An intelligent monitoring system and decision-making method for grinding power and energy consumption

An intelligent monitoring system and grinding power technology, applied in machining monitoring system, grinding power and energy consumption intelligent monitoring system and decision-making field, can solve the problem that grinding input parameters cannot be effectively established to monitor power data and grinding output results Feature mapping relationship, no monitoring database, data processing, analysis and decision-making, etc., to achieve good economic and social benefits, and solve the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

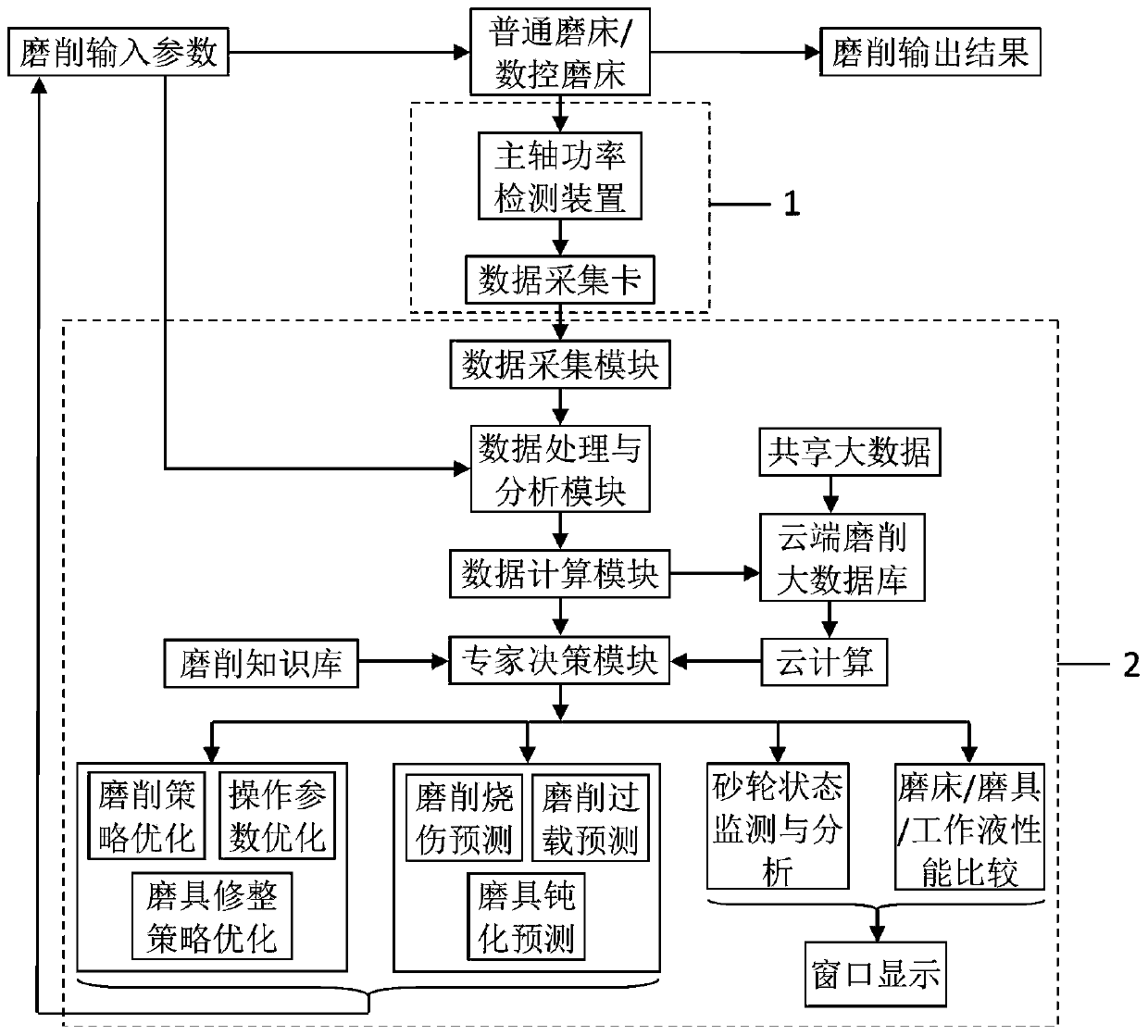

[0022] Specific implementation mode 1: combined with figure 1, detailing the invented intelligent monitoring system for grinding power and energy consumption, which is characterized in that it includes a hardware system-1 and a software system-2. The hardware system-1 includes a spindle power detection device and a data acquisition card; the software system-2 includes a data acquisition module, a data processing and analysis module, a data calculation module, a grinding knowledge base, a large shared grinding database, and expert decision-making module, function module. The spindle power detection device is used to detect the instantaneous power of the grinding machine spindle, and transmits the spindle power detection signal to the data acquisition card; the data acquisition card is used to collect the power sensor measurement signal, and convert the analog signal into a digital signal, and pass the data The interface is transmitted to the computer; the data acquisition modu...

