High temperature resistant bar code label, its manufacturing method, using method and application

A barcode label, high temperature resistant technology, applied in the field of labels, can solve the problems of wasting time, troublesome barcode labels, paper barcode labels not resistant to high temperature, etc., to improve enterprise management efficiency, prevent malicious damage, and improve after-sales quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

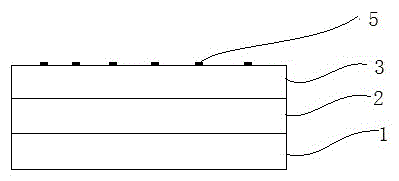

[0036] like figure 1 As shown, a high temperature resistant barcode label includes a carrier film 1, on which water-based PVA is coated to form a release layer 2, and water-based PVA is coated on the release layer 2 to form a transparent surface material layer 3, The thickness of the surface material layer 3 is 20 μm, and the carrier film 1 is a PET film. Put the label into the printing equipment, and print the barcode 5 on the face material layer 3 in reverse. When in use, glue is applied to one side of the surface material layer 3 on which the barcode 5 is printed, the label is pasted to the ceramic blank, and then the release layer 2 is peeled off. During the high temperature treatment, the surface material layer 3 is volatilized without ash residue, and the barcode 5 is perfectly fused with the surface of the ceramic blank.

Embodiment 2

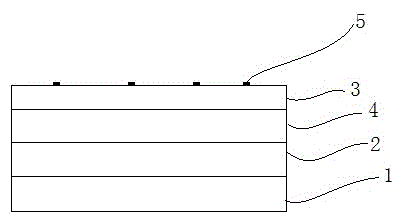

[0038] like figure 2As shown, a high temperature-resistant barcode label includes a carrier film 1, which is coated with water-based PVA to form a release layer 2, and is coated with glue on the release layer 2 to form an adhesive layer 4. A water-based PVA material added with titanium dioxide is coated on the adhesive layer 4 to form a surface material layer 3 with a white background, the thickness of the surface material layer 3 is 25 μm, and the carrier film 1 is a PET film. Put the label into the printing equipment, and print the barcode 5 on the face material layer 3 forward. When using, tear off the release film, and stick the adhesive layer to the ceramic blank. During the high temperature treatment, the main raw material of the surface layer, water-based PVA, volatilizes without ash residue. The barcode 5 is perfectly integrated with the ceramic surface, while the The white background formed by titanium dioxide produces a good contrast display, which makes the barcod...

Embodiment 3

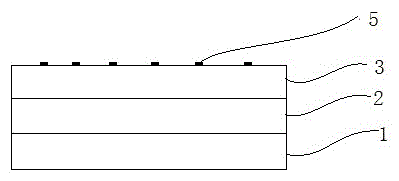

[0040] like image 3 As shown, a high temperature resistant barcode label includes a carrier film 1, on which water-based PVA is coated to form a release layer 2, and water-based PVA is coated on the release layer 2 to form a transparent surface material layer 3, The thickness of the surface material layer 3 is 20 μm, and the carrier film 1 is a PET film. Put the label into the printing equipment, and print the barcode 5 on the face material layer 3 in reverse. When in use, glue is applied to one side of the surface material layer 3 on which the barcode 5 is printed, the label is pasted on the initial product of the steel handicraft, and then the release layer 2 is peeled off. During the high temperature treatment, the surface material layer 3 evaporates without ash residue, and the barcode 5 is perfectly integrated with the surface of the steel handicraft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com