Patents

Literature

59results about How to "Full immersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

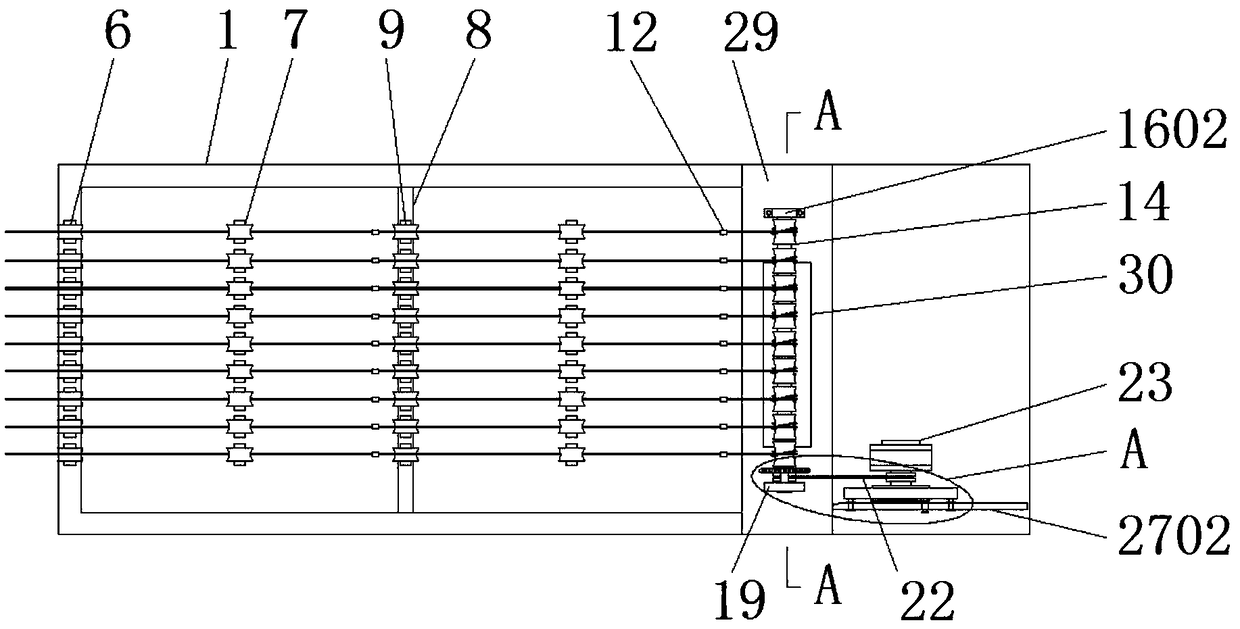

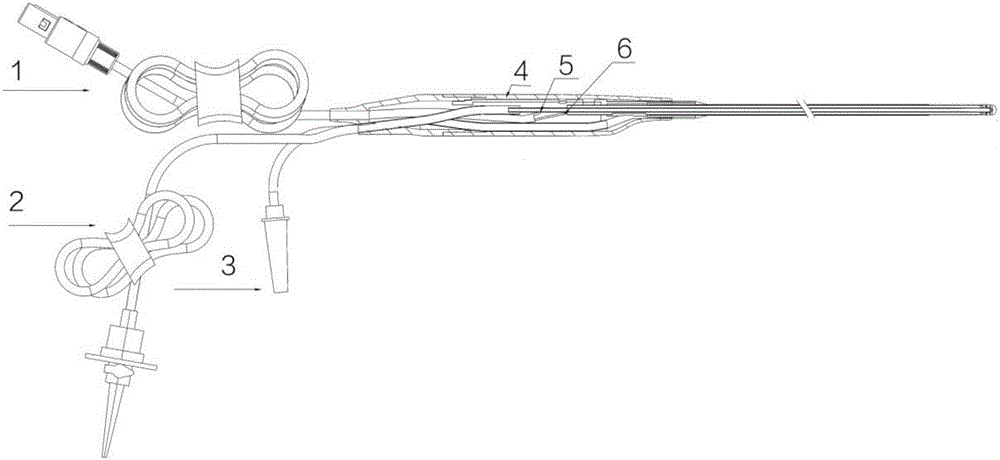

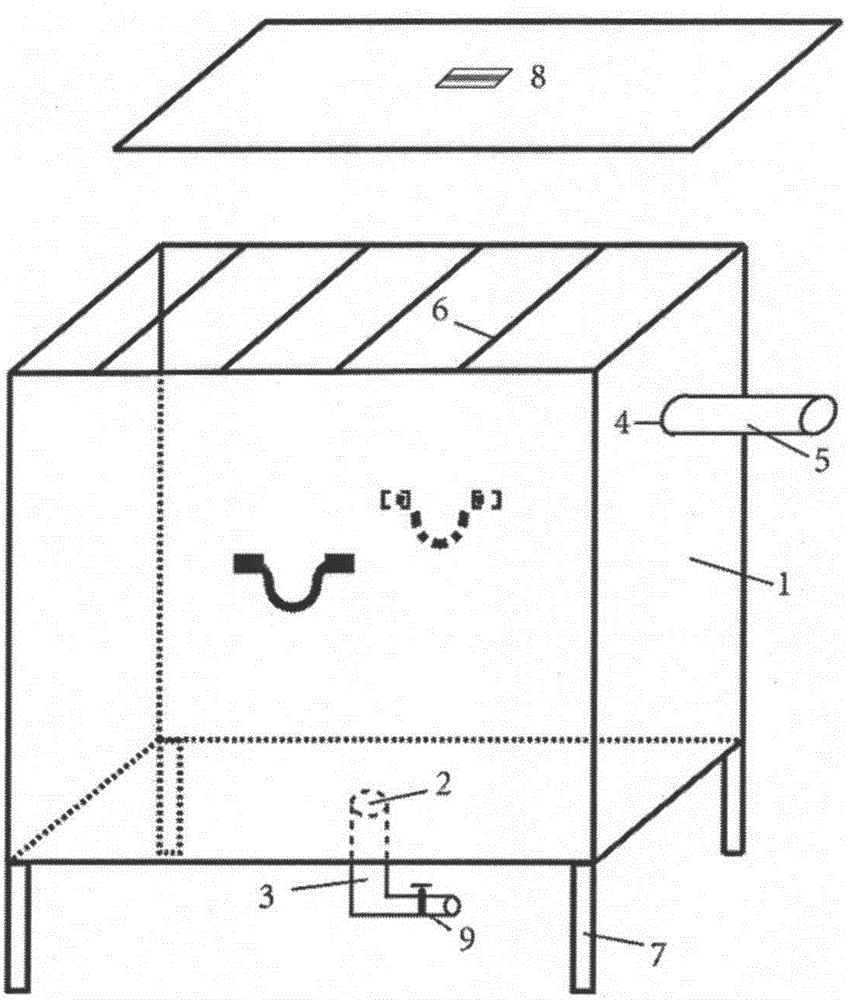

Integrated water-fertilizer micro-jetting irrigation fertilizing system

ActiveCN104303677ASafe and Fast DissolvingUnobstructed irrigationPressurised distribution of liquid fertiliserControl systemDissolution

