Waste-heat multilayer circulation light calcium carbonate energy-saving baking method and device

A light calcium carbonate, multi-layer circulation technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, drying, etc., can solve problems such as high labor intensity, high energy consumption, and large environmental pollution, and achieve reduction Occupying space, saving energy in production, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

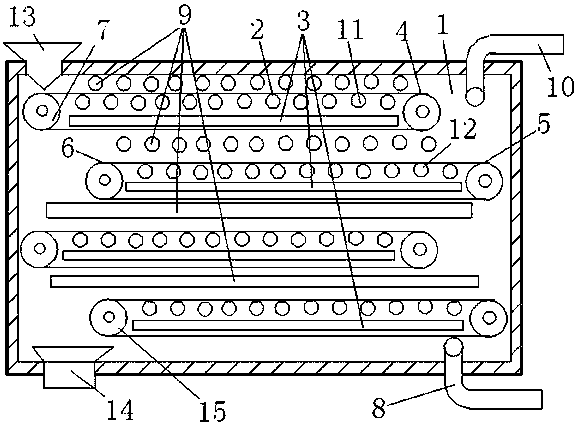

[0030] as attached figure 1 Shown, a kind of waste heat multi-layer circulating light calcium carbonate energy-saving baking device is a multi-layer circulating light calcium carbonate baking box, comprising a box body 1, and a conveyor belt 2 arranged in multiple layers is arranged in the box body 1, and each A heat tracing pipe 3 is arranged next to the conveyor belt, and the light calcium carbonate wet cake on the conveyor belt 2 is dried through the heat tracing pipe 3 .

[0031]Further, the conveyor belts 2 arranged in multiple layers are arranged in a top-to-bottom end-to-end arrangement, that is, below the position of the tail 4 of the uppermost conveyor belt 11 is the position of the head 5 of the next conveyor belt 12, and the position of the previous conveyor belt 12 is When the layer conveyor belt moves the light calcium carbonate wet cake to the tail, it will turn over and fall to the head position of the next layer of conveyor belt when the conveyor belt turns.

...

Embodiment 2

[0037] The principle of embodiment two is the same as that of embodiment one, except that the system device used is different. It is a waste heat multi-layer circulation light calcium carbonate energy-saving baking device, which is a multi-layer circulation light calcium carbonate baking box, including a rectangular In the box, there are multi-layered conveyor belts, and heat tracing tubes are arranged on the box next to each layer of conveyor belts, and the light calcium carbonate wet cake on the conveyor belt is dried through the heat tracing tubes. .

[0038] Further, the conveyor belts arranged in multiple layers are arranged end-to-end, that is, the position of the tail of the uppermost layer of conveyor belt is below the position of the head of the next layer of conveyor belt, and the upper layer of conveyor belt will lightly When the high-quality calcium carbonate wet cake moves to the tail, it will turn over and fall onto the head position of the next layer of conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com