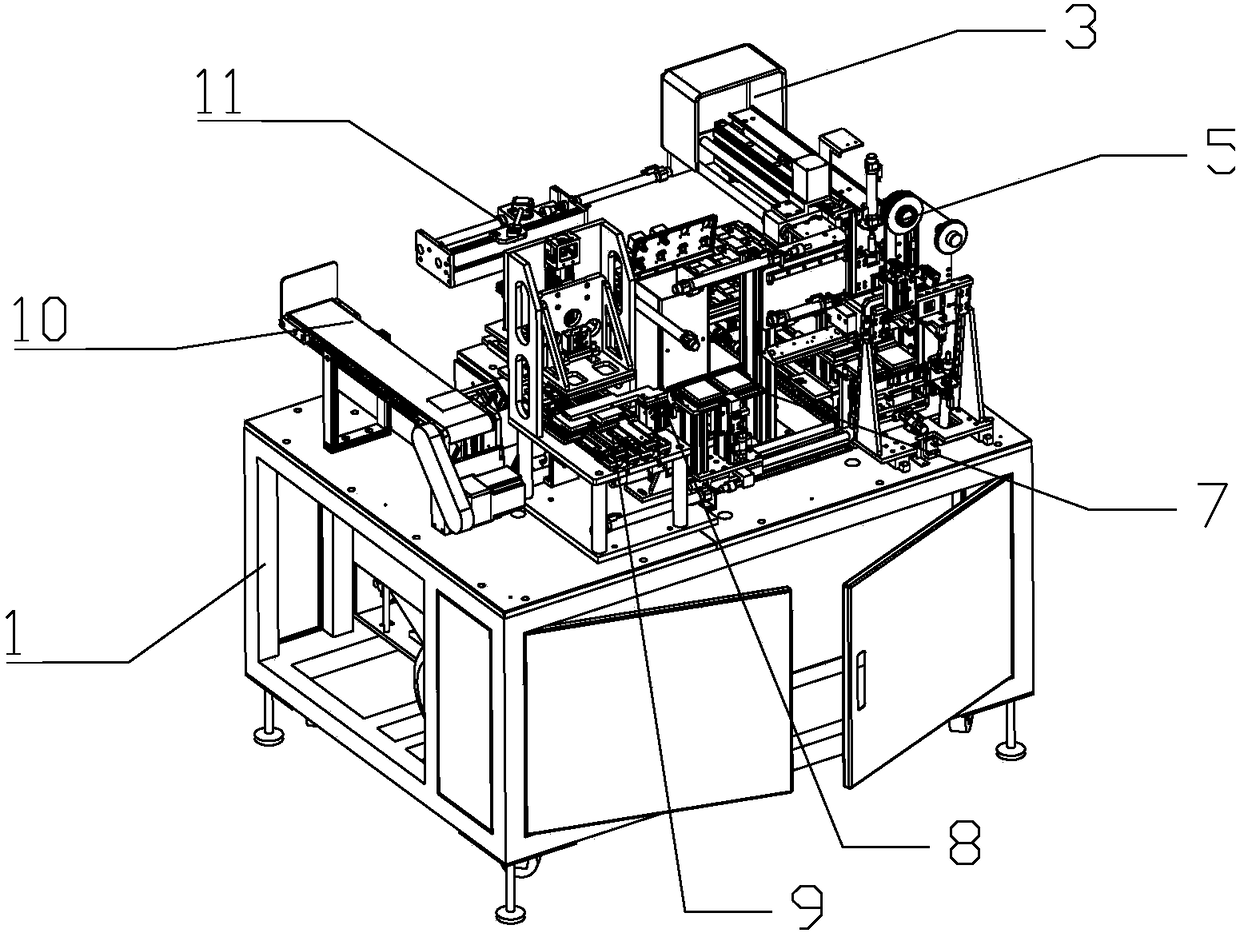

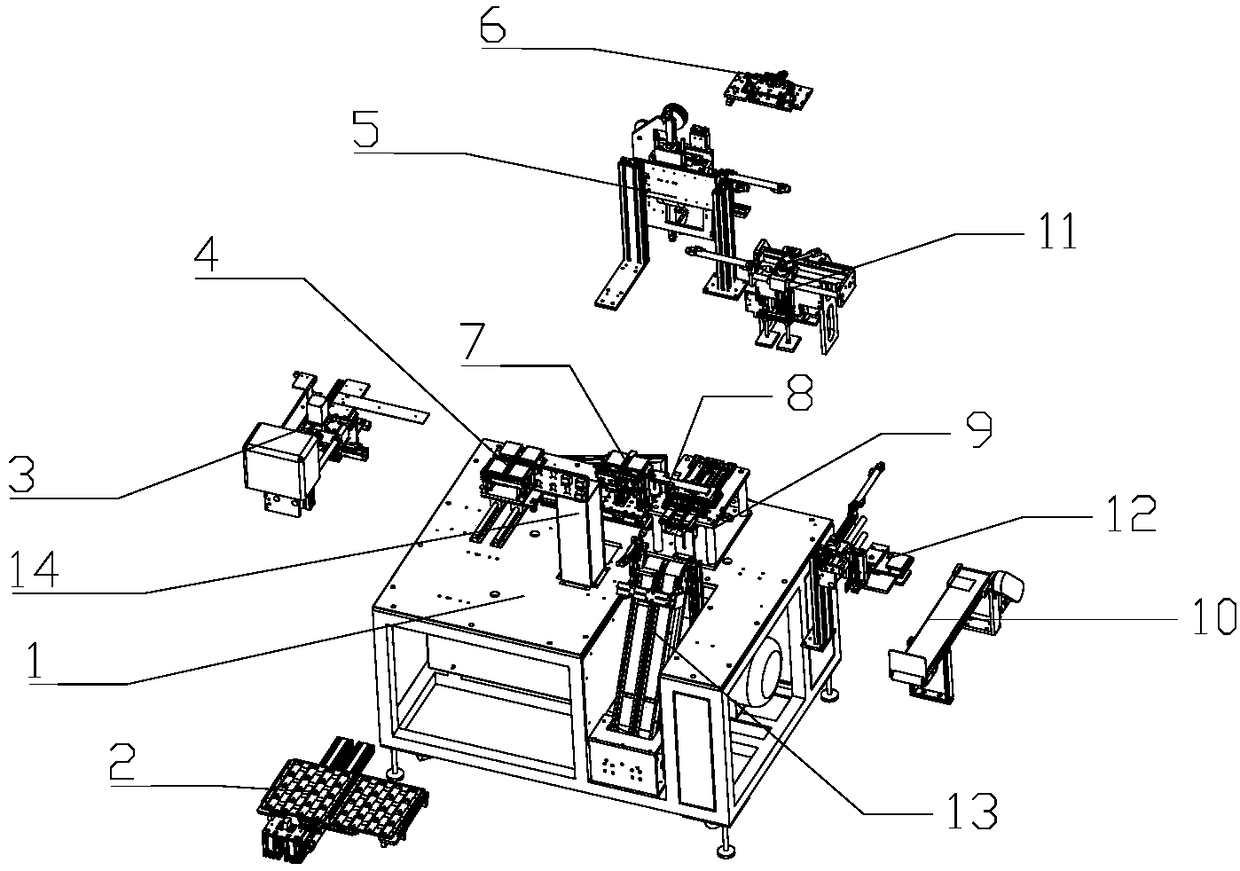

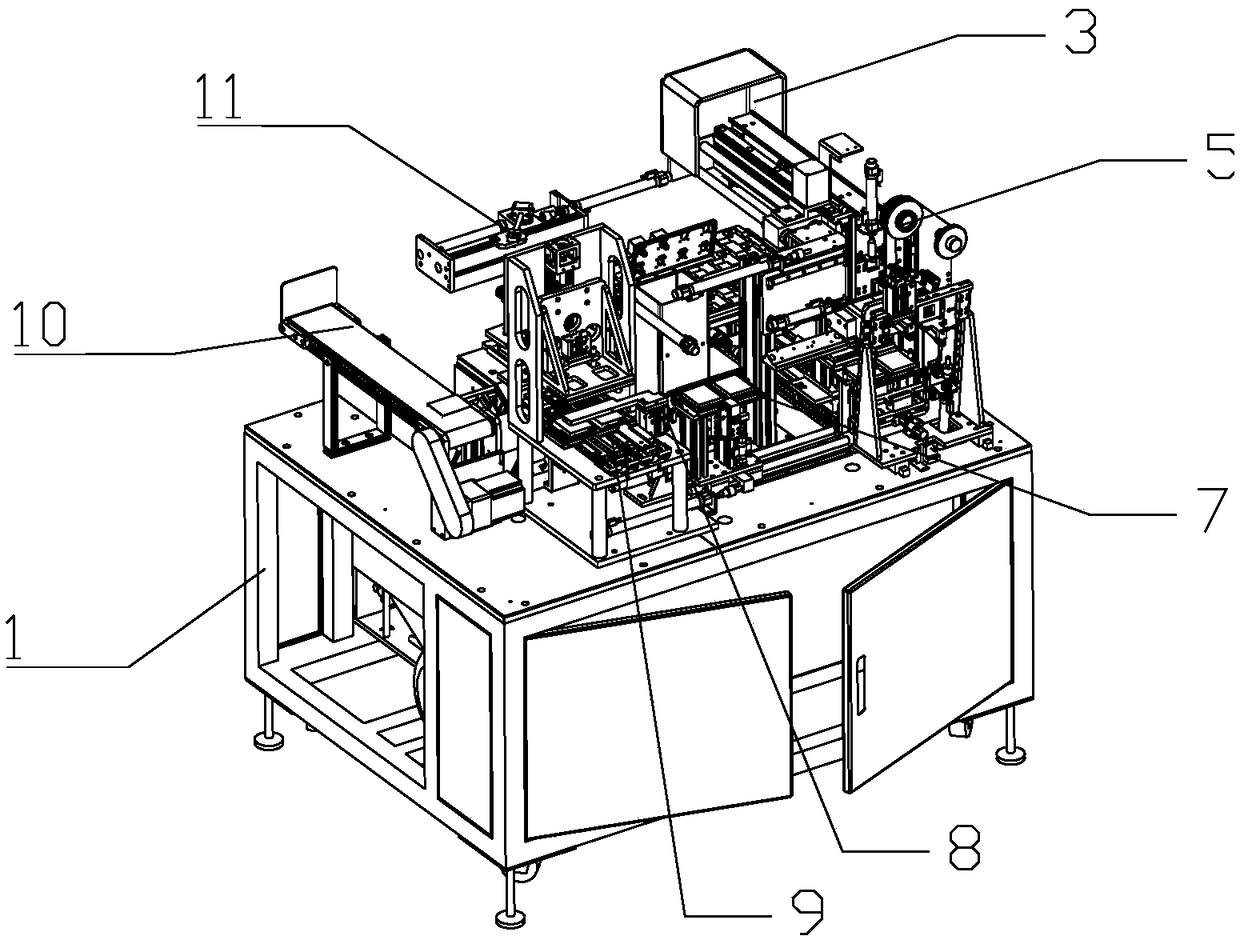

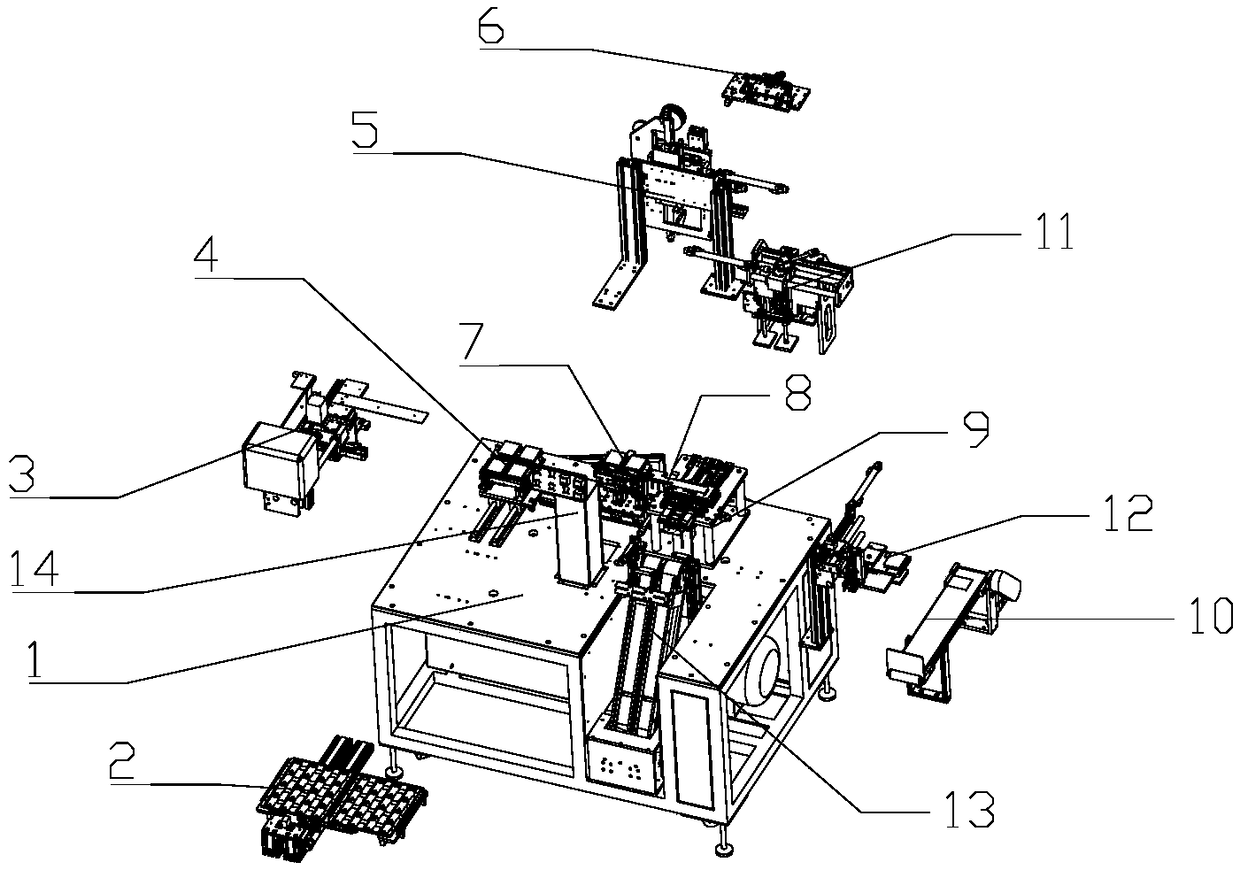

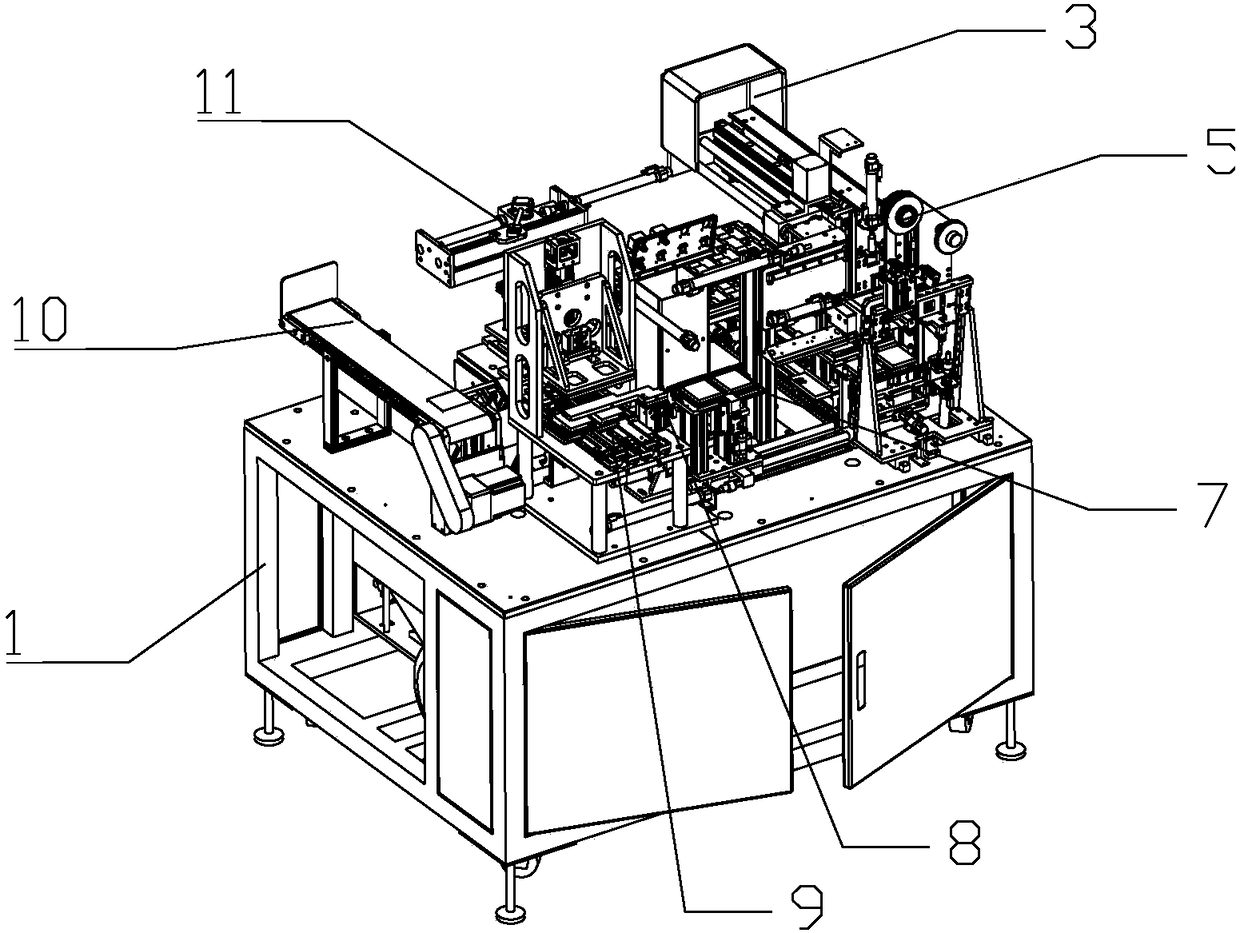

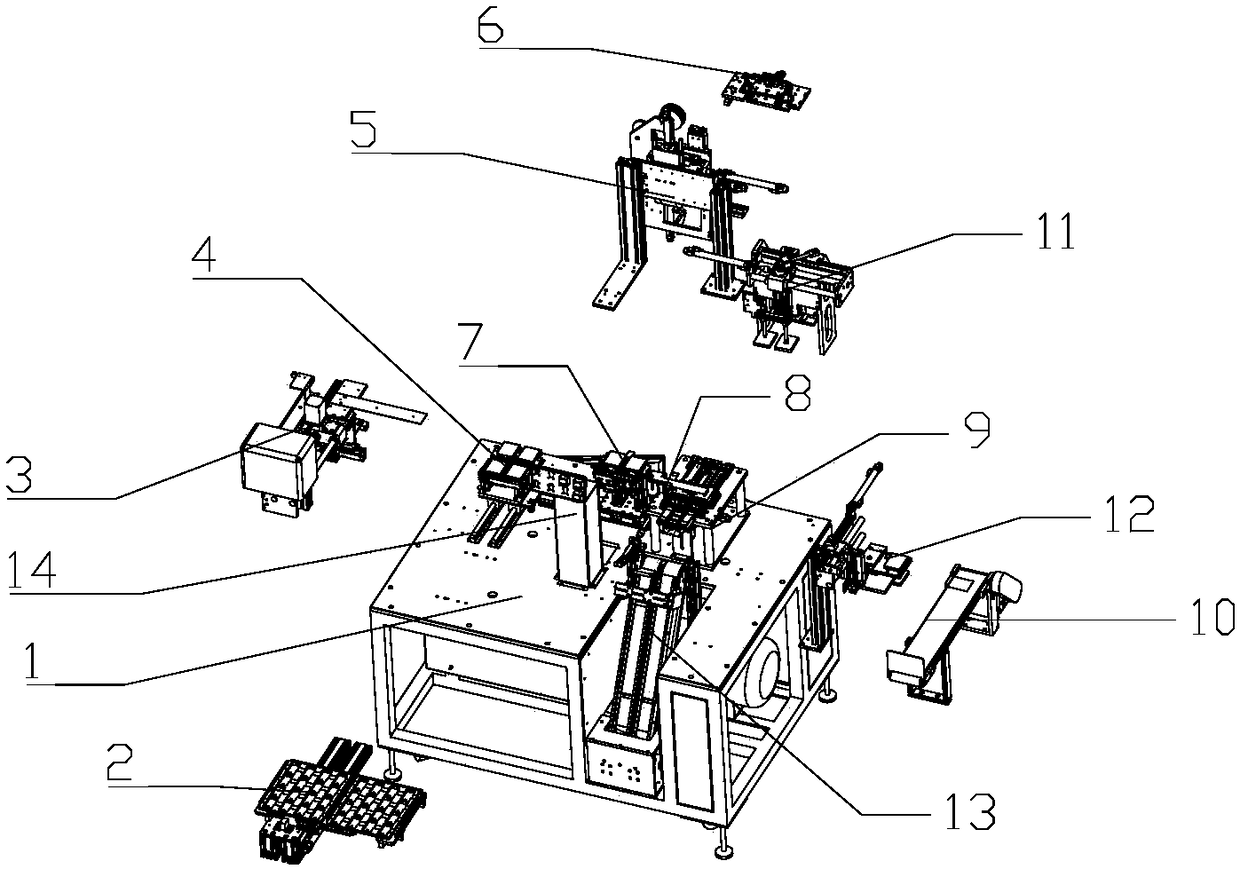

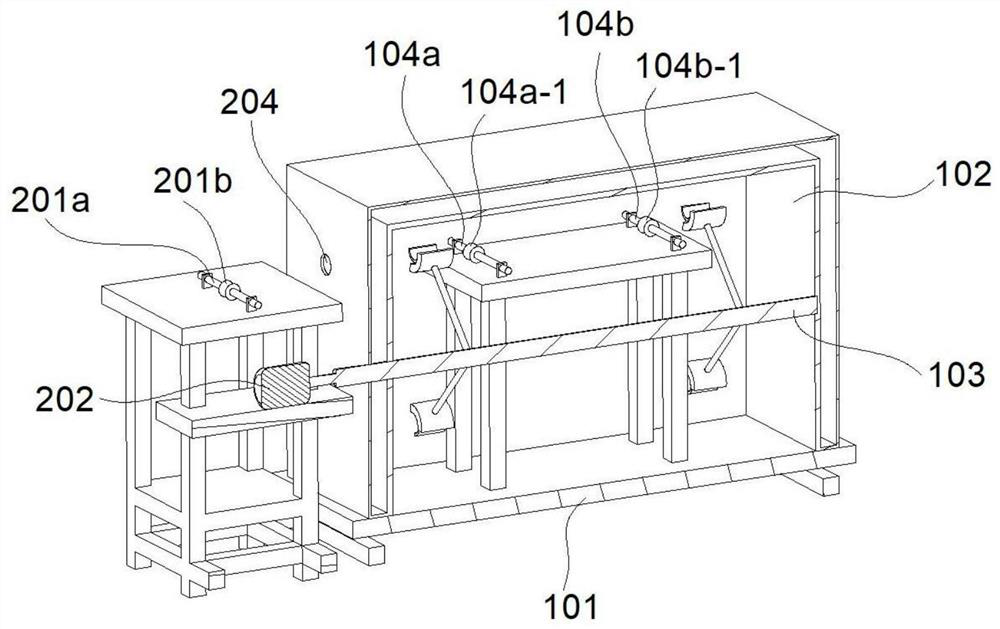

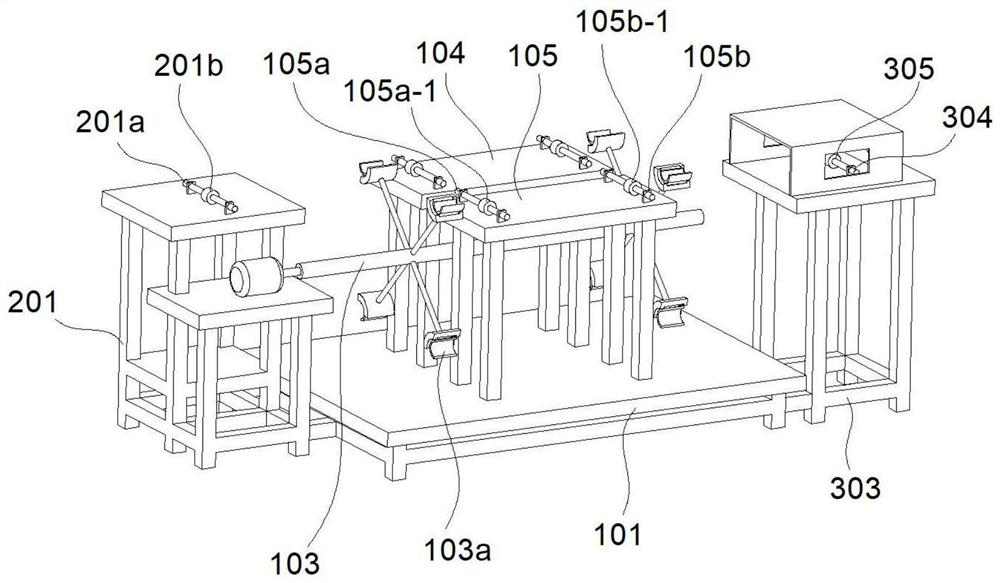

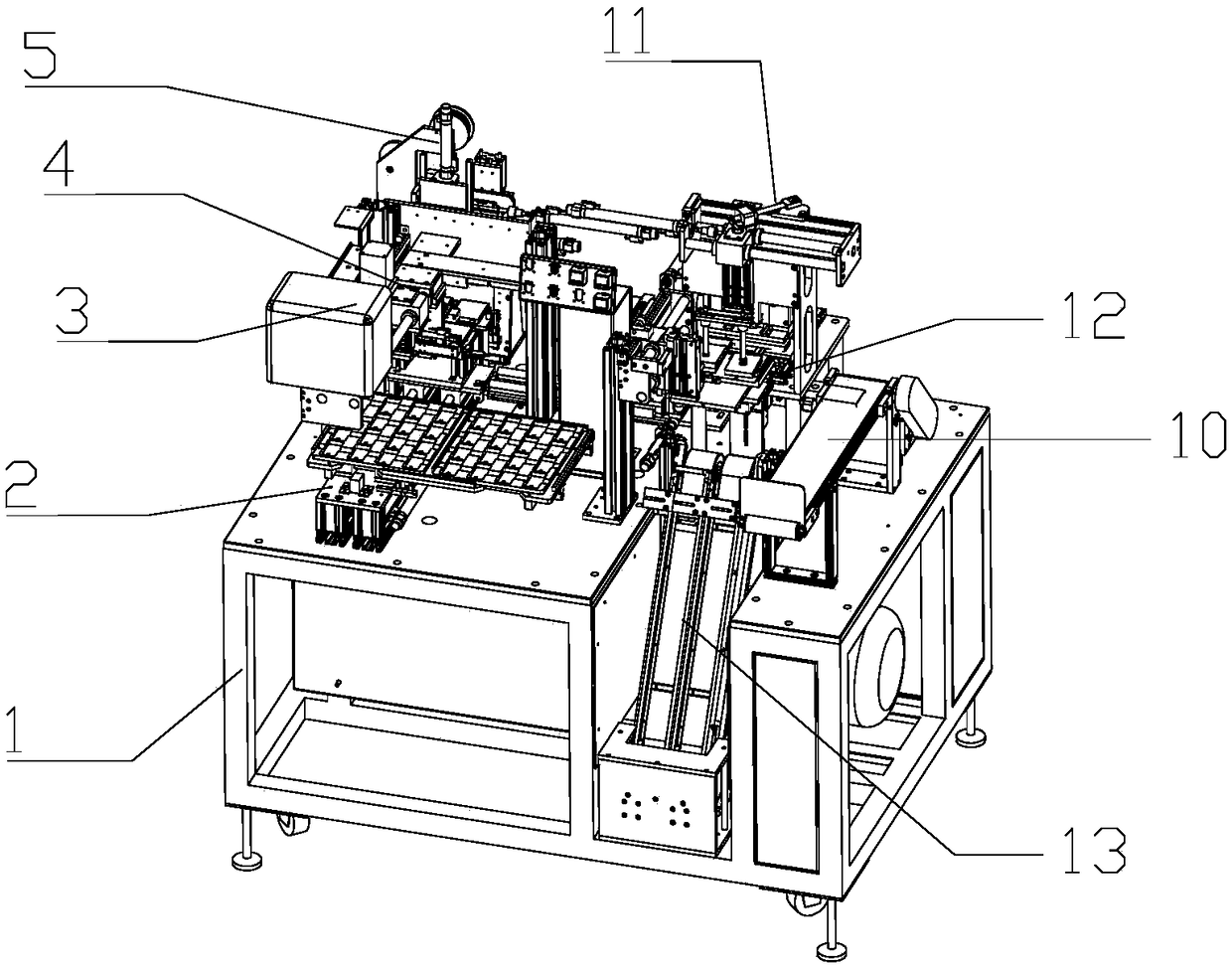

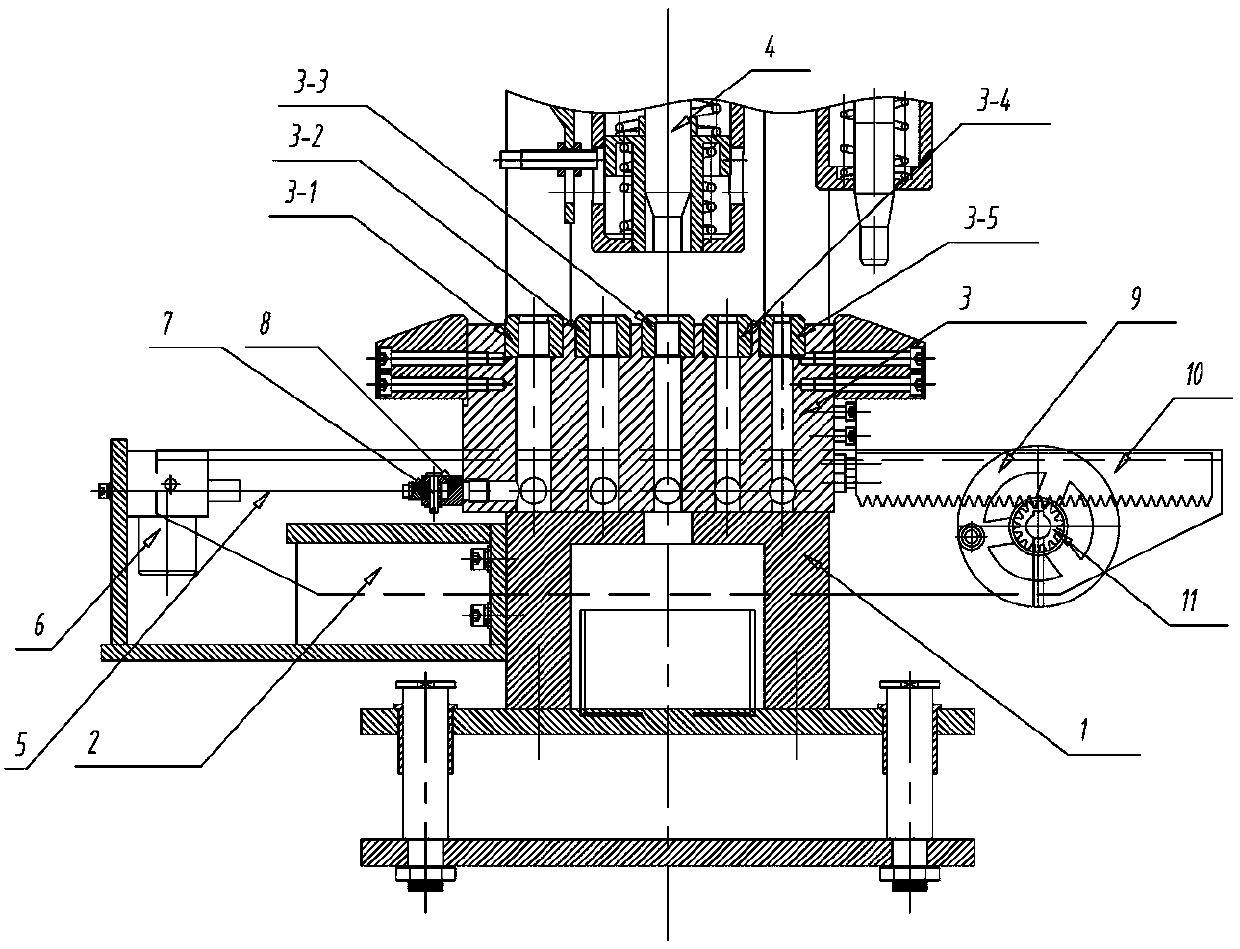

Counting device for cell packaging of power lithium batteries

InactiveCN108448155AIntelligent productionIncrease the level of automationAssembling battery machinesFinal product manufactureNew energyEngineering

The invention relates to the field of new energy lithium battery production, in particular to a counting device for cell packaging of power lithium batteries. The counting device for cell packaging ofthe power lithium batteries comprises a rack assembly, a second worktable, an aluminum casing feeding device, an aluminum casing carrying device, a battery delivery device, a finished product unloading device and a control assembly; the aluminum casing feeding device is fixedly arranged on the rack assembly, is arranged beside the second worktable and can move leftwards and rightwards; the battery delivery device can move a processed finished product out of the second worktable and send the finished product to the finished product unloading device, and the finished product unloading device isfixedly arranged on the rack assembly and used for bearing the finished product from the battery delivery device to complete discharging. The device completes packaging of cells in aluminum casings and performs counting and discharging, the automation level is improved, and the production of square lithium batteries is more intelligent.