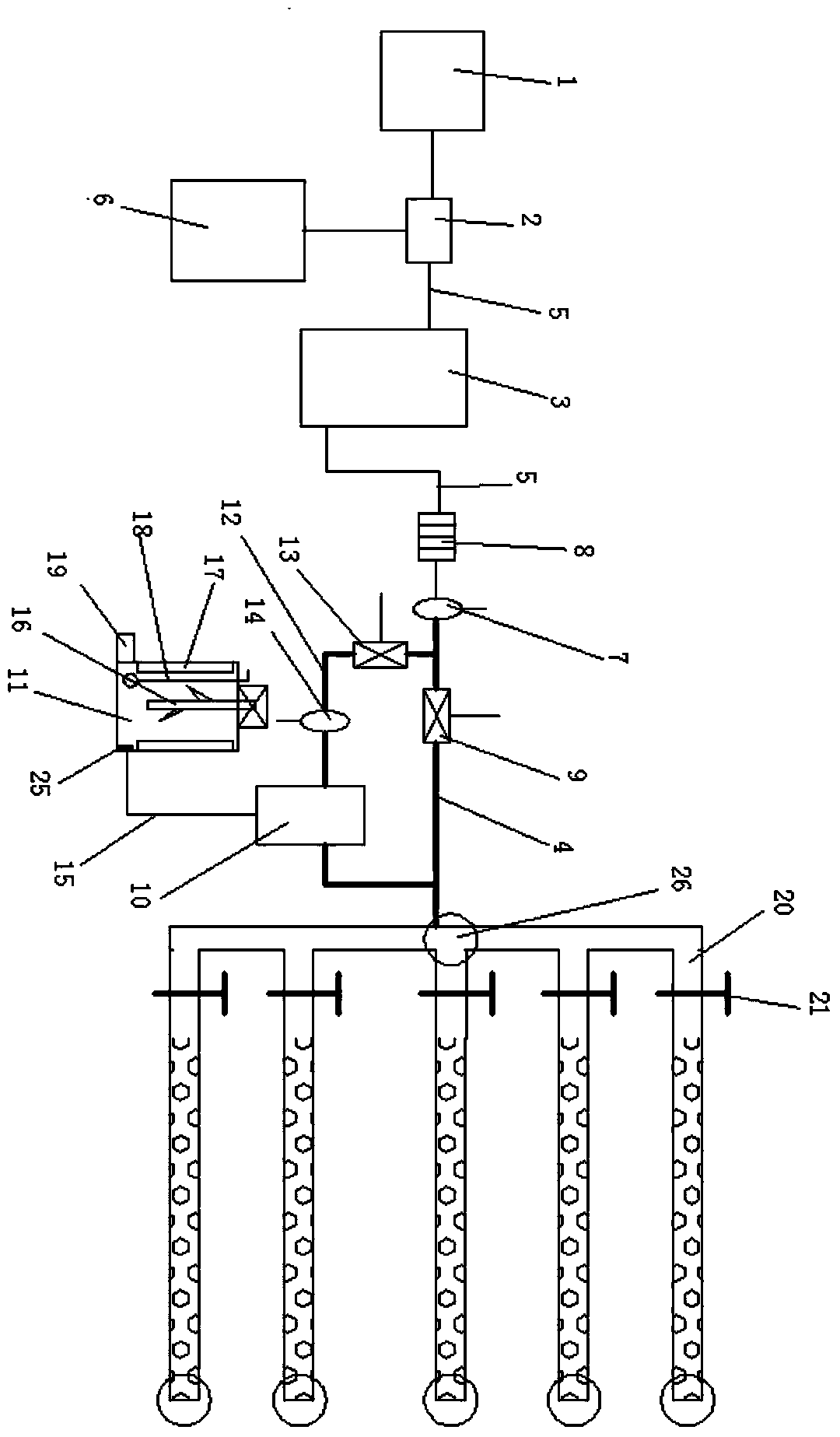

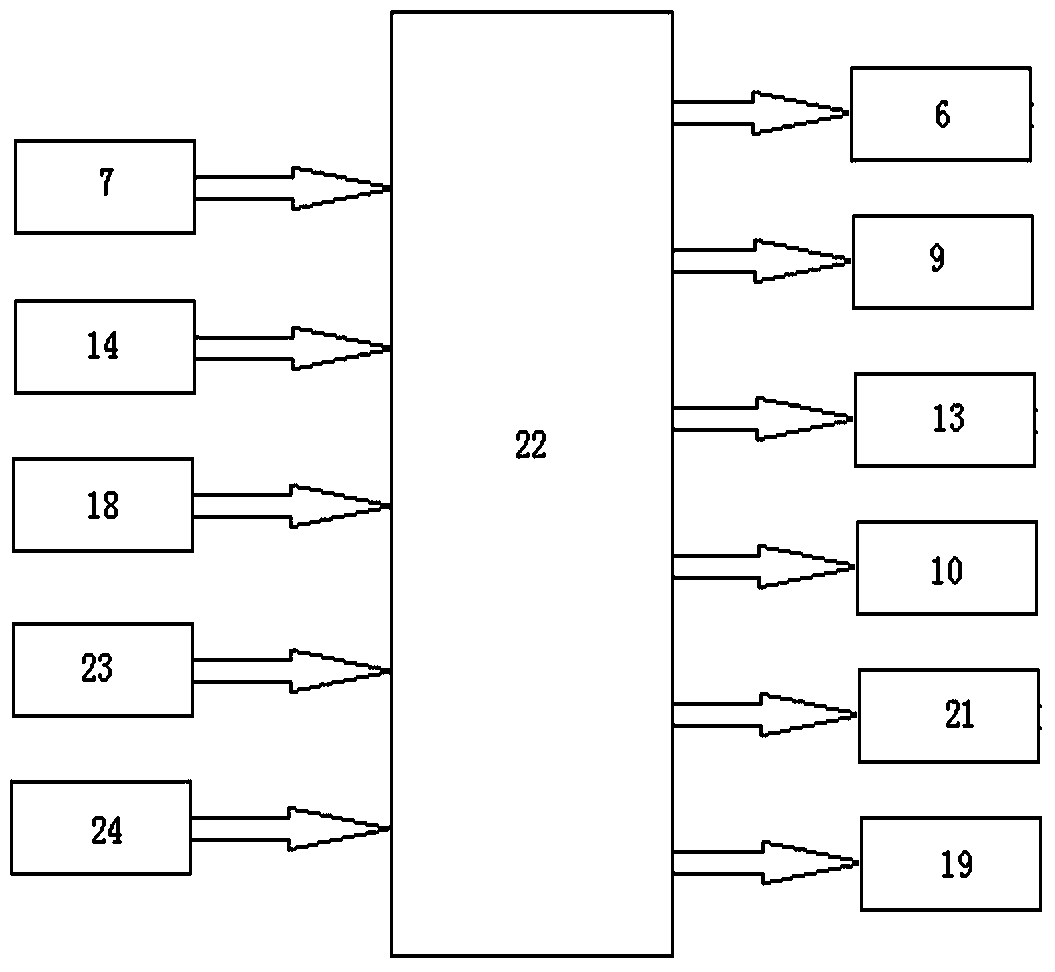

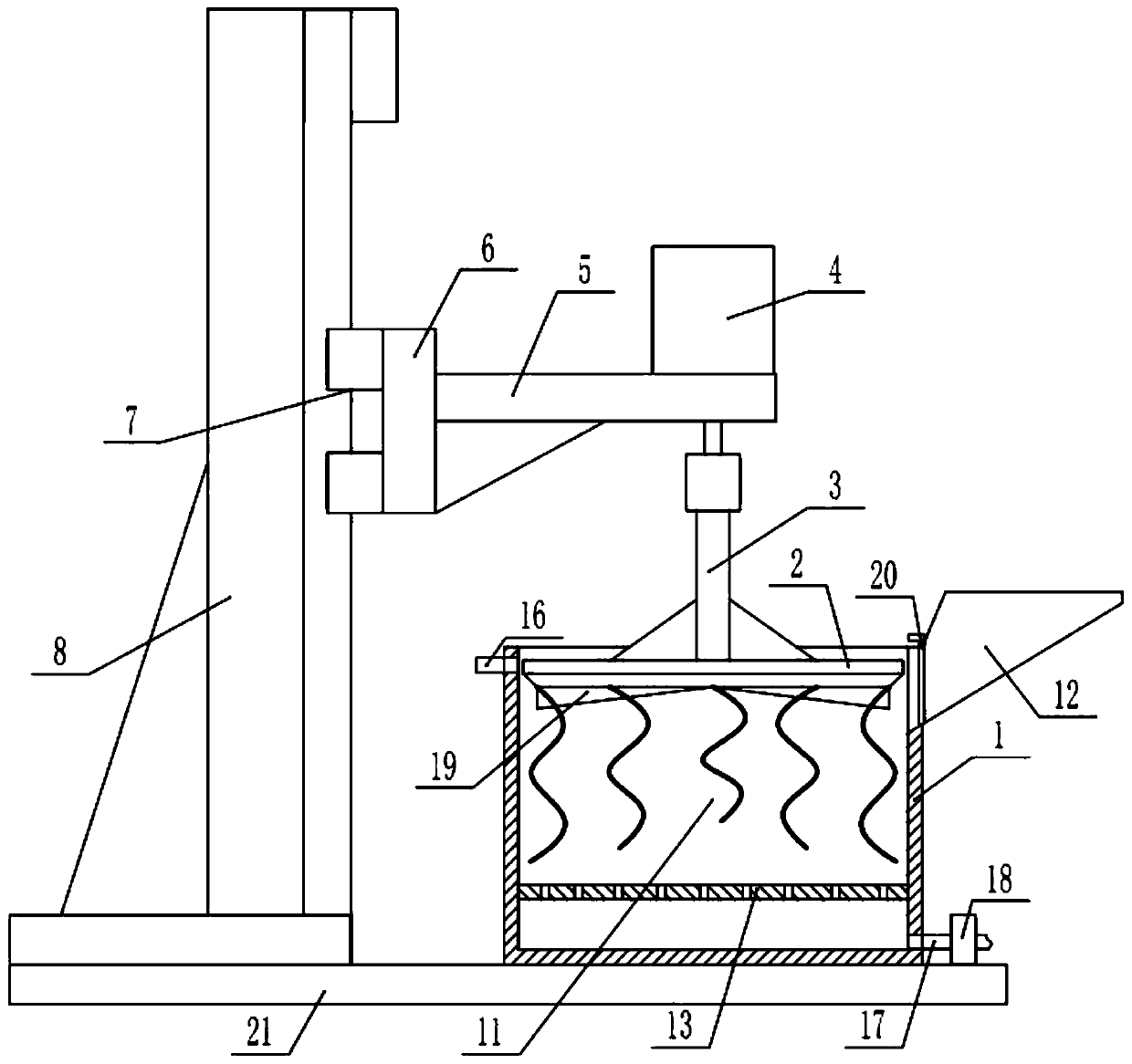

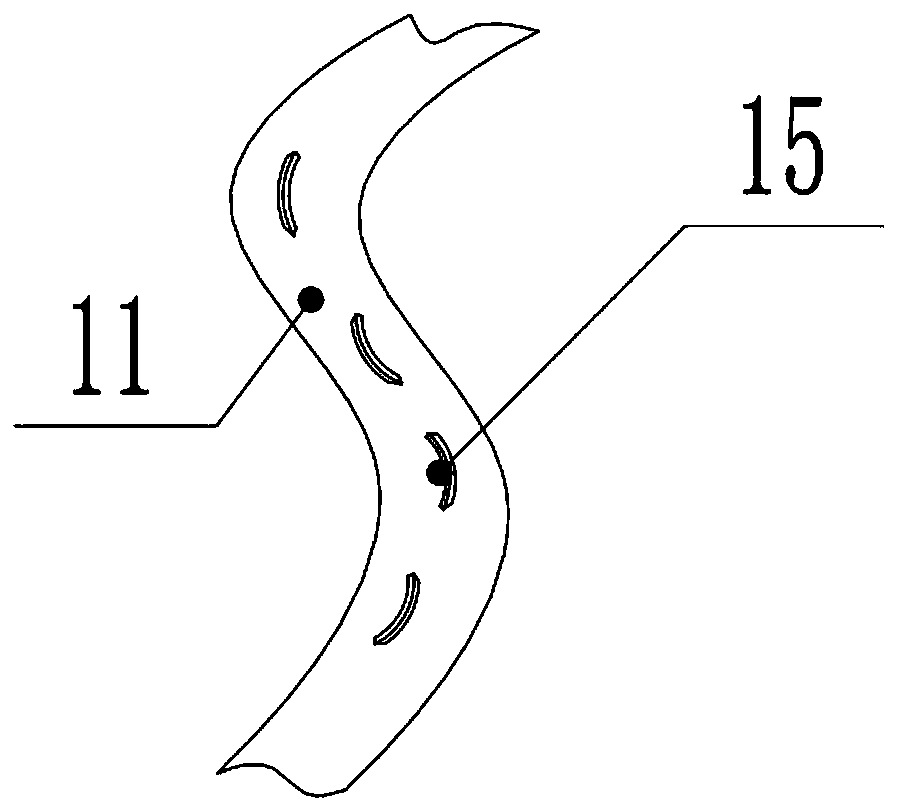

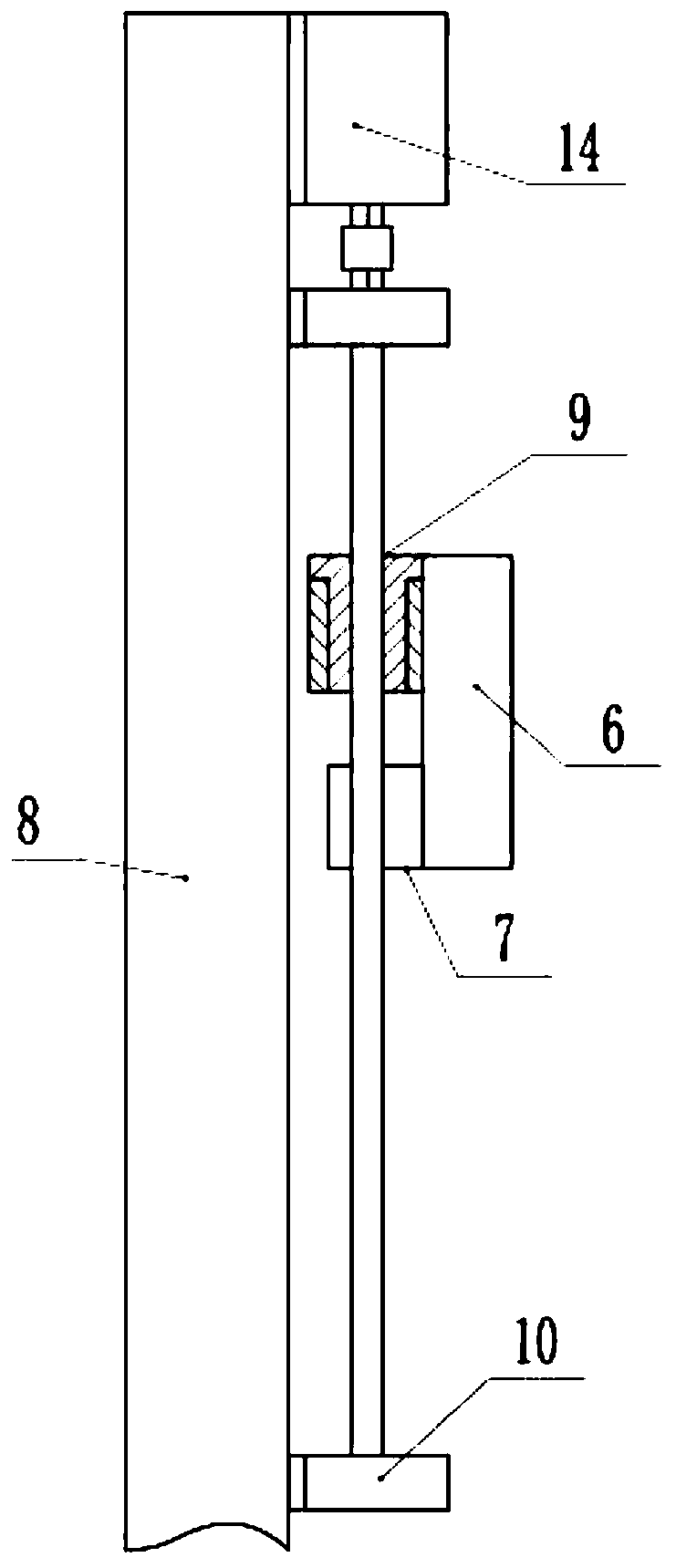

The invention discloses an integrated water-fertilizer micro-jetting irrigation fertilizing system. The system comprises an irrigation system, a fertilizing system, a micro-jetting system and a control system. Filtering devices are arranged on many parts of the system so as to guarantee smooth irrigation; because of a stirrer, a heating wire and a temperature sensor, the safe and quick dissolution of chemical fertilizers is facilitated; the height can reduced by a lifting column when the fertilization is required so that the fertilizers are fully immersed into the soil and the good fertilizing effect is realized; the height can be properly increased by the lifting column when the fertilization is required so that water mist can be sprayed toward crops downwards from a high place, and therefore, the good moistening and irrigation effect is realized, and intelligent control management is realized.

Owner:宿州学院

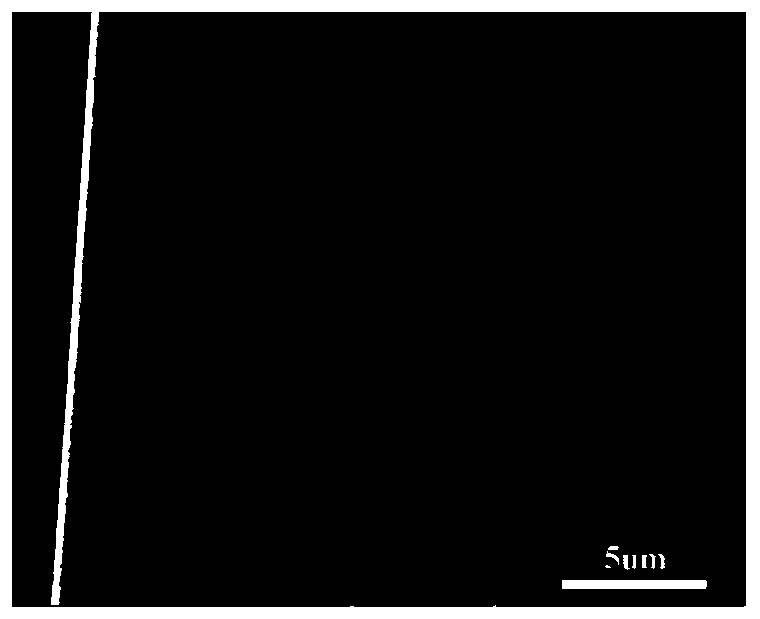

High-abrasion-resisting glass fiber fabric and preparation method thereof

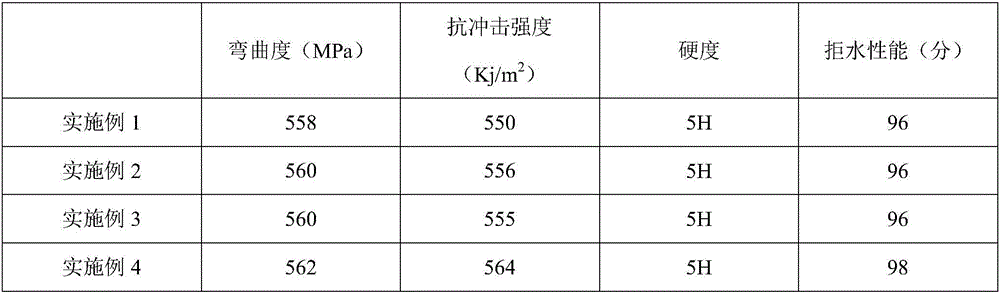

The invention discloses a high-abrasion-resisting glass fiber fabric and a preparation method thereof. The preparation method comprises the steps that 1, glass fiber monofilaments are plain-woven to obtain a basic glass fiber fabric; 2, the basic glass fiber fabric is put in a sizing agent to be dipped for 2-3 hours; 3, the excessive sizing agent on the basic glass fiber fabric is extruded out, and air bubbles are removed to obtain a preformed glass fiber fabric; 4, the glass fiber monofilaments are parallelly concentrated to obtain protofilaments, the protofilaments are cut according to the length of 60-70 mm and are randomly and uniformly laid on the preformed glass fiber fabric, then a bonder is applied, and heating and curing are performed to obtain a basic material; 5, the sizing agent in the step 2 is uniformly applied to two sides of the basic material in a coated mode, and then ultraviolet curing is conducted on the basic material to obtain the high-abrasion-resisting glass fiber fabric. The high-abrasion-resisting glass fiber fabric has high hardness, good mechanical strength and a high water-repellency performance value, and good abrasion resistance is reflected. The curvature and anti-impact strength are ideal, and it is indicated that the high-abrasion-resisting glass fiber fabric has good water repellency.

Owner:嘉兴杰特新材料股份有限公司

Concave soil adsorption material carrying manganite and method for removing S2- in tannery wastewater

ActiveCN103418338AImprove adsorption capacityHigh selectivityOther chemical processesWaste water treatment from animal processingCentrifugationManganese

The invention discloses a concave soil adsorption material carrying manganite and a method for removing S2- in tannery wastewater. First, a certain amount of concave soil water dispersion liquid going through special pre-treatment is prepared, and then a certain amount of manganese weak acid salt solution is added. Reaction occurs on proper conductions, and the concave soil adsorption material carrying manganite can be obtained after centrifugation, drying, grinding and calcination. A good adsorption effect can be achieved as long as a small number of adsorption materials are placed in tannery wastewater. According to the adsorption materials, preparation conditions are moderate, raw materials can be obtained easily. Moreover, when used for removing S2- in tannery wastewater, the adsorption materials are remarkable in adsorption effect and favorable to subsequent treatment of tannery wastewater, improves recovery rate, reduces cost for wastewater treatment, is incapable of generating bad influence on subsequent treatment, has the advantages of being efficient and protecting the environment, and has good application value.

