Used for punching and concave dies of channel steel beam punching equipment supporting error prevention mechanism

A convex-concave, error-proof technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low production efficiency, inability to realize online monitoring and mold position memory, and concave mold integration block errors, etc., to improve productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

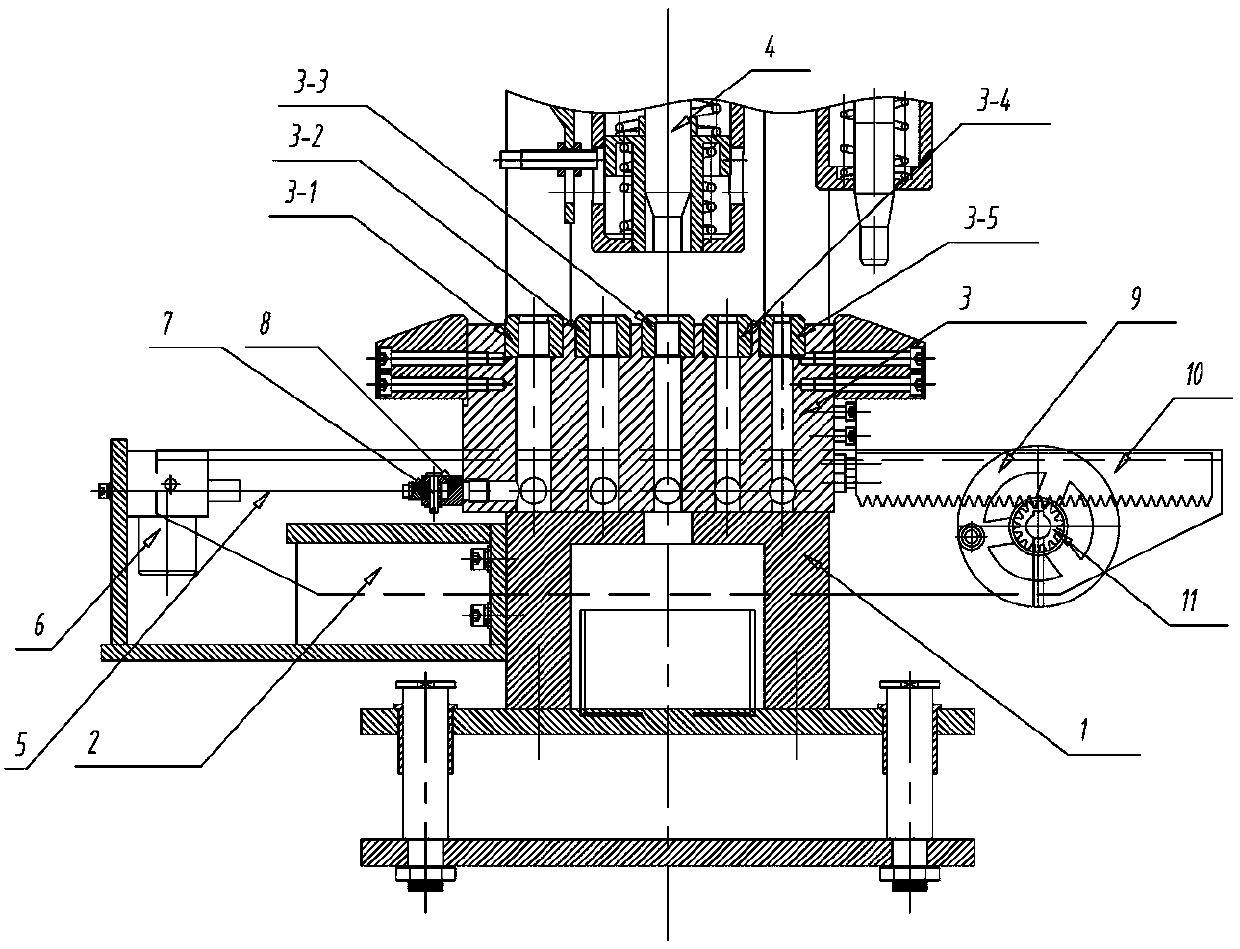

[0008] Such as figure 1 The shown error prevention mechanism for the convex and concave dies of the grooved steel beam punching equipment includes the punching clamp body 1 of the CNC punched steel beam hole equipment, the sliding positioning seat 2 of the die, the integrated block 3 of the multi-specification die, and the concave die assembly block 3. Die sliding positioning seat 2 is fixed on the punching pliers body, multi-standard die integrated block 3 is guided and supported on the punching pliers body 1, multi-standard die integrated block 3 passes through handwheel 9, gear rack pair (gear 11, rack 10) The drive realizes reciprocating movement, and a variety of different specifications of dies ( figure 1 There are five kinds of dies with different specifications, namely the first die 3-1, the second die 3-2, the third die 3-3, the fourth die 3-4, the fifth die Die 3-5), one end of multi-specification die integrated block is connected with a pull wire displacement senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com