Owner:吴崇清

Power lithium battery core packaging aluminum shell device

InactiveCN108539283AIntelligent productionIncrease the level of automationAssembling battery machinesFinal product manufactureNew energyEngineering

The invention relates to the field of new energy lithium battery production, in particular to a power lithium battery core packaging aluminum shell device, which comprises a rack assembly, a second work table, an aluminum shell feeding device and an aluminum shell transporting device, wherein the second work table is fixedly disposed on the rack assembly, the process of pressing a battery core andan aluminum shell is completed in the second work table, the aluminum shell feeding device is fixedly disposed on the rack assembly and beside the second work table and is used to transport the aluminum shell for processing, and the aluminum shell transporting device is fixedly disposed on the second work table, can move left and right and is used to transport the aluminum shell on the aluminum shell feeding device onto the second work table for processing. The power lithium battery core packaging aluminum shell device can be used to put the battery core into the aluminum shell, improves theautomation level and makes the production of square lithium batteries more intelligent.

Owner:吴崇清

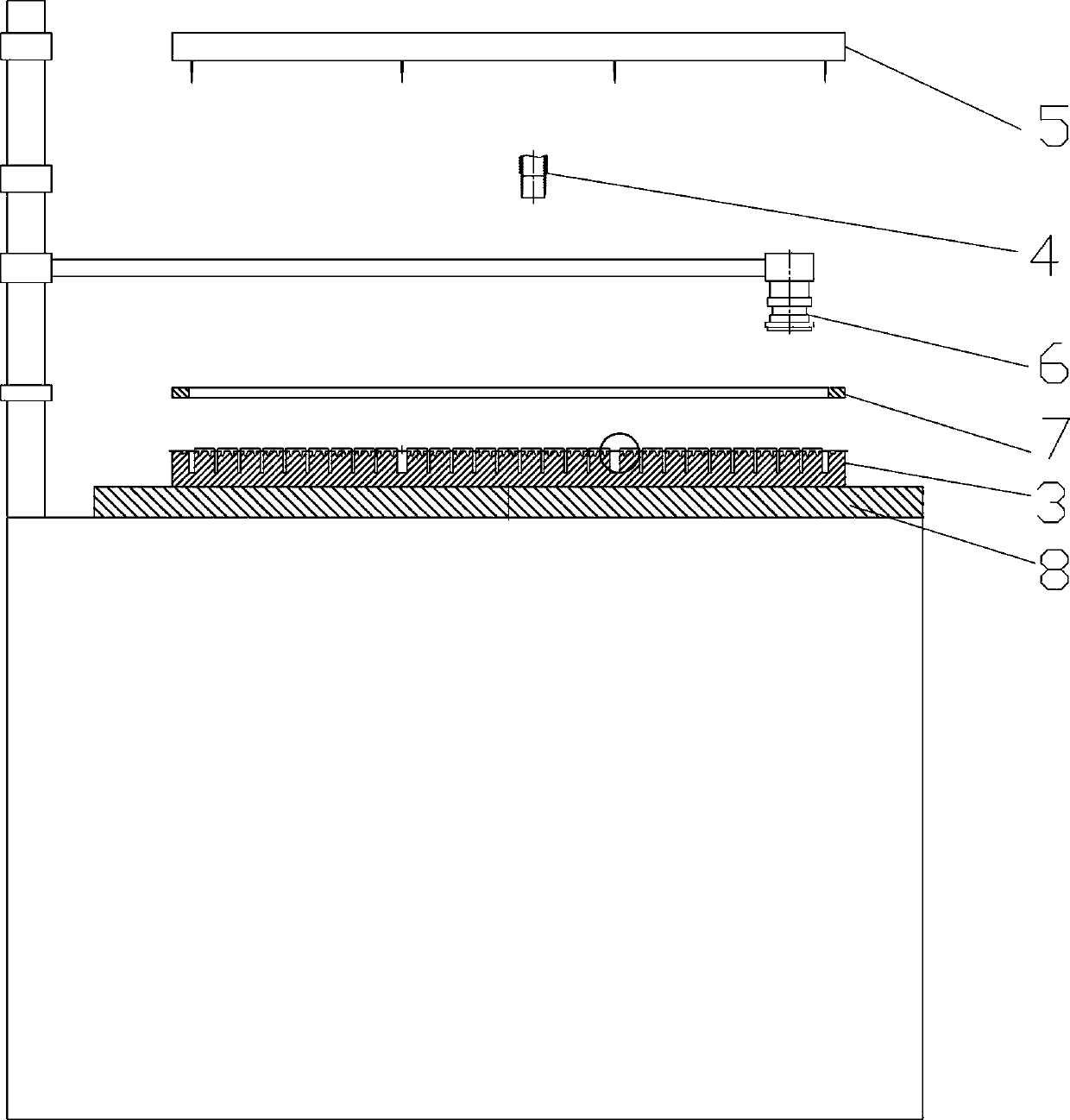

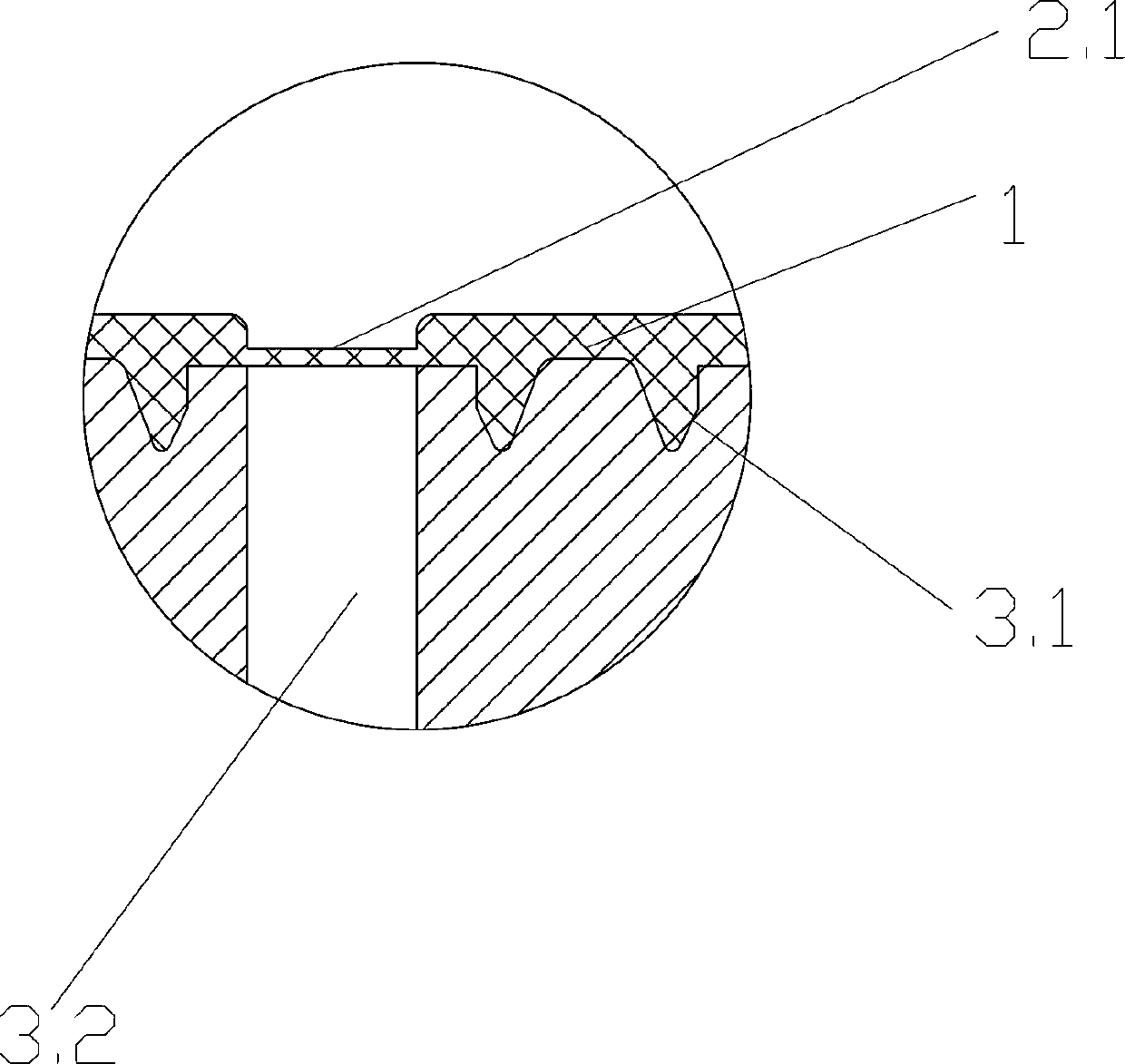

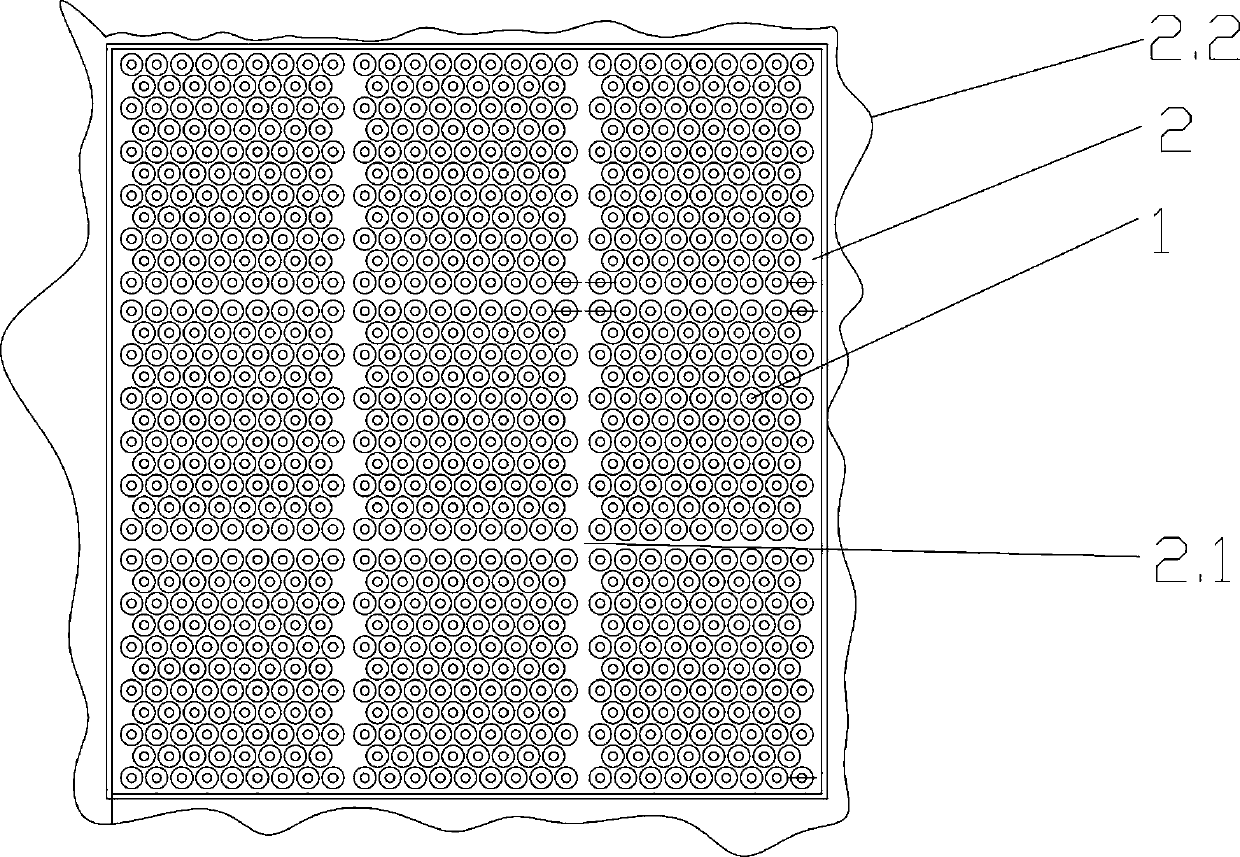

Cutting device and cutting method of rubber stopper vulcanized rubber sheet

The invention discloses a cutting device and cutting method of a rubber stopper vulcanized rubber sheet. The cutting device comprises a positioning plate used for positioning the rubber stopper and the vulcanized rubber sheet; and a cylindrical toothed knife used for removing defects of the rubber stopper and a square toothed knife used for cutting the vulcanized rubber sheet are arranged above the positioning plate. According to the cutting device and the cutting method, the defective rubber stoppers on the vulcanized rubber sheet can be quickly and automatically removed, the whole vulcanizedrubber sheet can be quickly cut into small plates while the excess rubber edge of the whole vulcanized rubber sheet is cut off, so that the working efficiency is greatly improved, and the labor intensity of workers is reduced.