Owner:SICHUAN UNIV

Mechanical yarn waxing device used for spinning machine and beneficial to rapid production

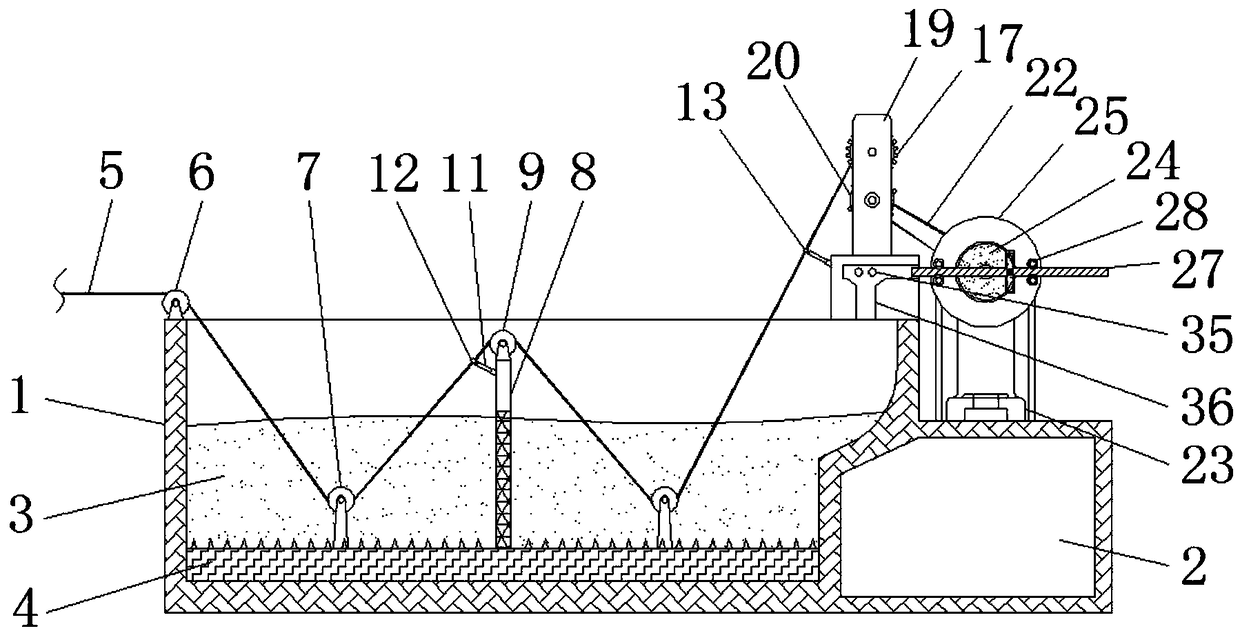

The invention discloses a mechanical yarn waxing device used for a spinning machine and beneficial to rapid production. The mechanical yarn waxing device used for the spinning machine and beneficial to rapid production comprises a main body, a textile yarn and a driving disc. A storage bin is fixedly welded to the right side of the main body. A supporting device is connected to the tail end of a winding shaft. A connecting rod is arranged on the front side of a driven disc. A shifting rod is mounted on the outer side of the driving disc. A wax box is arranged on the left side of a scraping device. A mounting groove is formed in the wax box. A fixing base is mounted at the top end of a spring. A fixing hole is formed in the outer side of the top of a wax rod. According to the mechanical yarn waxing device used for the spinning machine and beneficial to rapid production, yarns can be protected and can be kept in order; the yarns can be sufficiently soaked in liquid wax, so that the waxing uniformity is ensured; and the liquid wax can be kept sufficient all the time in use and can be kept in the liquid state, so that rapid waxing is facilitated, and the production efficiency is improved.

Owner:吴子侠

Preparation method of flame-retardant core-board

The invention discloses a preparation method of a flame-retardant core-board, comprising the following steps of: a first step, preparing a core bar of the core-board; a second step, injecting or infusing a water-based flame-retardant agent solution into the core bar through a secondary vacuumizing / pressurizing flame-retardant agent injection technology; a third step, preparing a block board with the core bar obtained in the second step; a fourth step, performing surface flame-retardant treatment on a veneer; a fifth step, assembling the veneer processed in the fourth step with the block board; a sixth step, compressing the obtained assembly with adhesive, wherein the used adhesive is a biological glue; and performing final trimming and sanding to get the finished product of the core-board. By using the preparation method of the flame-retardant core-board, the flame-retardant performance of the core bar of the block board is improved, the flame-retardant agent is a non-halogen material, and the used adhesive is the biological glue, so that formaldehyde emission is greatly reduced, and the board with very excellent flame-retardant performance and environmental performance can be prepared.

Owner:上海荷雨木业有限公司

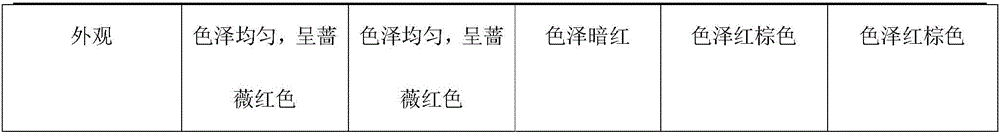

Making method of dried pitaya peel fruit

InactiveCN107183296ALong storage timeGet the most out of your nutrientsConfectionerySweetmeatsFreeze-dryingDesorption

The invention relates to a making method of dried pitaya peel fruit. The method comprises the following steps of (1), pretreatment of a raw material: removing the peel of the pitaya, washing the peel by using distilled water, trimming, and slitting for later use; (2), sugar soaking: soaking the peel of the pitaya, which is subjected to the pretreatment, into a sugar alcohol solution, and treating by using an ultrasonic wave; (3), congealing: putting the peel of the pitaya, which is subjected to sugar soaking treatment, into a refrigerator for freezing until free water and bound water in the peel of the pitaya are both congealed; (4), sublimation drying: putting the peel of the pitaya, which is subjected to congealing treatment, into a vacuum freeze drier, and meanwhile, turning on a vacuum pump to extract air in the dryer; (5), desorption drying: putting the peel of the pitaya, which is subjected to the sublimation drying, into a freeze dryer, and meanwhile, turning on the vacuum pump, wherein the moisture of the freeze-dried peel is always maintained to be between 2 percent and 4 percent; further, the peel is subjected to collapse, coking and oxidation; (6), packaging: charging nitrogen for packaging the freeze-dried peel of the pitaya by using an aluminum foil-polyethylene material.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Manufacturing method of pure-cotton flame-retardant protective clothing

ActiveCN103799575AAvoid wastingComfortable to wearChemical protectionHeat protectionFiberPulp and paper industry

The invention discloses a manufacturing method of pure-cotton flame-retardant protective clothing, and belongs to the technical field of lifesaving devices. The manufacturing method is characterized by sequentially comprising the following steps: (1) measuring the shrinkage ratio of cotton cloth; (2) manufacturing clothing; (3) desizing and drying; (4) soaking with a flame retardant; (5) pressing sizing. The flame retardant clothing manufactured by the manufacturing method can be made into cotton cloth clothes at first, and then is subjected to the follow-up operation such as soaking with the flame retardant according to customer' requirements, so that the function failure or reduction of the flame retardant clothing due to out of date of a flame retardant, a functional fiber or cloth in the prior art is avoided; waste of expensive raw materials such as the flame retardant in which the clothing but not un-tailored cloth is socked is avoided; the flame retardant clothing combines cotton cloth rich in China and the flame retardant, so that the flame retardant clothing is comfortable to wear and low in cost, and meets the our national actual conditions better.

Owner:淄博奥祥服装有限公司

Preparation method of preserved passion fruits

InactiveCN105876054ASolve the astringency of preserved fruitShorten confection timeConfectionerySweetmeatsChemistryFlavor

The invention discloses a preparation method of preserved passion fruits. The preparation method of the preserved passion fruits comprises the following steps: selecting raw materials, pre-cooking the selected raw materials, carrying out pre-drying, cutting peels of the pre-cooked passion fruits, performing graded sugaring, carrying out low-temperature drying, carrying out shaping and so on. By using the methods of appropriately prolonging pre-cooking time, carrying out pre-drying, carrying out peel cutting, applying cellulase and hemicellulase and so on, the time-consuming and laborious step of removing peels of the passion fruits is saved, and no additional color protecting and hardening processes are required. Pectin, acidic substances, a series of anti-oxidant substances and the like are fully utilized in the preparation method, so that the prepared preserved passion fruits are simple in processing method, high in finished product rate, few in additives, good in product flavor and resistant to storage.

