Combustion control system of foamed glass foaming furnace

A control system, foam glass technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of poor temperature uniformity, increased production, low production, etc., to achieve high reliability and cost performance, improve Combustion efficiency and the effect of eliminating energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

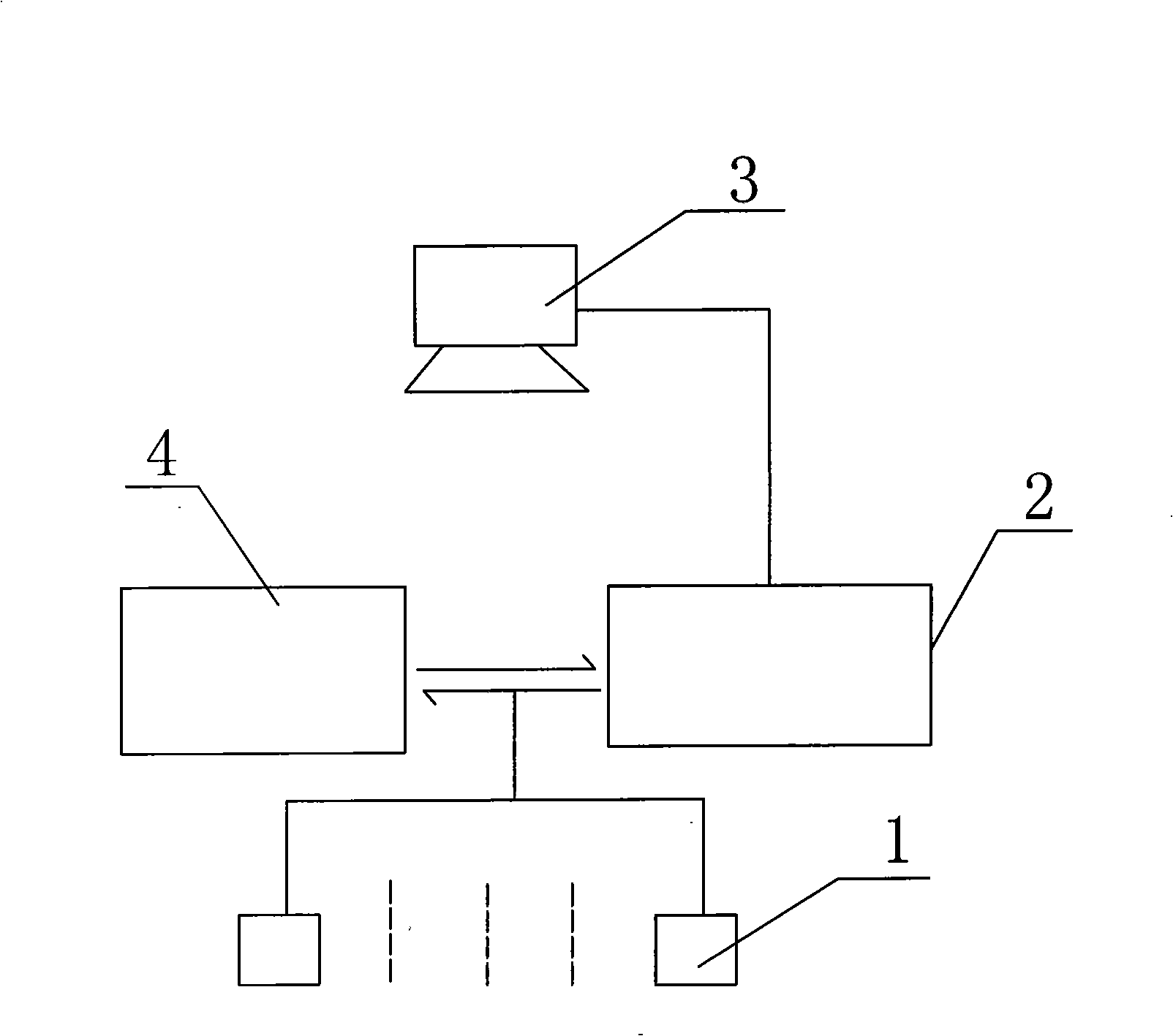

[0028] refer to figure 1 , a foaming furnace combustion control system for foam glass, the foaming furnace adopts high-speed burners for gas heating, including:

[0029] ①Temperature control system: The foaming furnace is divided into 12 furnace zones, and each furnace zone is divided into 2 temperature zones, and each temperature zone is equipped with a temperature control point 1, and each temperature control point 1 is connected with HC900 small distributed controller 2 connection; HC900 small distributed controller 2 automatically adjusts the gas ratio by controlling the air / fuel ratio regulating valve at temperature control point 1, so as to achieve the consistency of the atmosphere in the furnace;

[0030] ② Host computer: Industrial computer 3 is used as the host computer, combined with industrial con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com