Owner:程逸豪

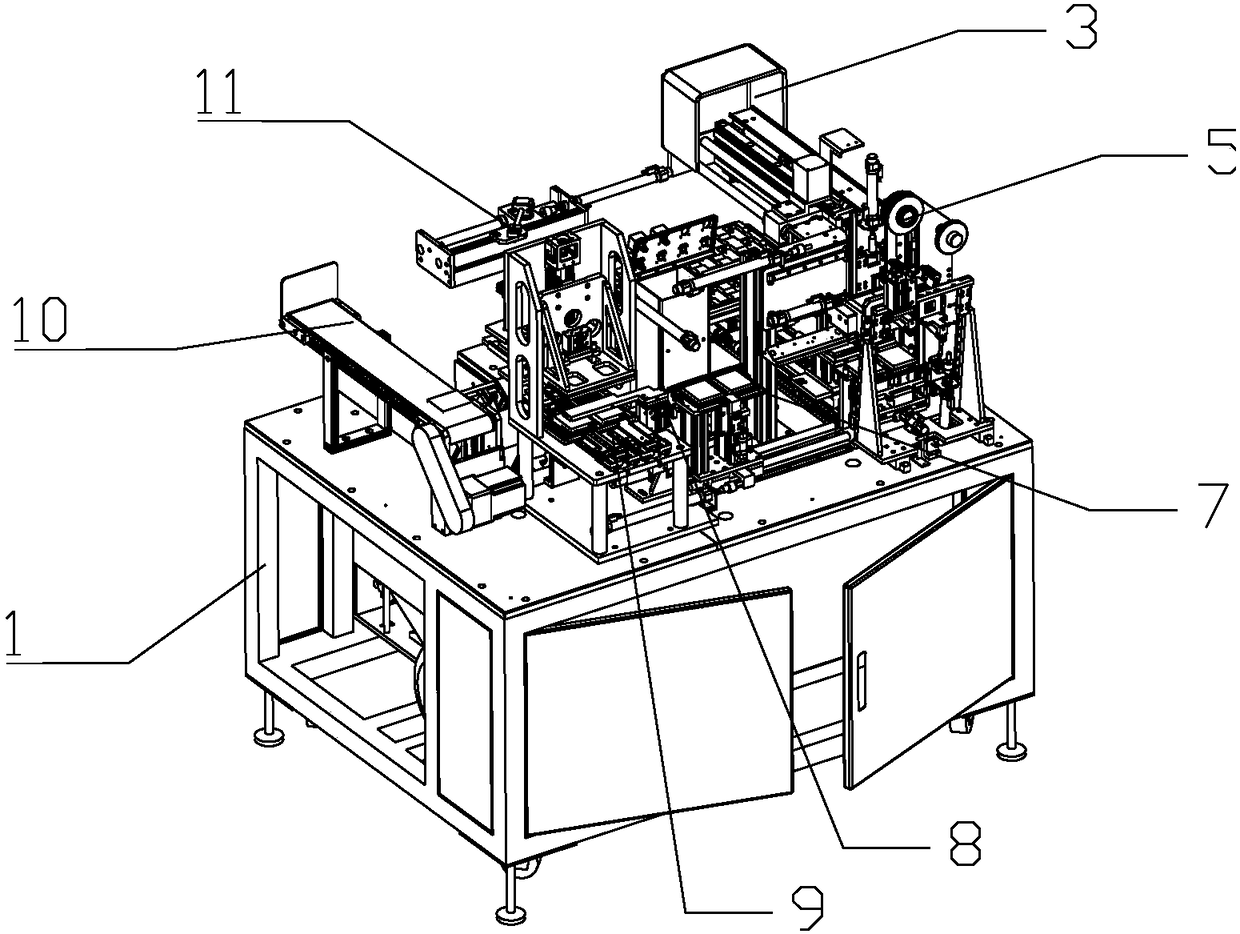

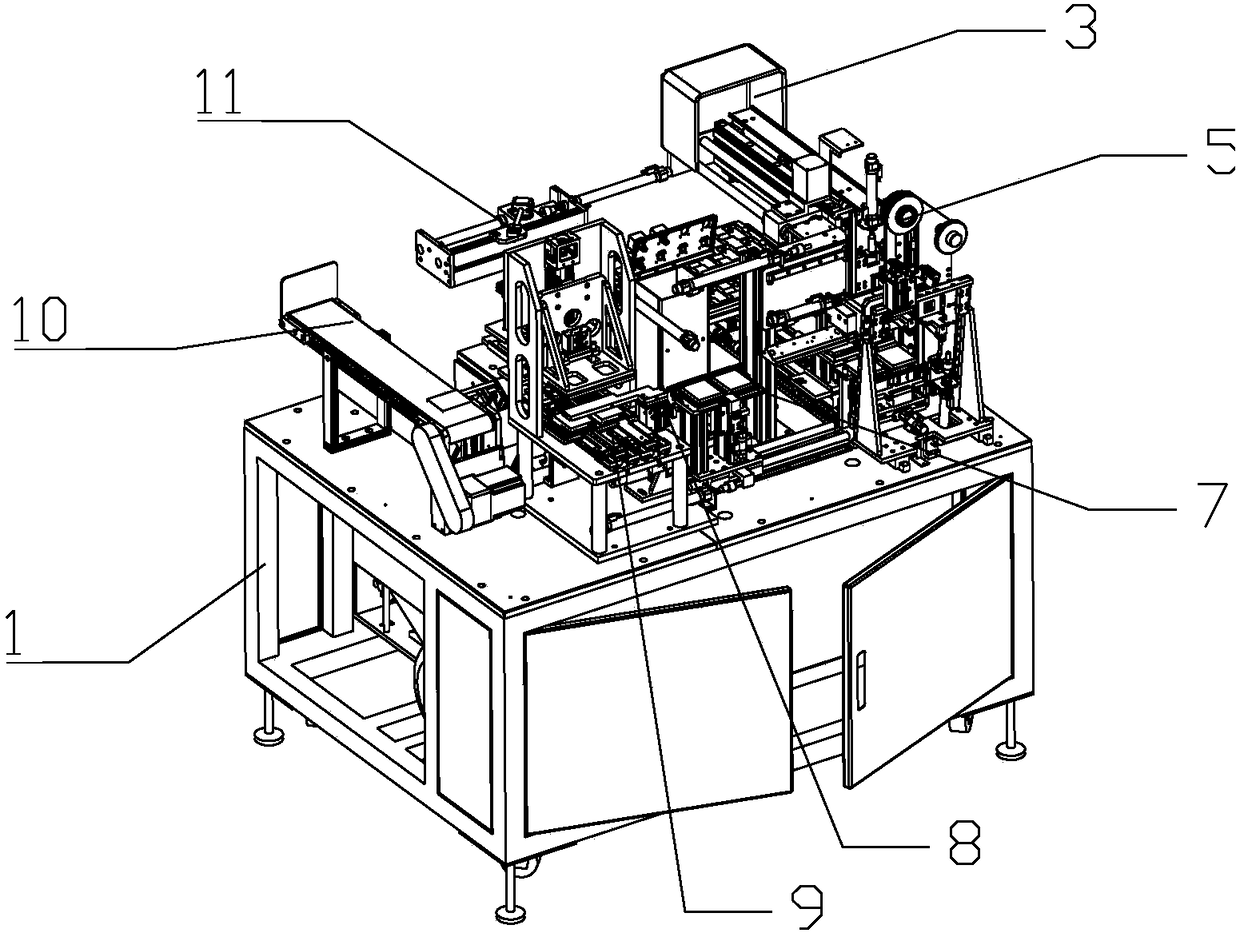

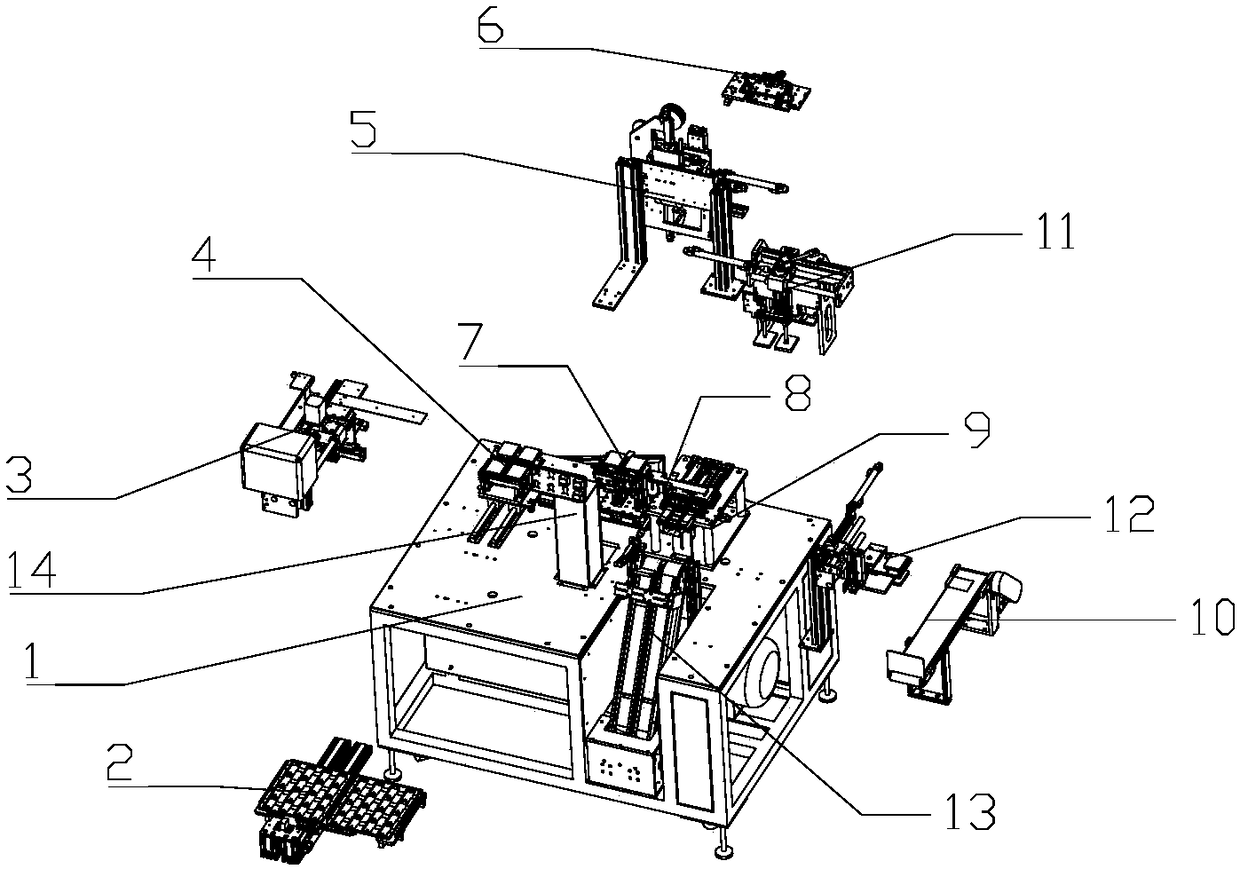

An automated method for adhesive packaging of new energy lithium battery cells

ActiveCN108306054BIntelligent productionIncrease the level of automationFinal product manufactureElectrolyte accumulators manufactureNew energyAutomated method

The invention relates to the field of new energy, in particular to an automatic method for adhesive packaging of new energy lithium battery cells. An automatic method for adhesive packaging of new energy lithium battery cells. The equipment used in the method includes a frame assembly, a cell material tray device, a cell handling device, a first workbench, an adhesive tape fixed-length cutting device, and an adhesive tape Adhesive device, translational transfer device, flip transfer device, second workbench, aluminum shell feeding device, aluminum shell handling device, battery unloading device, finished product blanking device and control assembly; this method simultaneously completes the square lithium-ion cell Paste the bottom adhesive tape and automatically put the battery cells into the aluminum shell, which improves the automation level and makes the production of square lithium batteries more intelligent.

Owner:扬州兴通锂电科技有限公司

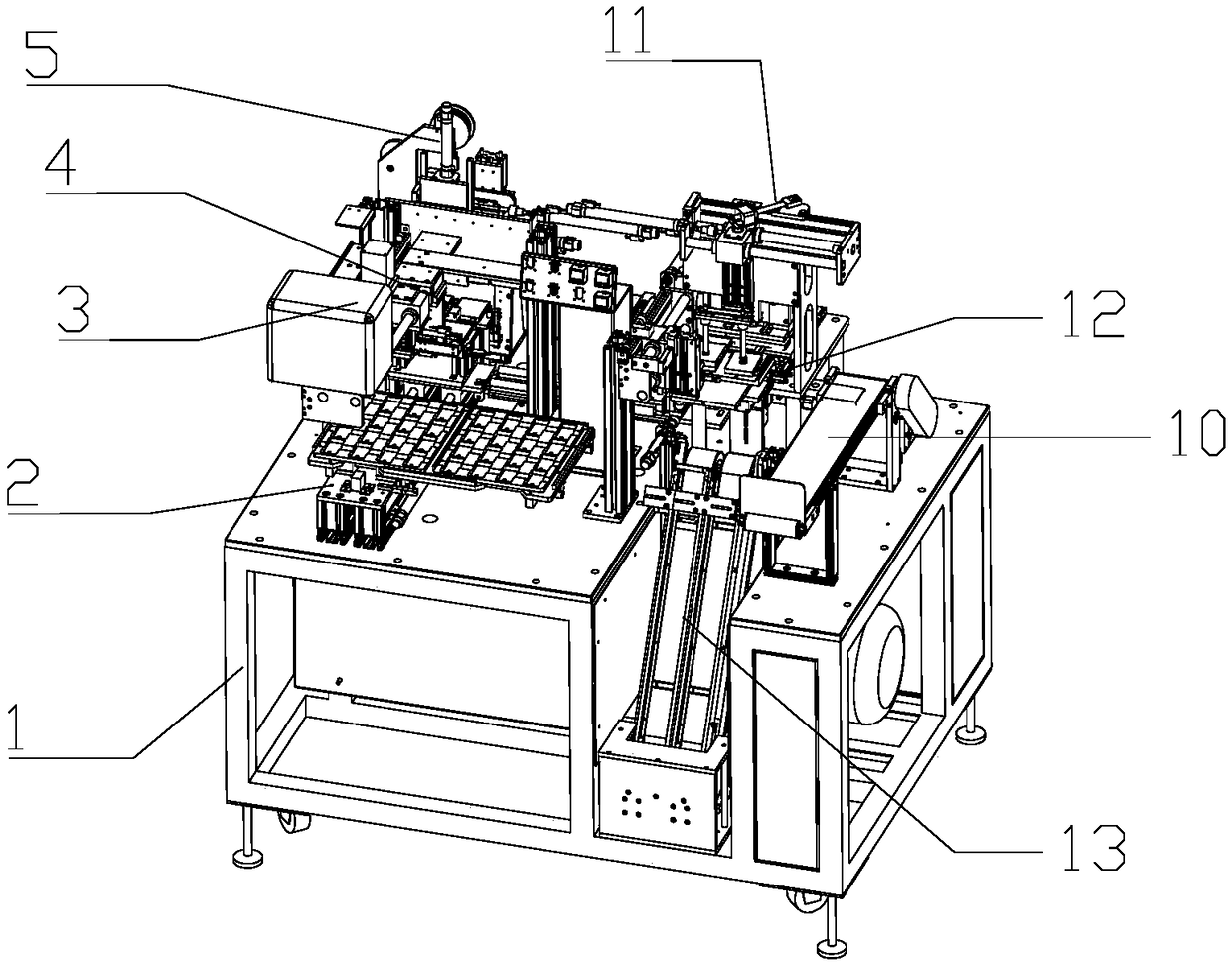

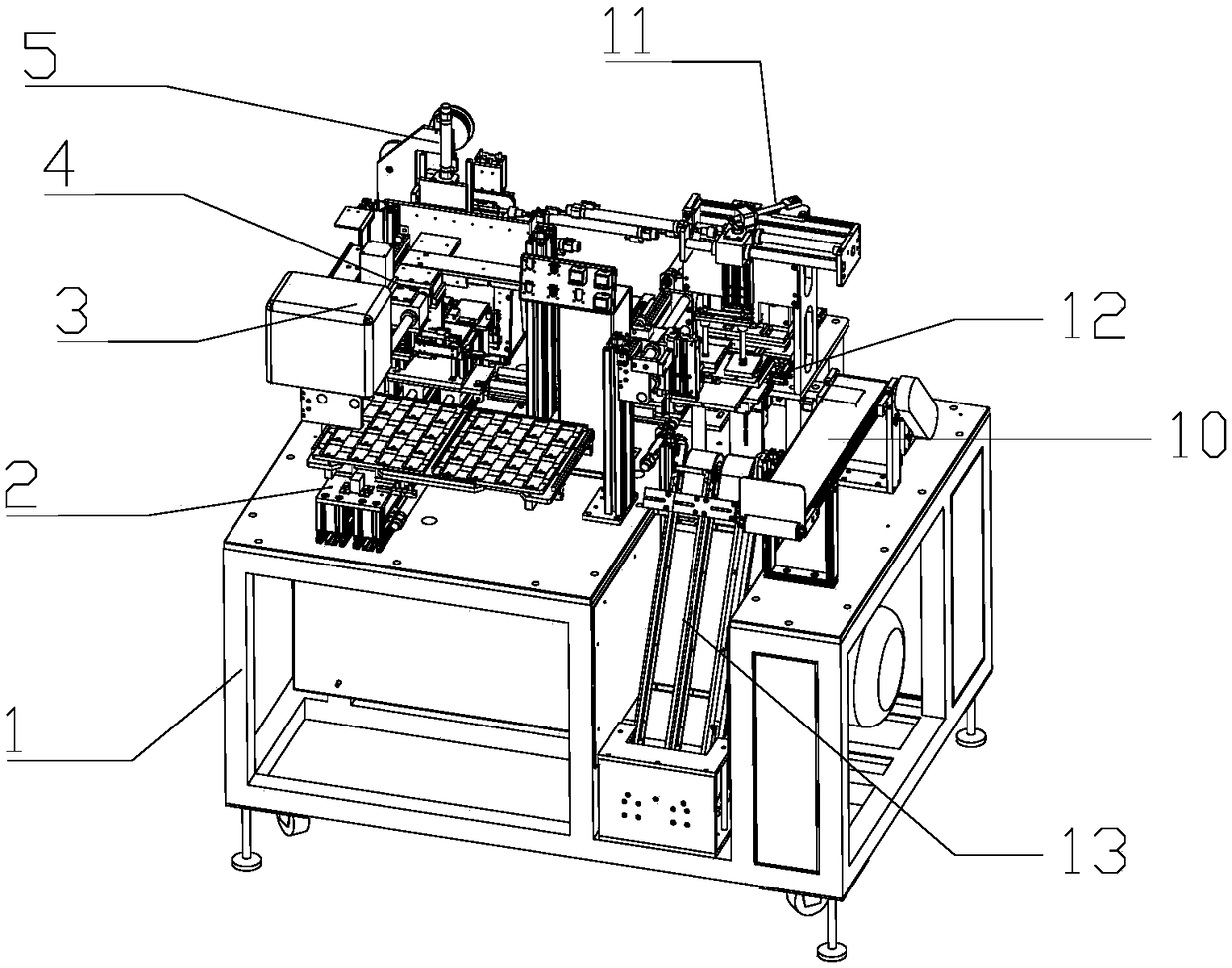

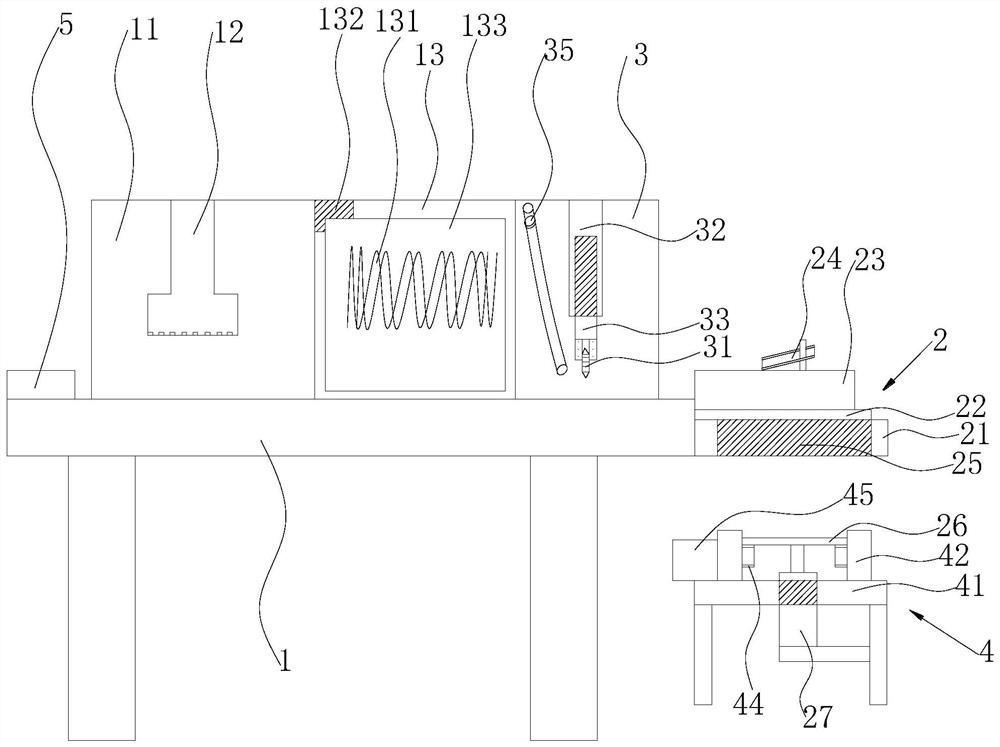

Device for sticking bottom gummed paper to battery core of power lithium battery

InactiveCN108598583AIntelligent productionIncrease the level of automationAssembling battery machinesFinal product manufacturePaper sheetLithium electrode

The invention relates to the field of new energy lithium battery production, and relates to a device for sticking bottom gummed paper to a battery core of a power lithium battery. The device for sticking the bottom gummed paper to the battery core of the power lithium battery comprises a frame component, a battery core material tray device, a battery core carrying device, a first workbench, a gummed paper fixed-scale cutting device, a gummed paper sticking device and a control component, wherein the frame component is used for installing other devices, the battery core material tray device isfixedly arranged on the frame component, the battery core carrying device is fixedly arranged on the frame component and is arranged above the battery core material tray device, the first workbench isfixedly arranged on the frame component and is connected with the battery core material tray device, the gummed paper fixed-scale cutting device is fixedly arranged on the frame component and is installed directly above the first workbench, and the gummed paper sticking device is fixedly arranged on the frame component and is connected with the first workbench and the gummed paper fixed-scale cutting device. According to the device, the process of sticking the bottom gummed paper to a square lithium ion battery core can be completed, the automation level can be improved, and the production ofa square lithium battery can be more intelligent.