Owner:广西绿享科技有限公司 +1

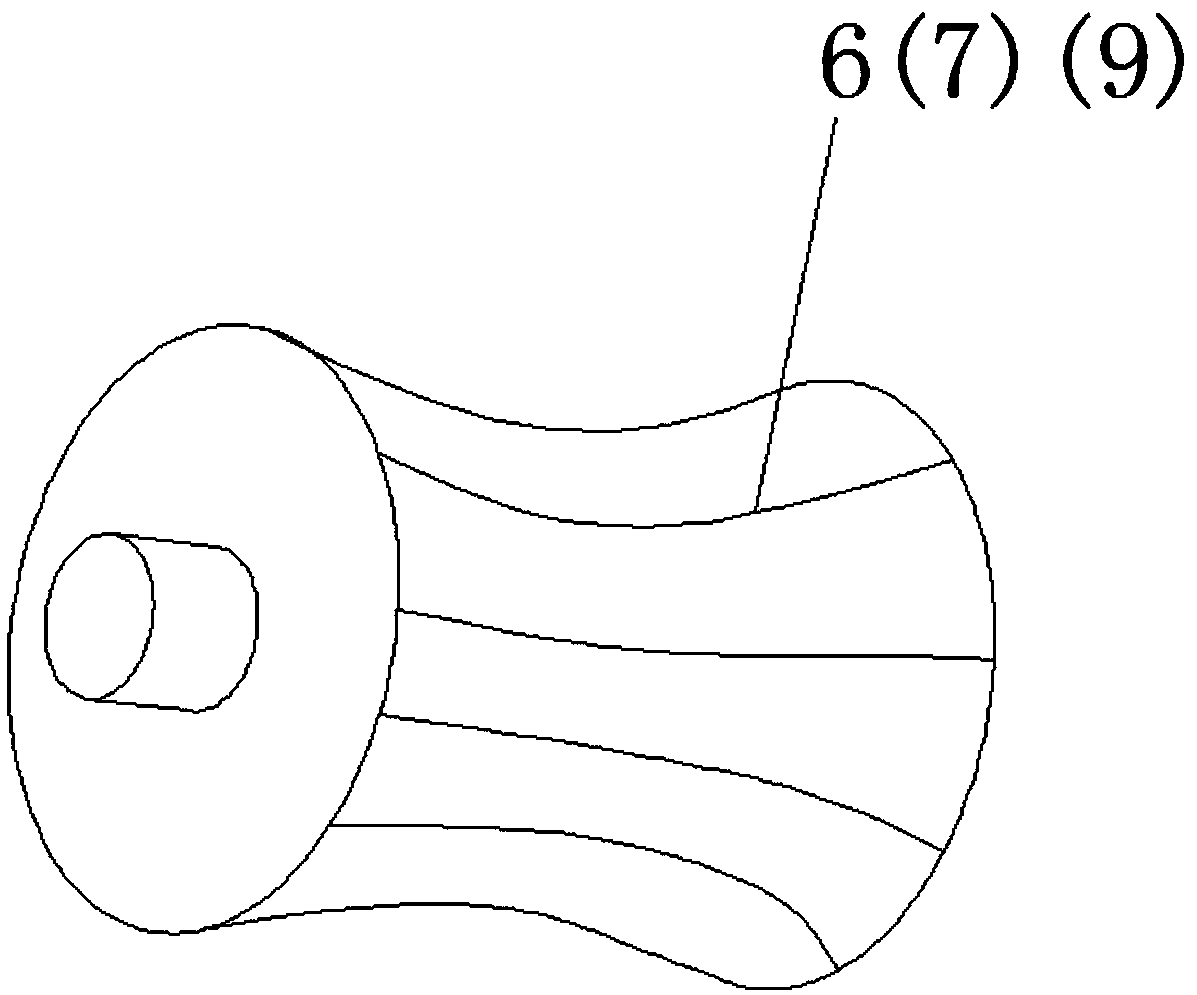

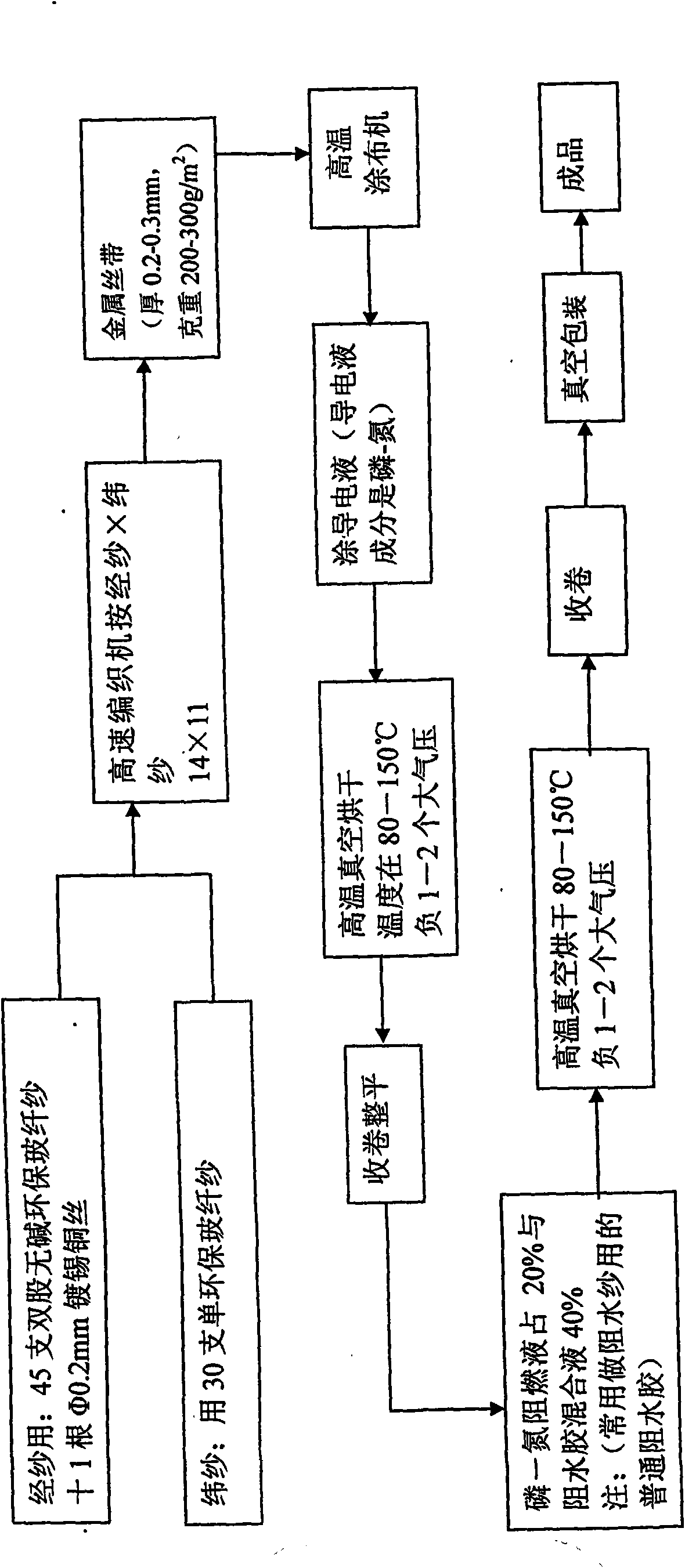

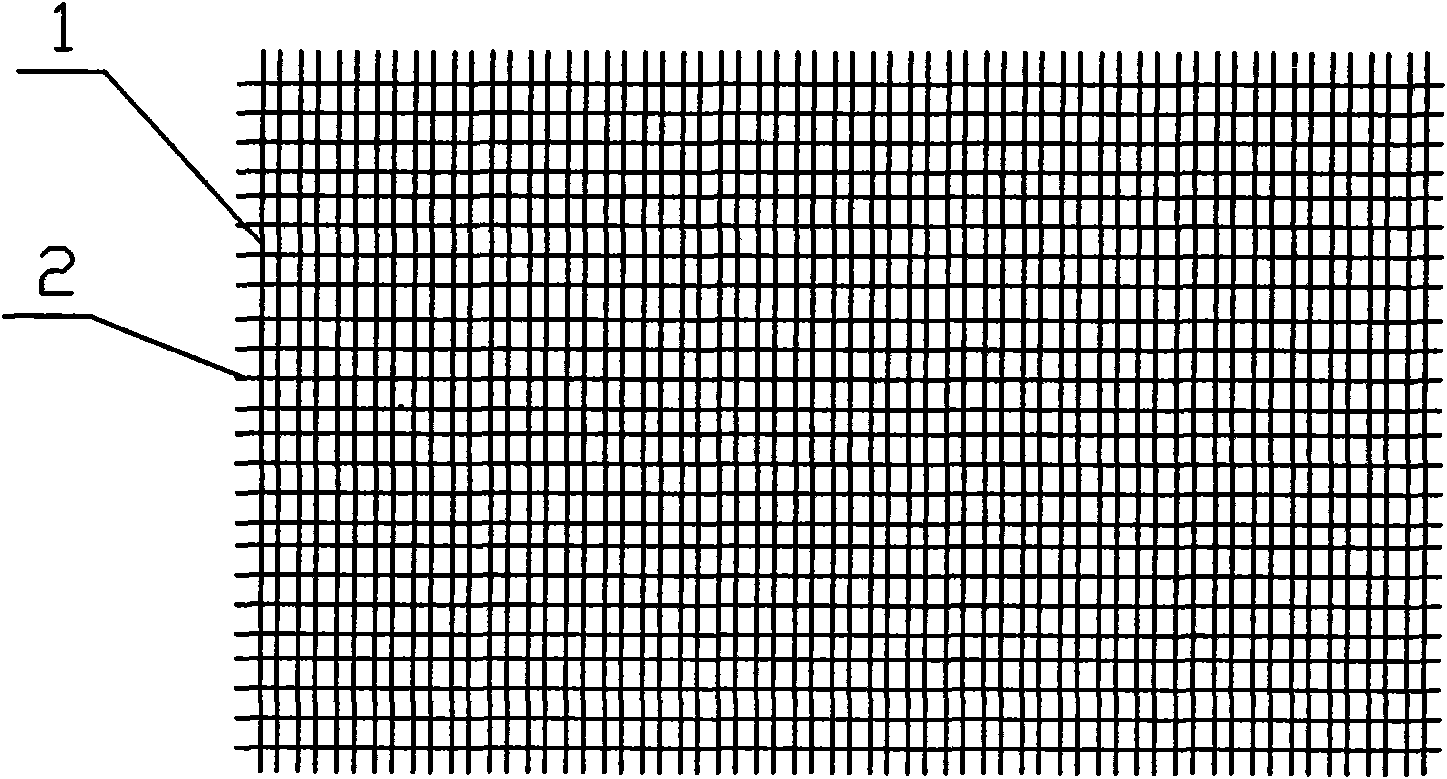

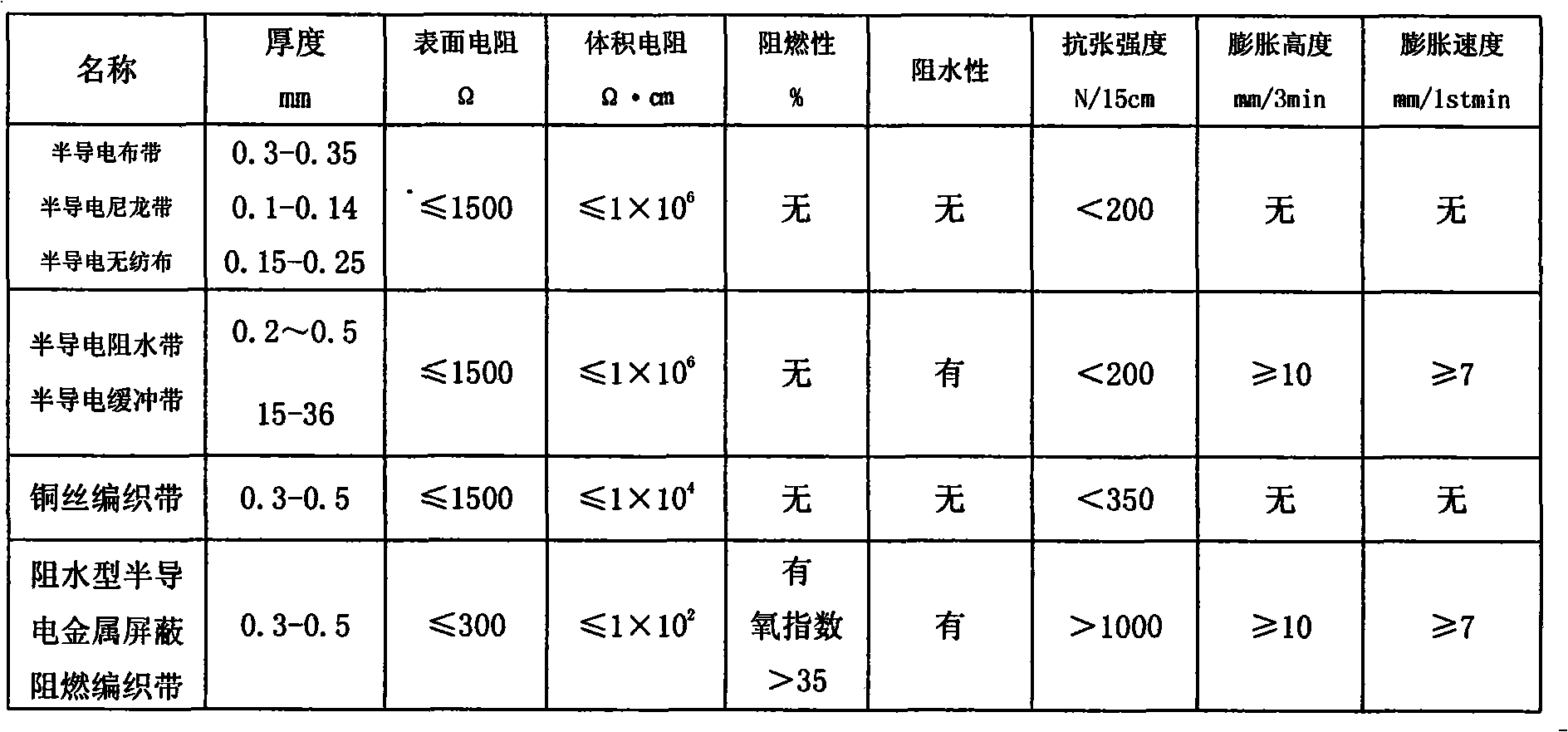

Water-repellent semiconducting metal-shielded flame-retardant braided strap and processing technology thereof

InactiveCN101908390AFull immersionSemi-conductiveClimate change adaptationPower cables with screens/conductive layersSemiconductionAdhesive

The invention discloses a water-repellent semiconducting metal-shielded flame-retardant braided strap. The water-repellent semiconducting metal-shielded flame-retardant braided strap comprises a base fabric, and conductive liquid, flame-retardant liquid and a water-repellent adhesive attached to the base fabric; and the base fabric is formed by braiding wraps and wefts. The processing technology comprises the following technological steps of: 1) sorting: sorting the wraps and the wefts; 2) braiding: braiding the wraps and wefts by using a high-speed braiding machine; 3) coating the conductive liquid: coating the conductive liquid on the base fabric in a liquid-immersing groove; 4) drying: drying the base fabric, rolling and leveling; 5) coating the flame-retardant liquid: coating the flame-retardant liquid on the treated base fabric in the liquid-immersing groove; 6) drying: drying the base fabric, rolling and leveling; and 7) packaging: performing vacuum packaging on the braided strap to form a finished product. The water-repellent semiconducting metal-shielded flame-retardant braided strap has the advantages of semiconduction, water-repellent and flame-retardant property, high heat resistance grade, high tensile strength, and energy conservation, consumption reduction and environmental protection in the production process.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