specific Embodiment approach 2

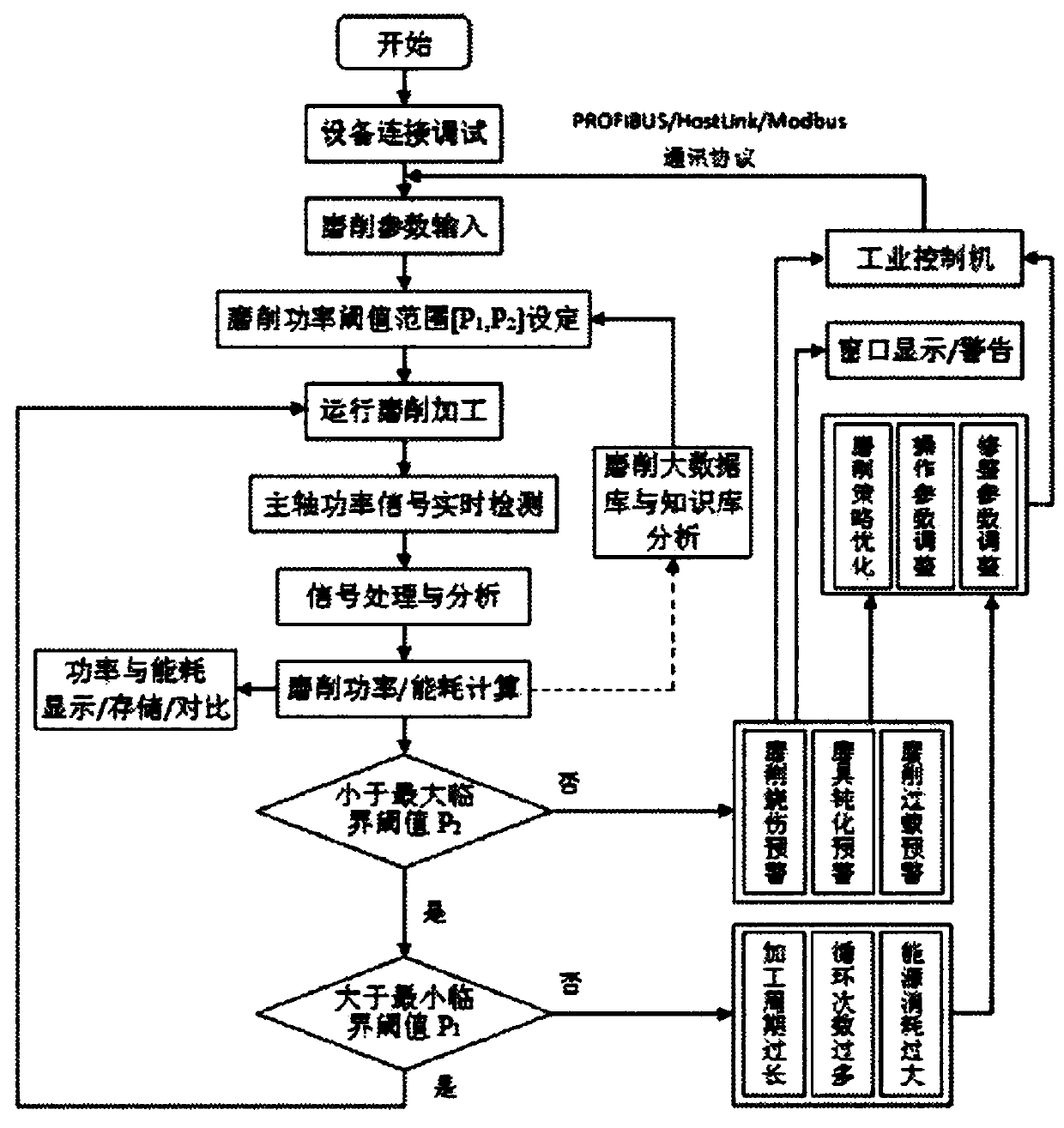

[0023] Specific Embodiment 2: Combining figure 1 and figure 2 , a detailed method for intelligent monitoring of grinding power and energy consumption invented, including the following steps:

[0024] Step 1: Connect the invented grinding power and energy consumption intelligent monitoring system with the grinding machine spindle drive motor;

[0025] Step 2: Set grinding input parameters for the grinding machine, such as: grinding tool speed, feed speed, grinding depth, grinding allowance, grinding tool dressing amount, dressing speed, dressing cycle, dressing feed rate;

[0026] Step 3: Match the current grinding input parameters, the required grinding results with the grinding knowledge base and the grinding examples and data in the cloud grinding large database, and use cloud computing and big data analysis modern information technology to obtain the current grinding The lower limit of the power threshold of grinding processing under the input parameters of grinding P 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com