Owner:吴崇清

Straw strip knitting machine

InactiveCN108356941AImprove work efficiencyIncrease productivityCane mechanical workingEnergy consumptionPressure sensor

The invention discloses a straw strip knitting machine which comprises a vehicle body. A feeding opening is formed in the front end of the vehicle body, and a discharging opening is formed in the rearend of the vehicle body. A feeding device is arranged in the vehicle body. Seedling shifting wheels are arranged on one side of the feeding device. A straw containing table is arranged on one sides of the seedling shifting wheels. A straw separation wall is arranged at the top of the straw containing table. Filter element devices are arranged on one side of the straw containing table. A leaf crushing machine is arranged at the bottom of the filter element devices. According to the whole straw strip knitting machine, straw can be conveyed into the machine to be processed; during processing, the straw is firstly subjected to leaf removal and grinding, then is knitted into strips through a straw knitting machine and finally is rolled up by a straw rolling bar; whole straw treatment is meticulous; dual rows of straw are processed at the same time; the work efficiency is high; leaves are crushed to return to the field, straw cores are processed into blocks and are repeatedly utilized, andlater transporting and processing are convenient; and in addition, when a pressure sensor detects that straw exists on second rotating rollers, a PLC controls a grinding device, a leaf removal deviceand an air blowing device to work, and energy consumption is reduced.

Owner:冯云霞

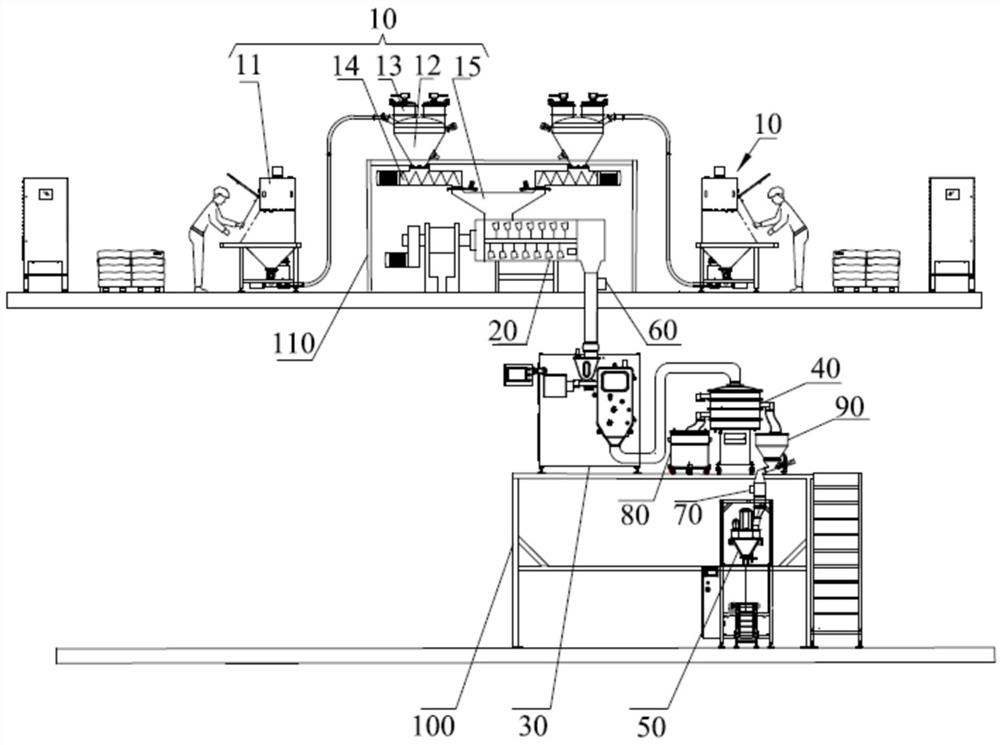

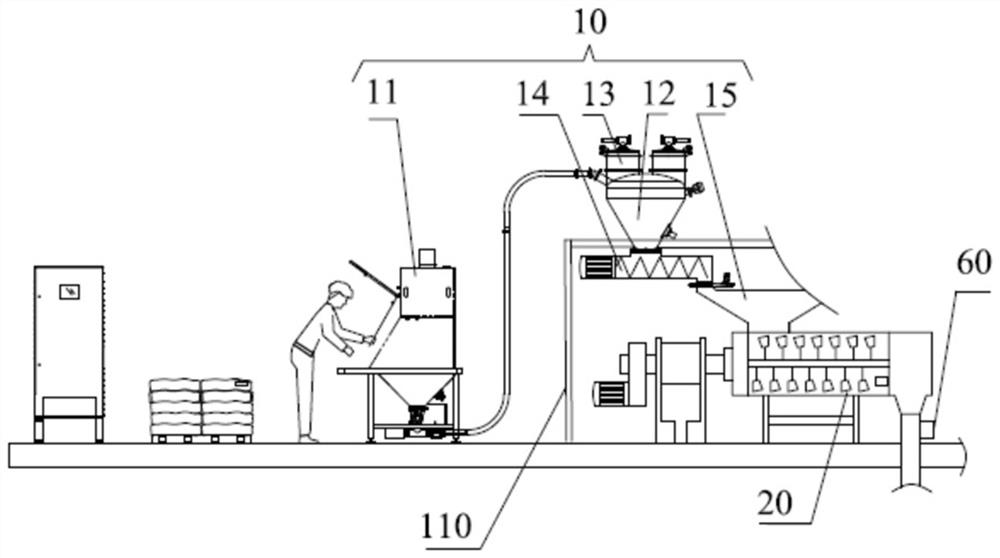

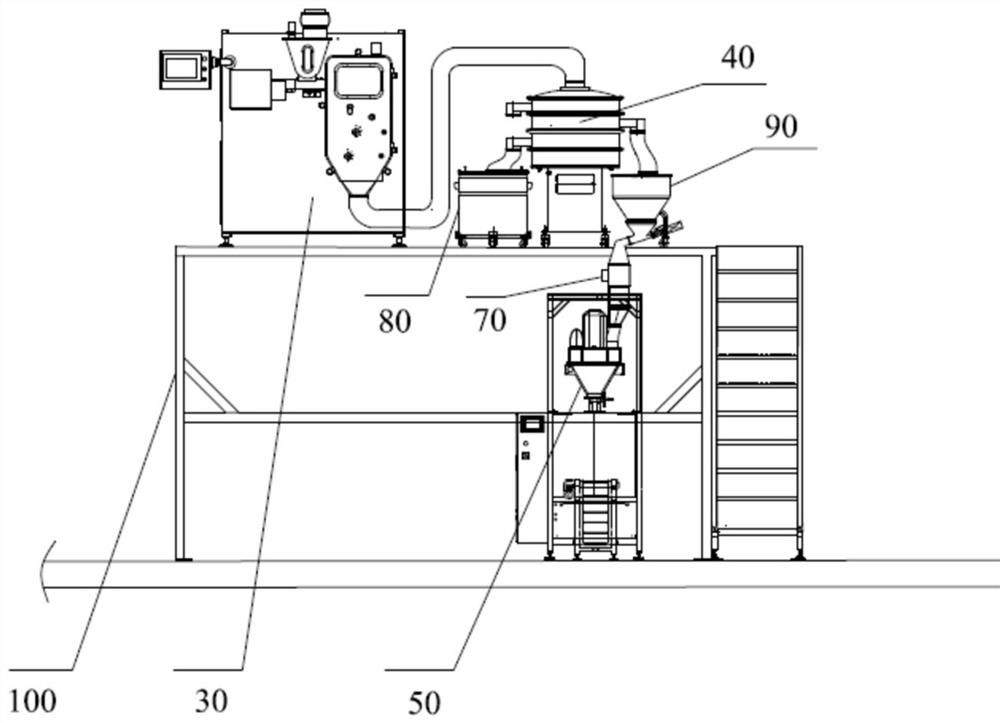

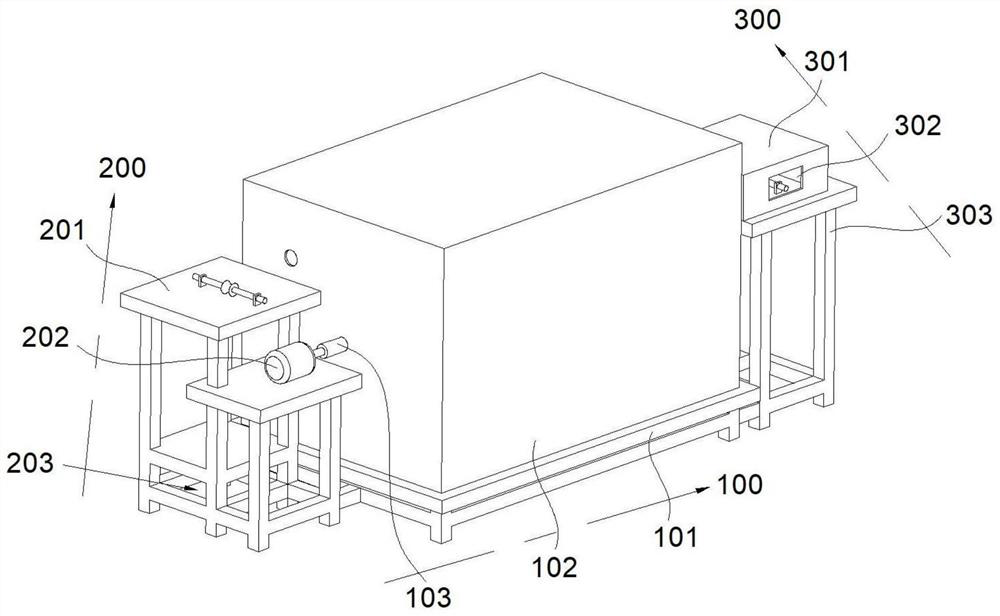

Traditional Chinese medicine continuous dry granulation system and granulation method

PendingCN113041956AReduce transshipmentReduce cacheSievingRotary stirring mixersProcess engineeringMixed materials

The invention provides a traditional Chinese medicine continuous dry granulation system and granulation method. The continuous dry granulation system comprises a feeding assembly for forming continuous granulation, material mixing equipment, a dry granulation machine, particle screening equipment and particle split charging equipment; the continuous dry granulation system comprises material uniformity inspection equipment used for inspecting the uniformity of a mixed material obtained by mixing of the material mixing equipment, and particle parameter inspection equipment used for inspecting parameters of qualified traditional Chinese medicine particles screened by the particle screening equipment. By adopting the continuous production equipment, the transfer and temporary storage of materials can be reduced, continuous production is realized, the problems of dust and the like in production are solved, and the production efficiency is improved; in addition, inspection equipment is arranged at a key position to monitor the state of materials in production in real time, so that closed-loop control can be formed by feeding back detected data, parameters of corresponding equipment are effectively adjusted, continuous and intelligent production is realized, and the quality is ensured to be qualified.

Owner:江西鼎峰智能装备有限公司 +1

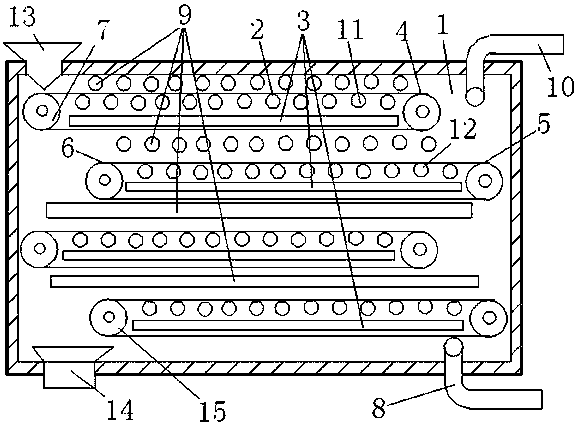

Intelligent rapid drying seamless steel pipe outer wall paint spraying device

ActiveCN113695198AAdjust the power level in timeReasonable designDrying gas arrangementsPretreated surfacesEngineeringMoisture sensor

The invention discloses an intelligent rapid drying seamless steel pipe outer wall paint spraying device. A work table assembly is arranged, electric rollers are arranged in a box body in the work table assembly to convey seamless steel pipes, a rotating shaft is arranged in the box body, the seamless steel pipes are driven to rotate, and heating and drying are fully conducted. Meanwhile, a heating assembly is arranged, the heating assembly is provided with a draught fan and heating wires, the design is reasonable, the heat efficiency is high, the drying effect is good, and the drying speed is high. On the other hand, the seamless steel pipe is used for detecting temperature and humidity through a humidity detection box connected outside the box body. By means of the device, a plurality of seamless steel pipes can be dried at the same time, data can be fed back through a temperature sensor and a humidity sensor, the power of the draught fan and the heating wires can be adjusted in time, the energy-saving effect is good, and production is intelligent.

Owner:CHANGZHOU UNIV

Light calcium carbonate chaff burning furnace heat-supplying and flue gas treatment device

InactiveCN107940977ASolve intractableReduce energy consumptionCalcium/strontium/barium carbonatesUsing liquid separation agentCombustionSulfate

A light calcium carbonate chaff burning furnace heat supply and flue gas treatment device, including a light calcium carbonate filter cake drying device, a drying hot air pipe is arranged in the light calcium carbonate filter cake drying device, and the drying hot air pipe is connected to The hot air supply pipes of the hull combustion furnace are connected, and the drying hot air of the light calcium carbonate filter cake drying device is produced by the chaff combustion furnace. The hot air is sent to the hot air pipe of the drying box through the hot air supply pipe; the drying heat The outlet of the air duct is connected to the flue gas dust removal treatment device. After the hot air work is completed, it will enter the flue gas dust removal treatment device for treatment, and will be discharged through the flue after reaching the standard. The present invention uses the chaff burning furnace to produce hot air and sends it to the drying box through the hot air supply pipe to dry the light calcium carbonate filter cake. Reduced the energy consumption for drying the light calcium carbonate filter cake.

Owner:湖南恒旺碳酸钙有限公司

High temperature resistant bar code label, its manufacturing method, using method and application

PendingCN106557797AImprove management efficiencyImprove after-sales qualityStampsRecord carriers used with machinesSurface layerWater transfer

The invention discloses a high temperature resistant bar code label, its manufacturing method, using method and application, comprising a carrier film provided with a release layer wherein the release layer is provided with an aqueous PVA surface layer or an acrylic surface layer. Prior to the use of the bar code label, the bar code label's surface layer is printed by the bar code. After that, it can be used without having to undergoing the step of water transfer printing, therefore, greatly increasing the working efficiency. In addition, as the bar code is perfectly integrated with an initial stage product, the bar code label is durable.

Owner:广州市韦格尔材料科技有限公司

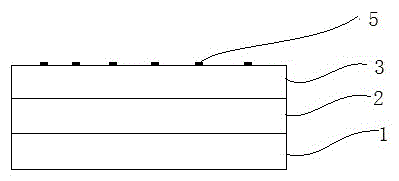

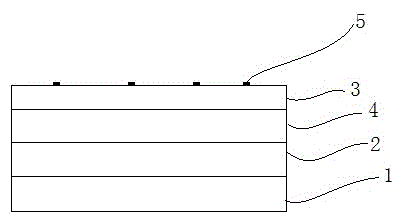

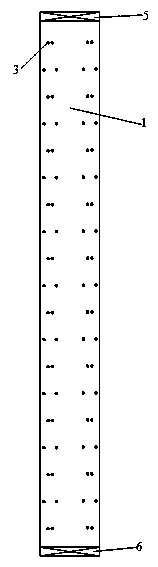

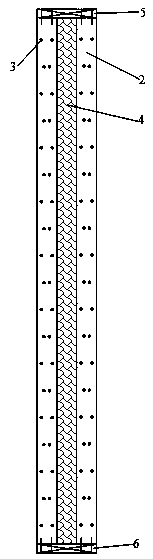

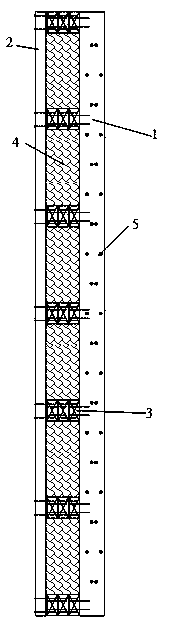

Modularized nailing layer building block heat insulation board

InactiveCN109235673AImprove mechanical performanceIncrease stiffnessHeat proofingSurface layerEcological environment

The invention provides a modularized nailing layer building block heat insulation board. Several wall-penetrating wide planks are vertically parallel to one another, two rows of dual-surface-layer narrow planks are arranged between every two wall-penetrating wide planks respectively, and cavities defined by the dual-surface-layer narrow planks and the wall-penetrating wide planks are all filled with inner filling heat insulation boards. Factory prefabrication is completely achieved, full-automatic and intelligent production can be achieved, the durability is significantly improved, the ecological environment is not damaged, the yield is greatly increased, integration of sound insulation and heat insulation is achieved, inner holes are maximized, the rigidity and intensity of the boards aregreatly improved, the shock resistance is improved so that the modularized nailing layer building block heat insulation board can be used for high-rise housing construction, and the dosage of materials is reduced. The modularized nailing layer building block heat insulation board is simple in structure, but has good stress performance and incomparable deformation recovery capability, and can be used for both heat insulation exterior walls and heat insulation roofs. The modularized nailing layer building block heat insulation board is low in cost for housing construction, easy to process and convenient to construct, the mounting efficiency is greatly improved, and the cost is lowered.