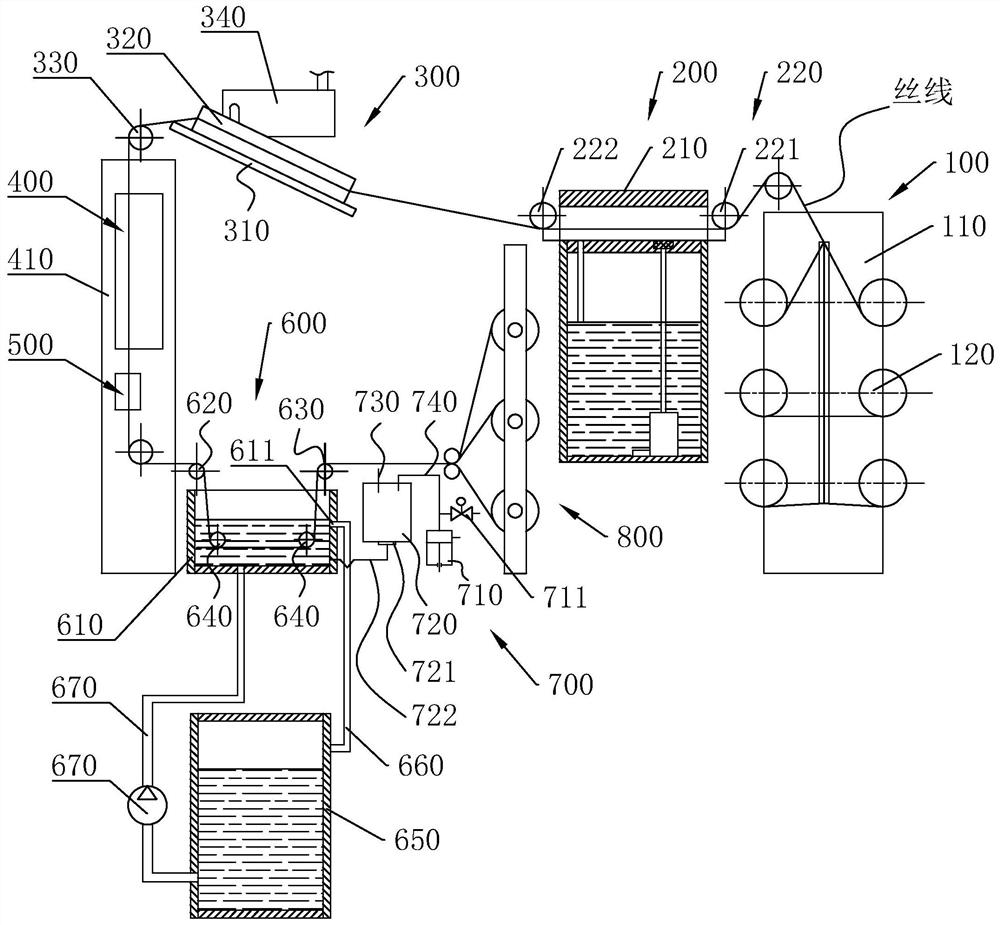

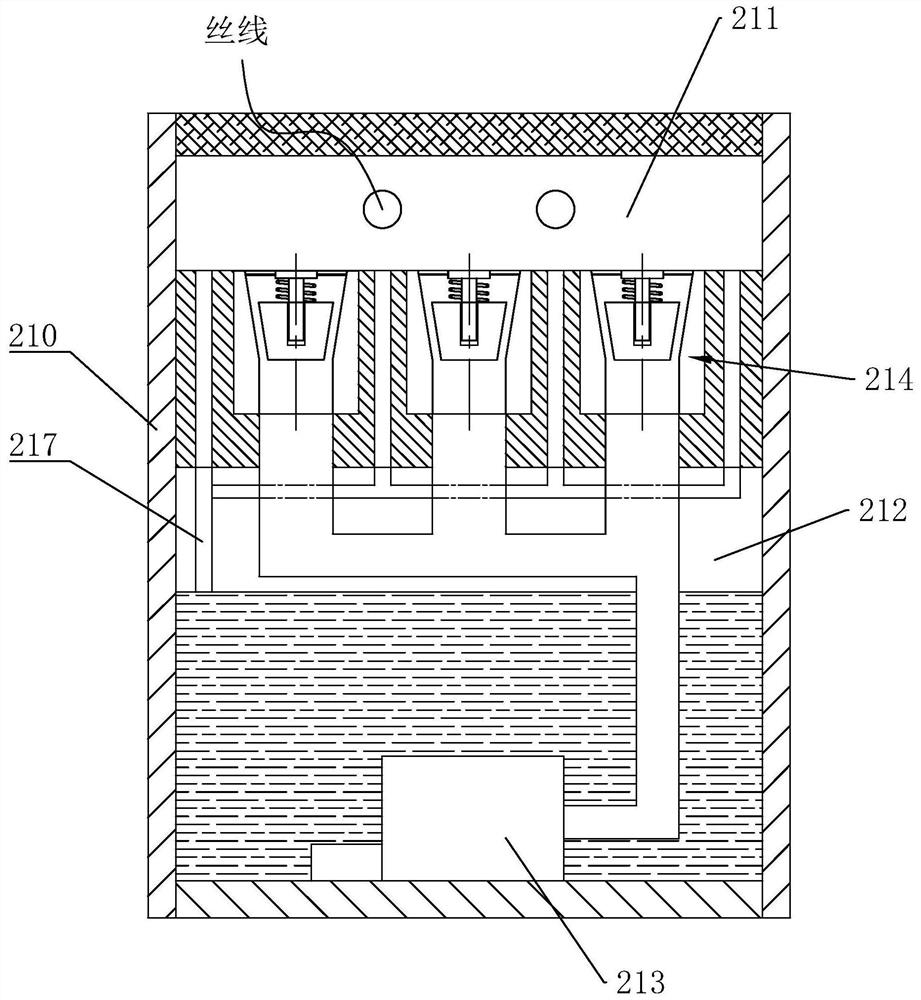

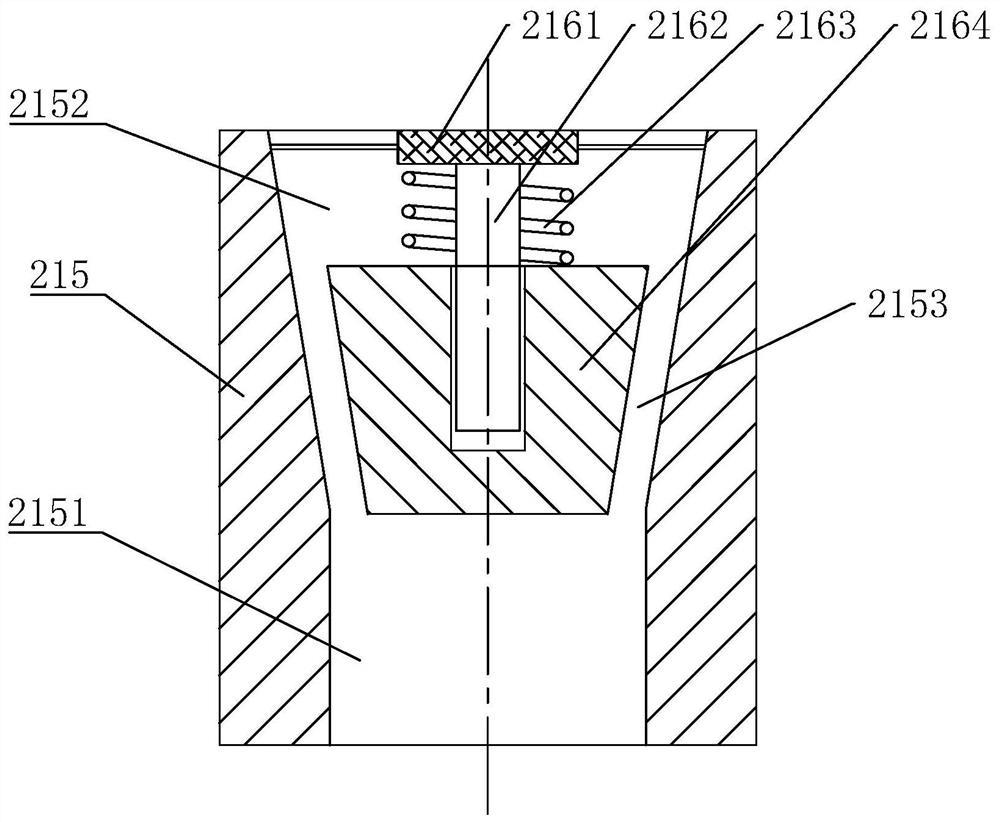

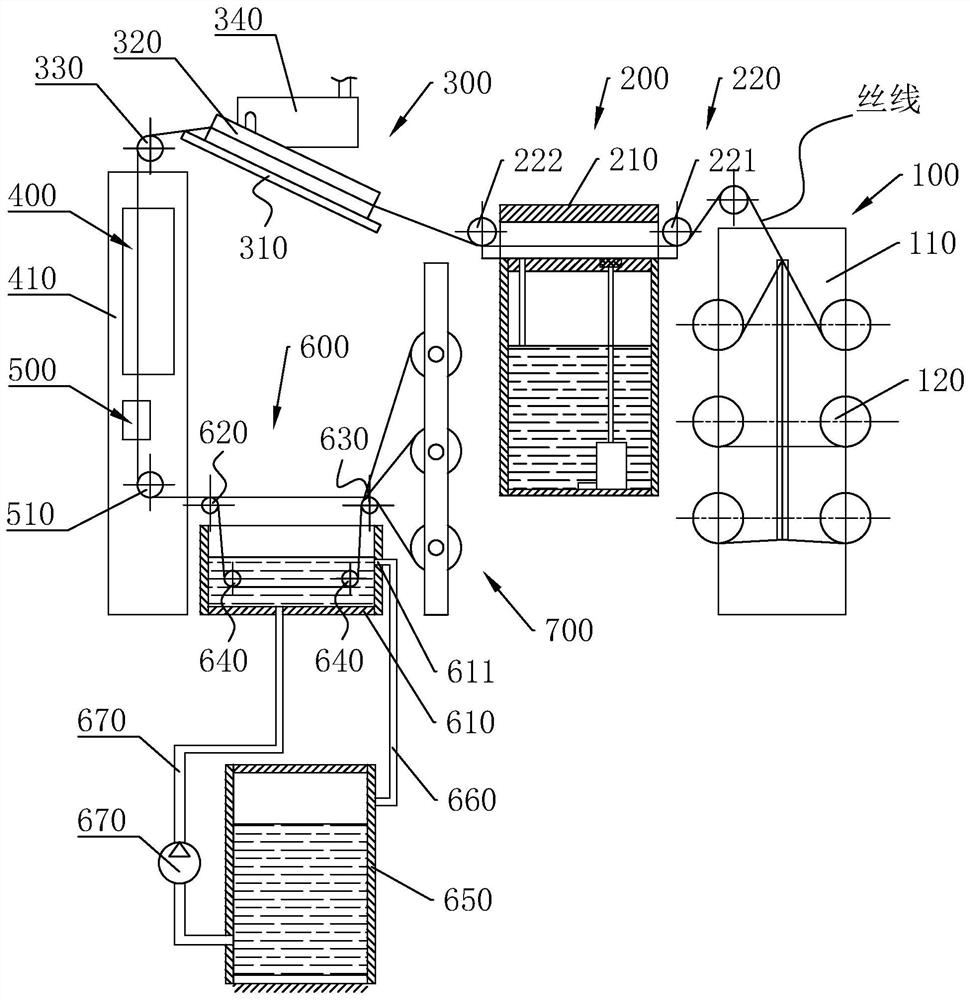

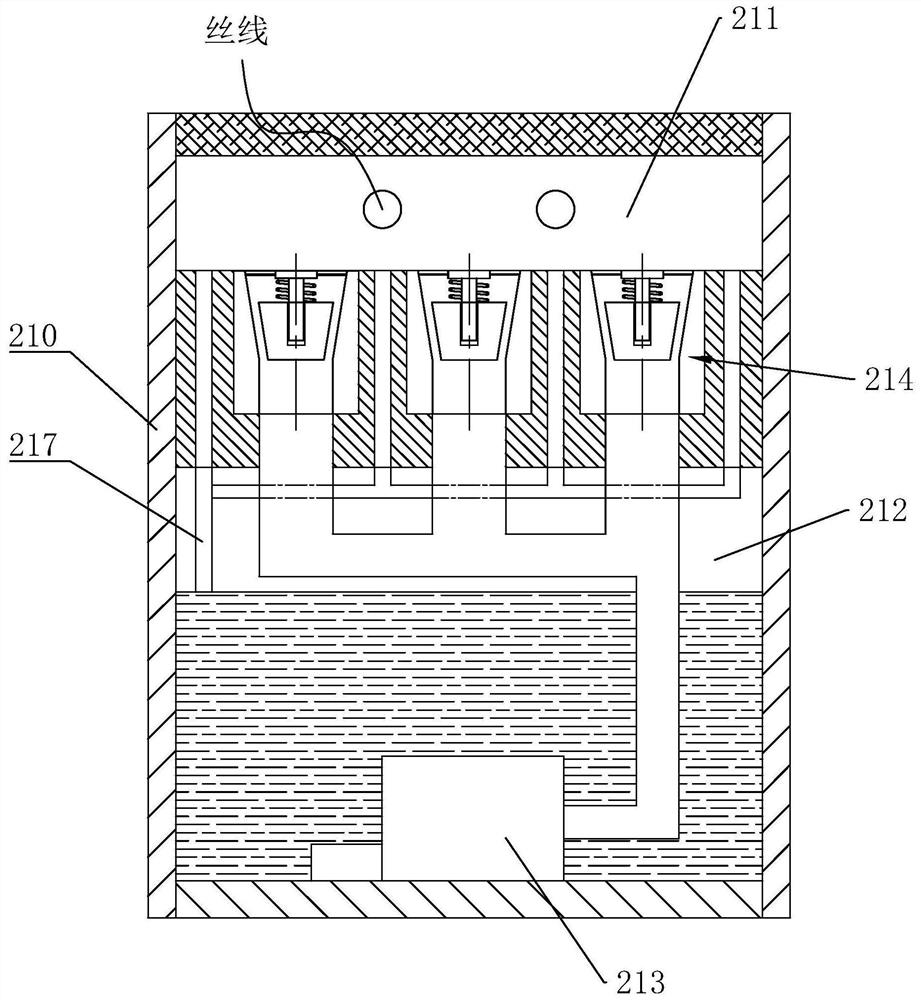

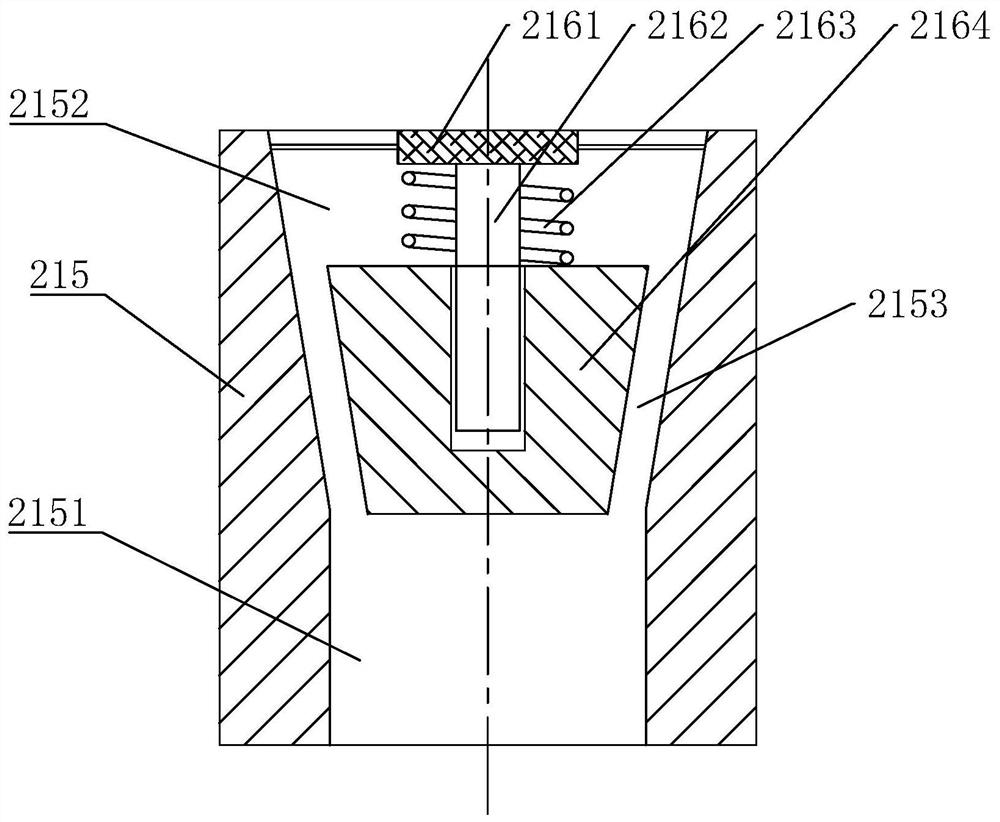

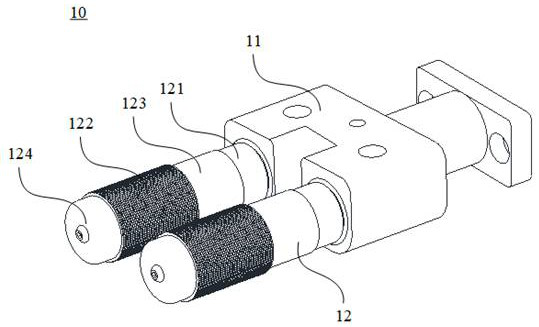

Chemical fiber spinning texturing system

ActiveCN111996634AWon't scratchEffective flowDispersed particle filtrationUsing liquid separation agentYarnPolymer science

The invention belongs to the technical field of chemic fiber spinning, and particularly relates to a chemical fiber spinning texturing system. The chemical fiber spinning texturing system comprises ayarn feeding device, a heating device, a cooling device, a false twister, an oiling device and a winding device which are sequentially arranged, wherein the yarn feeding device is used for placing andunwinding raw material silk yarns; the heating device is used for heating the unwound silk yarns; the cooling device is used for cooling the high-temperature silk yarns; the false twister is used forfalse twisting of the silk yarns; the oiling device is used for oiling and lubricating the silk yarns; the winding device is used for winding the oiled silk yarns; and the texturing system further comprises a deoiling device which is arranged at the rear part of the oiling device to absorb the excess oil on the silk yarns in a negative pressure adsorption way. According to the chemical fiber spinning texturing system, deoiling is conducted by the negative pressure adsorption way, after the oiled silk yarns pass through the upper part of a capillary branch pipe, under the action of a negativepressure pump, a port of the capillary branch pipe generates a certain suction force, the excess oil on the silk yarns can be effectively adsorbed by the suction force, so that the oil flows from thecapillary branch pipe to a main pipe, and then flows to a liquid storage tank, the deoiling efficiency is high, and the silk yarns can further not be scratched.

Owner:桐乡市骏马化纤股份有限公司

Chemical fiber spinning elasticizing device

ActiveCN112011866AImprove the lubrication effectShorten the production cycleLiquid/gas/vapor removalTextile treatment machine arrangementsYarnPolymer science

The invention belongs to the technical field of textile machinery, and particularly relates to a chemical fiber spinning elasticizing device which is characterized by comprising a yarn feeding system,a heating system, a cooling system, a false twister, an oiling system and a winding device which are arranged in sequence; the yarn feeding system is used for placing silk thread raw material and unwinding silk threads; the heating system is used for heating the unwound silk threads; the cooling system is used for cooling high-temperature silk threads; the false twister is used for false twistingof the silk threads; the oiling system is used for oiling and lubricating the silk threads; the winding device is used for winding the oiled silk threads; and an elasticizing device further comprisesa dyeing system which is located between the yarn feeding system and the heating system and used for dyeing the unwound silk yarn. Dyeing can be completed while the silk threads are elasticized, so that the production period is shortened, and the production cost is reduced.

