Spare part assembling demand forecasting information processing method applied to inventory management

An information processing method and demand forecasting technology, applied in data processing applications, logistics, computing, etc., can solve problems such as low demand forecasting accuracy, poor forecasting effect, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

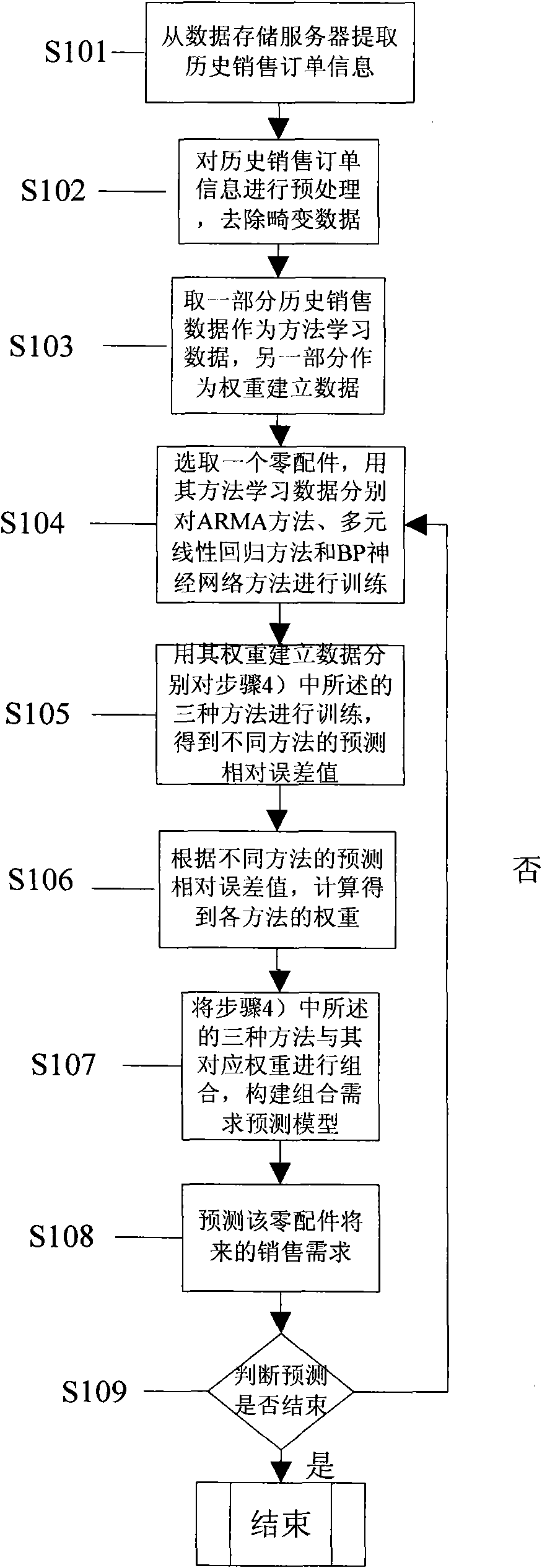

[0028] A method for processing demand forecasting information of spare parts combination applied to inventory management. The method can accurately predict the demand for different types of auto parts, reasonably control the quantity of different auto parts in inventory, reduce inventory costs, and improve order fulfillment rate .

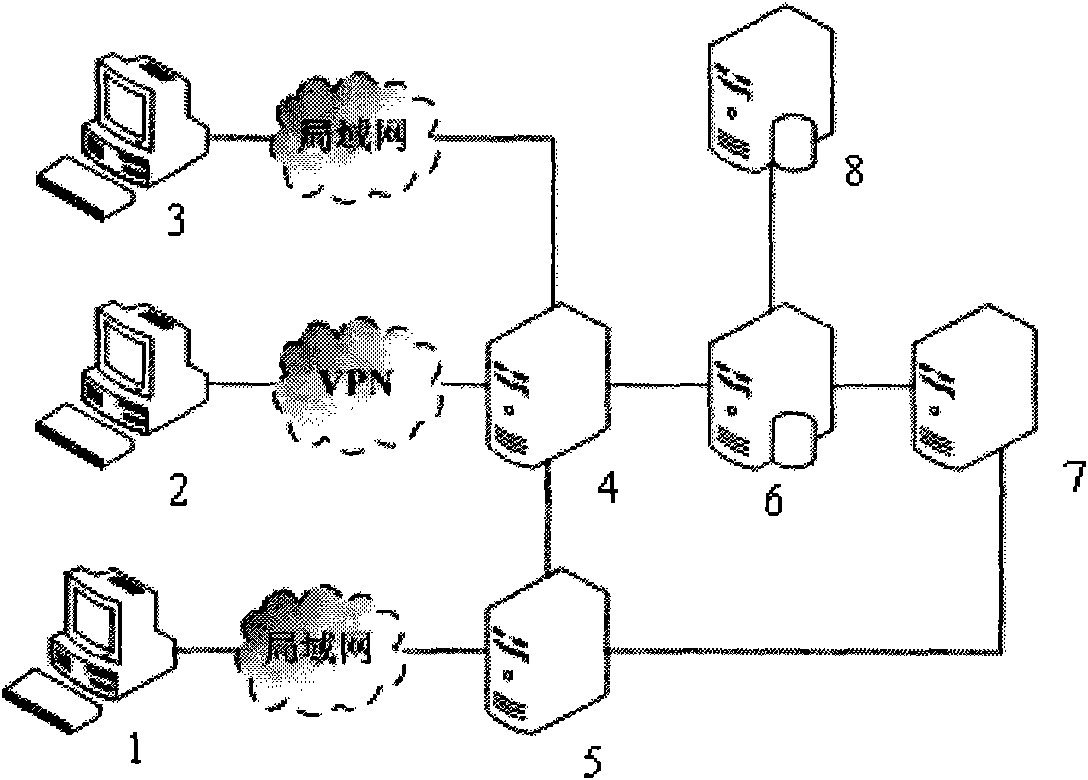

[0029] like figure 2 As shown, the second client 2: consists of multiple PCs or laptop computers, which can be general-purpose computers or computers dedicated to the terminal; the users of the second client 2 are dealers and retailers at all levels; The second client 2 is connected with the first application server 4 through VPN; the second client 2 sends the purchase order information to the first application server 4;

[0030] The third client 3: composed of multiple PCs or laptop computers, which can be general-purpose computers or computers dedicated to limited terminals; the users of the third client 3 are sales and financial management per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com