Owner:SHENYANG JIANZHU UNIVERSITY

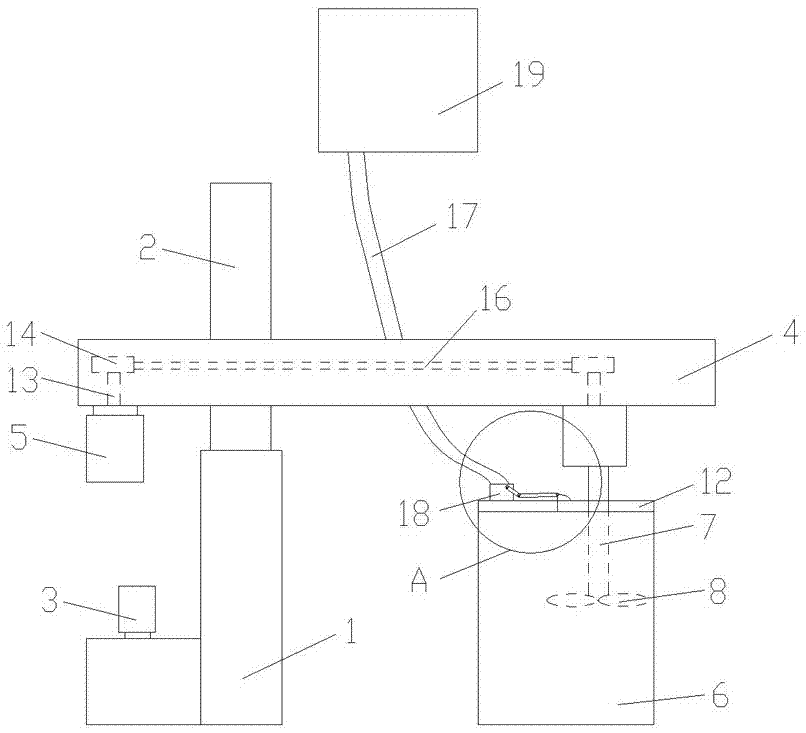

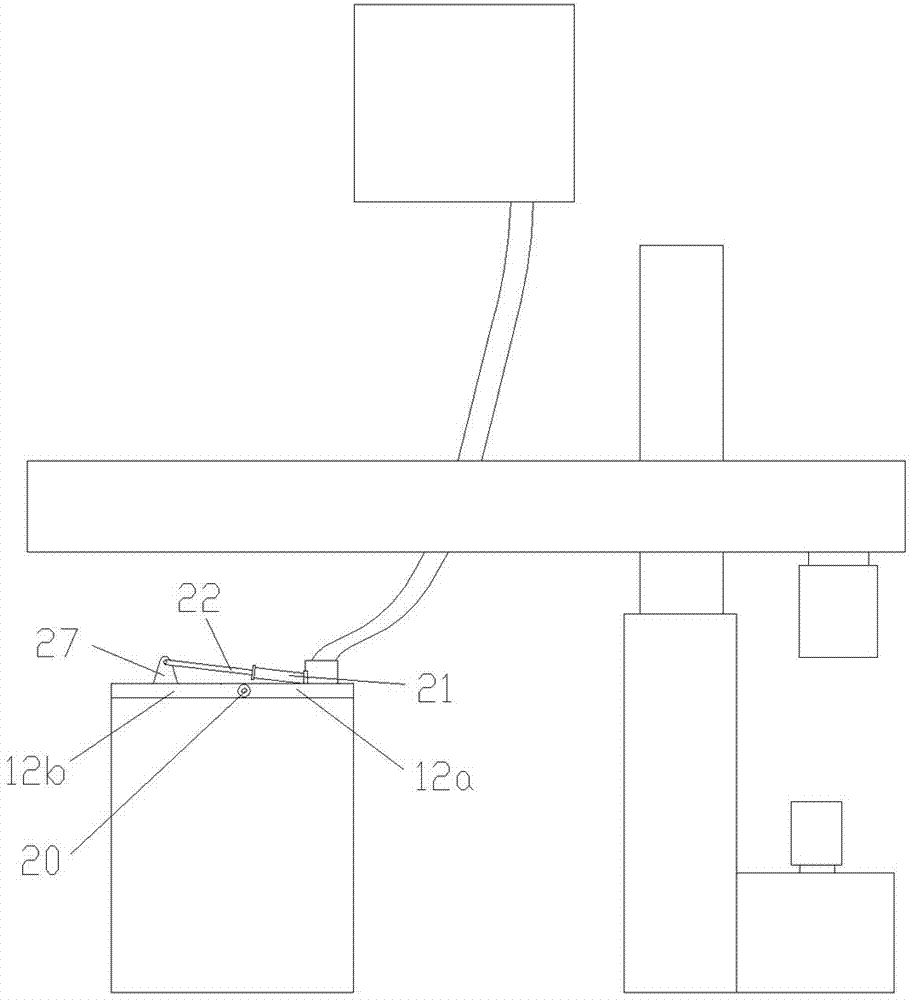

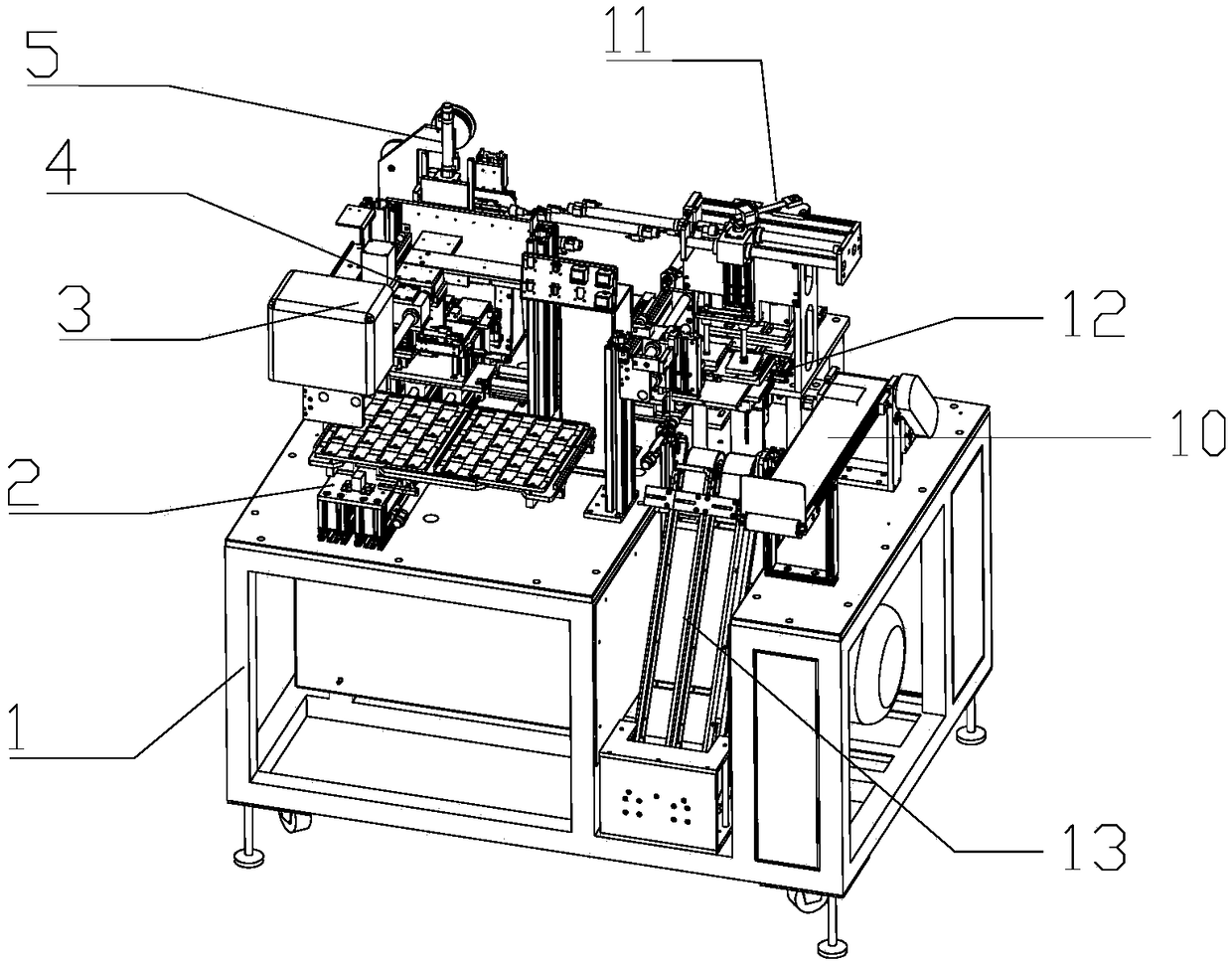

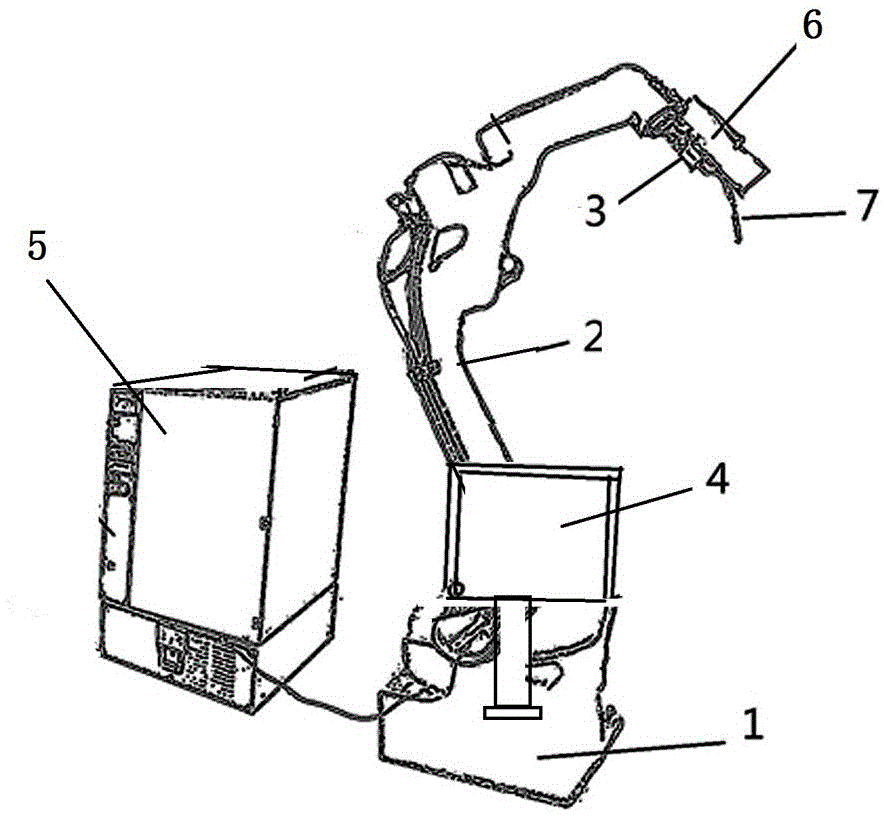

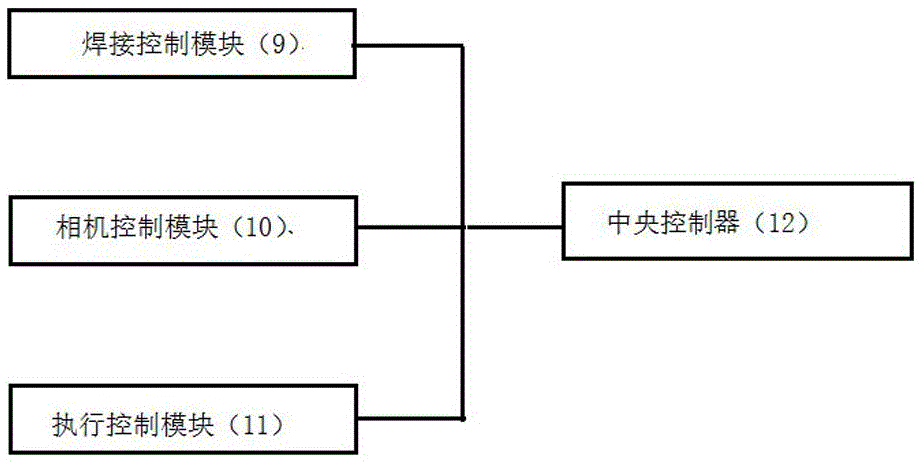

Control device for automatic welding for grid plate of robot, and working method thereof

ActiveCN106735980AIntelligent productionSimple processWelding/cutting auxillary devicesAuxillary welding devicesData informationControl engineering

The invention discloses a control device for automatic welding for a grid plate of a robot. The control device comprises a base, a mechanical arm, wrist joint, a touch screen and a control device, wherein an industrial camera and a welding gun are arranged on the wrist joint, the mechanical arm is arranged on the base, the wrist joint is arranged on the end part of the mechanical arm, the touch screen is arranged on a support frame of the base, the mechanical arm, the wrist joint, the touch screen and the industrial camera are all connected with the control device, and an electric control cabinet is arranged in the control device. According to the control device disclosed by the invention, the touch screen is arranged on the robot, the signal information of the grid plate is manually entered, then the grid plate is shot through the industrial camera, then the control device calls the type information of the grid plate from the entered database of the grid plate according to the shot data, and the control device commands a welding control device to weld the grid plate according to the called data information. The whole process is simple and convenient; and the control device realizes intelligent production and effectively improves the welding quality.