Owner:诸暨市双冠化纤有限公司

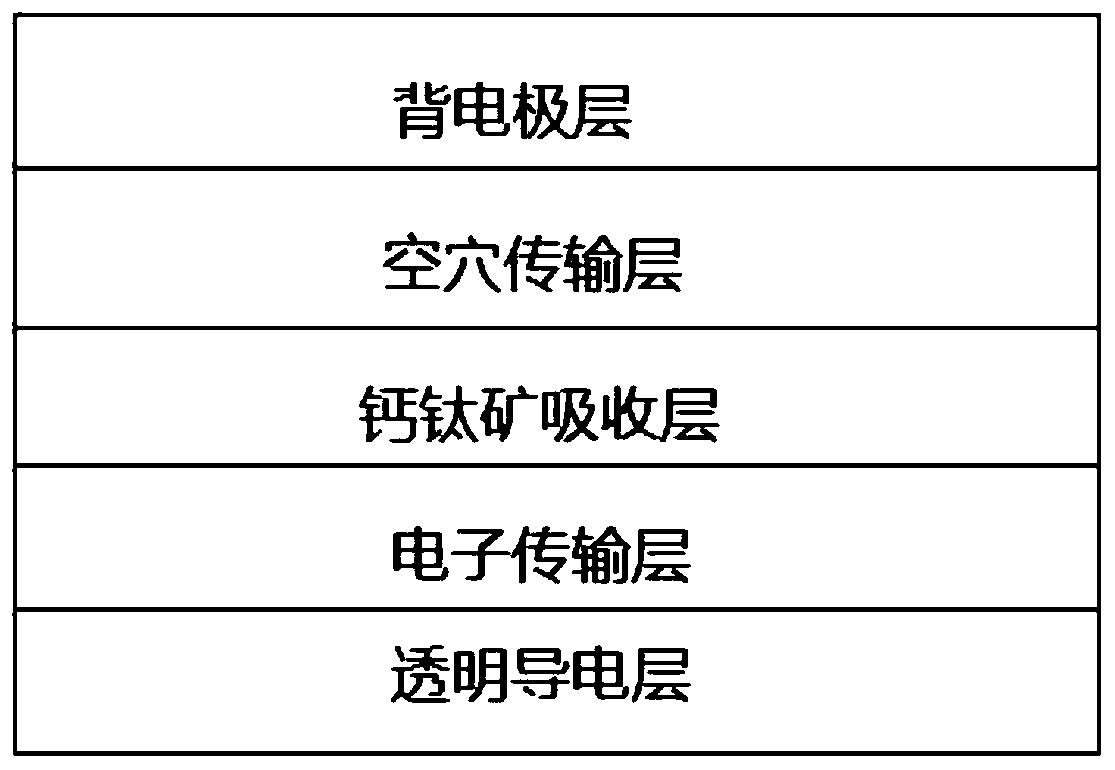

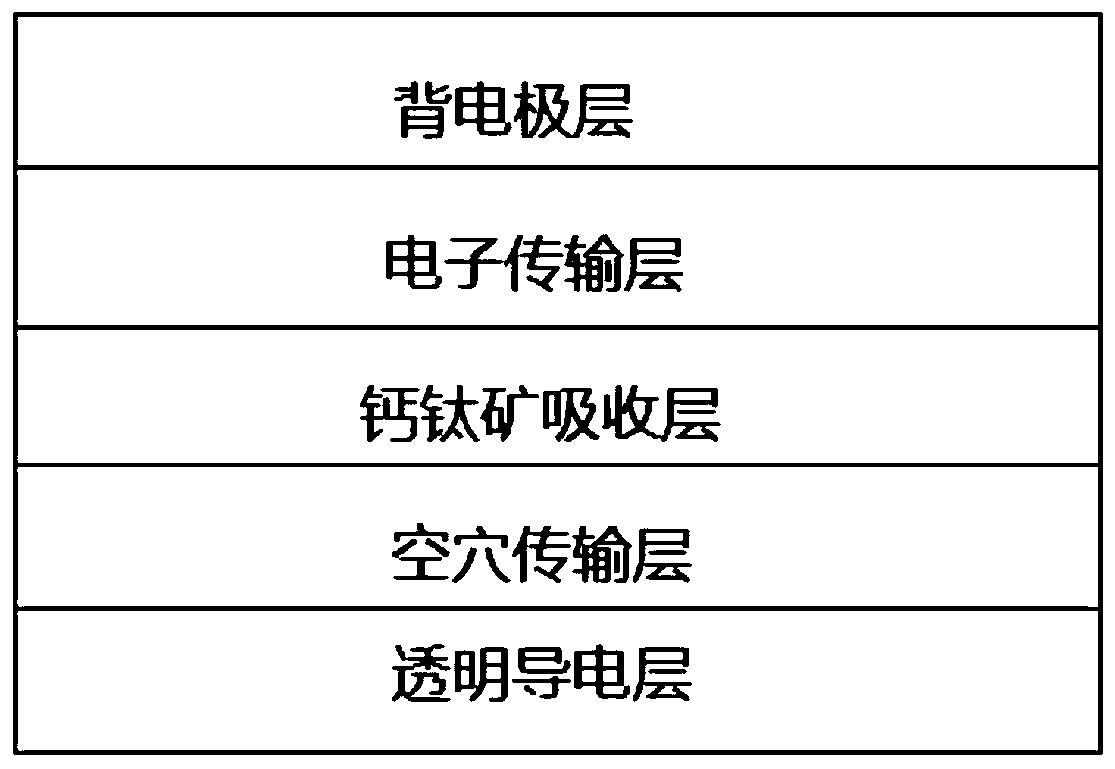

Preparation method of large-area perovskite solar cell

InactiveCN110112296AAvoid Excessive Membrane RoughnessGuaranteed battery efficiencyFinal product manufactureSolid-state devicesElectron transmissionPerovskite solar cell

The invention provides a preparation method of a large-area perovskite solar cell. The preparation method concretely comprises the steps: preparing an electron transmission layer and a hole transmission layer by a scraping coating method and preparing a perovskite absorption layer by a spraying and scraping coating method. The electron transmission layer and the hole transmission layer are prepared by the scraping coating method, which can ensure the good film quality, provide the basic platform for the perovskite layer and realize good combination between the perovskite absorption layer and the electron transmission layer and between the perovskite absorption layer and the hole transmission layer. The perovskite layer prepared by the spraying and scraping coating method is uniform and flat and the surface defects are greatly reduced, which has a high gain effect on improving the efficiency of the perovskite solar cell. The preparation method of scraping coating and spraying is simpleand feasible and the requirement for the equipment is low so that the method can be applied to preparation of the large-area perovskite solar cell; and the material can be fully utilized, the cost canbe saved to the greatest extent and the green production can be realized.

Owner:北京宏泰创新科技有限公司

Aluminum honeycomb core with filling material and preparation method of aluminum honeycomb plate

ActiveCN108395653AReduce dosageLow costNon-macromolecular adhesive additivesLaminationFilling materialsAluminum honeycomb

The invention provides an aluminum honeycomb core with a filling material and a preparation method of an aluminum honeycomb plate. Through the formation of through holes and through grooves in the aluminum honeycomb core preparation process, residue air in the honeycomb core can be sufficiently discharged during the welding of the honeycomb core and aluminum plate. The oxidization of aluminum foils of the honeycomb core in the high-temperature welding process is avoided; meanwhile, fiber reinforced and brazing flux foaming resin materials are further filled into the honeycomb core; the supportis formed inside the honeycomb core; the external force collapse of the honeycomb core is avoided; the structure intensity of the honeycomb core is improved.

Owner:合肥普飞精密工业有限公司

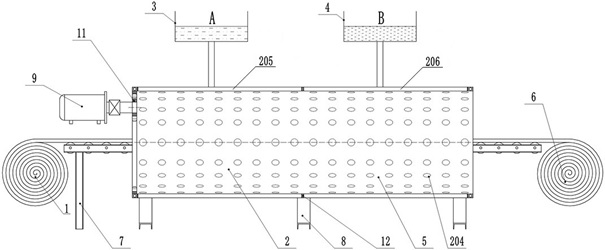

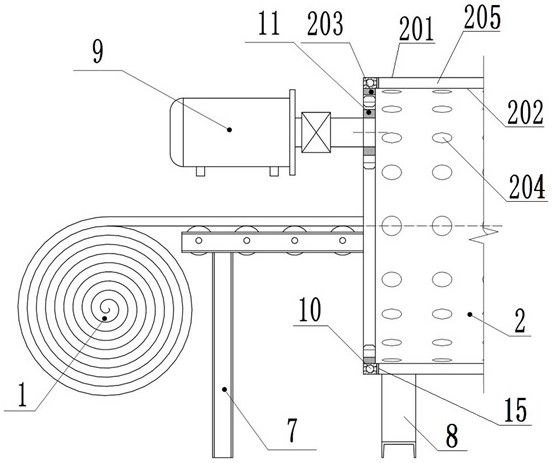

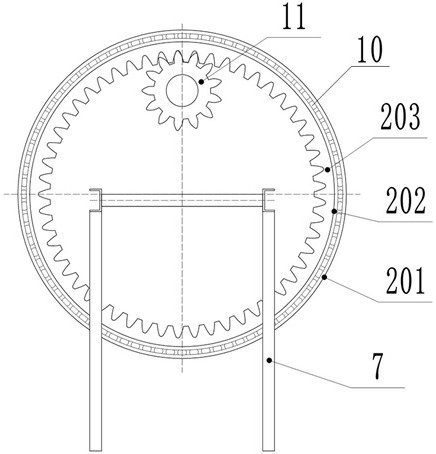

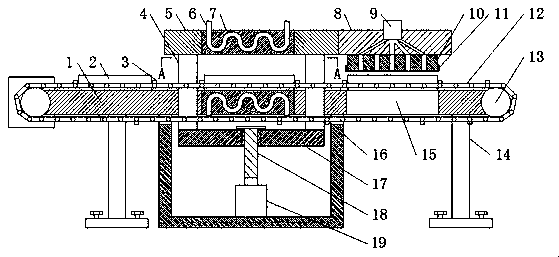

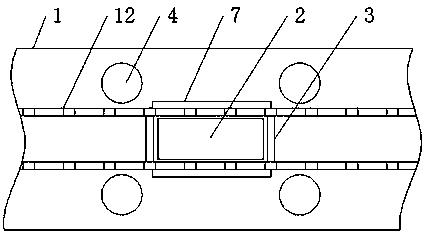

Equipment and method for rapidly preparing gel felt

The invention provides equipment and method for quickly preparing a gel felt. The equipment for quickly preparing the gel felt comprises an outer cylinder, an inner cylinder rotationally arranged in the outer cylinder and provided with an inner cavity for an unfolded fiber felt to penetrate through the inner cylinder, and a driving device which is in transmission connection with the inner cylinder and used for driving the inner cylinder to rotate; the inner cylinder and the outer cylinder are arranged in a spaced mode to form an annular cavity; the two axial ends of the annular cavity are closed; an inlet allowing silica sol, a catalyst or catalytic sol to enter the annular cavity is formed in the outer cylinder; a plurality of communicating holes for communication between the inner cavity of the inner cylinder and the annular cavity are formed in the inner cylinder; and when the inner cylinder rotates, the silica sol, the catalyst or the catalytic sol entering the annular cavity enters the inner cavity of the inner cylinder through the communicating holes and is sprayed to the surfaces of the two sides of the fiber felt under the rotation action of the inner cylinder. The all-directional spraying effect can be achieved, so that it is guaranteed that the silica sol, the catalyst or the catalytic sol is fully and evenly immersed into the fiber felt, and the good heat preservation and heat insulation performance of the gel felt is guaranteed.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Processing method for red date slices containing AD calcium

The invention discloses a processing method for red date slices containing AD calcium. The processing method comprises the following steps of: taking red dates as raw materials; cleaning, coring, slicing and drying the red dates; impregnating the red date slices in vacuum; drying the red date slices at a low temperature in vacuum; sterilizing the red date slices in microwave; packaging the red date slices and the like. On one hand, as functional components such as vitamin A, vitamin D, calcium lactate and the like are added into impregnation liquid, so that vitamins and calcium which are easyto lack in a human body can be supplemented, and the red date slices can be impregnated in the impregnation liquid more sufficiently; on the other hand, as vacuum impregnating technology is combined with vacuum drying technology, effective components are not easy to damage and lose, and healthcare effect is enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing preserved meat

InactiveCN105231180AGreat tasteGood colorClimate change adaptationFood preparationDry soilYounger people

The invention relates to the processing field of meat products, in particular to a method for preparing preserved meat, which comprises steps: a material selection, pork of soil black pigs which are scattered to feed is selected; b pickling, the pork of the soil black pigs is smeared with hot salt after being cut into slices, thereby preparing salted soil black pork; c charging seal, materials with parts by weight: anises 4 parts, Chinese prickly ashes 2 parts, citrus 2 parts, radix angelicae dahuricae 1 part and fennel 1 part are prepared to be a mixture, the mixture is ground to be 0.01mm-0.5mm fine powder, and the mixture and the salted soil black pork are sealed for 10 days after being mixed according to 5% weight radio; d drying, the salted soil black pork is taken out to dry 1-2 days after being charged and sealed; and e toasting, fume materials are arranged, and the dried soil black pork is smoked without open fire in a smokehouse for 1-2 days by adopting the fume materials. The method for preparing the preserved meat is simple and easy to remember, is convenient for operation of young people, and the preserved meat which is prepared through the method for preparing the preserved meat is savory and beautiful in color.

Owner:贺正旺

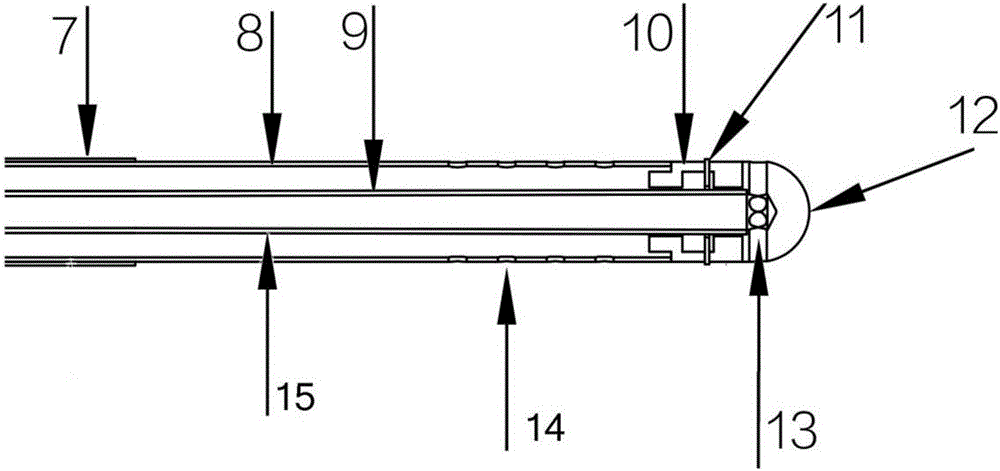

Liposuction cutter

ActiveCN105854095ATo achieve the effect of liposuctionReduce area ratioInstrument handpiecesMedical devicesLiposuctionPlasma generator

A liposuction cutter comprises a liposuction tool bit and a handle, wherein the liposuction tool bit is mounted on the handle, and comprises an inner metal pipe and an outer metal pipe; a cavity is formed between the inner metal pipe and the outer metal pipe; a water inlet pipe is communicated to the end, near the handle, of the inner metal pipe; a metal sheet serving as an electrode is mounted at the other end of the inner metal pipe; a water suction pipe is communicated to the end, near the handle, of the outer metal pipe; both the inner metal pipe and the outer metal pipe are connected with conducting wires; the conducting wires are connected to a generation electrode of a plasma generator. Through the adoption of the liposuction cutter, the problems that the efficiency of mashing fat in an inserting and pulling manner in the conventional medical technology is low, and postoperative skin is bumpy due to non-uniform liposuction are solved.

Owner:CHENGDU MECHAN ELECTRONICS TECH

Rabbit-meat miscellaneous rice dumpling and preparation method thereof

InactiveCN106136078AOvercome the disadvantages of difficult cookingEven taste inside and outFood scienceBiotechnologyWater Chestnuts

The invention discloses a rabbit-meat miscellaneous rice dumpling and a preparation method thereof. The dumpling comprises, by weight, 600-800 parts of glutinous rice, 300-350 parts of spiced rabbit meat, 120-150 parts of bacon, 80-120 parts of pork belly meat, 50-80 parts of sweet potato, 80-120 parts of water chestnuts and 400-600 parts of green beans. In the course of the operation, glutinous rice is soaked with allspice powder, green beans are treated with slightly salty water; then the dumpling is moderately steamed and cooked and simmered for a long time. The dumpling made using the preparation method has tender but not greasy meat, strong fragrance of indocalamus leaves, fragrant grains and a long aftertaste.

