Sewage pump station monitoring system

A technology of sewage pumping station and monitoring system, applied in general control system, control/regulation system, pump control and other directions, can solve the problem of burning out the water pump, excessive current, running time, power consumption can not record storage, query, statistics and other issues to achieve the effect of improving automation and management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

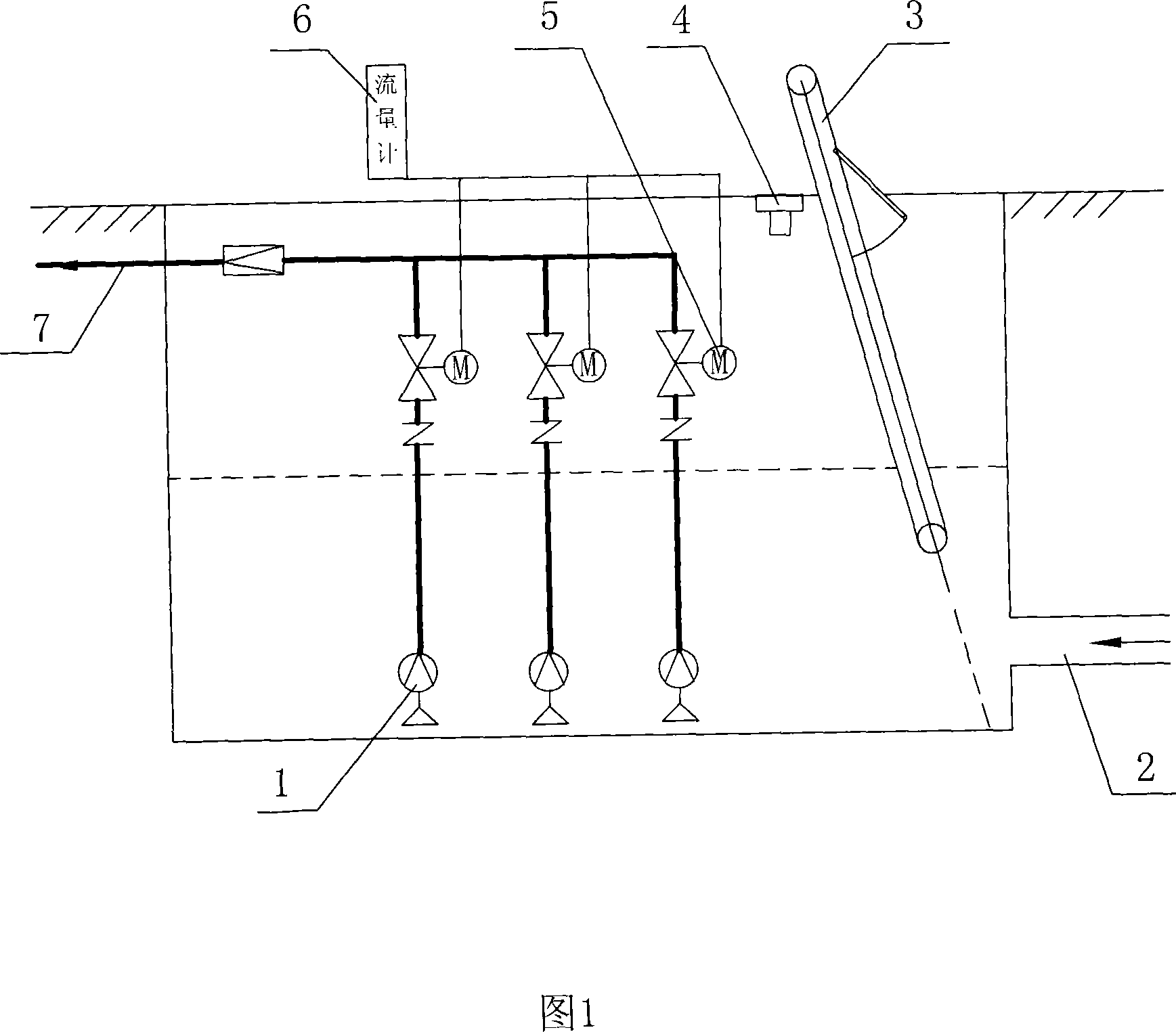

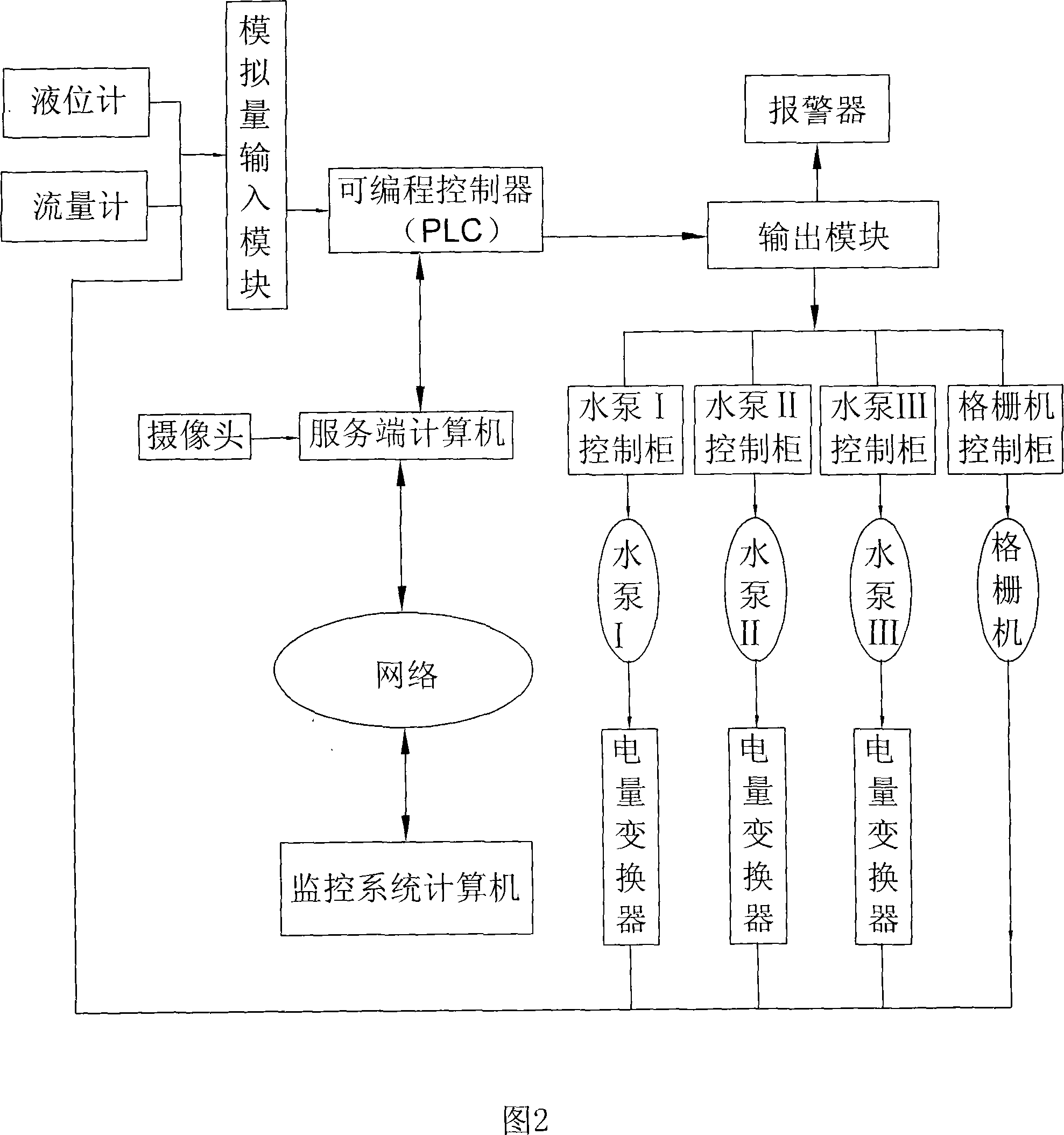

[0020] The sewage pumping station of the embodiment of the sewage pumping station monitoring system is shown in Figures 1 and 2. A sewage pumping station includes 3 water pumps 1 and 1 grid machine 3 installed in the sewage pool with the water inlet 2 and the water outlet 7 , also includes a server computer, a programmable controller, a liquid level meter 4, and a flow meter 6. Water pump 1 is a submersible pump. The liquid level gauge 3 is an ultrasonic liquid level gauge, and the sensors 5 of the flowmeter 6 are installed at the water outlets of each water pump 1, and one-to-three flowmeters can be used. The liquid level meter 4 and the flow meter 6 send the liquid level signal and the output water flow signal of each water pump 1 to the programmable controller through the analog input module, and the programmable controller is connected to the control cabinet of each water pump 1 through the output module. The electric valve is connected with the electric switch in the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com