Owner:苏州鹄珂智能科技有限公司

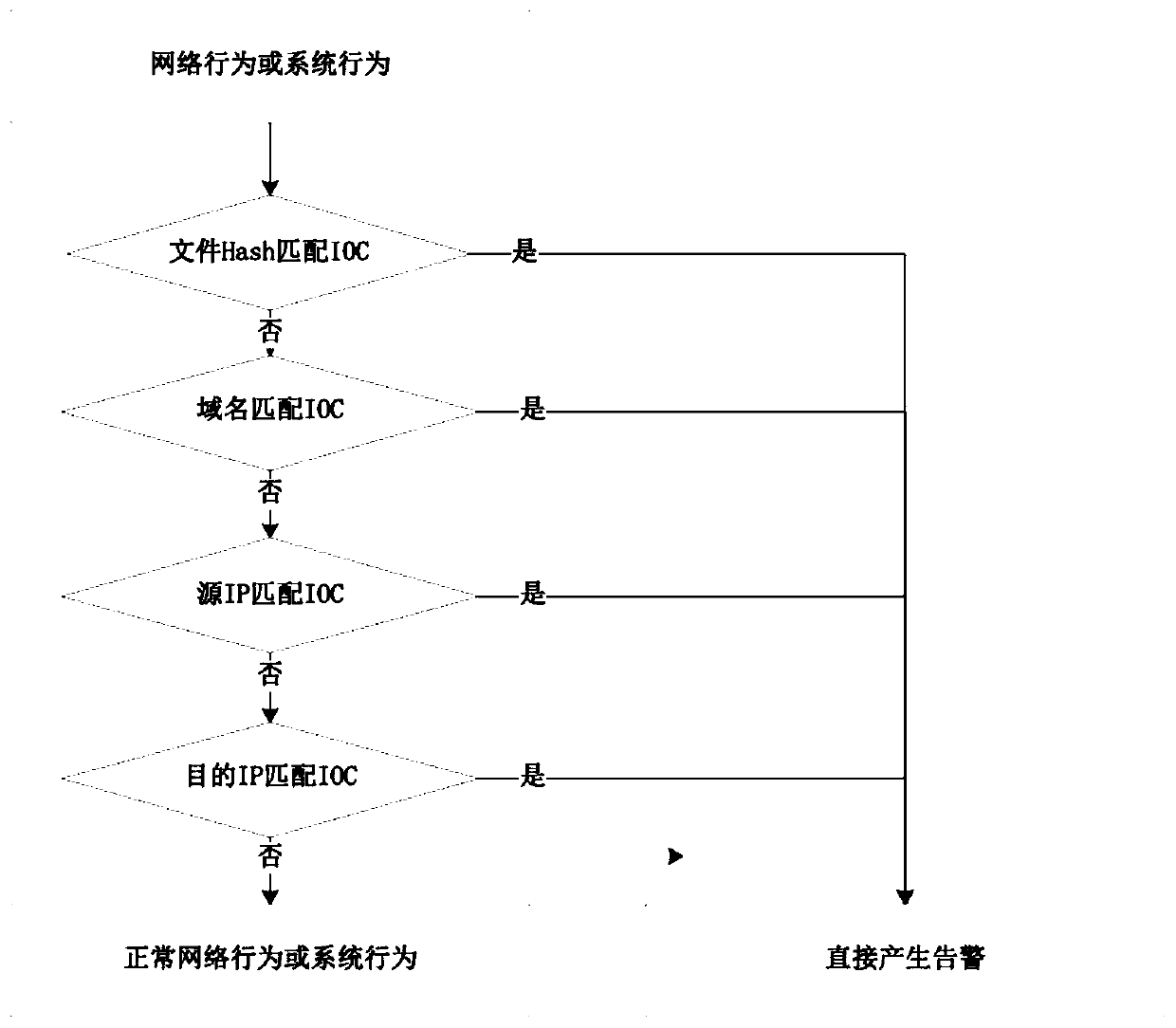

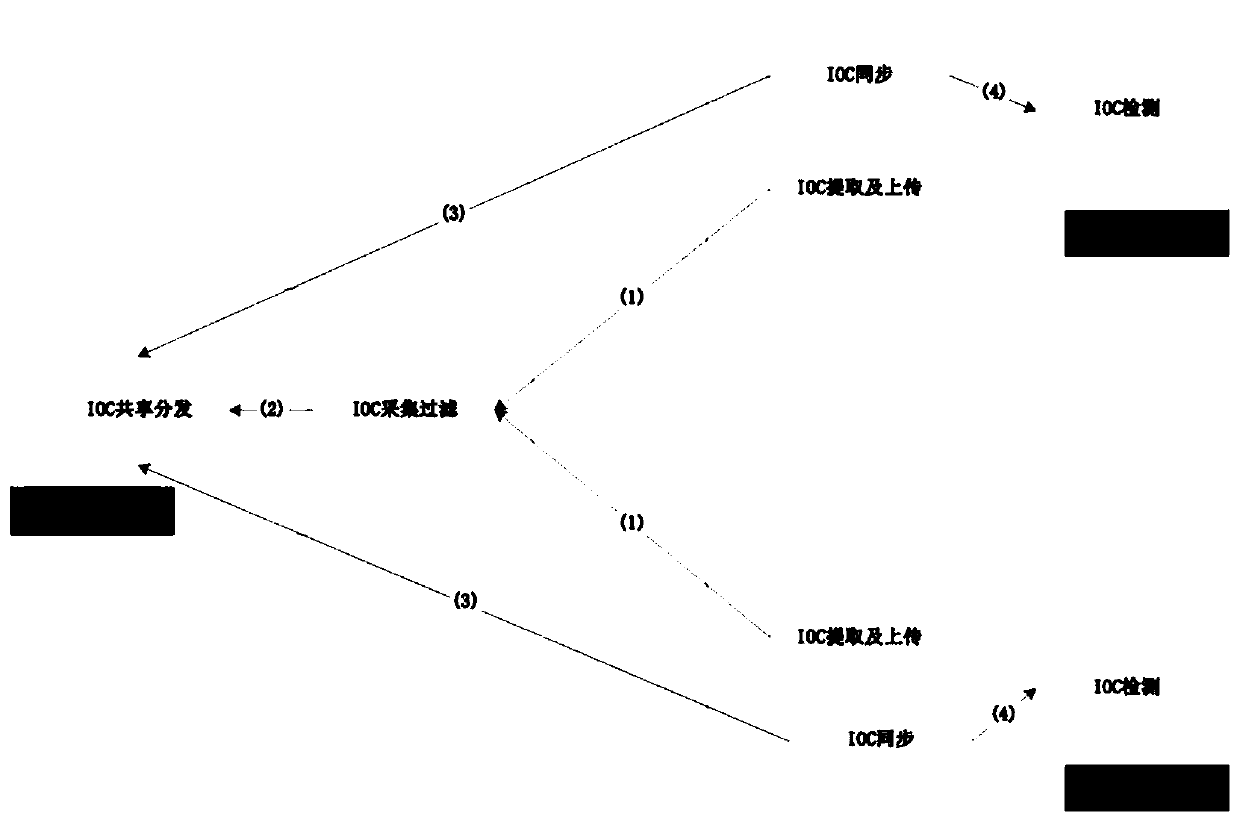

Collaborative defense method based on IOC intelligent extraction and sharing

The invention provides a collaborative defense method based on IOC intelligent extraction and sharing. The collaborative defense method comprises the following steps: S1) an IOC extraction and uploading module on a single detection device uploads extracted latest IOC data to an IOC acquisition and filtering module of a cloud IOC information center module; S2) the IOC acquisition and filtering module of the cloud IOC information center module allows the latest IOC data to match the existing IOC in the cloud IOC information center module, updates or newly adds a shared distribution IOC information library, and notifies the IOC to change data to an IOC shared distribution module of the cloud IOC information center module; S3) the IOC synchronization module of the single detection device synchronizes the latest IOC from the IOC shared distribution module of the cloud IOC intelligence center; and S4) the IOC detection module of the single detection device performs matching detection on thenetwork behavior according to the IOC to generate an alarm. According to the invention, a collaborative defense system with higher detection capability and less resource consumption can be formed.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

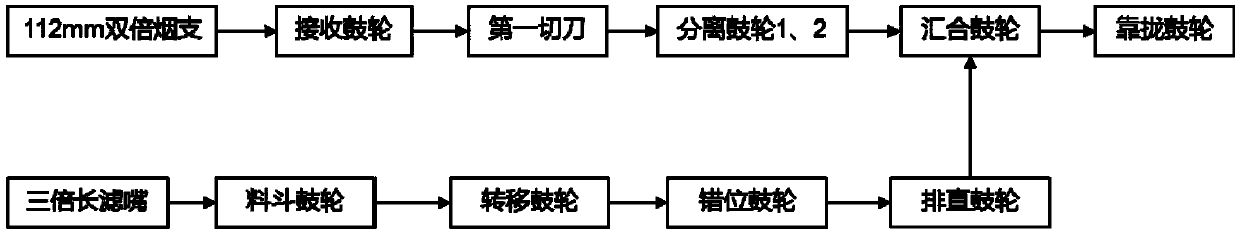

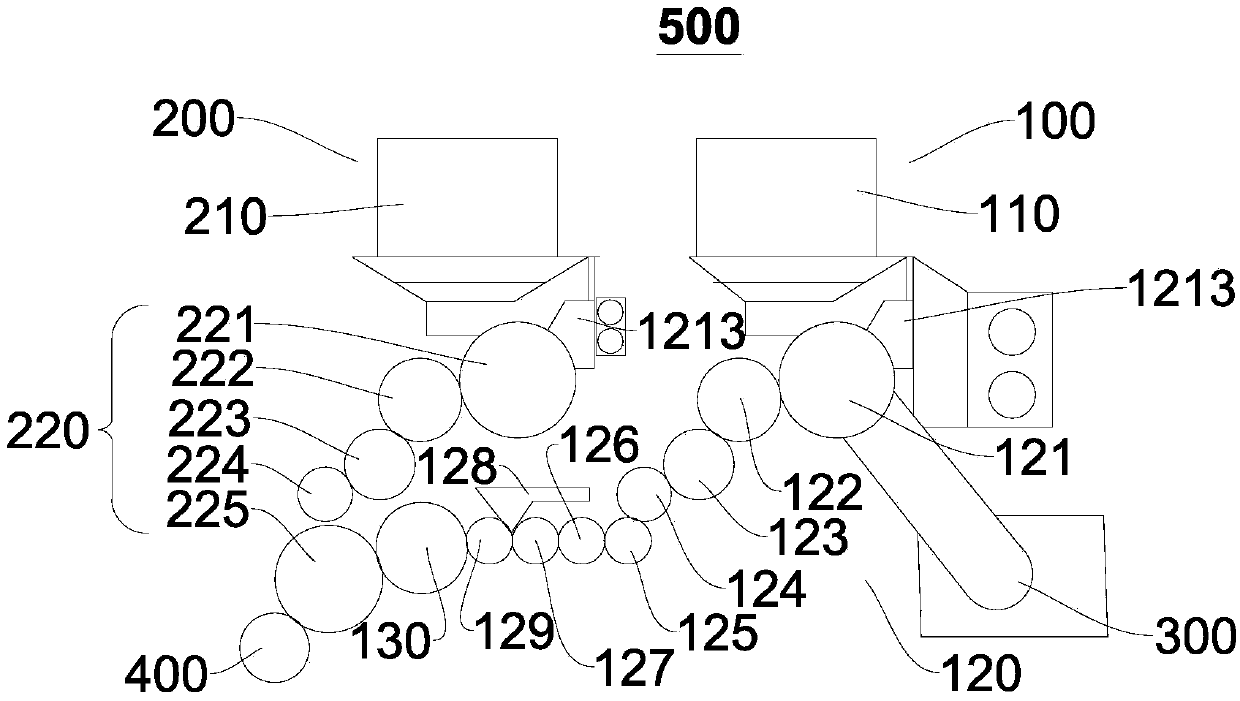

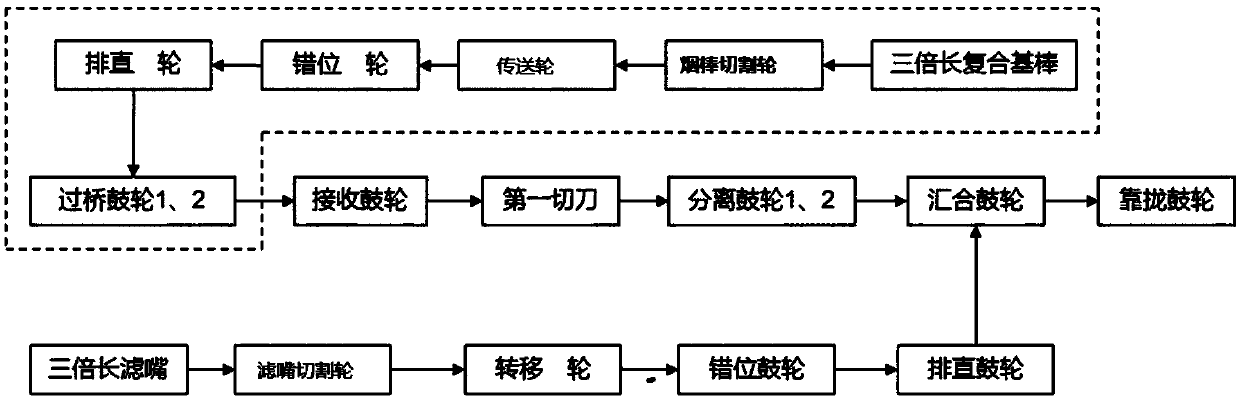

Heating non-burning cigarette assembling machine and use method thereof

PendingCN109588765AImprove efficiencyRealize Binary CompositeCigarette manufactureBurn cigaretteEngineering

The invention provides a heating non-burning cigarette assembling machine and a use method thereof, and relates to the field of cigarette manufacturing. The heating non-burning cigarette assembling machine comprises a filter tip supply system and a cigarette rod supply system, wherein the cigarette rod supply system comprises a tobacco pipe and a drum component, and the drum component comprises acigarette rod cutting wheel, a conveying wheel, a dislocation wheel, a straightening wheel, a first bridge drum, a second bridge drum, a receiving drum, a first separation drum and a second separationdrum which are sequentially and rotationally connected; and the filter tip supply system and the cigarette rod supply system realize combination of a base rod and a filter tip by arranging a mergingdrum, and the merging drum is rotationally connected with the second separation drum. The heating non-burning cigarette assembling machine provided by the invention can be used for batch and high-speed production of multi-section composite heating non-burning cigarettes. The invention also provides a use method of the heating non-burning cigarette assembling machine, and the use method is simple and convenient.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

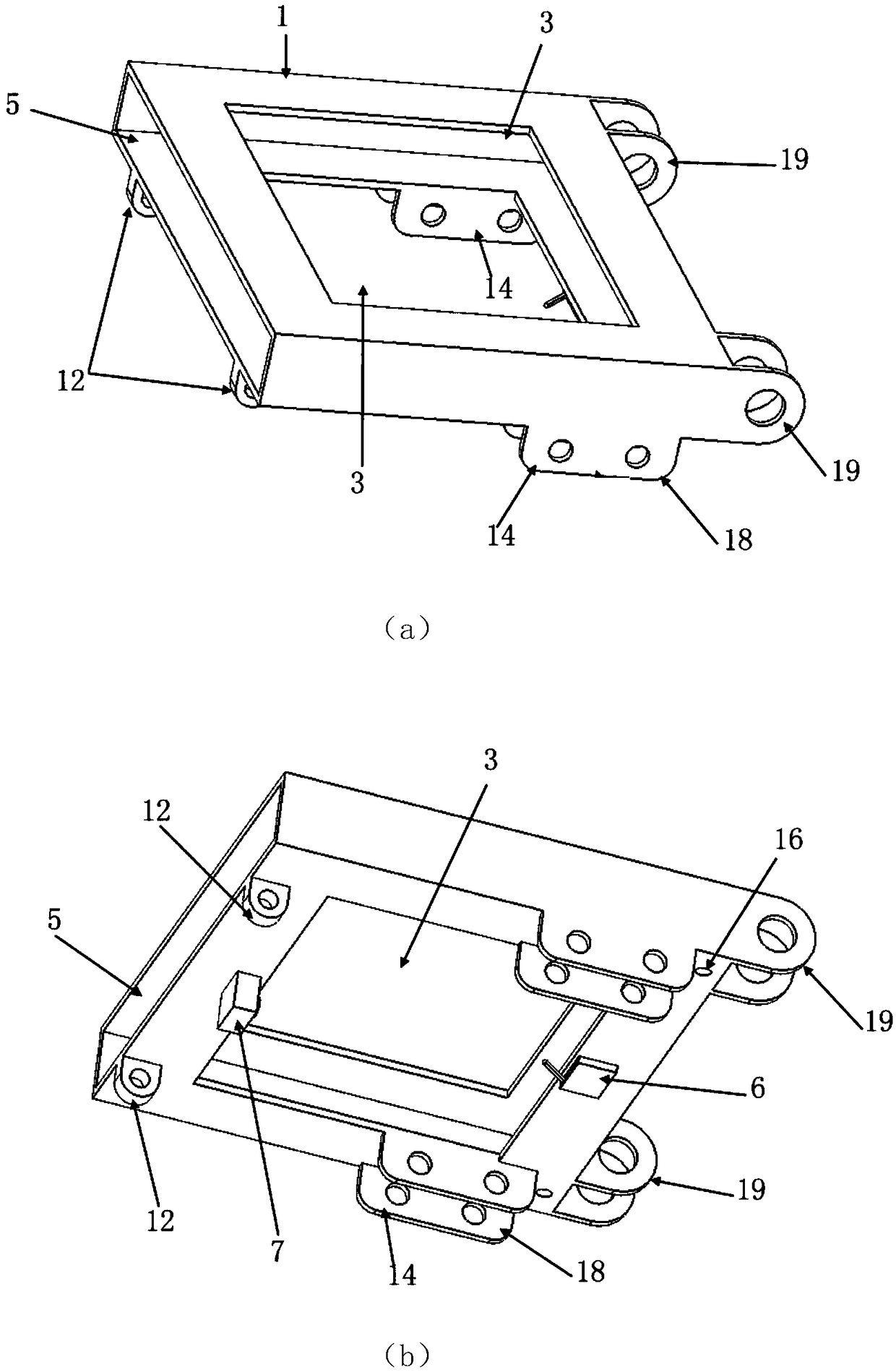

Male die and female die matching error prevention mechanism used for trough-type steel beam punching equipment

ActiveCN105562505AImprove productivityEfficient productionMetal working apparatusNumerical controlPunching

The invention provides a male die and female die matching error prevention mechanism used for trough-type steel beam punching equipment. A female die sliding positioning base is fixed to a punching forcep body of the numerical control trough-type steel beam punching equipment; an integrated block of multiple specifications of female dies is supported on the female die sliding positioning base in an oriented mode, achieves reciprocating movement through driving of a hand wheel and a gear and rack pair and is provided with the multiple female dies of different specifications; one end of the integrated block of the multiple specifications of female dies is connected with a stay wire and displacement sensor through a connection block and a connection pin; the stay wire and displacement sensor is connected with an electrical control system; output of position analog signals of the different specifications of female dies is achieved through the stay wire and displacement sensor, and the electrical control system transmits monitoring signals to a control console touch screen. Online and real-time monitoring of the positions of the different specifications of female dies is achieved through the stay wire and displacement sensor, the punching productivity is improved, and the phenomenon that as matched displacement of the integrated block of the multiple specifications of female dies is forgotten during hole machining and production, an error is caused is avoided.