Owner:MAANSHAN ZHONGAN FOOD TECH CO LTD

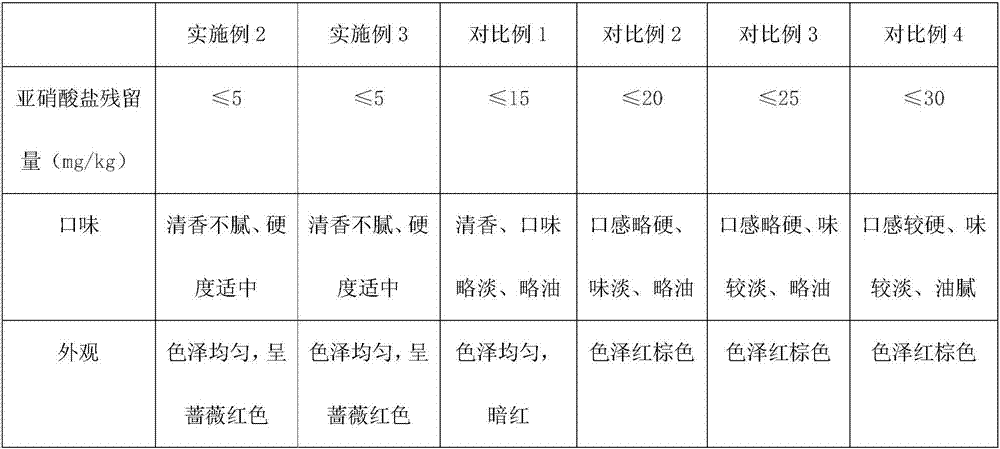

Pork sausages and making method thereof

InactiveCN106879974AStrong tasteGreat tasteNatural extract food ingredientsFood ingredient functionsLean meatHot peppers

The invention provides pork sausages and a making method thereof, and belongs to the field of food processing. The making method of the pork sausages comprises the following steps of firstly selecting pork which is reasonable in proportion of lean meat to fat meat in proportion as a raw material, thoroughly cleaning the selected pork, mixing the cleaned pork with seasoning spices which are prepared from salt, Chinese prickly ash, black peppers, hot peppers, garlic, fermented bean curds and white granulated sugar, performing uniform mixing, and performing beating for 50-55min; then mincing the pork, mixing the minced pork with auxiliary materials, and performing stirring for 20-25min so as to obtain a mixture; wrapping the mixture with a fresh-keeping film, performing pickling at the temperature of minus 1-1 DEG C for 5-6h, and taking out the pickled mixture; and then pouring the taken-out mixture into hog casings, wrapping the filled sausages with lotus leaves, putting the sausages wrapped with the lotus leaves in a roasting house, performing roasting under the environment of the temperature being 67-68 DEG C for 5-6h, taking out the roasted sausages, and drying the taken-out sausages in shade so as to obtain the pork sausages. The pork sausages disclosed by the invention are convenient to eat, good in mouth feel, nutritive, healthy, high in eating safety and delicately fragrant in taste, after many pork sausages are eaten, people cannot feel oily, and the pork sausages have the efficacy of clearing away fire and reducing blood lipid.

Owner:广西顺康农业有限公司

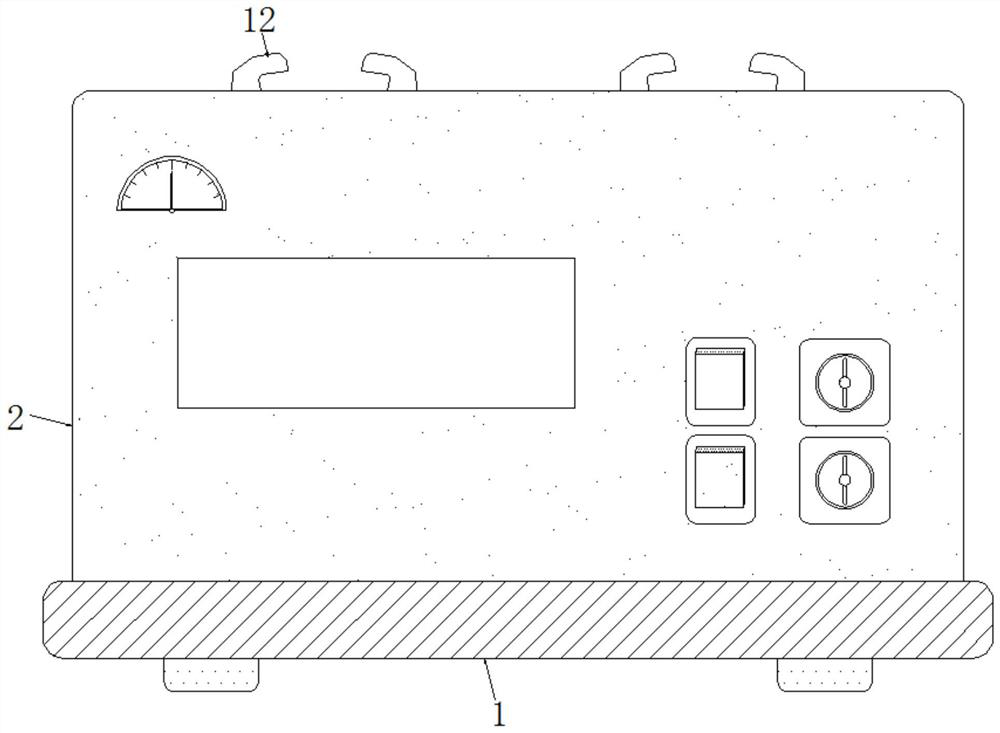

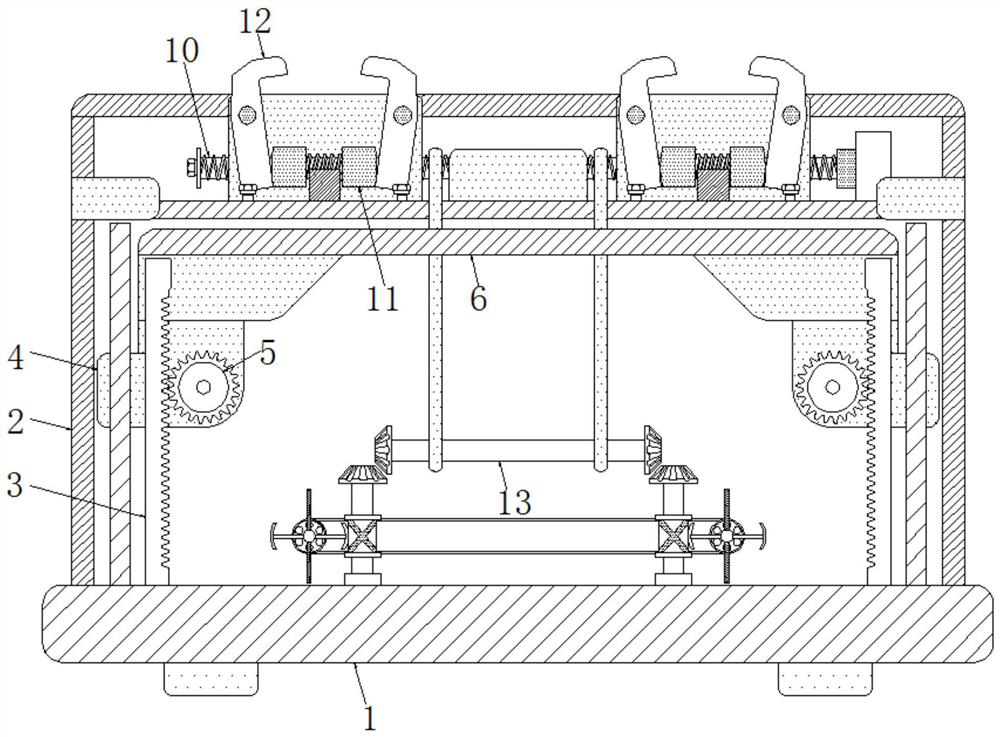

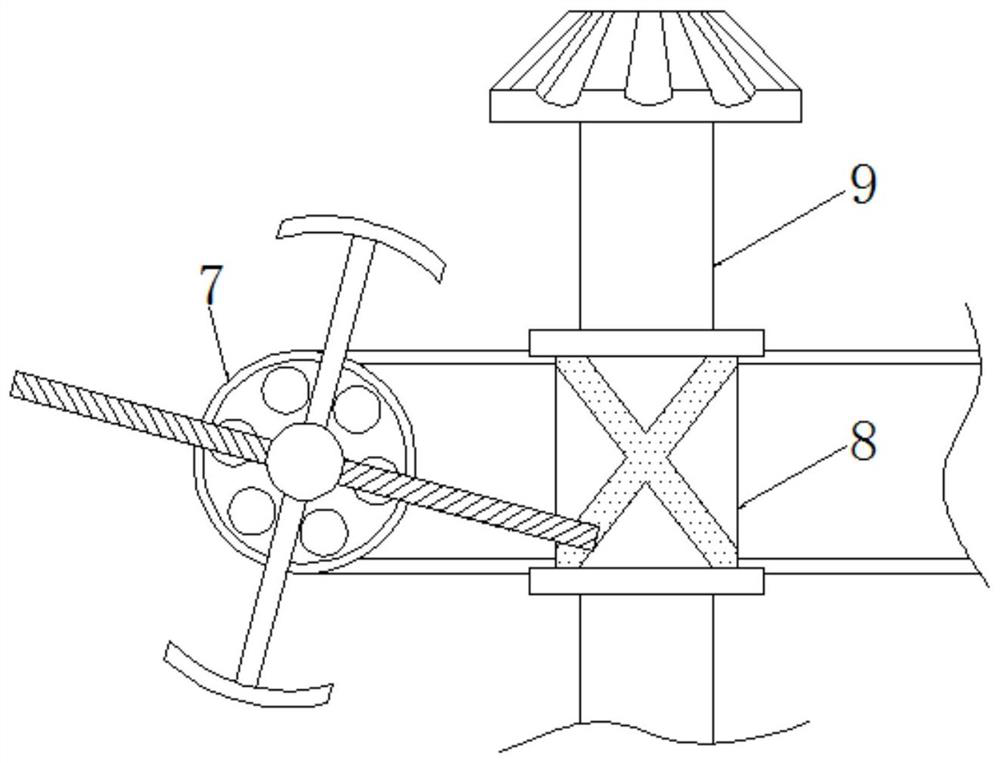

Water bath device with automatic clamping and height adjusting functions for food detection

InactiveCN111841683AGuaranteed stabilityImprove intelligenceWater/sand/air bathsSupporting apparatusGear wheelThreaded rod

The invention relates to the technical field of food detection. The invention discloses a water bath device with automatic clamping and height adjusting functions for food detection. The device comprises a base, and the base is used for supporting and stabilizing the whole device. A water tank is fixedly connected to the upper portion of the base and is used for water bath heating. Through cooperative use of a threaded rod, a moving block and a clamping plate, a beaker can be automatically clamped, and the stability of the beaker during water bath heating is ensured. After the water bath is finished, the beaker is automatically loosened, and the intelligence of the device is improved. Through cooperative use of a supporting block, a first gear and a supporting plate, the height of the beaker can be adjusted in a self-service manner, so that the beaker can be fully immersed in water, and insufficient water bath is avoided. Through cooperative use of a rotating wheel, a sleeve rod and arotating shaft, the two steps of clamping the beaker and adjusting the height of the supporting plate are linked, so that the linkage performance of the device is improved, and the operation is simpler.

Owner:周年生

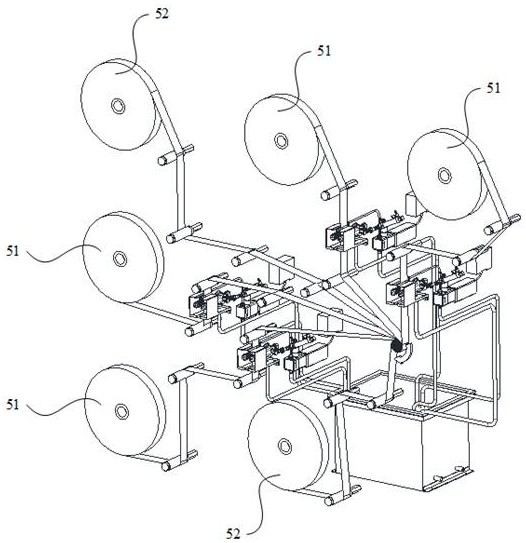

Leather bonding device and production process thereof

InactiveCN108891119AFull immersionQuality improvementLamination ancillary operationsLaminationEngineeringDislocation

The invention discloses a leather bonding device. The leather bonding device comprises a worktable, wherein the side wall of the worktable is sleeved with two corresponding chains, two corresponding chain wheels are rotatably connected to one end of the worktable and are respectively meshed with two chains, a plurality of handrails are uniformly arranged between the two chains, and two ends of thehandrails are fixedly connected with pin shafts of the two chains; a leather body is placed among the handrails, and the bottom of the leather body is connected with the top of the worktable in a sliding manner; a power supply box is fixedly connected to the bottom of the worktable, a stepping motor is fixedly connected to the bottom in the power supply box, a screw rod arranged in the vertical direction is fixedly connected to the tail end of an output shaft of the stepping motor, the side wall of the screw rod is sleeved with a connecting plate through threads, and connecting rods are fixedly connected to four corners at the top of the connecting plate, and a uniform extrusion purpose is achieved during the bonding of leather. The invention further discloses a production process of theleather bonding device. According to the leather bonding device, the local deformation and dislocation of the leather and lining cloth are avoided, and the yield is increased.

Owner:广州益合康科技材料有限公司

Device and method for cleaning wool in karst areas

The invention discloses a device and method for cleaning wool in karst areas. The device for cleaning wool in the karst areas comprises a storage barrel, an extrusion mesh plate, spiral rods and a stirring motor. A hopper is arranged on the side of the upper end of the storage barrel, and a drain pipe is arranged on a side surface of the bottom of the storage barrel; a filter screen plate is arranged at the position, which is close to the bottom, of the inner side of the storage barrel, the upper end of the extrusion mesh plate is connected with a stirring shaft and can be movably arranged inthe storage barrel; the lower end of the extrusion mesh plate is provided with a plurality of rows of radially arranged spiral rods; the upper end of the stirring shaft is connected to a stirring motor, and the stirring motor is fixedly connected to a cantilever beam; the cantilever beam is vertically and fixedly connected to a sliding plate, and the sliding plate is connected to a lifting device;the lifting device and the storage barrel are fixedly connected to the bottom plate. According to the invention, suspended wool is completely soaked in water, so that a complete soaking effect and afull wool stirring effect are achieved, the cleaning effect is better, the time and labor are saved, the operation is facilitated, the efficiency is greatly improved, by arrangement of the filter screen plate, rapid water drainage is facilitated, blockage is avoided, and the cleaning efficiency is improved.

Owner:GUIZHOU NORMAL UNIVERSITY

A pickles preserving method

InactiveCN1994121ADeliciousFull of nutritionClimate change adaptationFood preparationChemistryFlavor

The invention relates to a method for producing pickle, which comprises that: 1, preparing materials as meat root, leaf, flavoring, soup that boiling meat; 2, drying not pickled leaf; drying the meat, putting flavoring into soup; 3, putting meat and flavoring into container, adding water and boiling; 4, vacuum packing the leaf or meat prepared in steps 2 and 3. The invention has simple process.

