Modularized direction-changing nailed laminated wooden heat preservation structural board

A layered building block and modular technology, applied in thermal insulation, building components, building structures, etc., can solve problems affecting the normal use and maintenance of structures, affecting the durability of additional materials, increasing on-site operations, etc., to achieve good recovery deformation ability, The effect of maximizing internal holes and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

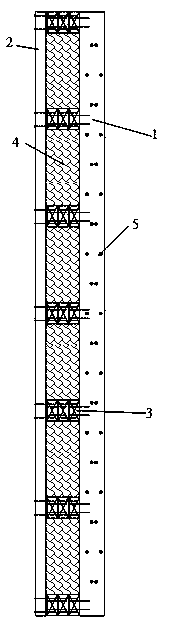

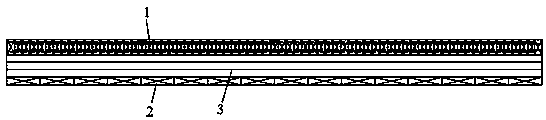

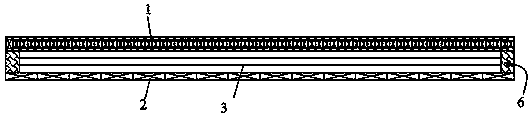

[0031] Embodiment: a kind of modular direction-changing nailed laminated wood insulation structure board, such as Figure 1~Figure 5 shown;

[0032] It mainly includes vertical and horizontal surface laminated boards 1, vertical and longitudinal surface laminated boards 2, interlayer horizontal laminated boards 3, inner-fill insulation core boards 4, nails 5, connection ports 6, connection tenon 7, and end-sealing boards 8;

[0033] Modular direction-changing nailed laminated wood insulation structural panels are divided into 4 types of panels: A panel, B panel, C panel and D panel;

[0034] A board:

[0035] The surface layer of the board body located on the outdoor side is a plurality of vertical and horizontal surface layer laminated planks 1 connected by nails 5, and the vertical and horizontal surface layer laminated planks 1 are vertical and horizontally arranged, that is, the wider boards are adjacent; After the laminated wooden boards 1 are connected by nails 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com