Owner:SHIYAN HANTANG ELECTROMECHANICAL ENG

Workbench device for adhering adhesive tape to bottom of lithium battery cell

InactiveCN108448157AIntelligent productionIncrease the level of automationAssembling battery machinesFinal product manufactureNew energyLithium-ion battery

The invention relates to the field of new energy lithium battery production, in particular to a workbench device for adhering an adhesive tape to the bottom of a lithium battery cell. The workbench device for adhering the adhesive tape to the bottom of the lithium battery cell comprises a rack assembly, a first workbench, an adhesive tape fixed-length cutting device, an adhesive tape adhering device and a control assembly, wherein the first workbench is fixedly arranged on the rack assembly and connected with a cell tray device; the adhering process of the battery cell is completed on the first workbench; the adhesive tape fixed-length cutting device is fixedly arranged on the rack assembly, mounted right above the first workbench and used for cutting the fixed-length adhesive tape, so that the adhesive tape is adhered to the cell by the adhesive tape adhering device; the adhesive tape adhering device is fixedly arranged on the rack assembly, connected with the first workbench and theadhesive tape fixed-length cutting device and used for adhering the adhesive tape to the bottom of the cell. According to the device, adhesion of the adhesive tape to the bottom of the square lithiumion battery cell is completed, and the automation level is improved, so that production of the square lithium ion battery is more intelligent.

Owner:吴崇清

Used for punching and concave dies of channel steel beam punching equipment supporting error prevention mechanism

ActiveCN105562505BImprove productivityEfficient productionMetal working apparatusNumerical controlPunching

The invention proposes an anti-error mechanism for the convex and concave dies of the grooved steel beam punching equipment. The sliding positioning seat of the die is fixed on the punching pliers of the CNC punching grooved steel beam hole equipment, and the integrated blocks of the multi-standard die are guided and supported on the On the sliding positioning seat of the concave mold, the multi-specification concave mold integrated block realizes reciprocating movement through the hand wheel and the rack and pinion auxiliary drive. The multi-specification concave mold integrated block is installed with a variety of different specifications of the concave mold, and one end of the multi-standard concave mold integrated block The connecting block and the connecting pin are connected with a pull wire displacement sensor, and the pull wire displacement sensor is connected with the electrical control system. Through the pull wire displacement sensor, the output of the analog signal of the die position of different specifications is realized, and the electrical control system transmits the monitoring signal to the touch screen of the operating table. The invention uses a wire displacement sensor to realize on-line real-time monitoring of the positions of dies of different specifications, improves the punching productivity, and avoids the phenomenon of forgetting matching displacement of multi-standard die integrated blocks during hole processing and production, and causing errors.

Owner:SHIYAN HANTANG ELECTROMECHANICAL ENG

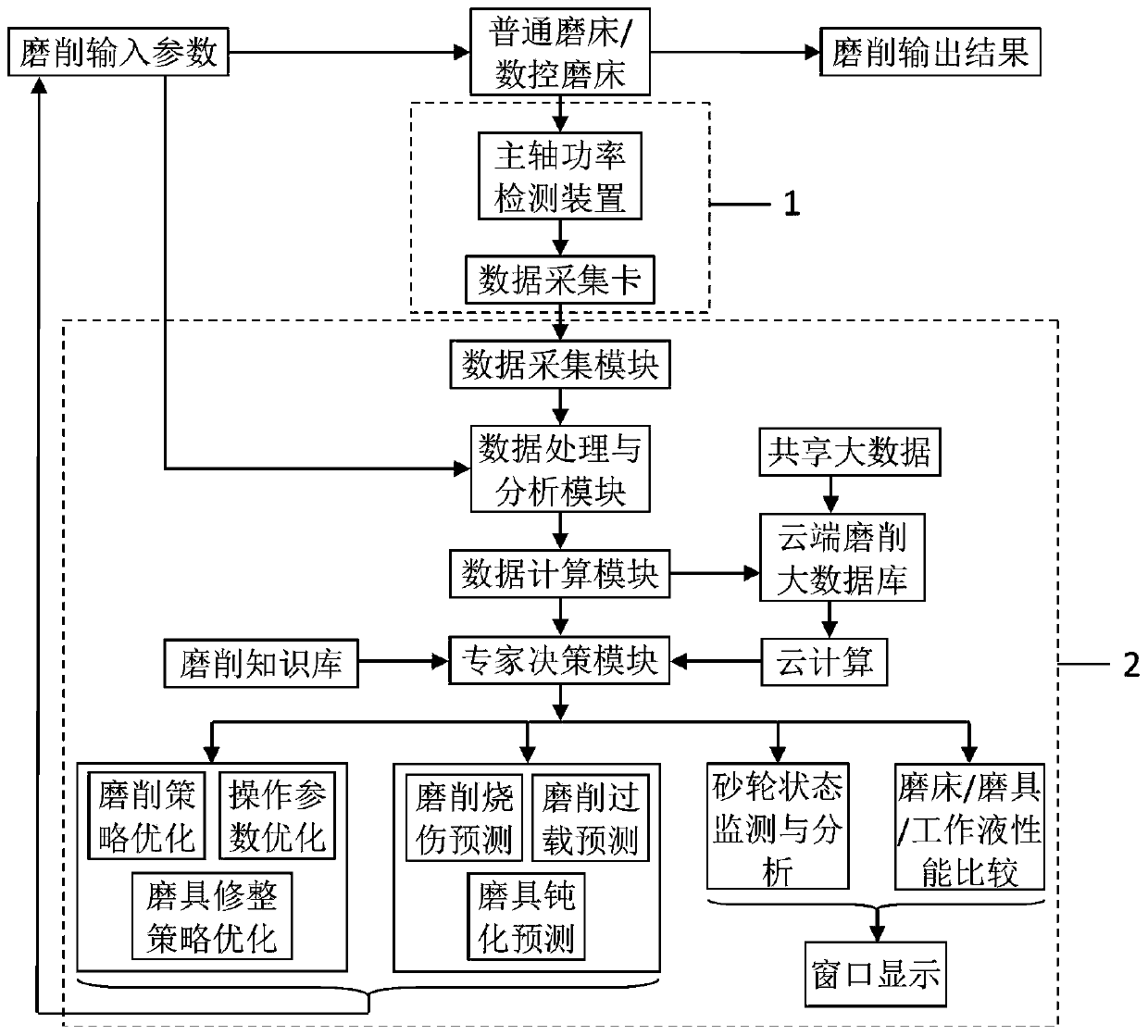

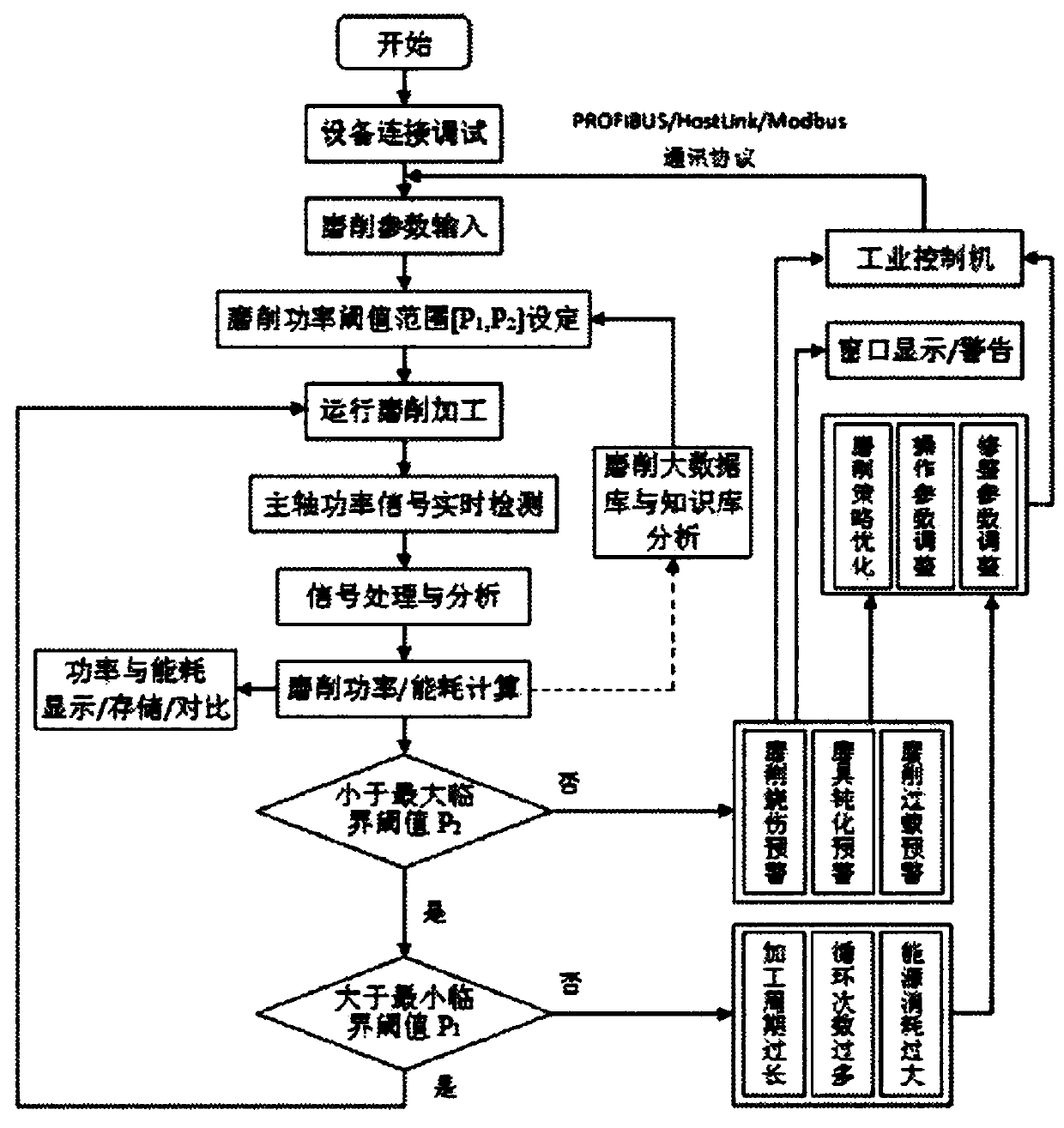

An intelligent monitoring system and decision-making method for grinding power and energy consumption

The invention discloses a grinding power and energy consumption intelligent monitoring system and a decision-making method, belonging to the technical field of machine tool monitoring. Aiming at the current actual grinding process practice, mainly through the experience of looking at the grinding sparks and listening to the grinding sound to judge the grinding state, set and adjust the grinding parameters, an intelligent grinding power and energy consumption is invented. Monitoring software and hardware systems, big data analysis and decision-making systems and methods, to achieve real-time monitoring and analysis of power and energy consumption during the grinding process, with performance comparison and analysis of grinding machines, grinding tools, working fluids, and grinding processing strategies and processes Parameter optimization function. By comparing the real-time grinding power with the lower limit of the critical power threshold P 1 and upper limit P 2 The relationship between the size and size of the grinding machine can be judged, and the effective analysis and prediction of grinding overload, grinding tool passivation, and grinding burn can be realized. The invention can be applied to abrasive materials, abrasive tools and grinding-related manufacturing industries to promote the realization of high efficiency, low energy consumption and intelligent production.

Owner:SHANDONG UNIV OF TECH

Wig strip dyeing device

InactiveCN112609351AEasy to separateNot messyLiquid/gas/vapor removalTextile treatment by spraying/projectingDyeingManufacturing engineering

The invention relates to the technical field of wig production and making, in particular to a wig strip dyeing device. The wig strip dyeing device comprises a working platform, a conveying device, a carding device and a collecting device, wherein a dyeing box is arranged on the working platform; a spray dyeing head is arranged in the dyeing box; a drying box is arranged at any end of the dyeing box and used for dyeing and drying wig strips; the conveying device is arranged on the working platform; the conveying device comprises a conveying frame; a conveying belt is arranged on the conveying frame; a sliding plate is arranged on the conveying belt; a fixing device is arranged on the sliding plate and used for fixing the wig strips; the conveying device is used for conveying and tidying the wig strips subjected to spray dyeing; the carding device is arranged on any side of the drying box and used for carding the wig strips subjected to spray dyeing; and the collecting device is arranged at the end, away from the dyeing box, of the conveying device and used for collecting and tidying the wig strips subjected to spray dyeing. Through intelligent control, wig strip dyeing and carding are more intelligent, time-saving and labor-saving.

Owner:邵阳县瑞祥发制品有限公司

An efficient and environmentally friendly explosion-proof, low-pressure water cooling system

ActiveCN105241148BAvoid working slowerReduce CooldownDomestic cooling apparatusLighting and heating apparatusExpansion tankExhaust valve

The invention discloses an efficient environment-friendly explosion-proof low-pressure water cooling system. The water cooling system comprises an expansion tank and a control system; an exhaust valve and an exhaust pipe are arranged on the expansion tank; an electric three-way valve, a filter, a heater, a degassing tank, an ion exchanger, a cooling device, a heat exchanger and the expansion tank all are connected with the control system. According to the efficient environment-friendly explosion-proof low-pressure water cooling system, as the exhaust pipe is arranged on the expansion tank, and when a pressure in the expansion tank expands to a certain degree, the control system will command the exhaust valve to be opened automatically for exhausting, and therefore, the expansion tank can be effectively prevented from explosion due to a too high pressure; meanwhile, due to the arrangement of the exhaust pipe, the exhausting of the whole system is accelerated, and the working of the whole cooling system is prevented from becoming slow due to the too high pressure of the expansion tank; as a result, the system is capable of shortening the time of cooling cooled materials while guaranteeing a cooling effect; the effects of energy conservation and environmental protection are achieved while the whole operational efficiency is improved.

Owner:BIHE ELECTRIC TAICANG CO LTD

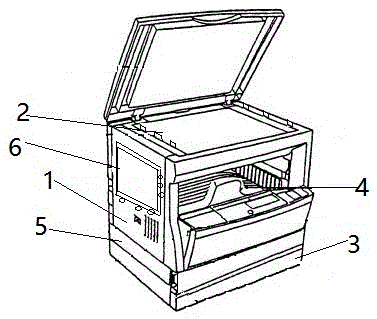

Intelligent copying machine and remanufacturing process therefor

InactiveCN105629689ALow input costMeet needsElectrographic process apparatusControl systemPulp and paper industry

The invention discloses an intelligent copying machine. The intelligent copying machine comprises a machine body, an original manuscript table, a paper-placing box, a paper-out tray, a carbon powder box, an operating floor and a control system, wherein the original manuscript table is arranged at the upper part of the machine body; the paper-placing box is arranged at the lower part of the machine body; the paper-out tray is arranged below the original manuscript table; the carbon powder box is arranged below the paper-out tray; the operating floor is arranged on one side of the machine body; and the control system is provided with an exposure system, a photographic fixing system, a conveying mechanism, a calibration mechanism, an adjusting mechanism, a self-inspection mechanism and a control mechanism. The calibration mechanism is added to the copying machine to calibrate the copying positions of papers; the adjusting mechanism is used for fine adjustment for the positions of the copied papers, so that the copying effect is improved; meanwhile, the self-inspection mechanism is added to monitor the overall operating process of the copying machine, so that the intelligent production of the copying machine is realized, and production requirements can be better satisfied by the intelligent copying machine; and the invention also relates to a remanufacturing process for the intelligent copying machine.

Owner:南京田中机电再制造有限公司

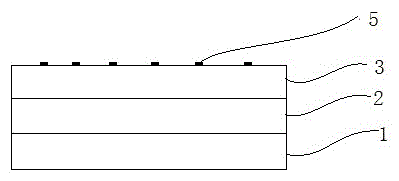

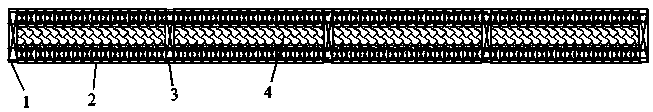

Modularized direction-changing nailed laminated wooden heat preservation structural board

InactiveCN109296093AImprove work levelHigh yieldConstruction materialHeat proofingEcological environmentSurface layer

The invention provides a modularized direction-changing nailed laminated wooden heat preservation structural board. A plurality of vertical transverse surface laminated boards are arranged on the surface layer, located on one outside side, of a board body; a plurality of interlayer horizontal laminated boards are arranged from top to bottom on one side of the indoor direction of the vertical transverse surface laminated boards; a plurality of vertical longitudinal surface layer boards are connected with interlayer horizontal layer boards; and the boards are filled with in-fill heat preservation core boards. According to the modularized direction-changing nailed laminated wooden heat preservation structural board, full factory fabrication is realized, full-automatic and intelligent production can be fully realized, ecological environment is not damaged, the product rate is greatly improved, sound insulation and thermal insulation integration is realized, internal holes are maximized, the board rigidity and strength are greatly improved, and the shock resistance is improved, and material utilization amounts are reduced; the structure is simple, but the stress performance is good, themodularized direction-changing nailed laminated wooden heat preservation structural board has incomparable deformation and recovery capacity, can be used as a heat preservation outer wall, and further can be used for heat preservation roofing; the cost is low, the construction is convenient, the installation efficiency is greatly improved; and in addition, after the building is completed, nails are hidden inside, aesthetics performance is achieved, and durability is obviously improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com