Owner:范晨阳

Pork sausage and preparation method thereof

InactiveCN106616488ADoesn't mask the flavorDoes not mask the scentFood scienceAllium sativumMinced pork

The invention provides a pork sausage and a preparation method thereof and belongs to the field of food processing. The preparation method of the pork sausage comprises the following steps of firstly, proportionally selecting pork with a reasonable lean / fat ratio as a raw material, cleanly washing the pork, then, uniformly mixing the washed pork with flavoring spices, which consist of salt, pericarpium zanthoxyli, black pepper, bay leaves, fennel seeds, capsicum, allium sativum, fermented bean curd, round cardamon seeds, perilla seeds, dried ginger and cherry leaves, carrying out beating for 50 to 55 minutes, then, mincing the pork, then, mixing the minced pork with auxiliaries, carrying out stirring for 20 to 25 minutes, then, carrying out sousing for 9 to 11 hours at the temperature of -1 DEG C to 1 DEG C under the condition that the mixture is wrapped by preservative films, then, taking out the mixture, then, injecting the mixture into hog intestines, exhausting gas inside the hog intestines, carrying out bundled sealing, carrying out shade-drying, and then, carrying out packaging in a vacuum packaging manner, thereby obtaining the pork sausage. The pork sausage provided by the invention is convenient to eat, relatively good in taste, high in eating safety and faint-scent in flavor, is nutritional and healthy, is not greasy in case of more eating and has the effects of clearing away fire and reducing fat.

Owner:广西聚银牧业集团岭南客家陆川猪肉制品有限公司

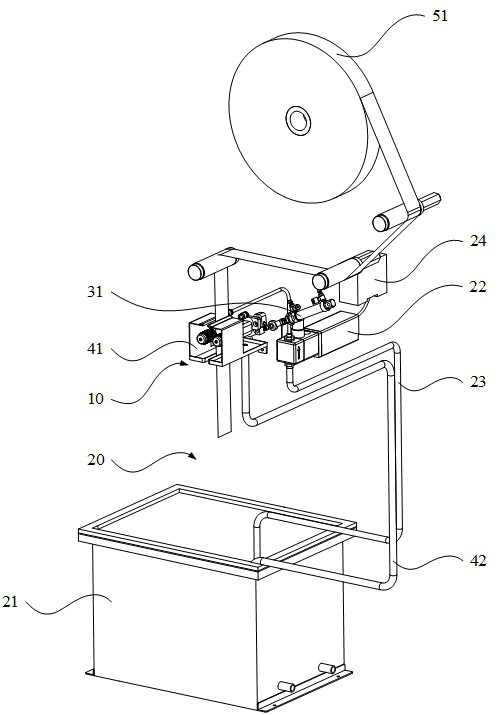

Capacitor liquid coating device and capacitor manufacturing method

ActiveCN111341563BSimple structureEasy to useLiquid electrolytic capacitorsDrying/impregnating machinesElectrolytic agentLiquid storage tank

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Dialysis device special for regenerated silk fibroin laboratory and use method of dialysis device

PendingCN106589089AContinuous ambulatory dialysisSave human effortPeptide preparation methodsAnimals/human peptidesWater dischargeWater pipe

The invention provides a dialysis device special for a regenerated silk fibroin laboratory and a use method of the dialysis device. The dialysis device special for the regenerated silk fibroin laboratory comprises a box body, wherein at least one fixing stick for fixing a dialysis bag for filling a regenerated silk fibroin solution is fixed at the top end of the box body; the box body is provided with a water supply system, a water drainage system and a water discharging system; the water supply system and the water drainage system share a connection opening and a water pipe; the connection opening is formed in the bottom surface of the box body and is connected with the water pipe; a valve is arranged on the water pipe; the water discharging system comprises a water outlet formed in the side wall of the box body; and the water outlet is connected with a water discharging pipe. The dialysis device is simple in structure and convenient to use; and a more flexible scheme is supplied to different scales of dialysis of the regenerated silk fibroin solution, so that the number and the lengths of the dialysis bags are optimized, and waste is avoided. The dialysis device realizes continuous, dynamic and full dialysis of the regenerated silk fibroin solution, greatly saves labor and time and reduces the risk of dialysis pollution.

Owner:DONGHUA UNIV

Method for preparing adsorbent from straw

InactiveCN110898814AImprove adsorption capacityHigh porosityOther chemical processesWater contaminantsBiotechnologySorbent

The invention discloses a method for preparing an adsorbent from straw, belonging to the technical field of straw utilization. The adsorbent prepared from corn straw and the like has a good adsorptioneffect on heavy metal ions such as Cd (II), Pb (II) and the like, and is high in desorption rate and high in reproducibility. According to the invention, sesame stalks, clamshells and corn stalks arepuffed after being activated by steam, so the inner structure of the above raw materials can be completely opened, which is beneficial for complete immersion of yeast liquid; then fermentation is performed, the fermented raw materials have porous structures and improved porosity; and carbonization is cooperatively conducted to harden a skeleton structure, so the obtained adsorbent has the characteristics of good porosity, good specific surface area, good mechanical properties and improved regeneration performance.

Owner:安徽正基生态农业有限公司

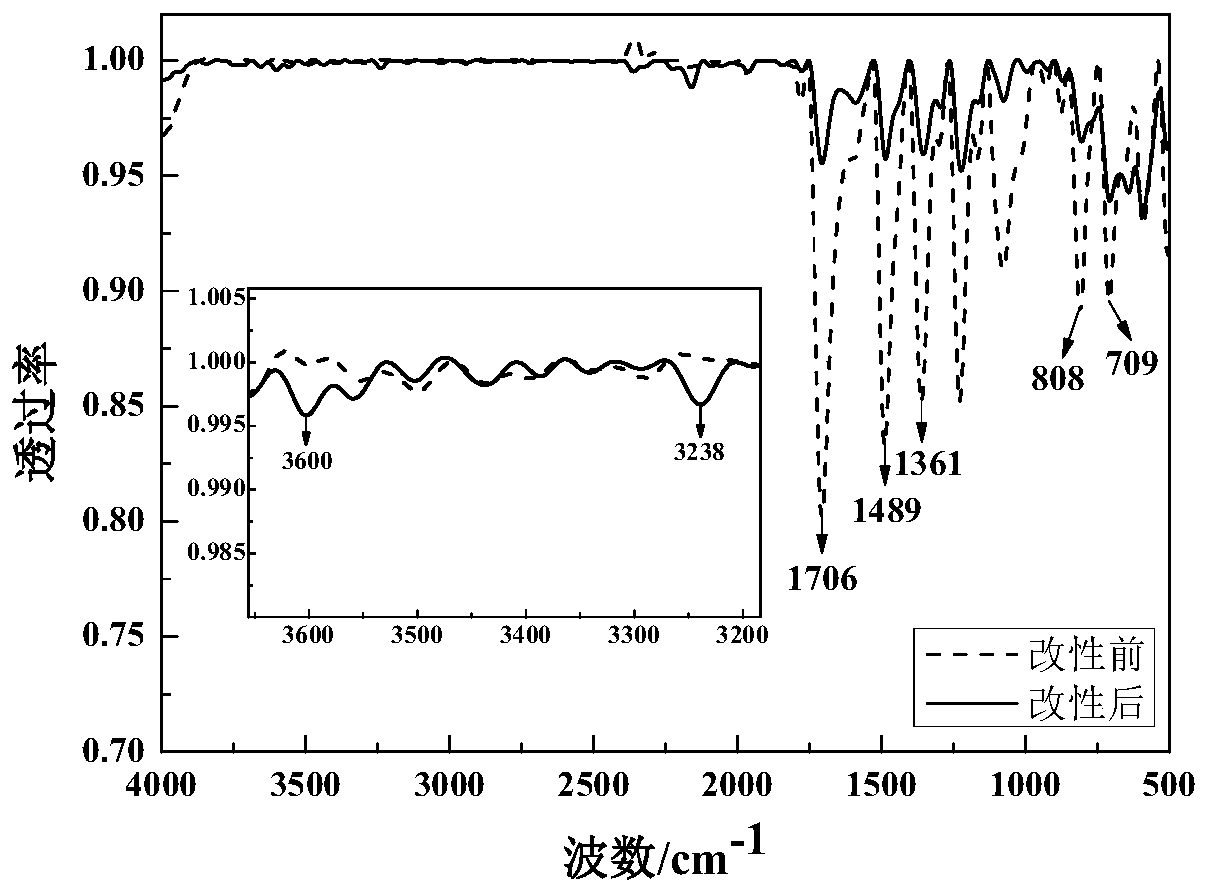

Glucose-modified polyimide fiber and preparation method thereof

The invention discloses a glucose-modified polyimide fiber and a preparation method thereof. Carbon spheres are attached to the surface of the glucose-modified polyimide fiber, the fiber does not depend on a matrix material, and the amorphous carbon spheres attached to the surface have abundant hydroxyl and carboxyl groups, so that the surface of the whole polyimide fiber has a large number of active groups (the hydroxyl and carboxyl groups), and the processability and cohesiveness of the matrix material-polyimide fiber can be effectively improved; application of the fiber in composite materials is further expanded. According to the preparation method, glucose which is low in cost and easy to purchase is adopted as a modifier and a carbon source, the nano carbon spheres are subjected to in-situ synthesis on the surface of the polyimide fiber, and the surfaces of the carbon spheres have the carboxyl and hydroxyl groups, so that the active groups on the surface of the whole polyimide fiber are greatly increased; according to the preparation method, an organic solvent is not used, the glucose which is low in cost, wide in source and environmentally friendly is adopted as the carbon source, and environmental protection requirements are met.

Owner:SHAANXI UNIV OF SCI & TECH

Processing method of instant pot-stewed pigtails

The invention belongs to the technical field of cooked food, and in particular relates to a processing method of instant pot-stewed pigtails, comprising the steps of pretreatment, unhairing, washing, preparation of stewing soup, stewing, airing, steaming, sterilizing and packaging. Compared with the prior art, the processing method has the following advantages: through refrigeration and scalding after pretreatment, bristles in the pigtails can be removed conveniently, then nutrient components can be sufficiently infused into meat by marinating and steaming; before steaming, a rosa roxburghii tratt wine diluent containing okra pod extract is applied to the surface of the pigtails, so the color and nutrition of the pigtails are maintained; the retention time is prolonged; the pigtails are convenient to carry, sanitary and healthy after vacuum packaging and conforms to correlated national food safety requirements; and the process is reasonable, easy in operation, free of additives and suitable for popularization and production.

Owner:安徽省家乡食品有限公司

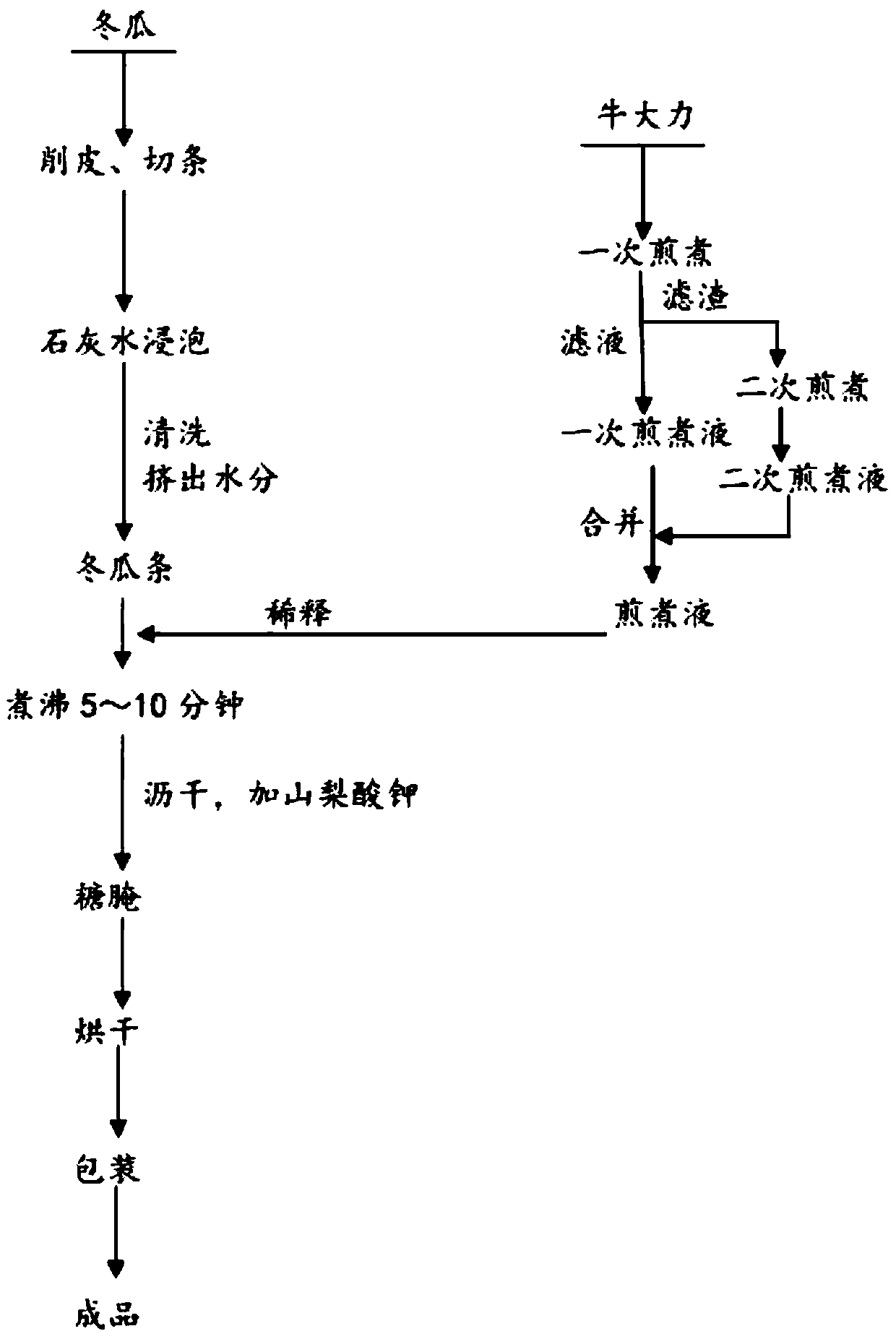

Beautiful millettia root candied melon and preparation method thereof

The invention discloses a beautiful millettia root candied melon which comprises the following components in parts by weight: 10-20 parts of beautiful millettia root, 200-400 parts of wax gourd, 80-150 parts of saccharose and 50-120 parts of potassium sorbate. A preparation method of the beautiful millettia root candied melon comprises the following steps: slitting wax gourd, boiling in water anddraining off; twice boiling beautiful millettia root in water and then diluting, thereby acquiring a decoction liquor; boiling wax gourd in the decoction liquor; pickling in sugar after the ending ofboiling; drying and bagging. The beautiful millettia root candied melon disclosed by the invention has the effects of clearing away heat and toxic materials, inducing diuresis to alleviate edema, moistening lung for reducing phlegm, nourishing kidney and tonifying deficiency, and the like. The preparation method of the candied melon is simple and easy to realize.

Owner:广西子持医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com